High-flow-rate underground oil-water separation and annular space testing and regulating system

A technology of oil-water separation and oil-water separator, which is applied in the direction of wellbore/well components, production fluid, earthwork drilling and production, etc. It can solve the problems of accurate monitoring and control of the flow rate of large-capacity downhole oil-water separation system, and achieves a wide range of applications. , The structure of the system is simple and the working conditions are stable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

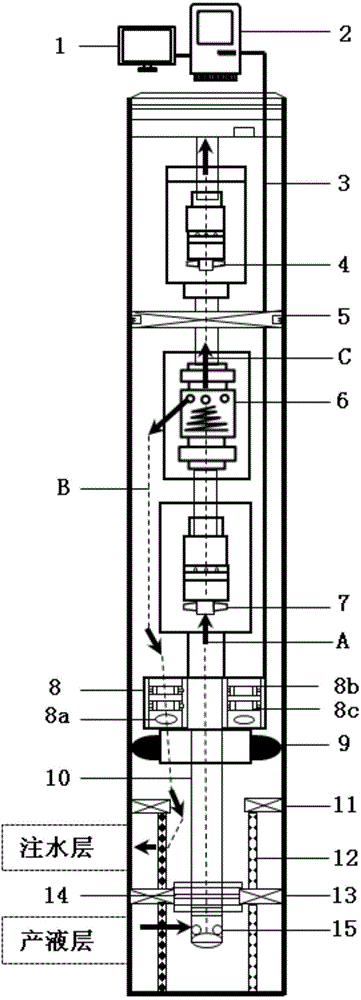

[0015] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

[0016] Such as figure 1 As shown, this embodiment discloses a large-displacement downhole oil-water separation annulus measurement and adjustment system, which mainly includes a large-displacement downhole oil-water separation string and an Injection and production fluid up to 3000m 3 / d large displacement oil-water separation process, by monitoring the pressure and flow of low oily sewage in the annular space reinjection channel, and adjusting the reinjection flow, so as to adjust the ratio of the reinjection flow to the total liquid production flow, that is, the split ratio, Ensure the stability of the downhole oil-water separation system.

[0017] The large-displacement downhole oil-water separation string includes an outer layered isola...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com