Large-aperture pipe circular seam line-up clamp and large-aperture pipe circular seam line-up clamping method

A technology of large-diameter and matching device, which is applied in the large-diameter pipe ring seam matching device and large-diameter pipe ring seam matching field. It can solve the problems of unreasonable structure of the matching device, low operating efficiency, inconvenient use, etc., and achieve workpiece connection. Firm and reliable, satisfying the effect of fixed-point welding and continuous welding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

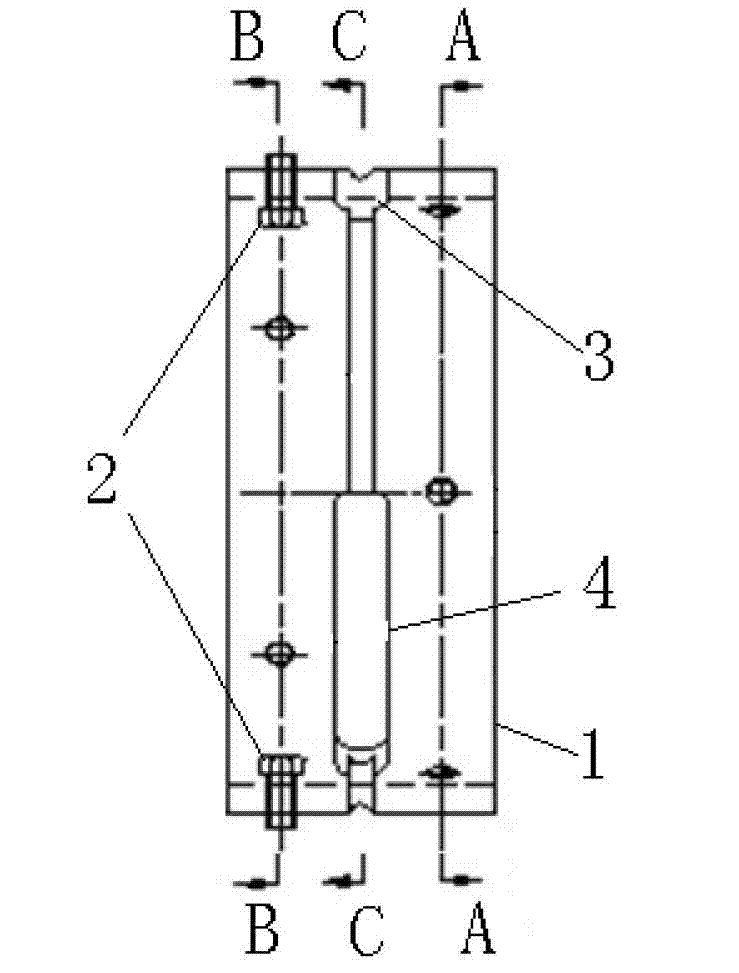

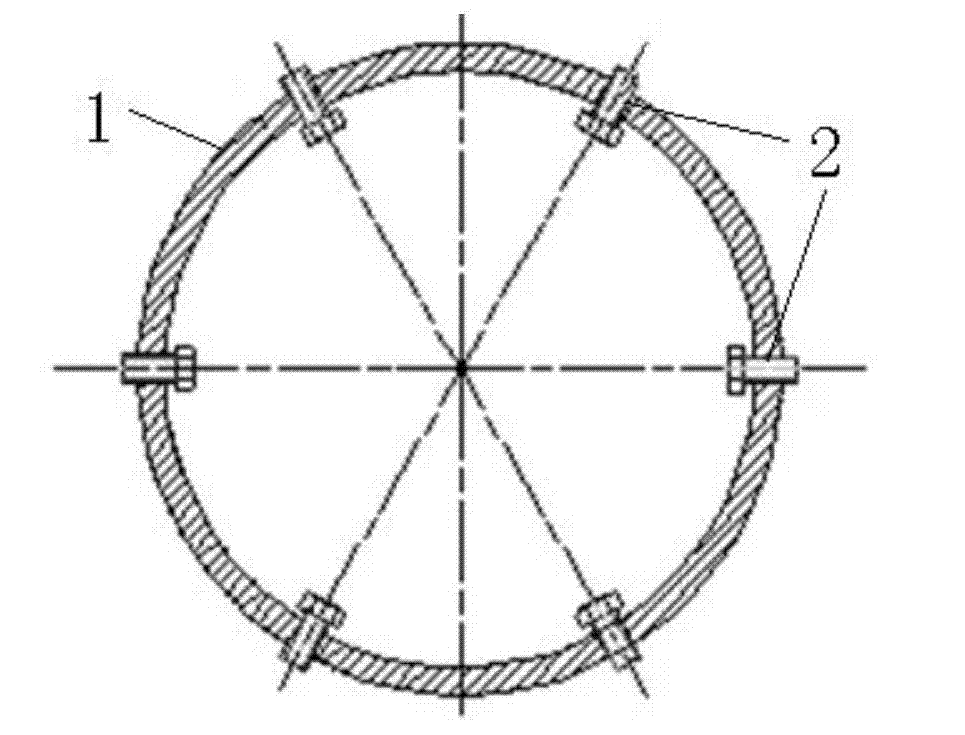

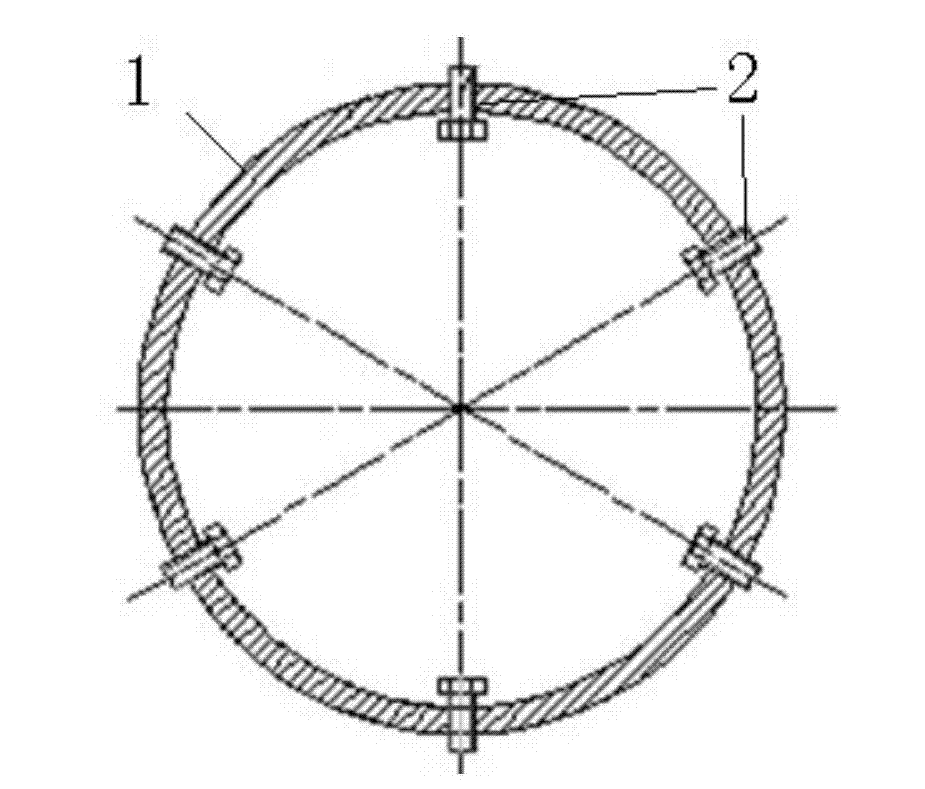

[0021] See figure 1 , figure 2 , image 3 , Figure 4 , The large-diameter pipe circumferential seam aligner structure of the present invention includes a sleeve body 1 made of steel. The sleeve body 1 is provided with two sets of tightening-adjusting mechanisms along the circumference, and each set of tightening-adjusting mechanisms is located In the circumferential section at a certain distance from the end of the sleeve body 1, each set of tightening-adjusting mechanism includes multiple sets of adjusting bolts 2 evenly arranged along the circumference (the number of adjusting bolts 2 is preferably 6-8 groups), all adjusting bolts 2 The end of the bolt cap faces the axis of the sleeve body 1, and the adjustment bolts 2 of the two sets of tightening-adjustment mechanisms are also arranged at intervals in the circumferential direction; the axial center (middle) section of the sleeve body 1 A ring of grooves 3 are arranged on the outer wall, and a plurality of observation holes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com