Patents

Literature

145 results about "Igbt power modules" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

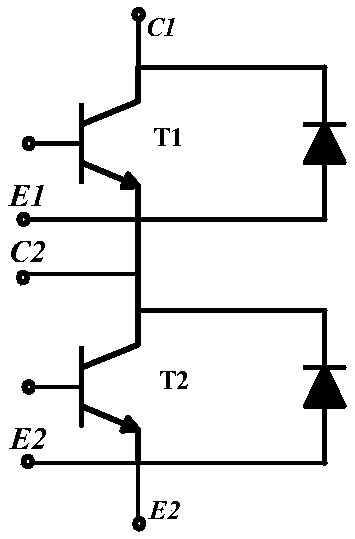

Insulated-gate bipolar transistor is power semi-conductor device usually used as electronic switch for mid to high power range. While igbt module consists of some igbt's meant to even higher capacity power range.

Device and method for dynamic characteristic measurement of IGBT

ActiveCN104198906AHigh precisionAdjustableIndividual semiconductor device testingTransformerCurrent sensor

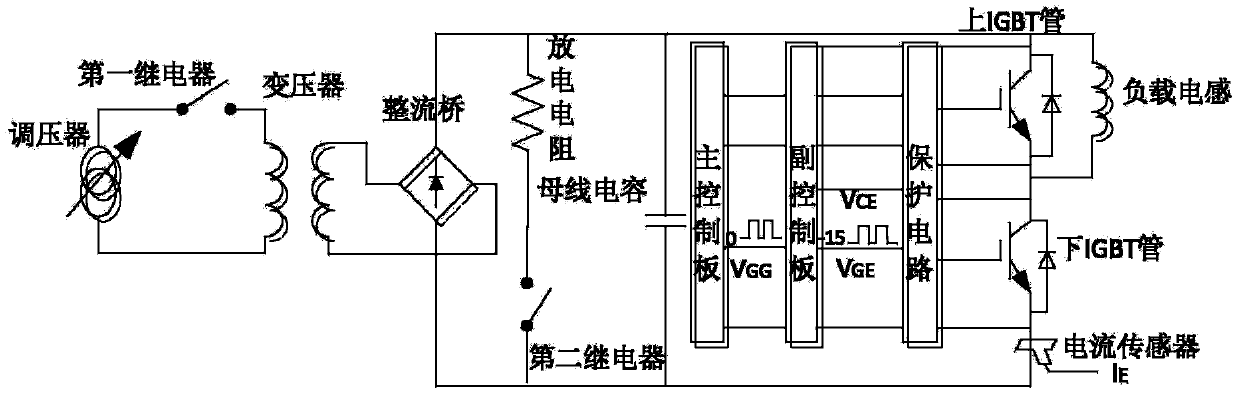

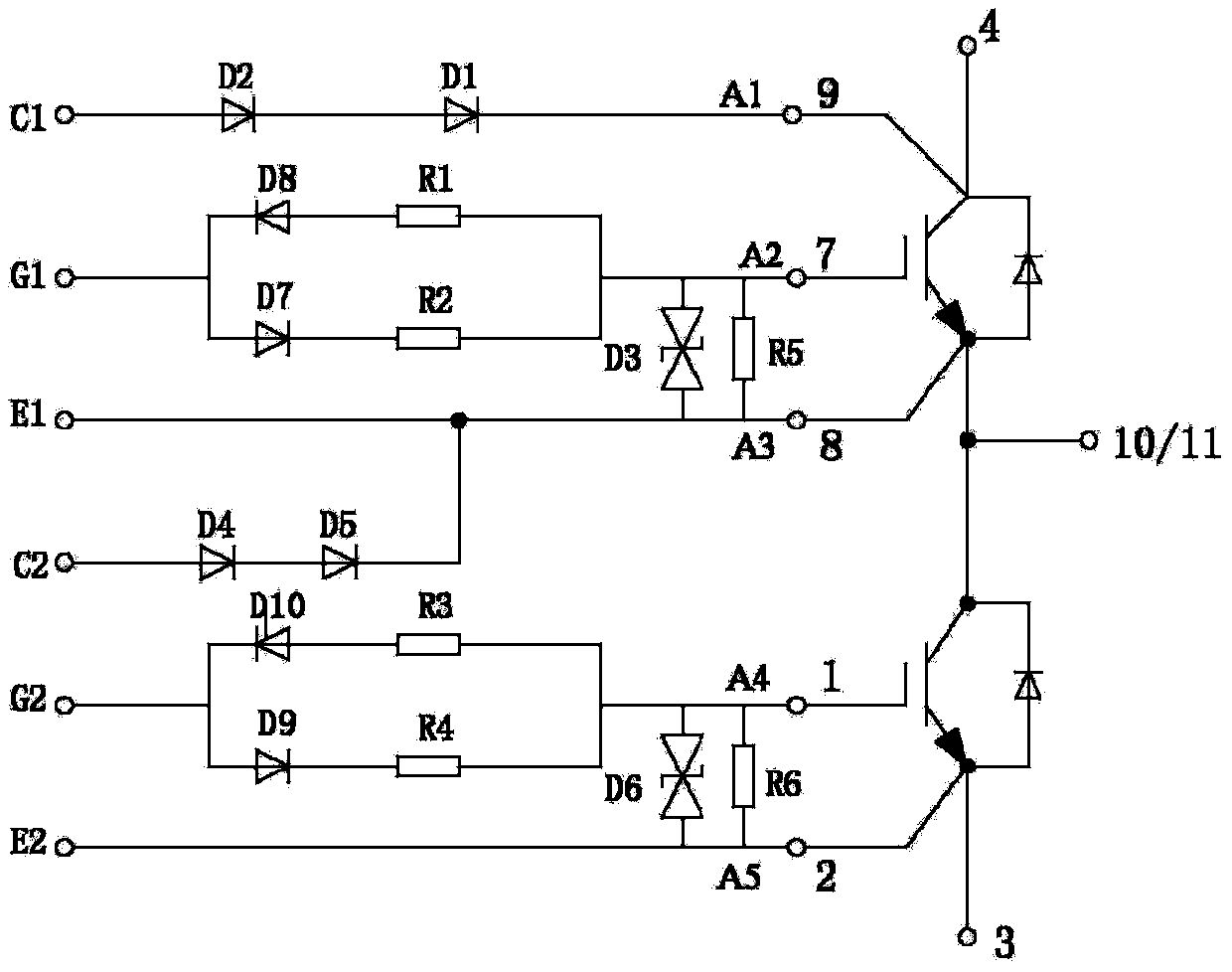

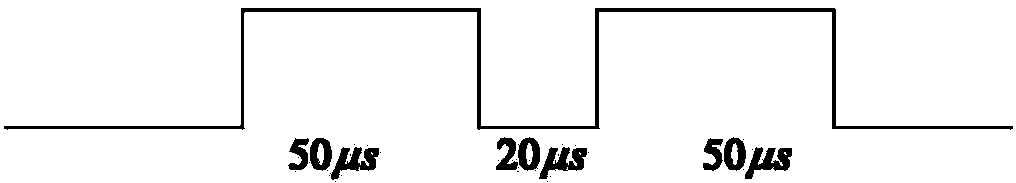

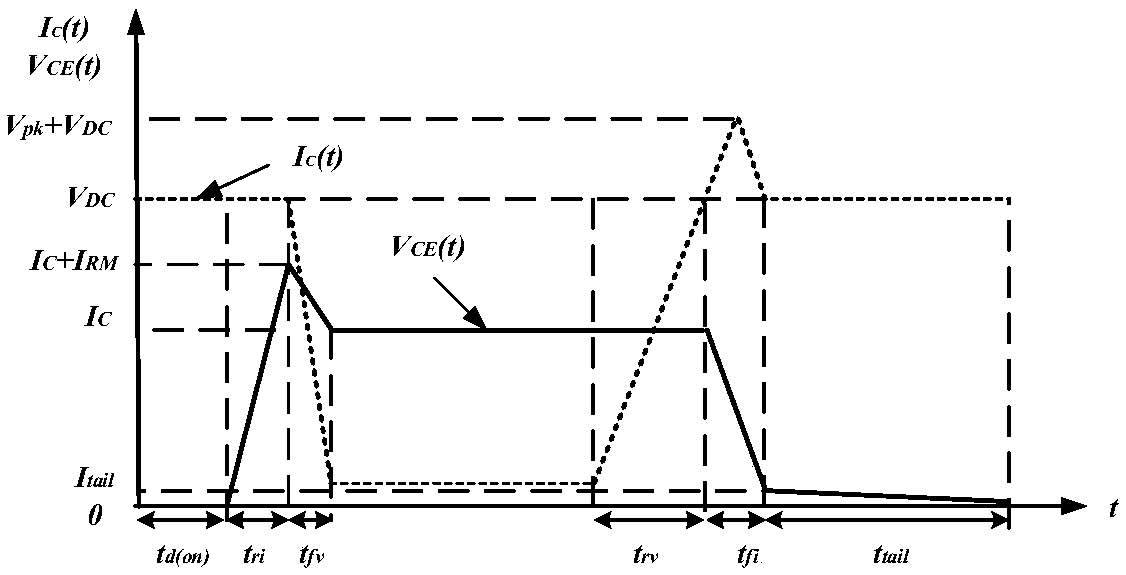

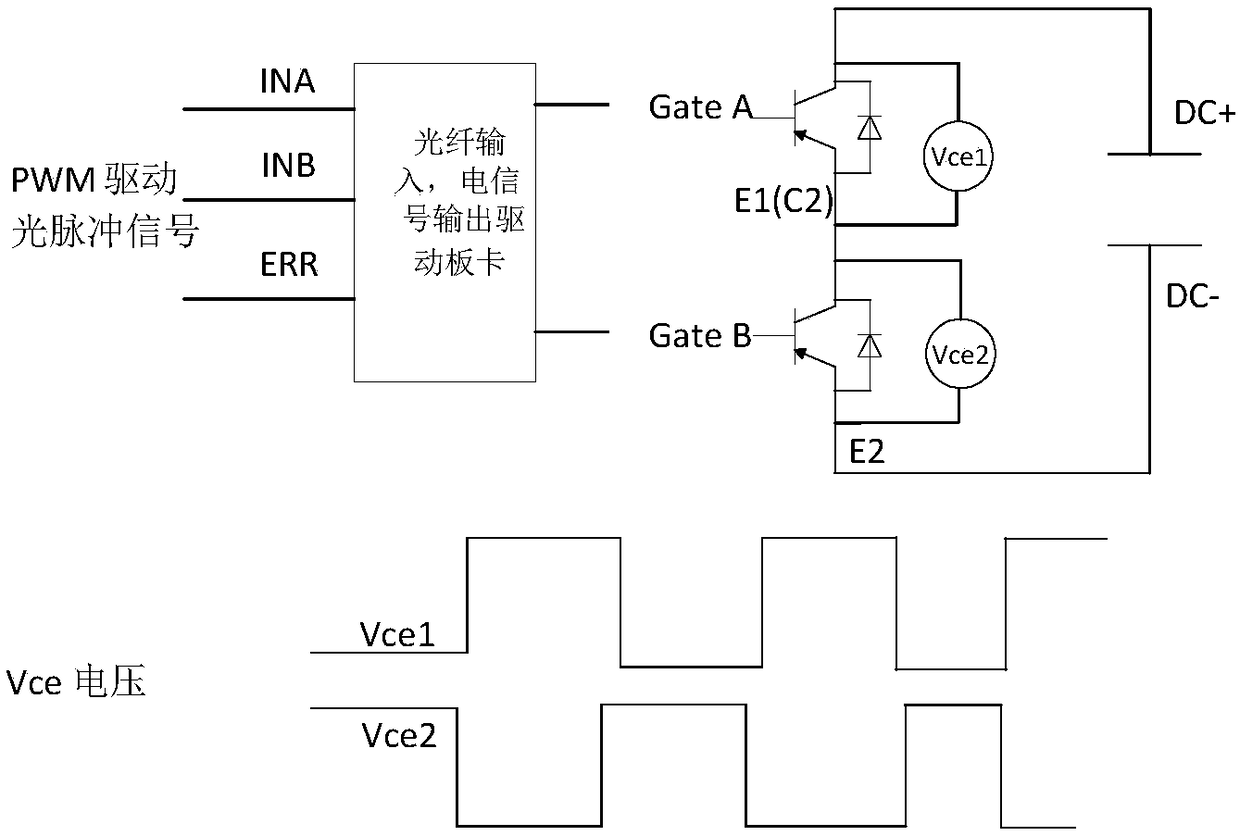

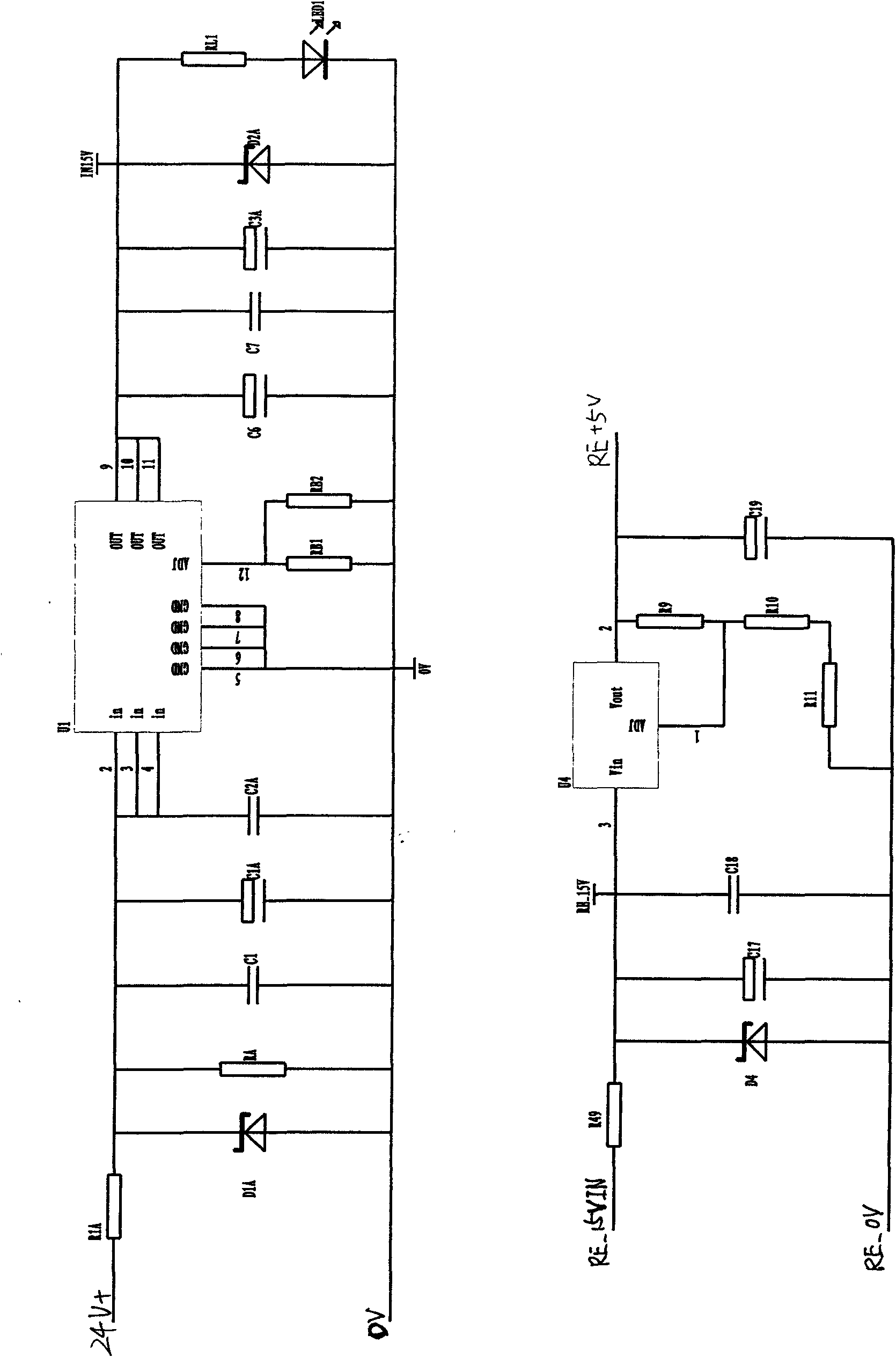

The invention belongs to the technical field of power electronic device measurement and particularly relates to a device and a method for dynamic characteristic measurement of an IGBT. The device mainly comprises a voltage regulator, a transformer, a rectifier bridge, a bus capacitor, a discharge resistor, a first relay, a second relay, a main control panel, an auxiliary control panel, a protection circuit, an IGBT power module, a load inductor, a current sensor, a shielding box and an oscilloscope. Firstly, the first relay is switched on, the second relay is disconnected, the voltage regulator is zeroed after being adjusted to be at the voltage to be detected, and the first relay is disconnected; secondly, electrification is implemented, and the oscilloscope obtains a dual-pulse signal, IGBT two-end voltages and collector electrode current waveforms. The crosstalk of different signals, interference of a space magnetic field on measured signals and other factors are excluded, high-accuracy dynamic process waveforms can be obtained, and the device and the method have good reproducibility on delay and overshoot of voltage and current signals. The load inductor with a tap enables the circuit to be adjustable, and the device and the method can be used for measurement of different devices.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING) +2

method for estimating the junction temperature of an IGBT power module on line

InactiveCN109871591AHigh measurement accuracyHigh simulationThermometers using electric/magnetic elementsUsing electrical meansJunction temperatureEngineering

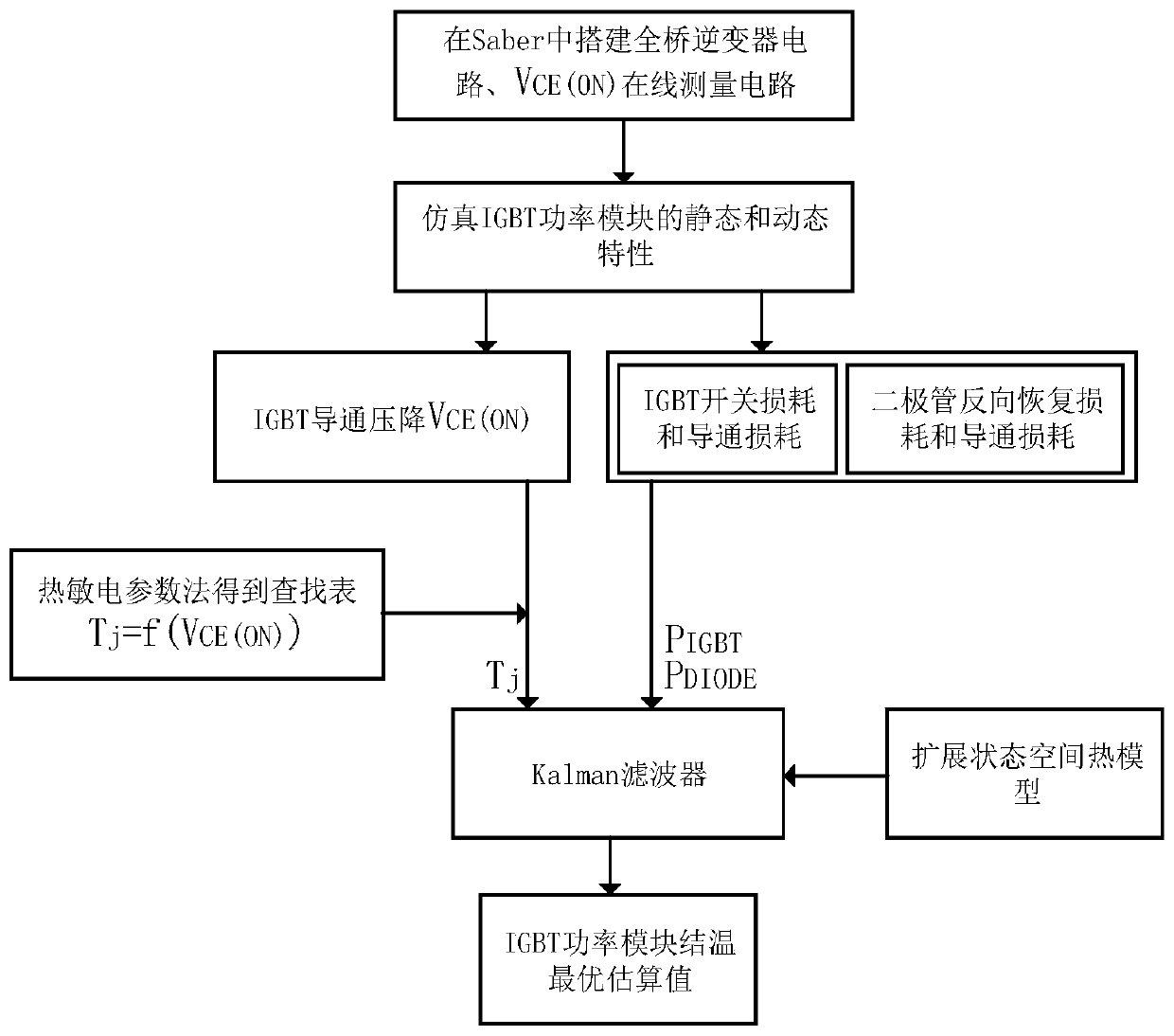

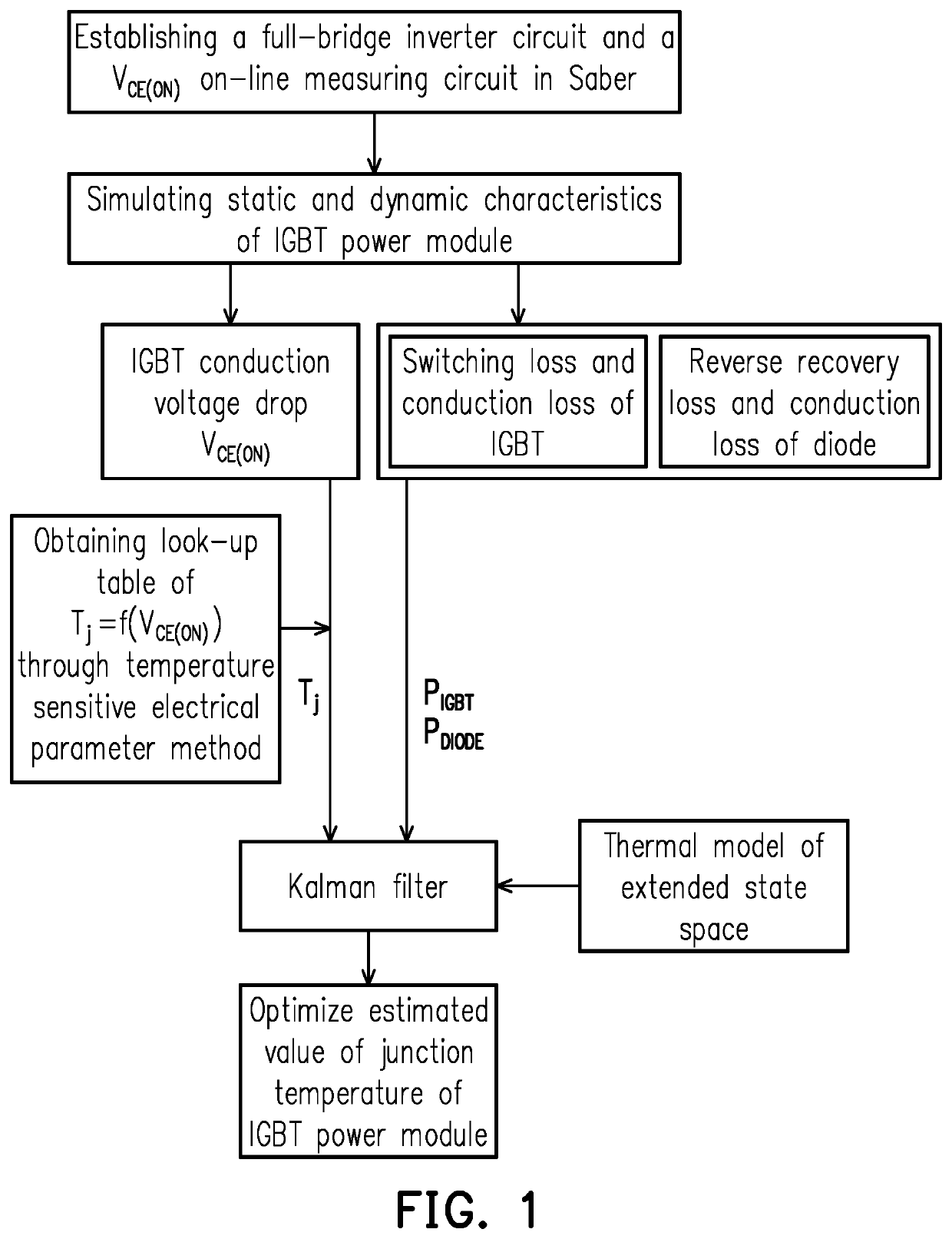

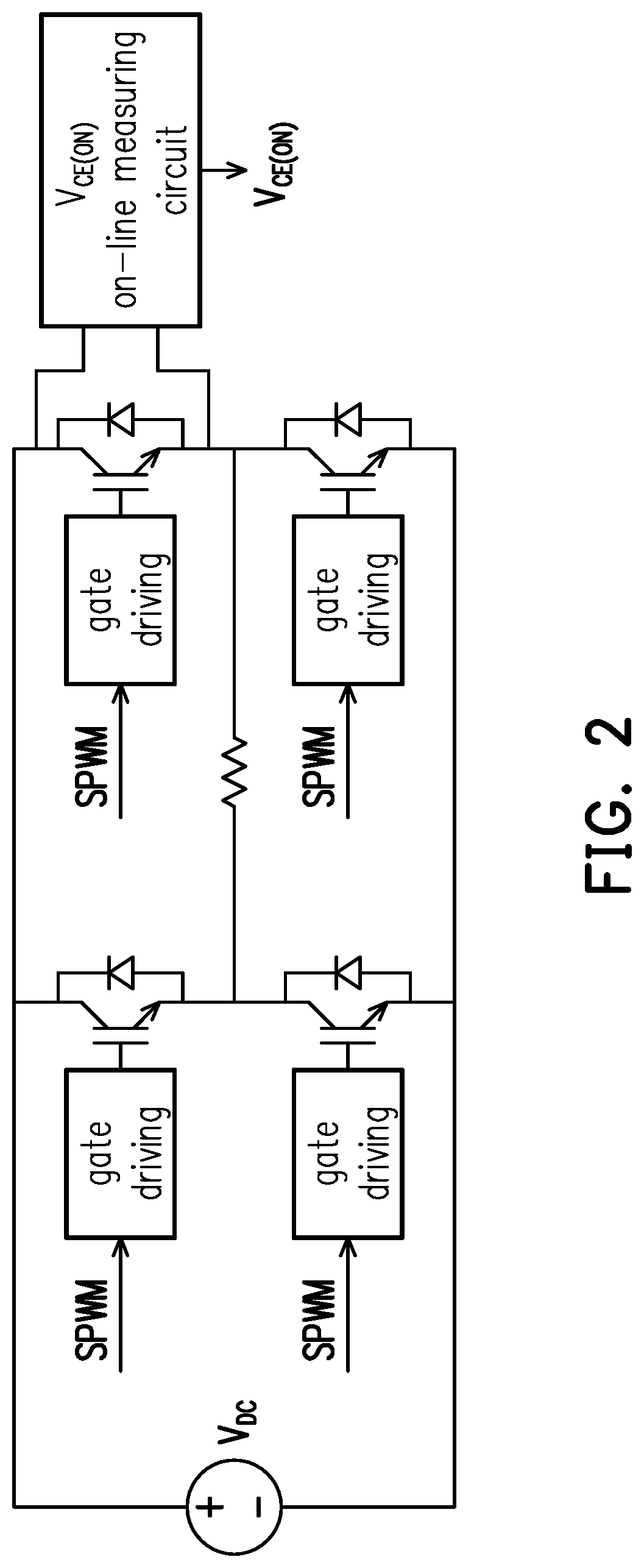

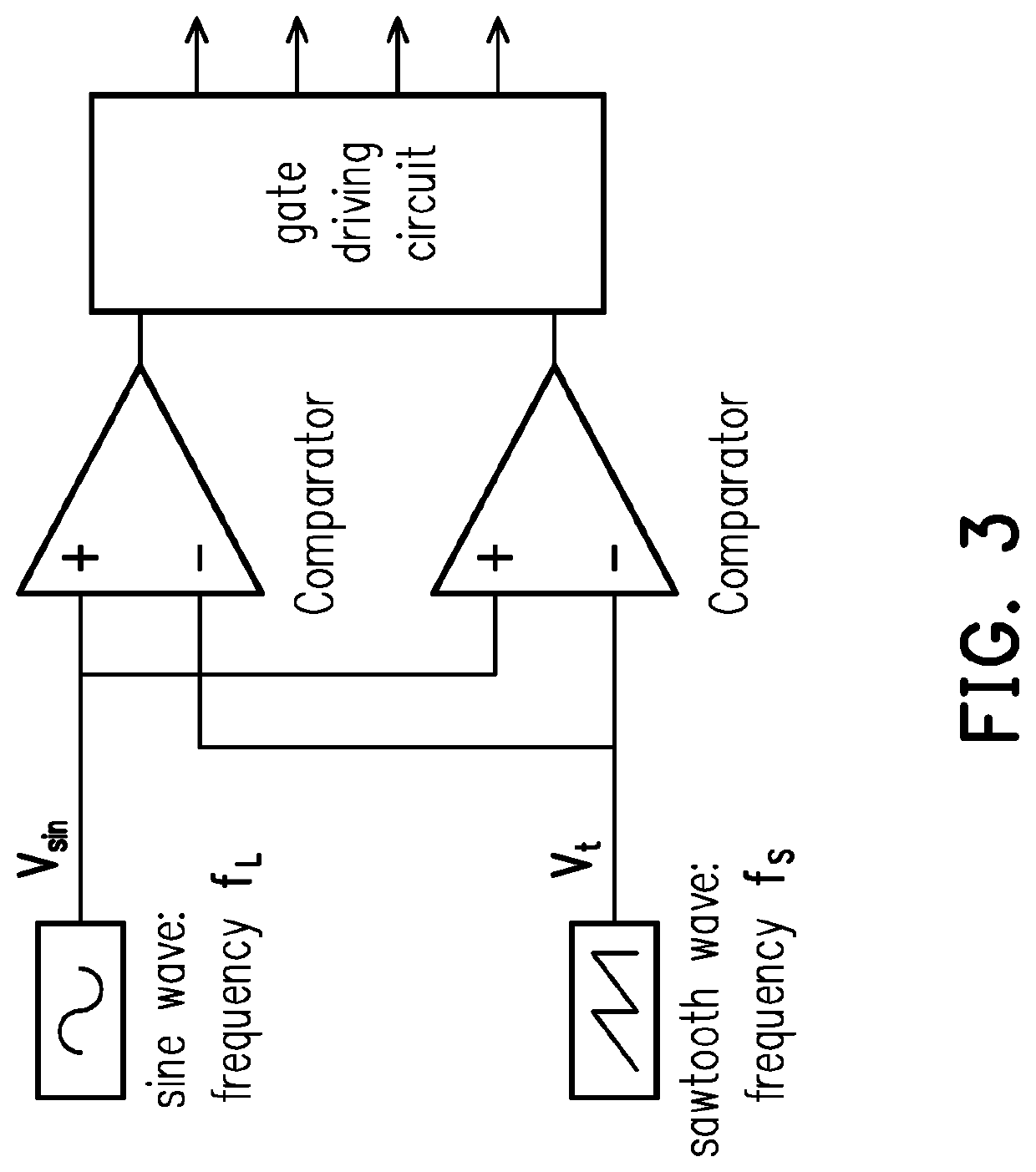

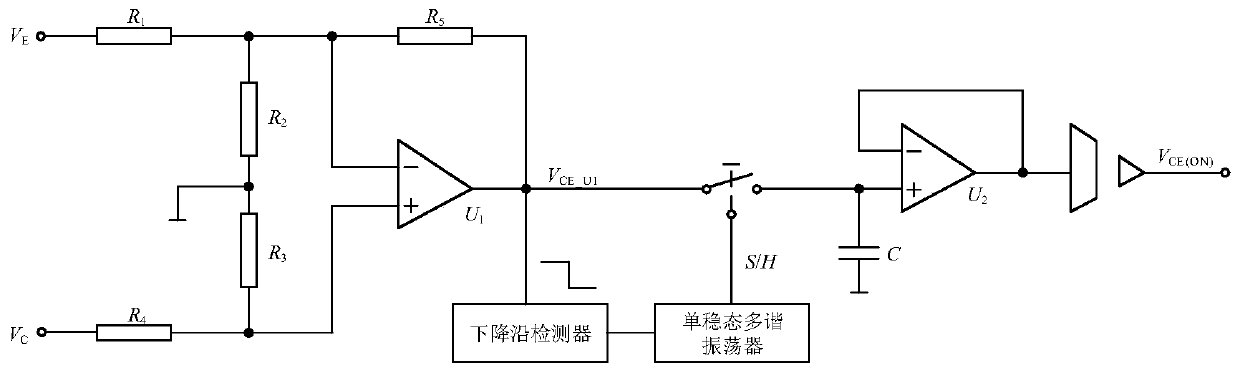

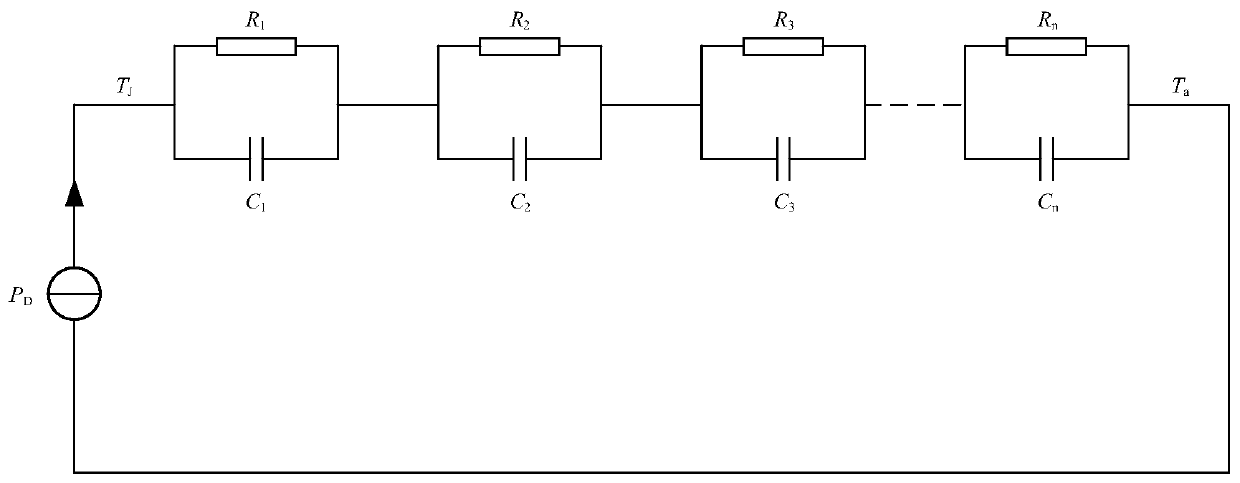

The invention discloses a method for estimating junction temperature on line by an IGBT (Insulated Gate Bipolar Transistor) power module. The method comprises the following steps: estimating the junction temperature by using a thermo-sensitive electrical parameter method; establishing an extended state space thermal model; and applying a Kalman filter in junction temperature estimation. The thermosensitive electrical parameter method can estimate the junction temperature of an IGBT power module in real time, an IGBT conduction voltage drop VCE (ON) is selected as a thermosensitive electrical parameter, and a VCE (ON) online measurement circuit is provided. On the basis of a Foster thermal network model, the influence of diode coupling is considered, and an extended state space thermal model comprising self-heating and coupling heat is provided; And taking the power loss of the diode and the IGBT and the junction temperature estimation value obtained by using the thermosensitive electrical parameter method as the input of the Kalman filter, and considering the measurement noise and the process noise, thereby obtaining the optimal junction temperature estimation value. According to the method, electrical insulation is achieved, measurement is carried out without changing a control strategy of the power converter, noise is reduced, the intermittent influence of voltage measurementis eliminated, and the junction temperature measurement precision is improved.

Owner:WUHAN UNIV

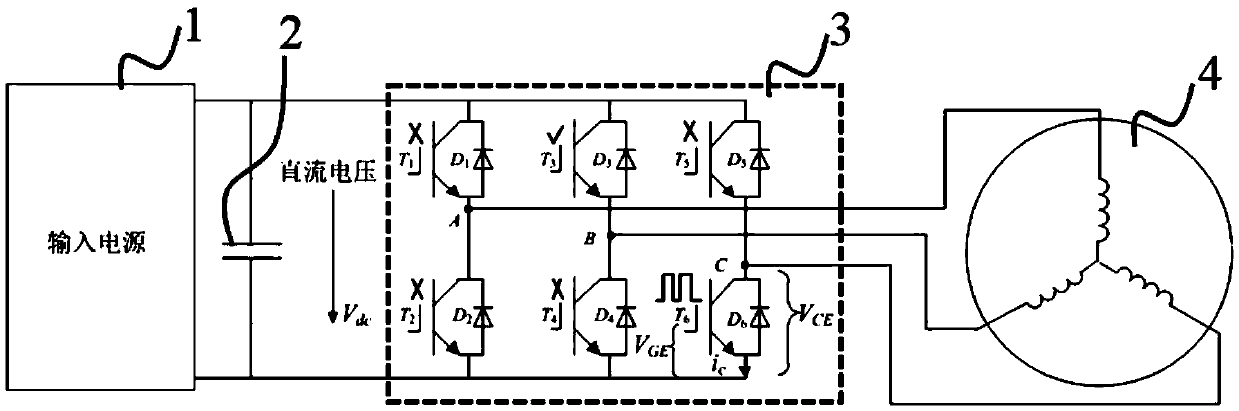

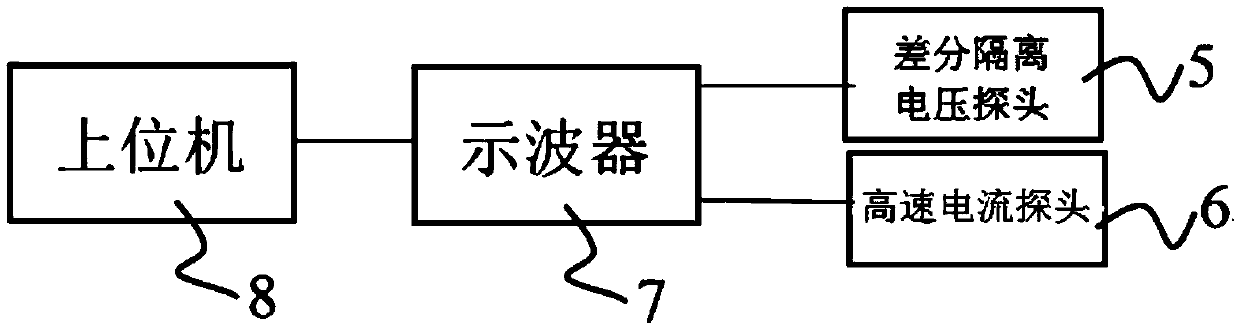

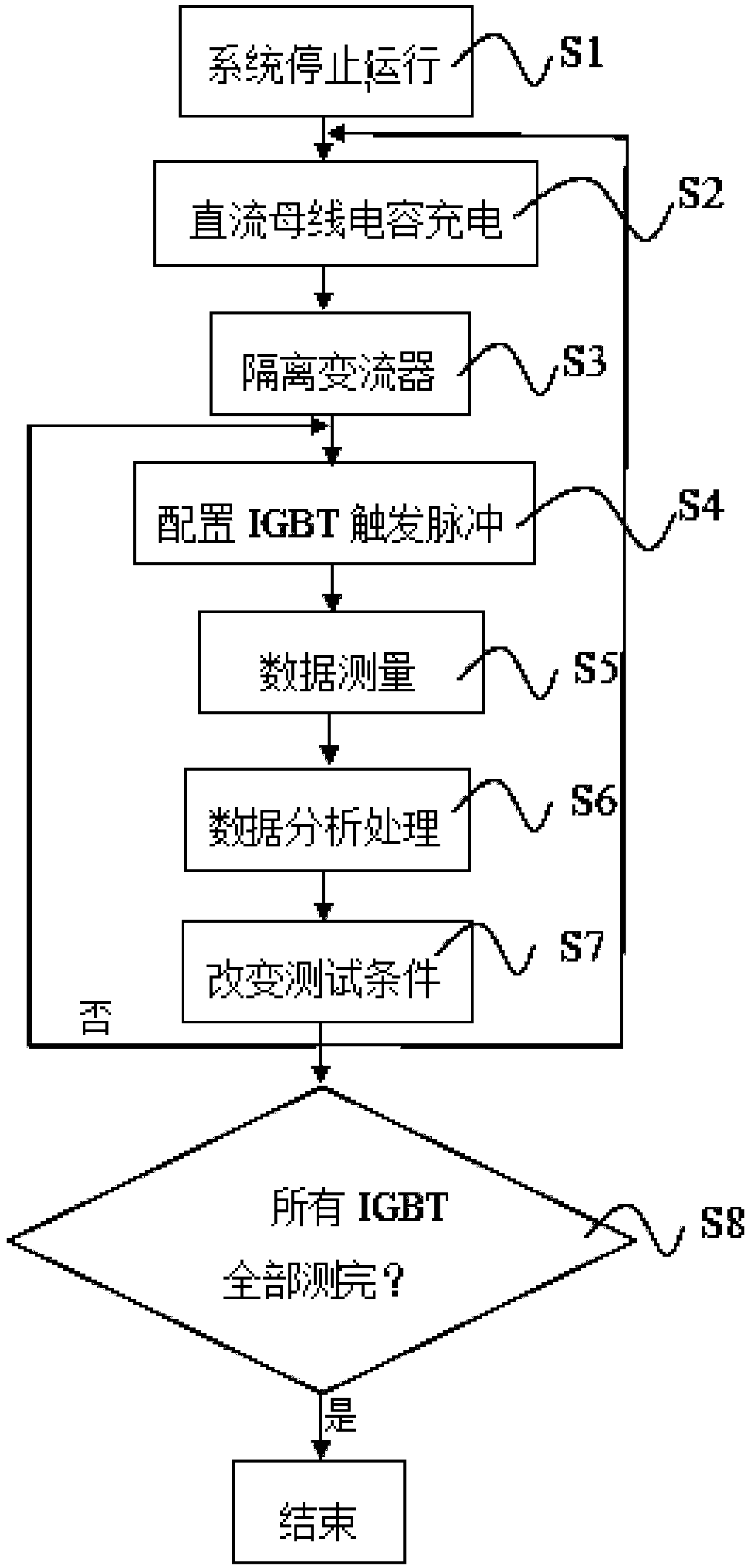

Current transformer IGBT power module field double-pulse testing system and method

InactiveCN105510792AAccurate Switching CharacteristicsAccurately obtain switching characteristicsBipolar transistor testingEngineeringIgbt power modules

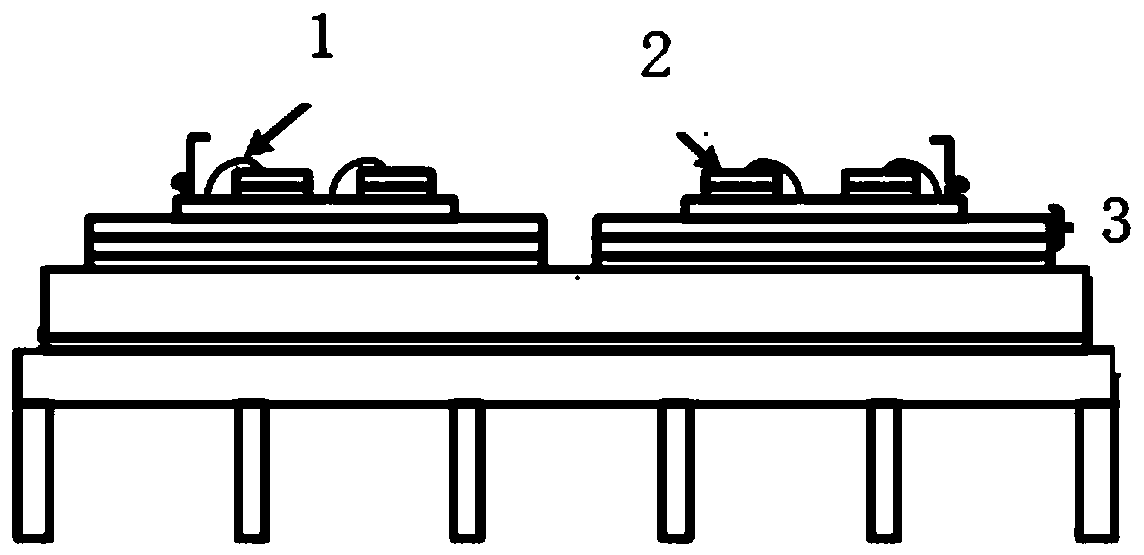

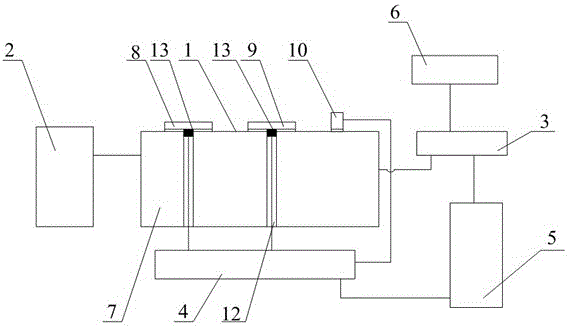

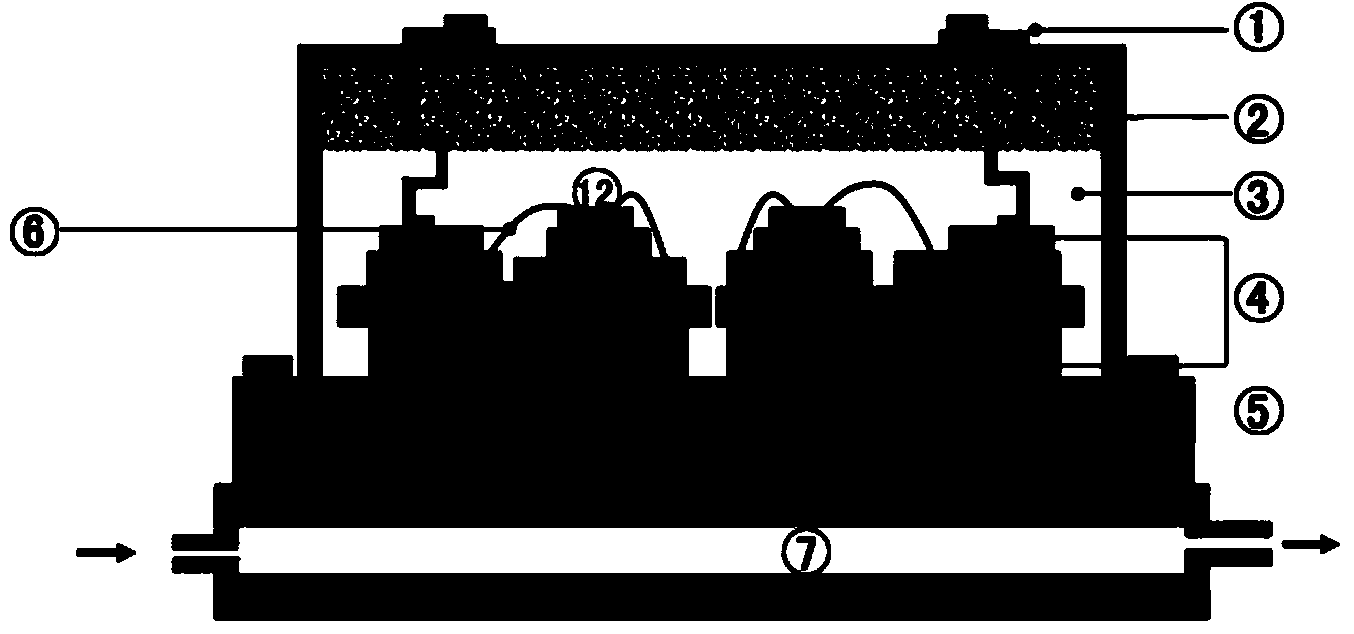

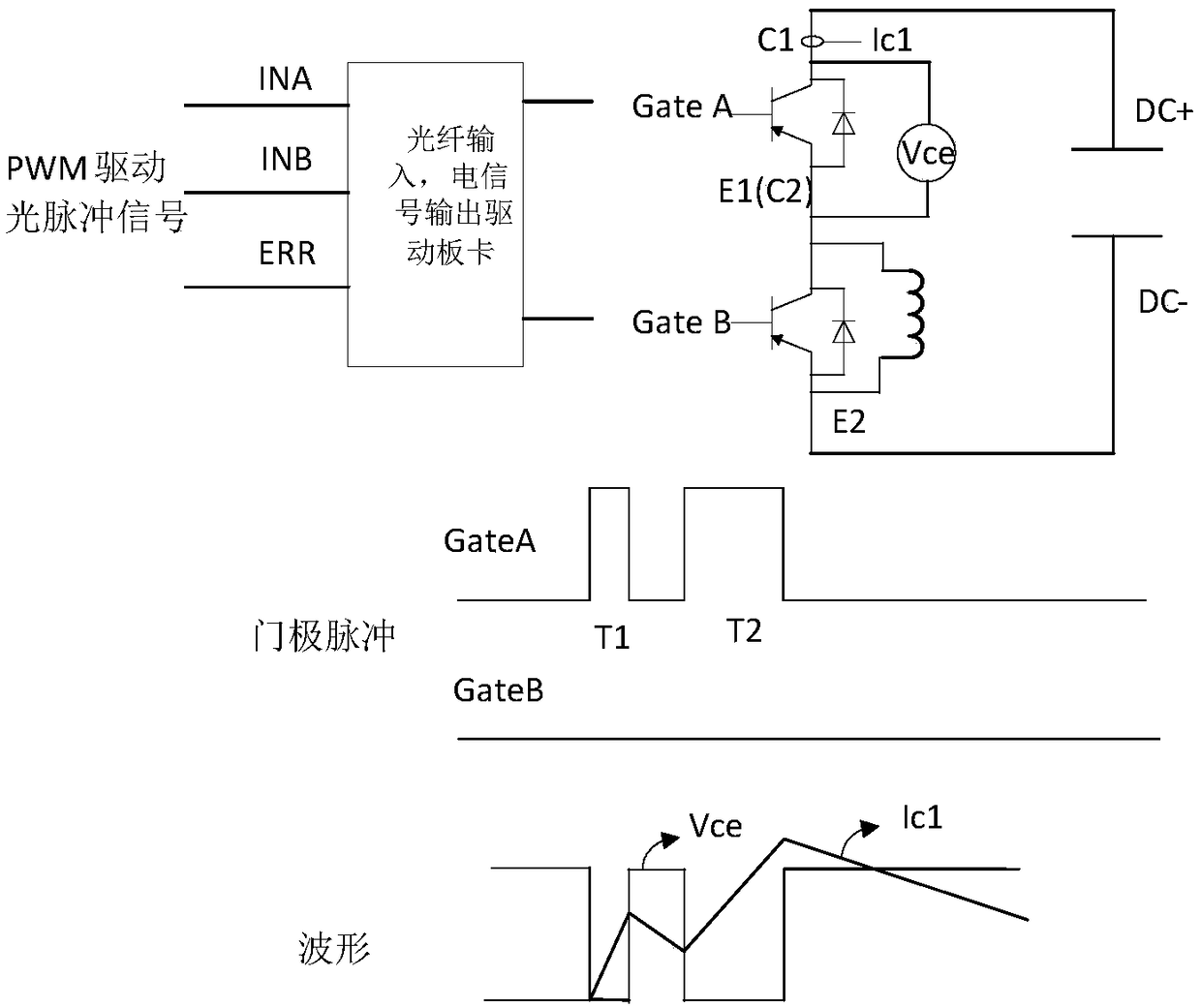

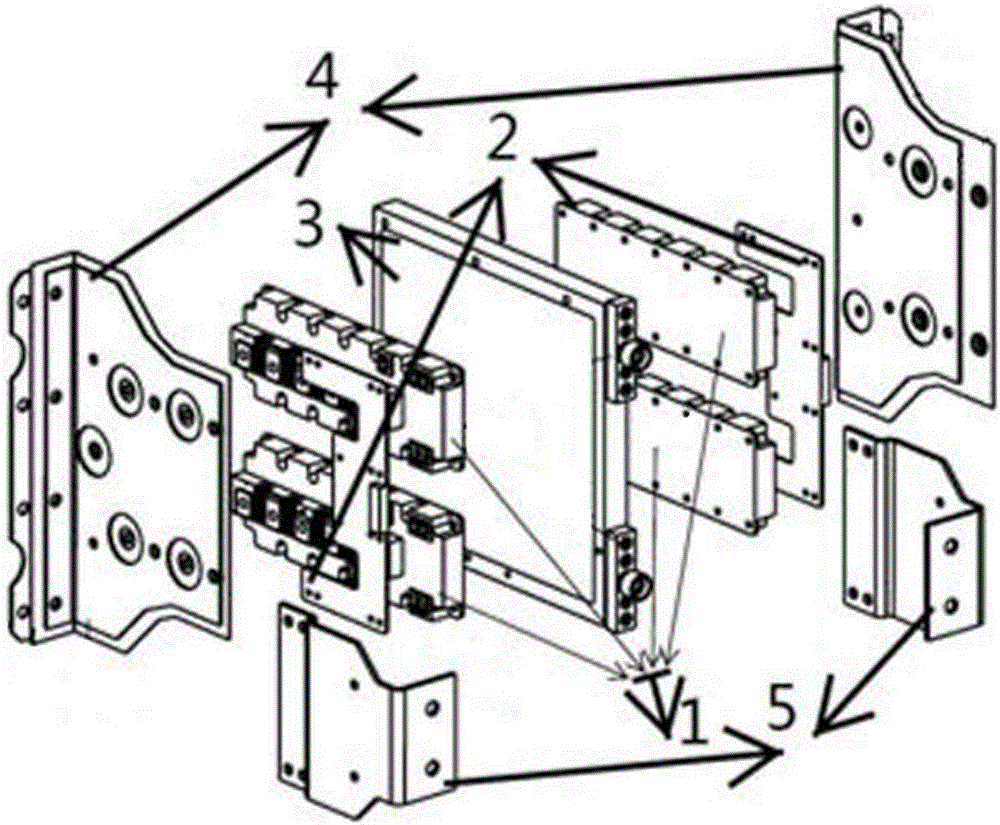

The present invention relates to a current transformer IGBT power module field double-pulse testing system and a method. The testing system comprises a double-pulse testing circuit which comprises a double-pulse testing circuit which comprises an input power supply (1), a current transformer and a load which are connected in order, a detection unit which is used for detecting the relevant parameters of each IGBT in the IGBT power module (3) in the current transformer, a data acquisition unit which is connected to the detection unit and is used for collecting the measured relevant parameters of the IGBT, and a data processing unit which is connected to the data acquisition unit and is used for carrying out analyzing processing on the measured relevant parameters of the IGBT. The testing method comprises the steps of (1) constructing a double-pulse testing circuit, (2) carrying out data measurement to measure the switch parameter of each IGBT in the IGBT power module (3) in the current transformer, and (3) carrying out data processing to carrying out analyzing processing on the measured switch parameter of the IGBT. Compared with the prior art, the system and the method have the advantages of accurate measurement and convenient measurement and are suitable for field measurement.

Owner:TONGJI UNIV

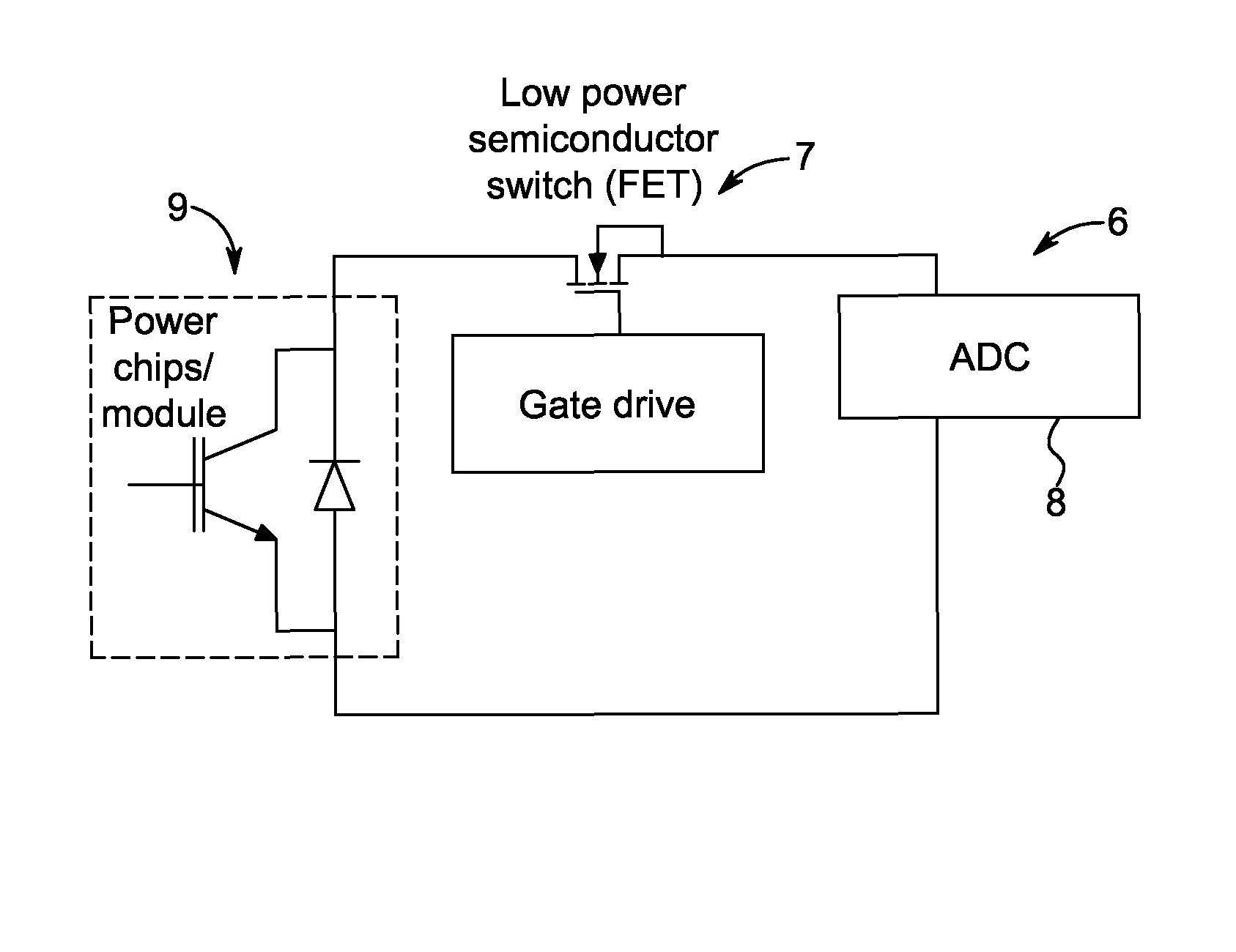

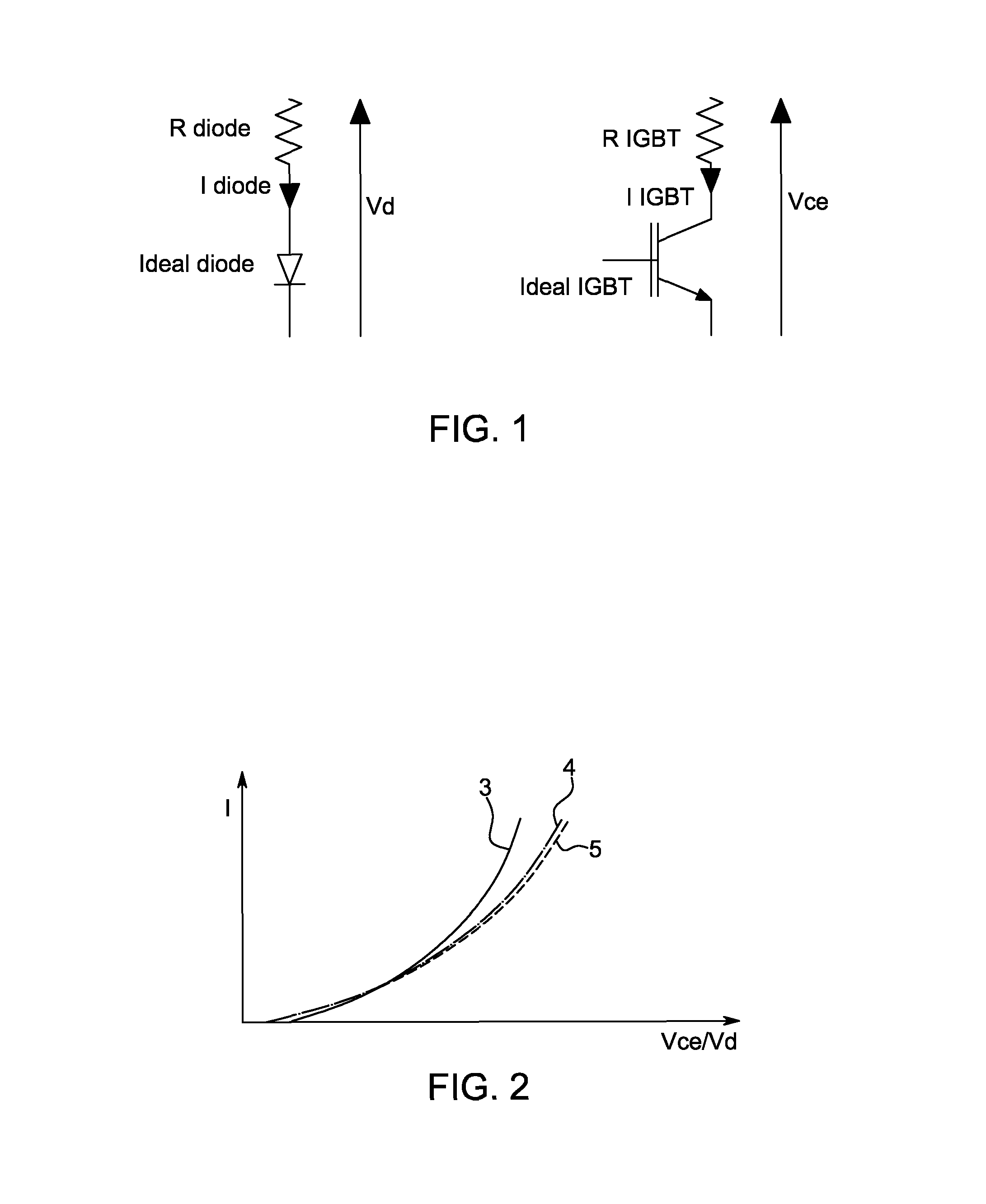

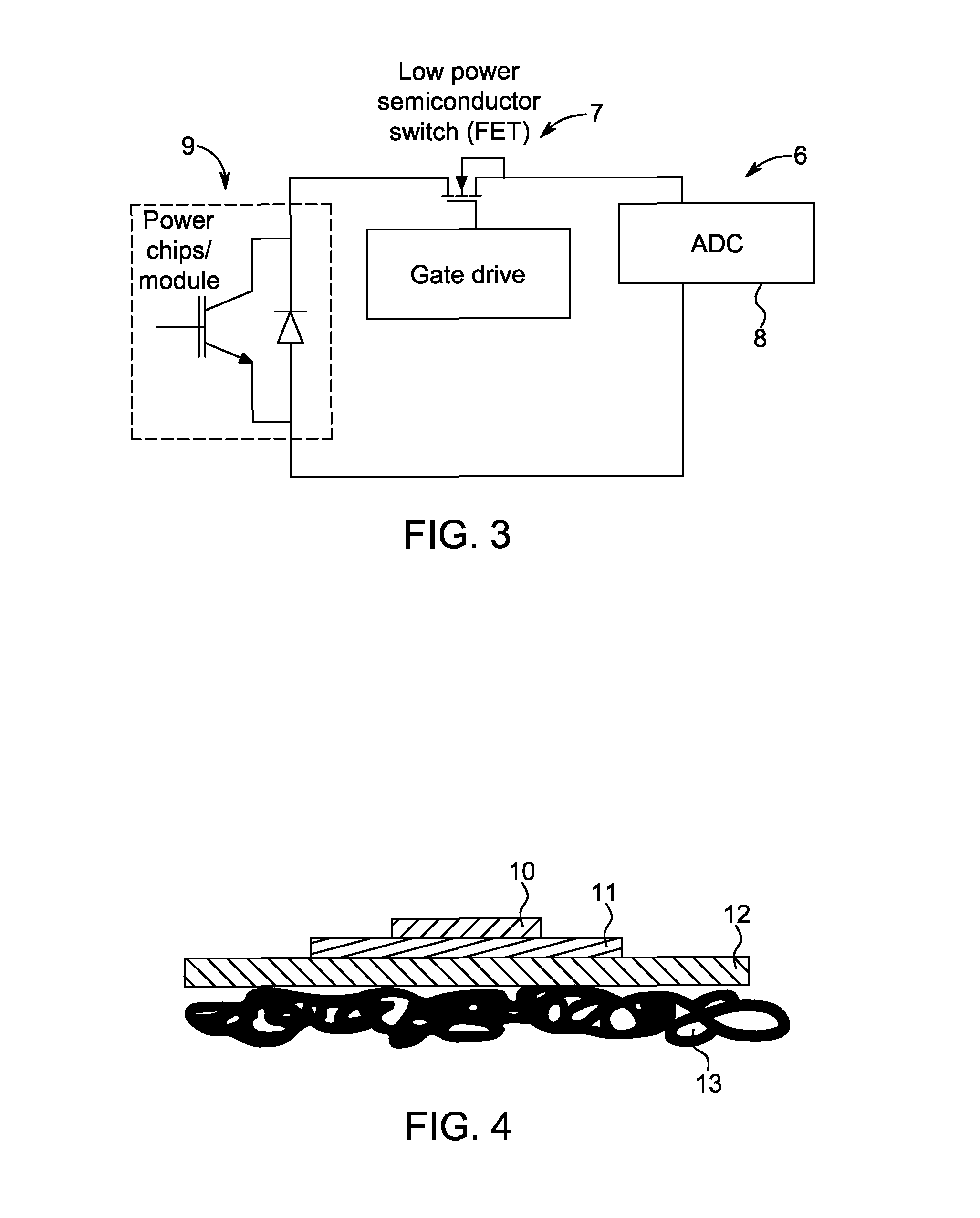

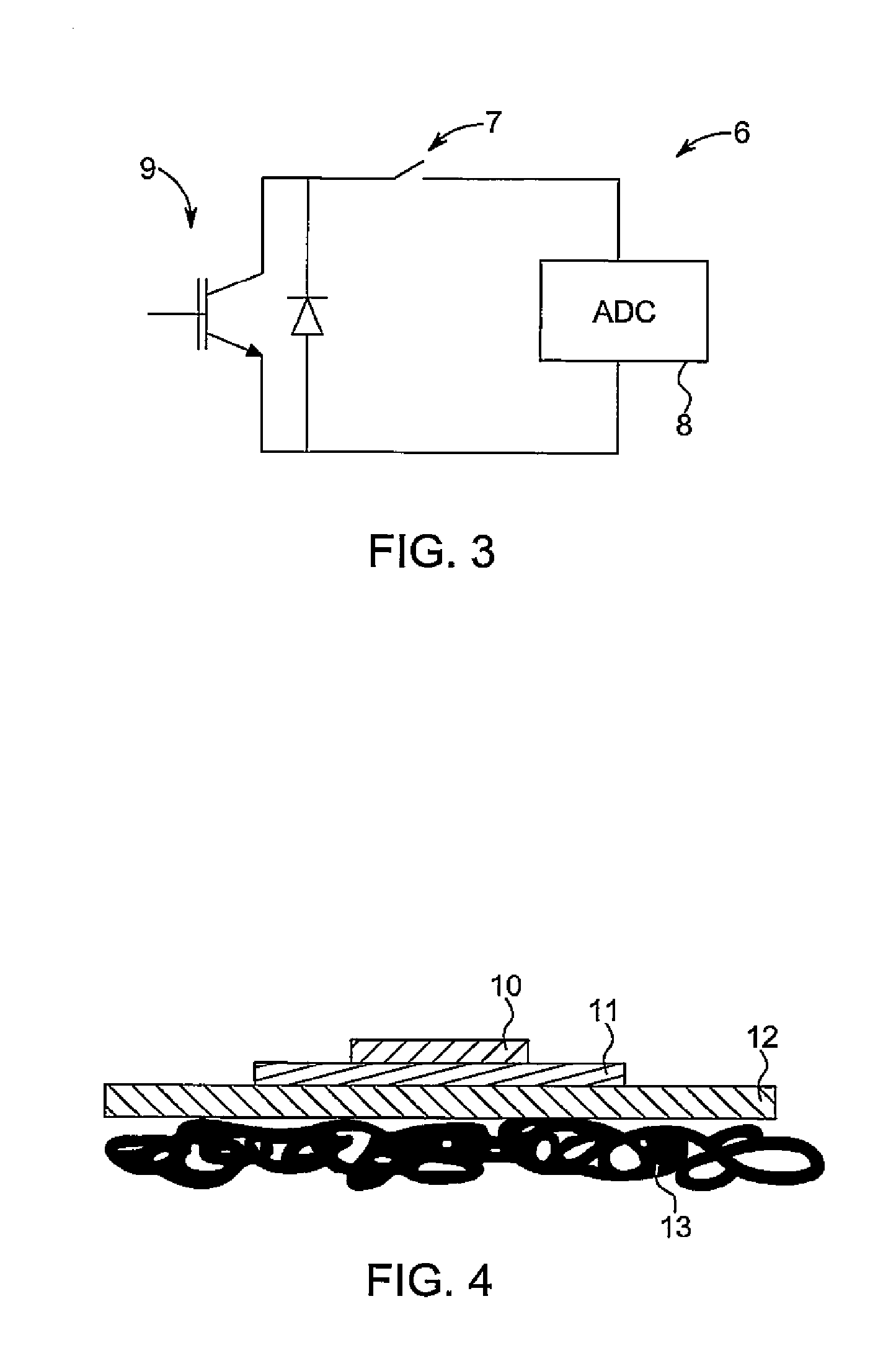

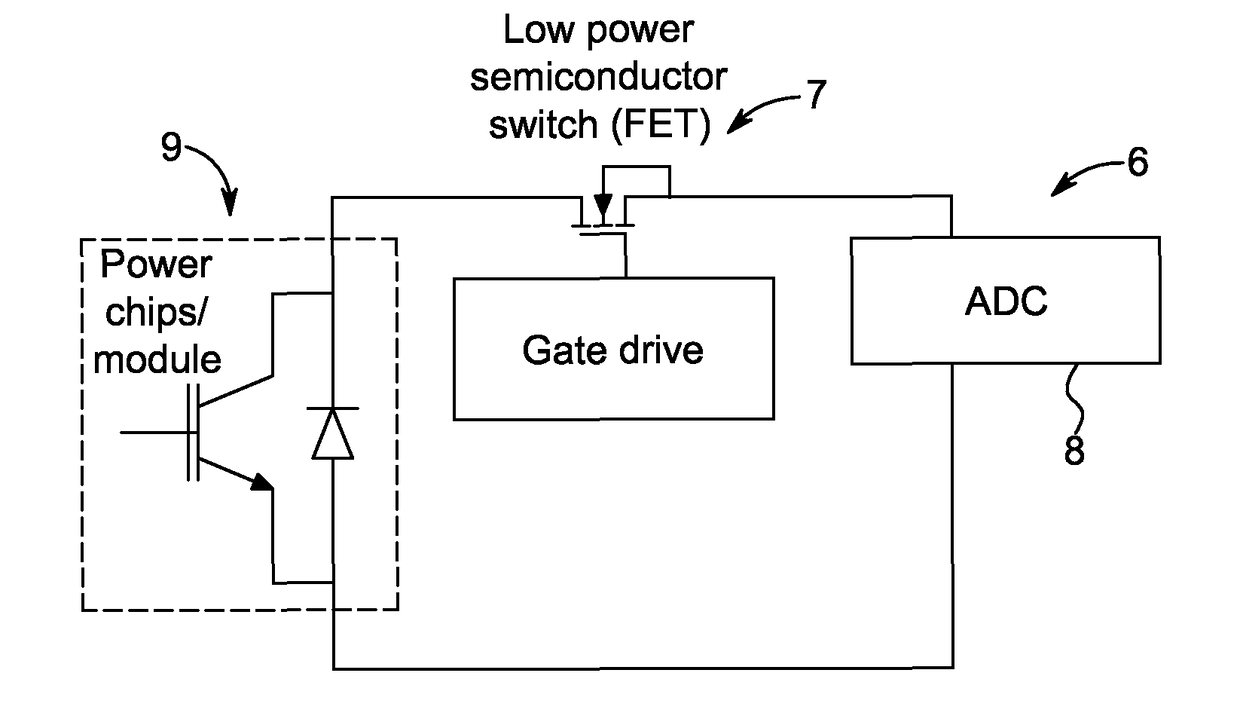

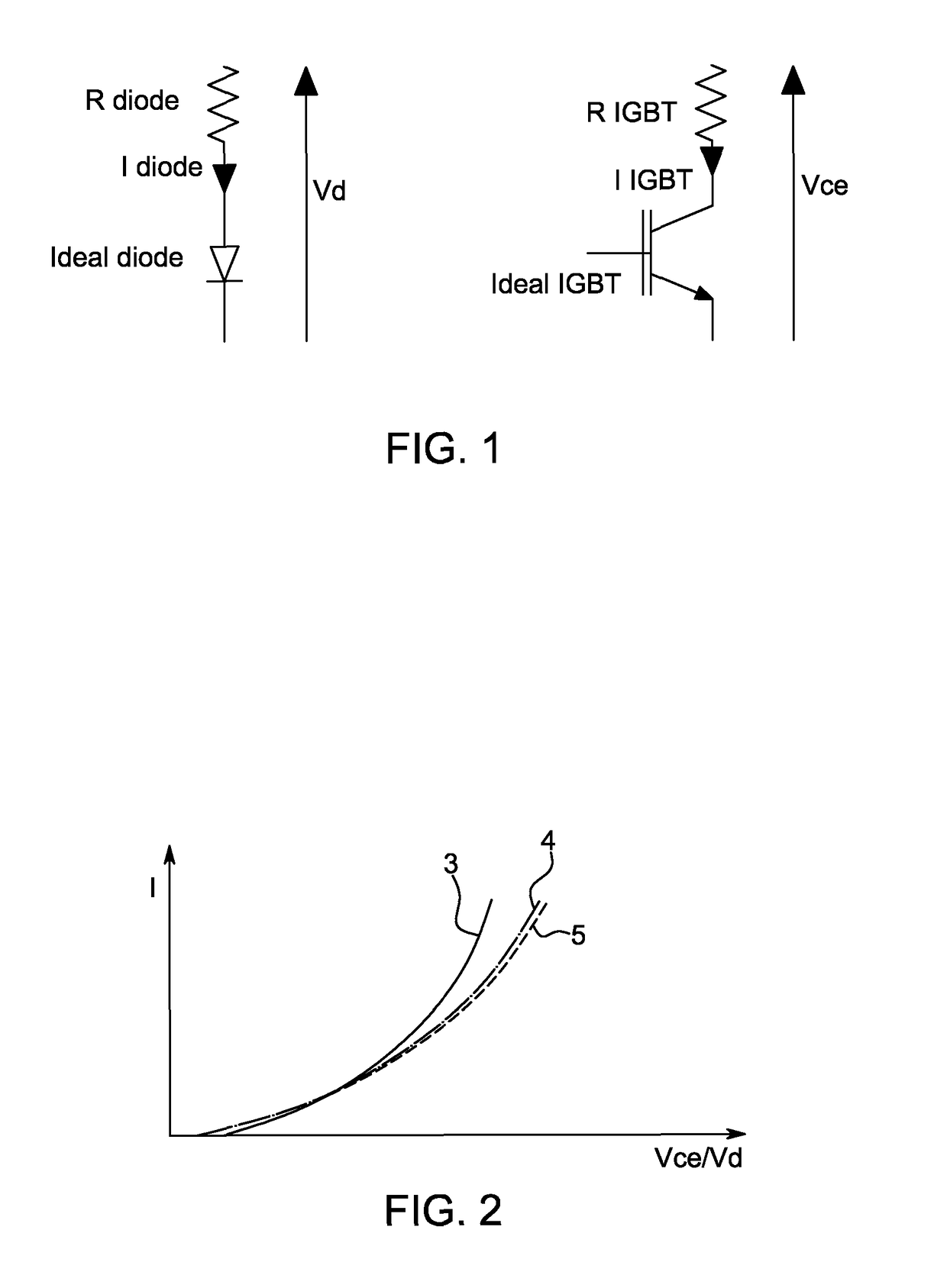

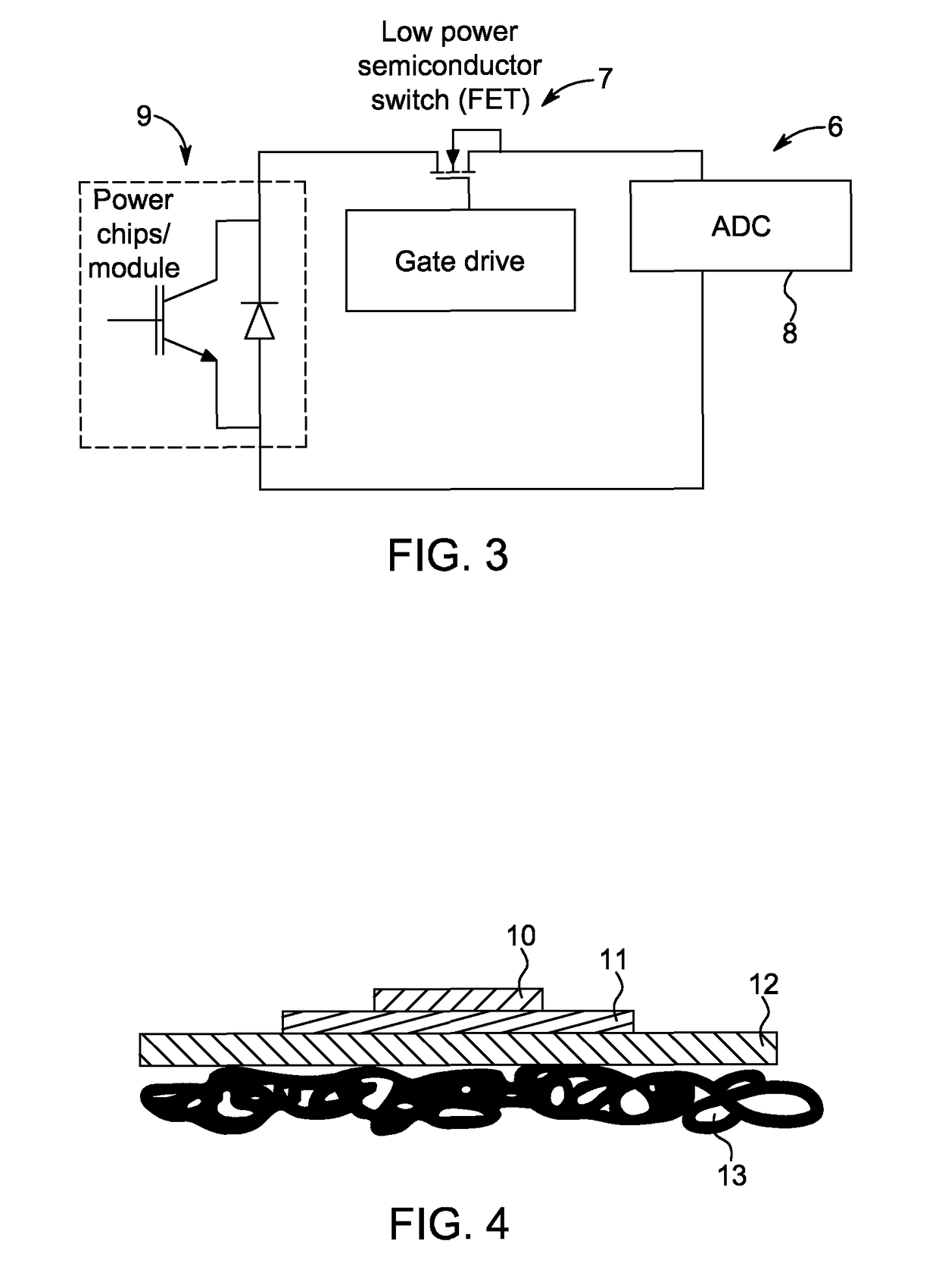

Method and apparatus for estimating the temperature of a semiconductor chip

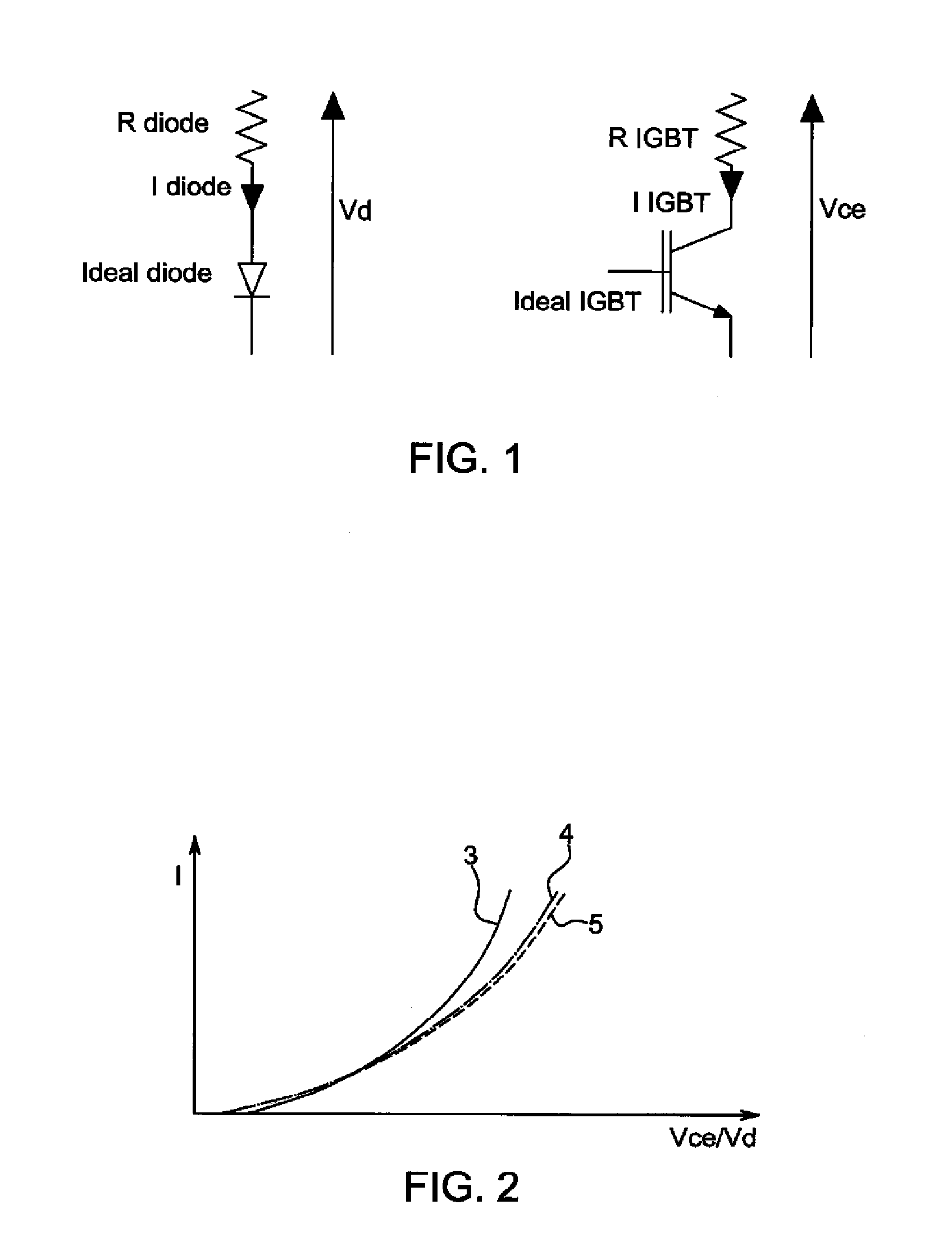

ActiveUS20140212289A1Versatile estimationOptimized areaPropellersSemiconductor/solid-state device detailsPower semiconductor devicePower flow

The invention regards a method for estimating the temperature of a semiconductor chip accommodated in a power semiconductor device in operation, such as an IGBT power module, the method comprising the steps of; while the power semiconductor device is in operation determining a voltage drop over the power semiconductor device for a value of applied load current and; estimating the temperature of the semiconductor chip by evaluating the relationship between the determined voltage drop and the value of applied load current on the basis of a semiconductor chip temperature model. The invention also regards the corresponding apparatus for estimating the temperature of a semiconductor chip, as well as a wind turbine comprising such an apparatus.

Owner:K B ELECTRONICS INC

Method for estimating junction temperature on-line on IGBT power module

ActiveUS20200240850A1High simulationHigh measurement accuracyThermometers using electric/magnetic elementsUsing electrical meansKaiman filterJunction temperature

A method for estimating the junction temperature on-line on an insulated gate bipolar transistor (IGBT) power module, including the following steps. Estimate the junction temperature by the temperature sensitive electrical parameter method, set the space thermal model of the extended state, and apply the Kalman filter to the junction temperature estimation. The temperature sensitive electrical parameter method estimates the junction temperature of the IGBT power module in real time, selects the IGBT conduction voltage drop VCE(ON) as the temperature sensitive electrical parameter, and provides a VCE(ON) on-line measuring circuit. The power loss of the diode and IGBT and the estimated value of junction temperature obtained by the temperature sensitive electrical parameter method are taken as the input of the Kalman filter, and measurement noise and process noise are considered to obtain an optimal estimated value of junction temperature.

Owner:WUHAN UNIV

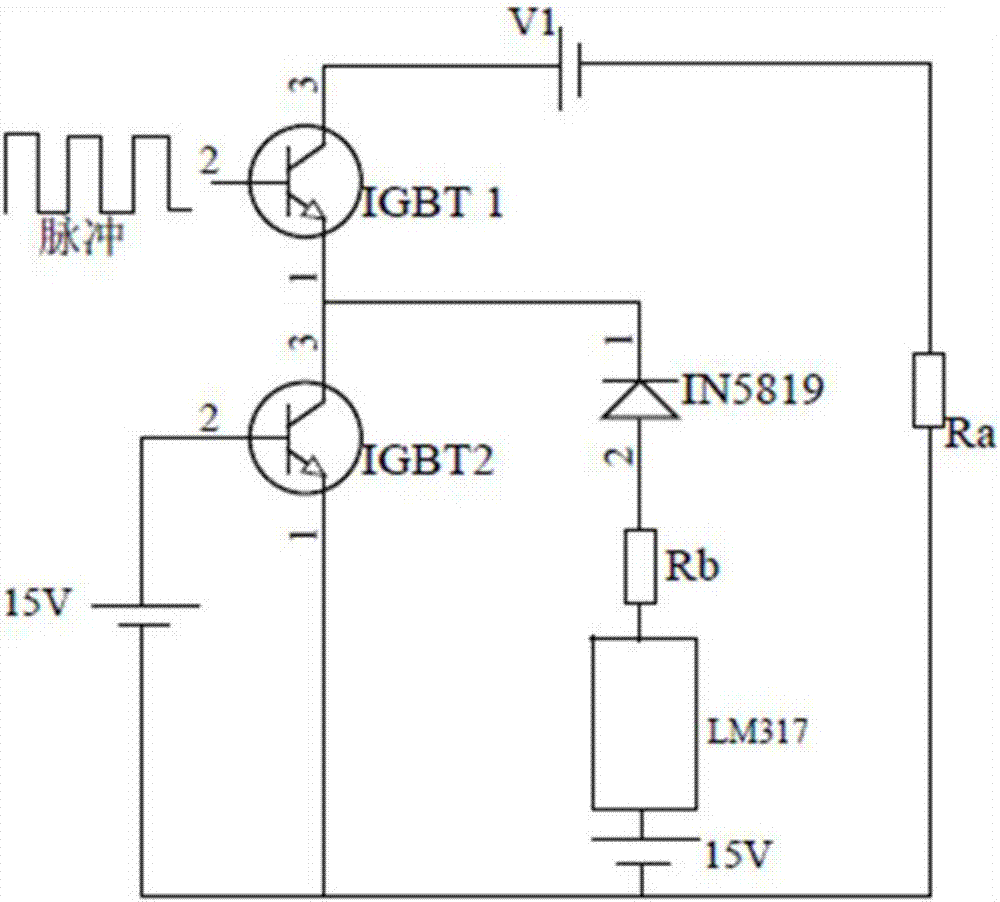

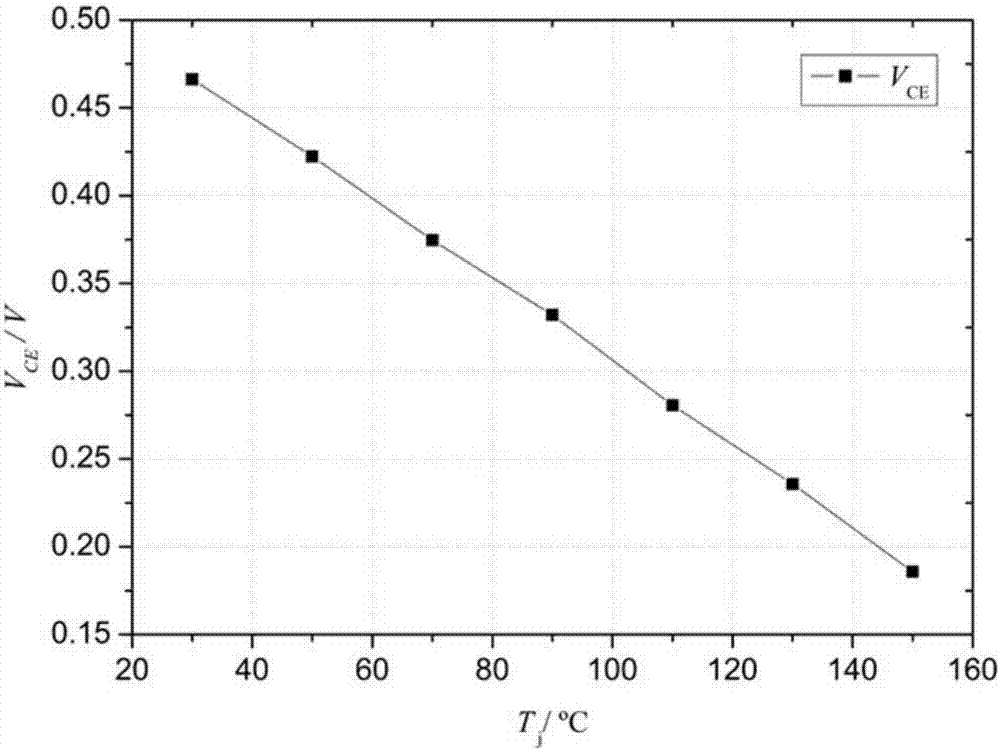

On-line detection device for measuring junction temperature of IGBT power module based on saturation voltage drop

ActiveCN106969851AThermometers using electric/magnetic elementsUsing electrical meansElectricityJunction temperature

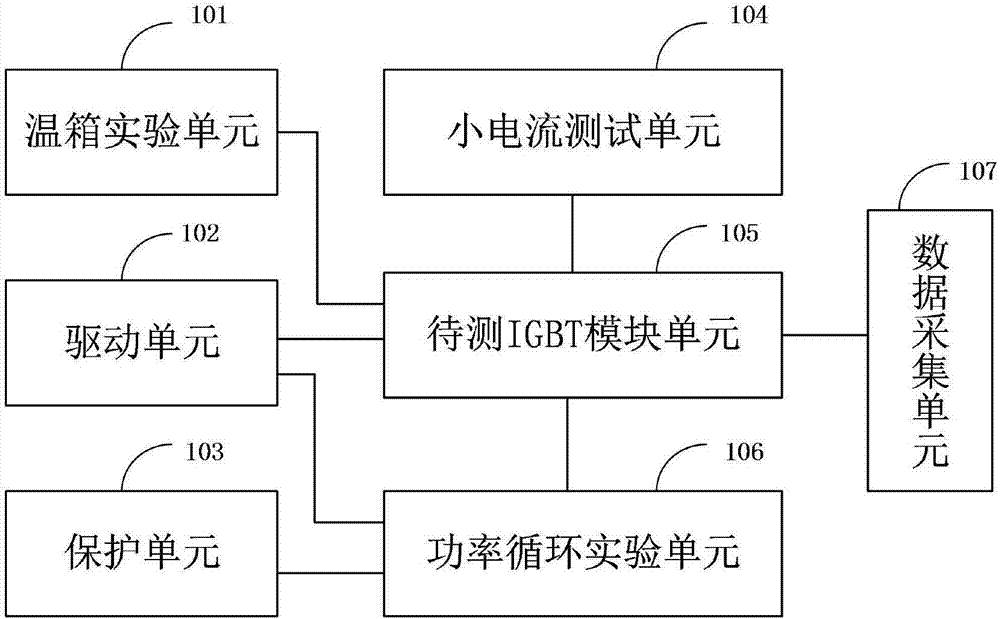

The present invention provides an on-line detection device for measuring the junction temperature of an IGBT power module based on saturation voltage drop. According to the device, the voltages VCE of a collector and an emitter under small current are selected as temperature sensitive parameters. The detection device comprises a temperature box experimental unit. A function relationship between saturation voltage drop VCE and junction temperature Tj under the small current is determined; the switching off of high current is controlled through a switch IGBT module under a power cyclic condition; the change of the VCE at the moment when an IGBT to be detected is switched off is monitored; and the change of the VCE is introduced into the function relationship which is obtained in advance, and the change process of the junction temperature Tj can be obtained. With the device adopted, the junction temperature of the IGBT can be detected in real time. According to the device, an overcurrent unit and an overtemperature unit are additionally adopted, and therefore, the IGBT device can be protected in real time through an automatic power-off means, and therefore, the device of the present invention can obtain the junction temperature of the IGBT more simply and quickly than devices which obtain junction temperature through opening covers or changing circuit structures.

Owner:BEIJING UNIV OF TECH

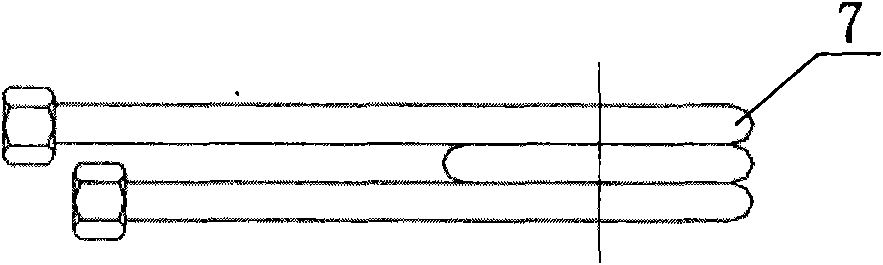

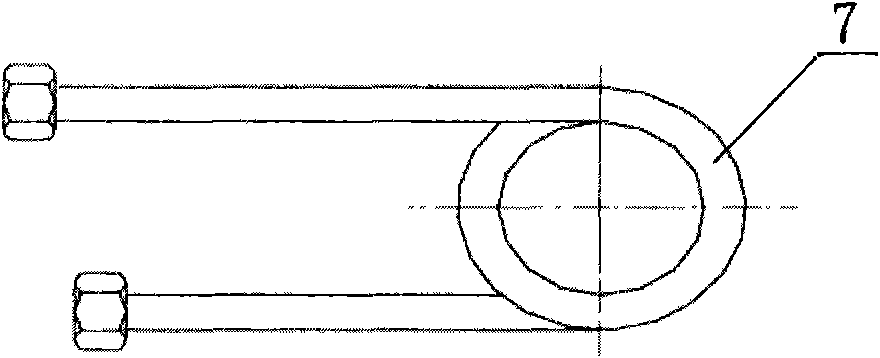

Induction welding method for aluminum water-cooling base plate and stainless joint

ActiveCN101642840ASolve Welding ProblemsFull shapeWelding/cutting media/materialsSoldering mediaIgbt power modulesInduction welding

The invention relates to an induction welding method for an aluminum water-cooling base plate and a stainless joint, which mainly comprises the following steps: processing the stainless joint and thewater-cooling base plate by sodium hydroxide and sulfuric acid solution and drying; bending a zinc-aluminum alloy flux-cored welding wire with a melting point of 420-480 DEG C into a circle and placing the zinc-aluminum alloy flux-cored welding wire to the root part of the stainless joint exposing out of the end surface of the water-cooling base plate and the chamfering position of a screw hole ofthe end surface of the water-cooling base plate; connecting an induction coil of the water-cooling base plate with one induction heating power supply and placing the water-cooling base plate into theinduction coil; connecting an induction coil of the stainless joint with the other high frequency induction heating power supply and placing the stainless joint into the induction coil. The temperature in the welding position of the water-cooling base plate rises to 450-480 DEG C and the temperature in the welding position of the stainless joint rises to 500-550 DEG C during welding. The invention more ideally solves the problem of welding two different material components of aluminum and stainless steel; welded brazing filler metal has full and even appearance and completely fills a seam andcan lead the welding position to be sealed permanently; and the stable working state of an IGBT power module is ensured.

Owner:CRRC DALIAN INST CO LTD

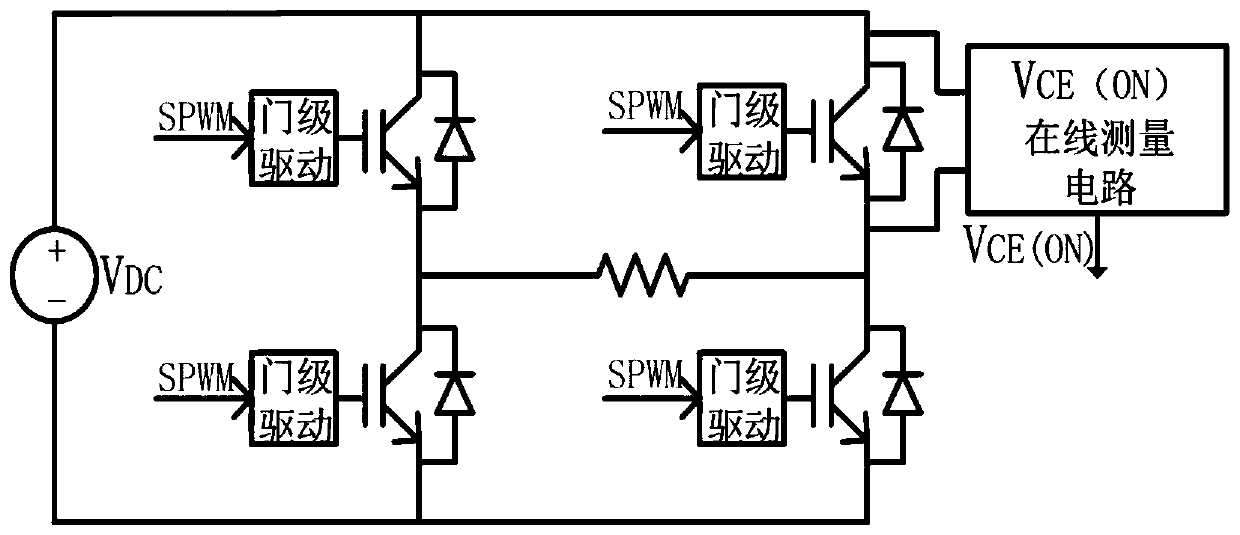

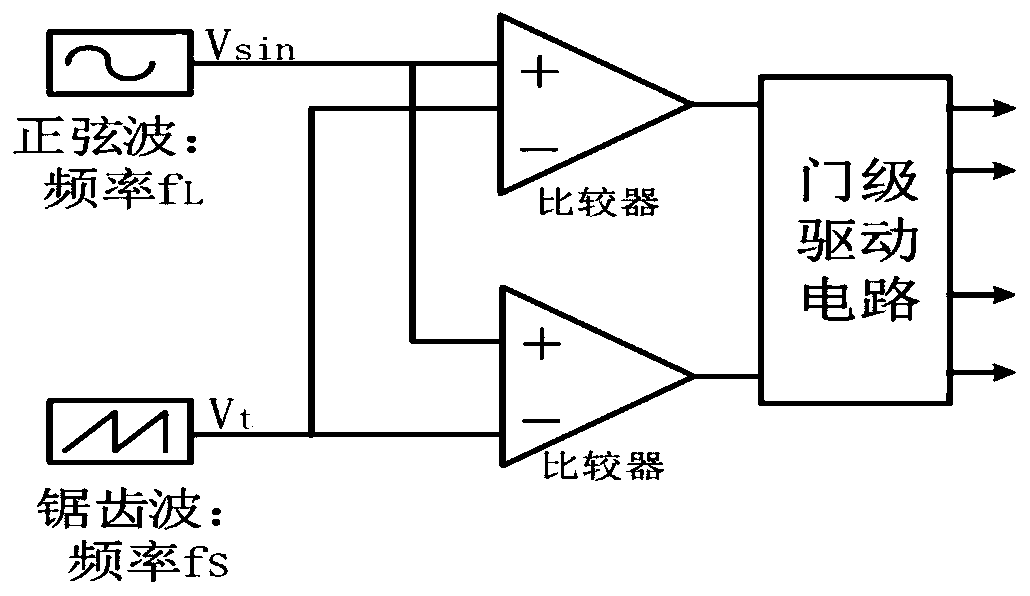

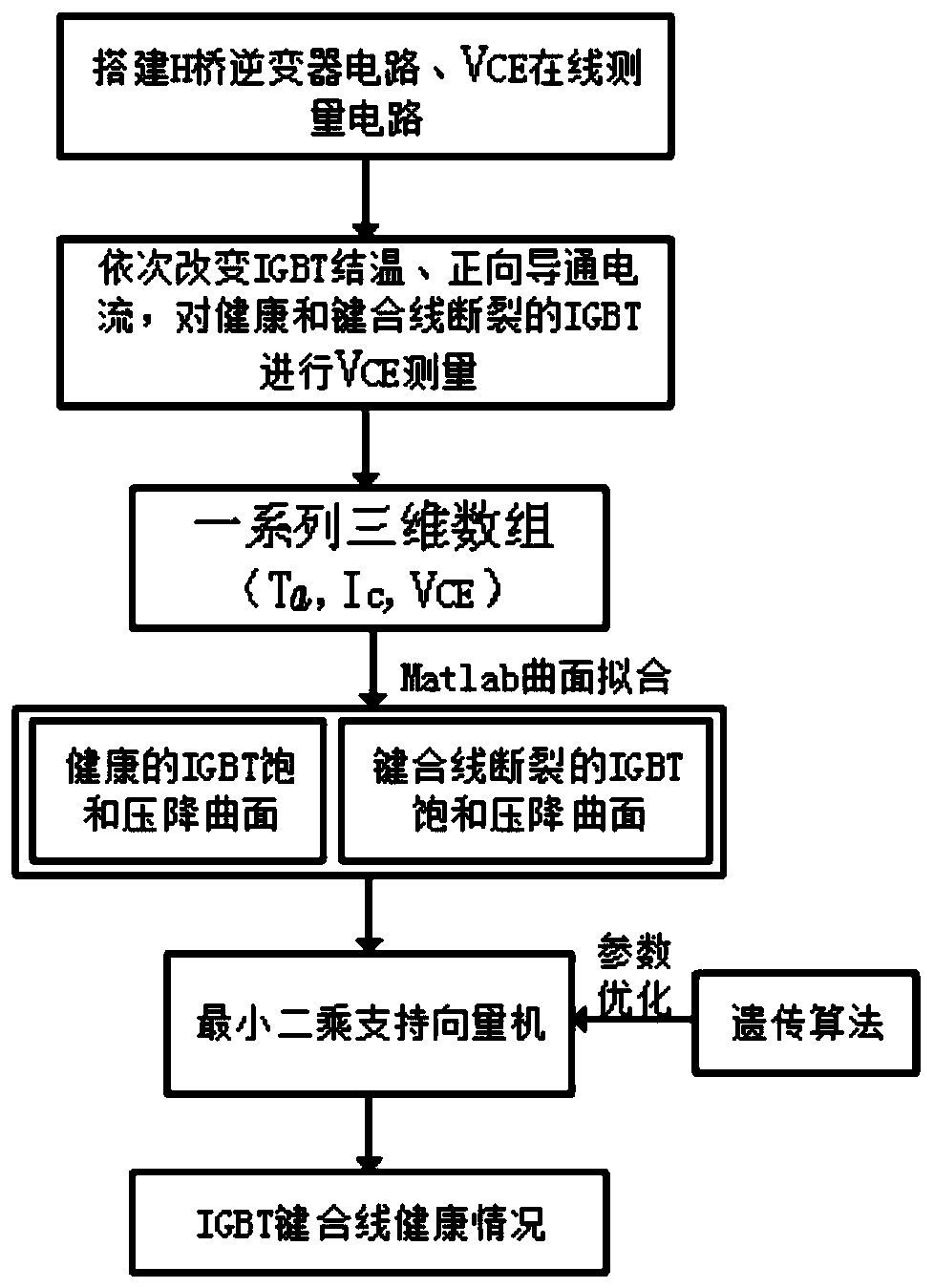

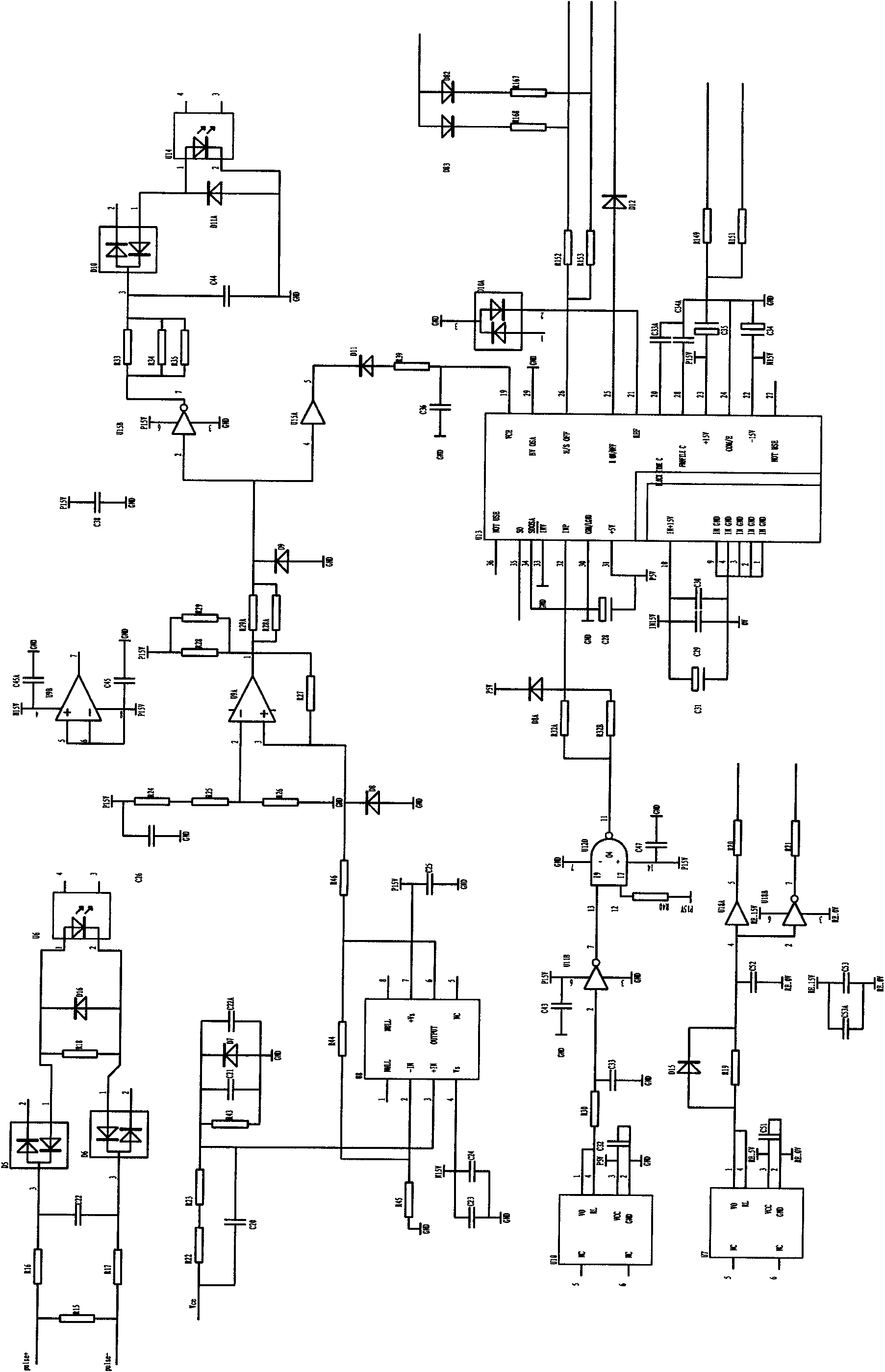

Method for monitoring online condition of IGBT module bonding wire

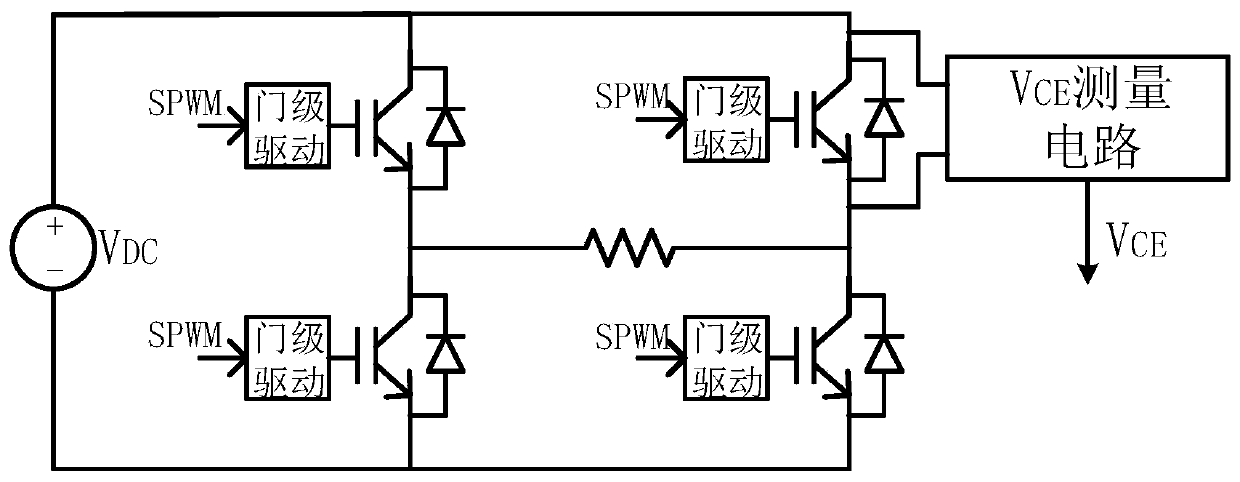

ActiveCN110221189AAccurate saturation pressure dropImprove anti-interference abilityBipolar transistor testingCurrent/voltage measurementComputer moduleLeast squares support vector machine

A method for monitoring online condition of an IGBT module bonding wire comprises the following steps of step 1, building a full-bridge inverter circuit and a VCE online measurement circuit, and connecting both input terminals of the VCE online measurement circuit to the collector and emitter of the IGBT power module of the full-bridge inverter circuit to realize the connection between the full-bridge inverter circuit and the VCE online measurement circuit; step 2, establishing a three-dimensional data model of the healthy IGBT; step 3, establishing an IGBT three-dimensional data model of thebond wire break; step 4, optimizing the least squares support vector machine by a genetic algorithm; and step 5, using the optimized least squares support vector machine to evaluate the state of the 3D data model obtained in the steps 2 and 3. The method provided by the invention closely links the online monitoring and state evaluation, and helps to improve the health management mechanism of the IGBT module bonding wire.

Owner:HEFEI UNIV OF TECH

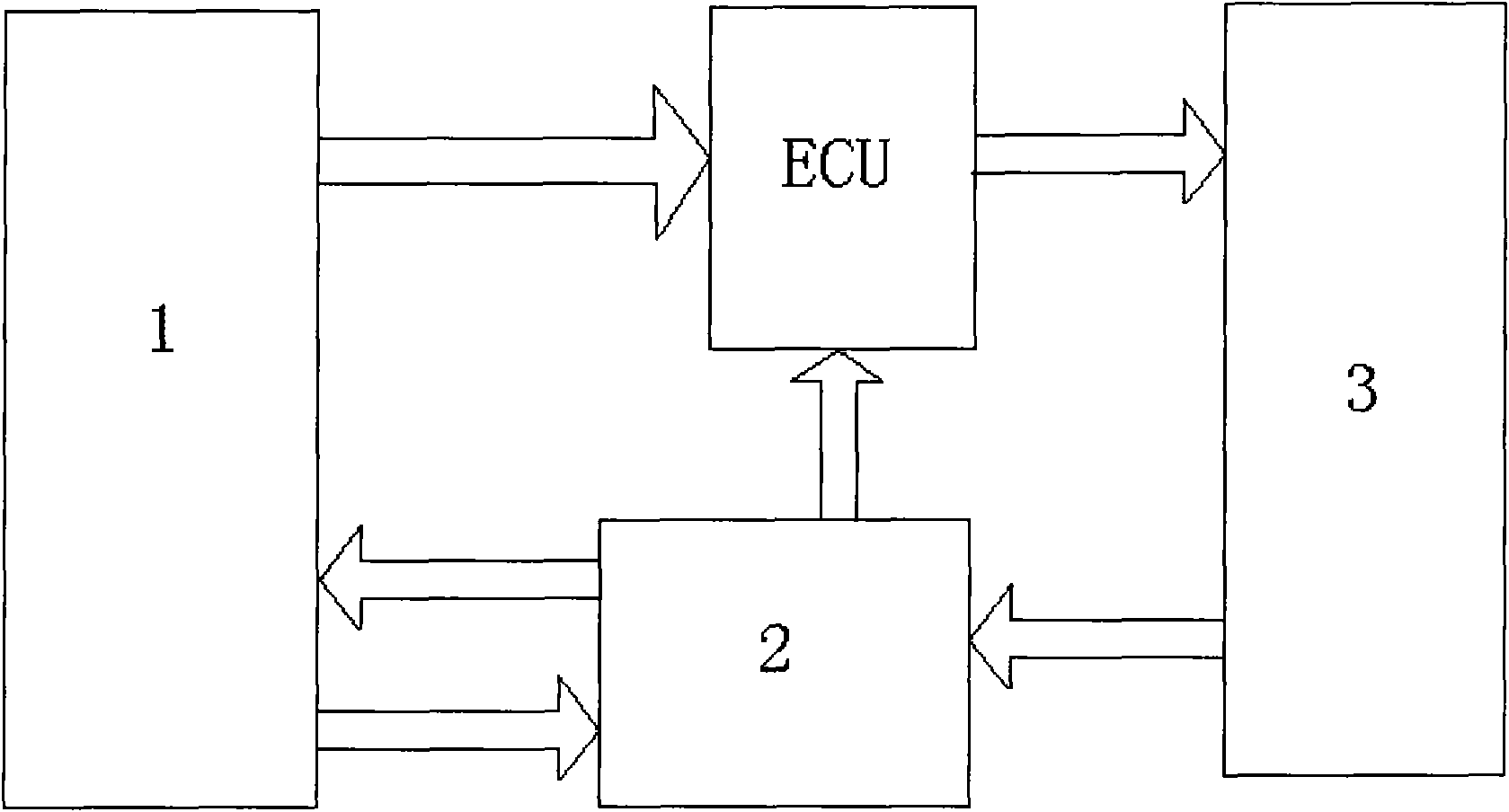

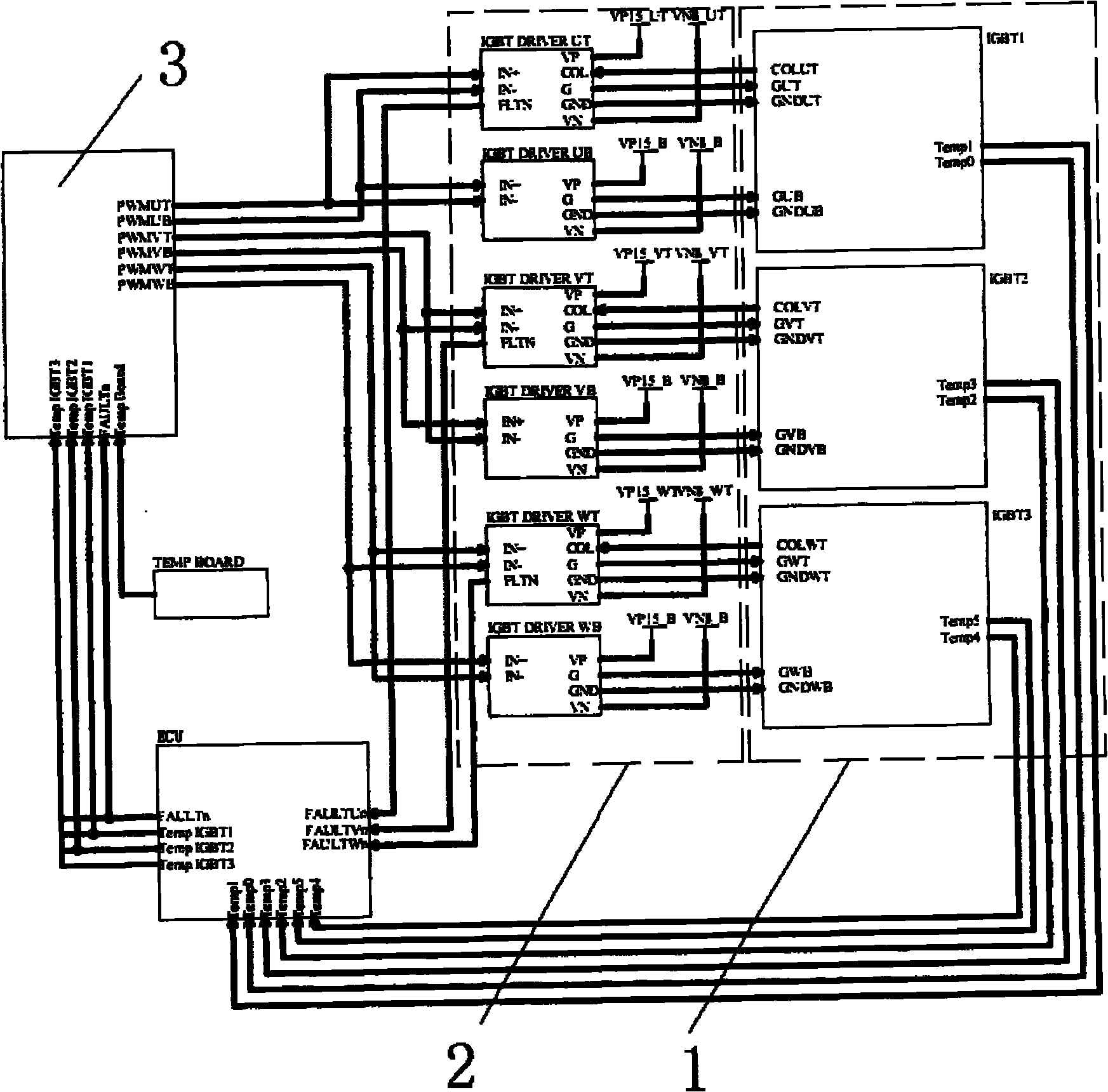

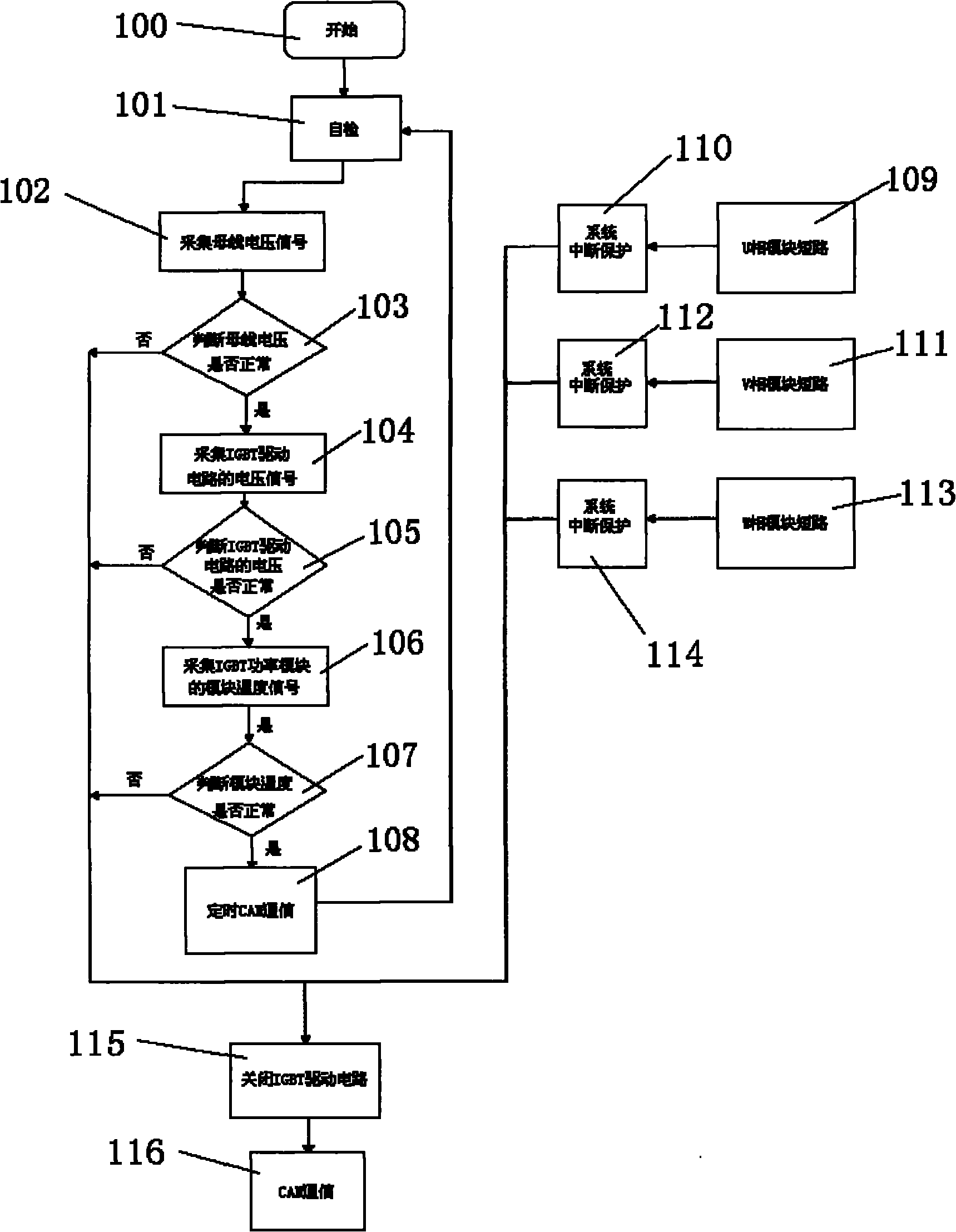

IGBT intelligent driving module for new energy automobile and control method thereof

ActiveCN101916984AEasy to collectLow costArrangements responsive to excess currentArrangements responsive to undervoltageMicrocontrollerNew energy

The invention discloses an insulated gate bipolar transistor (IGBT) intelligent driving module for a new energy automobile. The IGBT intelligent driving module comprises a controller ECU, a vehicle-mounted controller, an IGBT power module, an IGBT driving circuit and a driving power supply, wherein an output end of the controller ECU is connected with an input end of the vehicle-mounted controller; the output end of the vehicle-mounted controller is connected with the IGBT power module through the IGBT driving circuit; the IGBT power module is connected with the input end of the controller ECU; the IGBT driving circuit is connected with the controller ECU; and the control method thereof comprises the steps of detecting bus voltage, detecting driving voltage and detecting module temperature. The module and the method have the advantages that: 1, a singlechip is introduced to serve as a substituent for a digital AD converting circuit, and the cost of the driving module is reduced by means of the characteristics of simplicity, convenience and a plurality of interfaces; and 2, the temperature signal of the power module can be conveniently acquired, and meanwhile, the sampling of the driving voltage is realized and the system is simplified.

Owner:WUHU MOTIONTEC AUTOMOTIVE +1

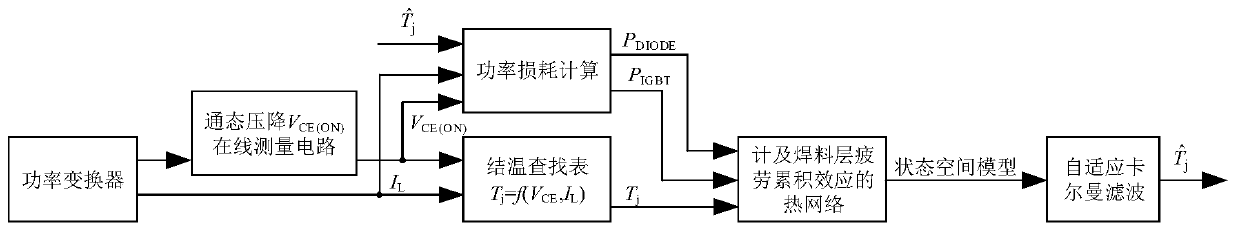

IGBT module junction temperature online estimation circuit system and method

InactiveCN110988641AImprove estimation accuracyImprove accuracyIndividual semiconductor device testingThermodynamicsJunction temperature

The invention discloses an IGBT module junction temperature online estimation circuit system and method, and the method comprises the following steps: 1, carrying out the online measurement of the IGBT on-state voltage drop VCE(ON) of an IGBT power module, and building an IGBT junction temperature Tj lookup table; 2, calculating the power loss of an IGBT and a diode in the IGBT power module; 3, periodically and timely updating the IGBT equivalent thermal network model by adopting a thermal network updating strategy considering the fatigue accumulation effect of the solder layer; 4, establishing a state space model by taking the junction temperature Tj and the IGBT and diode power loss as state variables according to the IGBT equivalent thermal network model, and updating the state space model; and 5, designing an adaptive Kalman filtering algorithm program according to the state space model to obtain an IGBT junction temperature Tj estimated value. The method integrates the advantagesof model estimation and online measurement, overcomes the defect that on-state voltage drop VCE (ON) measurement is inaccurate, keeps signal continuity, reduces noise interference, is high in estimation precision, and can estimate the IGBT module junction temperature in real time in a non-intervention mode.

Owner:WUHAN UNIV

Method for estimating the end of lifetime for a power semiconductor device

ActiveUS20140125366A1Avoid lostProduct's lifetimeBipolar transistor testingSemiconductor operation lifetime testingPower semiconductor deviceVoltage drop

The invention regards an method for estimating the end of lifetime for a power semiconductor device, such as an IGBT power module, comprising the steps of; establishing the temperature of the power semiconductor device, determining the voltage drop over the power semiconductor device for at least one predetermined current where the current is applied when the power semiconductor device is not in operation, wherein the end of lifetime is established dependent on the change in a plurality of determined voltage drops.

Owner:K B ELECTRONICS INC

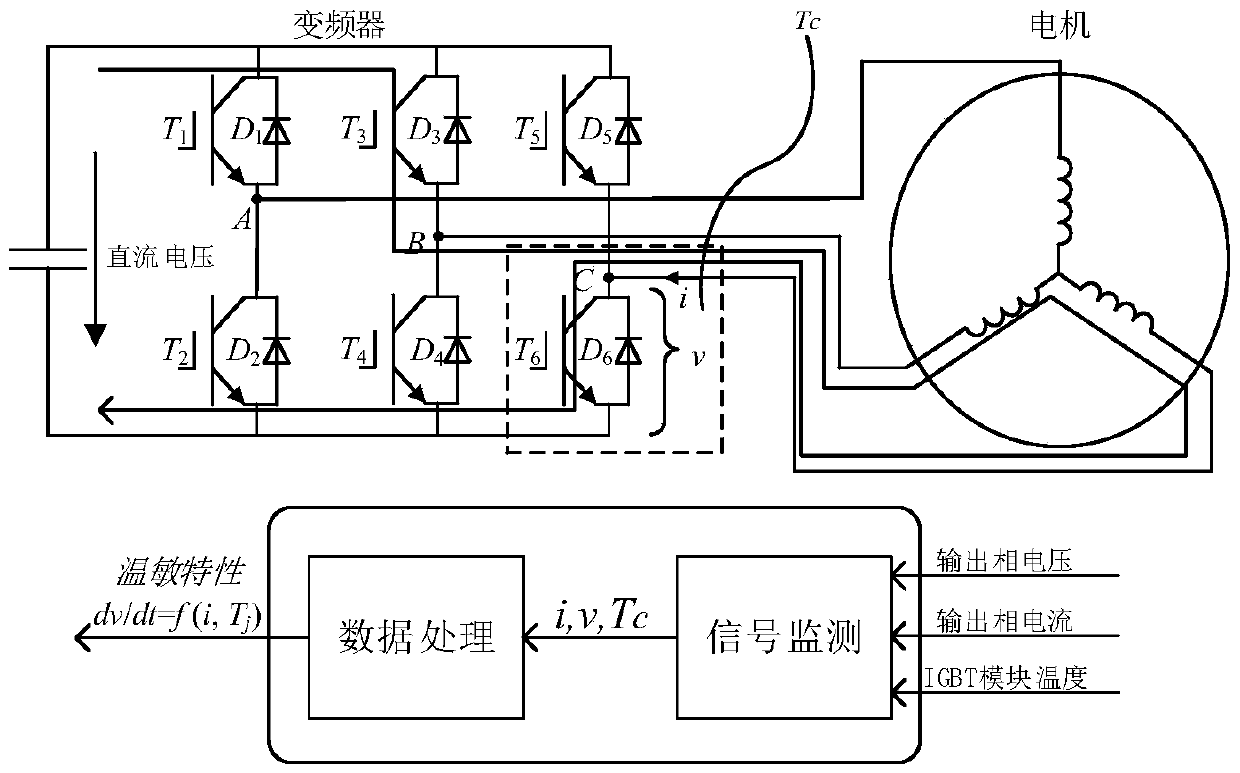

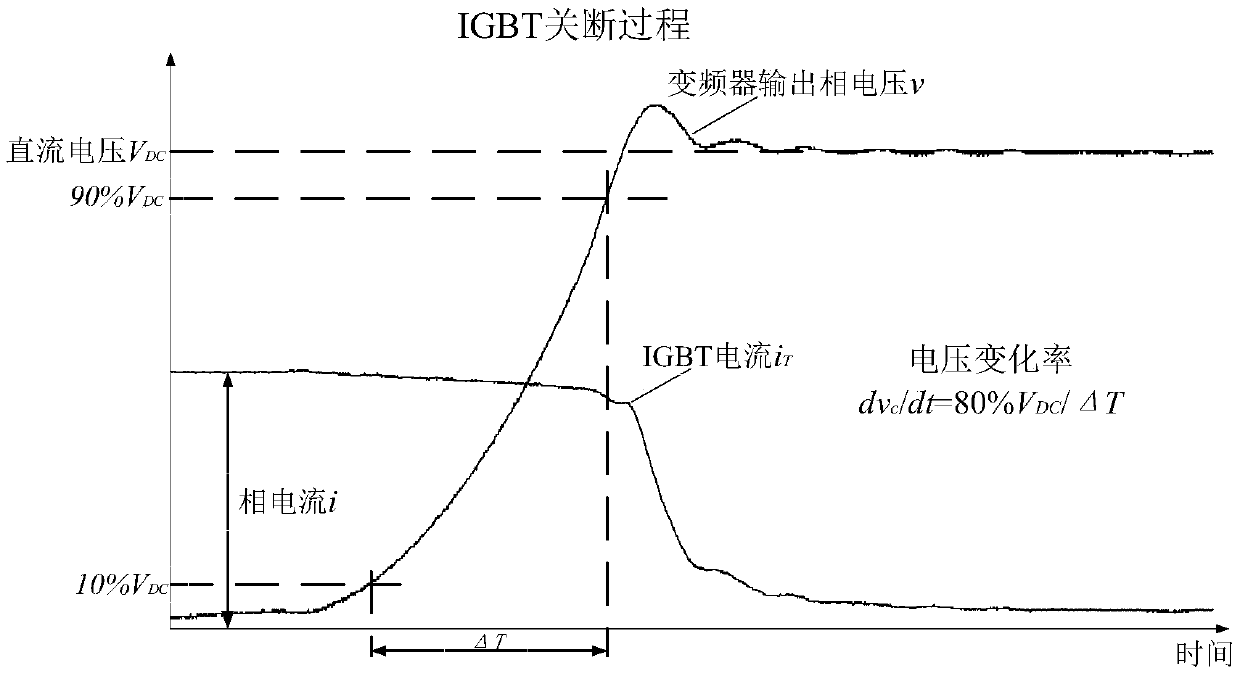

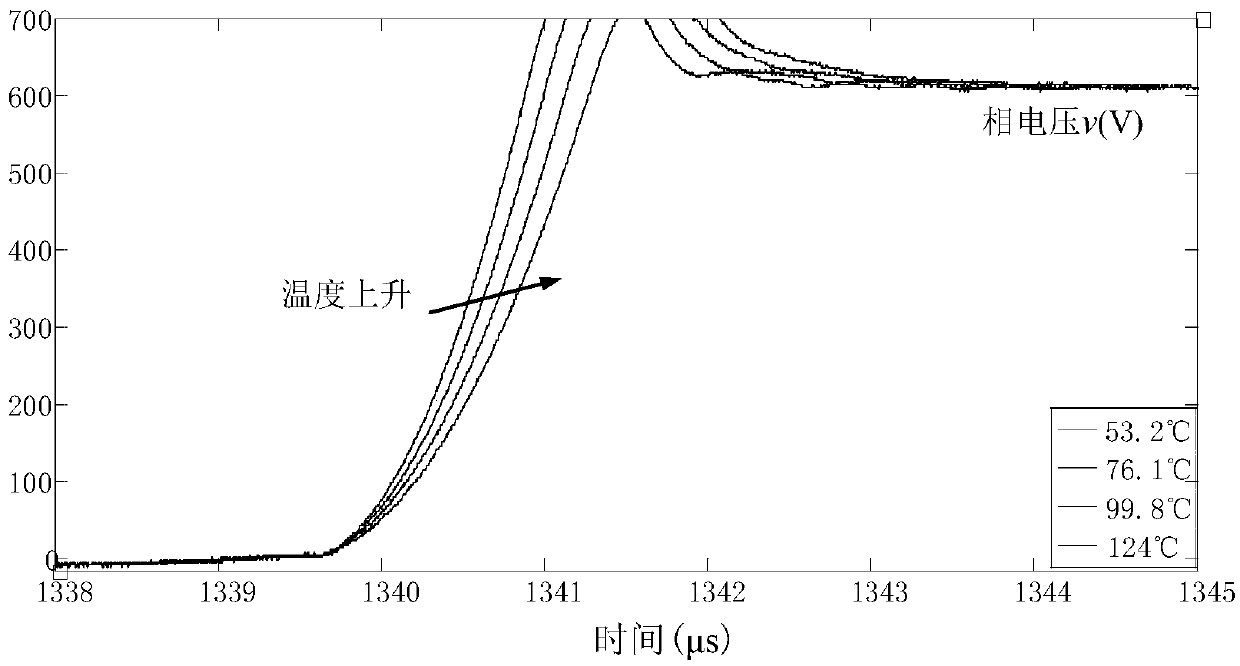

Self-calibration method of converter IGBT power module junction temperature measurement

ActiveCN105510793ALow costReduce technical difficultyThermometer applicationsIndividual semiconductor device testingJunction temperatureVoltage variation

The invention relates to a self-calibration method of converter IGBT power module junction temperature measurement. The self-calibration method comprises the following steps that: 1) the three-dimensional temperature sensitive characteristic table of an IGBT module is obtained; and 2) the operating junction temperature of the IGBT module is calculated according to the three-dimensional temperature sensitive characteristic table dv / dt=f(Tj,i) as well as actually measured operating current and voltage data of the IGBT module to be measured. The step 1) further includes the following steps that: 11) self heating of a converter is carried out: with a converter cooling device turned off, the converter is loaded through a load under control, so that the temperature of the IGBT module is increased gradually to achieve an instruction value; 12) after self heating is completed, IGBT gate signals are locked, load current is cut off, and therefore, the temperature Tc of the IGBT module after self heating is completed can be slowly decreased to ambient temperature; and 13) in a process in which the temperature of the IGBT module is slowly decreased to the ambient temperature, current scanning and temperature scanning of a double-pulse test are performed on the IGBT module, so that the three-dimensional temperature sensitive characteristic table dv / dt=f(Tj,i) of the IGBT module based on voltage change rate dv / dt can be obtained. Compared with the prior art, the self-calibration method of the invention has the advantages of suitability for industrial sites, simple measurement, accurate measurement and the like.

Owner:TONGJI UNIV

Temperature calibrating apparatus for IGBT power module chip and temperature correction method thereof

ActiveCN105928637AReal-time monitoring of junction temperatureFast junction temperatureThermometer testing/calibrationData acquisitionJunction temperature

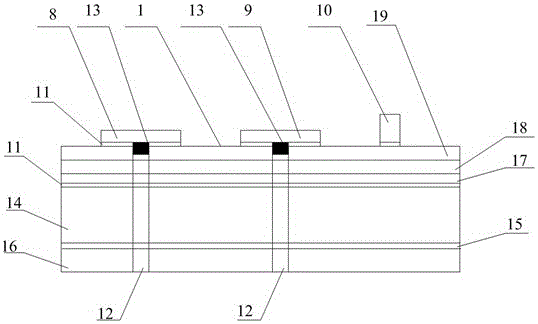

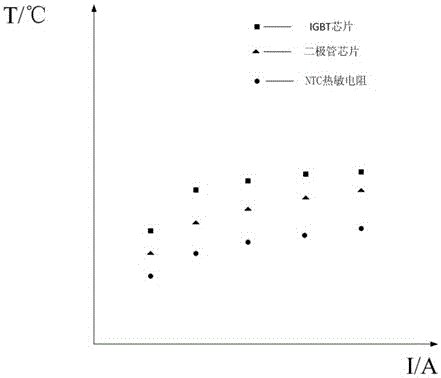

The invention relates to the technical field of temperature detection, specifically to a temperature calibrating apparatus for an IGBT power module chip and a temperature correction method thereof. The temperature calibrating apparatus comprises an IGBT power module including an IGBT chip, a diode chip, an NTC and a heat radiation substrate, wherein temperature sensors are arranged on the lower ends of the IGBT chip and the diode chip, and the IGBT power module is respectively connected with a load, a driver and a data acquisition instrument. The driver and the data acquisition instrument are respectively connected with a host computer, and the driver is connected with a power supply. The acquired temperature is compared with the temperature measured by NTC, temperature correction curves MAP for the IGBT chip and the diode chip are formed based on NTC temperature. Operation junction temperature of the IGBT chip and the diode chip is monitored by checking a table by using real-time monitored NTC temperature and calibrated temperature MAP. Rapid, accurate and real-time operation junction temperature detection can be achieved without consuming calculating resources of a driving system.

Owner:BINZHOU UNIV

Dynamic prediction method for junction temperature of IGBT power module

ActiveCN108108573AEnables dynamic junction temperature predictionGeometric CADDesign optimisation/simulationCouplingJunction temperature

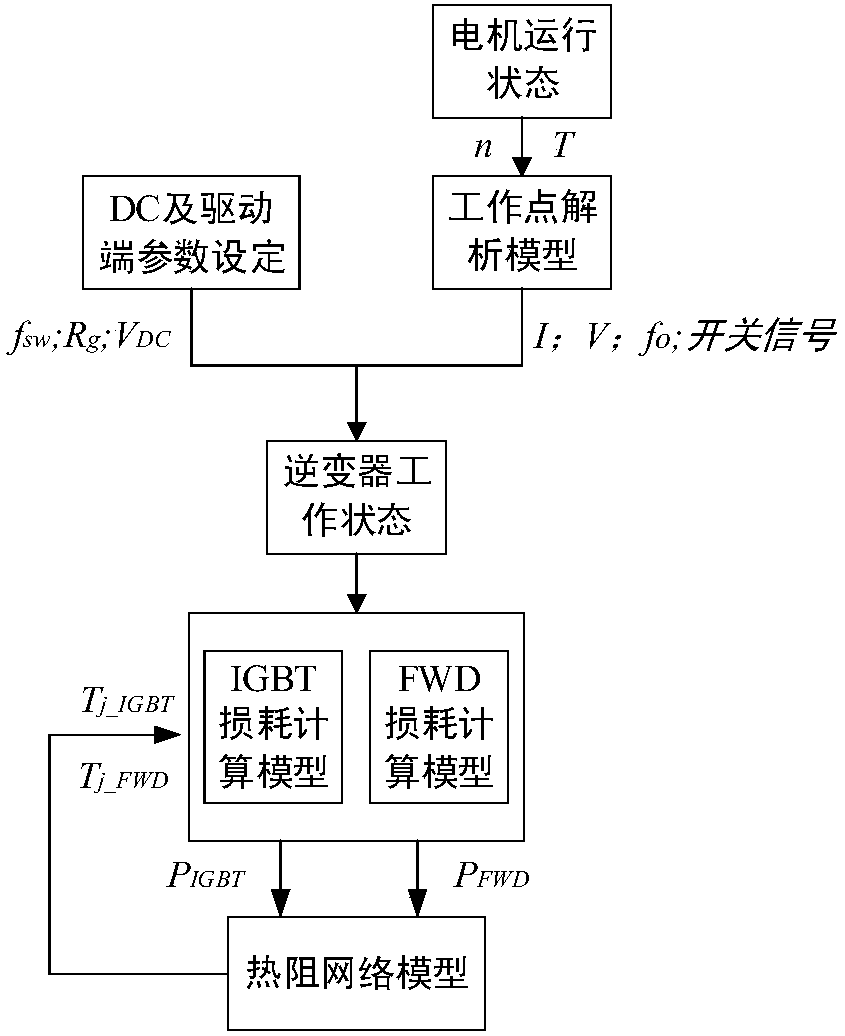

The invention provides a dynamic prediction method for junction temperature of an IGBT power module. The method solves the problem of excessive derating and an irrational thermal design for avoiding failure caused by excessive junction temperature and excessive fluctuation of the IGBT power module. According to the running state of a motor, dynamic analysis is conducted on circuit parameters suchas modulation ratio, output current, output voltage, output frequency and the like, an analytical value is input into a junction temperature calculation model considering electrothermal coupling, anddynamic junction temperature prediction under working conditions is achieved.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

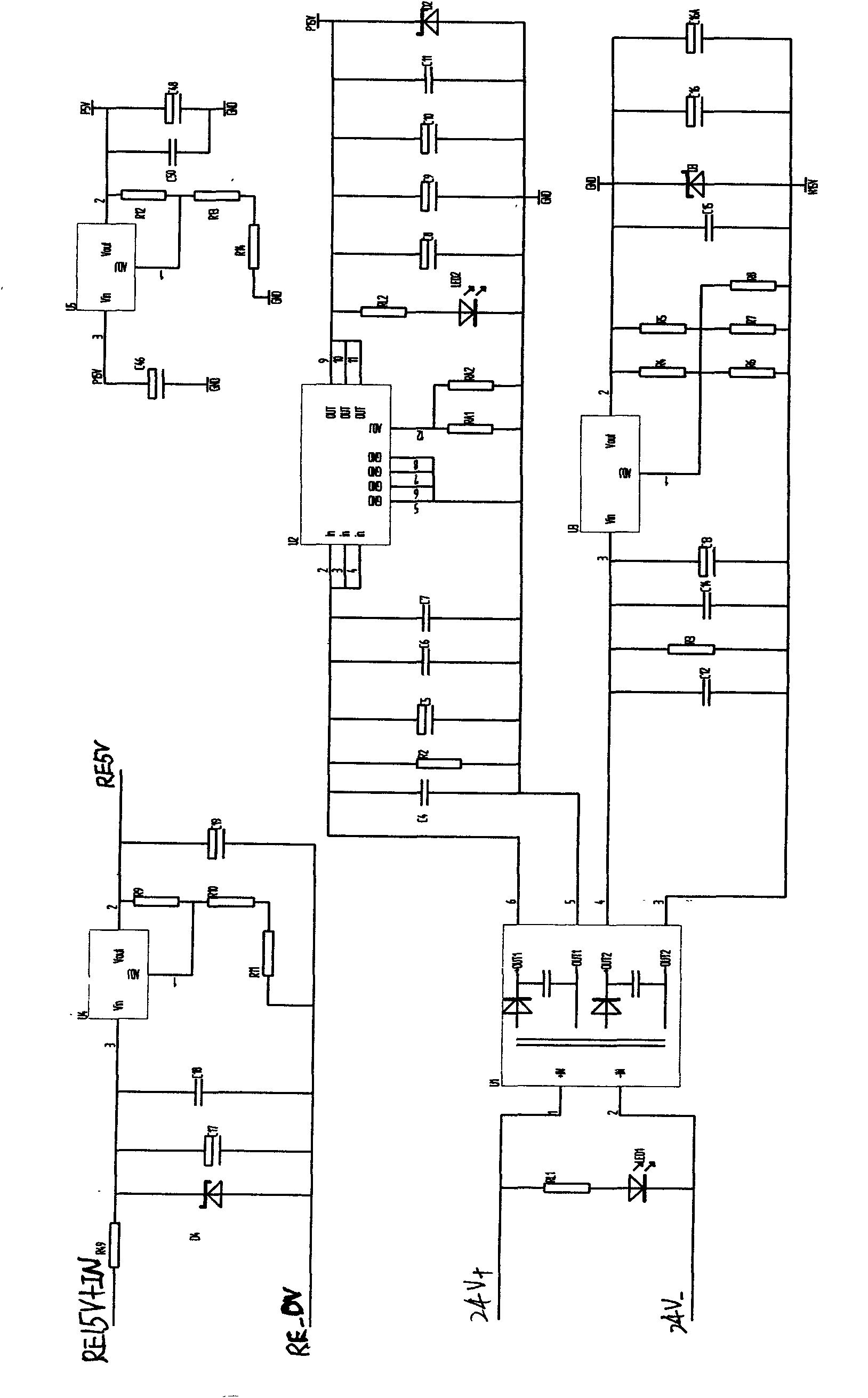

Driving circuit of high-voltage current transformer

InactiveCN101630910AFlexible and adjustable overcurrentFlexible and adjustable short circuit protection functionDc-dc conversionElectric variable regulationFour quadrantsHigh voltage igbt

The invention relates to a high-voltage current transformer, in particular to a driving circuit of the high-voltage current transformer. Thanks to the invention, the problem that at present no well-developed driving circuit is provided for high-voltage current transformers can be solved. The driving circuit of the high-voltage current transformer comprises a driving circuit, a power circuit and a protecting circuit. Apart from the self characteristics of the circuits, the driving circuit of the high-voltage current transformer is substantially characterized in that fiber optic transmitters and fiber optic receivers are used in the driving circuit and the protecting circuit; a high-voltage isolating chip is used in the power circuit; therefore the high-voltage isolation of the driving circuit of the high-voltage current transformer from other circuits is effectively realized, and the other circuits connected with the driving circuit are effectively protected against being possibly damaged by the high voltage and the large current, which flow past a high-voltage IGBT in the high-voltage current transformer, through the driving circuit. The driving circuit can achieve 10 kV of electric isolation, feed back the voltage status of a main loop and protect the safe performance of an IGBT power module. The driving circuit is successfully assembled in a four quadrant and an inversion module of a motor train unit.

Owner:CRRC YONGJI ELECTRIC CO LTD

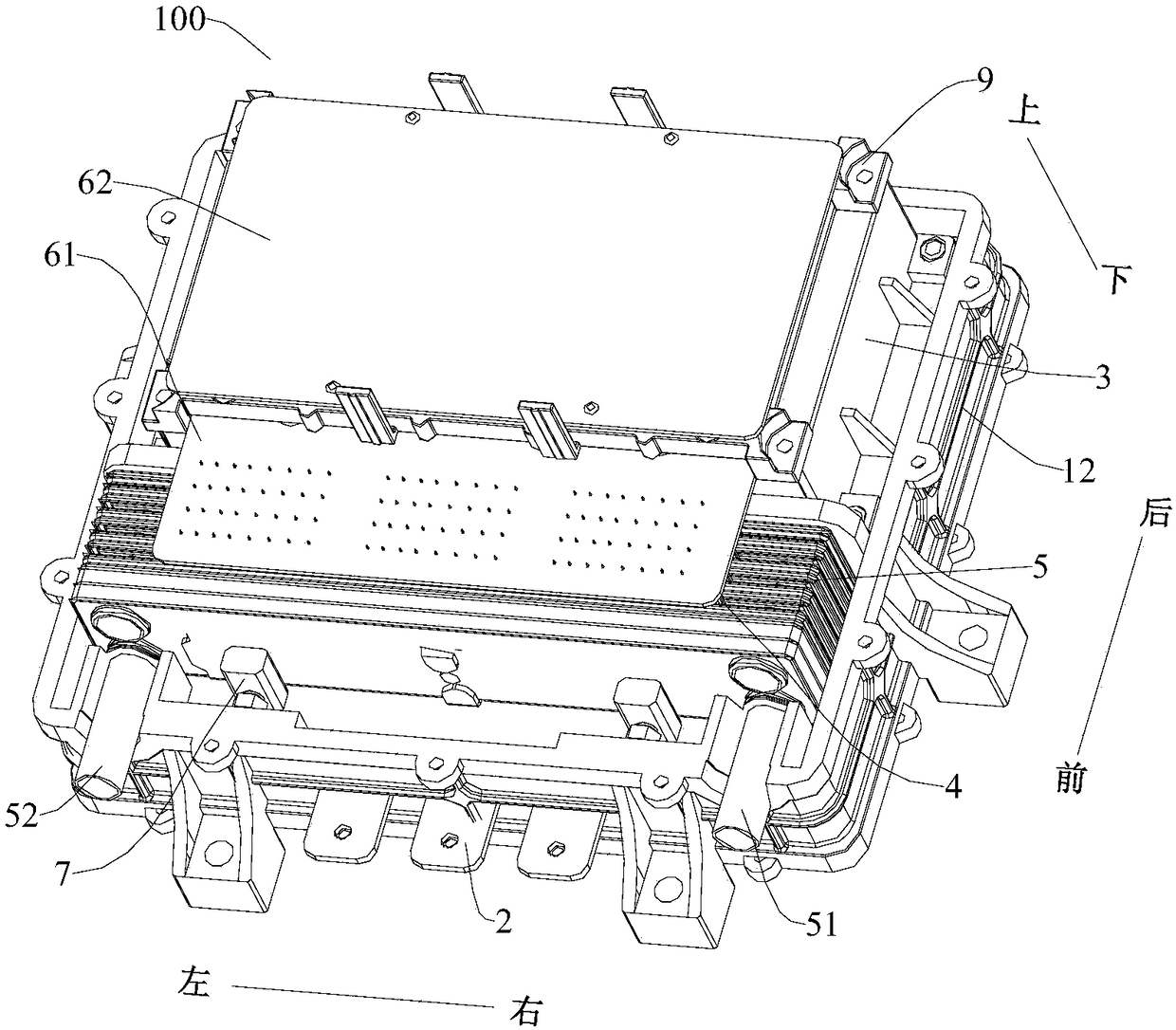

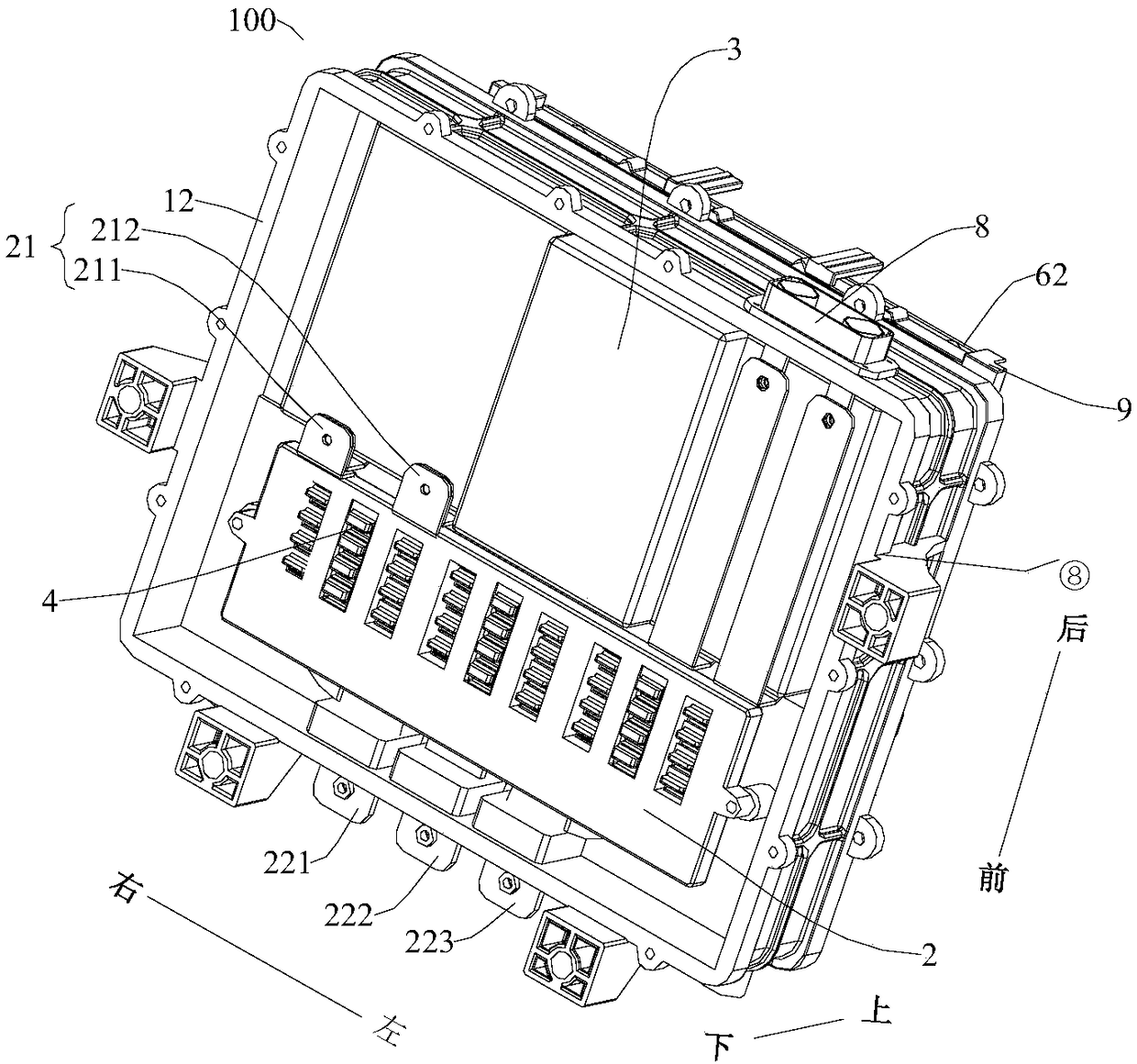

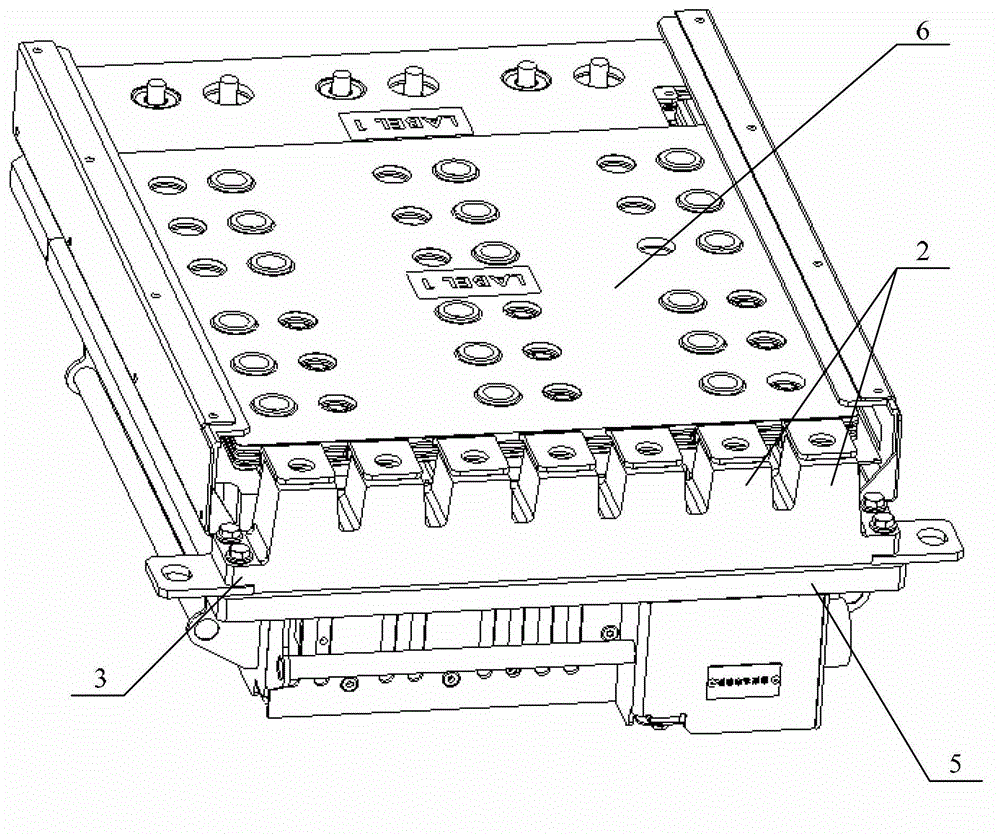

Load controller and electromobile with load controller

ActiveCN108075672ASmall footprintSmall spaceSemiconductor/solid-state device detailsConversion constructional detailsCapacitanceBusbar

The invention discloses a load controller and an electromobile with the load controller. The load controller comprises a casing, a busbar module, a capacitor, an IGBT power module, a heat radiation module, a driving circuit board and a control circuit board; the busbar module comprises a DC busbar and an AC busbar connected to a load; the capacitor is connected with an external DC power supply andthe DC busbar; the input end of each IGBT is connected with the DC busbar, and the output end of each IGBT is connected with the AC busbar; the heat radiation module comprises radiating fins, each IGBT in the same column is clamped between two adjacent radiating fins; the driving circuit board is electrically connected with each IGBT; the control circuit board is connected with the driving circuit board; and the busbar module, the IGBT power module, the heat radiation module, the driving circuit board and the control circuit board are mounted on the casing; According to the load controller ofthe invention, the heat radiation efficiency is high, the heat radiation effect is good, and the size is small.

Owner:BYD SEMICON CO LTD

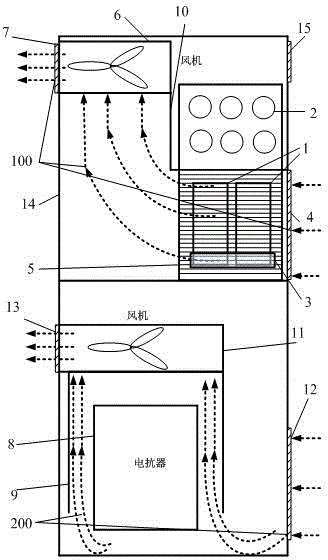

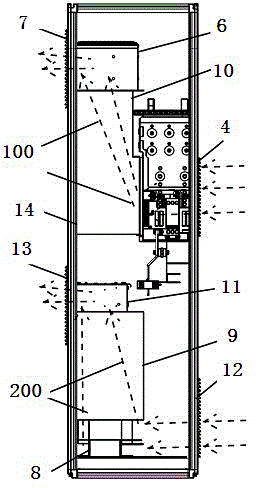

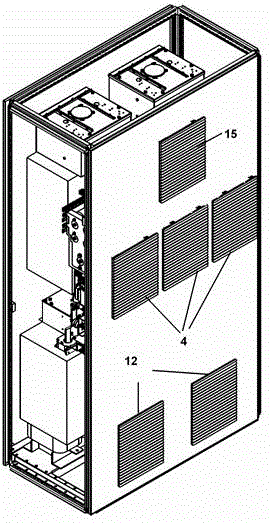

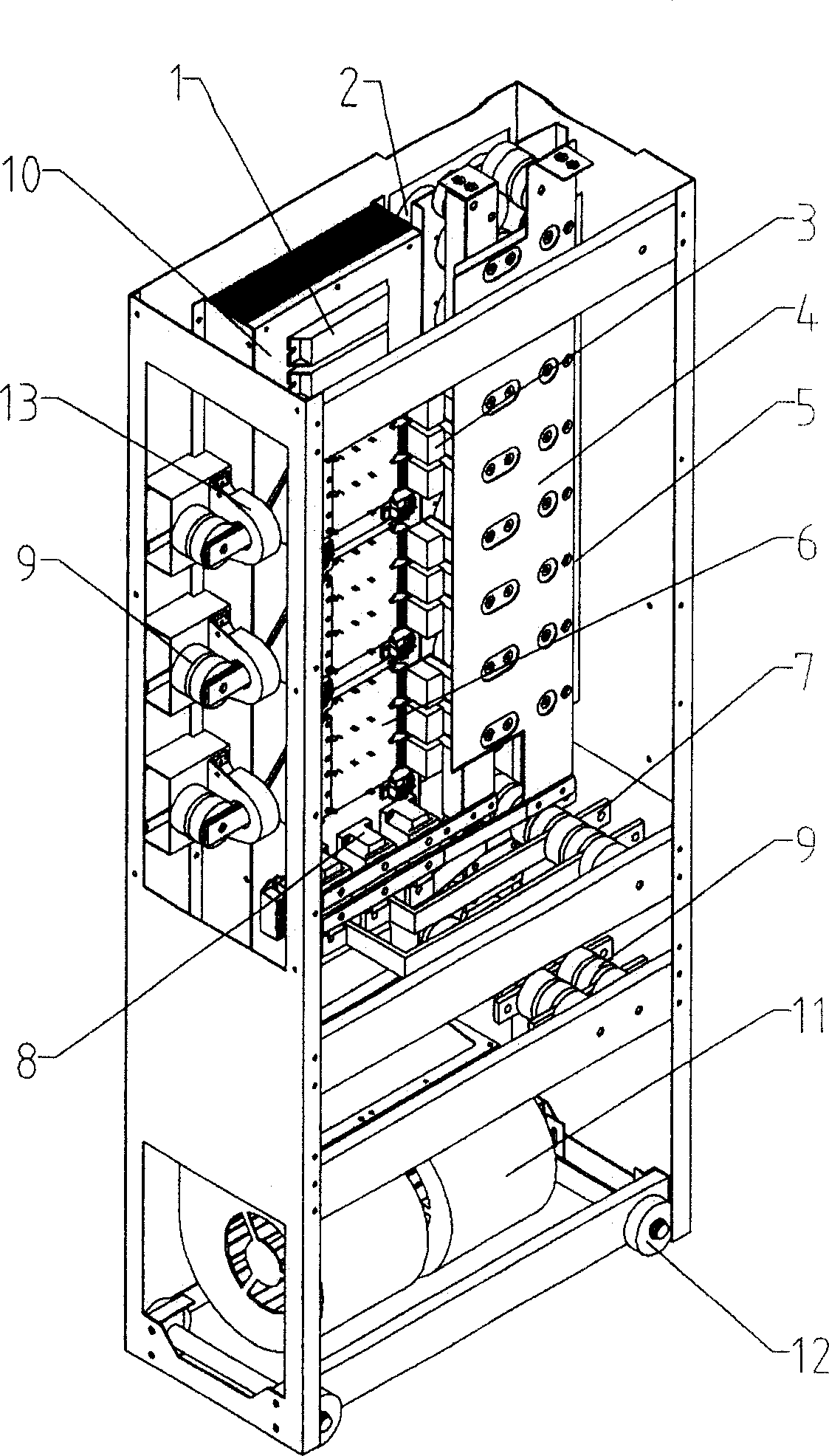

Converter power cabinet

InactiveCN104868702ASmall pressure lossImprove pressure lossModifications for power electronicsWind energy generationNuclear engineeringIgbt power modules

The invention discloses a converter power cabinet. A sealed cooling system comprises an IGBT power module, a fan, a reactor, an air damper and a cabinet body. the power cabinet is divided into an upper independent cooling air duct and a lower independent cooling air duct, the upper part is a power module cooling air duct 100, the lower part is a reactor cooling air duct 200, the two air ducts are isolated mutually, mutual influences are avoided, the air duct length can be reduced as two independent air ducts are divided, pressure losses of the fan are reduced, and the cooling efficiency is improved.

Owner:ZHEJIANG HAIDE NEW ENERGY

Method and apparatus for estimating the temperature of a semiconductor chip

ActiveUS9689754B2Versatile estimationOptimized areaSemiconductor/solid-state device detailsThermometers using electric/magnetic elementsPower semiconductor deviceComputer module

Owner:K B ELECTRONICS INC

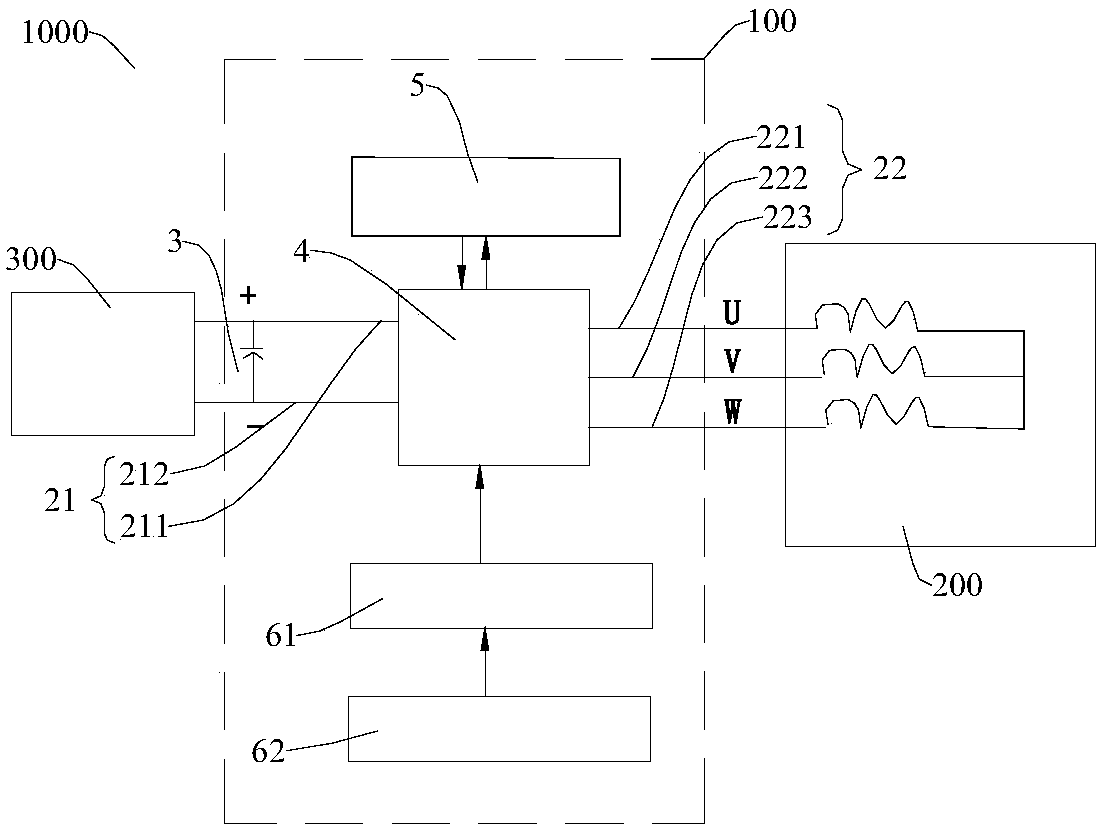

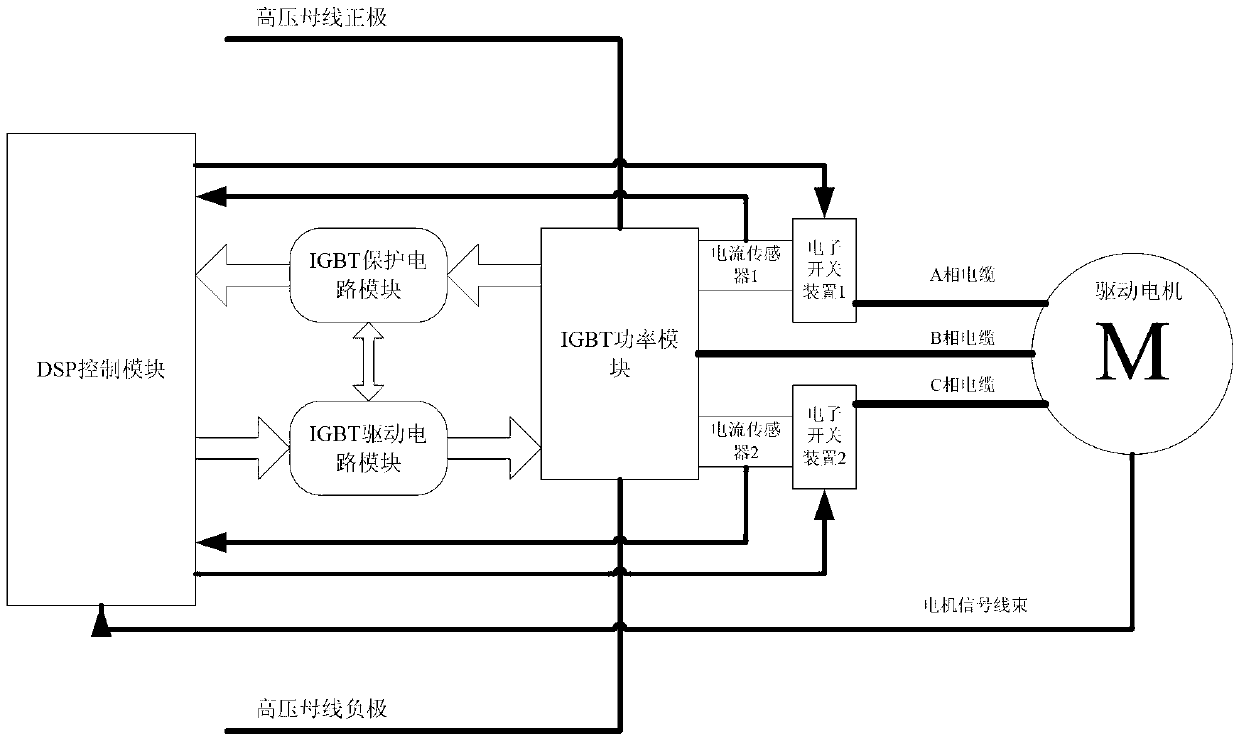

Passive rectification protection system of electric vehicle motor controller

ActiveCN102991374AExtended service lifeSimple structureSpeed controllerElectric energy managementCurrent sensorElectronic switch

The invention relates to a passive rectification protection system of an electric vehicle motor controller. The passive rectification protection system comprises a motor controller, wherein the motor controller comprises an IGBT (Insulated Gate Bipolar Transistor) power module which is internally provided with a high-speed diode, an IGBT protection circuit module, an IGBT drive module and a DSP (Digital Signal Processor) control module, a current sensor and an electronic switching device are arranged on any two phases in a three-phase cable between the IGBT power module and a drive motor in a serial connection way, the current sensor is used for transferring a current signal to the DSP control module, and meanwhile, the DSP control module outputs a level signal for controlling on-off of the electronic switching device. With the adoption of the passive rectification protection system, the problem that the traditional electric vehicle motor controller is easy to damage in the state of passive rectification of a whole vehicle is solved, thus improving the using reliability of the motor controller; and the passive rectification protection system can be widely applied to the field of the electric vehicle motor controllers.

Owner:奇瑞新能源汽车股份有限公司

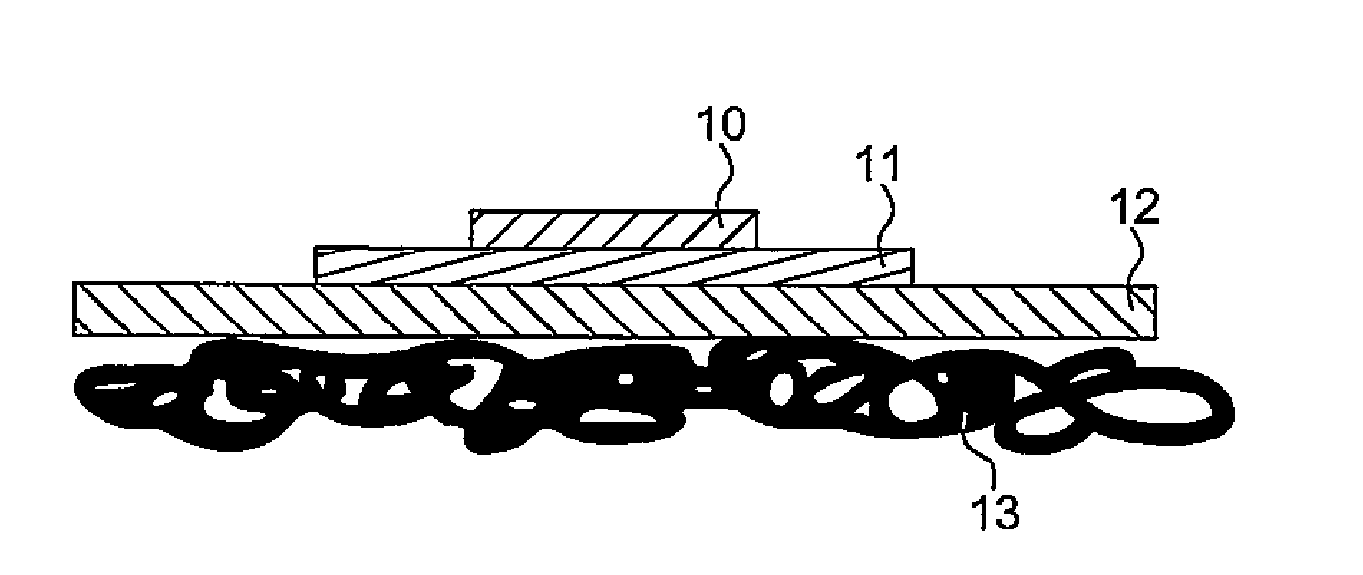

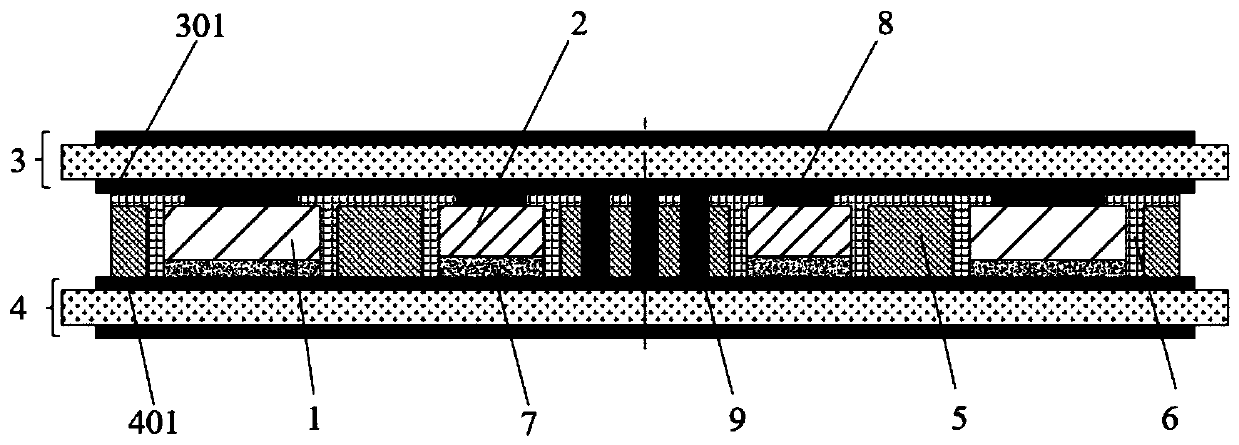

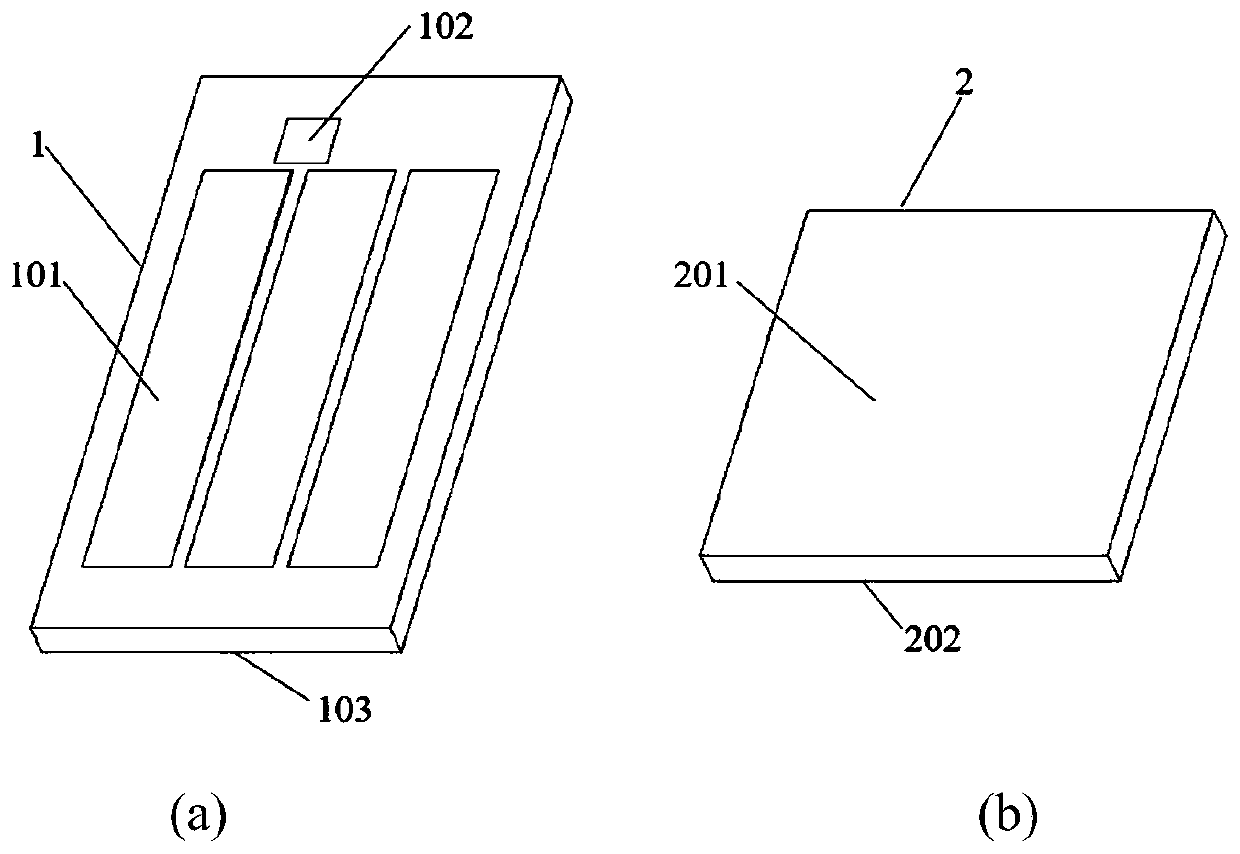

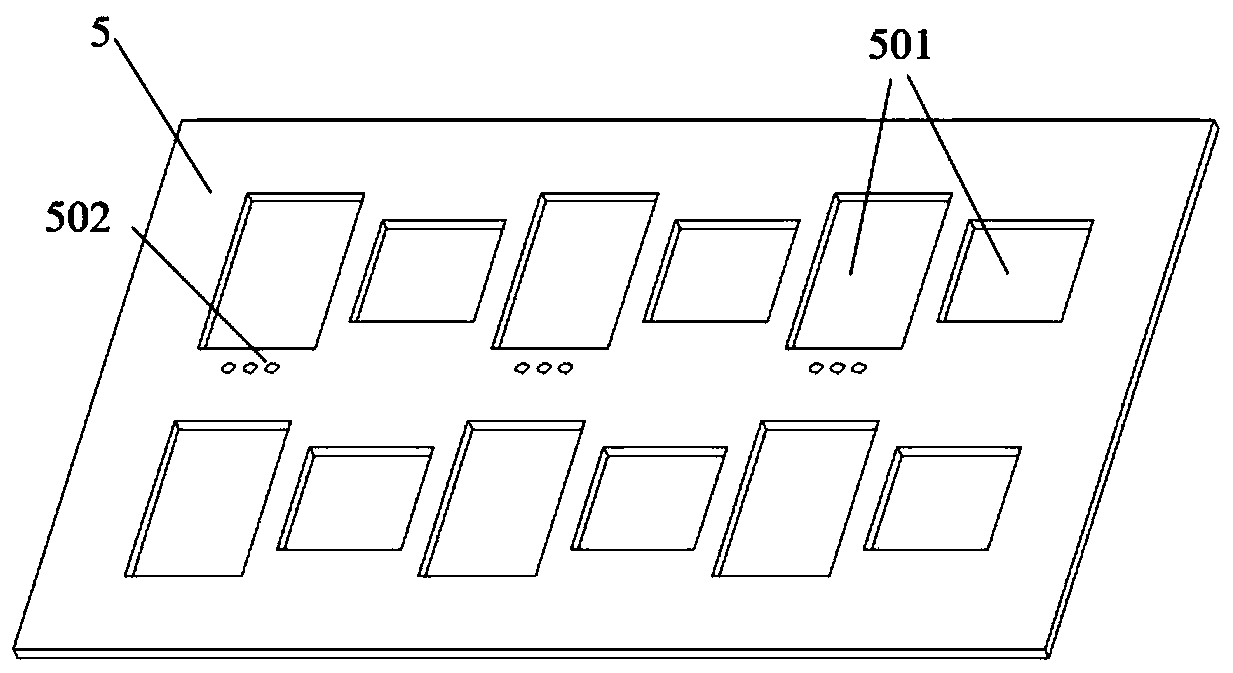

Embedded double-sided interconnection power module packaging structure and manufacturing method

ActiveCN110854103AReduce package sizeImprove power densitySemiconductor/solid-state device detailsSolid-state devicesEngineeringIgbt power modules

The invention discloses an embedded double-sided interconnection power module packaging structure and a manufacturing method. The embedded double-sided interconnection power module packaging structureis composed of an IGBT power chip, a diode chip, an upper DBC substrate, a lower DBC substrate, an intermediate adapter plate, a dielectric filling layer, a solder layer, a rewiring layer, via hole conductive metal and power terminals. According to the invention, the IGBT power chip and the diode chip are connected with the lower DBC substrate through the solder layer; meanwhile, a rectangular frame is manufactured on the intermediate adapter plate, and the IGBT power chip and the diode chip are embedded into the intermediate adapter plate by filling dielectric materials; the upper surfaces of the chip and the adapter plate are coated with conductive metal layers; the upper surface and the lower surface of the intermediate adapter plate are interconnected with the upper DBC substrate andthe lower DBC substrate respectively; and the power terminals are led out from the conductive copper-clad layers of the upper DBC substrate and the lower DBC substrate to obtain an embedded double-sided interconnection power module. According to the invention, double-sided heat dissipation of the IGBT power module can be realized, and the heat dissipation efficiency is improved; and bonding wiresare not used, so that the parasitic inductance of the module is reduced.

Owner:BEIJING UNIV OF TECH

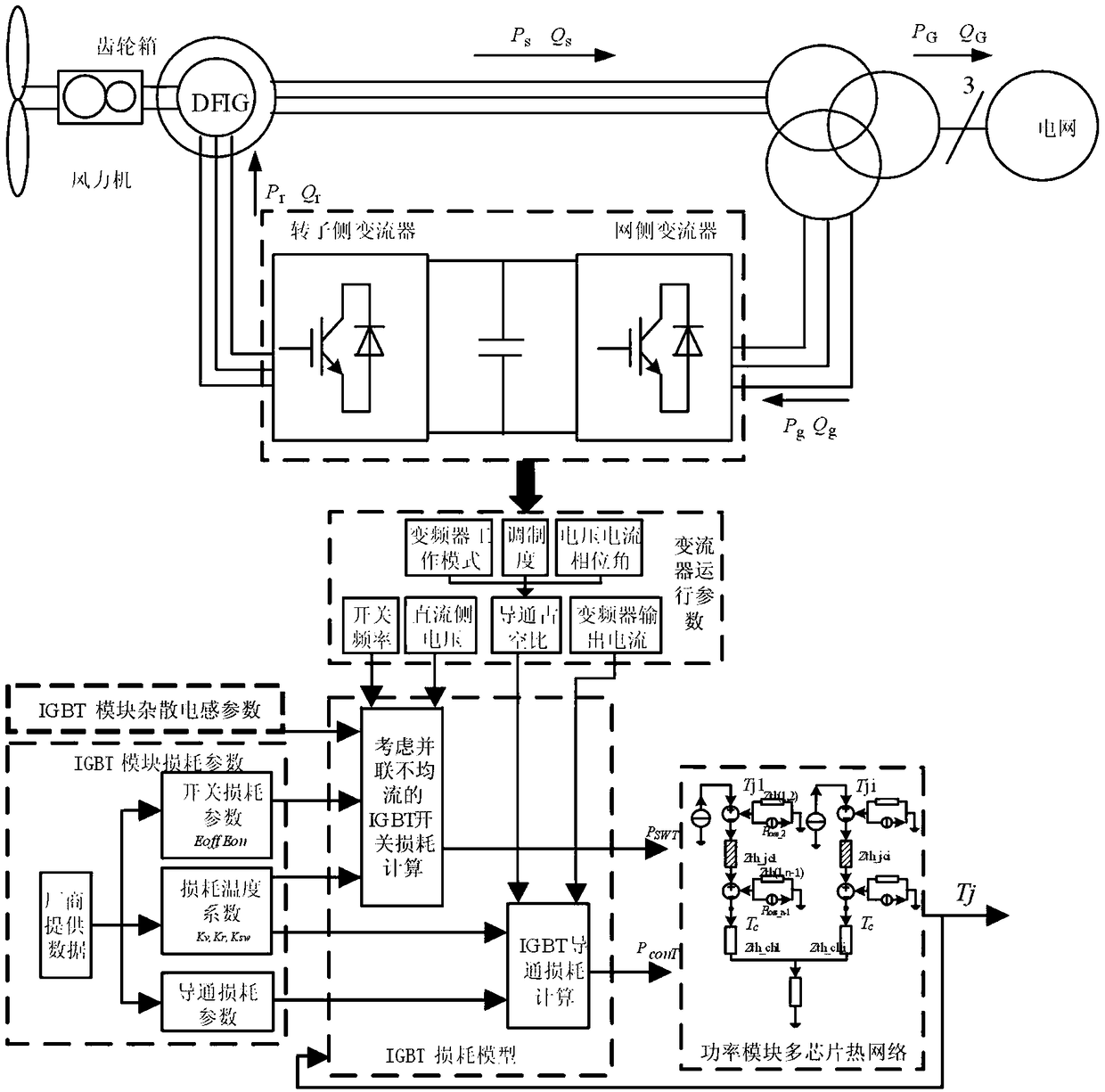

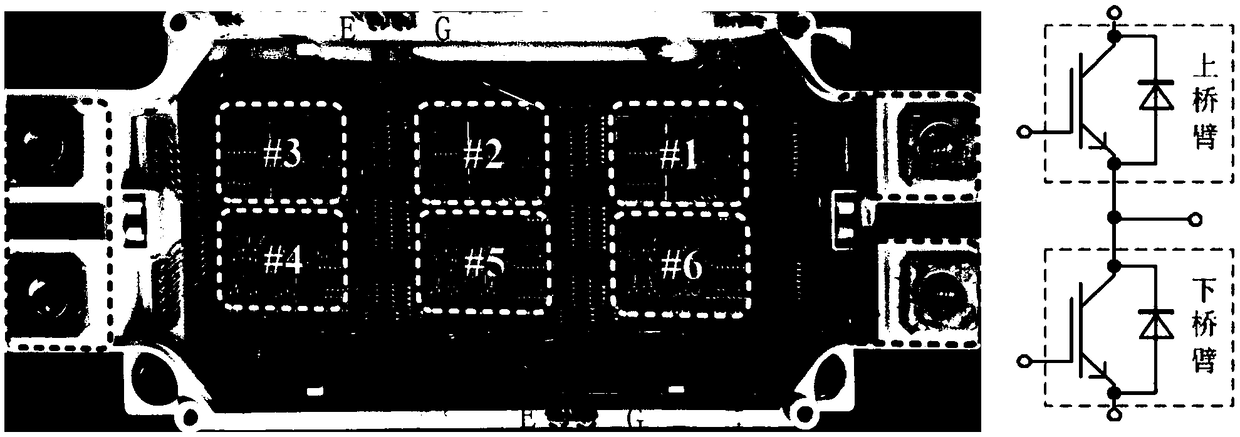

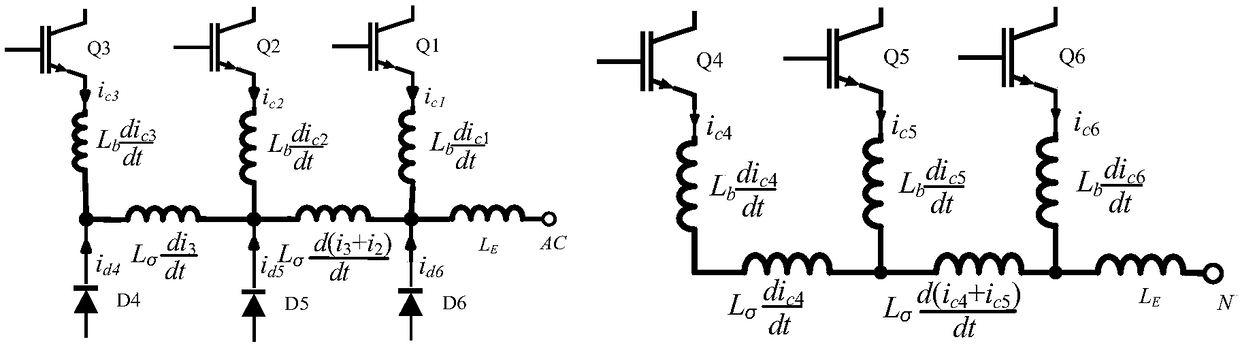

Dynamic junction temperature calculation method of IGBT power module of wind power converter considering the influence of stray inductance

ActiveCN109274255AImproved Thermal Management Control StrategiesAccurately reflectSingle network parallel feeding arrangementsWind energy generationNew energyStray inductance

The invention relates to a method for calculating the dynamic junction temperature of an IGBT power module of a wind power converter considering the influence of stray inductance, The invention belongs to the technical field of high-power power electronic device reliability for new energy power generation. The method comprises the following steps: S1, establishing an equivalent circuit model of anIGBT module according to the dynamic uneven current between parallel multi-chips caused by stray inductors; S2: deriving The mathematical relationship between the stray inductance parameters and theswitching-on loss; S3: Introducing the equivalent thermal coupling impedance to establish the thermal network model considering the thermal coupling between chips; 4, establishing a dynamic junction temperature calculation model of that IGBT module, feeding the junction temperature distribution result back to a mathematical relation model of los, and iteratively obtaining the dynamic junction temperature distribution among chips in the IGBT module. The invention can accurately reflect the dynamic heat distribution inside the IGBT power module, effectively characterize the heat weak links inside the module, and improve the heat management control strategy of the wind power converter, thereby improving the reliability thereof.

Owner:重庆平创半导体研究院有限责任公司

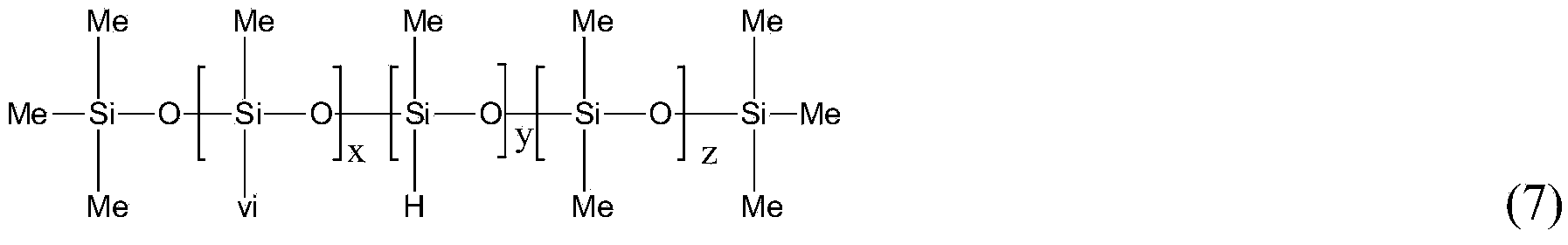

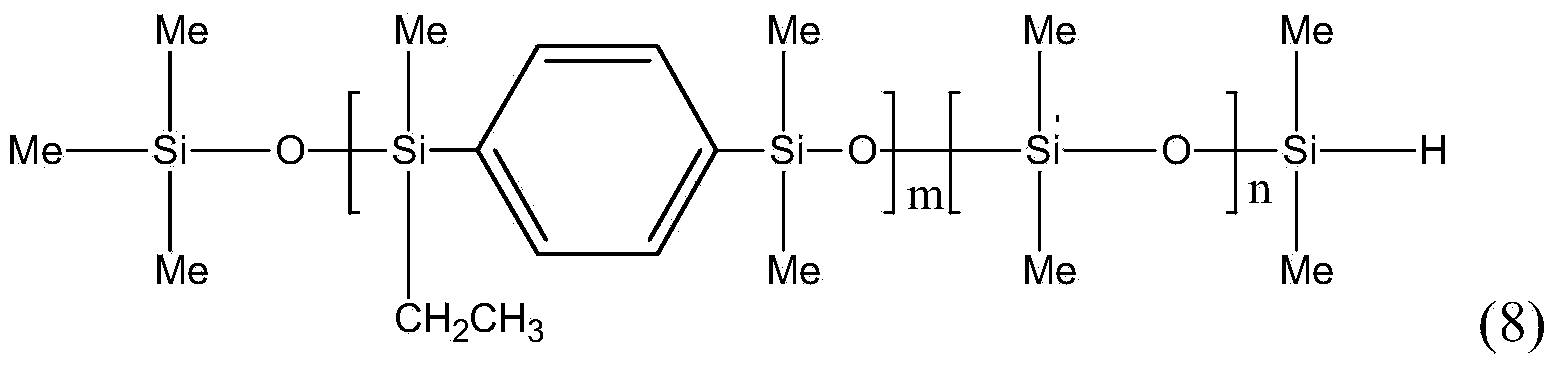

High-strength IGBT high-power module encapsulation silica gel and encapsulation process thereof

InactiveCN104178080AHigh strengthLow water absorptionSemiconductor/solid-state device detailsSolid-state devicesWeather resistancePower flow

The invention provides high-strength IGBT high-power module encapsulation silica gel and an encapsulation process thereof. The encapsulation gel is high in strength, can resist outside impact, is excellent in weather resistance and has high compatibility and adhesion strength with an IGBT power module. An effect of protecting and insulating the IGBT power module is effectively achieved. The encapsulation requirement of the high-power high-frequency high-voltage large-current IGBT power module is met. The silica gel provided by the invention is a two-component heating and curing adhesive and is prepared by mixing a component A and a component B according to a ratio of 1:1.

Owner:YANTAI DEBANG ADVANCED SILICON MATERIALS

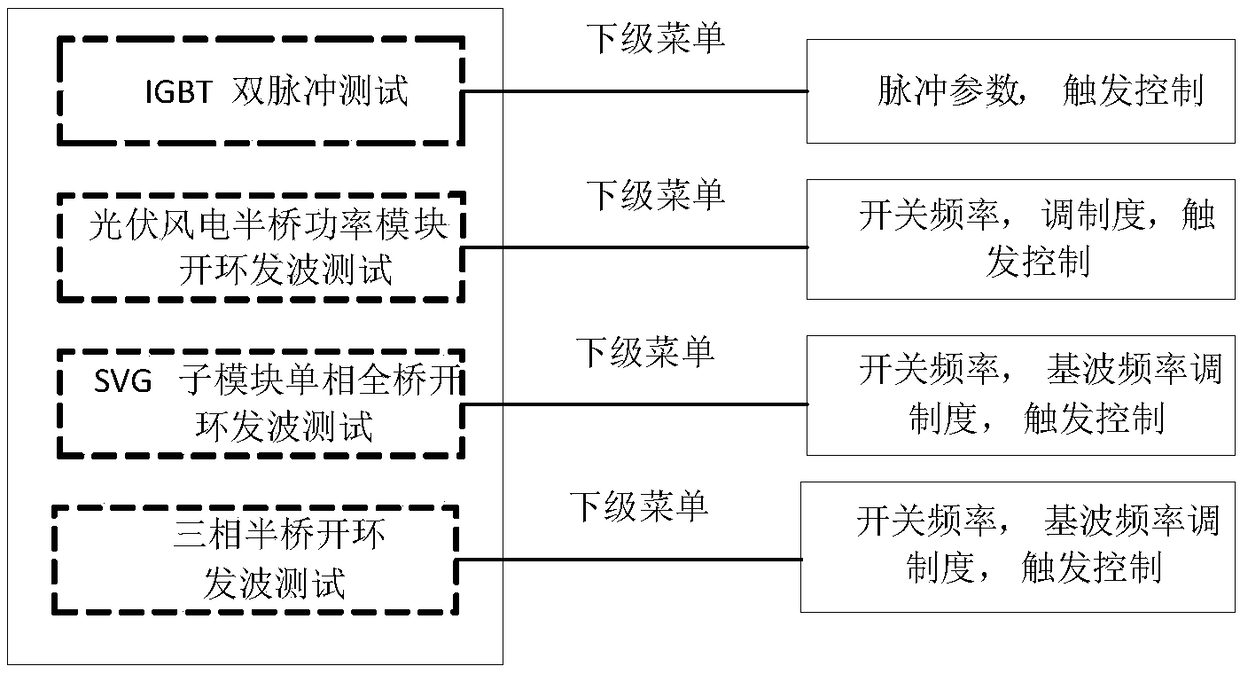

IGBT power module test system

InactiveCN109143009AVersatilityEasy to carryIndividual semiconductor device testingCommunication interfaceComputer module

The invention provides an IGBT power module test system. The system comprises an optical fiber communication interface, an acquisition interface and a fault wave recording interface, wherein the optical fiber communication interface is used for connecting an SVG power module / a flexible direct-current power module, the acquisition interface is used for acquiring the output voltage of the SVG powermodule / the flexible direct-current power module, and the wave fault recording interface is connected with a fault wave recording module and is used for performing wave recording on the SVG power module / the flexible direct-current power module; the output end of the fault wave recording module is connected with a computer through a photoelectric conversion communication module; the computer is used for displaying the test results of the SVG power module / the flexible direct-current power module; the system further comprises an optical fiber driving interface used for connecting a wind power converter power module / photovoltaic inverter power module; and the optical fiber driving interface is used for transmitting driving signals to test the wind power converter power module / photovoltaic inverter power module. The test system of the invention is suitable for testing various power modules, and has the advantages of universality, portable convenience, stable work, and high safety during test.

Owner:XJ ELECTRIC +2

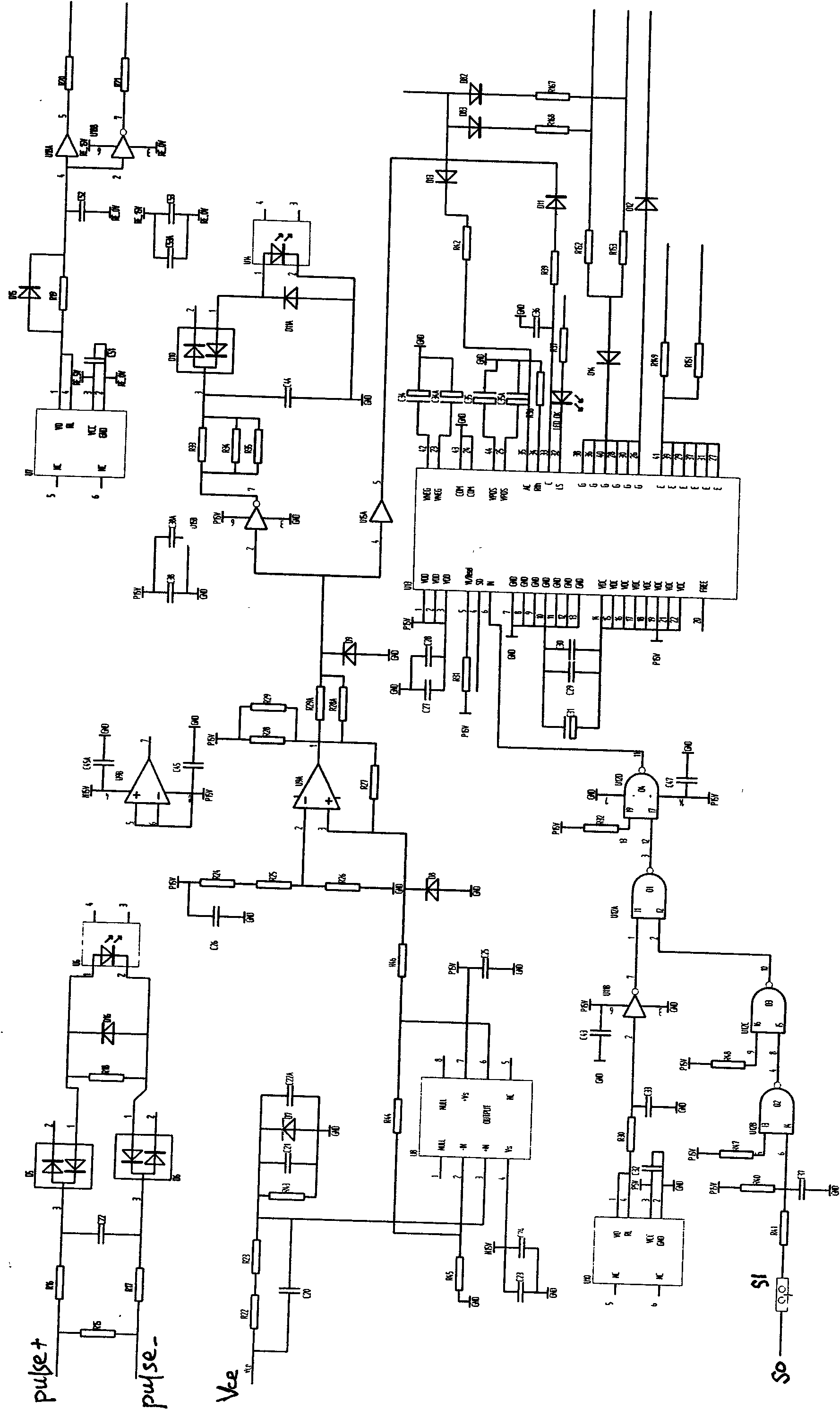

Simplified driving circuit of high-voltage converter

InactiveCN101635508AMeet needsAvoid damageDc-dc conversionElectric variable regulationFour quadrantsHigh voltage igbt

The invention relates to a high-voltage converter, in particular to a simplified driving circuit of the high-voltage converter, aiming at solving the problem of the driving circuit of the existing immature high-voltage converter. The simplified driving circuit comprises the driving circuit, a power supply circuit and a protective circuit; besides, the structure of the function circuits of the simplified driving circuit of the high-voltage converter has the self characteristics, the simplified driving circuit is essentially characterized in that an optical fiber emitter and an optical fiber receiver are respectively adopted in the driving circuit and the protective circuit, and a driving chip U13 with the functions of power supply output and high voltage isolation is selected for use, so that the high voltage isolation between the simplified driving circuit of the high-voltage converter and other circuits can be effectively realized, and the high voltage and heavy current of a high voltage IGBT flowing through the high-voltage converter is effectively prevented from damaging other circuit connected with the simplified driving circuit. The electrical isolation can reach 10kV; the voltage state of a main loop can be feedback, and an IGBT power module can be protected to run safely; furthermore, at present, the driving circuit can be successfully assembled on four quadrants and an inverter module of a motor train unit.

Owner:CRRC YONGJI ELECTRIC CO LTD

Medium power low voltage frequency converter based on insulation grating bipolar transistor

InactiveCN1988338ASmall footprintSmall stray inductanceCircuit arrangements on support structuresAc-dc conversionCapacitanceLow voltage

This invention relates to a mid-power low voltage frequency converter based on an insulation grid dual polarity transistor including: a mean-voltage resistor, a DC capacitor, an absorption capacitor, a cascade bus, a cascade bus insulation board, an IGBT power module, an input power terminal, a redtifying diode, an output power terminal, a radiator, a fan, a wheel and a current sensor, which is advantaged that the structure is compact, the volume is small, power density is big and easy to be installed.

Owner:BEIJING ARITIME INTELLIGENT CONTROL +1

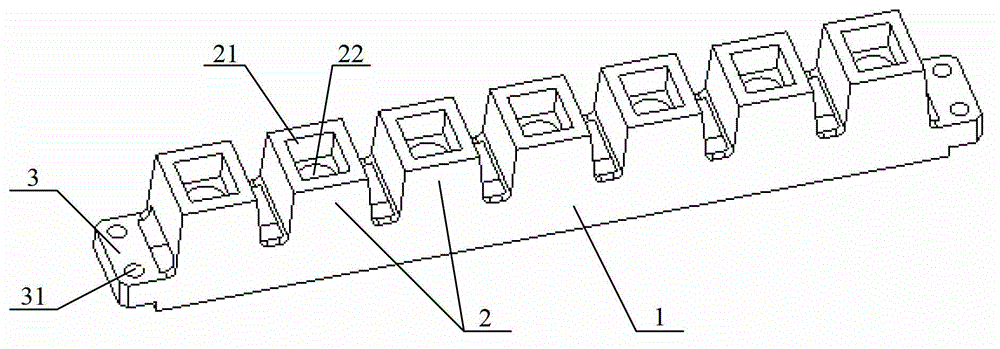

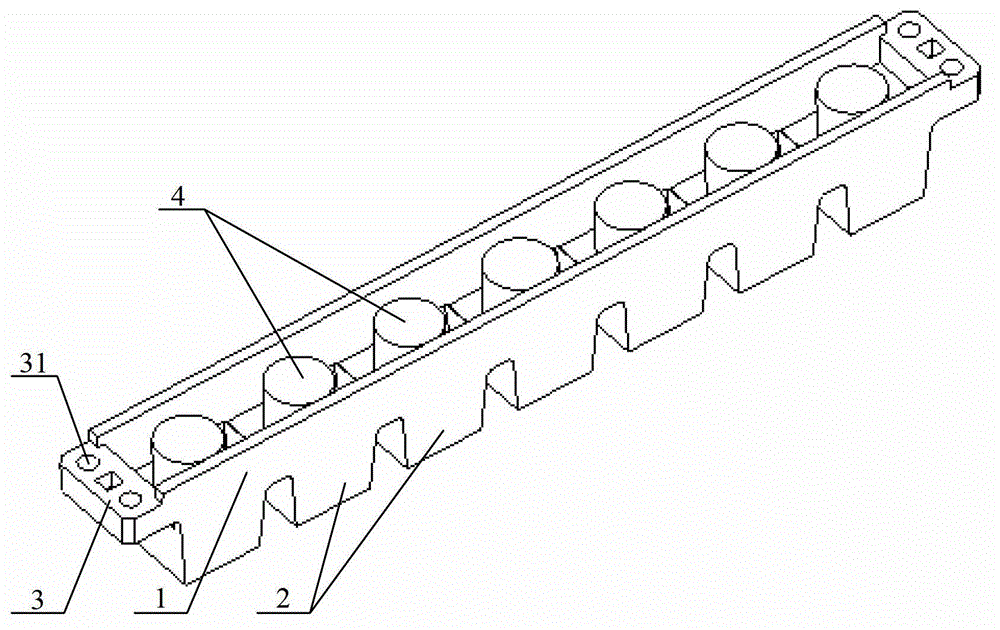

Composite busbar insulation supporting device and IGBT power module

ActiveCN103915795AAvoid deformationImprove electricity safetyBus-bar installationPower conversion systemsBusbarComputer module

The invention provides a composite busbar insulation supporting device and an IGBT power module. The composite busbar insulation supporting device comprises a strip-shaped insulation supporting body, wherein a plurality of bosses are arranged on the upper surface of the insulation supporting body at intervals, the bosses are provided with nut installation countersinks and bolt blind holes, and the two ends of the insulation supporting body are provided with installation lugs which are provided with installation holes for installing the IGBT power module. By means of the composite busbar insulation supporting device and the IGBT power module, due to the fact that the bosses are arranged on the strip-shaped insulation supporting body, and the nut installation countersinks and the bolt blind holes are formed in the bosses, the nut installation countersinks and the bolt blind holes can be used for electrically separating bolts and nuts used for fastening the composite busbar, electric safety of the IGBT power module is improved, the insulation supporting body can support the interface of the composite busbar and prevent the composite busbar from deformation due to stress.

Owner:CRRC YONGJI ELECTRIC CO LTD

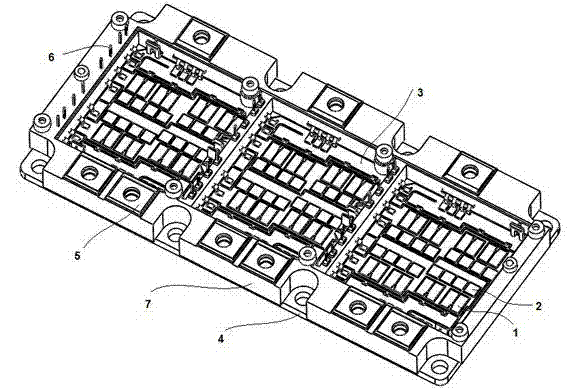

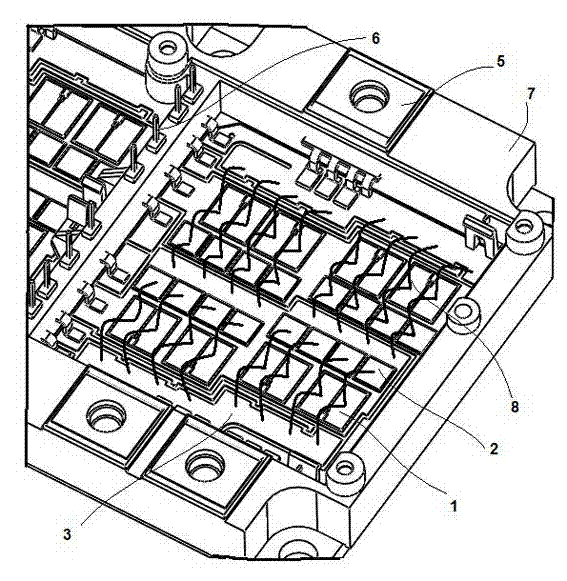

IGBT power module structure

InactiveCN106253701AReduce volumeEasy maintenanceConversion constructional detailsOvervoltageStray inductance

The invention discloses an IGBT power module structure. The IGBT power module structure includes an IGBT module set, an IGBT driving board, a radiator of the IGBT module set, direct-current bus-bars connected with IGBT modules, and alternating-current copper bars connected in parallel with the IGBT modules, wherein the IGBT modules are arranged at two sides of the radiator. According to the IGBT power module structure, the stray inductance of the IGBT modules can be decreased, the turn-off overvoltage of the IGBT modules can be decreased; the IGBT modules can be arranged at the two sides of the radiator, so that the structure of the IGBT power module structure is more compact, and the power density of the IGBT power module structure can be improved; and the paths of the alternating-current copper bars are the same, so that the current equalization performance of IGBTs can be better, and reliability is higher.

Owner:ZHEJIANG HAIDE NEW ENERGY

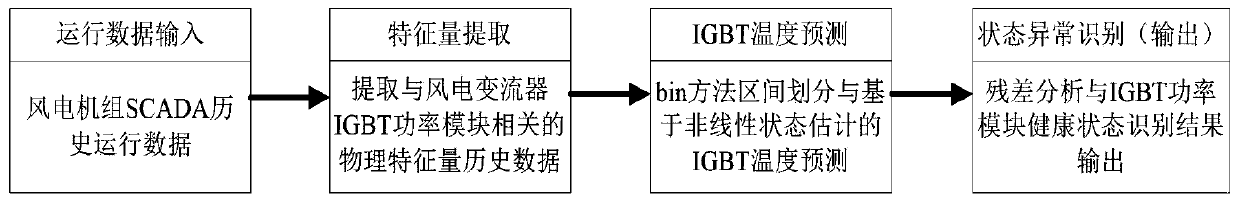

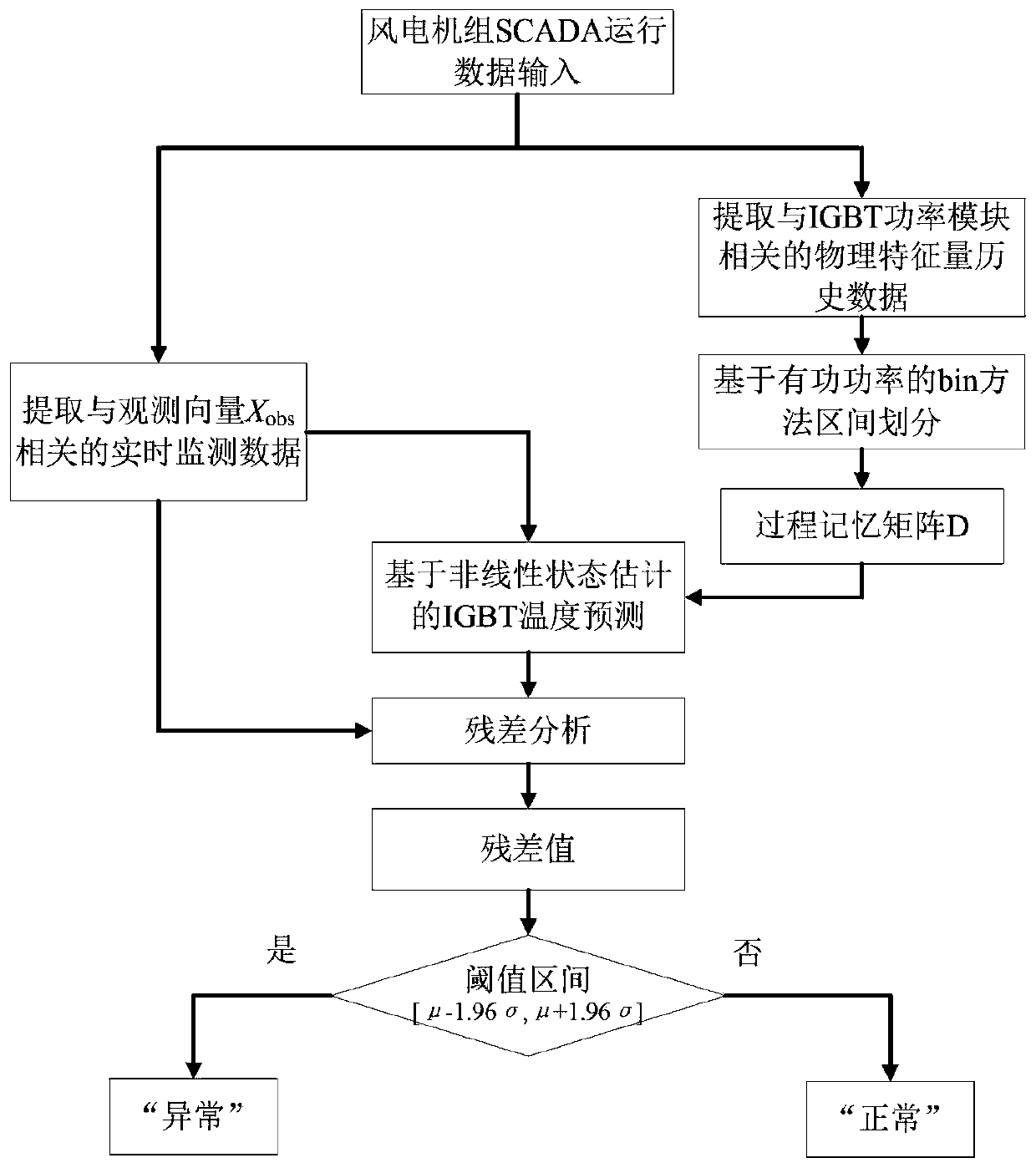

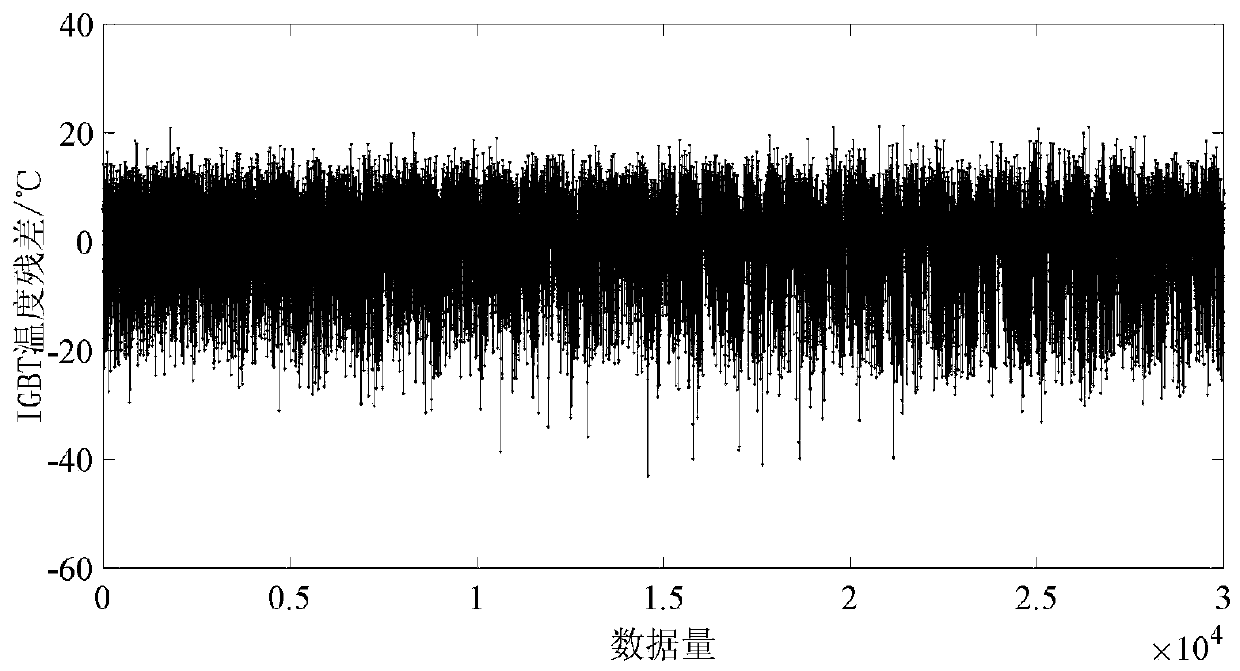

Method for identifying the abnormal health state of IGBT power module of wind power converter

InactiveCN110703025AAchieve forecastGuaranteed uptimeElectrical testingComplex mathematical operationsSCADAIgbt power modules

The invention relates to a method for identifying the abnormal health state of an IGBT power module of a wind power converter, and belongs to the technical field of wind turbine generator state monitoring. The method comprises three parts including a wind power converter monitoring data extraction part, an IGBT temperature prediction part, and a residual analysis and abnormal result identificationpart. On the basis of extracting historical operation data of various physical characteristic quantities such as active power and IGBT temperature in a wind turbine generator SCADA system, the activepower is taken as an interval division basis, and the interval division of the historical operation data of the various physical characteristic quantities is realized by utilizing a bin method, so that a process memory matrix is formed; the various extracted physical characteristic quantities are taken as observation vectors, and a nonlinear state estimation method is adopted to realize prediction of the IGBT temperature; and the actual monitoring value of the IGBT temperature is combined with the predicted value to obtain a residual error, and when the residual error value exceeds a threshold value, an abnormal result is given.

Owner:CHONGQING UNIV

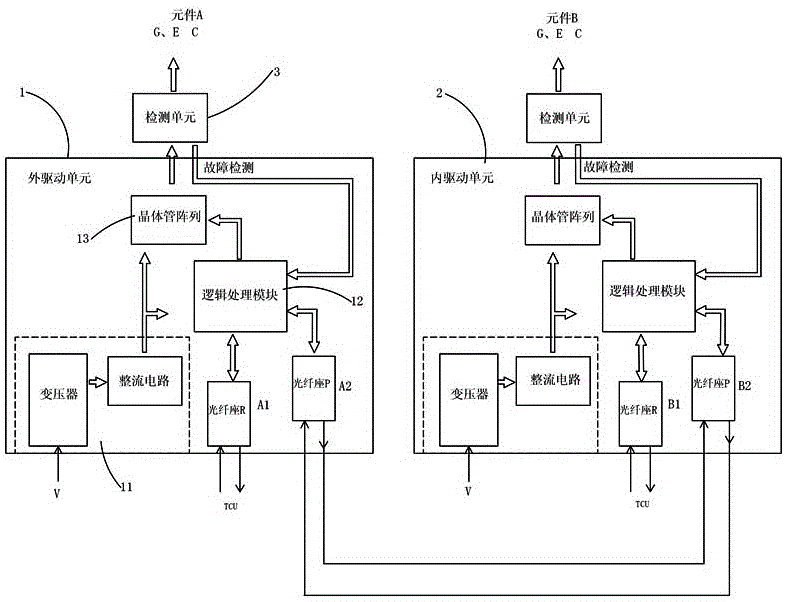

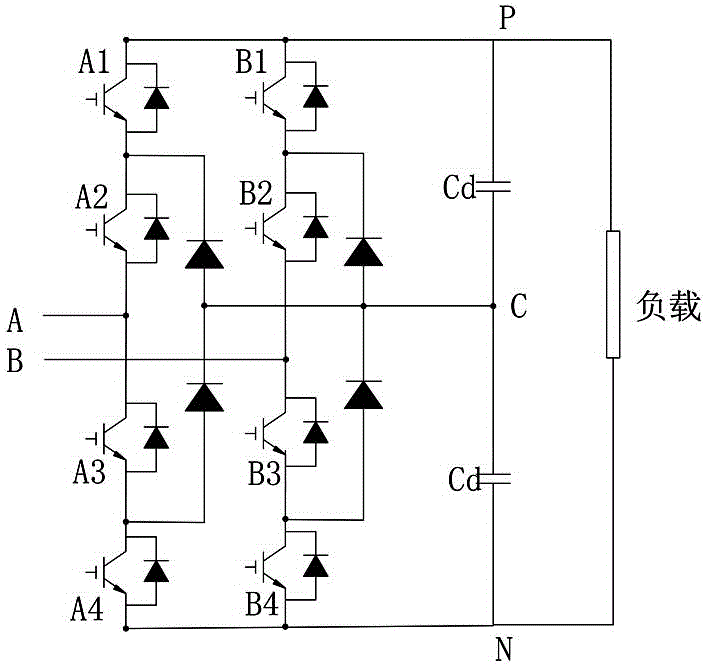

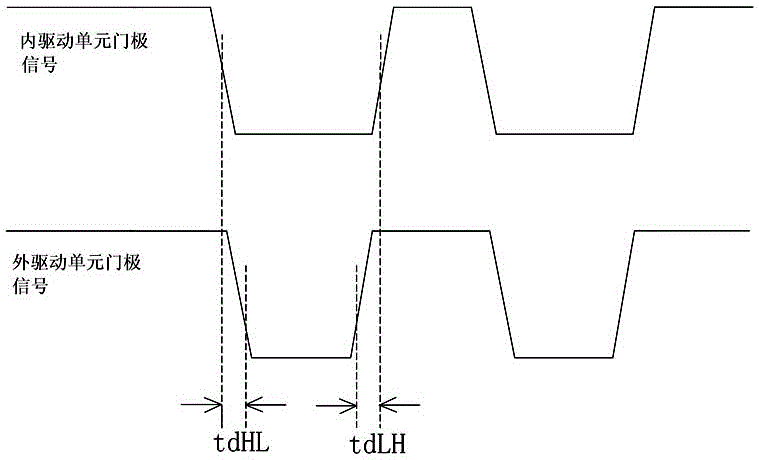

Driver of three-level IGBT power module and control method thereof

ActiveCN106803724AReliable drive workImprove stability and reliabilityEfficient power electronics conversionAc-dc conversionThree levelComputer module

The invention discloses a driver of a three-level IGBT power module. The driver comprises an outer drive unit corresponding to an outer IGBT element of the three-level IGBT power module and an inner drive unit corresponding to an inner IGBT element. The outer drive unit is connected and communicates with the inner drive unit. The outer drive unit and the inner drive unit are each provided with a detection unit correspondingly, and each drive unit is in signal connection with the corresponding IGBT element through the corresponding detection unit. The driver has the advantages of high reliability, high safety and the like. The invention also discloses a control method based on the above driver. The inner drive unit and the outer drive unit are connected and communicate with each other, and control the corresponding IGBT elements respectively to be on and off according to on-off logic, wherein the on-off logic is as follows: the inner IGBT element is switched on earlier than the outer IGBT element and is switched off later than the outer IGBT element. The control method has the advantages of high reliability and the like.

Owner:ZHUZHOU CSR TIMES ELECTRIC CO LTD

IGBT (Insulated Gate Bipolar Transistor) power module specific to electromobile

InactiveCN102738138AImprove power densityImprove reliabilitySemiconductor/solid-state device detailsSolid-state devicesSilver pasteMotor controller

The invention discloses an IGBT (Insulated Gate Bipolar Transistor) power module specific to an electromobile. The IGBT power module comprises an IGBT chip, a diode chip, an insulating ceramic substrate, a power terminal, a signal terminal plastic shell and a liquid-cooling heat radiator, and is characterized in that metal layers at two sides of the insulating ceramic substrate are copper material layers or aluminum material layers, the surfaces of the metal layers are alternatively plated with nickel materials; the IGBT chip and the diode chip are sintered and welded on the insulating ceramic substrate through silver paste; and the power terminal and the signal terminal are ultrasonically welded on the metal layers of the insulating ceramic substrate. The IGBT power module disclosed by the invention is suitable for electromotor controllers of electromoibles.

Owner:嘉兴斯达微电子有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com