Method for preparing heavy metal adsorption material from waste circuit board non-metal powder

A technology for waste circuit boards and adsorption materials, which is applied in the field of preparing heavy metal adsorption materials from non-metallic powders of waste circuit boards, which can solve the problems of low utilization value, few utilization methods, waste of resources, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

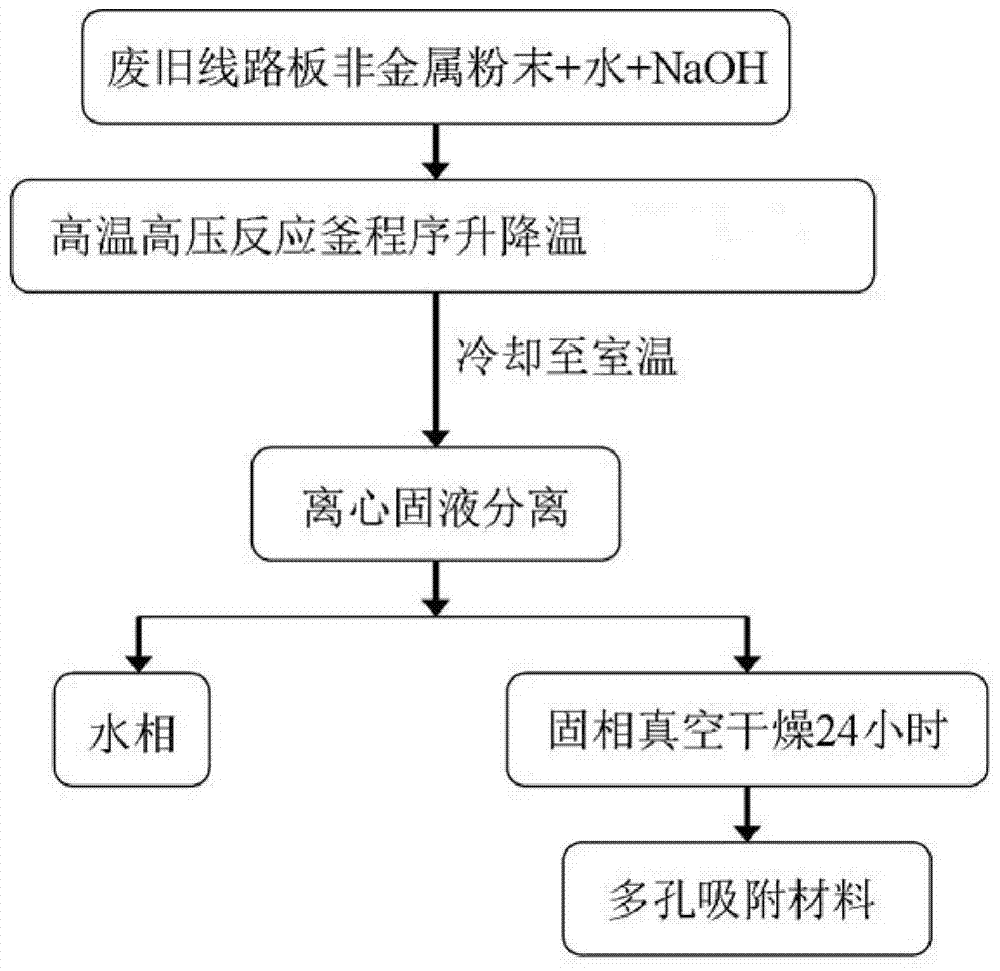

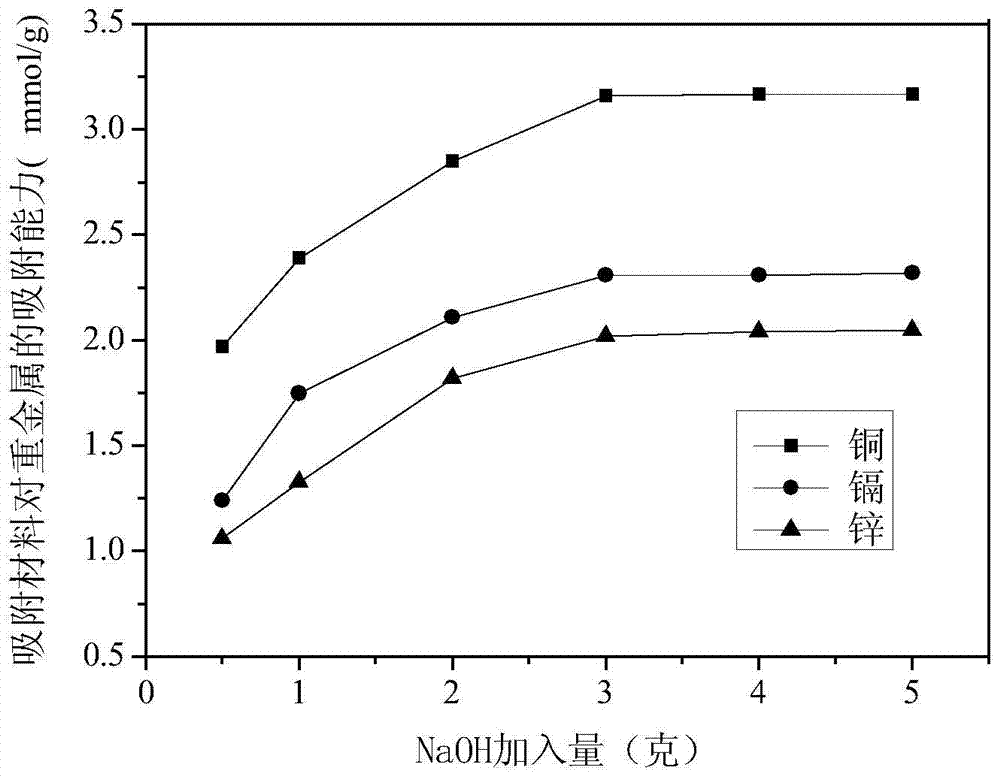

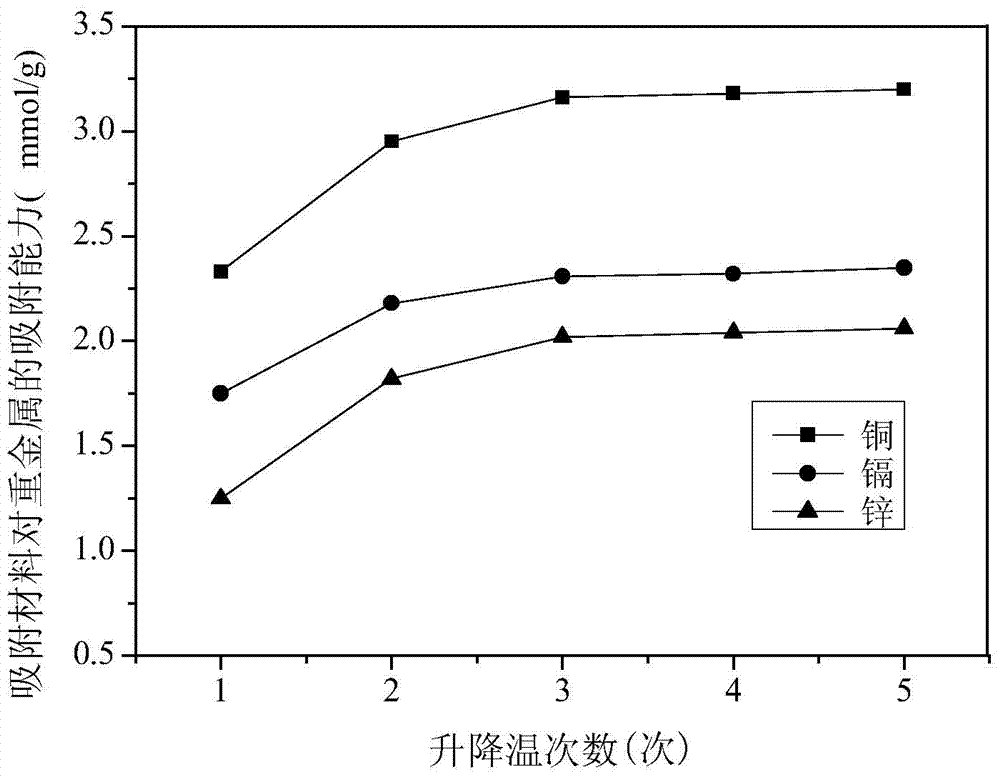

Embodiment 1

[0020] Such as figure 2 As shown, first place 10 grams of micron-sized waste circuit board non-metallic powder and 200 ml of water in a high-temperature and high-pressure reactor with a volume of 500 ml, then add 3 grams of NaOH to the reactor, seal the reactor, and start heating. The internal pressure of the reactor was controlled at 5 MPa by manual pressurization. The temperature was raised to 200°C at a rate of 10°C / min by temperature programming control, the heating was stopped, and the temperature began to drop. When the temperature dropped to 90°C, the temperature was raised to 200°C at a rate of 10°C / min. Heat up and down 3 times according to the above procedure. After the reaction, the reactor was cooled to room temperature. The cooled product was transferred to a centrifuge tube, centrifugally filtered, and the solid phase was washed three times with deionized water, each time with 10 ml of deionized water. Finally, the solid-phase product was vacuum-dried for 24 ...

Embodiment 2

[0022] Such as figure 2 As shown, first place 10 grams of micron-sized waste circuit board non-metallic powder and 200 milliliters of water in a high-temperature and high-pressure reactor with a volume of 500 milliliters, then add 0.5 grams of NaOH to the reactor, seal the reactor, and start heating. The internal pressure of the reactor was controlled at 5 MPa by manual pressurization. The temperature was raised to 200°C at a rate of 10°C / min by temperature programming control, the heating was stopped, and the temperature began to drop. When the temperature dropped to 90°C, the temperature was raised to 200°C at a rate of 10°C / min. Heat up and down 3 times according to the above procedure. After the reaction, the reactor was cooled to room temperature. The cooled product was transferred to a centrifuge tube, centrifugally filtered, and the solid phase was washed three times with deionized water, each time with 10 ml of deionized water. Finally, the solid-phase product was ...

Embodiment 3

[0024] Such as figure 2 As shown, first place 10 grams of micron-sized waste circuit board non-metallic powder and 200 ml of water in a high-temperature and high-pressure reactor with a volume of 500 ml, then add 1 gram of NaOH to the reactor, seal the reactor, and start heating. The internal pressure of the reactor was controlled at 5 MPa by manual pressurization. The temperature was raised to 200°C at a rate of 10°C / min by temperature programming control, the heating was stopped, and the temperature began to drop. When the temperature dropped to 90°C, the temperature was raised to 200°C at a rate of 10°C / min. Heat up and down 3 times according to the above procedure. After the reaction, the reactor was cooled to room temperature. The cooled product was transferred to a centrifuge tube, centrifugally filtered, and the solid phase was washed three times with deionized water, each time with 10 ml of deionized water. Finally, the solid-phase product was vacuum-dried for 24 h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com