Foam carbon preparation method based on waste biomass

A technology of waste biomass and foam carbon, which is applied in the direction of carbon preparation/purification, can solve the problem of high cost of foam carbon, achieve the effects of reducing economic costs, uniform size, and solving the shortage of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

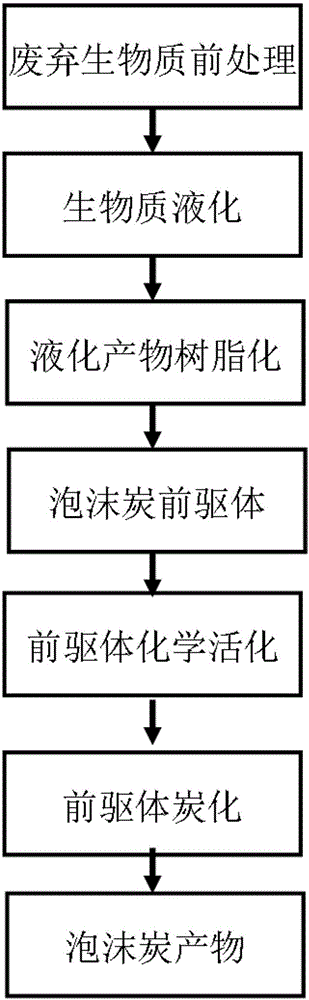

Method used

Image

Examples

Embodiment 1

[0031] The foam charcoal preparation based on eucalyptus wood powder comprises the following steps:

[0032] (1) Pretreatment of waste biomass: the eucalyptus wood chips taken from the wood processing plant are pretreated as raw materials after being cleaned, dried and crushed.

[0033] (2) Liquefaction of eucalyptus powder: Mix 5 g of pulverized eucalyptus powder with 15 g of phenol, add 0.25 mL of concentrated sulfuric acid (98%) and 1 mL of phosphoric acid (85%), and liquefy at 140° C. for 2 h. The liquefied product was cooled to room temperature, washed with methanol, filtered under reduced pressure to obtain a methanol-liquefied product, and then the methanol was distilled off under reduced pressure in a rotary evaporator at 50°C to obtain a liquefied product.

[0034] (3) Resinization of the liquefied product: the obtained liquefied product was placed in a three-necked flask, and an alkali catalyst, that is, 5 mL of 1.25 mol / L NaOH solution was added. At 60°C, 25 mL of ...

Embodiment 2

[0039] The foam charcoal preparation based on eucalyptus wood powder comprises the following steps:

[0040] (1) Pretreatment of waste biomass: the eucalyptus wood chips taken from the wood processing plant are pretreated as raw materials after being cleaned, dried and crushed.

[0041] (2) Liquefaction of eucalyptus powder: Mix 5 g of crushed eucalyptus powder with 15 g of catechol, add 0.25 mL of concentrated sulfuric acid (98%) and 1 mL of phosphoric acid (85%), and liquefy at 180°C for 2 hours. The liquefied product was cooled to room temperature, washed with methanol, filtered under reduced pressure to obtain a methanol-liquefied product, and then the methanol was distilled off under reduced pressure in a rotary evaporator at 50°C to obtain a liquefied product.

[0042] (3) Resinization of the liquefied product: the obtained liquefied product was placed in a three-necked flask, and an alkali catalyst, that is, 5 mL of 1.25 mol / L NaOH solution was added. After adding 25 m...

Embodiment 3

[0047] The foam charcoal preparation based on eucalyptus wood powder comprises the following steps:

[0048] (1) Pretreatment of waste biomass: the eucalyptus wood chips taken from the wood processing plant are pretreated as raw materials after being cleaned, dried and crushed.

[0049] (2) Liquefaction of eucalyptus wood powder: the eucalyptus wood chips taken from the wood processing plant are pretreated as raw materials after being cleaned, dried and crushed. Mix 5 g of crushed eucalyptus powder with 15 g of phenol, add 0.5 mL of concentrated sulfuric acid (98%) and 2 mL of phosphoric acid (85%), and liquefy at 160°C for 2 hours. The liquefied product was cooled to room temperature, washed with methanol, filtered under reduced pressure to obtain a methanol-liquefied product, and then the methanol was distilled off under reduced pressure in a rotary evaporator at 50°C to obtain a liquefied product.

[0050] (3) Resinization of the liquefied product: the obtained liquefied p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com