Method for preparing foam carbon adsorbing material with template process

A technology of adsorption material and foam carbon, which is applied in chemical instruments and methods, carbon compounds, inorganic chemistry, etc., can solve the problems of foam carbon oil and coal resource shortage, achieve uniform size, easy source of raw materials, and solve increasingly effect of shortage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

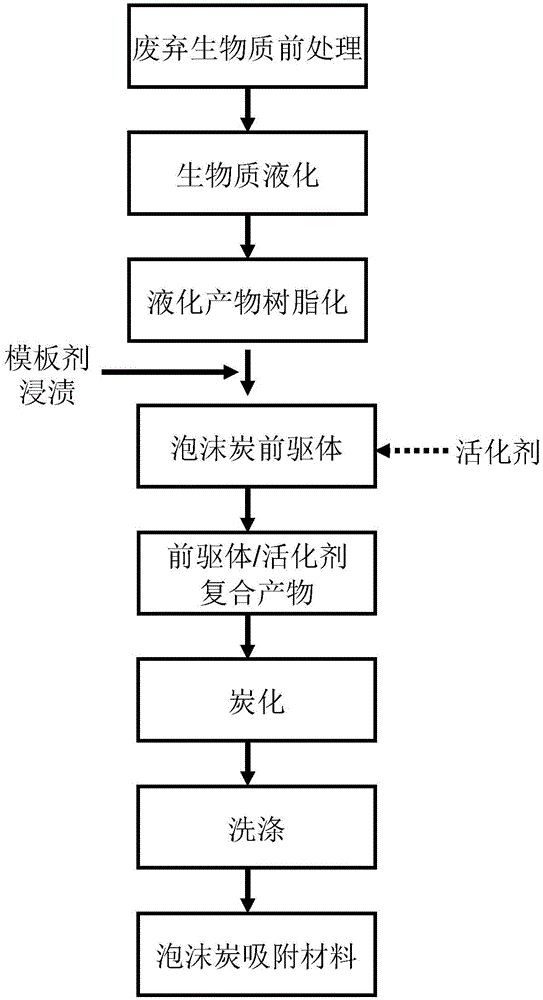

Method used

Image

Examples

Embodiment 1

[0030] The preparation of foam carbon adsorption material based on eucalyptus wood powder comprises the following steps:

[0031] (1) Pretreatment of waste biomass: The eucalyptus wood chips from the wood processing plant were pretreated by cleaning, drying and crushing, and then used as raw materials for future use.

[0032] (2) Liquefaction of eucalyptus powder: Mix 5 g of pulverized eucalyptus powder with 15 g of phenol, add 0.25 mL of concentrated sulfuric acid (concentration: 98%) and 1 mL of phosphoric acid (concentration: 85%), and liquefy at 180°C for 2 hours . The liquefied product was cooled to room temperature, washed with methanol, filtered under reduced pressure to obtain a methanol-liquefied product, and then the methanol was distilled off under reduced pressure in a rotary evaporator at 50°C to obtain a liquefied product.

[0033] (3) Resinization of the liquefied product: the obtained liquefied product was placed in a three-necked flask, and 5 mL of 1.25 mol / L...

Embodiment 2

[0038] The preparation of foam carbon adsorption material based on eucalyptus wood powder comprises the following steps:

[0039] (1) Pretreatment of waste biomass: The eucalyptus wood chips from the wood processing plant were pretreated by cleaning, drying and crushing, and then used as raw materials for future use.

[0040] (2) Liquefaction of eucalyptus powder: Mix 5 g of pulverized eucalyptus powder with 15 g of phenol, add 0.25 mL of concentrated sulfuric acid (98%) and 1 mL of phosphoric acid (85%), and liquefy at 160°C for 2 hours . The liquefied product was cooled to room temperature, washed with methanol, filtered under reduced pressure to obtain a methanol-liquefied product, and then the methanol was distilled off under reduced pressure in a rotary evaporator at 50°C to obtain a liquefied product.

[0041](3) Resinization of the liquefied product: the obtained liquefied product was placed in a three-necked flask, and 5 mL of 1.25 mol / L NaOH solution was added. Afte...

Embodiment 3

[0046] The preparation of foamed carbon adsorption material based on rice straw comprises the following steps:

[0047] (1) Pretreatment of waste biomass: the rice straws taken from the farmland are pretreated by cleaning, drying and crushing, and then used as raw materials for later use.

[0048] (2) Liquefaction of straw: Mix 5 g of pulverized powder with 15 g of phenol, add 0.25 mL of concentrated sulfuric acid (concentration: 98%) and 1 mL of phosphoric acid (concentration: 85%), and liquefy at 160°C for 2 hours. The liquefied product was cooled to room temperature, washed with methanol, filtered under reduced pressure to obtain a methanol-liquefied product, and then the methanol was distilled off under reduced pressure in a rotary evaporator at 50°C to obtain a liquefied product.

[0049] (3) Resinization of the liquefied product: the obtained liquefied product was placed in a three-necked flask, and 5 mL of 1.25 mol / L NaOH solution was added. After adding 25mL of 37% fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com