Patents

Literature

194 results about "Rate regulation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Rate regulation is a government activity in which the government or representatives of the government regulate rates charged to consumers. This practice is designed to protect consumers from excessive or unreasonable rates, to ensure that basic rates are fixed at low costs to make them accessible for people of low income,...

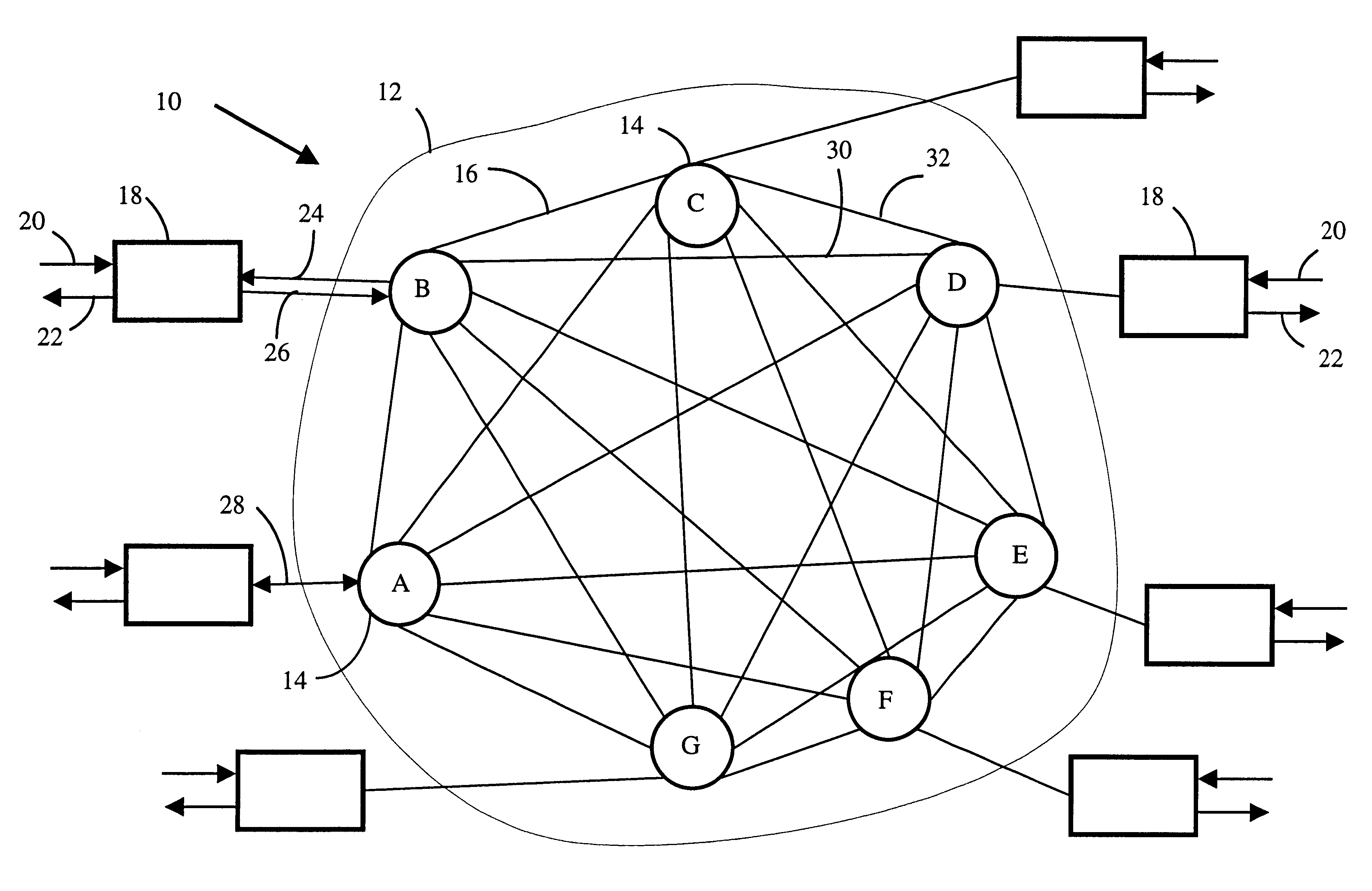

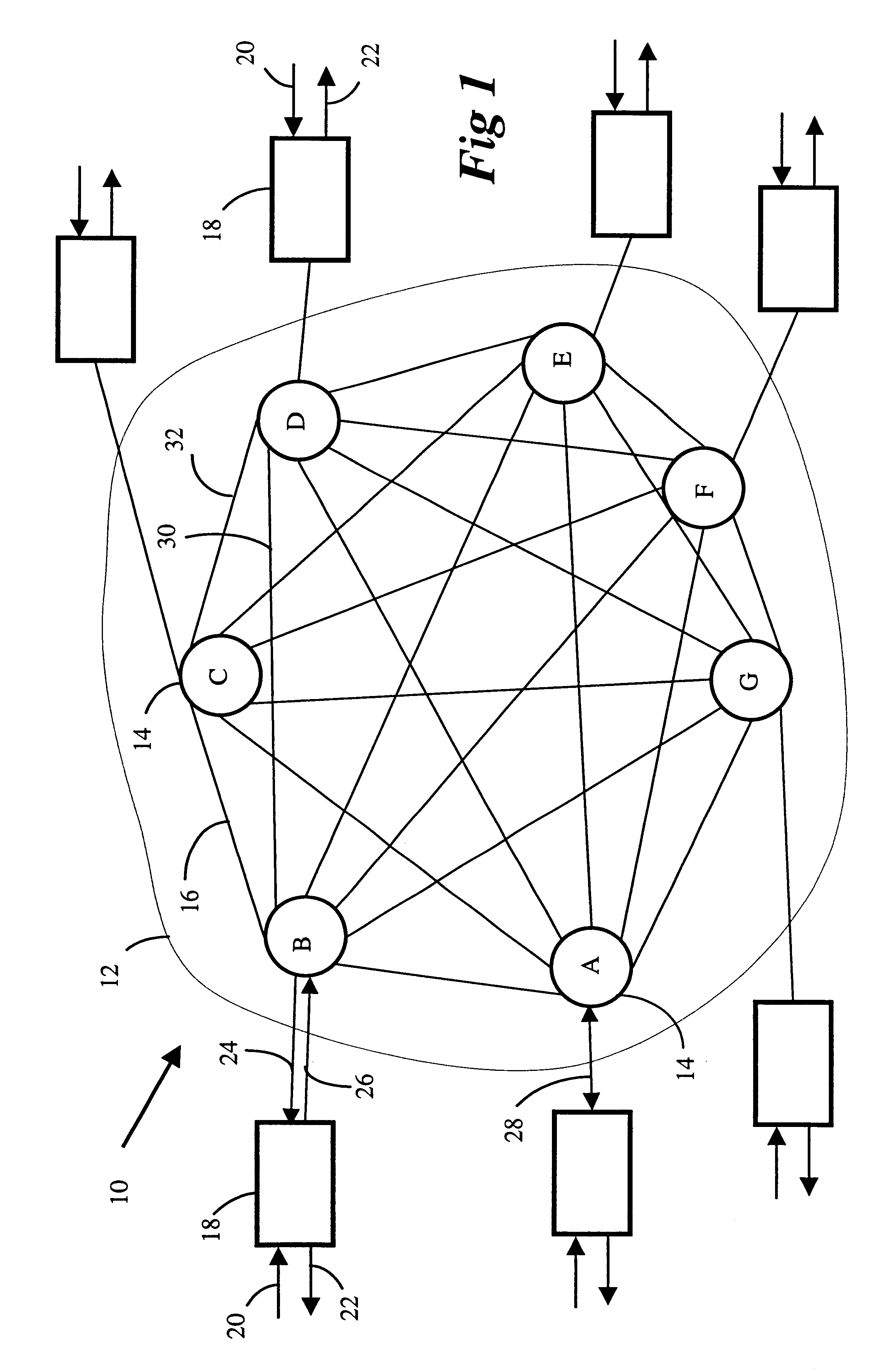

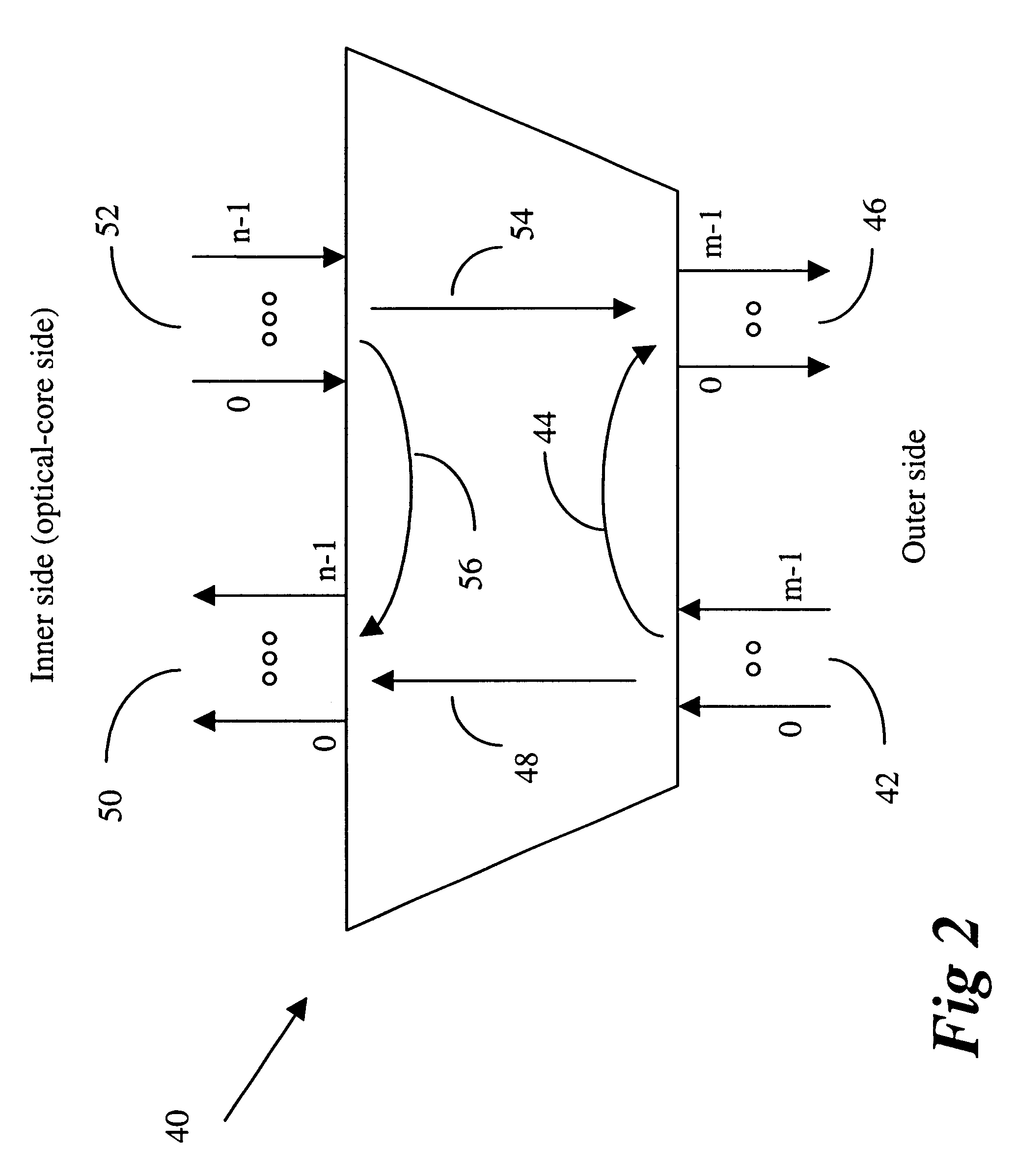

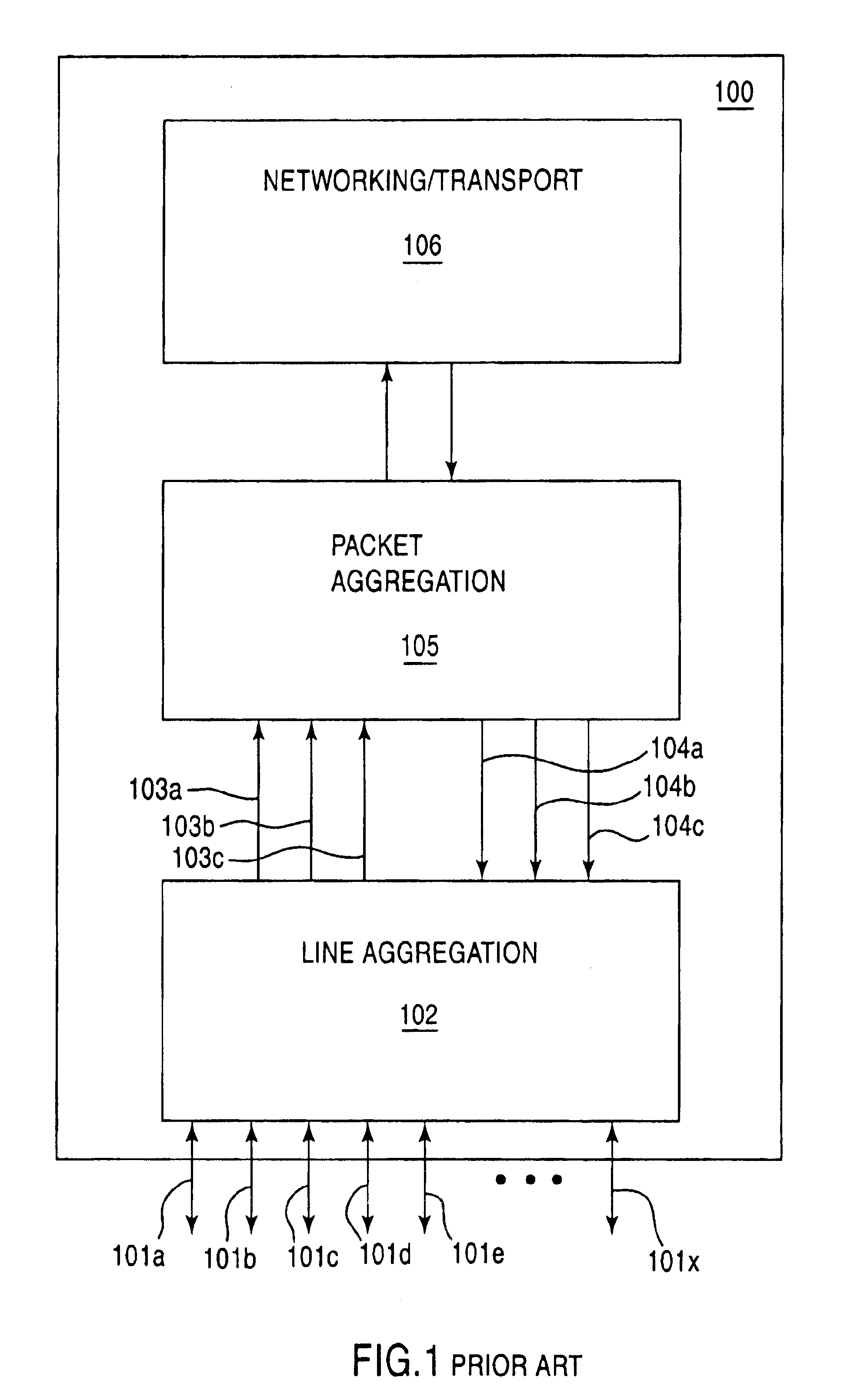

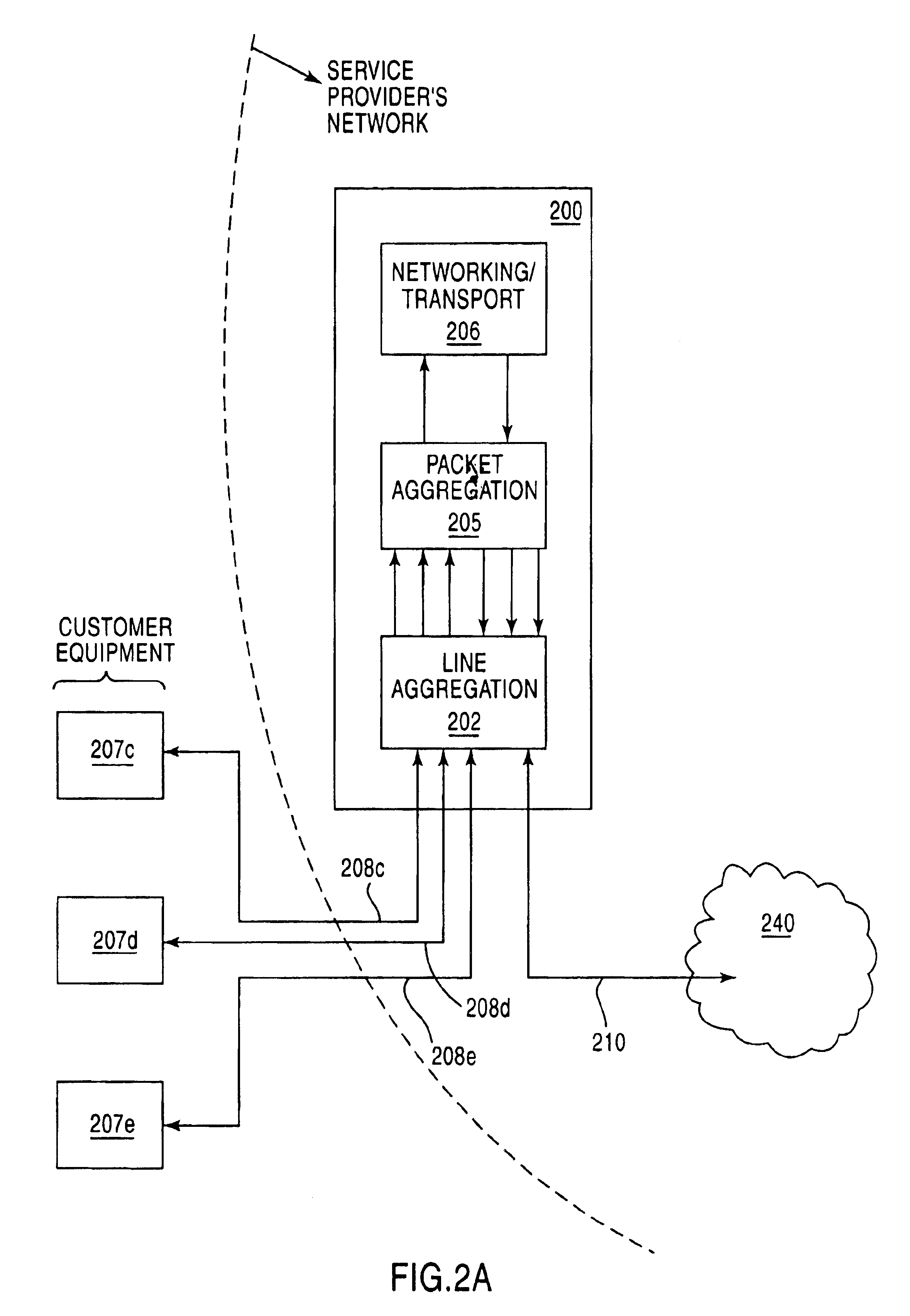

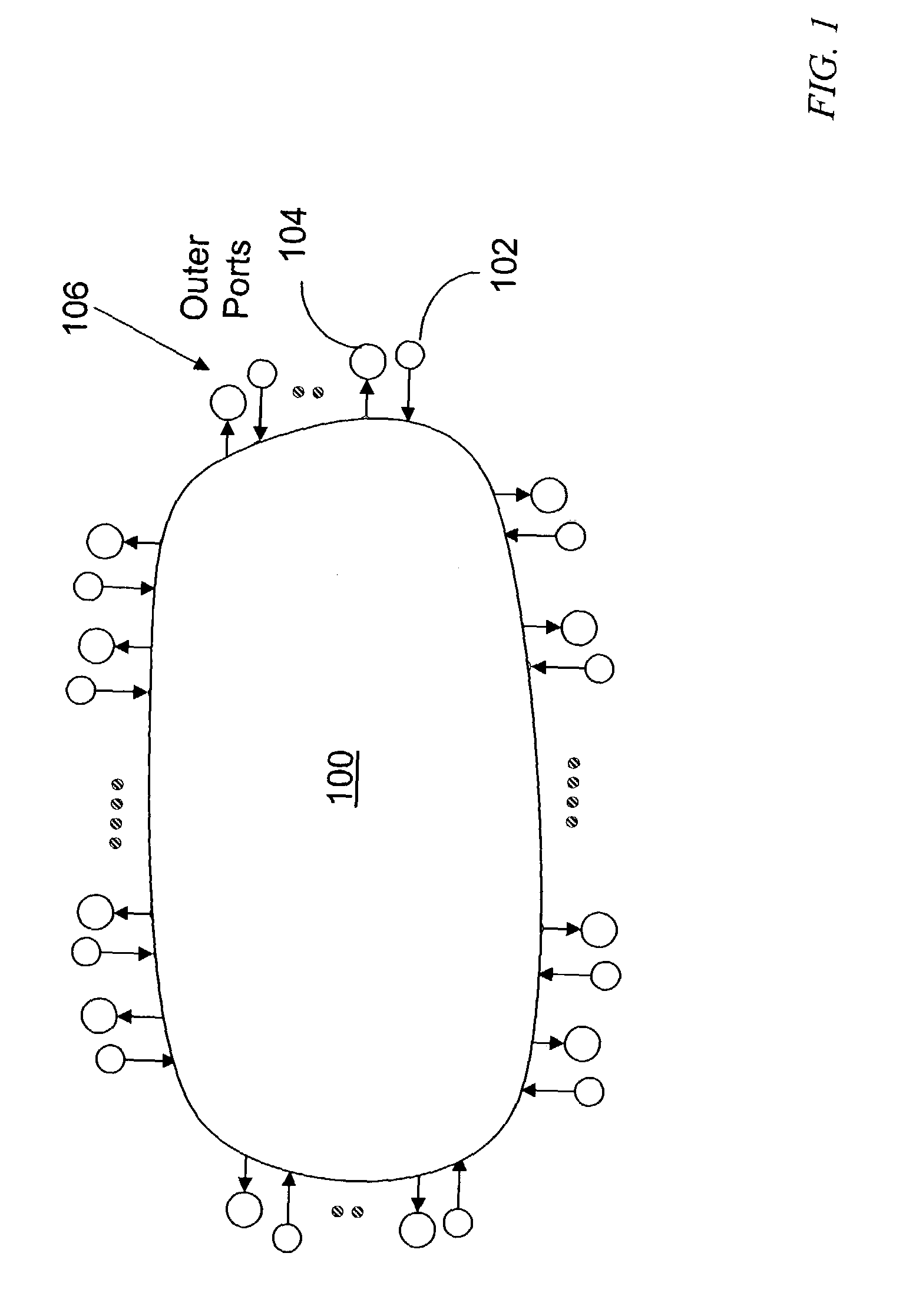

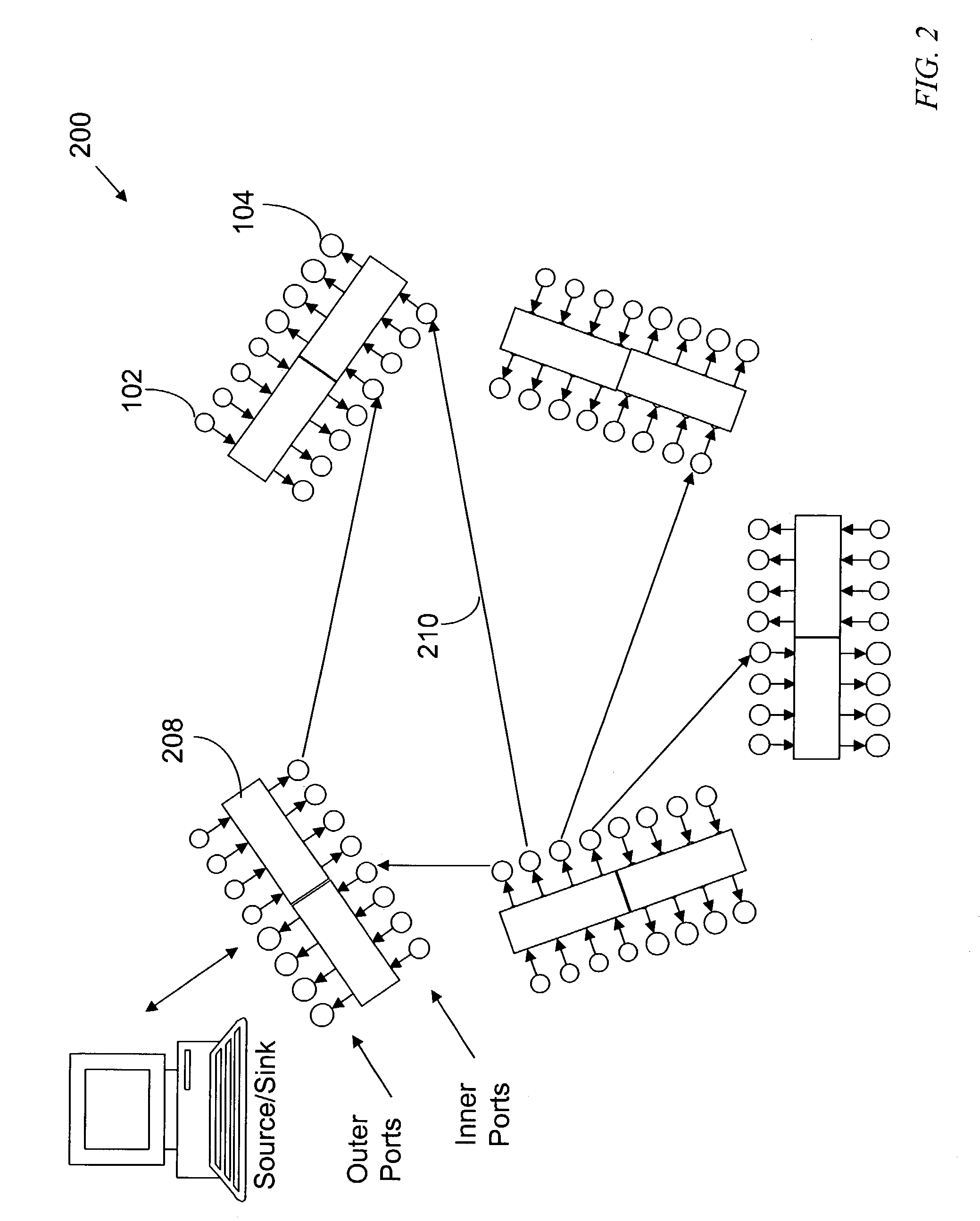

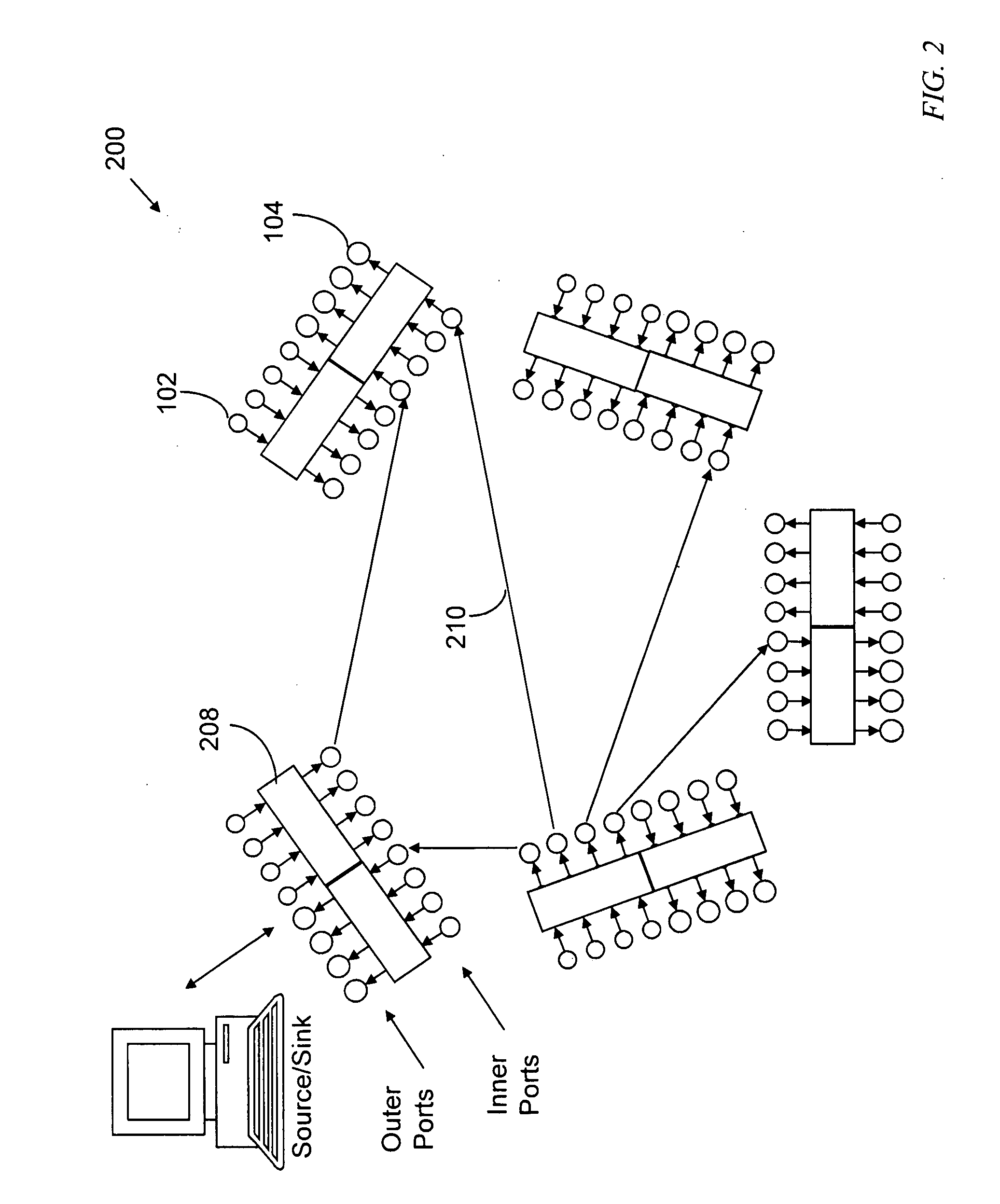

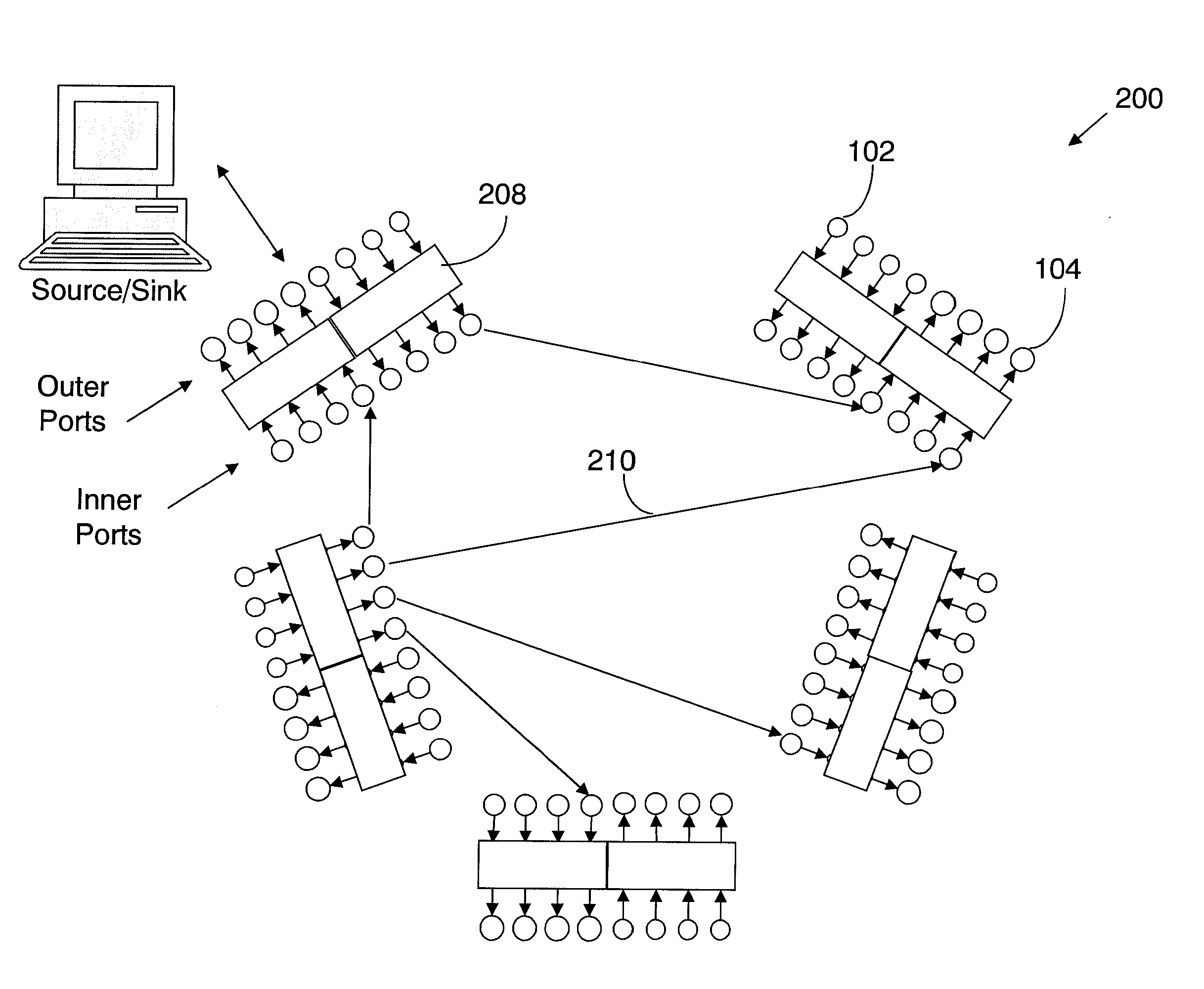

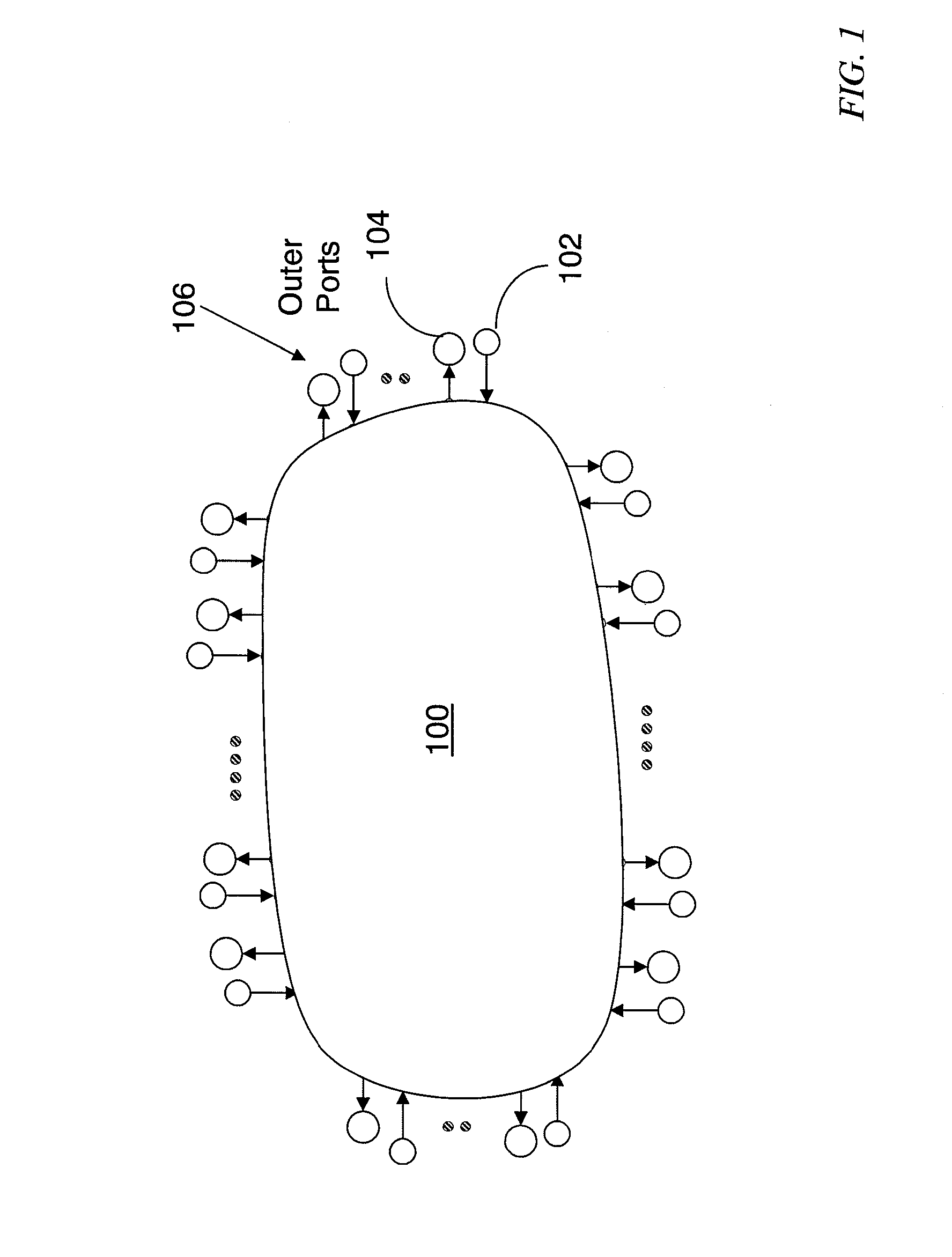

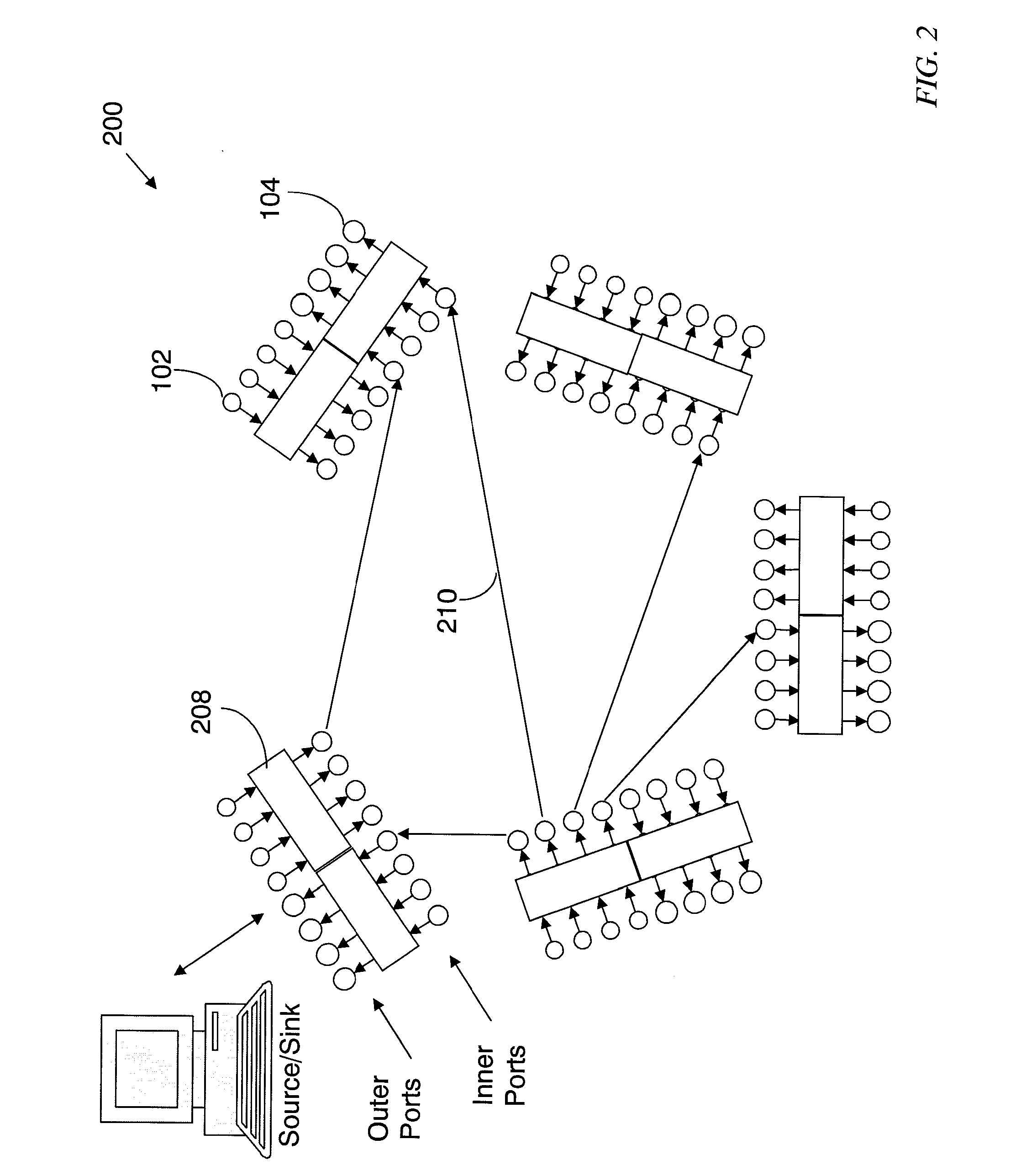

Large scale communications network having a fully meshed optical core transport network

InactiveUS6339488B1Easy to implementWavelength-division multiplex systemsData switching by path configurationTelecommunications networkEngineering

A fully meshed telecommunications network based on an optical core transport network having a plurality of optical nodes is described. An electronic edge switch is connected to an optical node and dedicated channels are established between all the possible pairs of electronic edge switches through their associated optical nodes and the optical core transport network. Connection paths are set up using a channel or channels between a pair of electronic edge switches which perform major functions concerning connection routes, including rate regulation, path establishment, etc.

Owner:CIENA

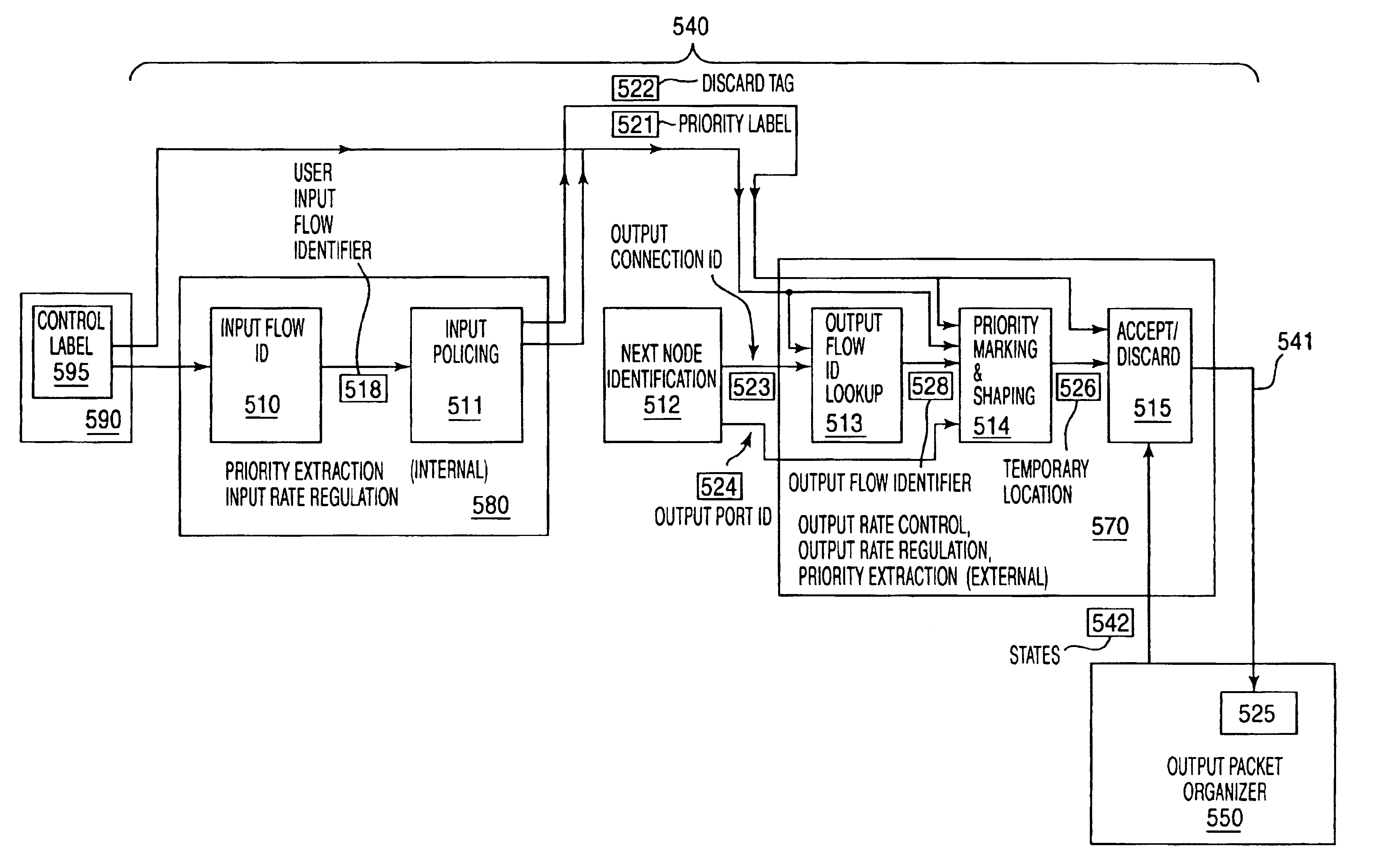

Method and apparatus for input rate regulation associated with a packet processing pipeline

InactiveUS6882642B1Multiplex system selection arrangementsCircuit switching systemsComputer sciencePacket processing

A method is described that involves presenting packet header information from a packet and packet size information for the packet to a pipeline that comprises multiple stages. One of the stages identifies, with the packet header information, where input flow information for the packet is located. The input flow information is then fetched. The input flow information identifies where input capacity information for the packet is located and the input capacity information is then fetched. Another of the stages compares an input capacity for the packet with the packet's size and indicates whether the packet is conforming or non-conforming based upon the comparison. The input capacity is calculated from the input capacity information.

Owner:NOKIA SOLUTIONS & NETWORKS OY

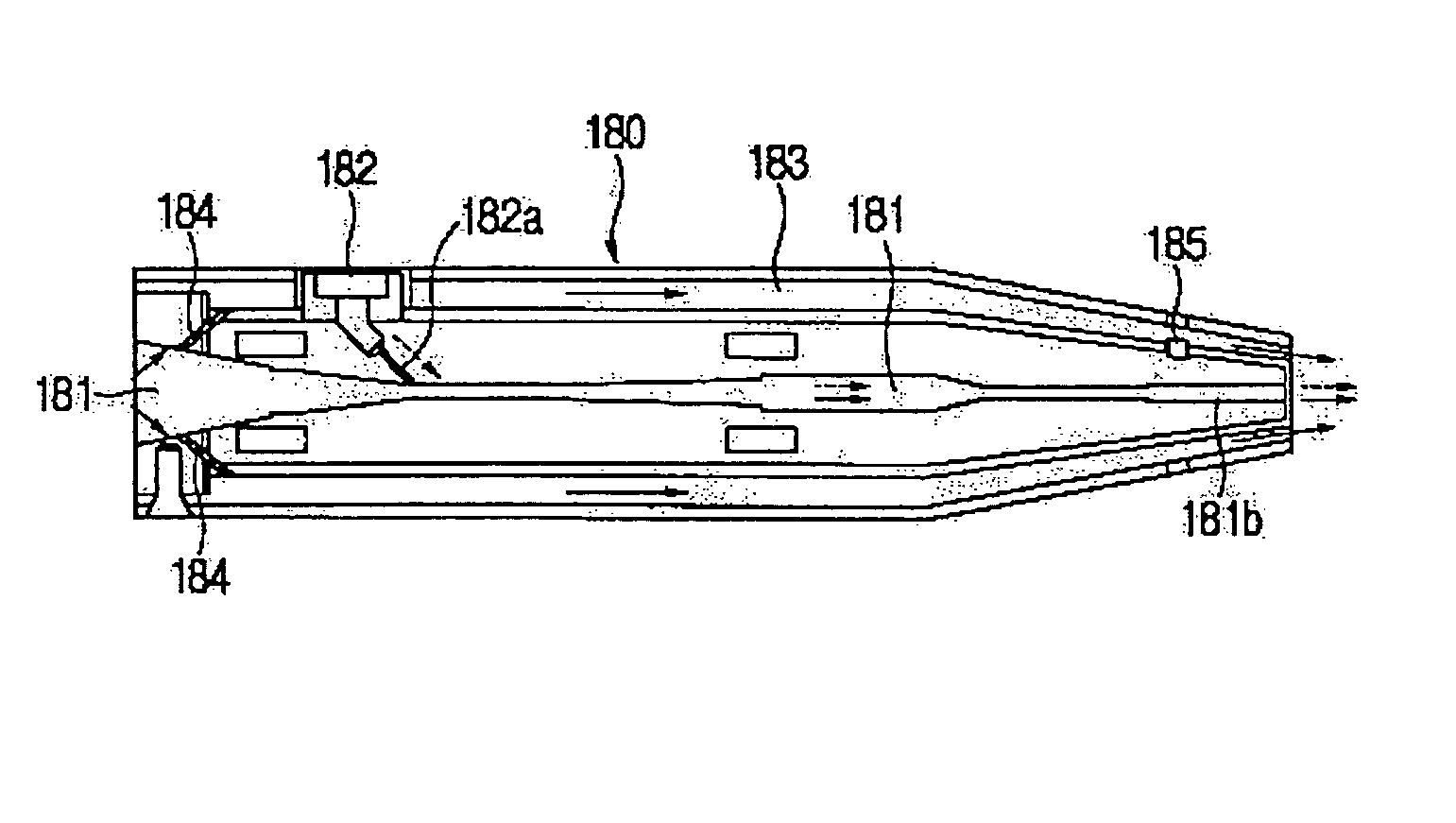

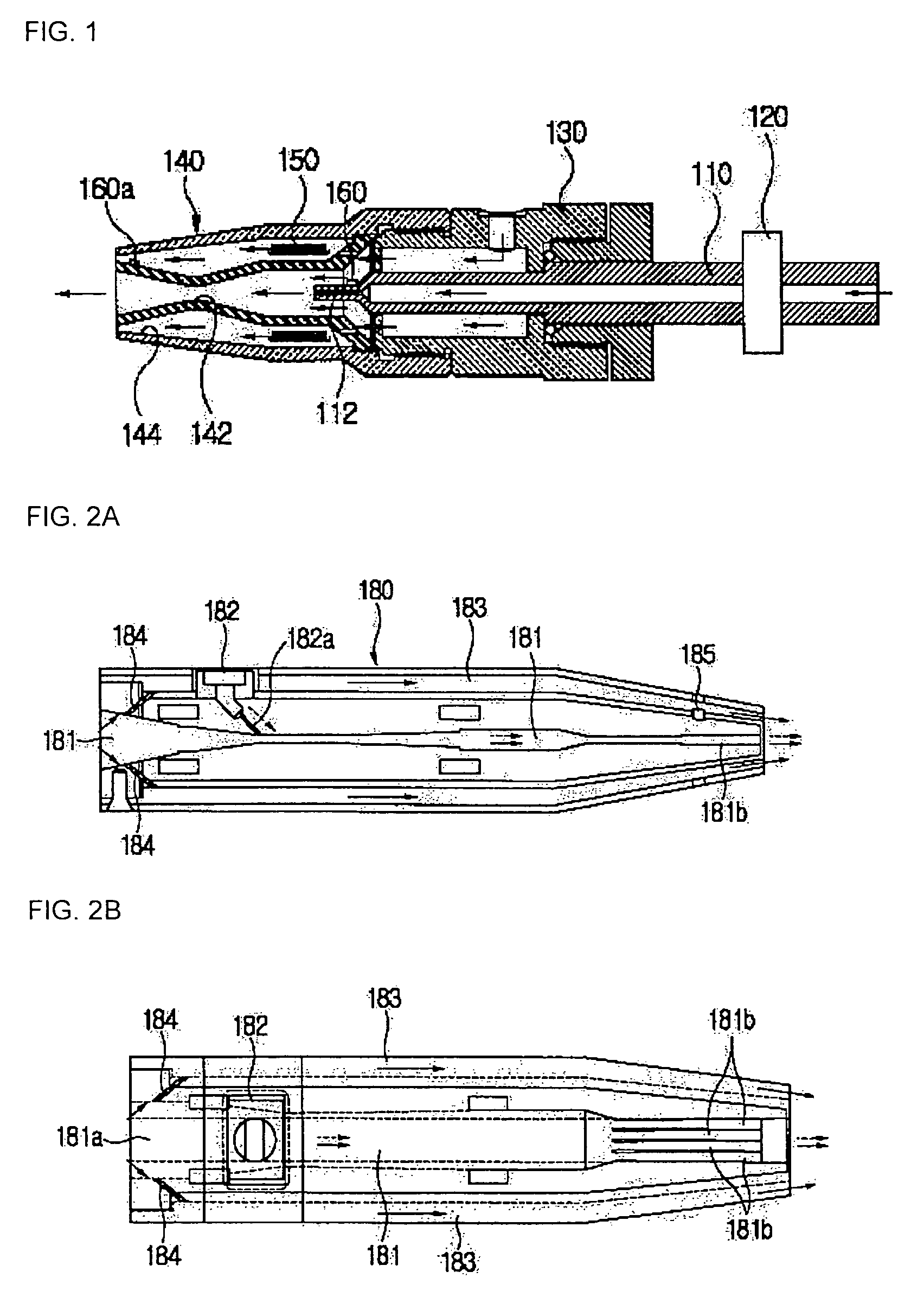

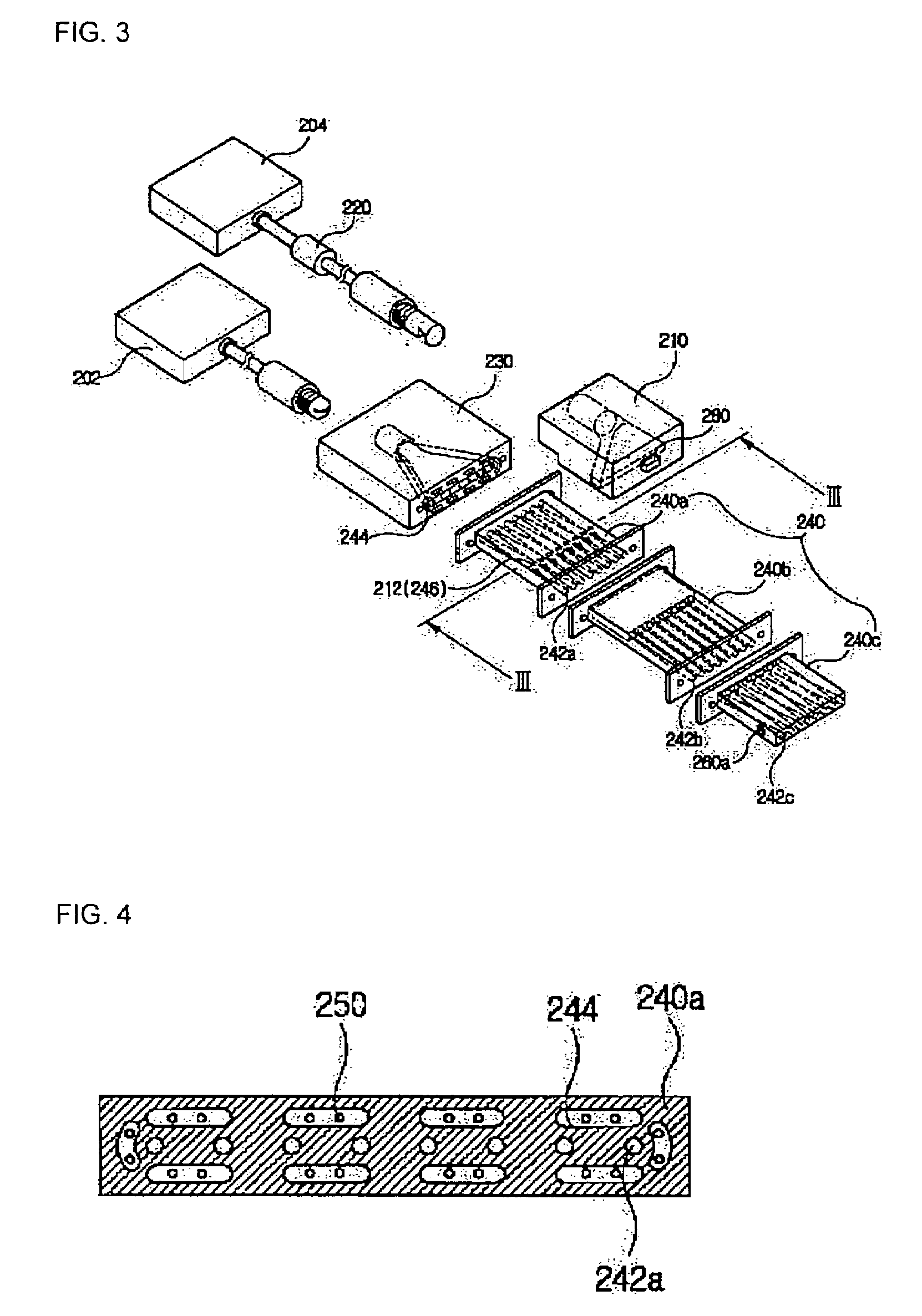

Nozzle for spraying sublimable solid particles entrained in gas for cleaning surface

ActiveUS7442112B2Blast gunsSemiconductor/solid-state device manufacturingSolenoid valveSolid particle

A nozzle for spraying sublimable solid particles and preventing frost from forming at surfaces of the nozzle. The nozzle includes: a cleaning agent block for phase-changing a cleaning agent into a snow containing sublimable solid particles; a nozzle block for growing the cleaning agent snow through adiabatic expansion and spraying the grown cleaning agent snow onto a surface of an object; a carrier gas block for supplying a carrier gas to the nozzle block to mix with the cleaning agent snow; and a heater for heating at least a portion of the carrier gas supplied from the carrier gas supply source. Fine dry ice particles and liquid CO2, passing through a solenoid valve from a CO2 reservoir tank and a pressure drop of a flow rate regulation valve, are introduced into the spray nozzle and then mixed with the carrier gas, such as N2 or purified air, and discharged.

Owner:K C TECH

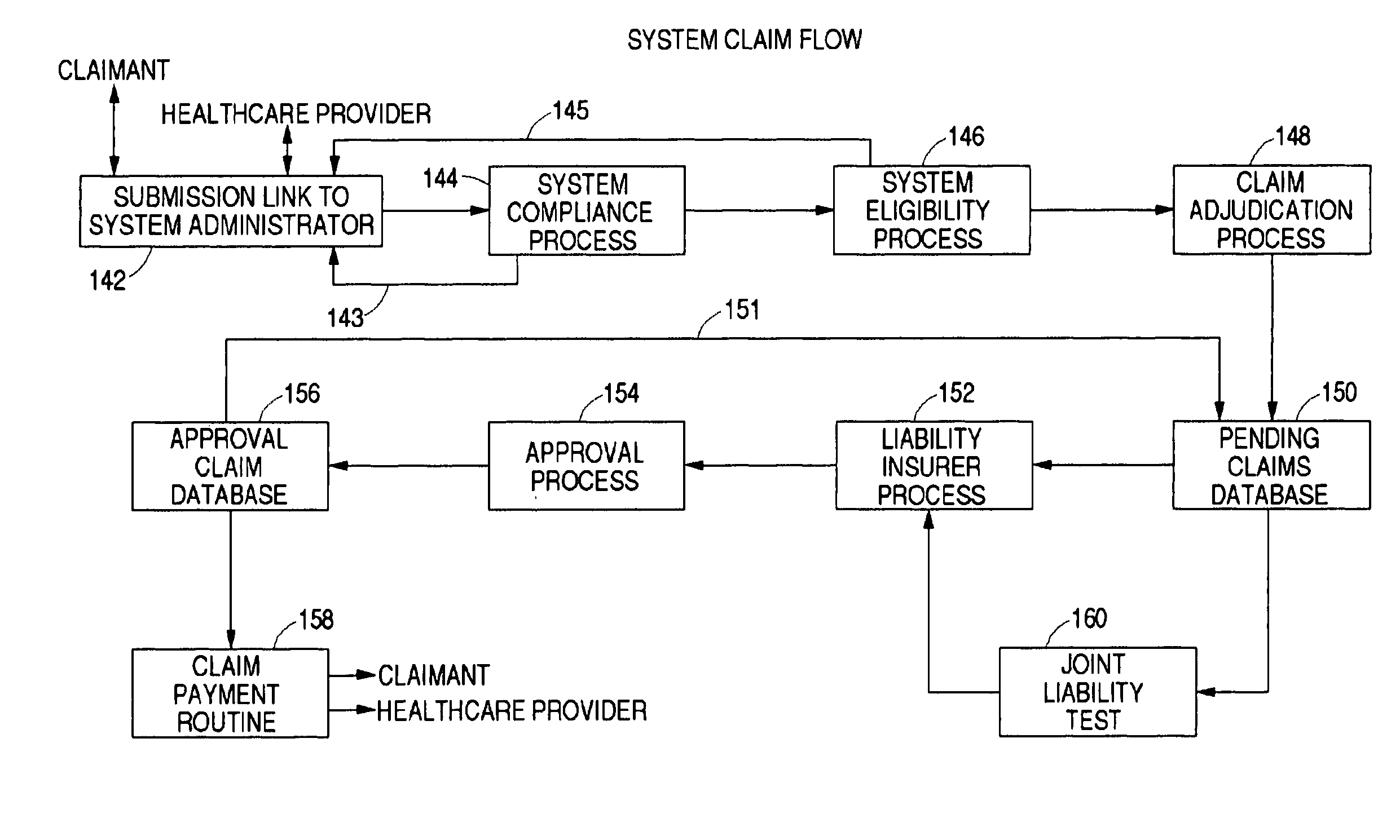

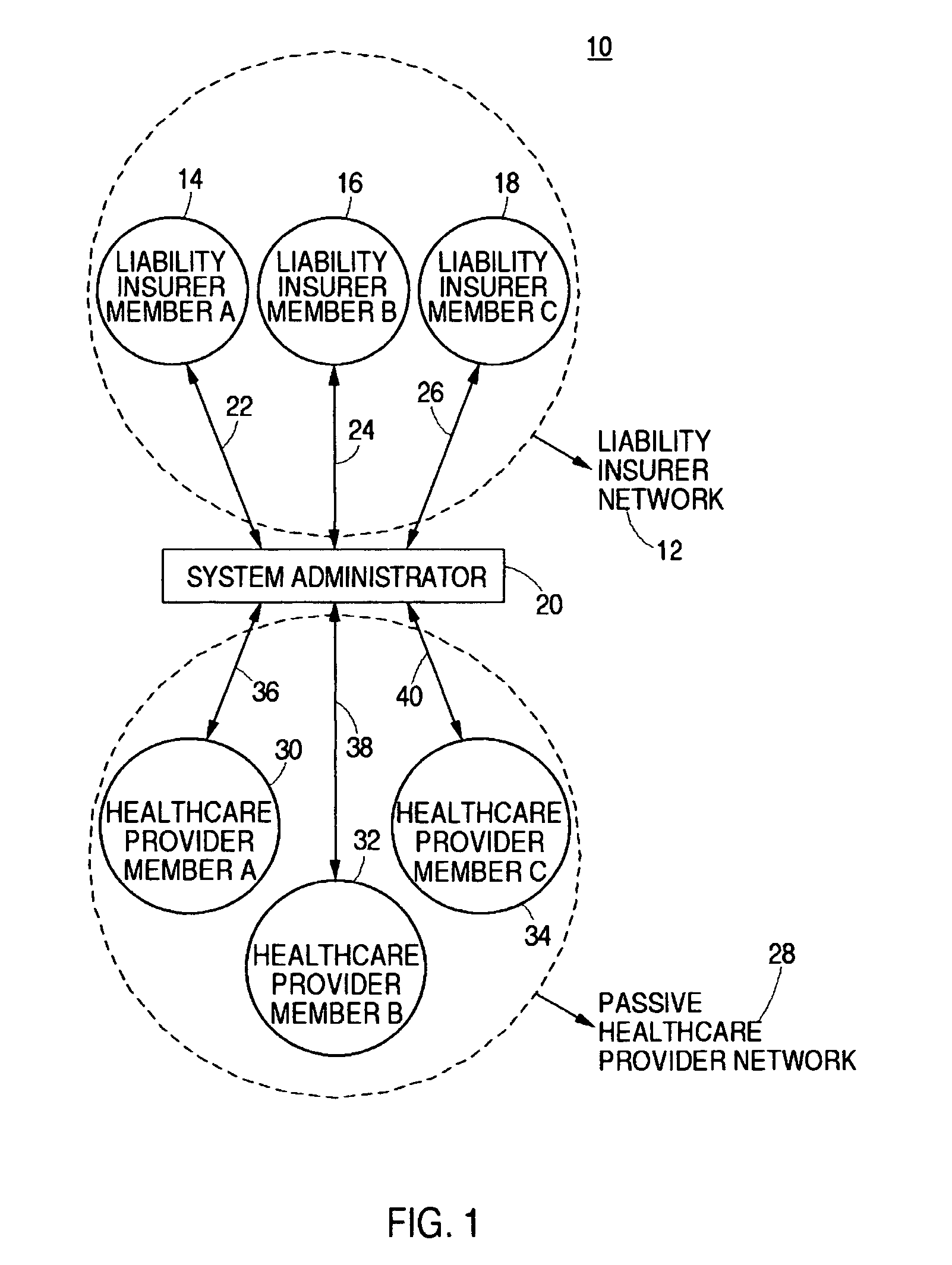

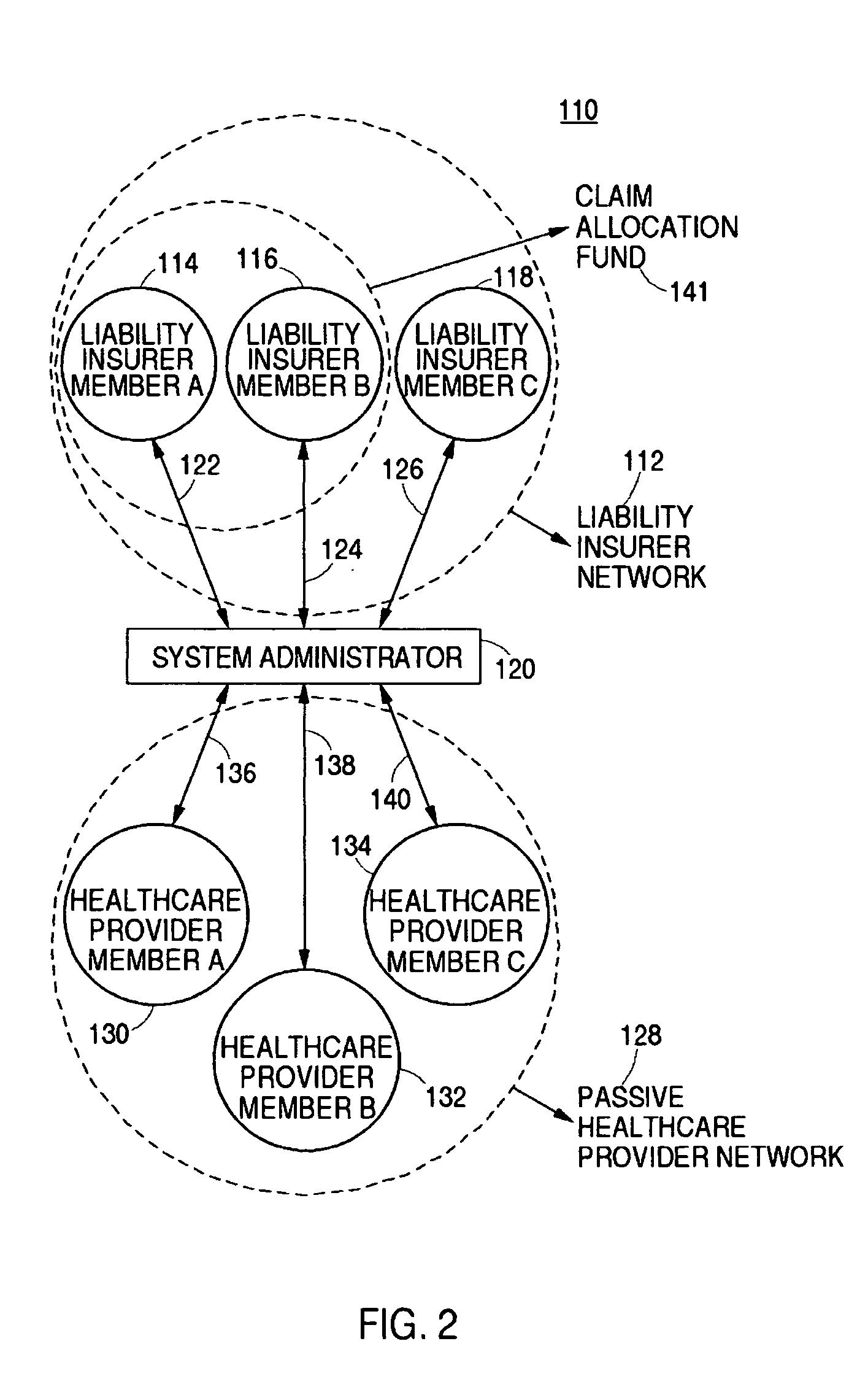

System and method for managing liability insurer healthcare claims

A system and method for managing liability insurer's healthcare claims, allows liability insurers, such as property and casualty insurers, who have no direct policy relationship with patients for whom they become financially responsible, to take advantage of healthcare provider “rate regulations,” and “healthcare management,” including incentives, heretofore only available to healthcare insurers from healthcare providers within an “active network.” A system administrator manages clamant healthcare claims from member passive network healthcare providers for member liability insurers that become financially responsible for these claims as a result of the actions or inactions of their liability policyholders. The liability insurer members within the insurer network are in contractual relationship with the system administrator who is in contractual relationship with member healthcare providers of the passive healthcare provider network such that when a provider of healthcare product or service submits a claim, for which a system liability insurer member is financially responsible, the system administrator validates the claim as falling in the system; applies the provider network rules; and applies provider coverage rules to determine the level of coverage by the member liability insurer for the claim. Based on this determination, that portion of the claim covered by the member liability policy the Claimant is paid by the system administrator. In another aspect, an Allocation Fund is provided to pay claims where more than one system liability insurer may be liable for the claim.

Owner:GREAT LAKES HLDG

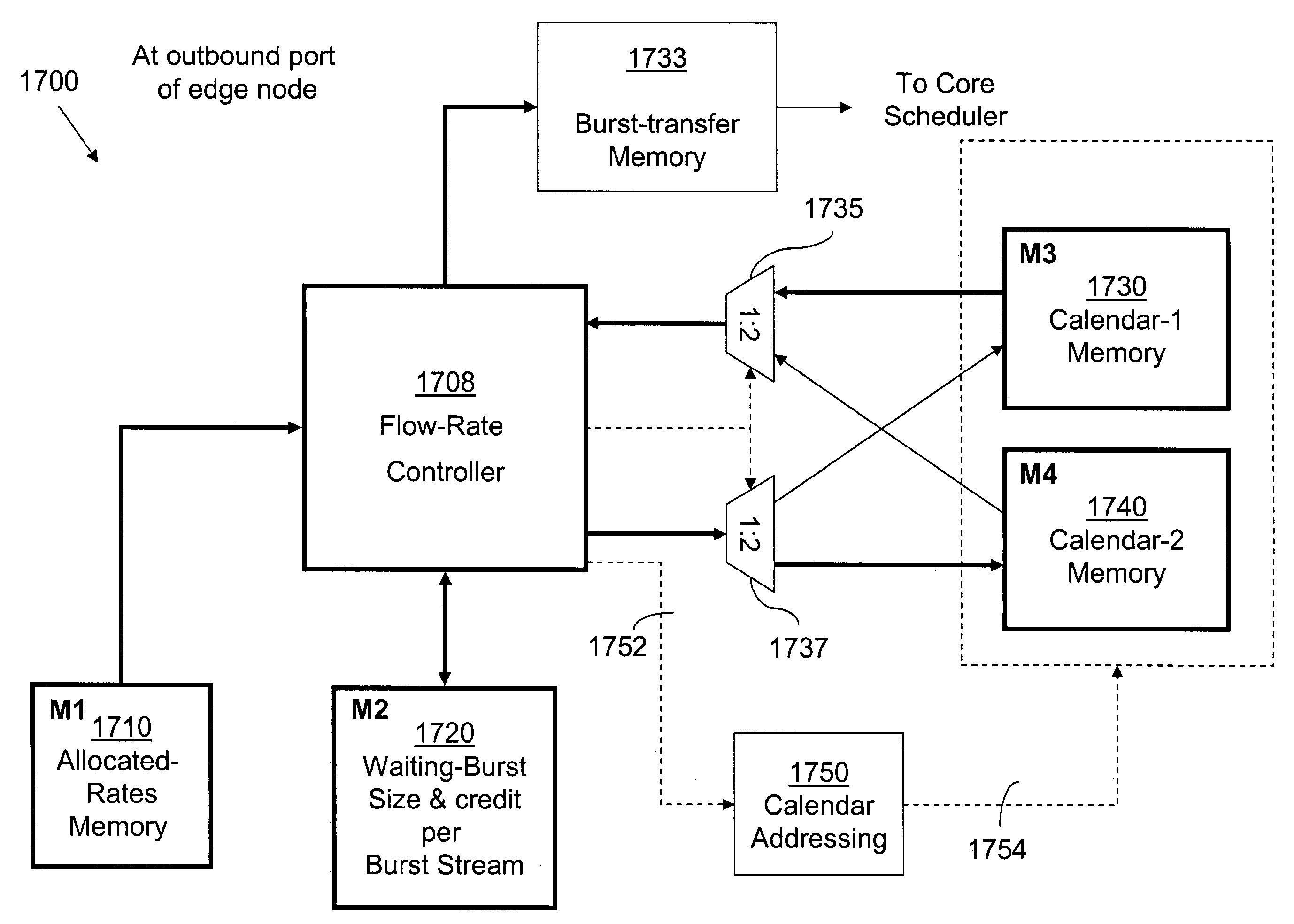

Regulating data-burst transfer

InactiveUS7369491B1Multiplex system selection arrangementsError preventionQuality of serviceDownstream processing

The invention discloses methods and apparatus for regulating the transfer of data bursts across a data network comprising electronic edge nodes interconnected by fast-switching optical core nodes. To facilitate switching at an electronic edge node, data bursts are organized into data segments of equal size. A data segment may include null data in addition to information bits. The null data are removed at the output of an edge node and the information data is collated into bursts, each carrying only information bits in addition to a header necessary for downstream processing. To ensure loss-free transfer of bursts from the edge to the core, burst transfer permits are generated at controllers of the optical core and sent to respective edge nodes based on flow-rate-allocation requests. Null-padding is not visible outside the edge nodes and only the information content is subject to transfer rate regulation to ensure high efficiency and high service quality.

Owner:RPX CLEARINGHOUSE

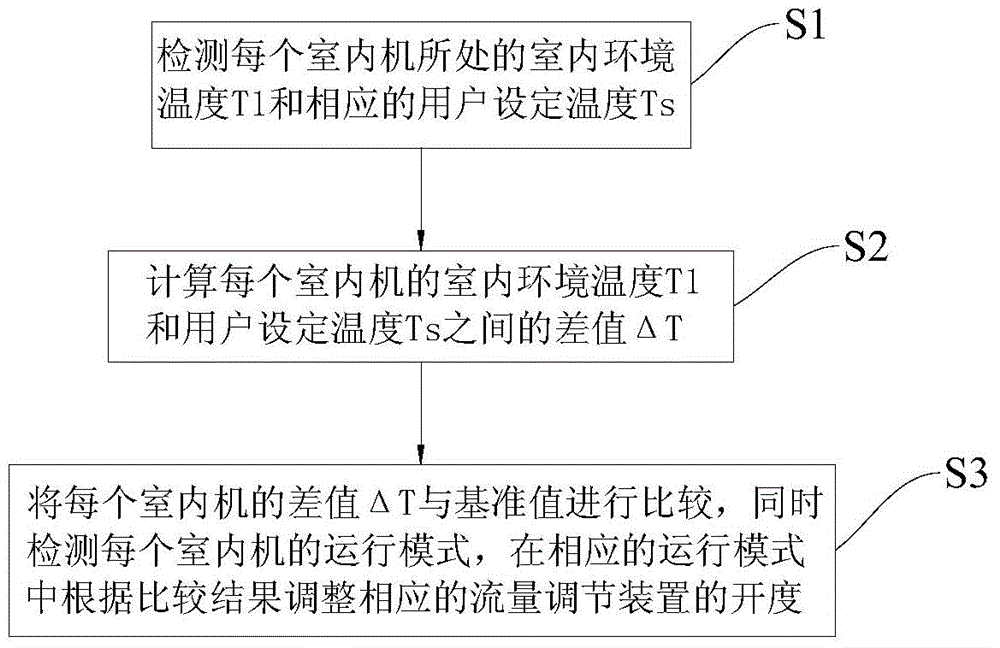

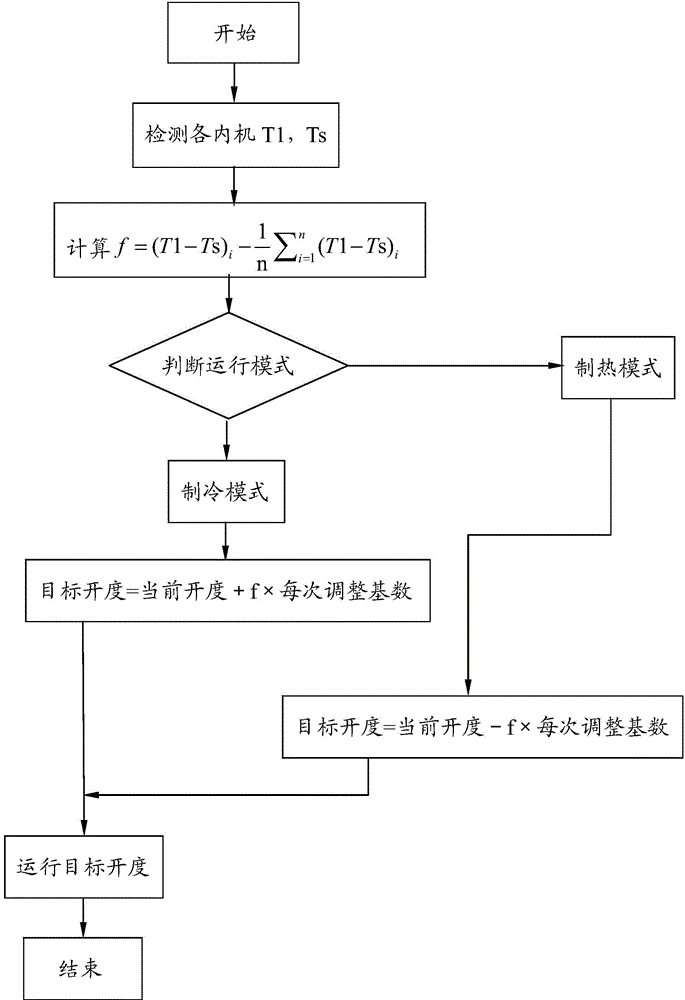

Control method of multi-split system

ActiveCN105091204AAccurate and reasonable distributionMeet the needs of different refrigerant volumesSpace heating and ventilation safety systemsLighting and heating apparatusOperation modeComputer science

The invention discloses a control method of a multi-split system. The method includes the following steps that S1, the indoor environment temperature T1 and the corresponding user set temperature Ts of each indoor unit are detected; S2, the difference value delta T between the indoor environment temperature T1 and the user set temperature Ts of each indoor unit is calculated; S3, the difference value delta T of each indoor unit is compared with the reference value, meanwhile the operation mode of each indoor unit is detected, and the opening of a corresponding flow rate regulating device is adjusted according to the comparison result in the corresponding operation mode. The control method of the multi-split system can meet different refrigerant amount requirements caused by different indoor environment temperatures T1 and user set temperatures Ts of different indoor units, meanwhile the indoor environment temperatures T1 and the user set temperatures Ts are directly used as calculation factors to calculate the opening of the flow rate regulation device, and it is guaranteed that refrigerant is distributed more accurately and reasonably.

Owner:GD MIDEA HEATING & VENTILATING EQUIP CO LTD +1

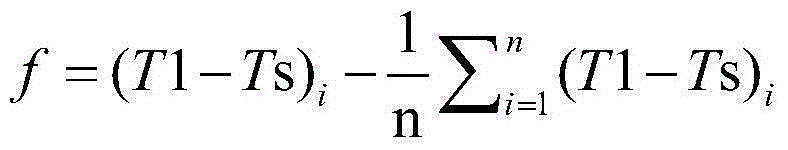

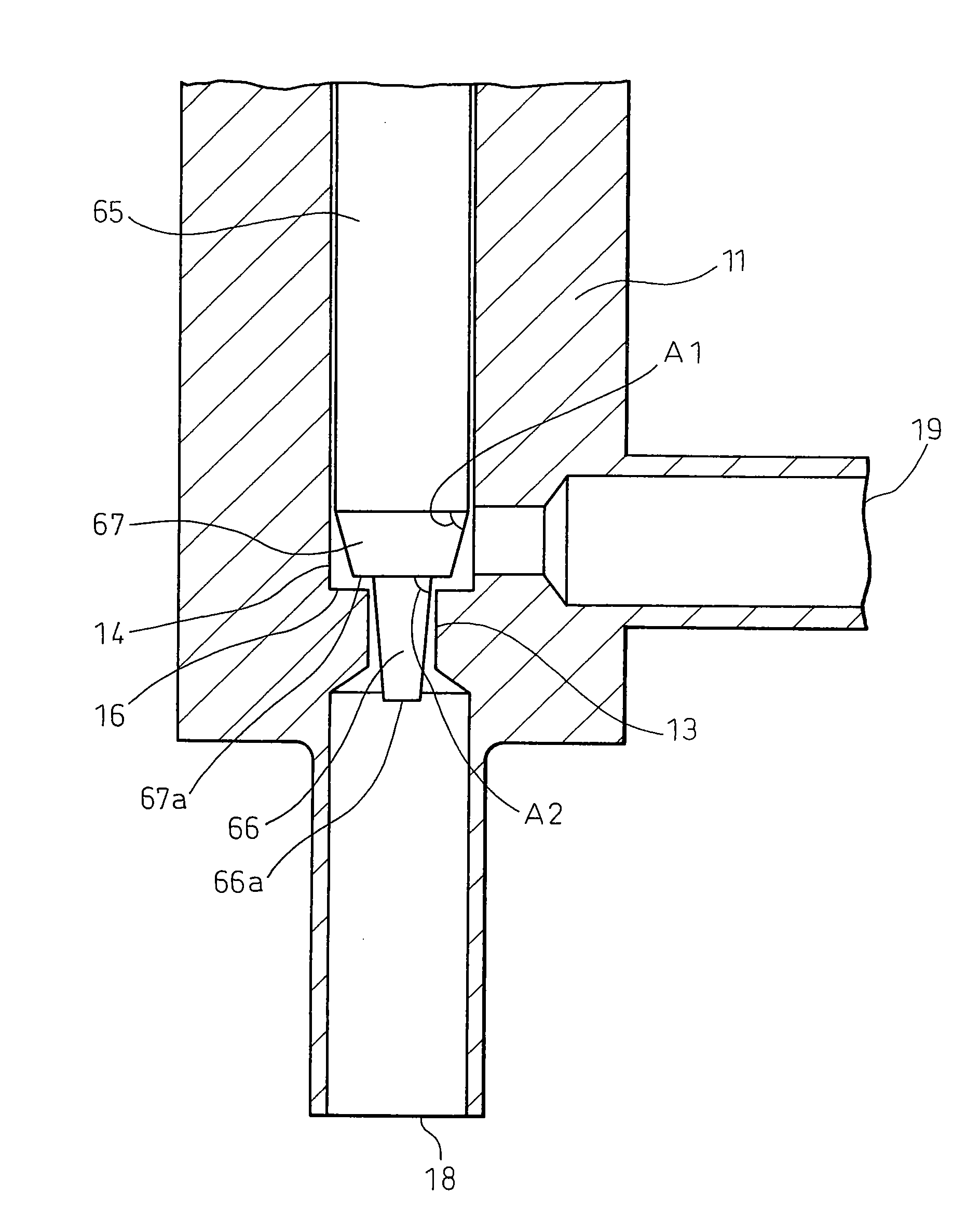

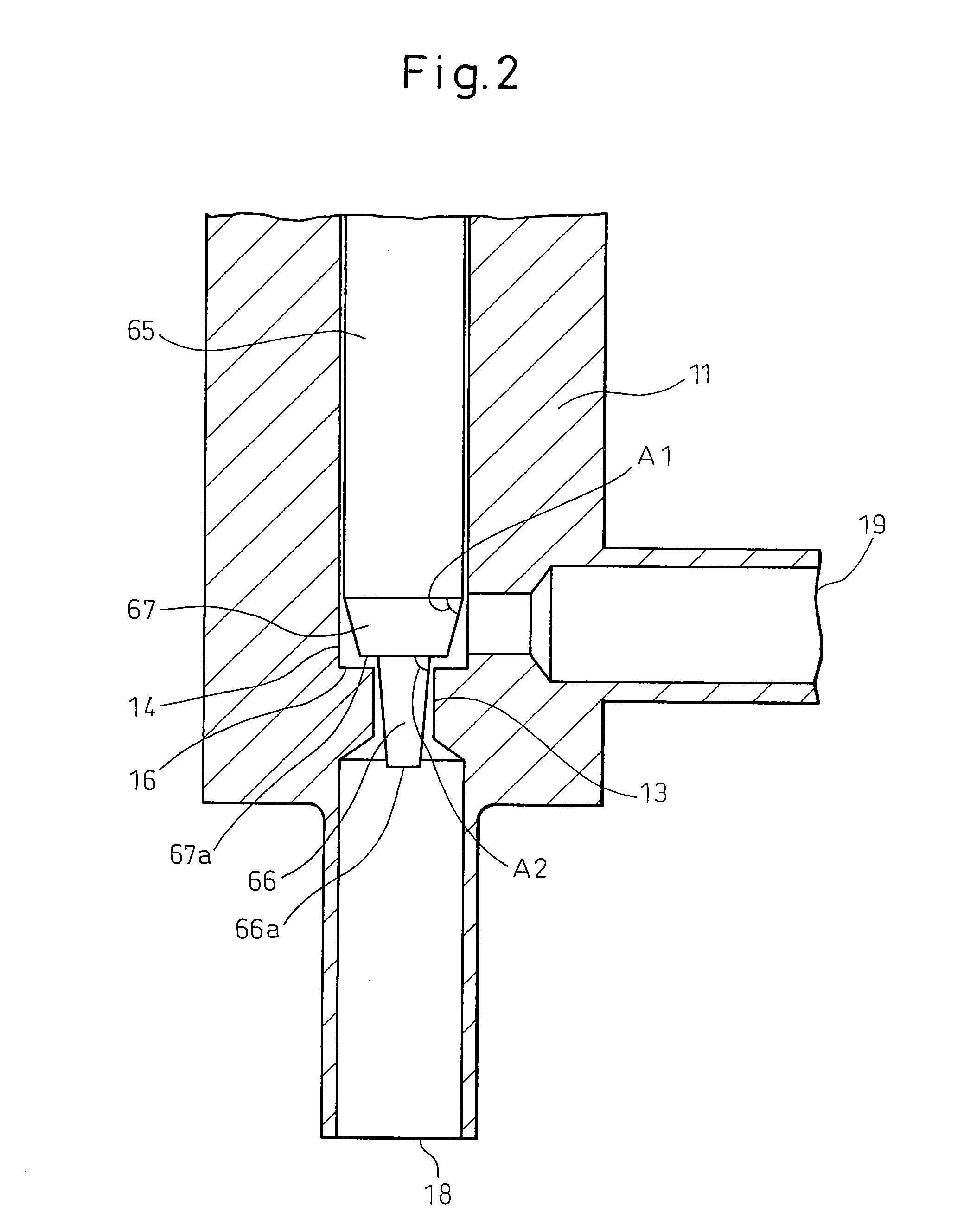

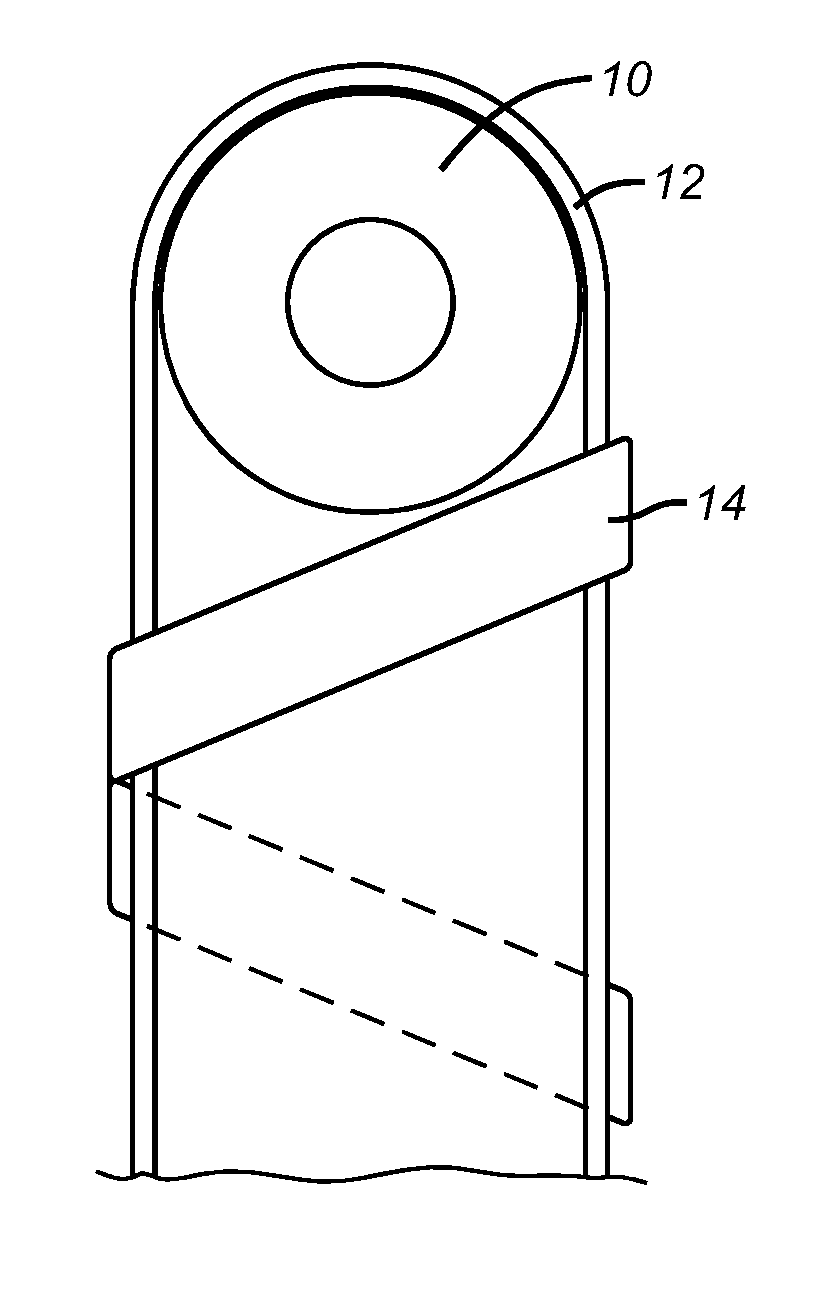

Flow Rate Regulation Valve

InactiveUS20080111089A1Increase flow rateEliminate differencesValve members for absorbing fluid energyPipe elementsStreamflowValve seat

A flow rate regulation valve (10) comprises a housing (11) formed with an axial hole (14) and a valve hole (13) communicating with the axial hole, a needle valve (60) adapted to move within the axial hole relative to a valve seat located between the axial hole and the valve hole, and a flow rate adjust knob (40) mounted at the proximal end of the needle valve extending from the housing. The needle valve is moved relative to the valve seat by rotating the flow rate adjust knob thereby to regulate the flow rate of the fluid flowing through the valve hole. A first valve body (67) is arranged at the forward end of the needle valve and a second valve body (65) extends from the end surface (67a) of the first valve body. The cross section of the first valve body is larger than that of the second valve body, so that at the time of closing the flow rate regulation valve, the end surface of the first valve body abuts with a valve seat (16) located between the axial hole and the valve hole, and the second valve body is inserted in the valve hole. As a result, fluid can be supplied in a stable fashion with a flow rate that is linearly maintained.

Owner:SURPASS IND

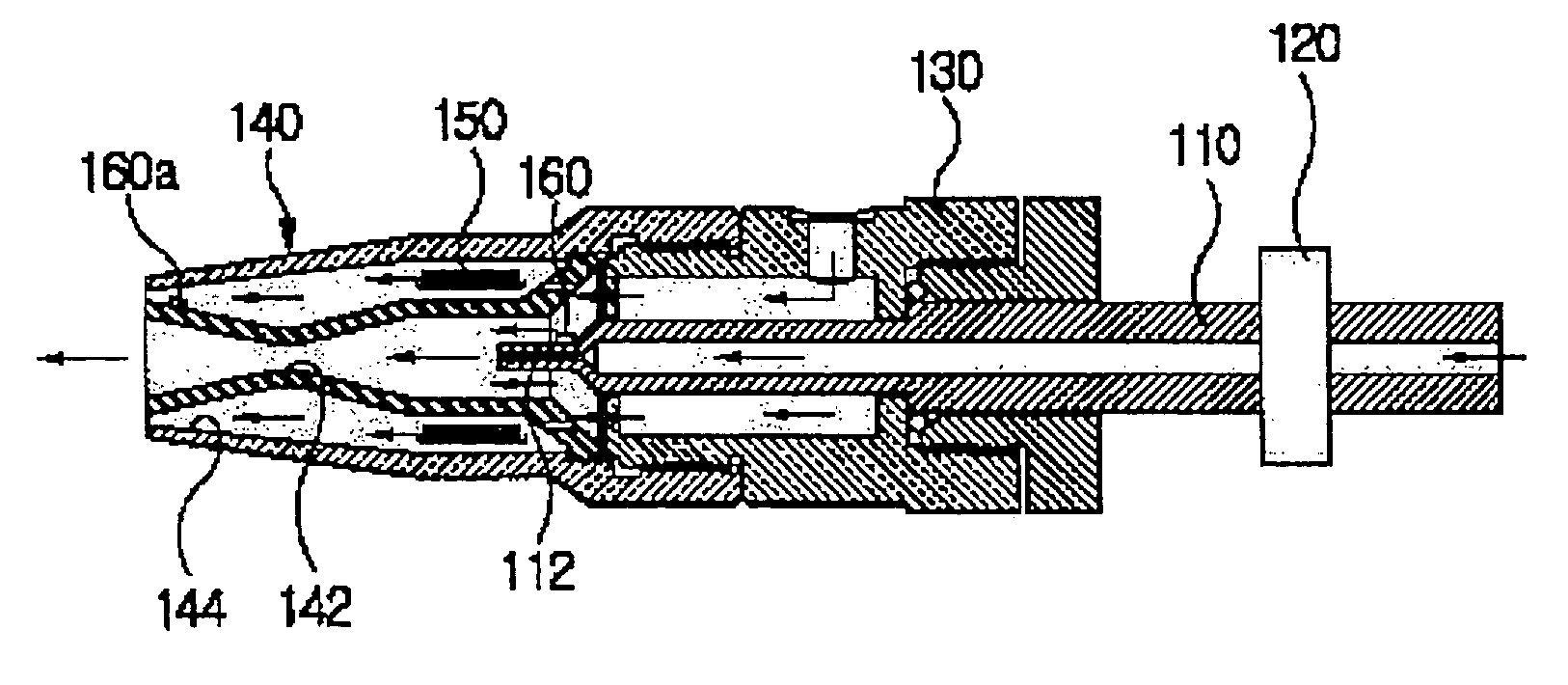

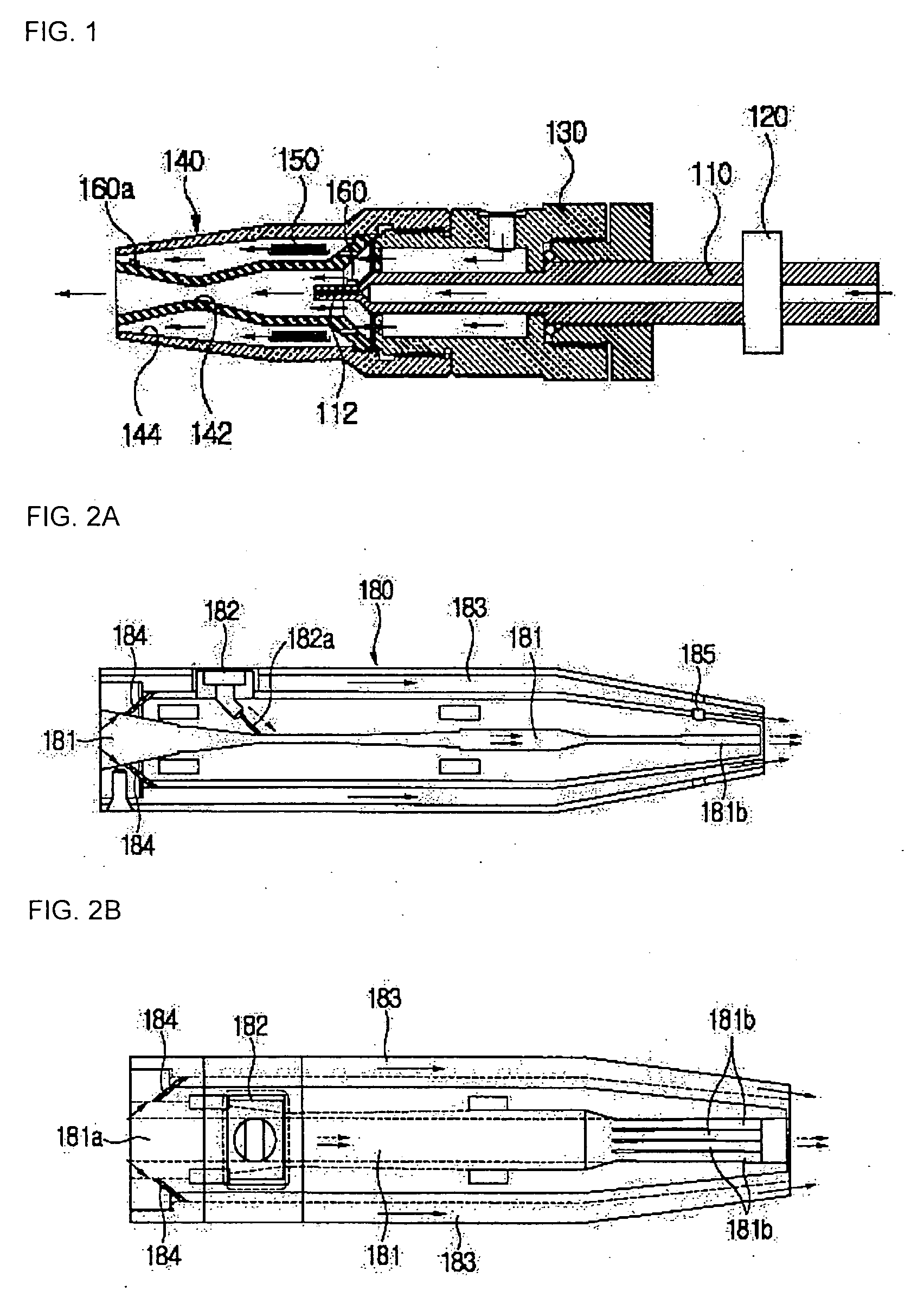

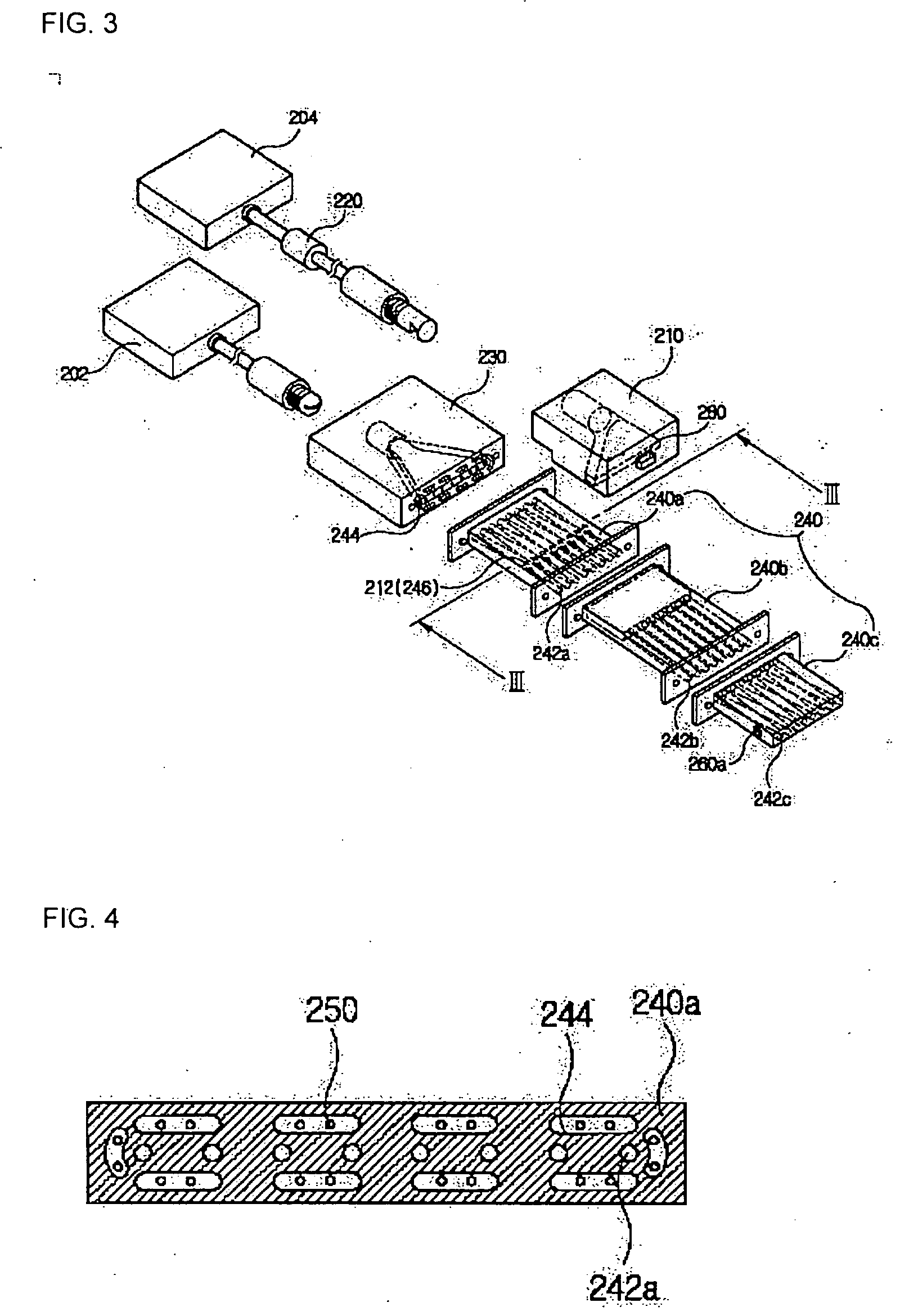

Nozzle for spraying sublimable solid particles entrained in gas for cleaning surface and method of cleaning surface using the same

ActiveUS20050266777A1Blast gunsSemiconductor/solid-state device manufacturingSolenoid valveEngineering

A nozzle for spraying sublimable solid particles and preventing frost from forming at surfaces of the nozzle. The nozzle includes: a cleaning agent block for phase-changing a cleaning agent into a snows containing sublimable solid particles; a nozzle block for growing the cleaning agent snow through adiabatic expansion and spraying the grown cleaning agent snow onto a surface of an object; a carrier gas block for supplying a carrier gas to the nozzle block to mix with the cleaning agent snow; and a heater for heating at least a portion of the carrier gas supplied from the carrier gas supply source. Fine dry ice particles and liquid CO2, passing through a solenoid valve from a CO2 reservoir tank and a pressure drop of a flow rate regulation valve, are introduced into the spray nozzle and then mixed with the carrier gas, such as N2 or purified air, and discharged.

Owner:K C TECH

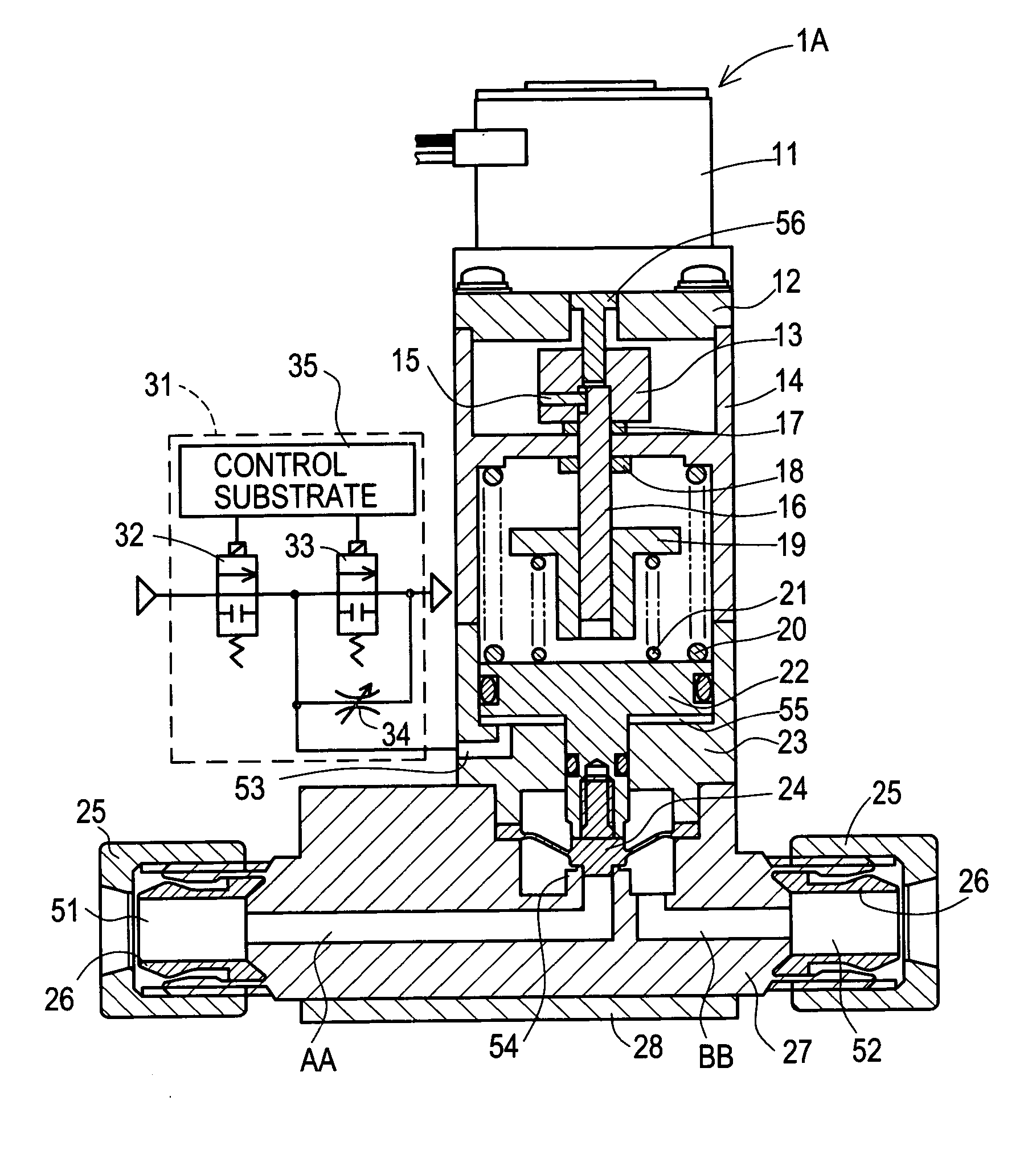

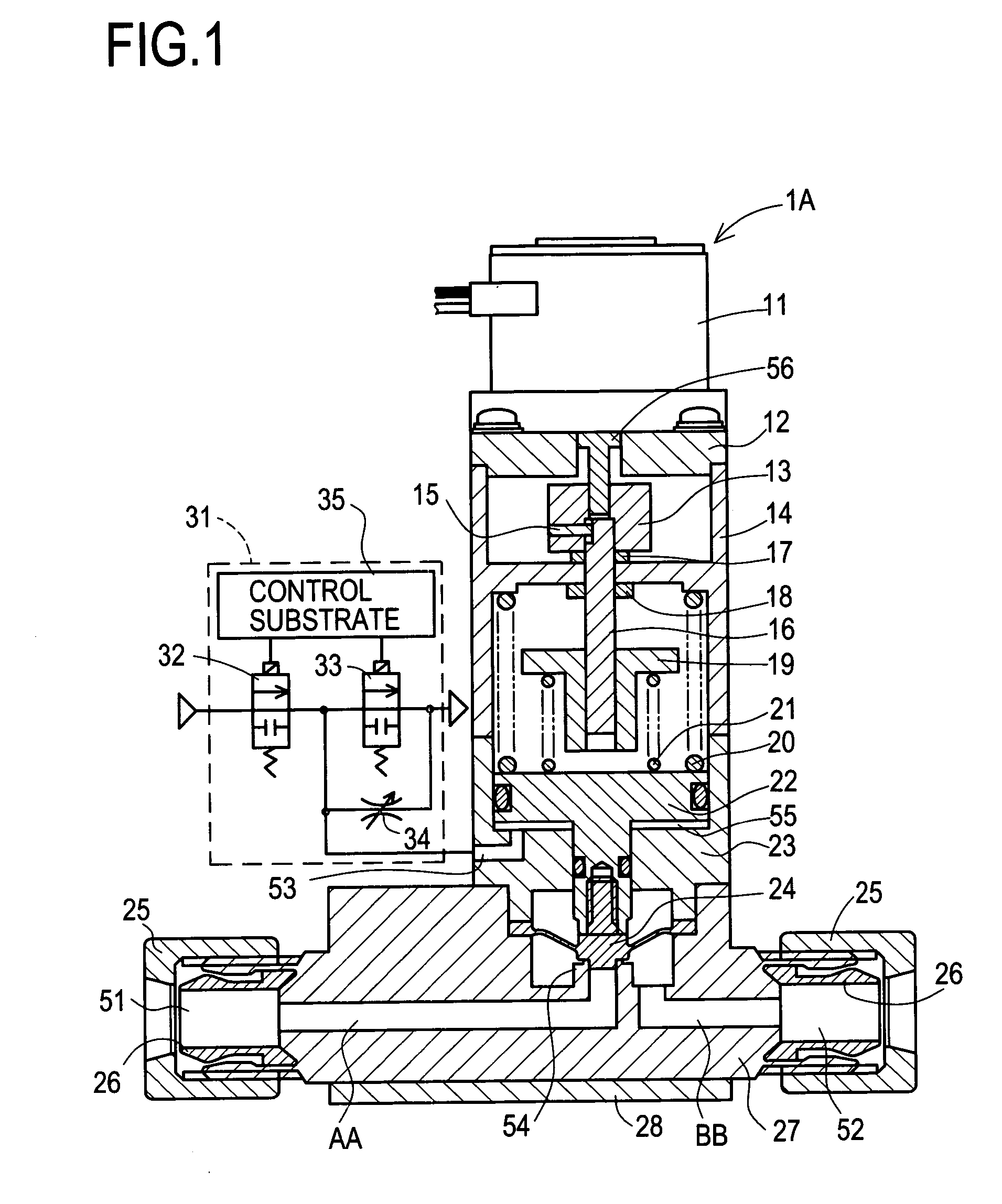

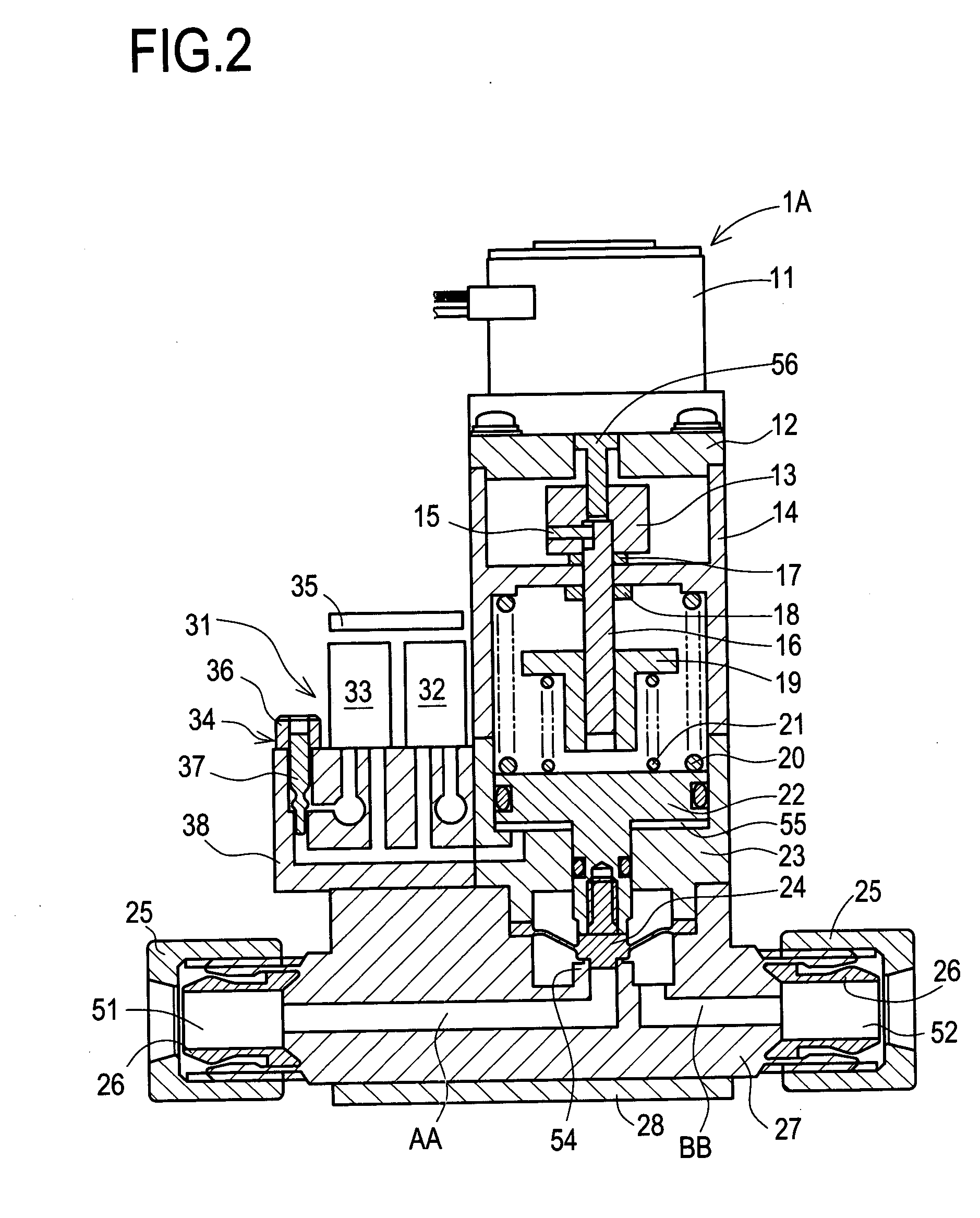

Flow control valve

InactiveUS20050253100A1Prevent outflowDiaphragm valvesOperating means/releasing devices for valvesEngineeringControl valves

There is disclosed a flow control valve which regulates a flow rate by determining a stop position of a piston by contact in an opened state, and which enables remote and high-precision flow rate regulation. In a closed state, an urging force of a return spring acts on a piston, bringing a diaphragm into close contact with a valve seat. In this state, when compressed air is supplied into a pilot chamber, moving the piston, the diaphragm is brought out of contact with the valve seat. Then, the piston comes into contact with a nut and the diaphragm is stopped providing a fixed clearance between the diaphragm and the valve seat. An opened state is established. Of course, the nut can be moved to any desired position by means of a serve motor or the like, so that a position at which the piston comes into contact with the nut can be changed.

Owner:CKD

Delaying swelling in a downhole packer element

ActiveUS7562704B2Easy to processRate of swelling is also slowFluid removalSealing/packingCoated surfaceThin layer

A swelling element rate regulation technique and product features an outer coating on a core of an element. The core is reactive to hydrocarbons or water depending on how it is configured. The surrounding coating is preferably formed of fine ground particles of a non-swelling polymer mixed in a solvent such as methyl-ethyl-ketone that is applied in a thin layer to the core exterior. This uncured outer layer is then contacted by a patterned surface. The patterned surface is pressed firmly against the uncured polymer / solvent mixture and transfers an inverse of the pattern to the surface of the coating. As pressure is applied, heat may also be applied to cure the coating. The resulting pattern is designed such that openings in the coating are created that regulate infiltration of water or other fluids through it and, as a result, the rate of swelling in the wellbore. Swell rate in governed in part by the ratio of the exposed area of the swelling compound to the total volume of the swelling compound. The smaller this ratio, the slower the rate of swell. The pattern created in the non-swelling layer may also provide limited mechanical restraint of the swelling element, further slowing the process.

Owner:BAKER HUGHES INC

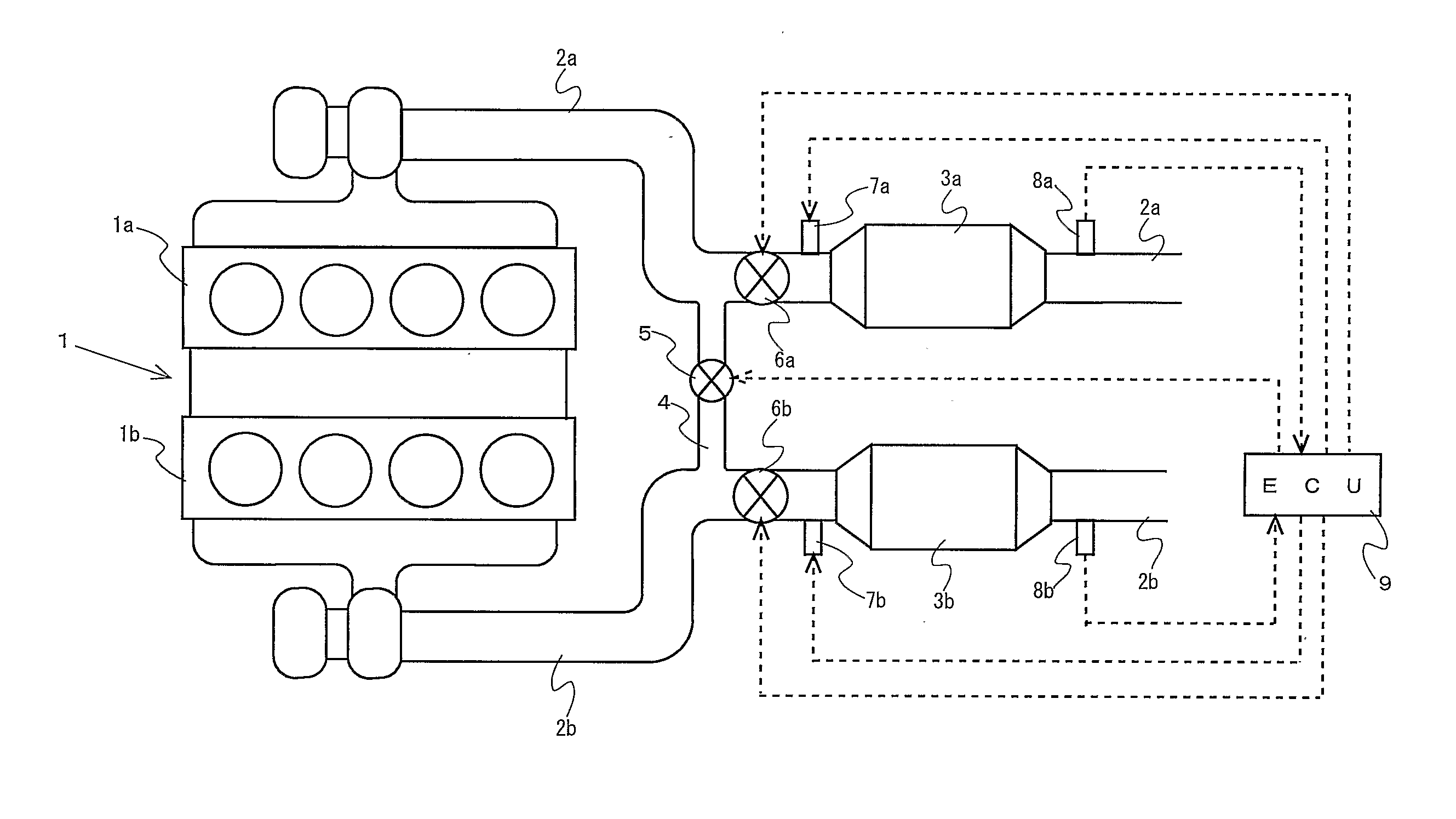

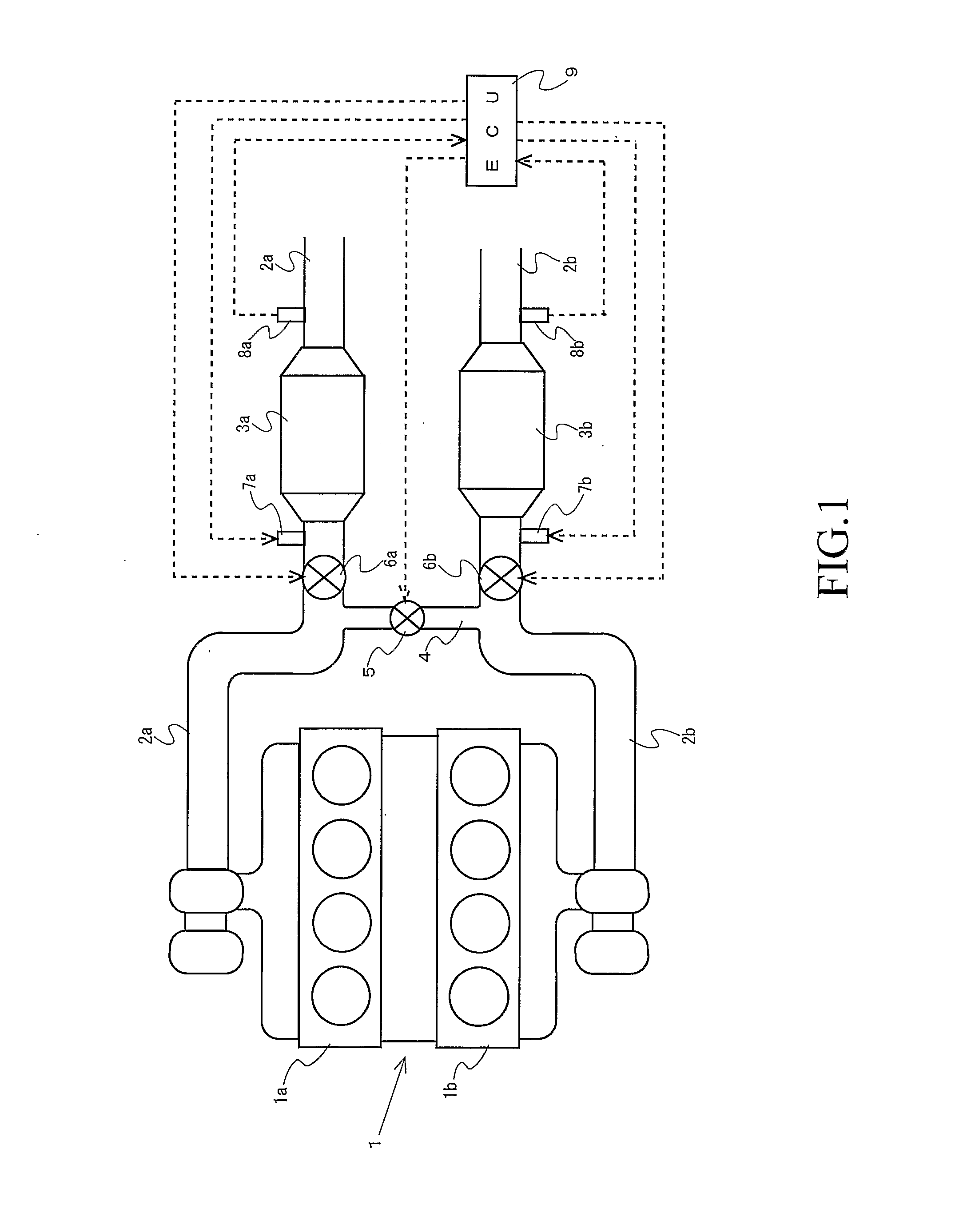

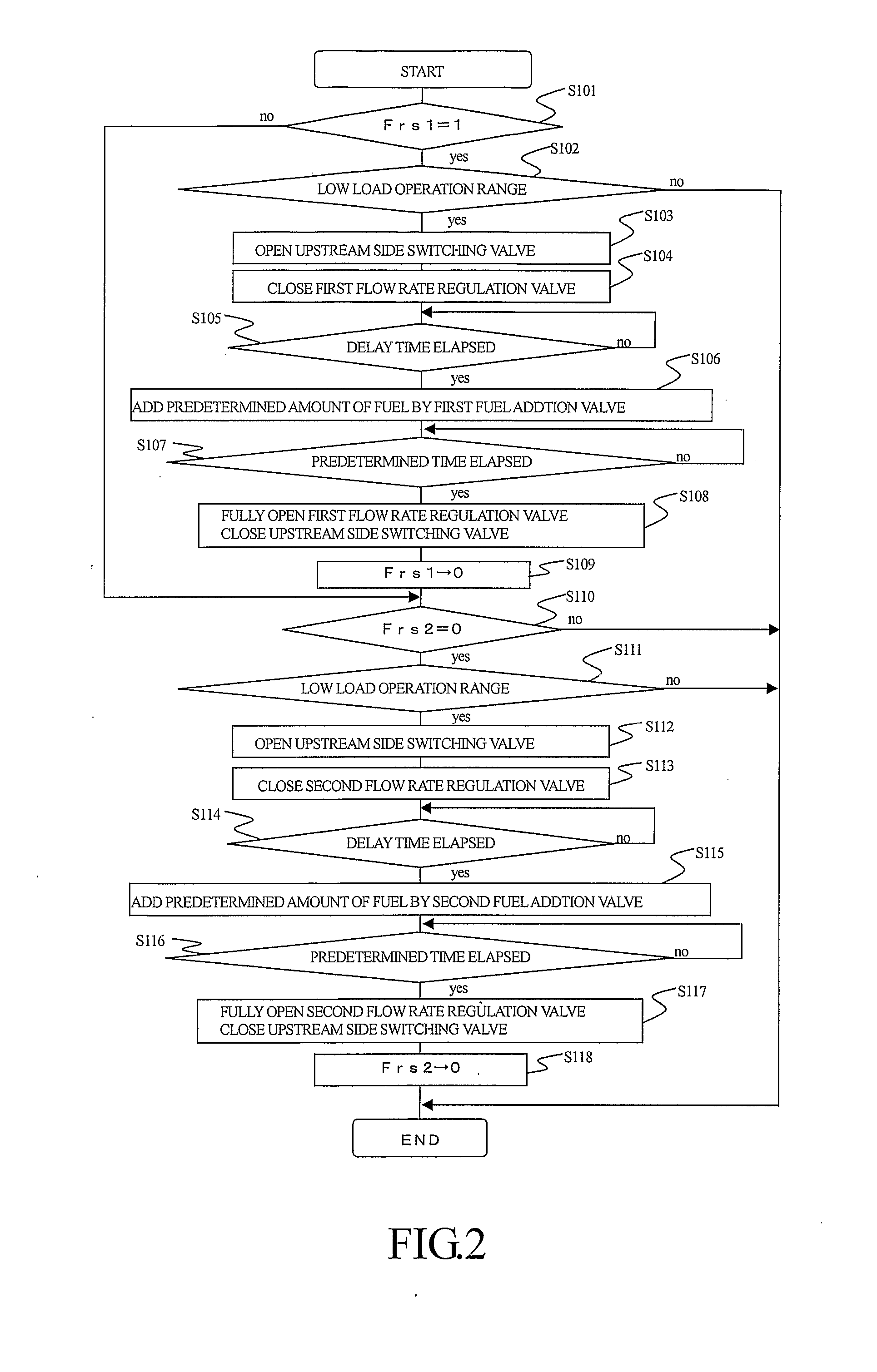

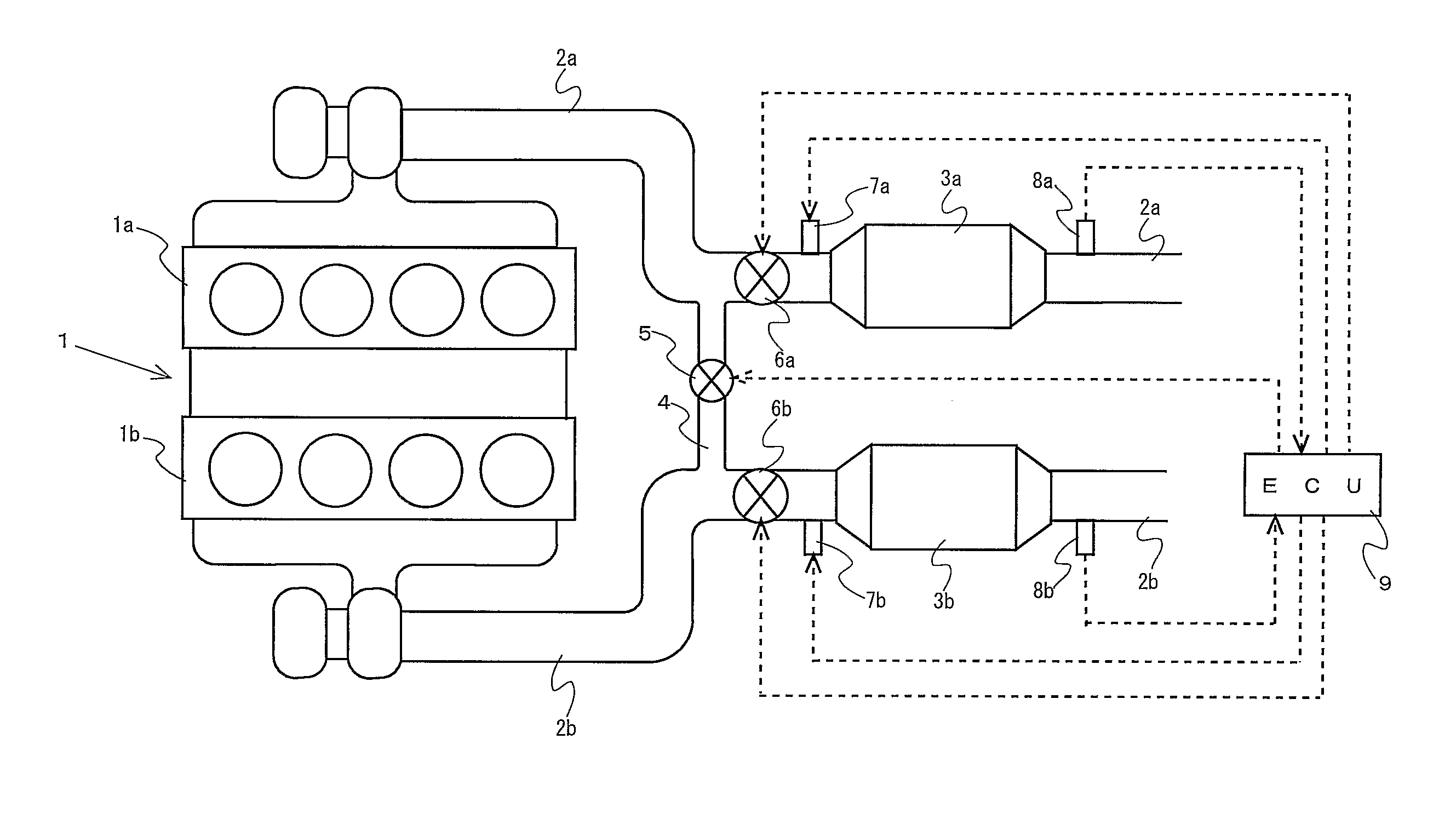

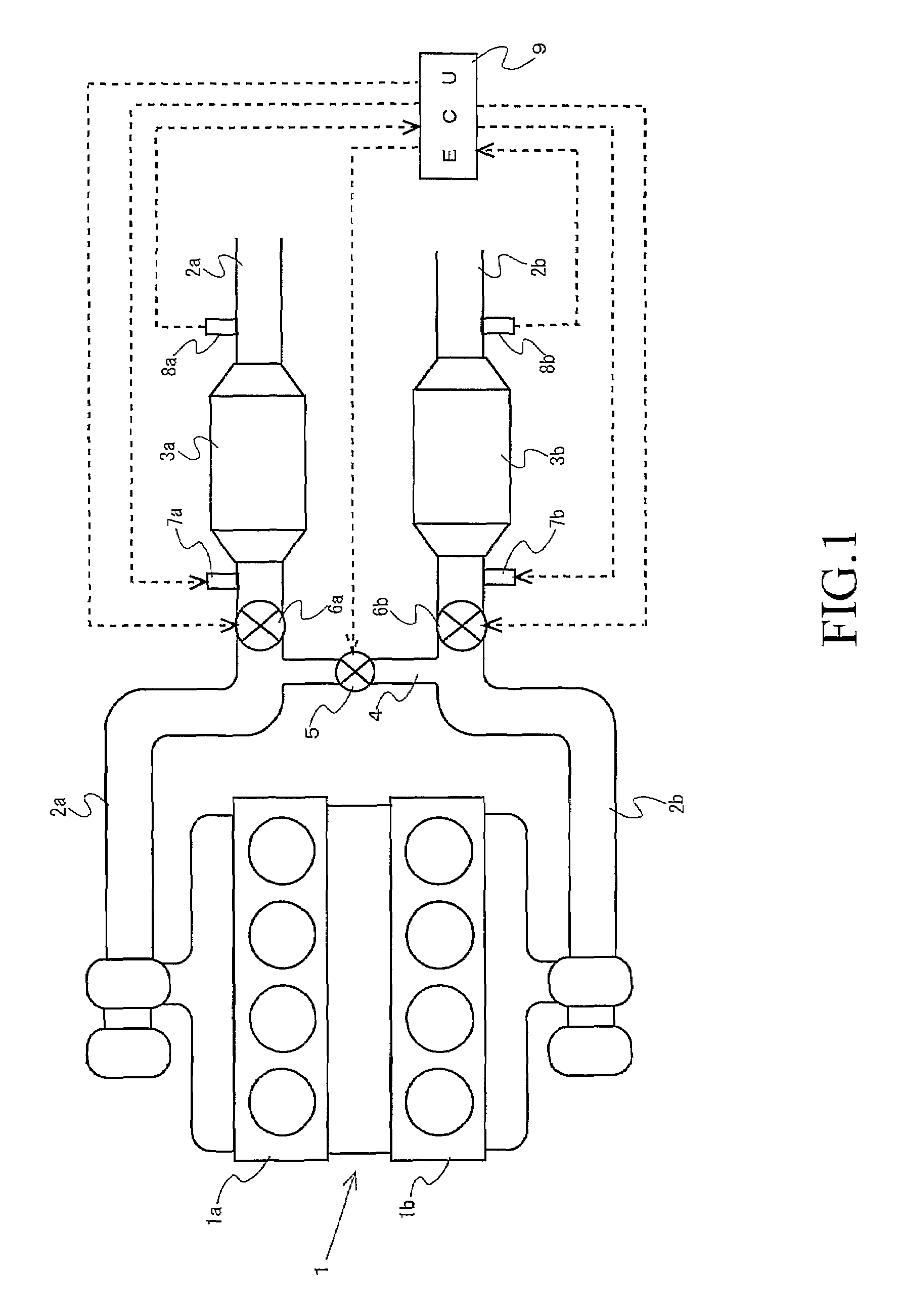

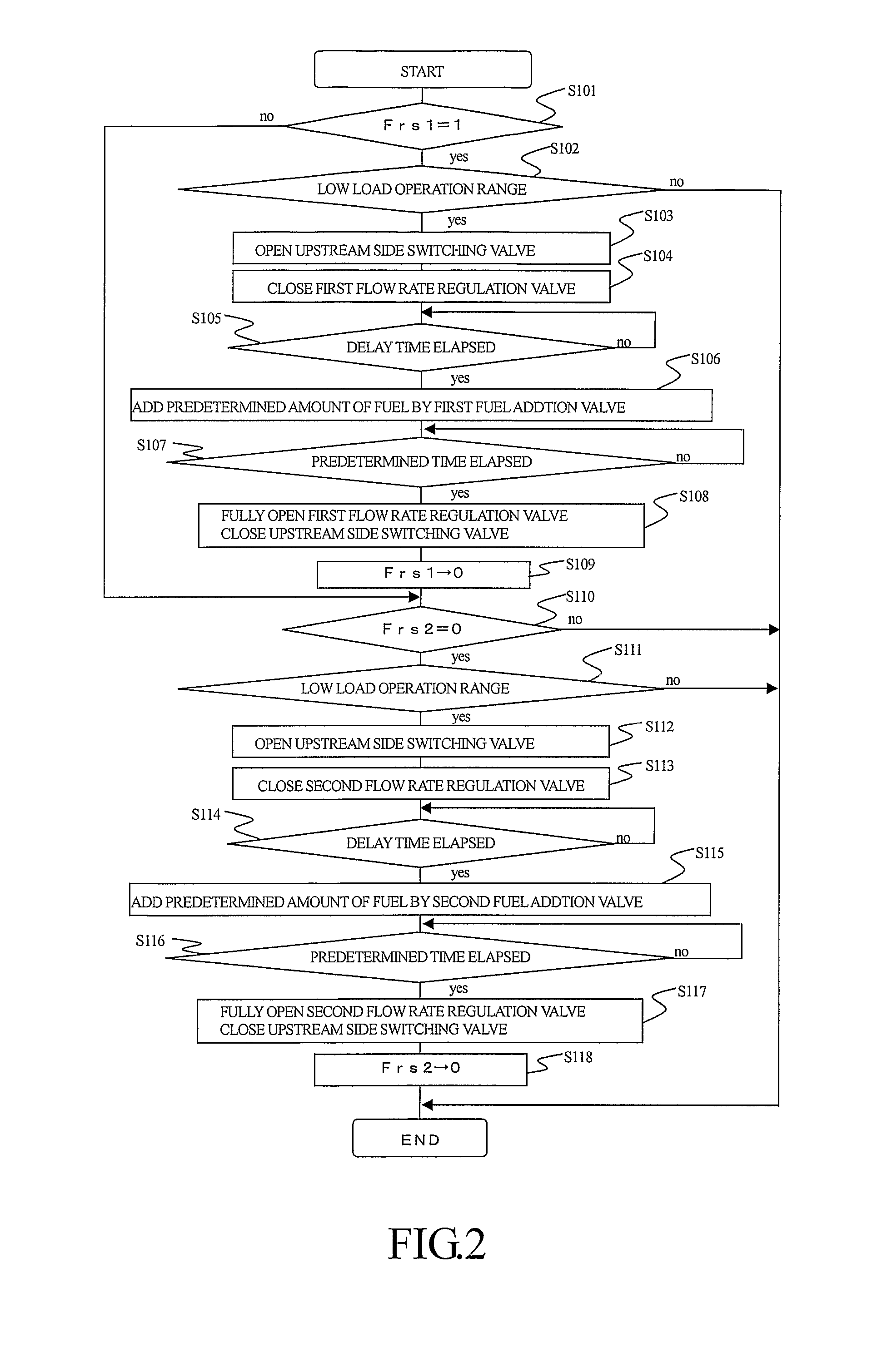

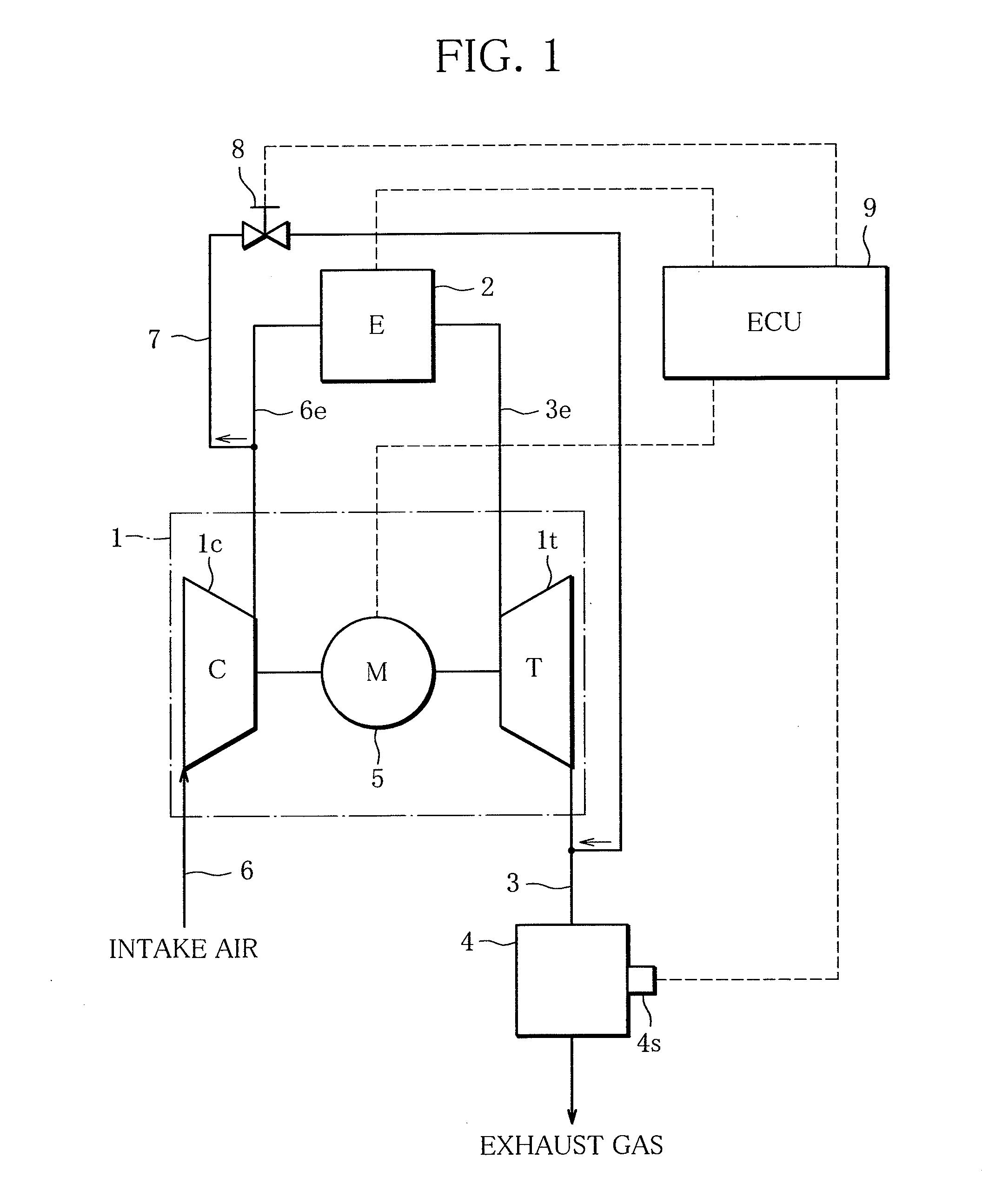

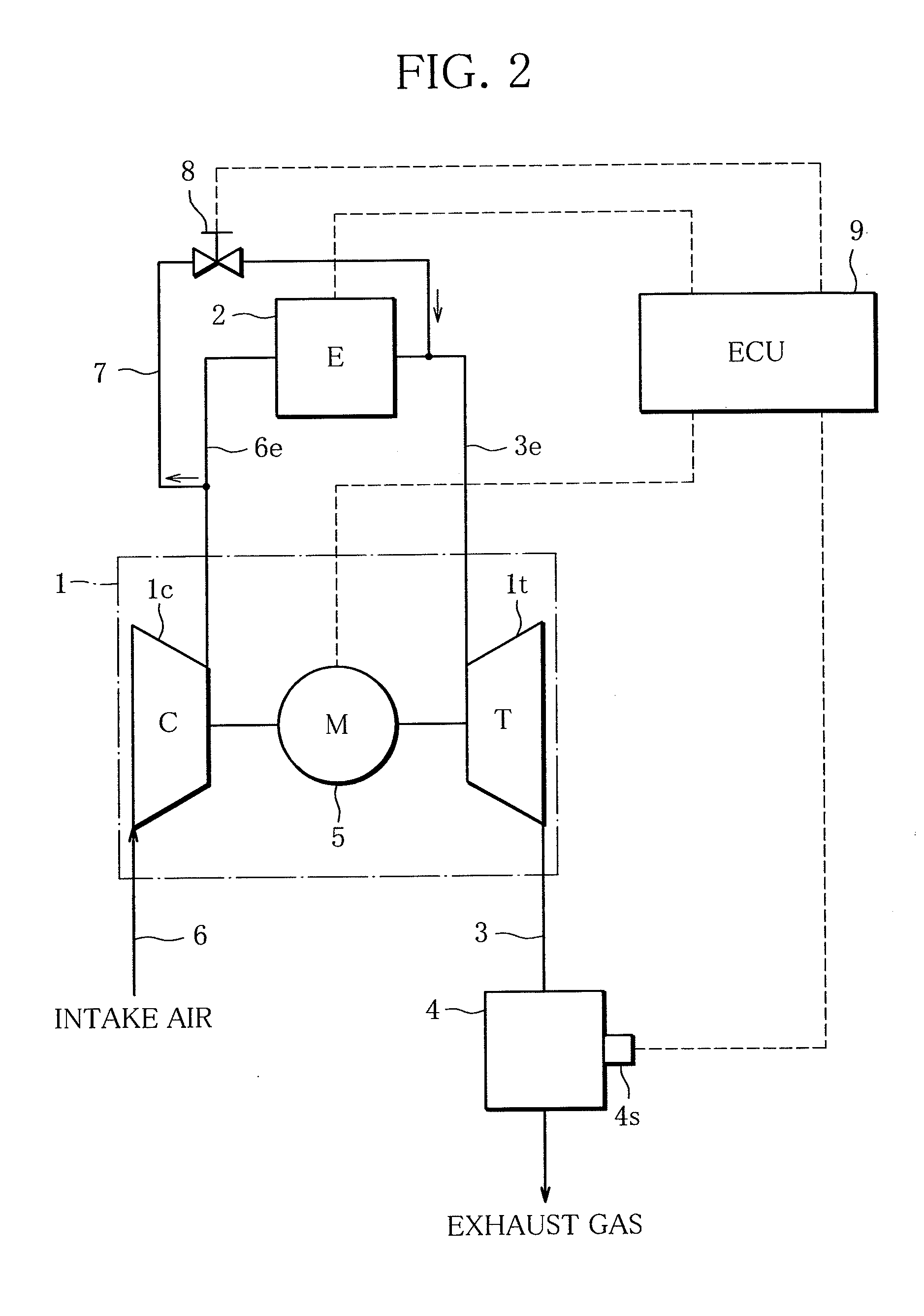

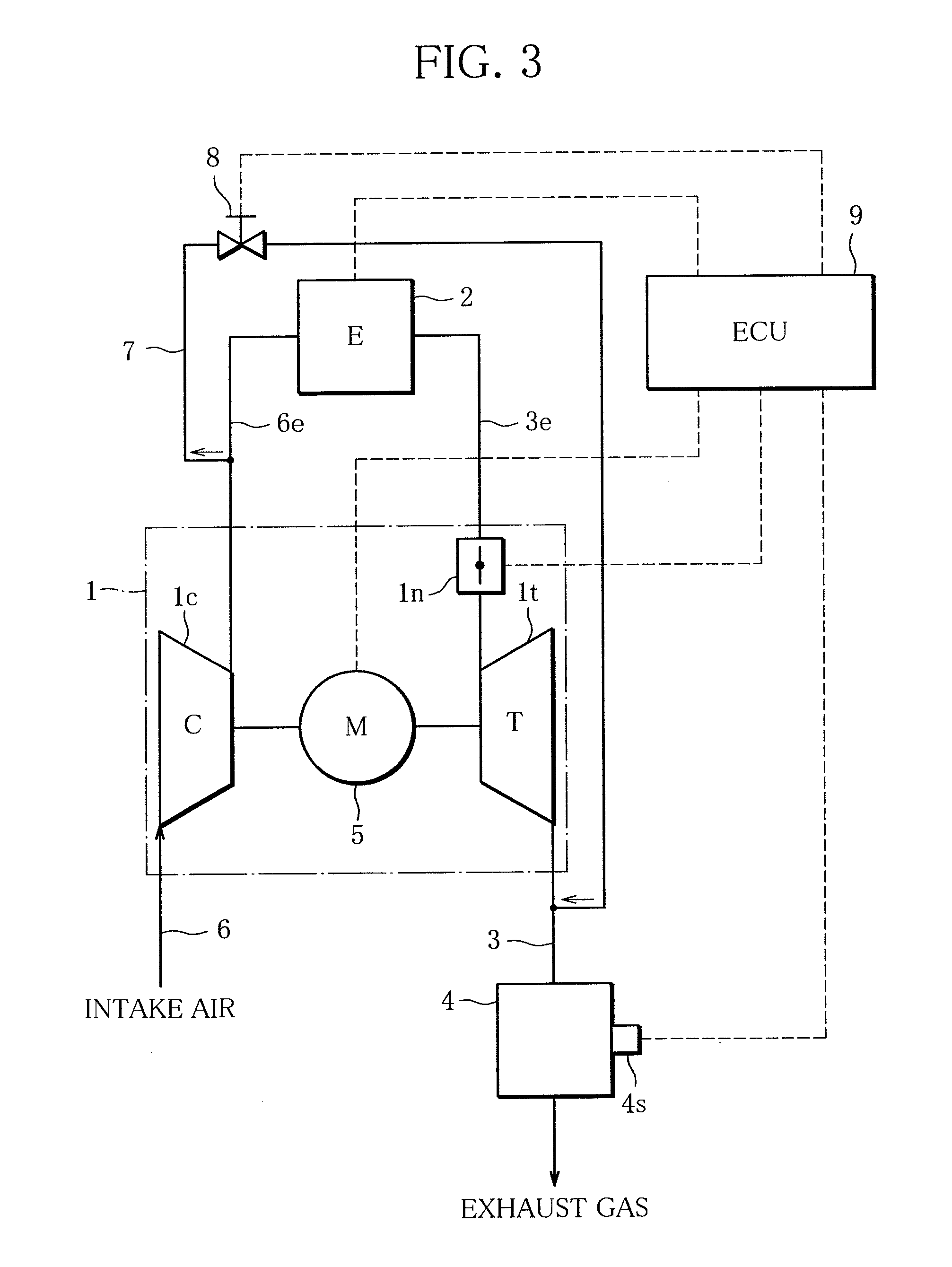

Exhaust Gas Purification Apparatus and Exhaust Gas Purification Method for Internal Combustion Engine

InactiveUS20070294999A1Processing is neededReduce the degree of openingElectrical controlInternal combustion piston enginesPurification methodsExhaust fumes

In an exhaust gas purification apparatus for an internal combustion engine (1) equipped with independent exhaust passages (2a, 2b) provided one for each cylinder group (1a, 1b) with a catalyst (3a, 3b) having a NOx trapping ability being arranged in each exhaust passage, the present invention is intended to provide a technique that can independently control the flow rates of exhaust gases flowing into the respective catalysts. To this end, the exhaust gas purification apparatus according to the present invention provides a communication passage (4) connecting mutually portions of said exhaust passages (2a, 2b) at upstream of said catalysts (3a, 3b), an upstream side switching valve (5) openning and closing said upstream side communication passage (4), a plurality of flow rate regulation valves (6a, 6b) being arranged at downstream of connecting portions of said exhaust passages with said upstream side communication passage, respectively, and a control section (9) controlling said upstream side switching valve (5) and said respective flow rate regulation valves (6a, 6b) in accordance with the states of said respective catalysts (3a, 3b). When the NOx trapping ability of one of the plurality of catalysts (3a, 3b) is regenerated, the control section (9) opens the upstream side switching valve (5), fully closes one flow rate regulation valve (6a, 6b) in one of the exhaust passages (2a, 2b) in which the one catalyst (3a, 3b) is arranged, and operates a reducing agent addition valve (7a, 7b) in such a manner that the reducing agent arrives at the one catalyst (3a, 3b) when the actual degree of opening of the one flow rate regulation valve (6a, 6b) becomes fully closed.

Owner:TOYOTA JIDOSHA KK

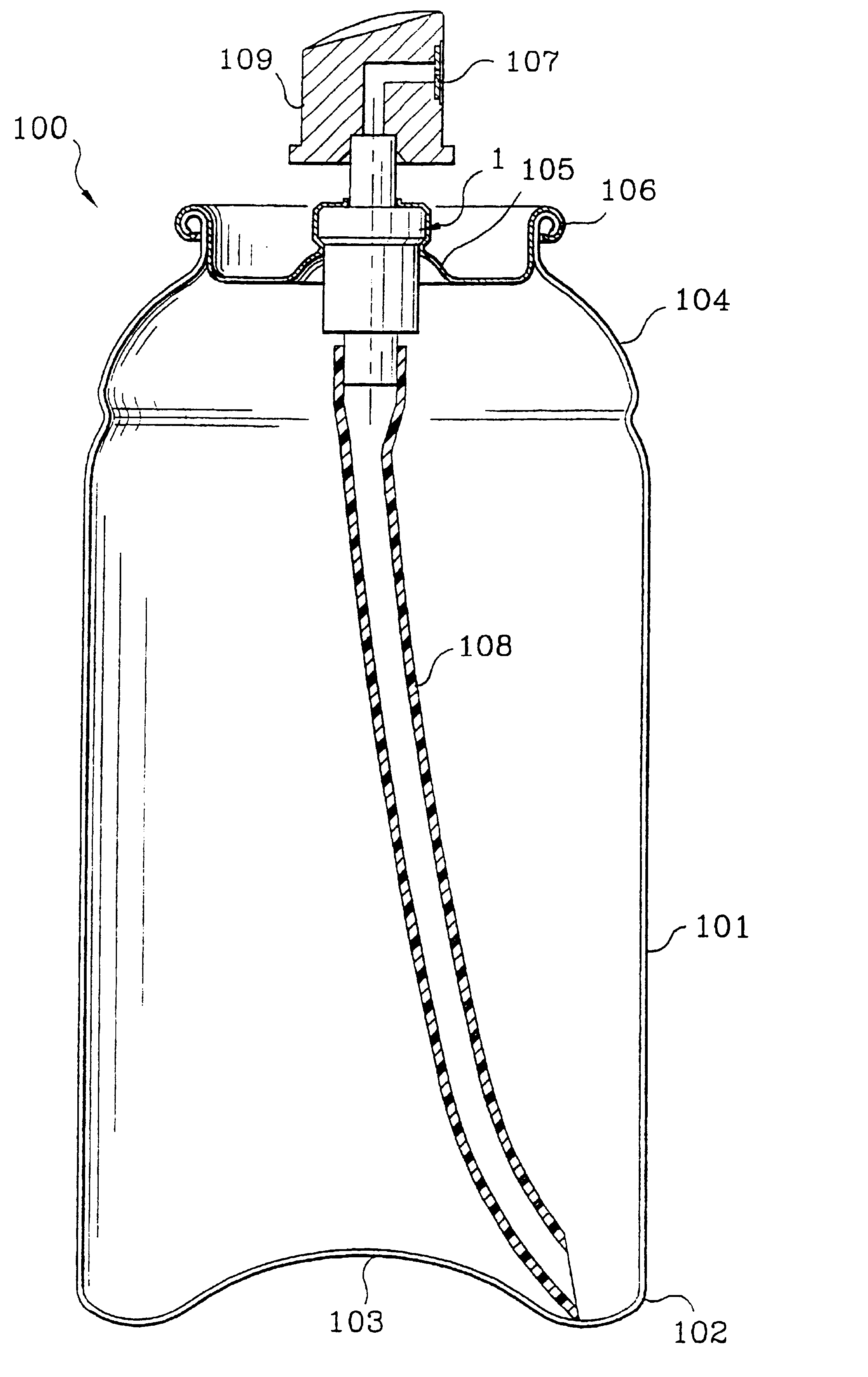

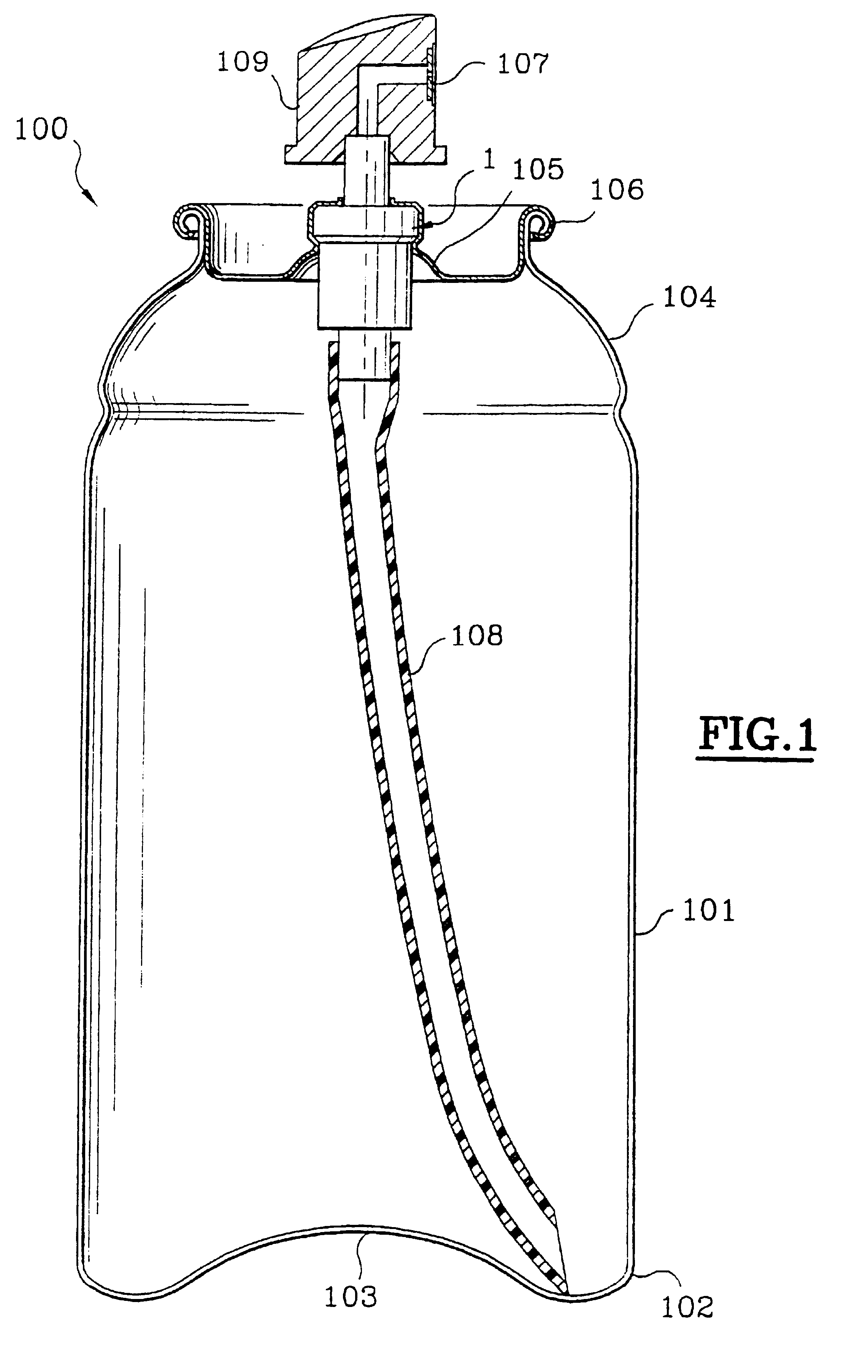

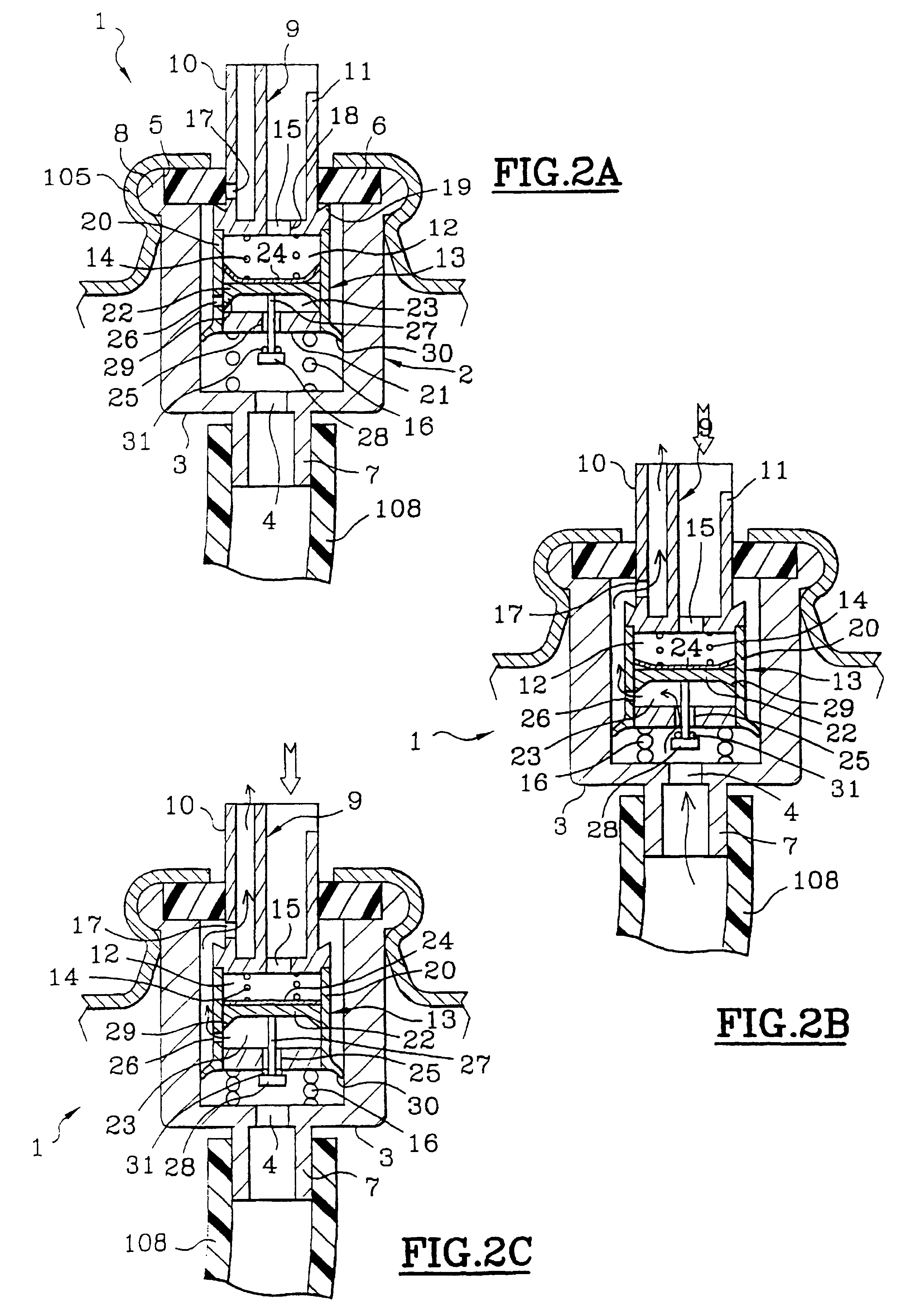

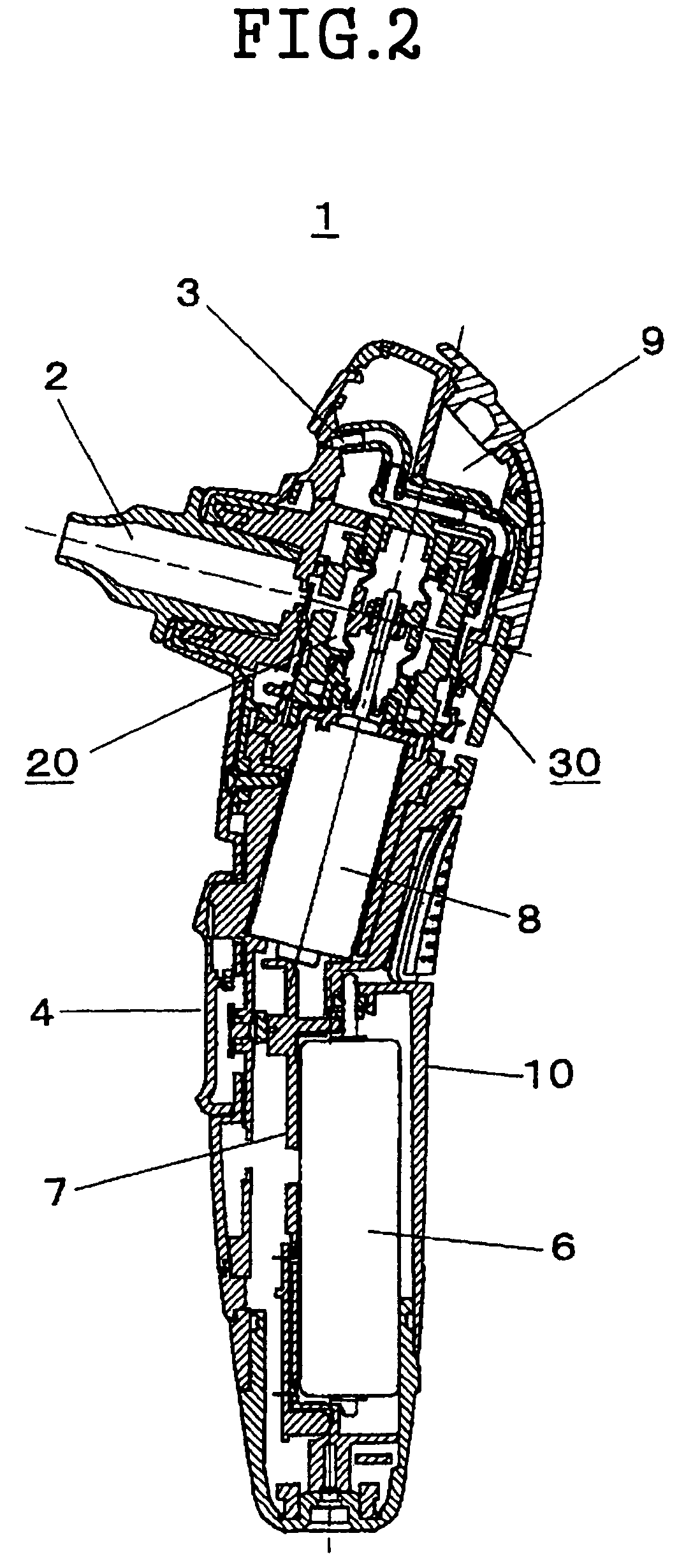

Valve with outlet flow rate regulation, and container equipped with such a valve

InactiveUSRE38207E1Improve sealingMinimal flow ratePackaging toiletriesPackaging cosmeticsInlet channelEngineering

A valve (1), particularly for an aerosol container, includes, inside a valve body (2), an inlet passage (4) communicating with the container and an outlet passage (10), a first elastic return (16) for urging the valve (1) into the closed position, and a regulator for regulating the product outlet flow rate, which includes a second elastic return (14) for supplying a set-point pressure for the regulator. The second elastic return (14) is arranged in a compartment (12) of the valve body (2) isolated from the product, the pressure inside the compartment (12) being equal to atmospheric pressure.

Owner:LOREAL SA

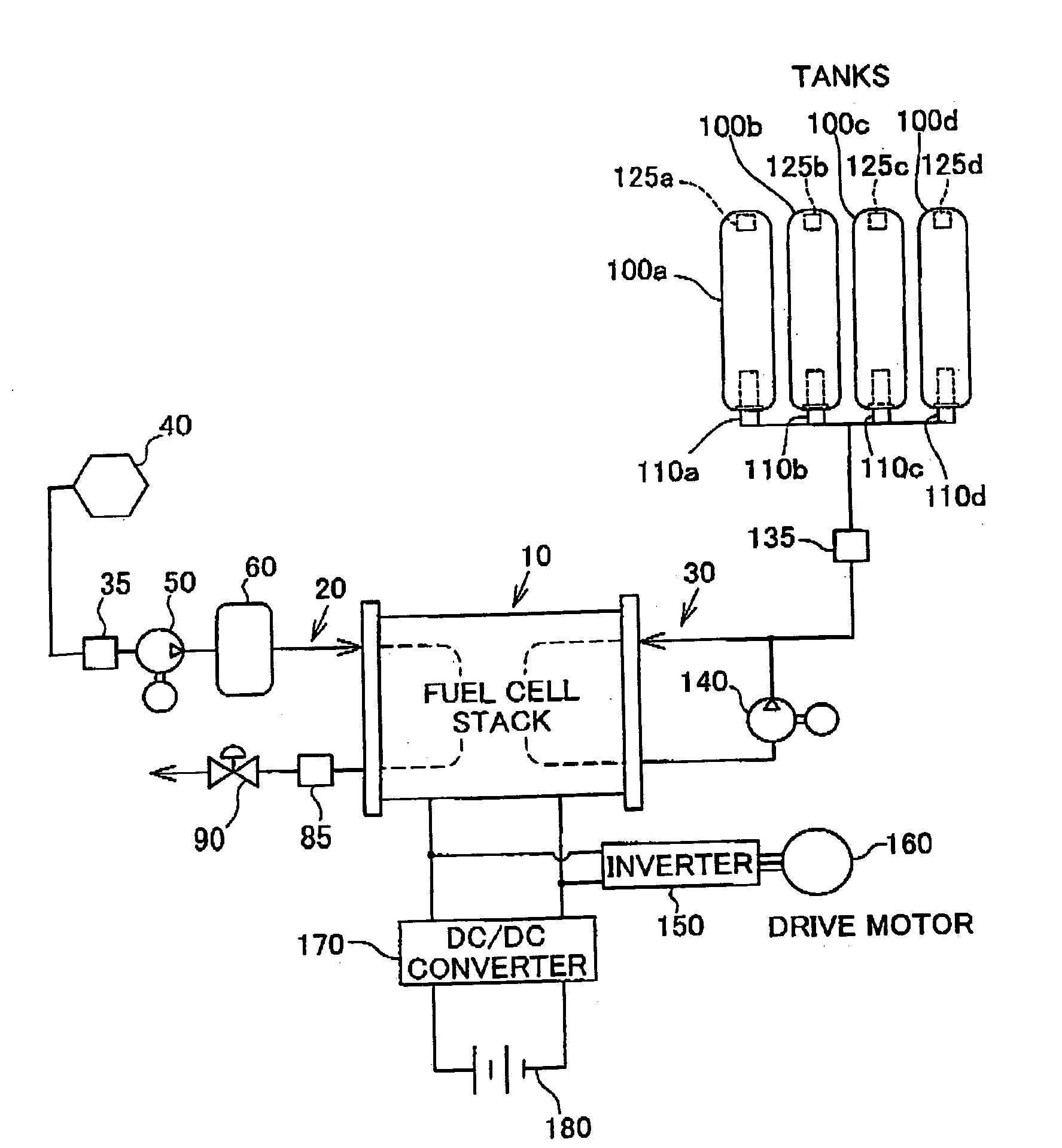

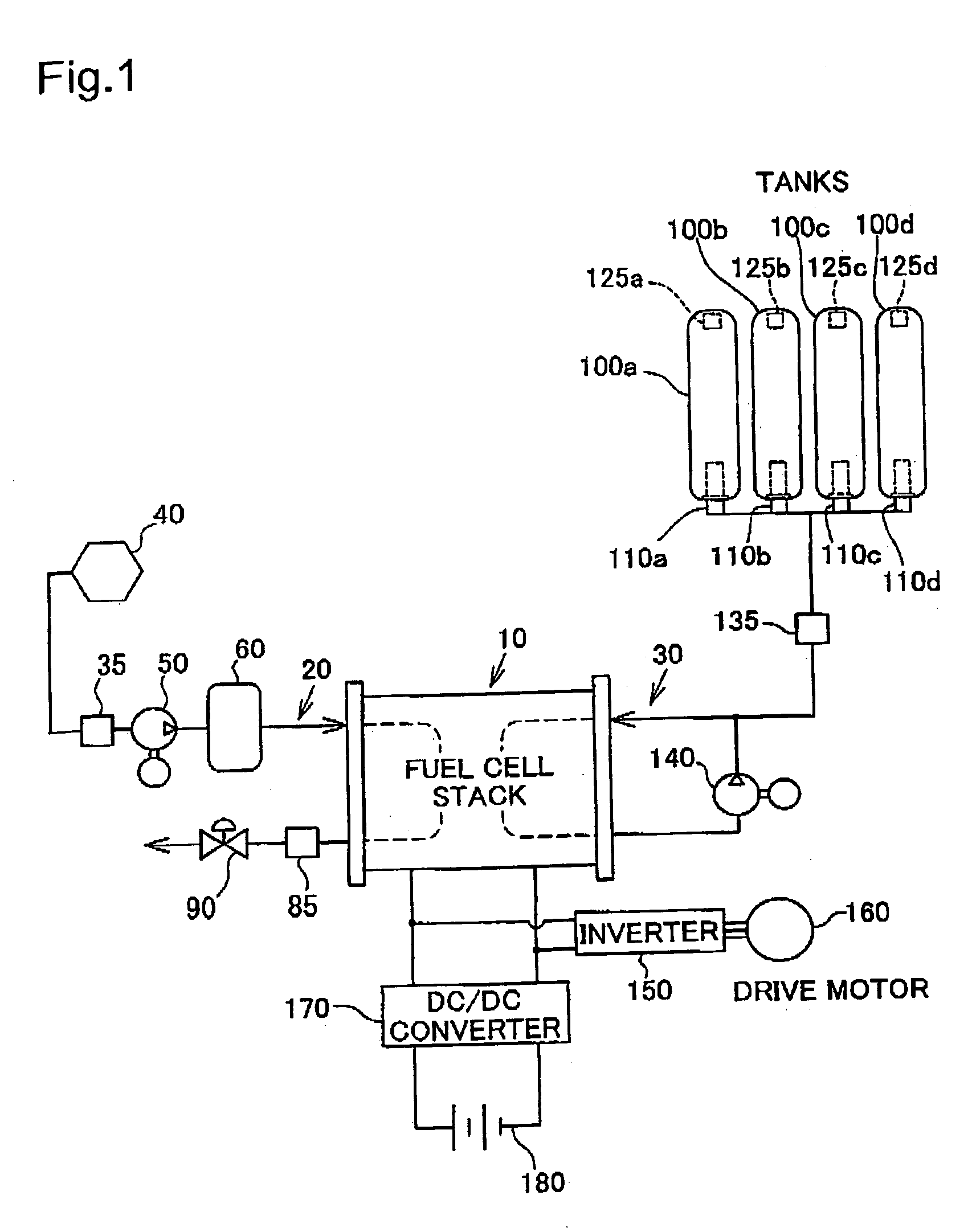

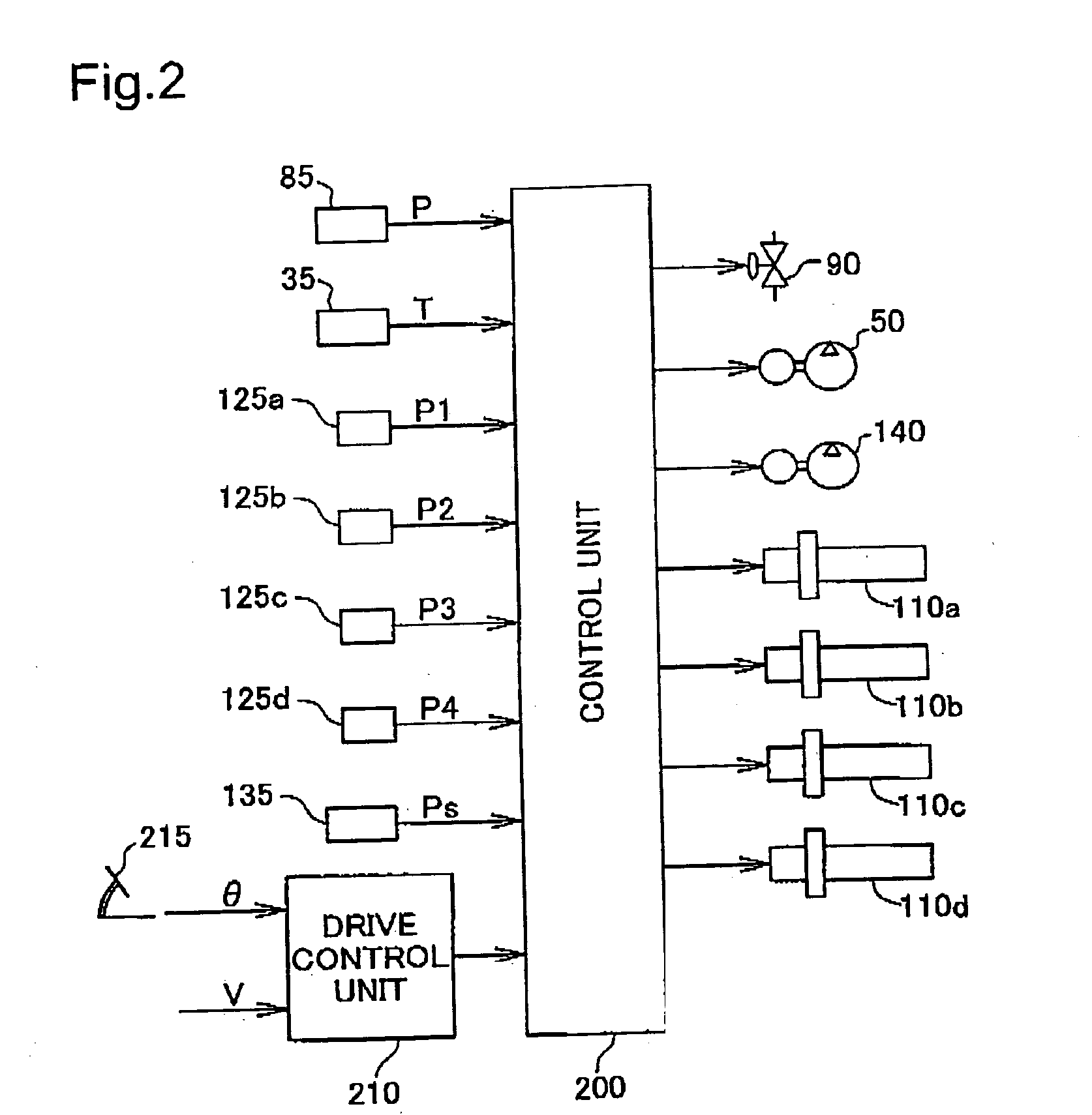

Tank system including multiple tanks and control method thereof

InactiveUS20050061371A1Gas handling applicationsGas handling/storage effectsInternal pressureEngineering

A tank system of the invention with multiple tanks makes a joint flow of a fluid released from the multiple tanks and supplies the joint flow to a downstream device, which is located downstream of the multiple tanks. The tank system includes: primary pressure measurement modules that individually measure internal pressures of the multiple tanks as primary pressures; a secondary pressure measurement module that measures a pressure of the joint flow of the fluid as a secondary pressure; flow rate regulation modules that individually regulate release flow rates of the fluid to be released from the multiple tanks; and a pressure control module that estimates a supply flow rate to be supplied to the downstream device from the measured secondary pressure, and then sets an allocation of the supply flow rate of the fluid to be released from each of the multiple tanks corresponding to the measured primary pressure with regard to the tank. This arrangement ensures adequate regulation of the release flow rates from the multiple tanks.

Owner:TOYOTA JIDOSHA KK

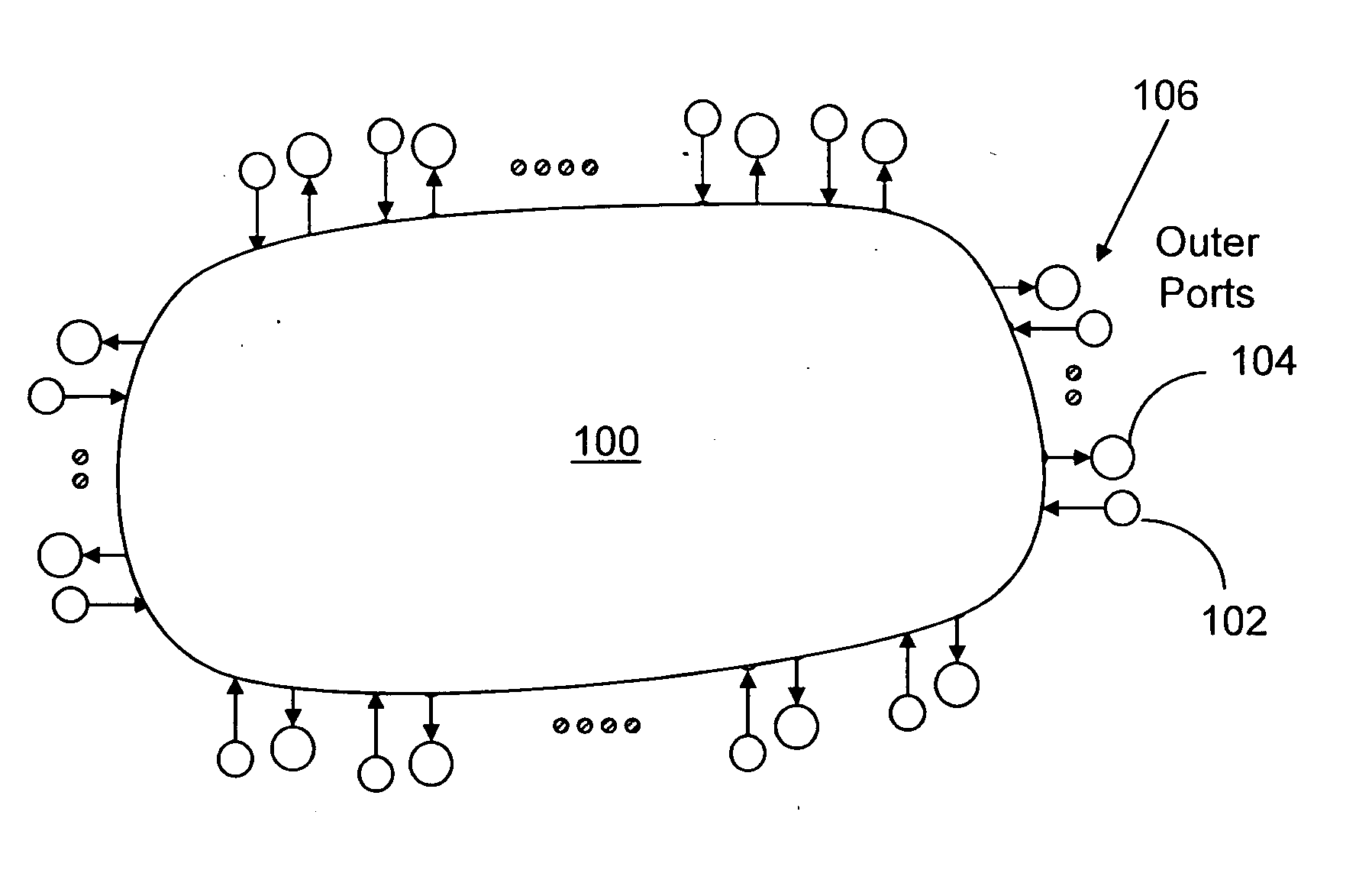

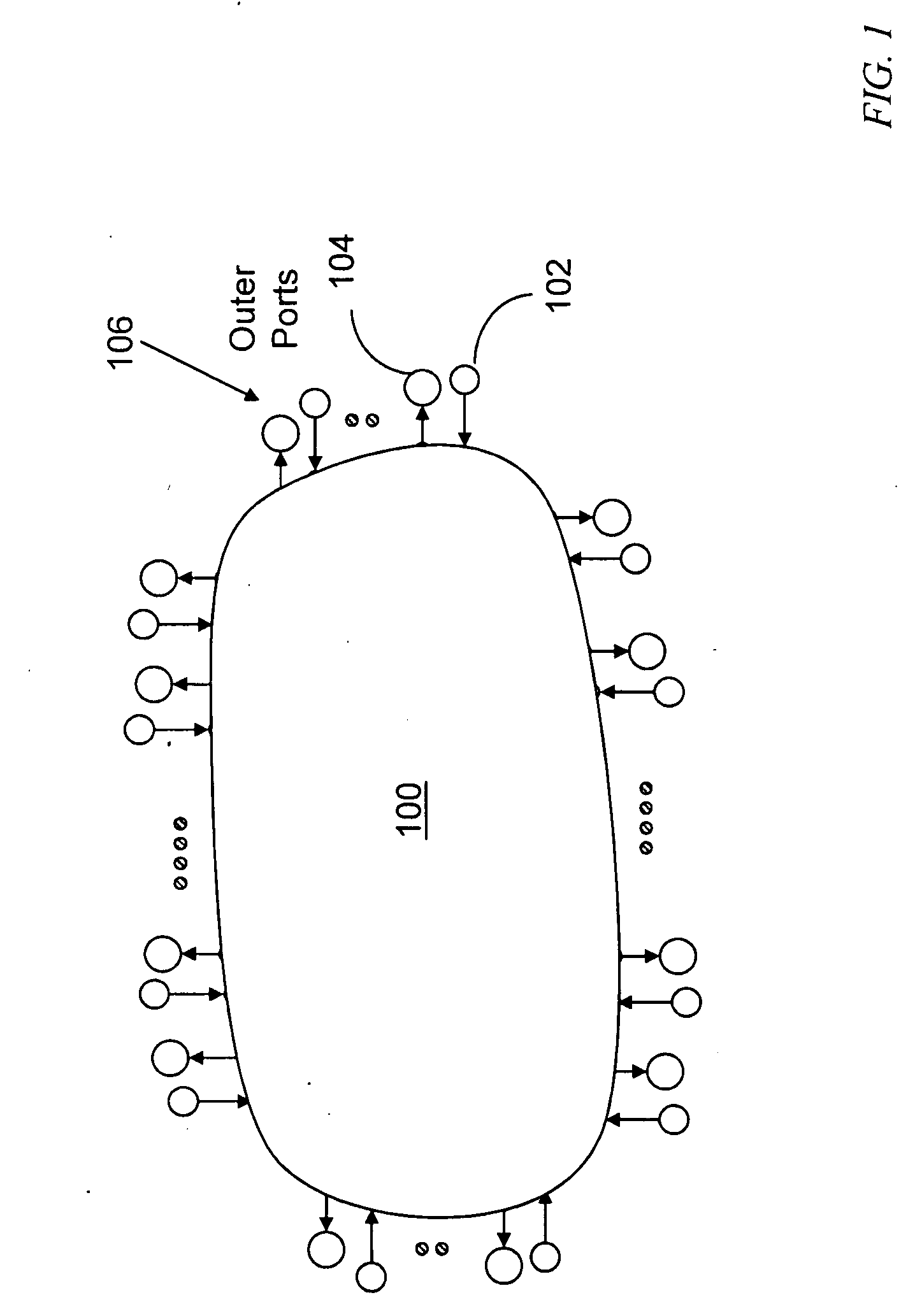

Flow-Rate-Regulated Burst Switches

InactiveUS20090207859A1Multiplex system selection arrangementsTime-division multiplexTraffic capacityData segment

Burst-switching nodes using a common-memory or a time shared space switch and employing flow-rate control are disclosed. Within a switching node, data bursts are segmented into data segments of a fixed size with some segments containing information bits as well as null bits. A switching node handles data streams allocated different flow rates and, for any data stream, the internal flow rate through the switching node can be higher than the external flow rate due to null padding of segmented data. The switching node is provided with a sufficient internal capacity expansion in order to offset the effect of null padding. A controller of the switching node is provided with a flow-rate-regulation apparatus to enable scheduling the transfer of data segments across the switching node in a manner that guarantees adherence to the allocated information flow rates.

Owner:RPX CLEARINGHOUSE

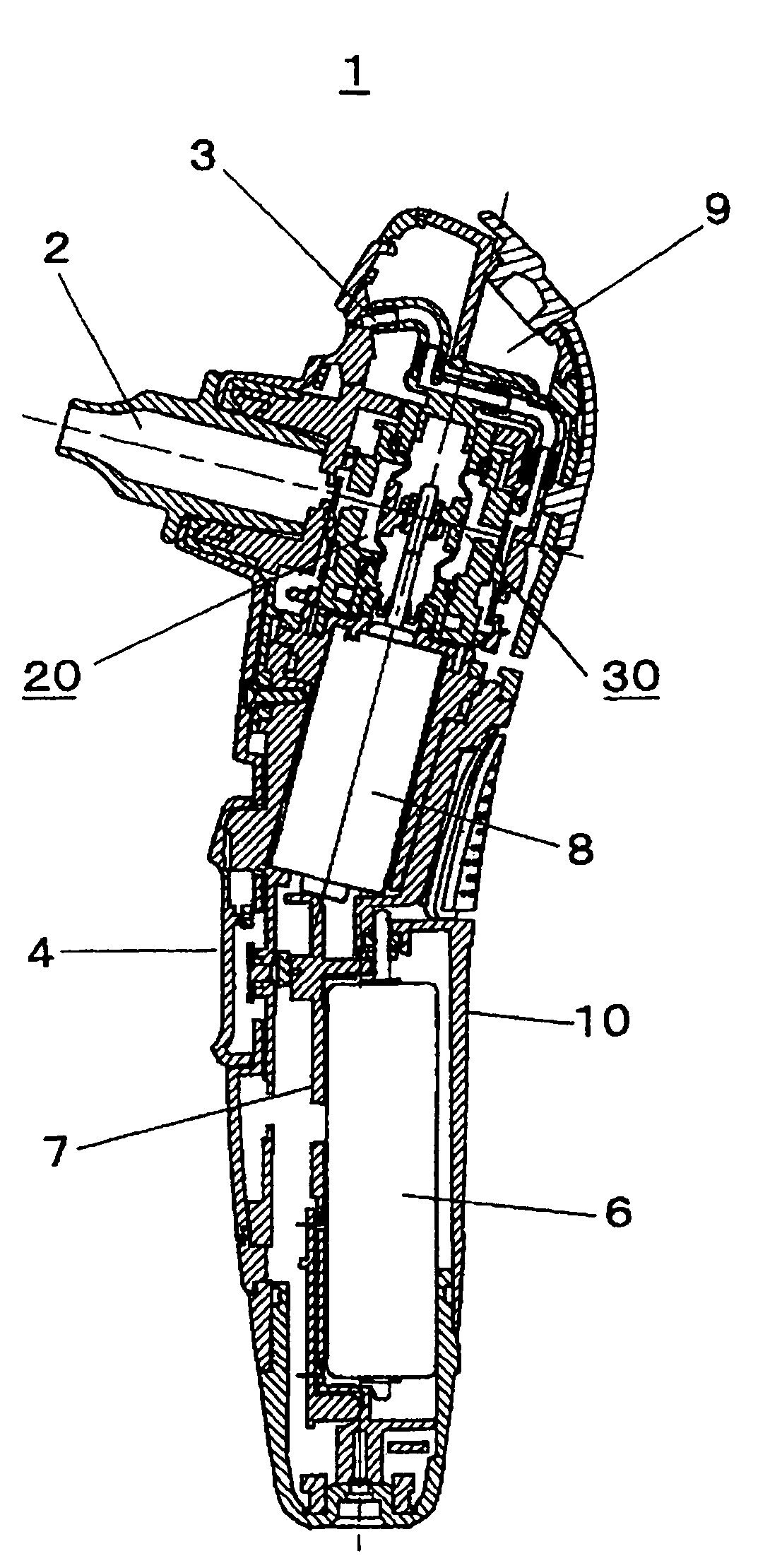

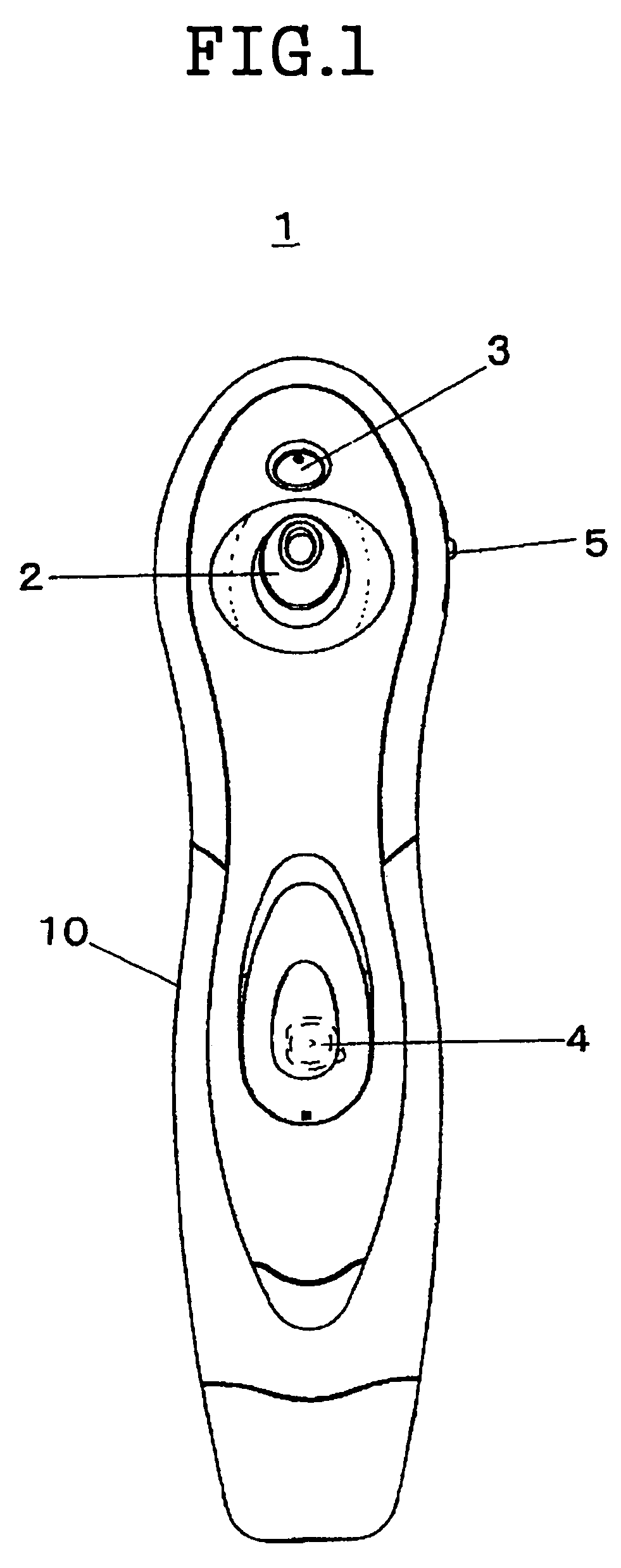

Skin care device for taking out and removing sebum or other cutaneous impurities

A skin care device includes a suction nozzle to be brought into contact with skin to suction skin impurities therefrom, a suction pump for generating a suction force of the suction nozzle, a mist nozzle installed near the suction nozzle, for ejecting a mist of liquid, a tank for storing therein a liquid to be supplied to the mist nozzle, a liquid supply pump for supplying the liquid to the mist nozzle from the tank, a drive motor for driving the suction pump and the liquid supply pump at the same time, and a liquid amount control unit for controlling an amount of the liquid ejected from the mist nozzle. The liquid amount control unit is a flow rate regulation device disposed between the tank and the mist nozzle.

Owner:MATSUSHITA ELECTRIC WORKS LTD

Air conditioning unit and control method and control device thereof

ActiveCN103912957ASpace heating and ventilation safety systemsLighting and heating apparatusEngineeringAir conditioning

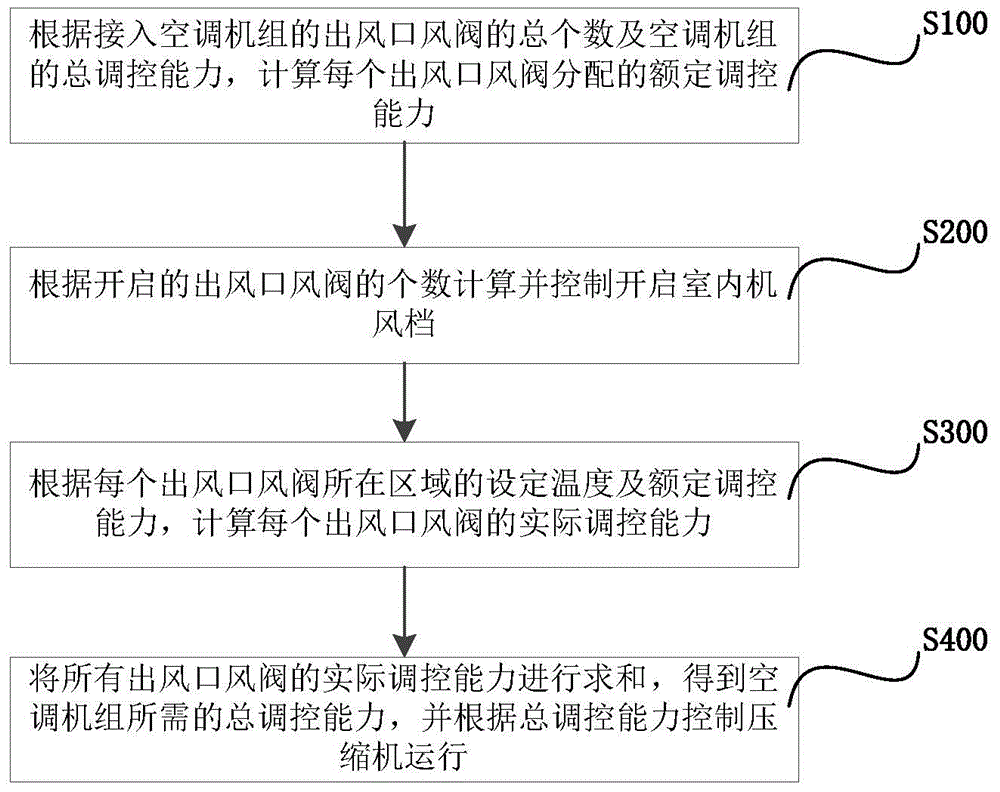

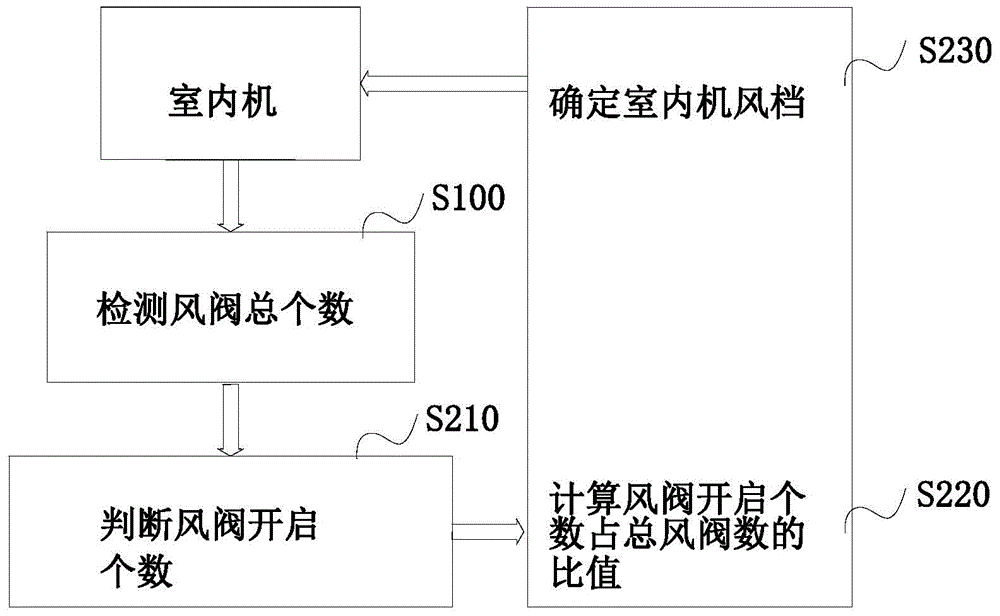

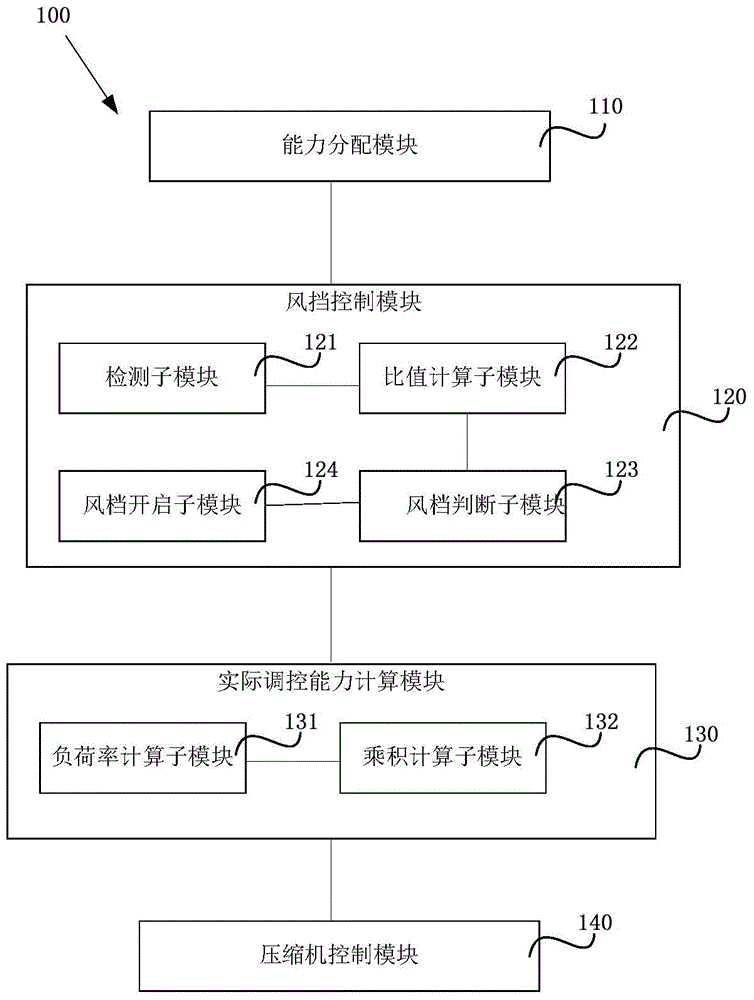

The invention discloses an air conditioning unit and a control method and a control device thereof. The method includes the following steps: according to total number of air-outlet air valves of the air conditioning unit and total regulation capacity of the air conditioning unit, computing rated regulation capacity distributed to each air-outlet air valve; according to the number of opened air-outlet air valves, computing and controlling opening air levels of an indoor unit; according to set temperature and the rated regulation capacity of an area where each air-outlet air valve is located, computing actual regulation capacity of each air-outlet air valve; summing the actual regulation capacities of all the air-outlet air valves to obtain total regulation capacity needed by the air conditioning unit, and controlling a compressor to run according to the total regulation capacity. One air-outlet air valve and a temperature controller are arranged in each regulation area independently, the opening air levels are controlled according to the number of the actually-opened air-outlet air valves, the actual regulation capacities of all the areas are integrated to control the compressor to run as required, multiple regulation areas are controlled centralizedly, and comfort and energy conservation requirements are met.

Owner:GREE ELECTRIC APPLIANCES INC

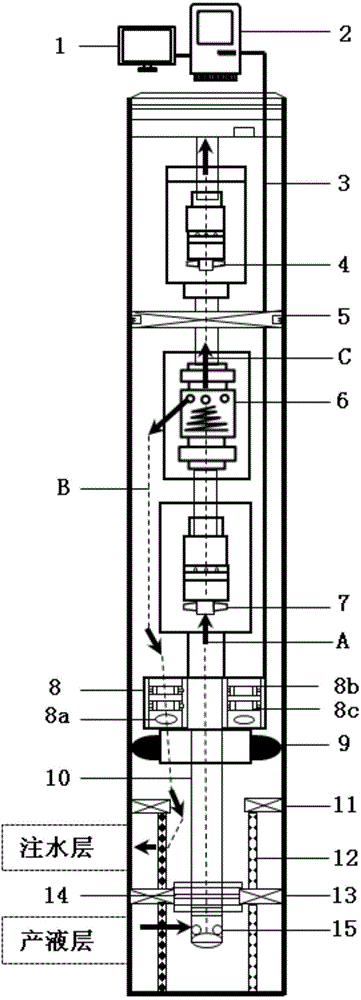

High-flow-rate underground oil-water separation and annular space testing and regulating system

The invention relates to an underground oil-water separating, testing and regulating technology, and discloses a high-flow-rate underground oil-water separation and annular space testing and regulating system, in particular to a system combining an annular space testing and regulating device with a high-flow-rate underground oil-water separation tubular column. The system is divided into a passage for enabling producing liquid on a liquid producing layer to enter an oil-water separator, a passage for reinjecting separated low-oil-content producing waterinto an annular spaceand a passage for lifting high-oil-content producing liquid by the high-flow-rate underground oil-water separation tubular column. The annular space testing and regulating device regulates the split ratio through monitoring the pressure and the flow rate of low-oil-content sewage in the annular space reinjection passage and performing reinjection flow rate regulation, and the stability of the underground oil-water separation system is ensured. The high-flow-rate underground oil-water separation and annular space testing and regulating system has the advantages that the stability of the high-flow-rate underground oil-water separation system can be ensured; the oil-water separation effect is improved; the precision of the testing and regulating system is high; the accurate producing liquid flow rate and rejection flow rate data can be provided for the oil reservoir scheme design; the scheme design accuracy is ensured; the system composition structure is simple; and the requirement of the annular space testing and regulating flow rate measuring range being 50 m<3> / d to 3,000 m<3> / d can be met.

Owner:CHINA NAT OFFSHORE OIL CORP +1

Exhaust gas purification apparatus and exhaust gas purification method for internal combustion engine

InactiveUS7640728B2Electrical controlInternal combustion piston enginesPurification methodsExhaust fumes

In an exhaust gas purification apparatus for an internal combustion engine (1) equipped with independent exhaust passages (2a, 2b) provided one for each cylinder group (1a, 1b) with a catalyst (3a, 3b) having a NOx trapping ability being arranged in each exhaust passage, the present invention is intended to provide a technique that can independently control the flow rates of exhaust gases flowing into the respective catalysts. To this end, the exhaust gas purification apparatus according to the present invention provides a communication passage (4) connecting mutually portions of said exhaust passages (2a, 2b) at upstream of said catalysts (3a, 3b), an upstream side switching valve (5) openning and closing said upstream side communication passage (4), a plurality of flow rate regulation valves (6a, 6b) being arranged at downstream of connecting portions of said exhaust passages with said upstream side communication passage, respectively, and a control section (9) controlling said upstream side switching valve (5) and said respective flow rate regulation valves (6a, 6b) in accordance with the states of said respective catalysts (3a, 3b). When the NOx trapping ability of one of the plurality of catalysts (3a, 3b) is regenerated, the control section (9) opens the upstream side switching valve (5), fully closes one flow rate regulation valve (6a, 6b) in one of the exhaust passages (2a, 2b) in which the one catalyst (3a, 3b) is arranged, and operates a reducing agent addition valve (7a, 7b) in such a manner that the reducing agent arrives at the one catalyst (3a, 3b) when the actual degree of opening of the one flow rate regulation valve (6a, 6b) becomes fully closed.

Owner:TOYOTA JIDOSHA KK

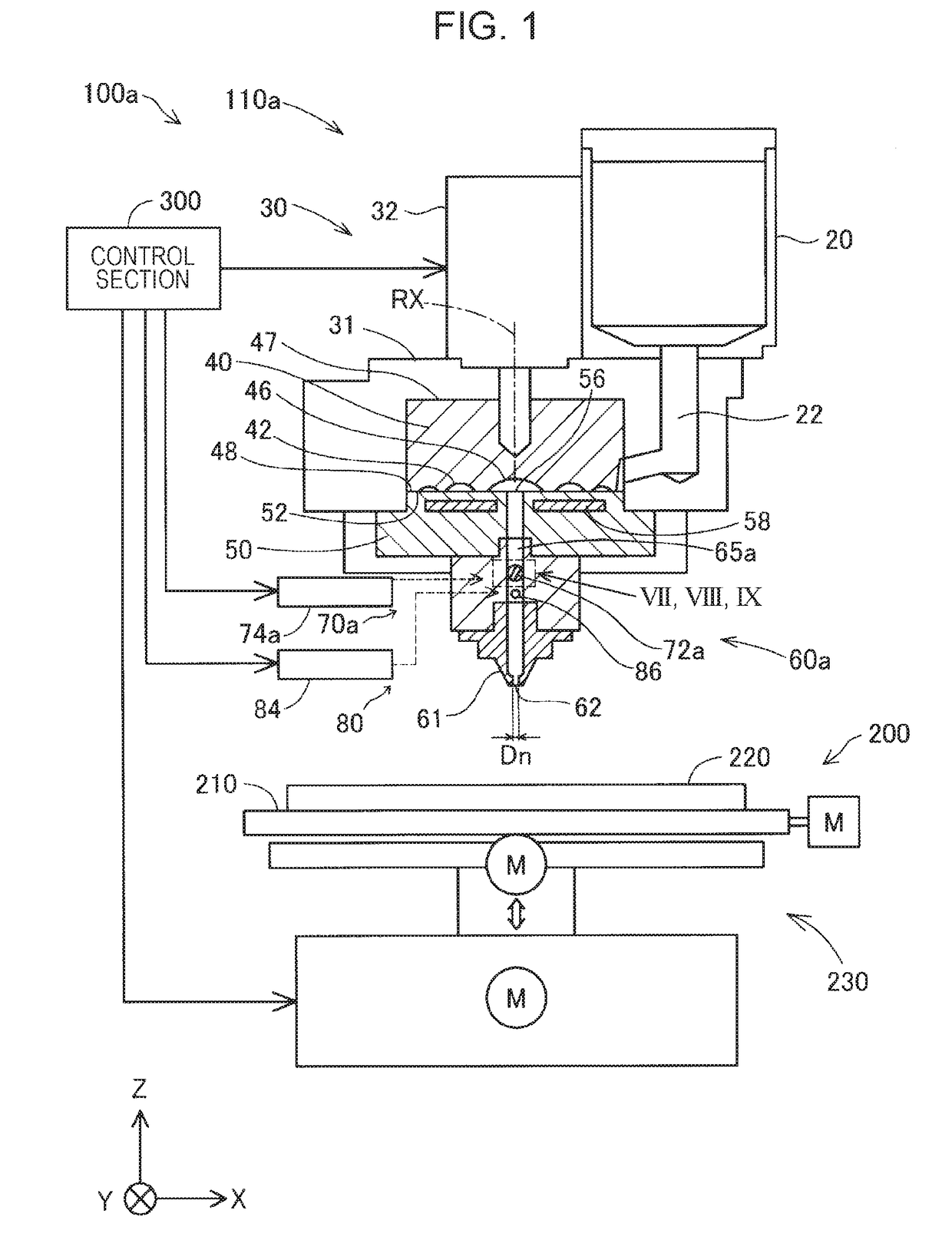

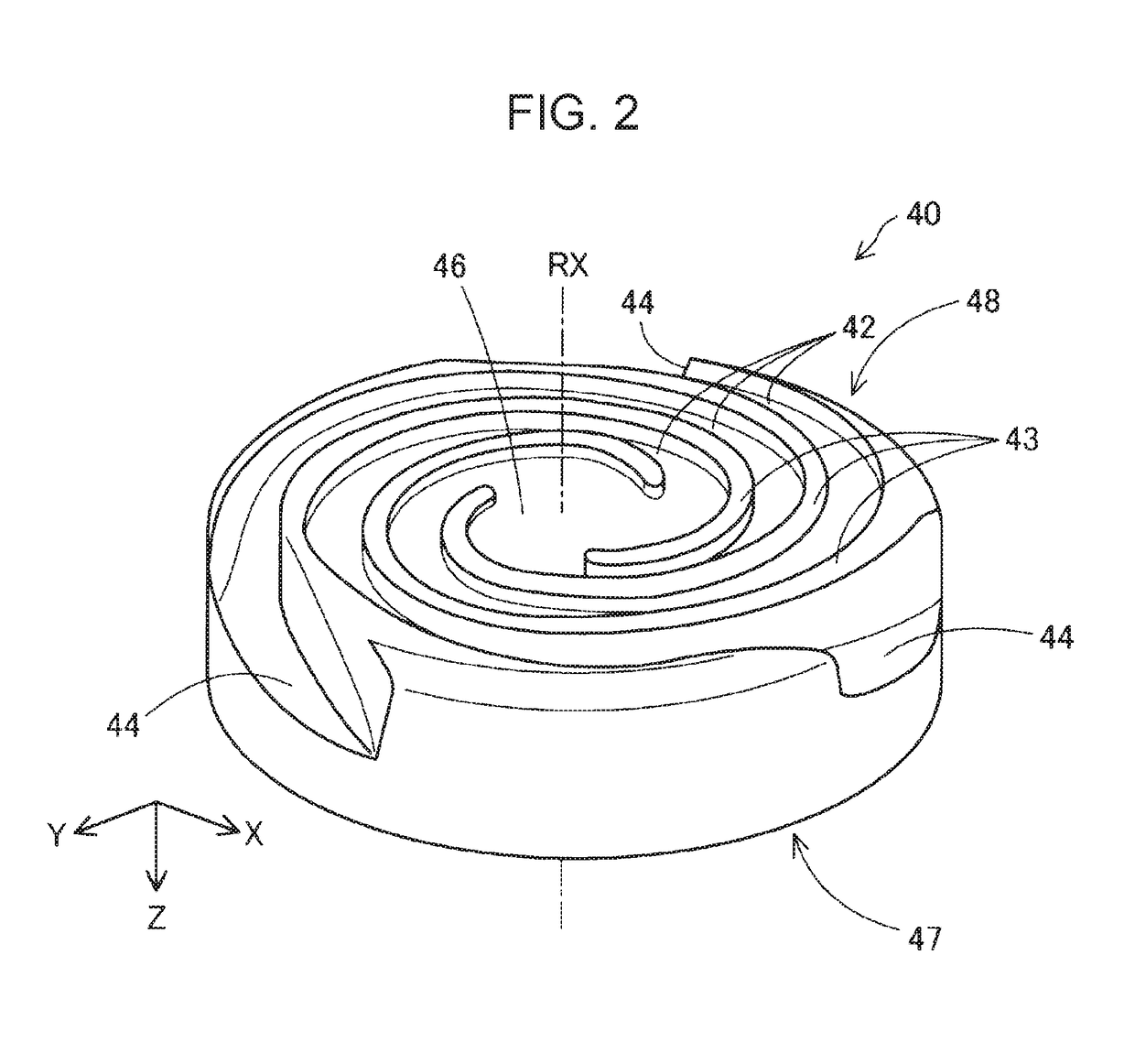

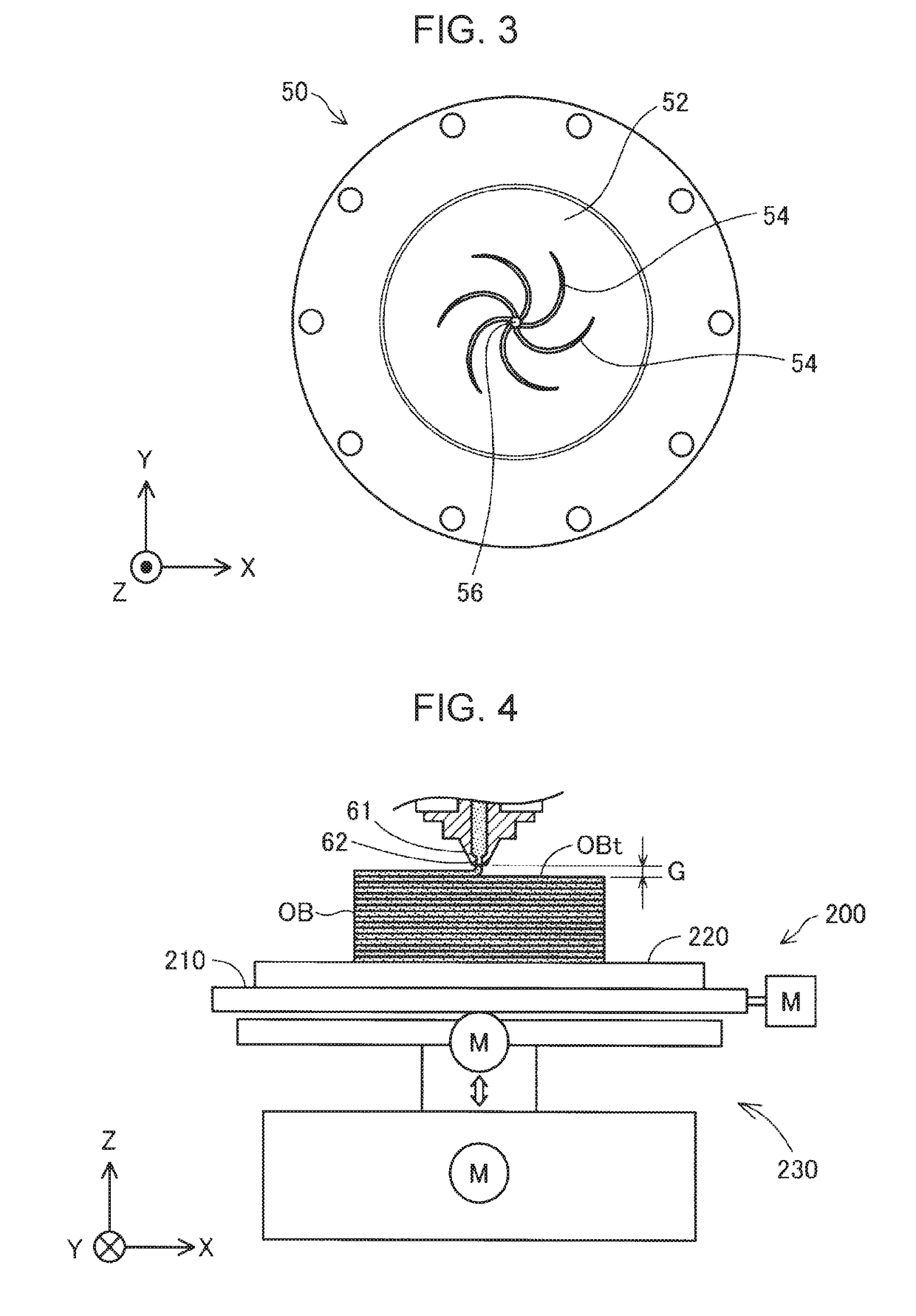

Shaping material supply device and three-dimensional shaping apparatus

ActiveUS20190061243A1High shape accuracySimple configurationCeramic shaping apparatusIncreasing energy efficiencyButterfly valveMaterial supply

Provided is a shaping material supply device for use in a three-dimensional shaping apparatus, which includes a first flow path through which a shaping material flows, a nozzle that communicates with the first flow path and discharges the shaping material, and a flow rate regulation mechanism that includes a butterfly valve provided in the first flow path.

Owner:SEIKO EPSON CORP

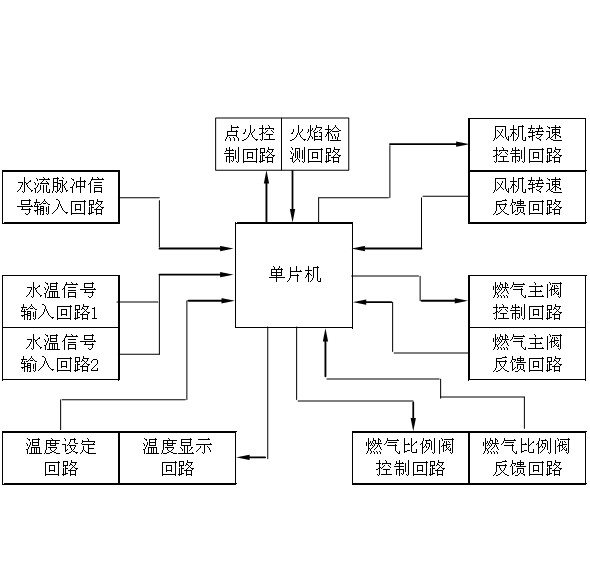

Constant-temperature-type gas water heater control system with rapid and accurate temperature-regulating characteristic and control method

InactiveCN102278820AImprove control regulationConstant responseFluid heatersTemperature responseAir volume

The invention discloses a constant-temperature-type gas water heater control system and with a rapid and accurate temperature-regulating characteristic and a control method. The control system is characterized by comprising a singlechip, an ignition control loop, a flame detection loop, a fan rotation speed control loop, a gas main valve control loop, a gas proportional valve control loop, a water flow pulse signal input loop, a water temperature signal input loop of cold-hot water temperature, a fan rotation speed feedback loop, a temperature setting loop, a temperature display loop and the like, wherein the water flow pulse signal input loop, the water temperature signal input loop of cold-hot water temperature and the temperature setting loop respectively transmit the water flow rate, the actual temperatures of inlet and outlet water and the set temperature to the singlechip in real time; and a gas main valve is used for the opening and closing control of a gas passageway, a gas proportional valve is used for achieving the dual closing of the gas passageway or the flow rate regulation and temperature control, and a fan control loop is used for achieving the air volume regulation function through controlling the rotation speed of a motor. The system and the method provided by the invention aim to overcome the defect that the existing gas water heater control system and the method can not combine the temperature regulation accuracy and response speed simultaneously, and aim to provide the control system and the method with high temperature regulation accuracy and rapid temperature response.

Owner:杭州恒杉电子有限公司

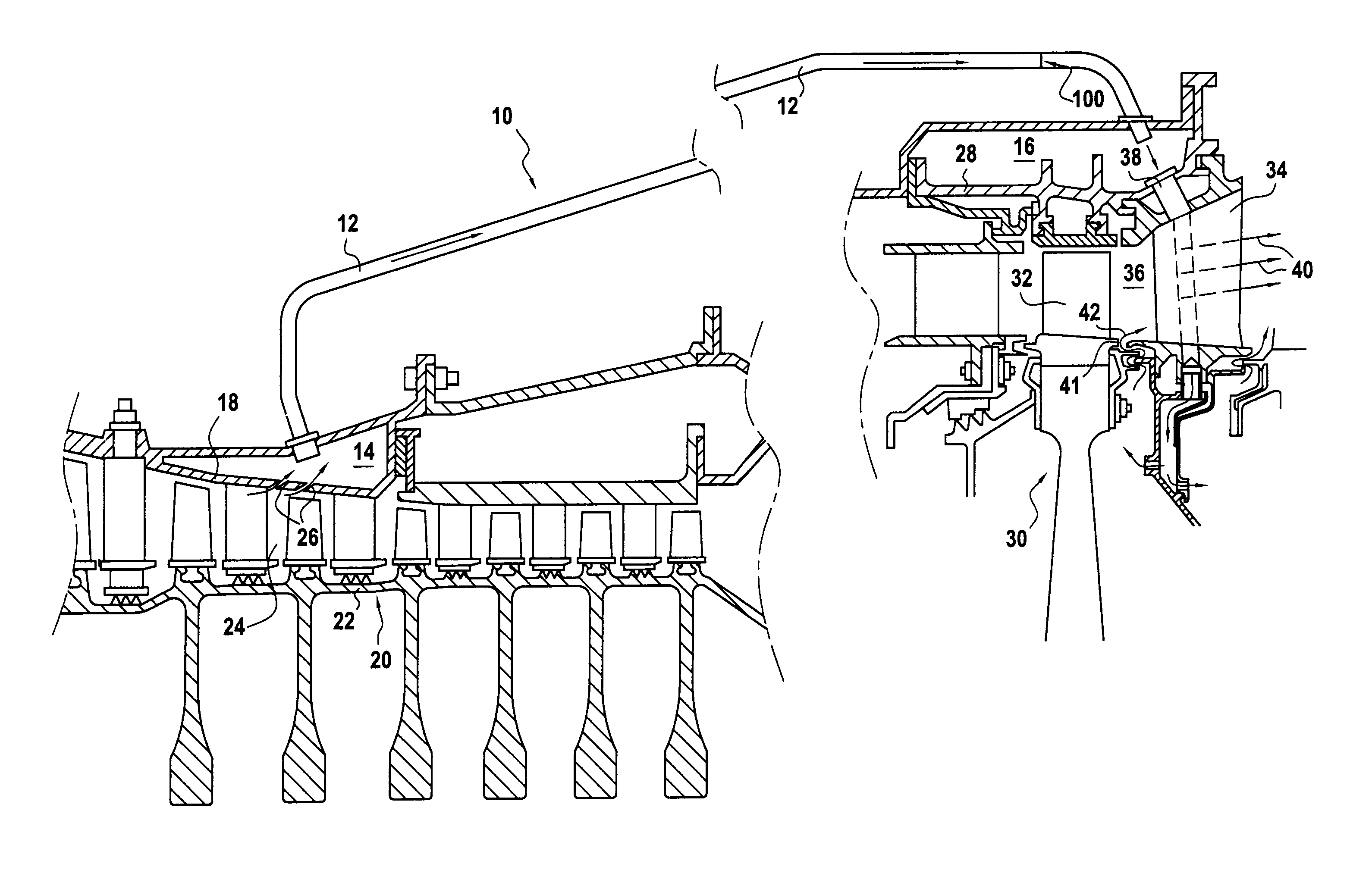

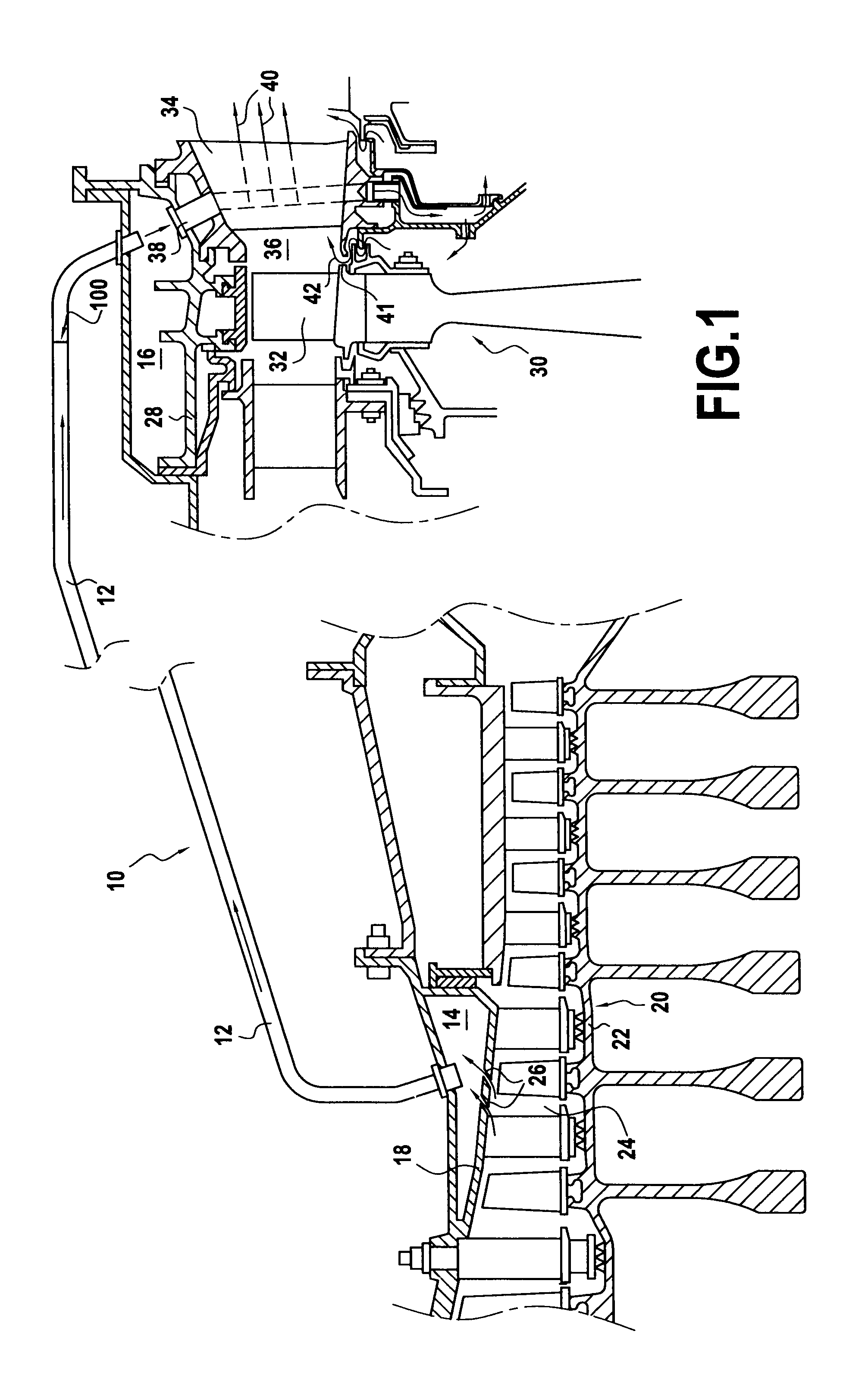

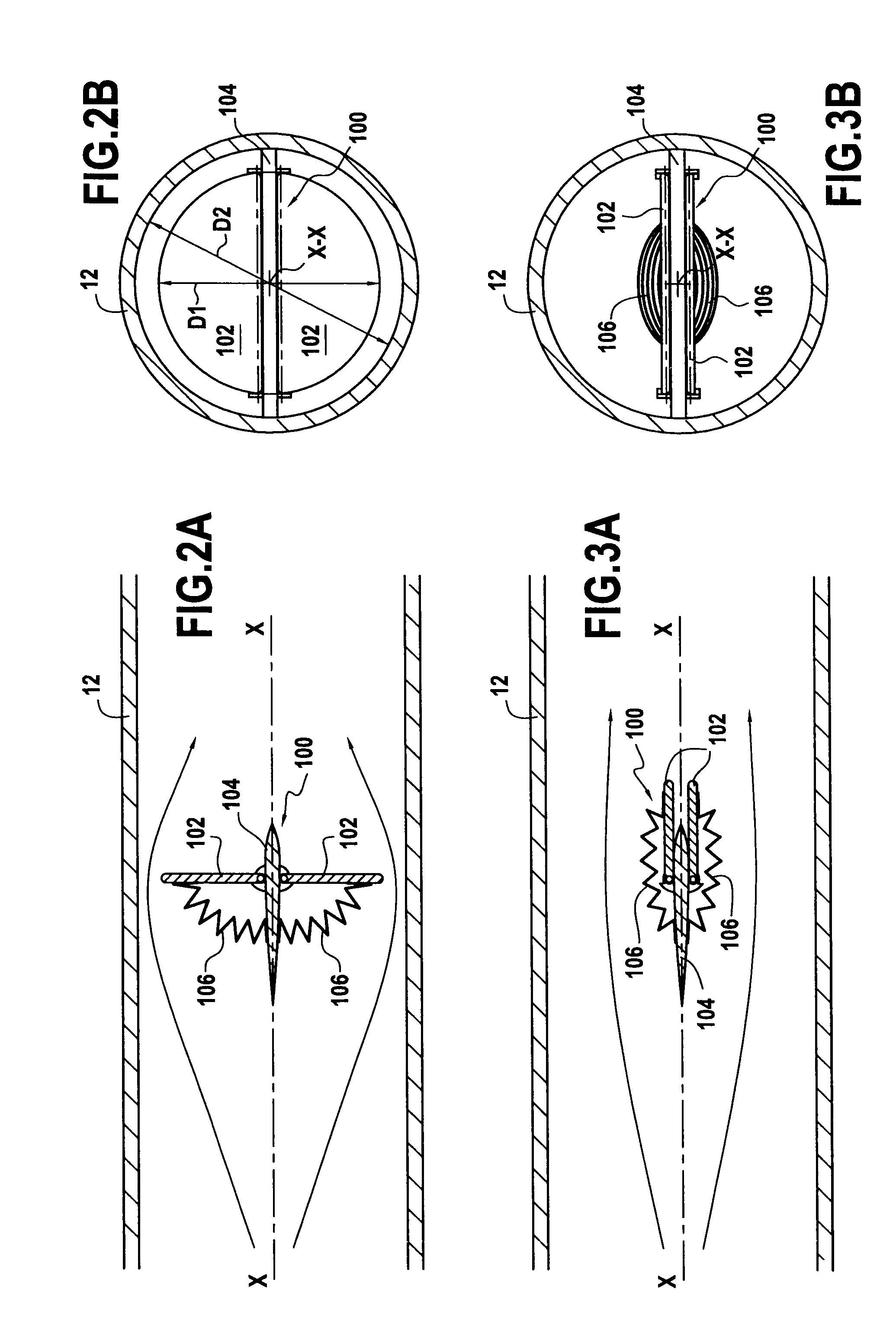

Device for regulating the flow rate of air feeding a turbine ventilation cavity of a turbomachine turbine section

ActiveUS20100119356A1Easy to take offReduce fuel consumptionWind motor controlEngine fuctionsInternal pressurePressure difference

The invention relates to a device for regulating the flow rate of air feeding a turbine ventilation cavity of a turbomachine turbine section, the device comprising at least one tubular duct opening into a take-off cavity and leading into a turbine ventilation cavity, the pressure inside the take-off cavity being higher than the pressure inside the turbine ventilation cavity, an air flow rate regulation valve disposed in the tubular duct, the valve being suitable for moving under the effect of the pressure difference between the take-off cavity and the turbine ventilation cavity, and mechanical return means for holding the valve in a maximum closure position for the duct so long as the pressure difference between the take-off cavity and the turbine ventilation cavity remains below a predetermined threshold pressure.

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

Regulating Data-Burst Transfer

InactiveUS20080165688A1Multiplex system selection arrangementsError preventionQuality of serviceBurst transmission

The invention discloses methods and apparatus for regulating the transfer of data bursts across a data network comprising electronic edge nodes interconnected by fast-switching optical core nodes. To facilitate switching at an electronic edge node, data bursts are organized into data segments of equal size. A data segment may include null data in addition to information bits. The null data are removed at the output of an edge node and the information data is collated into bursts, each carrying only information bits in addition to a header necessary for downstream processing. To ensure loss-free transfer of bursts from the edge to the core, burst transfer permits are generated at controllers of the optical core and sent to respective edge nodes based on flow-rate-allocation requests. Null-padding is not visible outside the edge nodes and only the information content is subject to transfer rate regulation to ensure high efficiency and high service quality.

Owner:RPX CLEARINGHOUSE

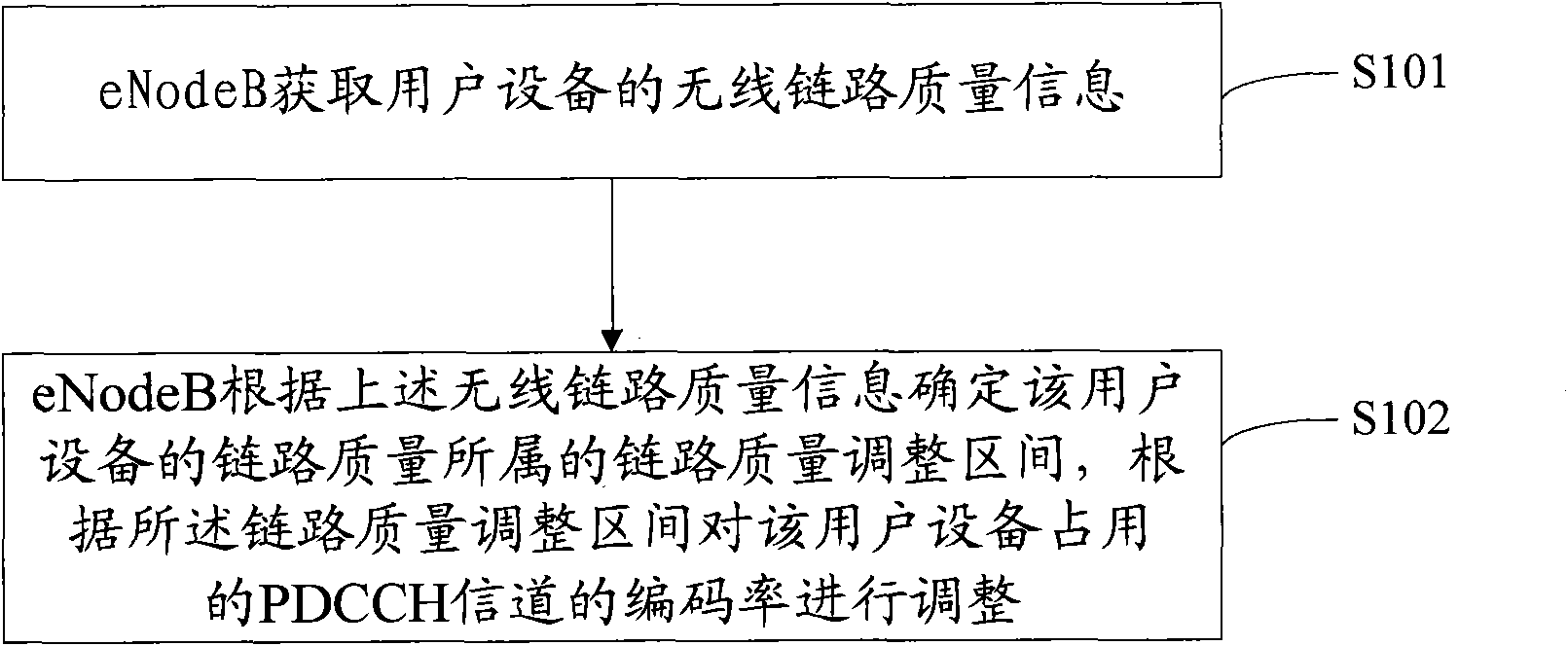

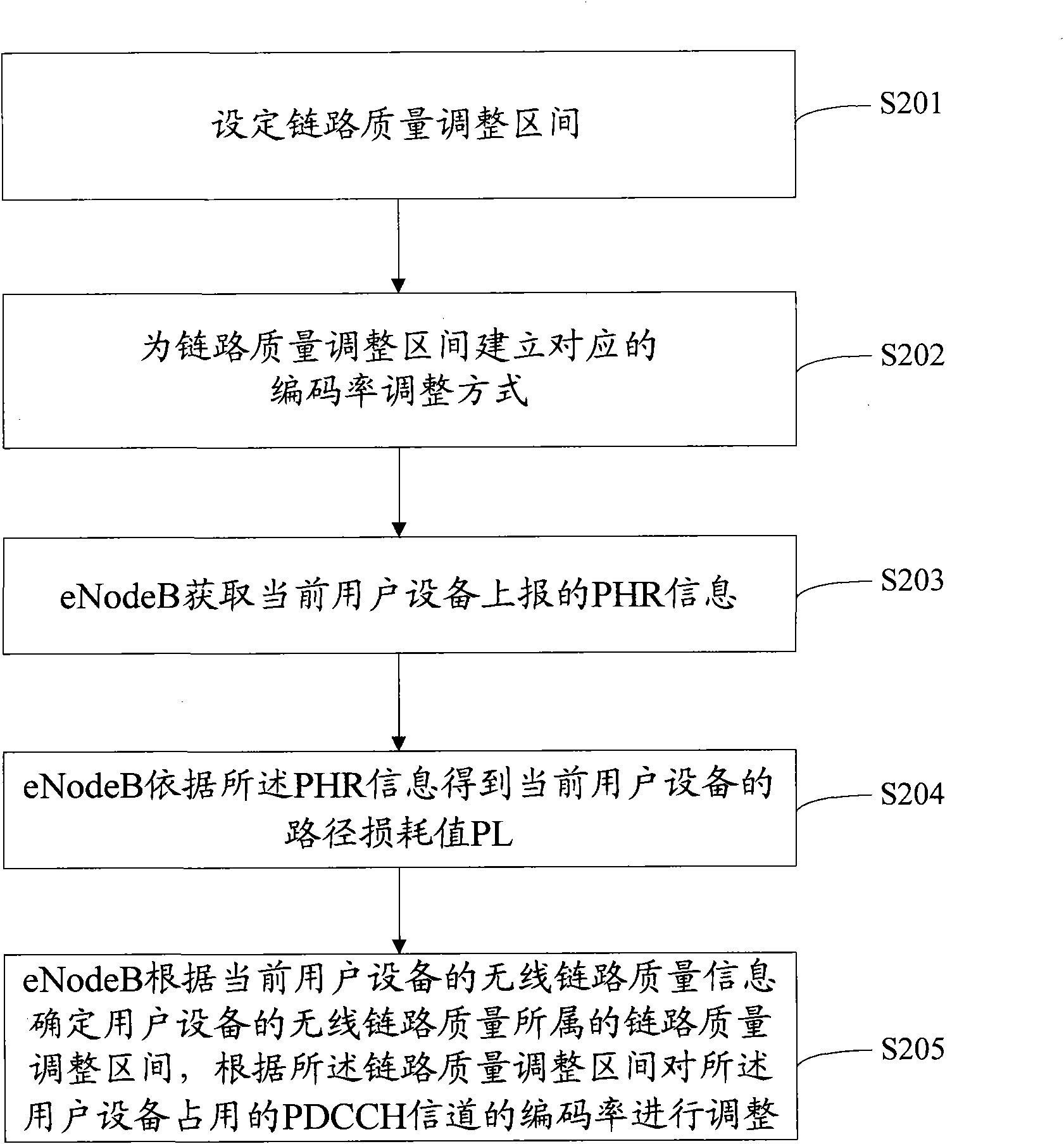

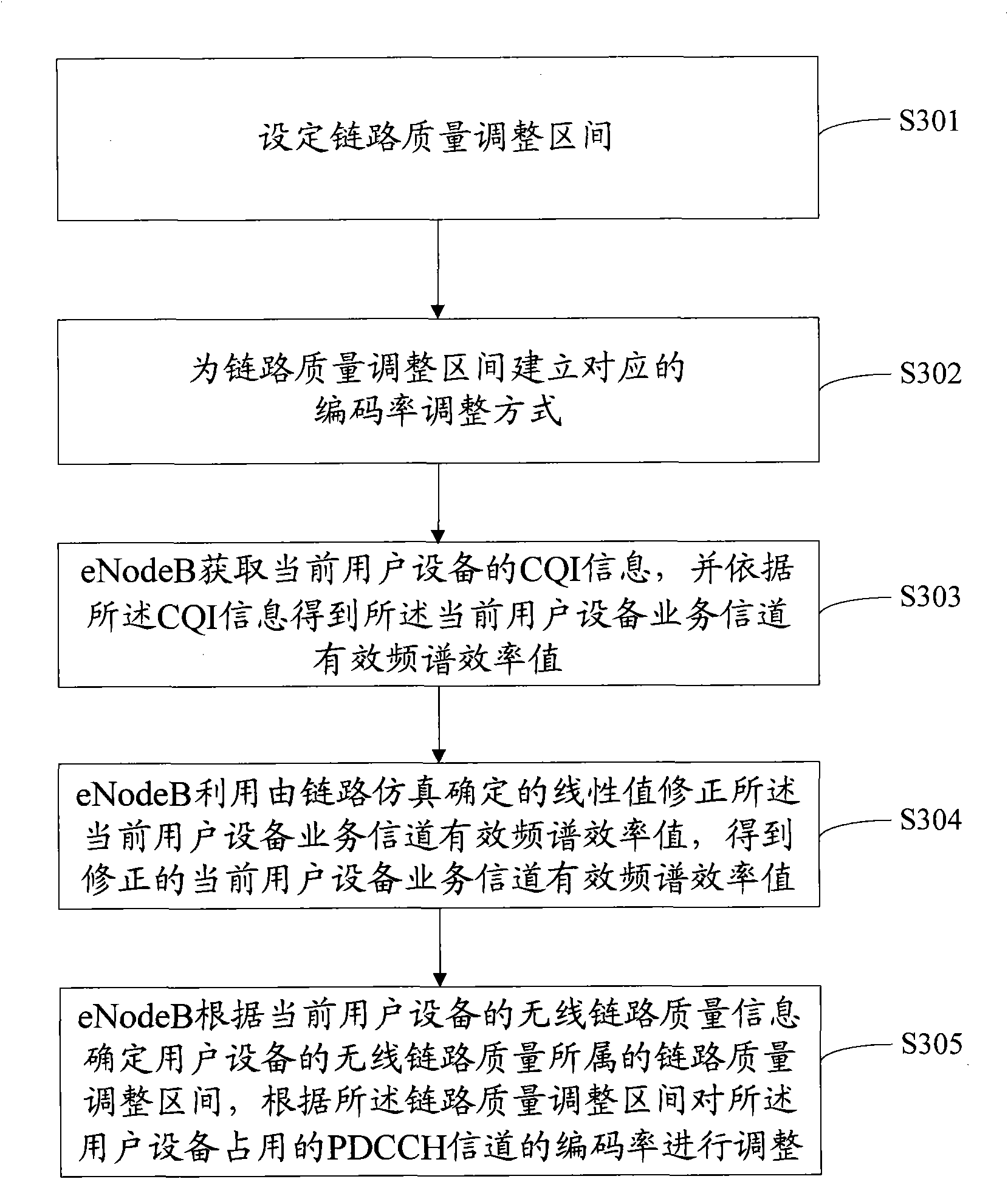

PDCCH channel encoding rate regulation method and evolution base station

InactiveCN101674654AImprove utilization efficiencyRadio transmission for post communicationWireless communicationUser equipmentQuality adjustment

The invention discloses a PDCCH channel encoding rate regulation method and an evolution base station, relating to the field of mobile communication. The method comprises the following steps: obtaining the radio link quality information of user equipment; according to the radio link quality information of user equipment, determining a link quality regulation zone to which the radio link quality ofthe user equipment belongs; and according to the link quality regulation zone, regulating the PDCCH channel encoding rate occupied by the user equipment. The base station comprises an acquisition module and a regulation module so as to reasonably choose the PDCCH channel encoding rate according to the practical condition of the current user equipment link quality, thus improving the utilization efficiency of controlling resource. Specifically, the embodiment of the invention improves the efficiency for the PDCCH channel to transmit scheduling Information to a user, thus improving the user number simultaneously scheduled by the same TTI and reducing the waiting time delay of user data on the sending side.

Owner:SHANGHAI HUAWEI TECH CO LTD

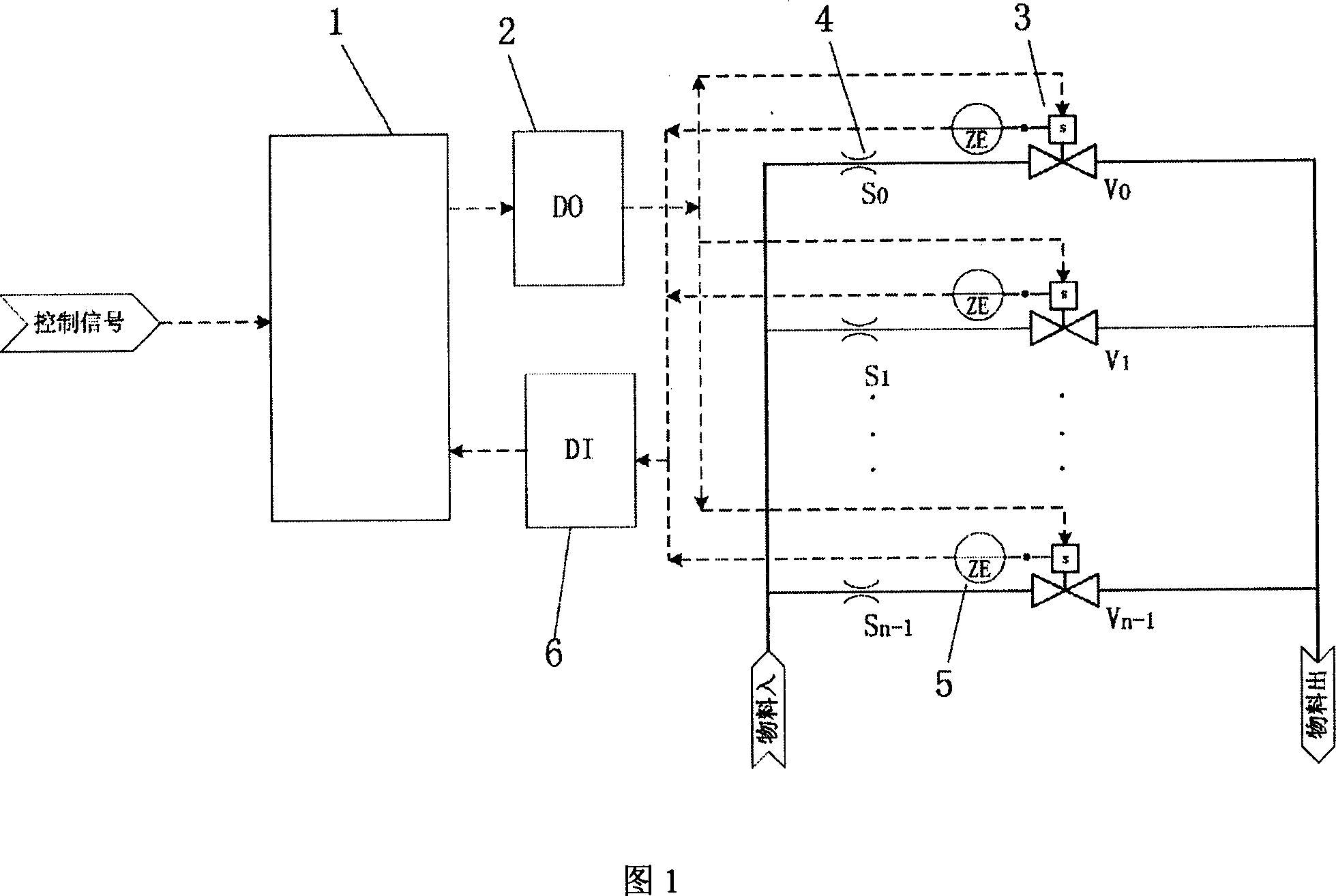

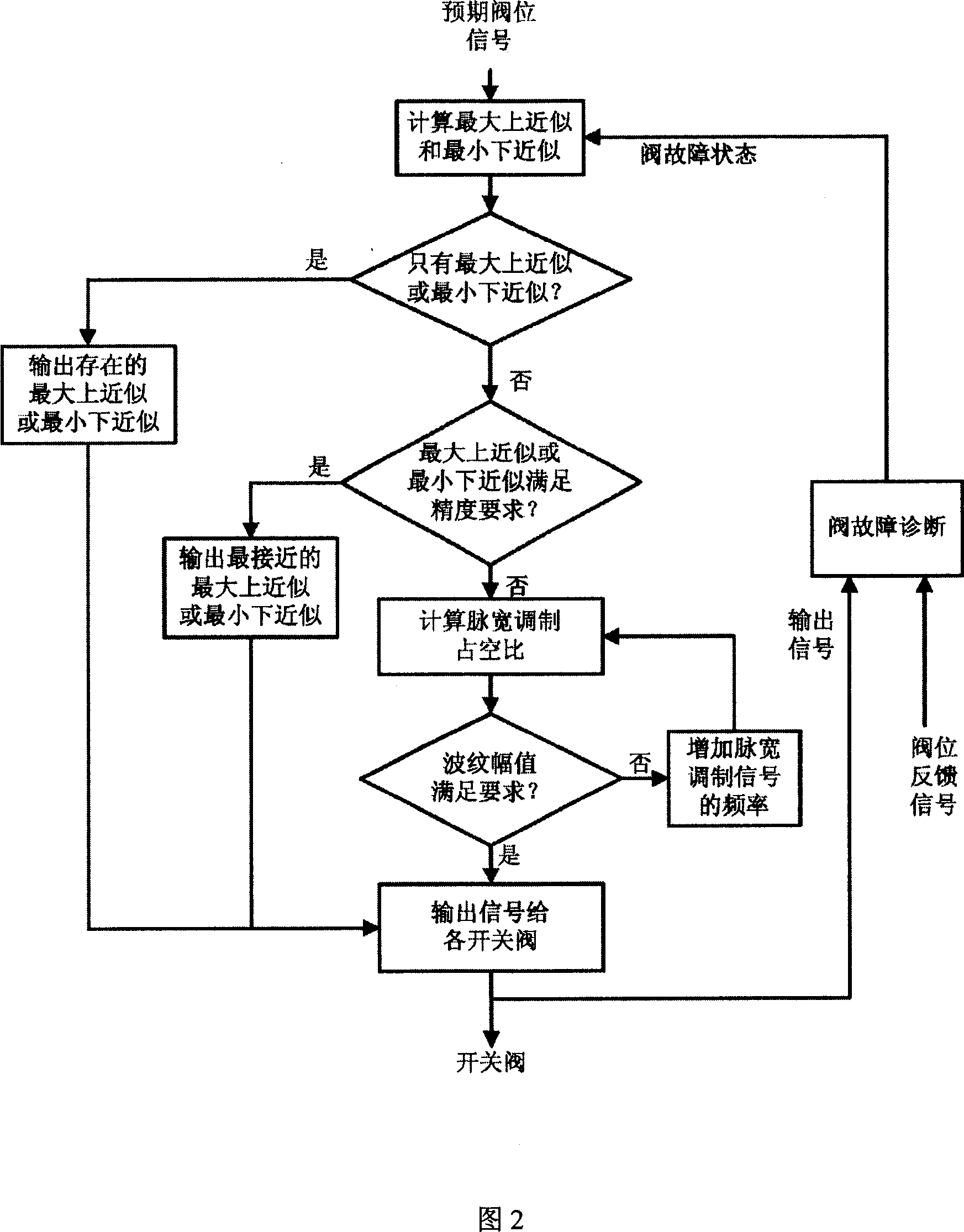

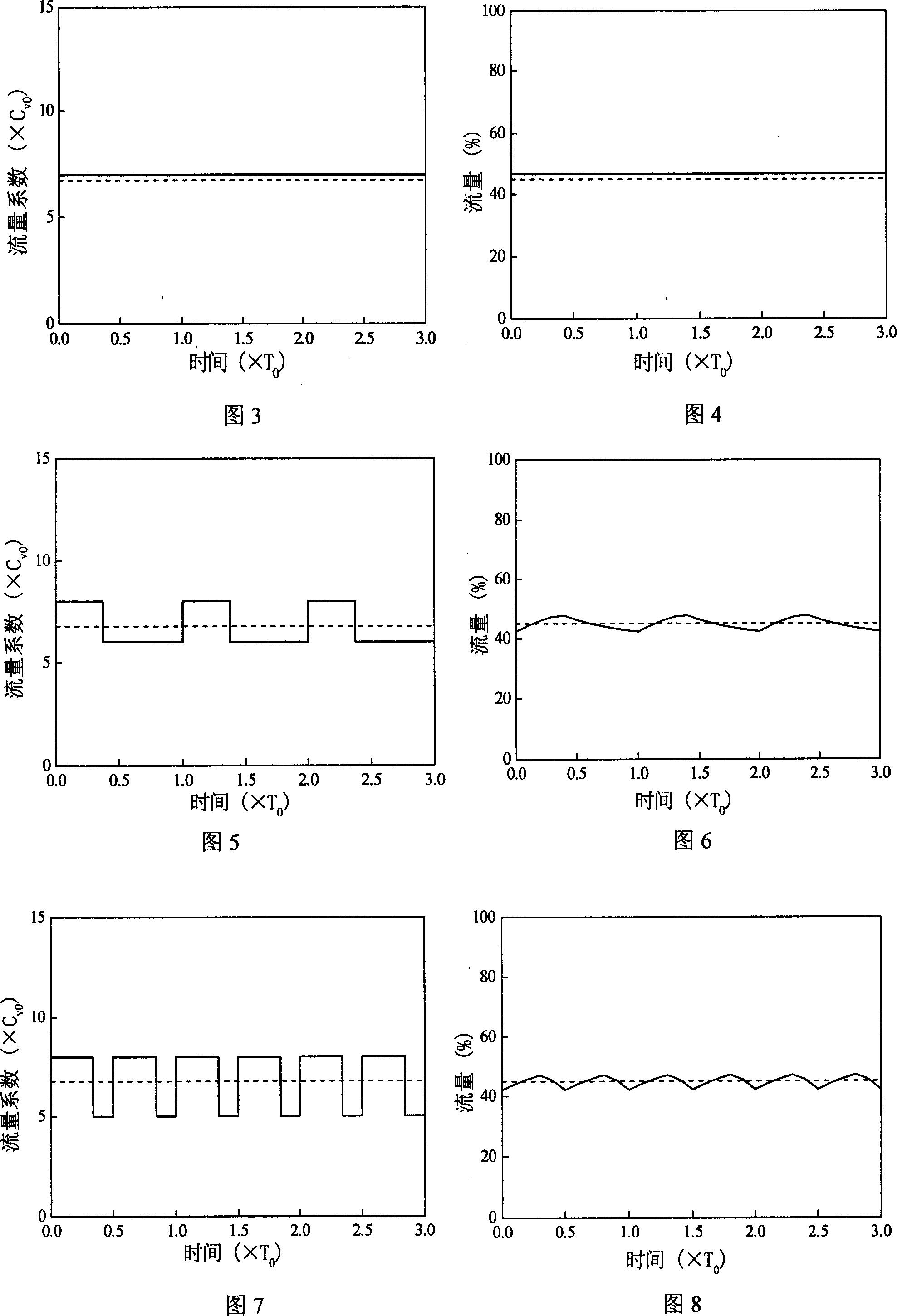

Flow control system and control method in mixed mode of pulse code modulation and pulse width modulation

InactiveCN101004612AWith fault self-healing abilityFlow control using electric meansControl signalControl system

A flow rate regulation system of pulse code modulation and pulse width modulation mixed type is prepared for sending valve control signal to controller and sending relevant switch state to a set of switch valves through switching valve output channel, arranging a throttle element on each branch path with switch valve to make flow rate coefficient of each valve be on certain ratio, obtaining feedback signal of valve state through state detection mechanism and sending obtained signal to controller then carrying out fault diagnosis on each valve by controller according to comparison of signals.

Owner:BEIJING UNIV OF CHEM TECH

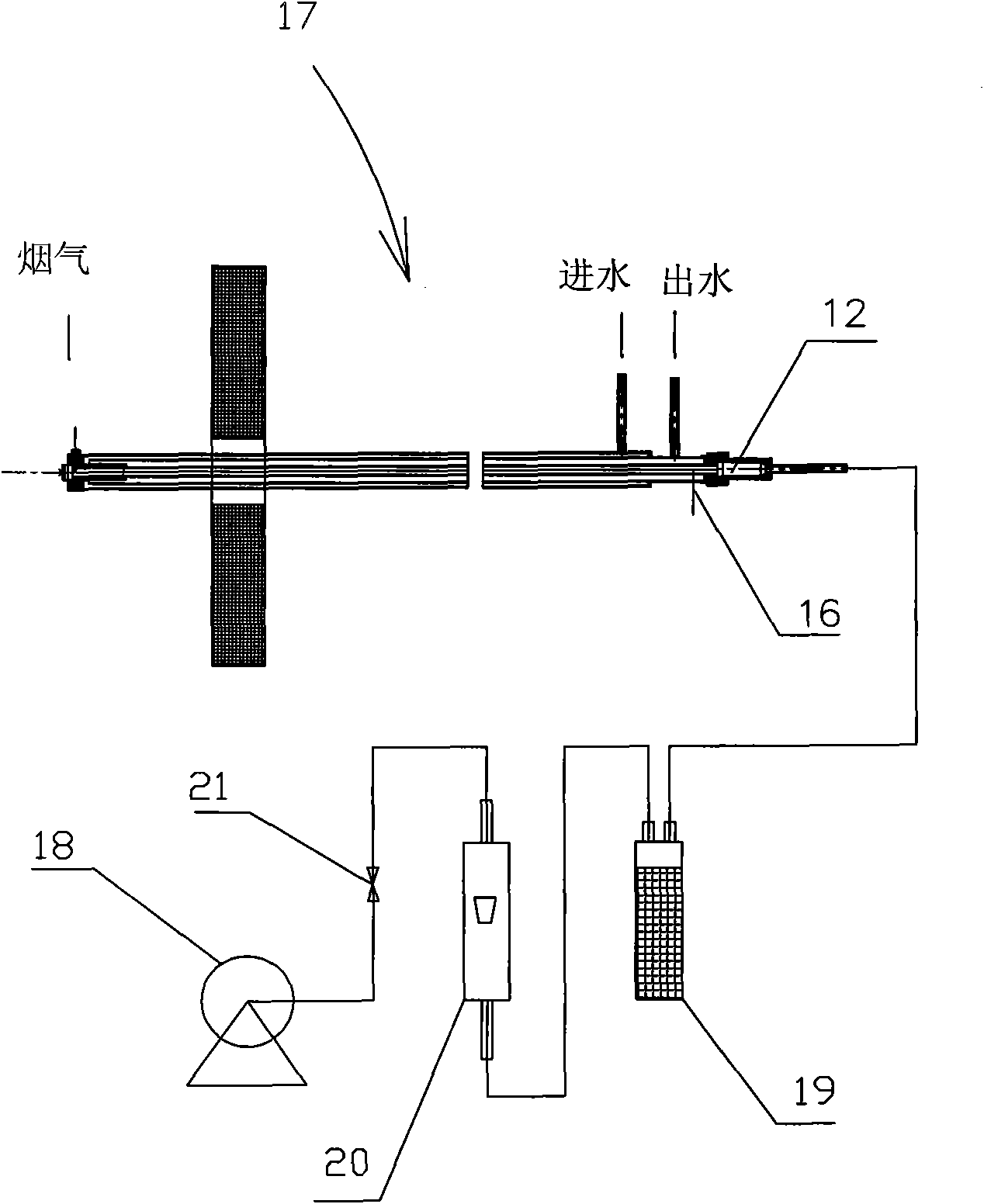

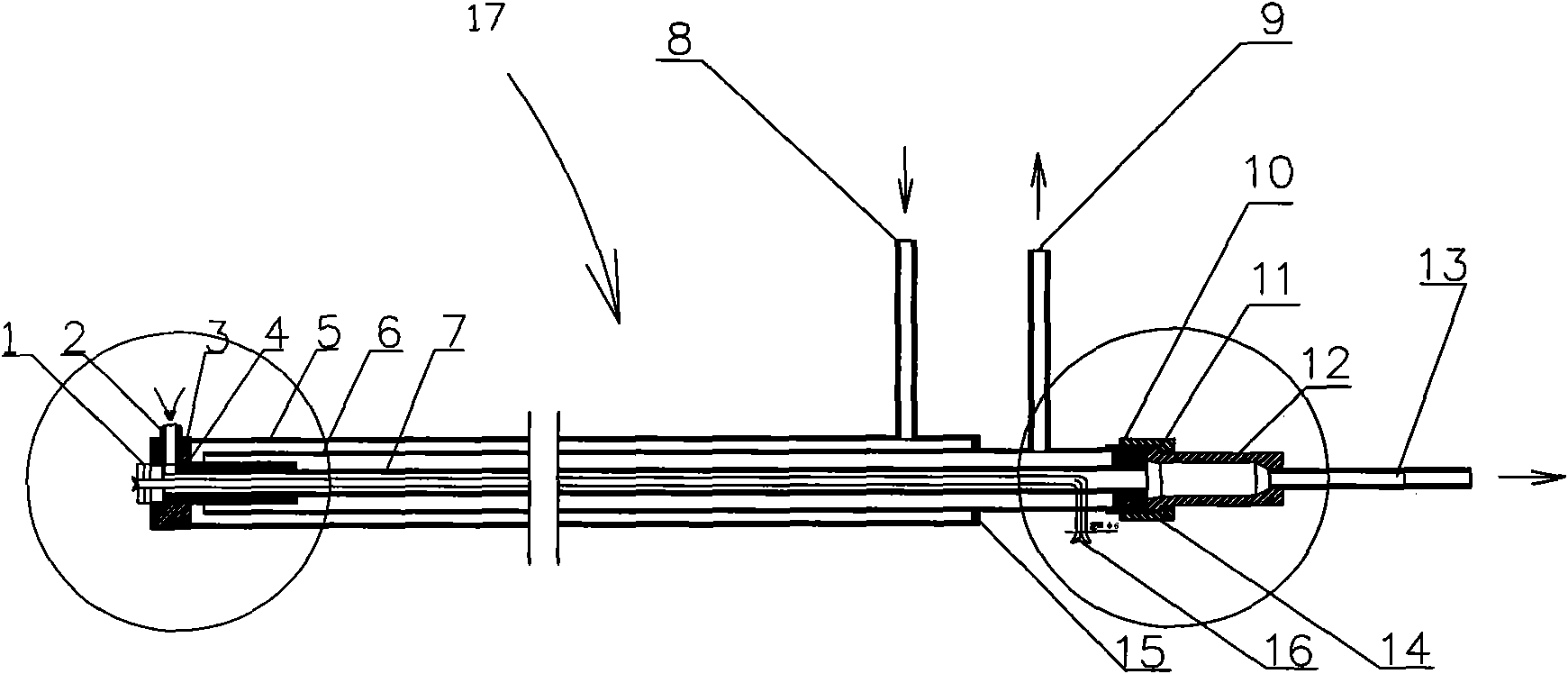

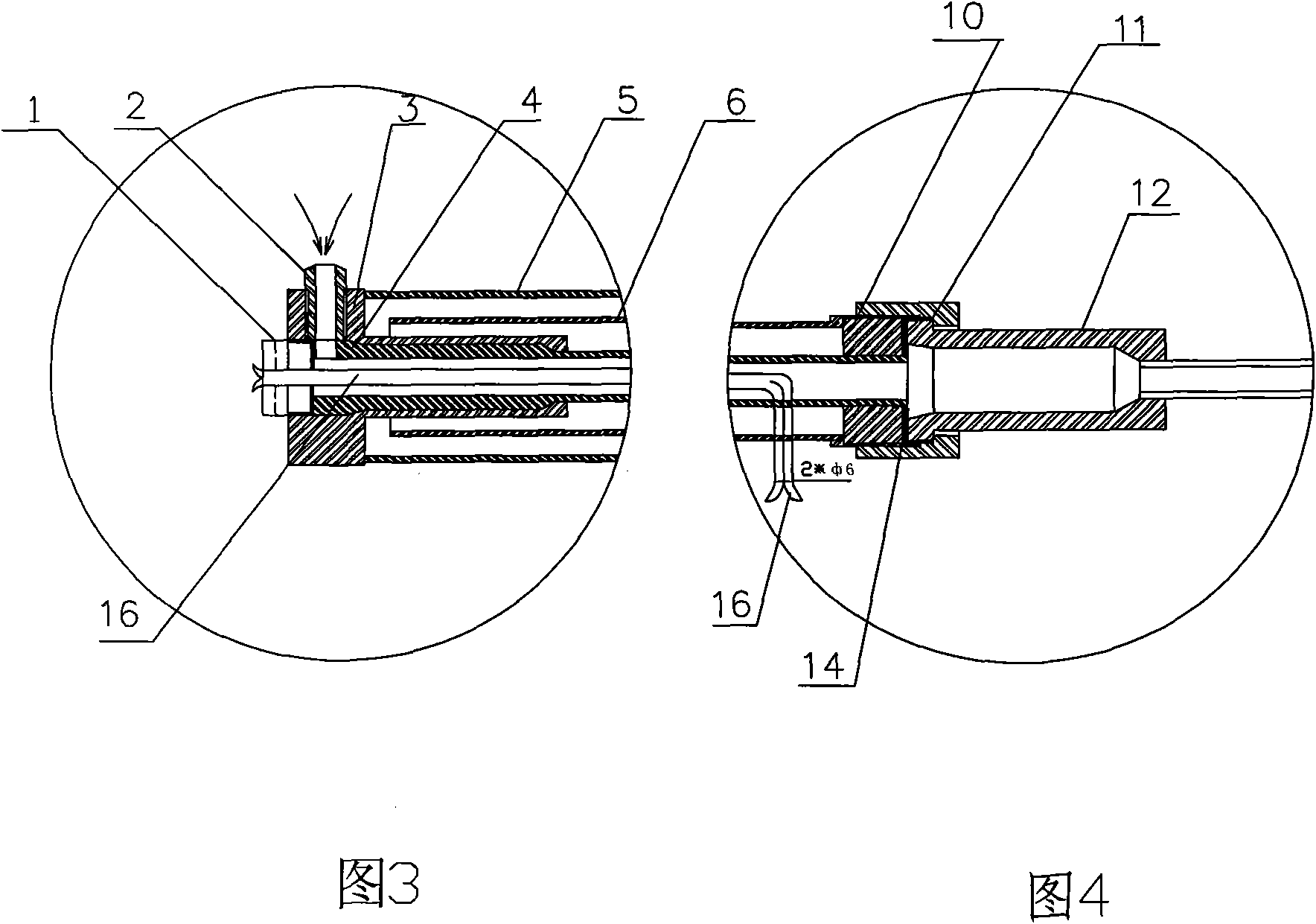

Water-cooling fly ash sampling device of circulating fluid bed boiler

ActiveCN101672732AReduce the temperatureAchieving Fly Ash SamplingWithdrawing sample devicesParticle size analysisMeasurement deviceEngineering

The invention relates to a water-cooling fly ash sampling device of a circulating fluid bed boiler, which comprises a sampling gun (17). The water-cooling fly ash sampling device of the circulating fluid bed boiler has the structure that the front end of a sampling tube (7) is connected with a sampling head (2), the sampling head (2) is provided with a fume inlet and is communicated with a tube cavity of the sampling tube (7), the back end of the sampling tube (7) is provided with a sampling barrel (12) used for holding sampled fly ash and a sampling connection tube (13), a back tube (16) is penetrated into the sampling tube, and the back end of the back tube (16) is connected with a pressure difference measurement device. The water-cooling fly ash sampling device of the circulating fluidbed boiler is characterized in that a water-cooling sleeve tube used for the passing of cooling water is sleeved outside of the sampling tube (7), and an inlet and an outlet of the cooling water of the sampling tube (7) are arranged at the back end of the water-cooling sleeve tube. Because the water-cooling tube is arranged outside the sampling tube of the sampling gun, the sampling device can work under a fume environment of 1100 DEG C and can sample the fly ash at constant speed aiming at different boiler loads and fume flow speeds and temperatures; the sampling head at the head part of thesampling gun can select the fly ash according to the actual fly ash concentration, an air exhaust blower and a flow rate regulation device which are arranged at the tail part of the sampling gun can regulate the flow rate, and approximately constant-speed sampling is realized.

Owner:ELECTRIC POWER RES INST OF GUANGDONG POWER GRID

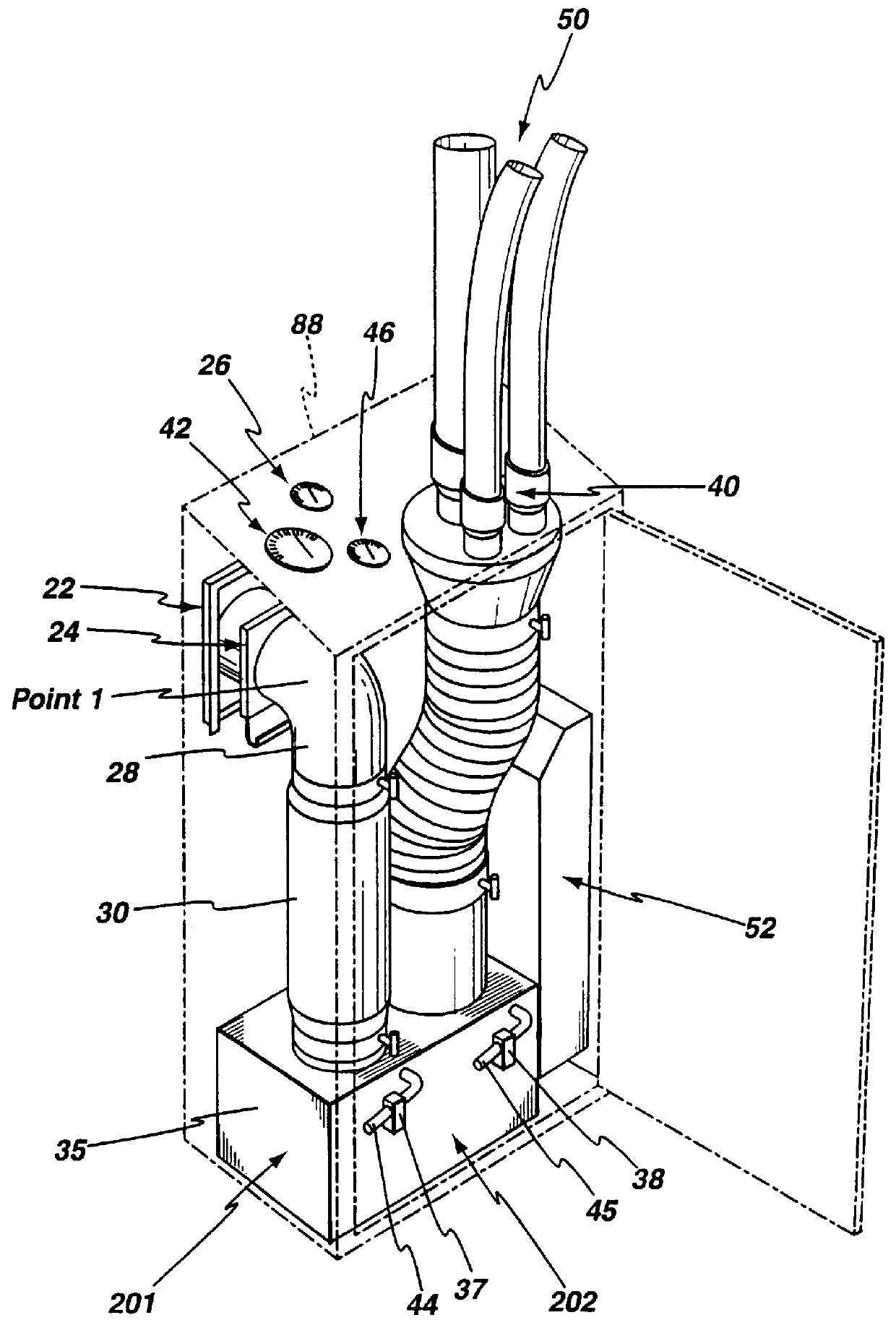

Airflow rate regulating device

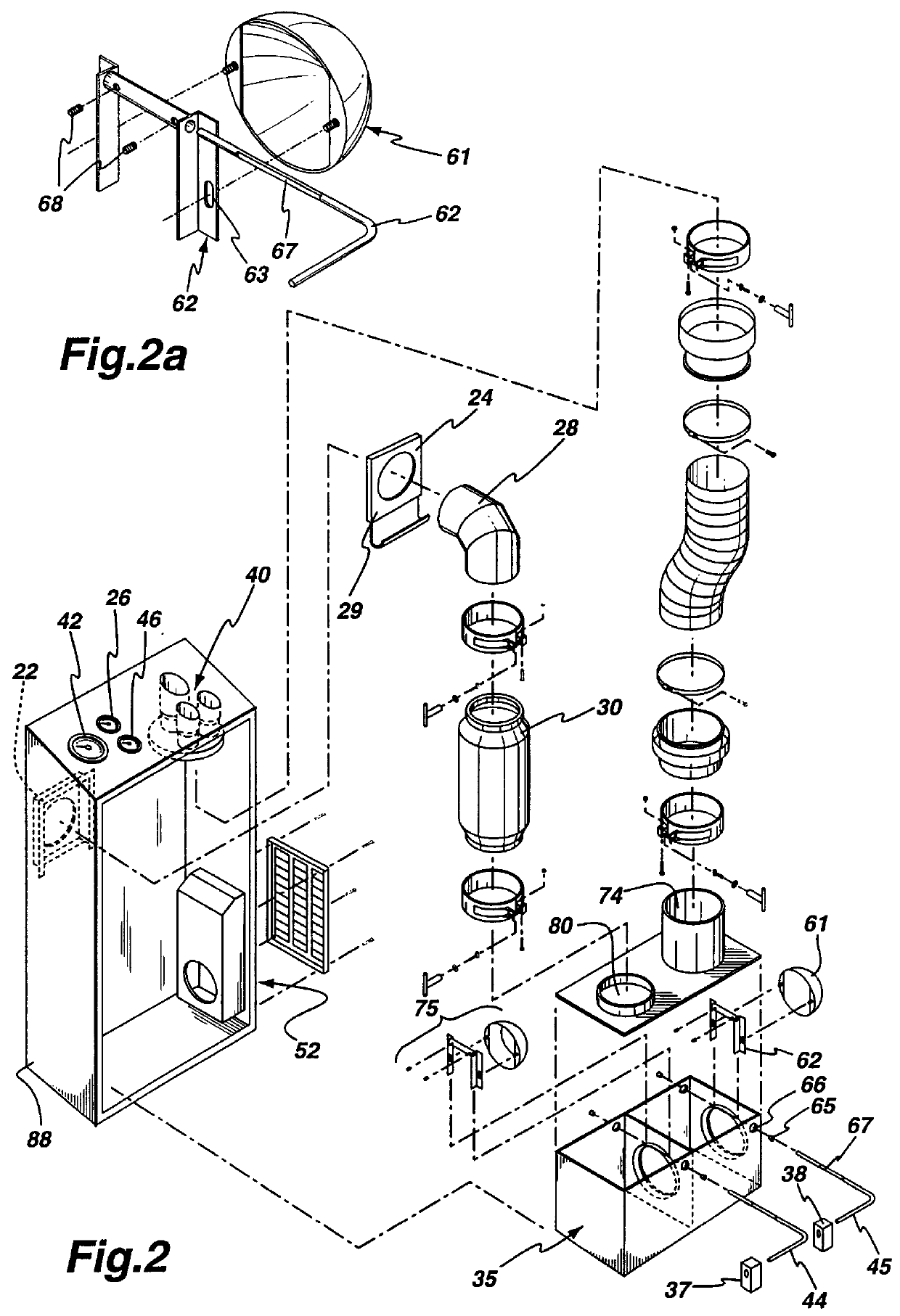

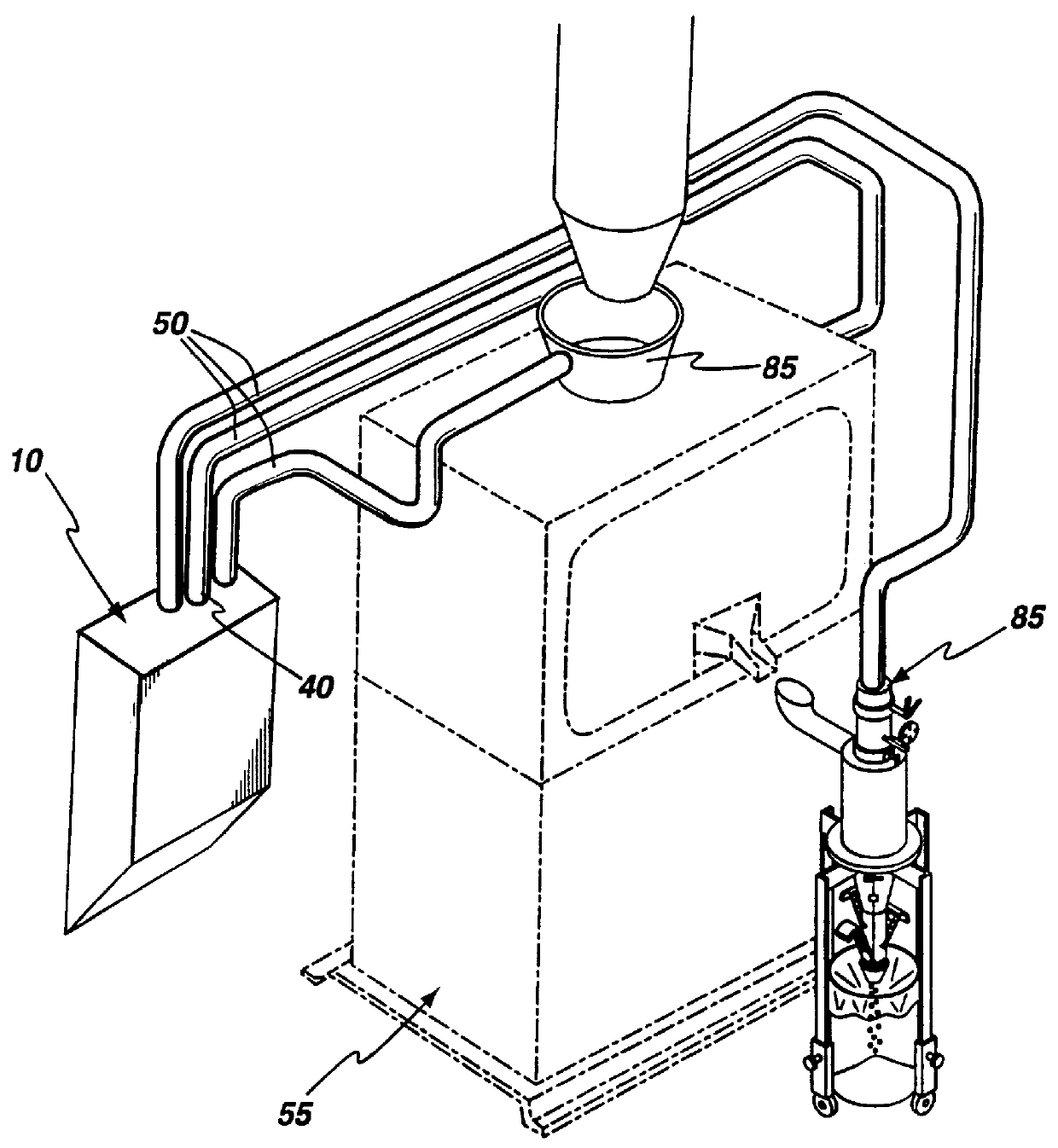

InactiveUS6009894AMitigate such drawbackIncrease airflow rateCheck valvesEqualizing valvesVacuum pressureEngineering

An airflow rate regulating device which is installed in a vacuum unit that collects contaminants from a processing station in a controlled space. This device enables a vacuum unit to maintain a continuous suction of contaminant particles from a processing station when there are pressure variations in the controlled space. The airflow rate regulating device is mounted in a suitable cabinet 88 and connected to a vacuum source. The airflow rate regulating device has a casing divided into two chambers separated by a wall having an passageway through which air flows from one chamber to the next. Each chamber features an airflow rate regulation valve comprising a movable member extending across the flow of air passing through the casing, that can be adjusted using counterweights. When a pressure disturbance occurs in the controlled room from a door opening, or when a hose leading the contaminant source is disconnected, the airflow rate regulation valves react to maintain sufficient vacuum pressure at the contaminants source. Since the airflow rate regulating device is mechanical, its response time to pressure is nearly instantaneous.

Owner:LES SYST & PROCEDES DYNAPHARM

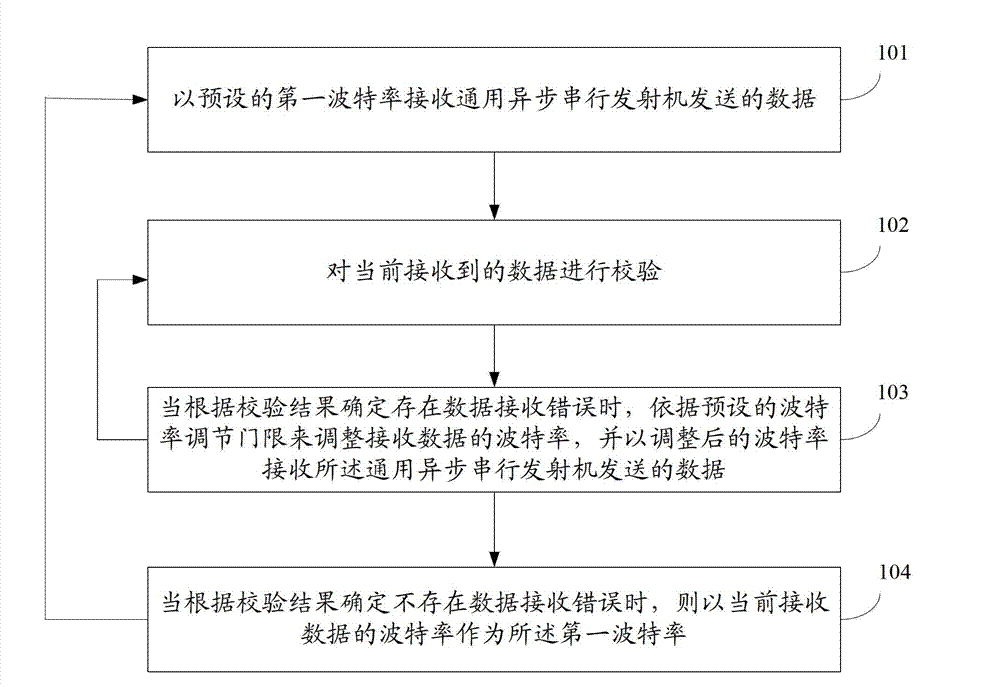

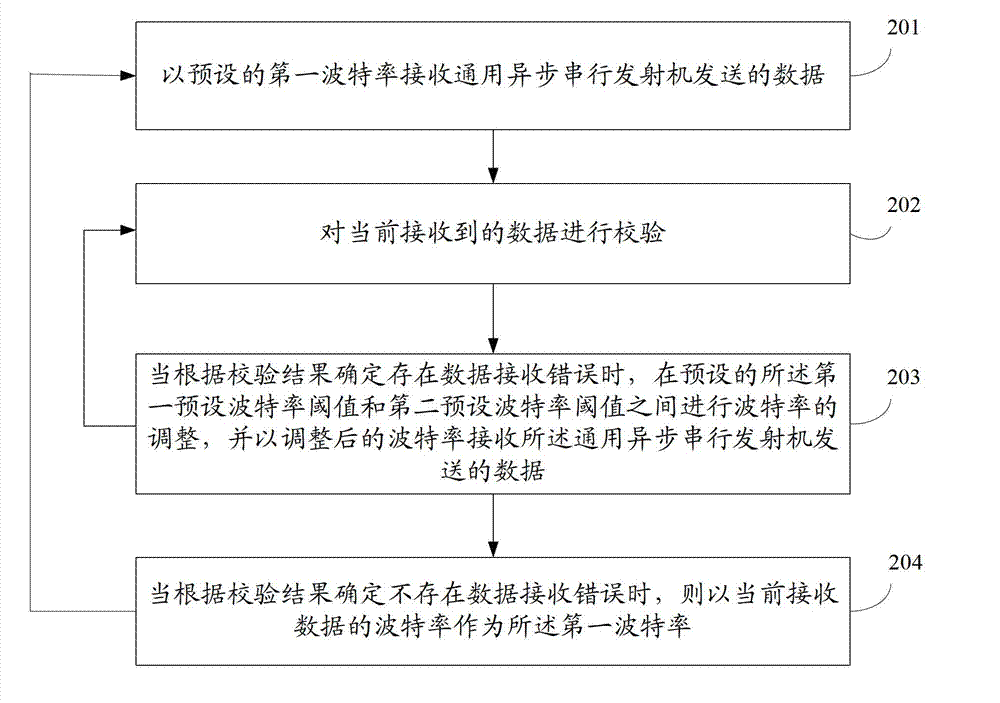

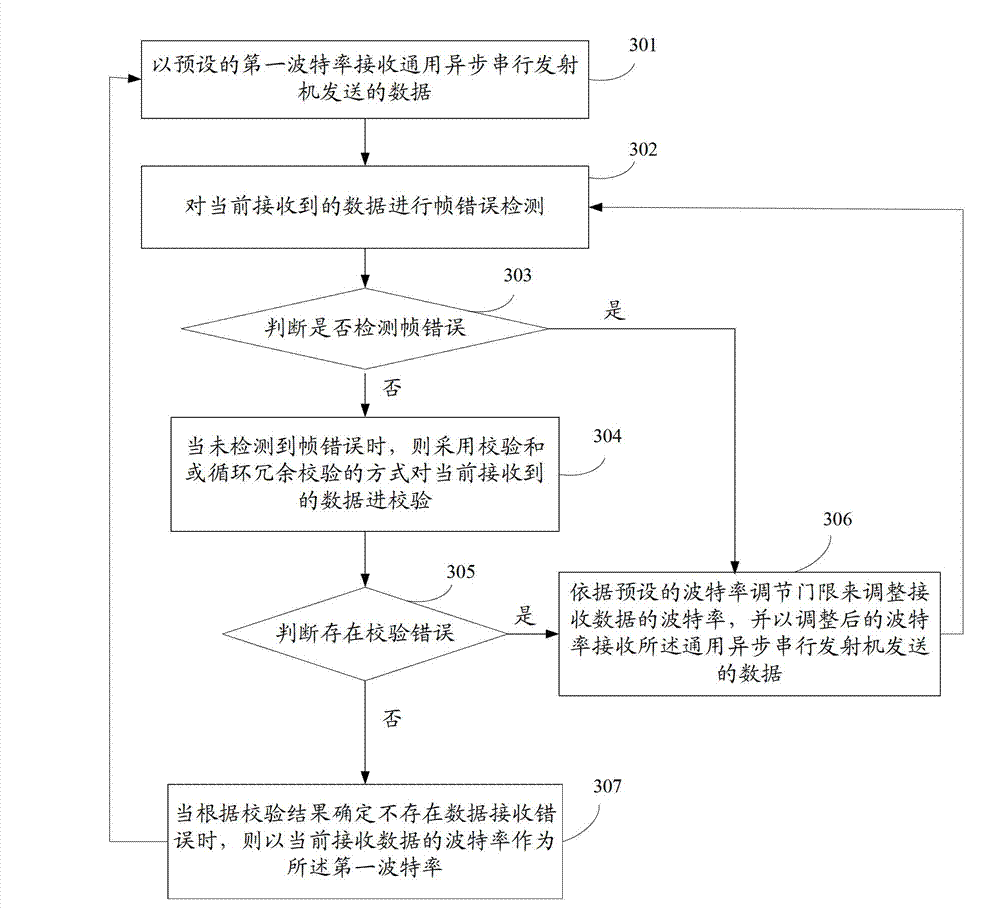

Method and device for regulating baud rate

The invention discloses a method and a device for regulating a baud rate. The method comprises the following steps of: receiving data which are transmitted by a universal asynchronous serial transmitter in a preset first baud rate; checking the data which are received currently; when determining that a data receiving error exists according to a checking result, regulating a data receiving baud rate according to a preset baud rate regulation threshold, receiving the data which are transmitted by the universal asynchronous serial transmitter in a regulated baud rate, and returning a checking result of the received data; and when determining that the data receiving error does not exist according to the checking result, receiving the data in a currently receiving data baud rate which is used as the first baud rate. By the method, when detecting that the data receiving error exists in a receiver, the baud rate for receiving data of the receiver can be automatically regulated to ensure that the baud rates of the receiver and the transmitter are maintained uniformly, so that normal data communication can be ensured.

Owner:BEIJING SUPLET +1

Method and system for regenerating particulate filter

InactiveUS20110146274A1Increase volumeEfficient combustionGas treatmentInternal combustion piston enginesParticulatesLine tubing

A particulate filter regeneration system regenerates a particulate filter provided in an exhaust line of an engine equipped with a turbocharger by burning matter trapped on the particulate filter by raising the temperature of exhaust gas at times that the particulate filter requires regeneration. The system has an electric motor functioning as an intake quantity regeneration portion capable of increasing the flow rate of compressed air without depending on the flow rate of exhaust gas flowing across a turbine of the turbocharger, a bypass line connecting an engine intake line upstream of the engine to a section of the exhaust line upstream of the particulate filter, a flow rate regulation valve regulating the flow rate in the bypass line, and a control portion controlling the electric motor and the flow rate regulator.

Owner:IHI CORP

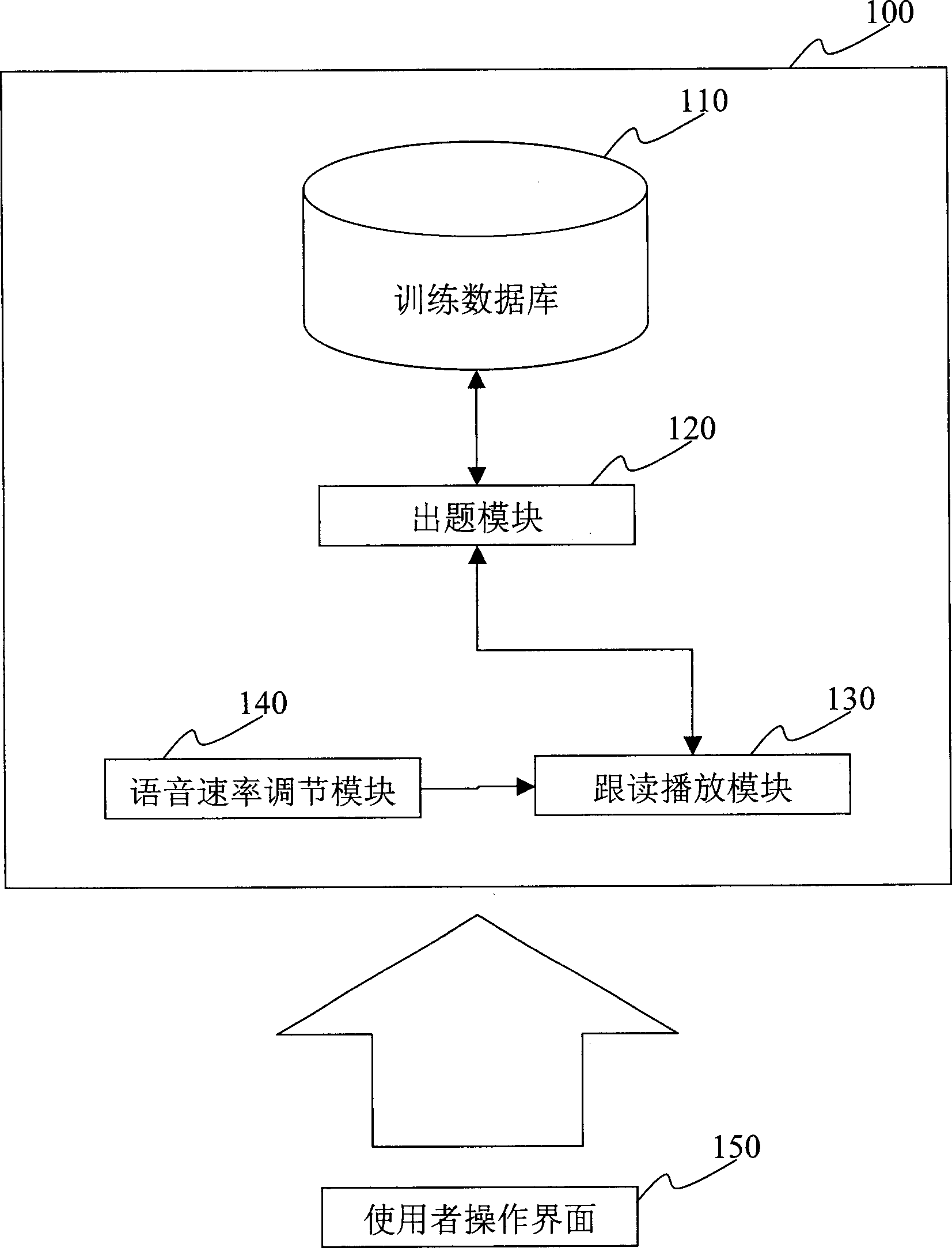

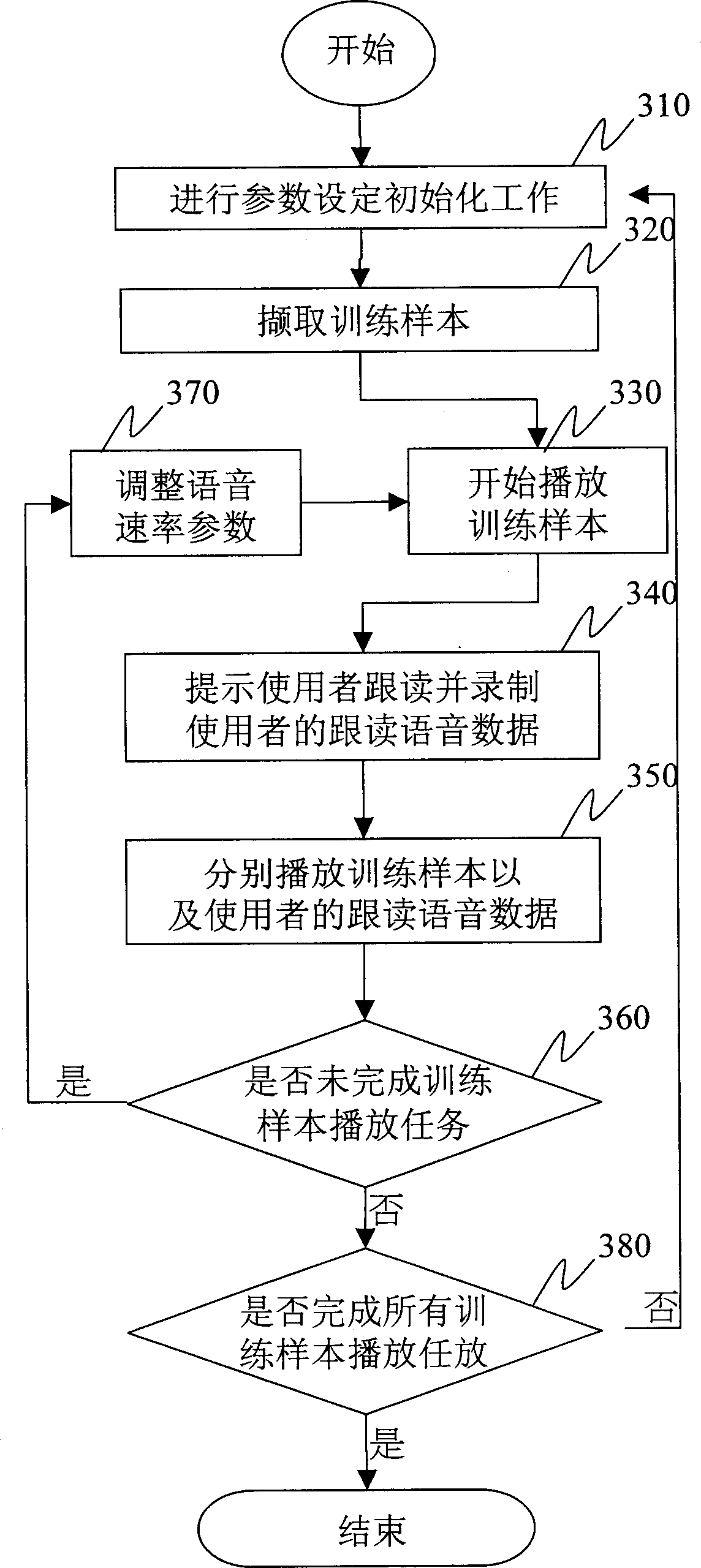

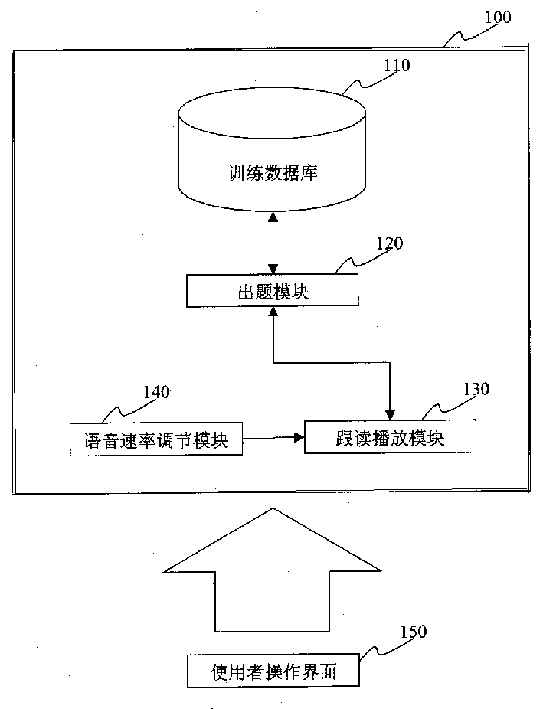

System and method for linear listening and speaking to learn languages

InactiveCN1510596ADigital recording/reproducingElectrical appliancesHabilitation trainingRate parameter

The system consists of training databank, question-making module, read-following broadcast module and pronunciation speed rate regulation module. The method includes the follows: parameter is initialized first, then training specimen is started to play broad cast task; in course of broadcasting, the user carrys on real-following and to record the real-following pronunciation data of the user; the training specimen and the read-following pronunciation data are broad casted separately and finally the pronunciation speed rate parameter is regulated according to times of training specimen playing till broadcast task of the training specimen is finished.

Owner:INVENTEC CORP

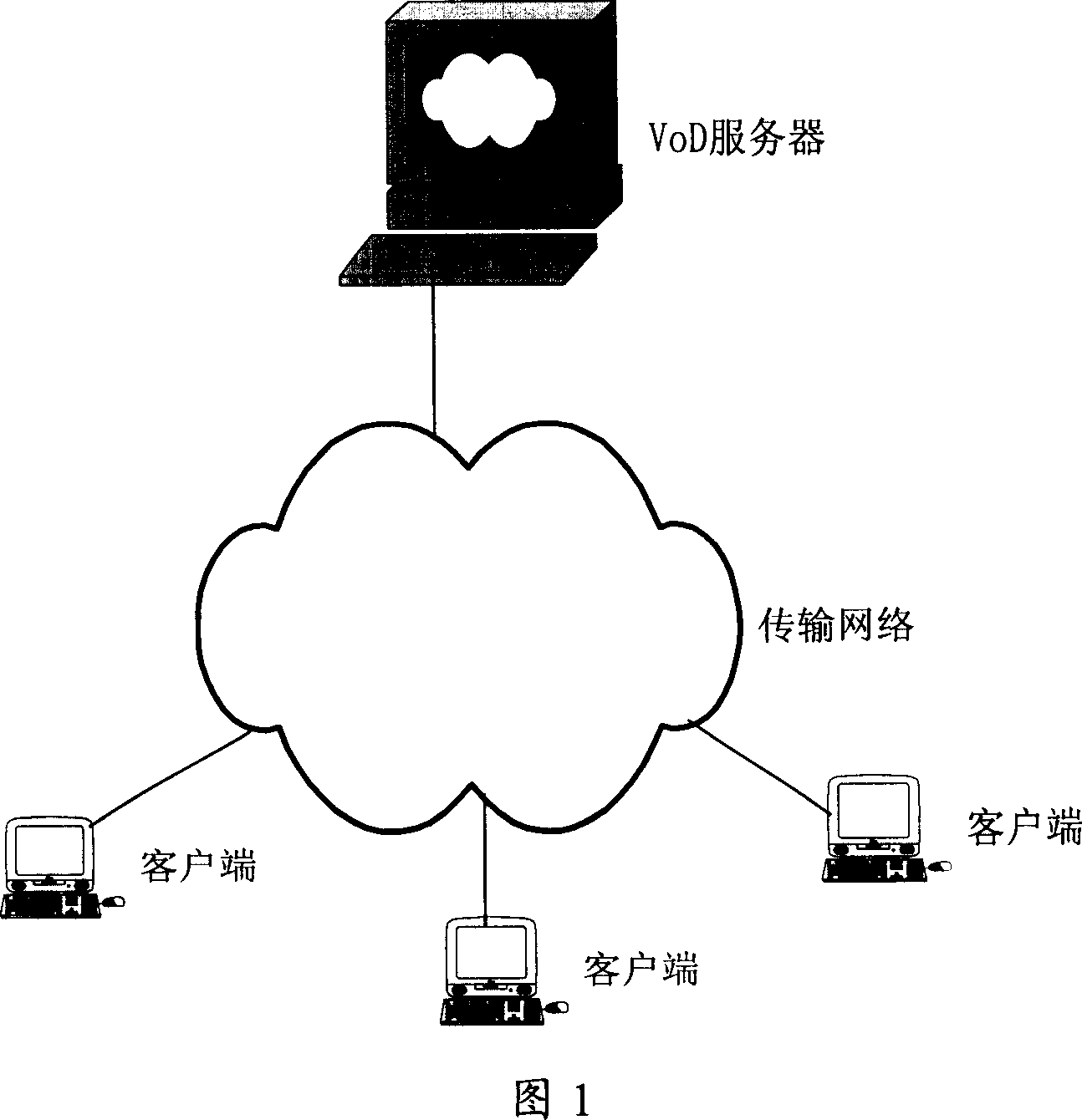

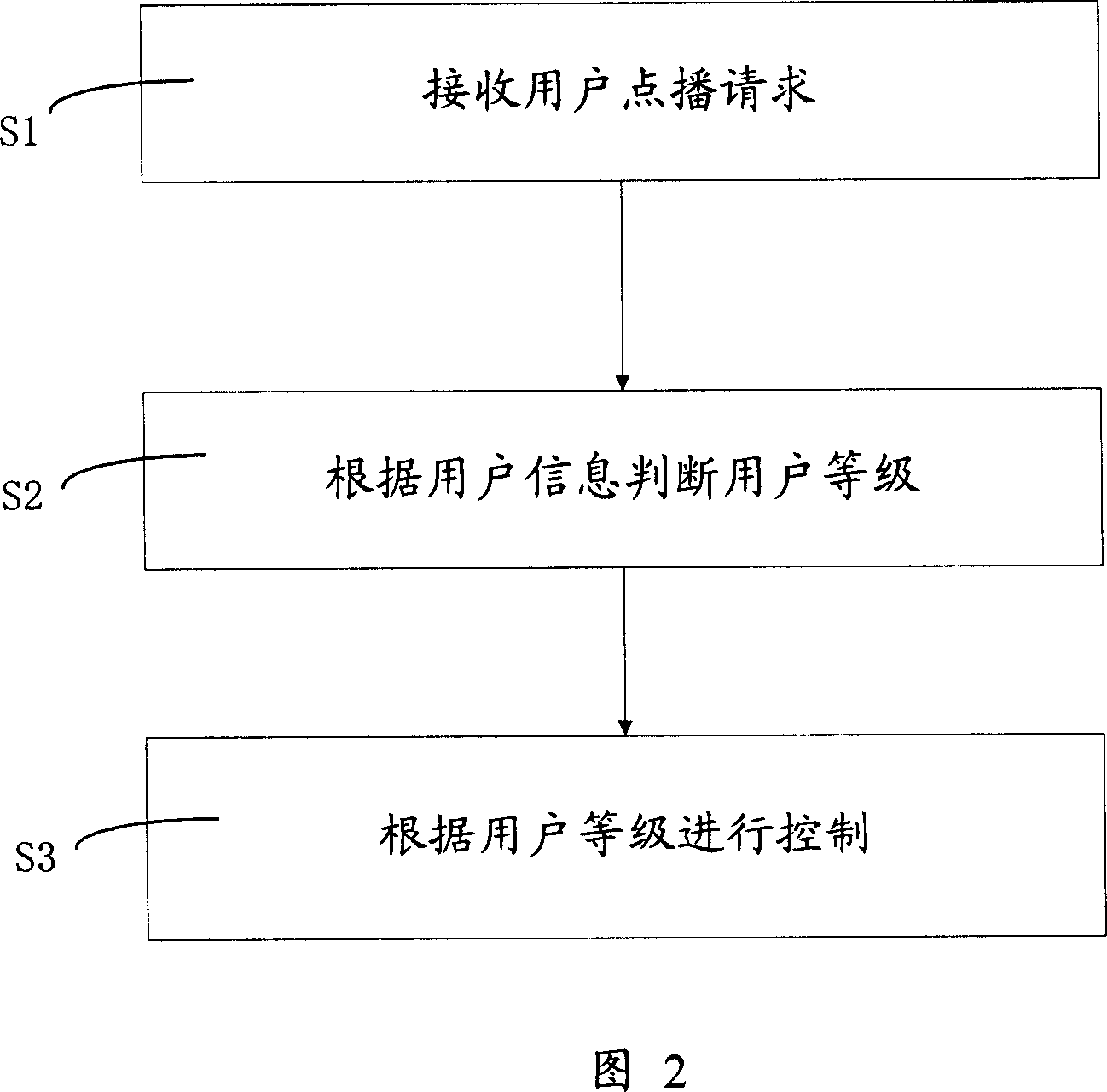

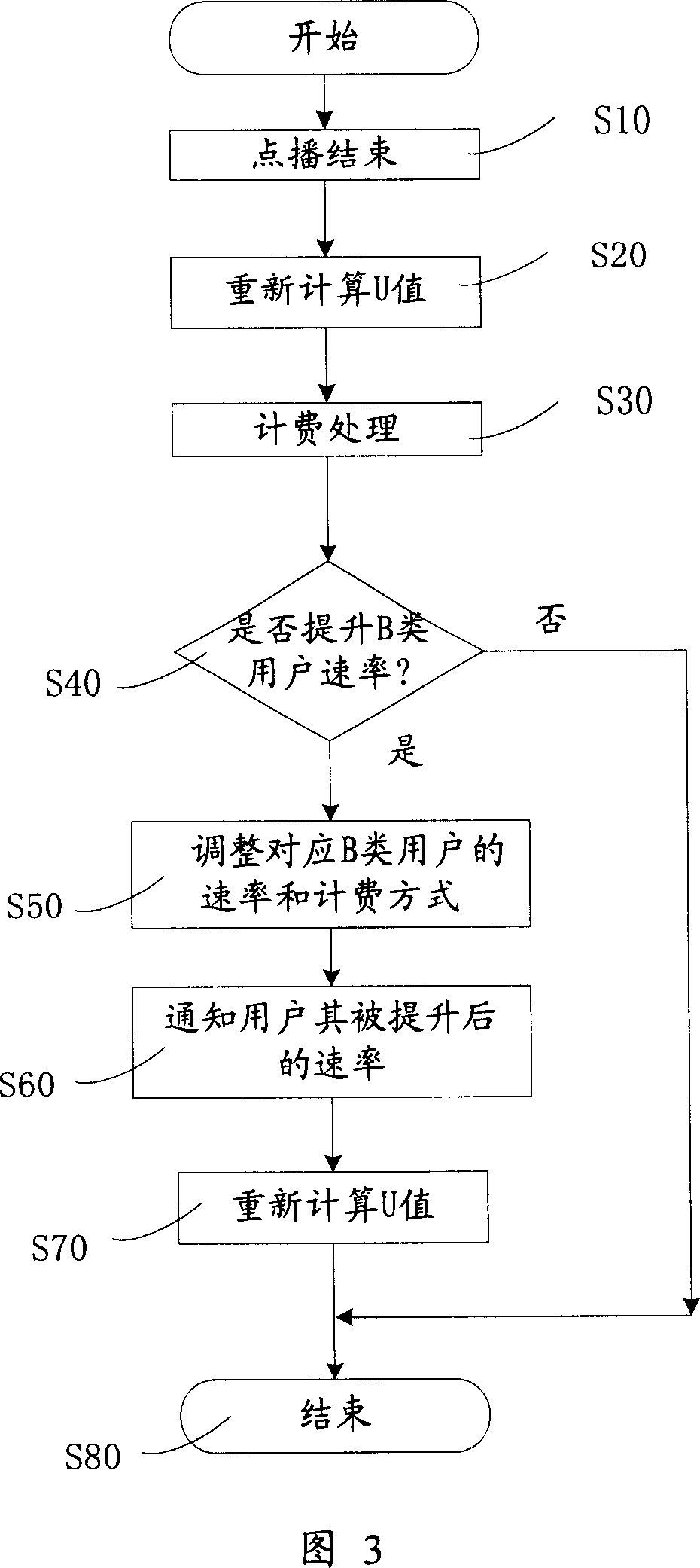

Control method, device and use for video frequency ordering

ActiveCN101052119AImproved ability to accept on-demand requestsEasy to useTwo-way working systemsSelective content distributionComputer scienceWideband

The method comprises: 1) receiving the user's program-ordering request; 2) according to the user's message, estimating the user's class; 3) according to the user's class, making control for the order. The invention also reveals a video program ordering apparatus comprises: a strategy data unit, a strategy selection unit, a calculation unit, a reception control unit, a rate regulation unit, a forced-termination unit, a billing control unit. Said acceptance control unit is used in deciding if the order request of user will be accepted according to the output wideband calculated by the calculation unit. The invention can satisfy the needs of different users. The invention also reveals a system thereof.

Owner:HUAWEI TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com