Vanadium-titanium mineral slag composite admixture for high-performance concrete and method

A technology of high-performance concrete and composite admixture, which is applied in the field of building materials, can solve the problems such as the inability to meet the activity requirements of mineral powder for high-performance concrete, and achieve the effects of good volume stability, high strength and alleviation of self-shrinkage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

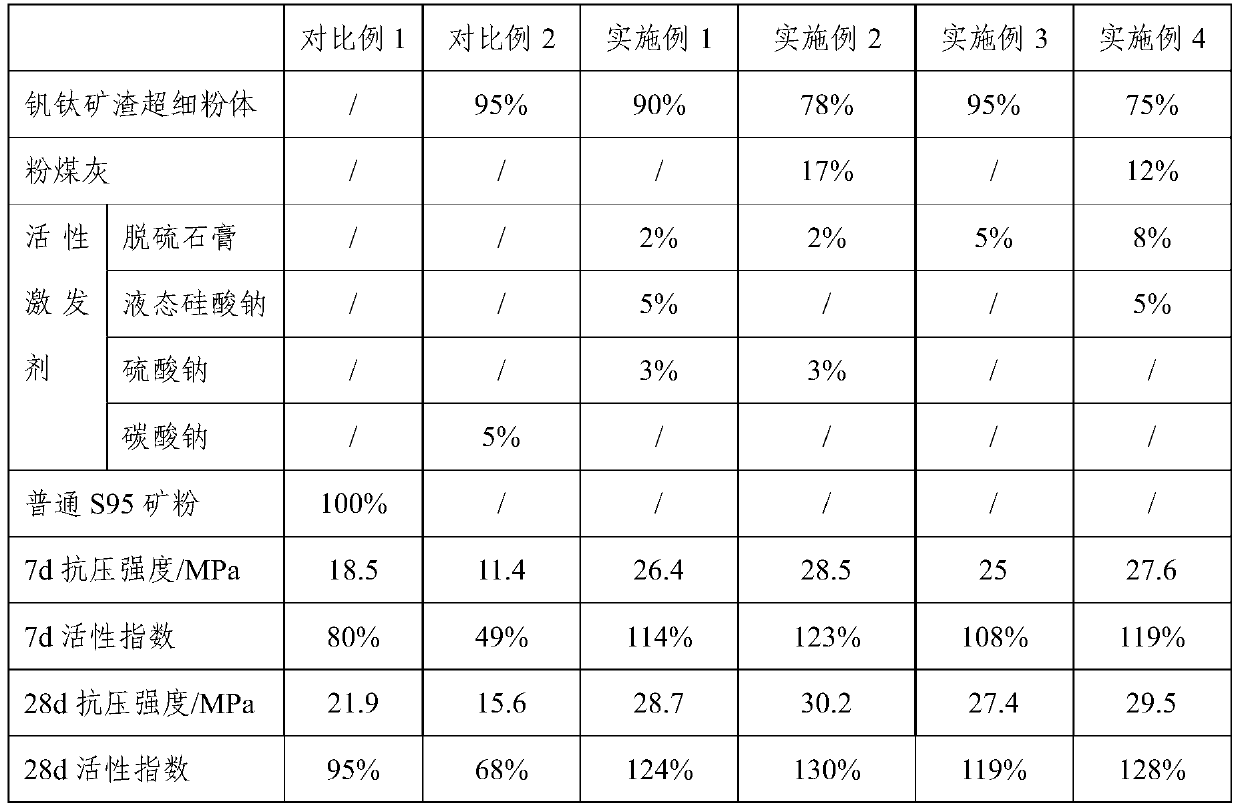

[0029] Preparation of the high-performance concrete composite admixture provided in this example: wash the slag with industrial water at 20±1°C for 3 to 4 times until the washing liquid is clarified, and dry the material at a temperature of 105°C to 110°C until the moisture content of the material is 2 / kg, the set speed is 10~20r / min, and the grinding time is 120~180min; after the centrifugal powder classifier sorts the 200-mesh qualified product, it is added to the ultrafine mill to continue grinding for 60~90min, and the speed is 300-400r / min, after being sorted by an ultra-fine powder separator with a rotating speed of 100-150r / min, the ultra-fine powder of vanadium-titanium slag (specific surface area of 700-800m 2 / kg). The vanadium-titanium slag superfine powder prepared above is mixed according to the ratio of raw materials of the composite admixture in Table 1 according to the weight ratio to obtain the composite admixture.

Embodiment 2-4

[0031] Using the preparation method of Example 1, Examples 2-4 were prepared according to the addition ratio shown in Table 1, and performance testing was carried out. The composition and performance of the composite admixtures of Examples 2-4 are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com