Activation technique for lumber chemical nickel plating

A technology of electroless nickel plating and wood, applied in liquid chemical plating, metal material coating process, coating and other directions, can solve problems such as strength reduction, and achieve the effects of low price, cost reduction, and simple preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

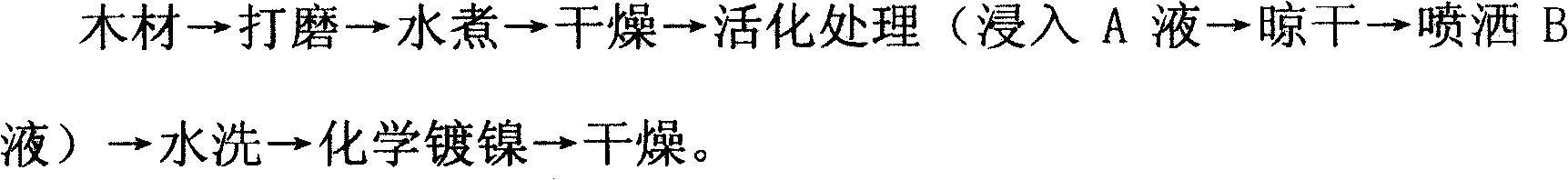

Method used

Image

Examples

Embodiment 1

[0018] First use a sander to smooth the burrs and burrs of the wood, then immerse the polished wood in water at 90°C, boil for 10 minutes, and dry at 100±2°C for 2 hours. Nickel sulfate is dissolved in the distilled water that has added hydrochloric acid (concentration is 37%), is mixed with the acid solution of nickel sulfate, is A liquid, and the weight ratio of nickel sulfate, hydrochloric acid, distilled water is: 0.004: 0.005: 1; Sodium is dissolved in distilled water added with sodium hydroxide to prepare an alkaline solution of sodium borohydride, ie liquid B. The weight ratio of sodium borohydride, sodium hydroxide and distilled water is: 0.016:0.005:1. Immerse the pretreated wood in liquid A for 5 minutes, take it out and dry it until there is no droplet on the surface, and then spray the liquid B in the atomizer evenly on the surface of the wood soaked in liquid A to complete the activation of the wood. After activation After the wood is rinsed with distilled water, ...

Embodiment 2

[0020] First use a sander to smooth the burrs and burrs of the wood, then immerse the polished wood in water at 80°C, boil for 15 minutes, and dry at 100±2°C for 2 hours. Dissolve nickel sulfate in distilled water that has added hydrochloric acid (concentration is 37%), be mixed with the acid solution of nickel sulfate, i.e. liquid A, the weight ratio of nickel sulfate, hydrochloric acid, distilled water is 0.012: 0.004: 1; Add sodium borohydride Dissolved in distilled water added with sodium hydroxide to prepare an alkaline solution of sodium borohydride, ie liquid B, the weight ratio of sodium borohydride, sodium hydroxide and distilled water is 0.008:0.004:1. Immerse the pretreated wood in liquid A for 3 minutes, take it out and dry it until there is no droplet on the surface, then spray the liquid B in the atomizer evenly on the surface of the wood soaked in liquid A to complete the activation of the wood. After activation After the wood is rinsed with distilled water, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com