Low cost activation technique of boron-rich slag

A process method, boron-rich slag technology, applied in the comprehensive utilization of resources, metallurgy, and chemical industry, can solve the problems of high energy consumption, long slow cooling time, etc., and achieve the effect of low energy consumption, low production cost, and less equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

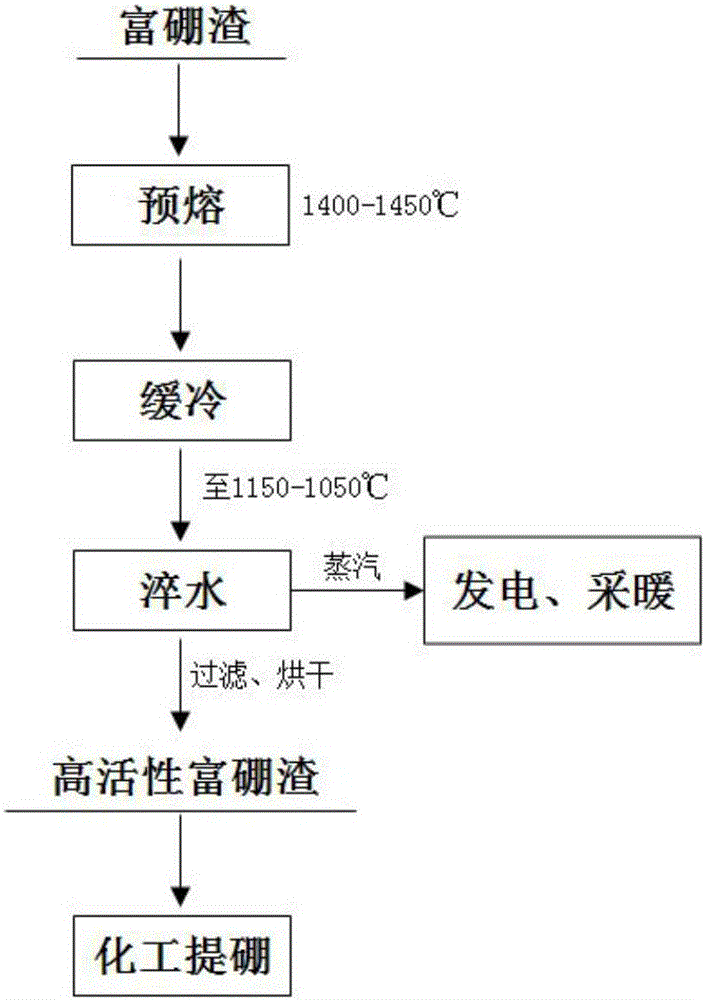

Method used

Image

Examples

Embodiment 1

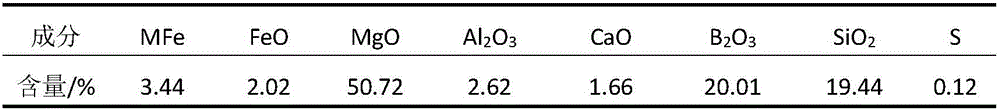

[0019] Table 1 shows the chemical composition of the boron-rich slag obtained after reduction and smelting of a boron-iron concentrate. Heat the boron-rich slag to 1400°C, keep it warm for 10 minutes, and then quickly pour the boron-rich slag into water for quenching. After the quenched boron-rich slag was dried, the activity was measured by alkaline hydrolysis at atmospheric pressure. It was found that the activity of the boron-rich slag was only 46.36%, which could not meet the needs of chemical production. The main reason was that the boron-rich slag had not yet started to crystallize.

[0020] Table 1 Main components of boron-rich slag

[0021]

Embodiment 2

[0023] Table 1 shows the chemical composition of the boron-rich slag obtained after reduction and smelting of a boron-iron concentrate. Heat the boron-rich slag to 1400°C and keep it warm for 10 minutes, then quickly pour the boron-rich slag into the slag tank preheated to 1200°C for natural slow cooling until room temperature. The activity of the boron-rich slag was measured by the atmospheric pressure alkaline hydrolysis method. At this time, the activity of the boron-rich slag was 86.46%, which was relatively high and fully met the requirements of boron chemical production. At this time, the boron-rich slag crystallized well, and the Suianite and Xiaotengite phases developed, and the highly active Suianite was the main boron-containing phase.

Embodiment 3

[0025]Table 1 shows the chemical composition of the boron-rich slag obtained after reduction and smelting of a boron-iron concentrate. Heat the boron-rich slag to 1400°C, keep it warm for 10 minutes, then quickly pour the boron-rich slag into the slag tank preheated to 1200°C for natural slow cooling, when the boron-rich slag is slowly cooled to 1100°C, open the slag tank, put The high-temperature solid boron-rich slag is poured into a closed water tank for rapid quenching, and a water vapor recovery device is used to collect the high-temperature water vapor generated during the quenching process. After the quenched boron-rich slag was dried, the activity was determined by alkaline hydrolysis at atmospheric pressure. It was found that the activity of the boron-rich slag was 87.02%, which was the highest activity, which fully met the requirements of boron chemical production. At the same time, the production cycle is shortened, and part of the sensible heat energy is recovered....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com