Method for preparing hydrogen gas by hot aluminum slag/vapor combined reaction

A technology of water vapor and aluminum slag, applied in the field of hot aluminum slag combined with water vapor reaction to prepare hydrogen, can solve problems such as difficulties, achieve low cost, improve system energy utilization efficiency, and promote high-temperature reactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The technical solutions in the embodiments of the present invention will be described in detail below with reference to the drawings in the embodiments of the present invention.

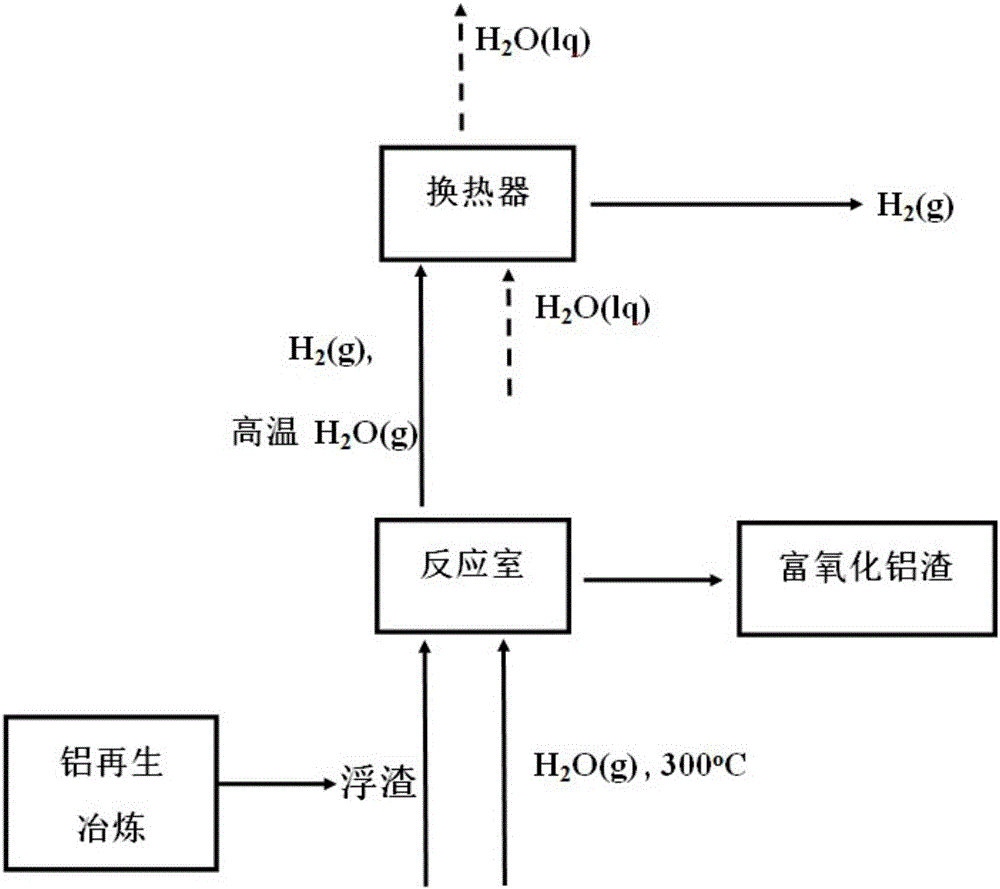

[0028] Such as figure 1 As shown, the present invention uses the solid waste thermal aluminum slag produced in the recycling and smelting process of metal aluminum as raw material, fully utilizes the metal aluminum and waste heat resources rich in aluminum slag, and reacts with water vapor to prepare hydrogen, and the thermal aluminum The salt flux in the slag acts as an auxiliary agent, which can greatly accelerate the reaction between metal aluminum and water vapor, and at the same time, use the huge amount of heat generated during the reaction to generate high-temperature water vapor.

[0029] The hydrogen production system of the present invention is composed of solid raw material and gaseous raw material. The solid raw material is scum just picked up from aluminum regeneration smelting, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com