Regeneration and activation technique of iodine pollution solid adsorbent

A solid adsorbent, regeneration and activation technology, applied in the direction of filter regeneration, combustible gas purification, combustible gas purification/transformation, etc., to achieve high industrialization implementation prospects, reduce deiodination costs, and low concentration effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

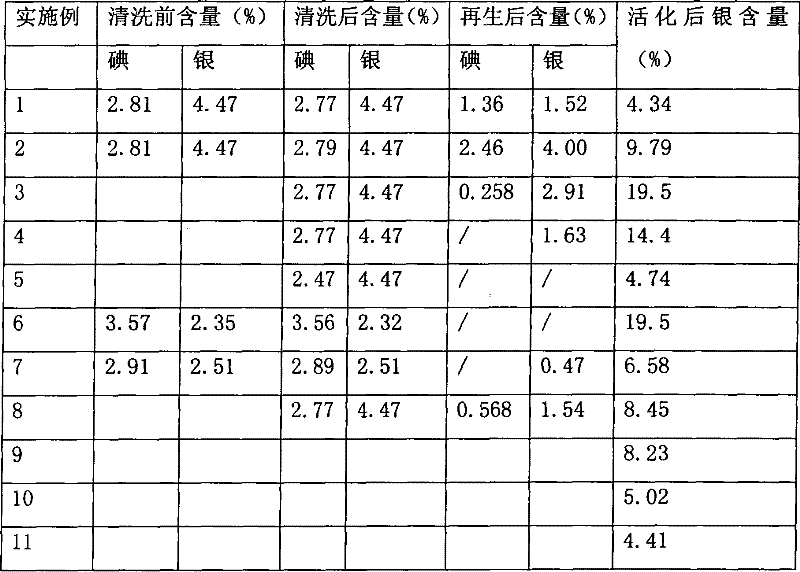

Examples

Embodiment 1

[0029] The regeneration and activation process of iodine polluted solid adsorbent comprises the following steps successively:

[0030] (1) Cleaning: Place 10 ml of iodine-contaminated solid adsorbent artificially synthesized zeolite molecular sieve ZSM-5 in 1% acetic acid for cleaning for 2 hours and dry;

[0031] (2) Regeneration Under conditions of 1-20° C. and normal pressure, soak the adsorbent treated in the step (1) in a standing state in a 1% sodium thiosulfate solution for 72 hours;

[0032] (3) Activated and then placed in the column, the liquid hourly space velocity is 18h -1 , the temperature is 30 ° C into the active metal Ag + Solution 0.15mol / l silver nitrate carries out ion exchange, until the active metal Ag on the solid adsorbent is polluted by iodine + The concentration reaches the concentration before being polluted again, and then it is washed and dried for deiodination.

Embodiment 2

[0034] (1) Cleaning Change the solid adsorbent polluted by iodine into natural zeolite molecular sieve LZ-210 and place in 0.05% acetic acid to clean for 5h, dry; carry out (2) regeneration, (3) by the same steps as in Example 1 Activation operation.

Embodiment 3

[0036] The step (2) of embodiment 1 is regenerated, and the iodine-contaminated solid adsorbent cleaned through step (1) is placed in the column instead, and the liquid hourly space velocity LHSV is 18h -1 , at a temperature of 18°C, feed 2% sodium thiosulfate solution until the concentration of sodium thiosulfate solution in the effluent tail liquid reaches the inlet concentration, and the appearance of the adsorbent carrier is beige as the new one, so that the iodine-contaminated Pollutants in the effective pores of the adsorbent are all precipitated, no desorption is performed, and other operations are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com