Method of using lanthanum ruthenate-bearing perovskite to activate peracetic acid to degrade fluoroquinolone antibiotics

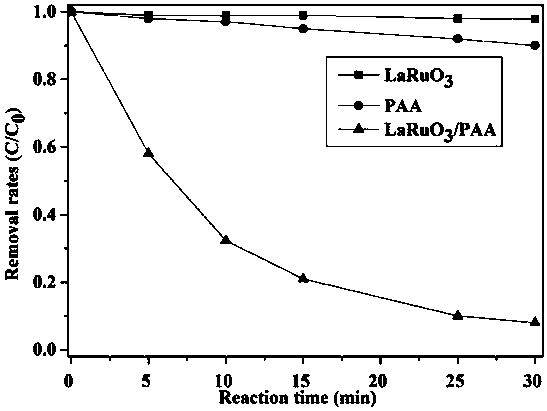

A technology of peracetic acid and fluoroquinolones, which is applied in chemical instruments and methods, chemical/physical processes, catalyst activation/preparation, etc., can solve problems such as secondary pollution and low activation efficiency of peracetic acid, and achieve economic cost reduction, Promote the promotion and application, improve the effect of activation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] (1) According to the molar ratio La:Ru:CA=1:1:2, weigh La(NO 3 ) 3 ·6H 2 O, RuCl 3 and C 6 h 8 o 7 ·H 2 O After mixing, add water to dissolve it, stir the solution vigorously, while raising the temperature to 65°C, continue to add ethylene glycol and keep it at this temperature until it becomes a viscous gel-like substance due to the slow evaporation of water;

[0031] (2) Transfer the beaker to a heating mantle to provide uniform heating, and the temperature rises to 120° C. for 1 hour, at which time a 3D polymer structure is formed through the reaction of citric acid and ethylene glycol;

[0032] (3) Place the beaker containing the remaining product in an oven (>100°C) to dry thoroughly;

[0033] (4) After drying, the polymer was pulverized and calcined at 800° C. for 8 hours to decompose the polymer and obtain the desired oxide phase.

Embodiment 2

[0035] (1) According to the molar ratio La:Ru:CA=1:5:6, weigh La(NO 3 ) 3 ·6H 2 O, RuCl 3 and C 6 h 8 o 7 ·H 2 O After mixing, add water to dissolve it, stir the solution vigorously, while raising the temperature to 65°C, continue to add ethylene glycol and keep it at this temperature until it becomes a viscous gel-like substance due to the slow evaporation of water;

[0036] (2) Transfer the beaker to a heating mantle to provide uniform heating, and the temperature rises to 120° C. for 1 hour, at which time a 3D polymer structure is formed through the reaction of citric acid and ethylene glycol;

[0037] (3) Place the beaker containing the remaining product in an oven (>100°C) to dry thoroughly;

[0038] (4) After drying, the polymer was pulverized and calcined at 900° C. for 7 hours to decompose the polymer and obtain the desired oxide phase.

Embodiment 3

[0040] (1) According to the molar ratio La:Ru:CA=1:2:3, weigh La(NO 3 ) 3 ·6H 2 O, RuCl 3 and C6 h 8 o 7 ·H 2 O After mixing, add water to dissolve it, stir the solution vigorously, while raising the temperature to 65°C, continue to add ethylene glycol and keep it at this temperature until it becomes a viscous gel-like substance due to the slow evaporation of water;

[0041] (2) Transfer the beaker to a heating mantle to provide uniform heating, and the temperature rises to 120° C. for 4 hours, at which time a 3D polymer structure is formed through the reaction of citric acid and ethylene glycol;

[0042] (3) Place the beaker containing the remaining product in an oven (>100°C) to dry thoroughly;

[0043] (4) After drying, the polymer is pulverized and calcined at 1000° C. for 6 hours to decompose the polymer and obtain the desired oxide phase.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com