Induction welding method for aluminum water-cooling base plate and stainless joint

A technology of water-cooled base plate and induction welding, which is applied in the direction of welding medium, welding equipment, welding/cutting medium/material, etc. It can solve the problems of locomotives not running normally, difficult to control welding temperature, and burning out electrical components, etc. Intelligent protection, automatic welding control and safe operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

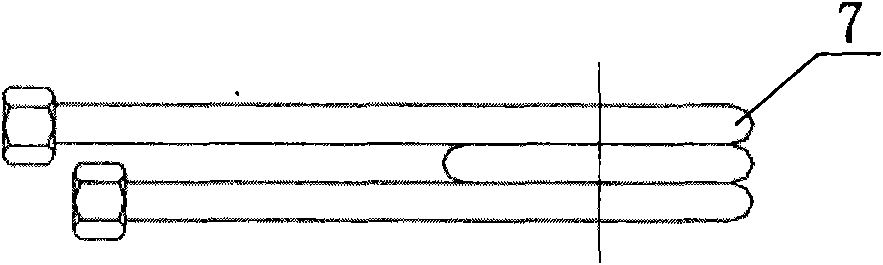

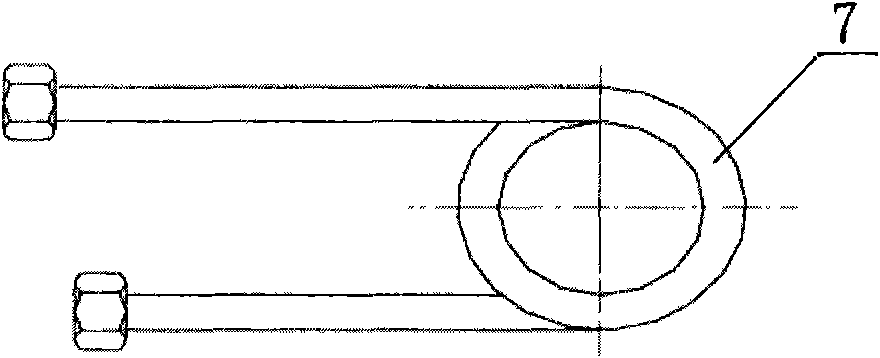

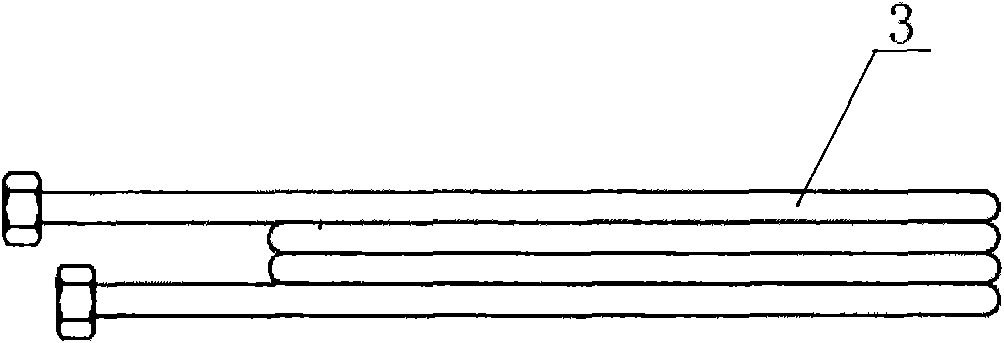

[0048] Soak the stainless steel joint and the end face of the water-cooled substrate in 8% sodium hydroxide solution at a temperature of 85°C for 20 seconds, take out the above-mentioned workpiece, and then soak it in 10% sulfuric acid solution at room temperature for 5 seconds, rinse with water The surface of the workpiece is dried, and then the stainless steel joint is installed on the end face of the water-cooled substrate. Take a zinc-aluminum alloy with a diameter of 2.5mm and a melting point of 420-480°C with a flux-cored welding wire. The calibration composition of the welding wire is as follows: Pb 0.005% MAX, Fe 0.005% MAX, Cu 0.005% MAX, Cd 0.005% MAX, Al 2.4% MAX, Zn balance. The above-mentioned welding wire is bent into a circle and placed at the root of the stainless steel joint exposing the end surface of the water-cooling substrate and the chamfer of the screw hole on the end surface of the water-cooling substrate, and the welding wire bent into a circle is tigh...

example 2

[0058] Soak the stainless steel joint and the end face of the water-cooled substrate in a 10% sodium hydroxide solution at a temperature of 75°C for 15 seconds, take out the above-mentioned workpiece, and then soak it in a 9% sulfuric acid solution at room temperature for 6 seconds, and rinse the cleaned parts with water. The surface of the workpiece is dried, and then the stainless steel joint is installed on the end face of the water-cooled substrate. Take a zinc-aluminum alloy with a diameter of 3.5mm and a melting point of 420-480°C with flux cored welding wire. The calibration composition of the welding wire is as follows: Pb 0.005% MAX, Fe 0.005% MAX, Cu 0.005% MAX, Cd 0.005% MAX, Al 2.4% MAX, Zn balance. The above-mentioned welding wire is bent into a circle and placed at the root of the stainless steel joint exposing the end surface of the water-cooling substrate and the chamfer of the screw hole on the end surface of the water-cooling substrate, and the welding wire b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com