Dynamic junction temperature calculation method of IGBT power module of wind power converter considering the influence of stray inductance

A wind power converter and stray inductance technology, which is applied to output power conversion devices, wind power generation, electrical components, etc. and other problems, to achieve the effect of improving thermal management control strategy, optimizing package heat dissipation design, and improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

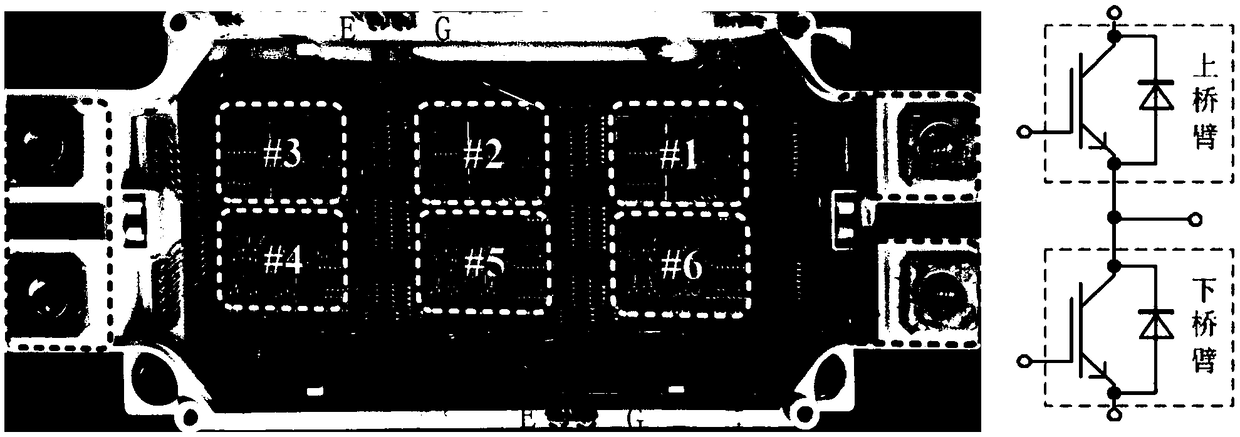

[0045] The preferred embodiment of the present invention will be described in detail below in conjunction with the accompanying drawings. This embodiment selects a certain 1.5MW wind power converter IGBT module, the specific model is FF450R17ME4, and implements it under the premise of the technical solution of the present invention. The implementation mode and specific operation process.

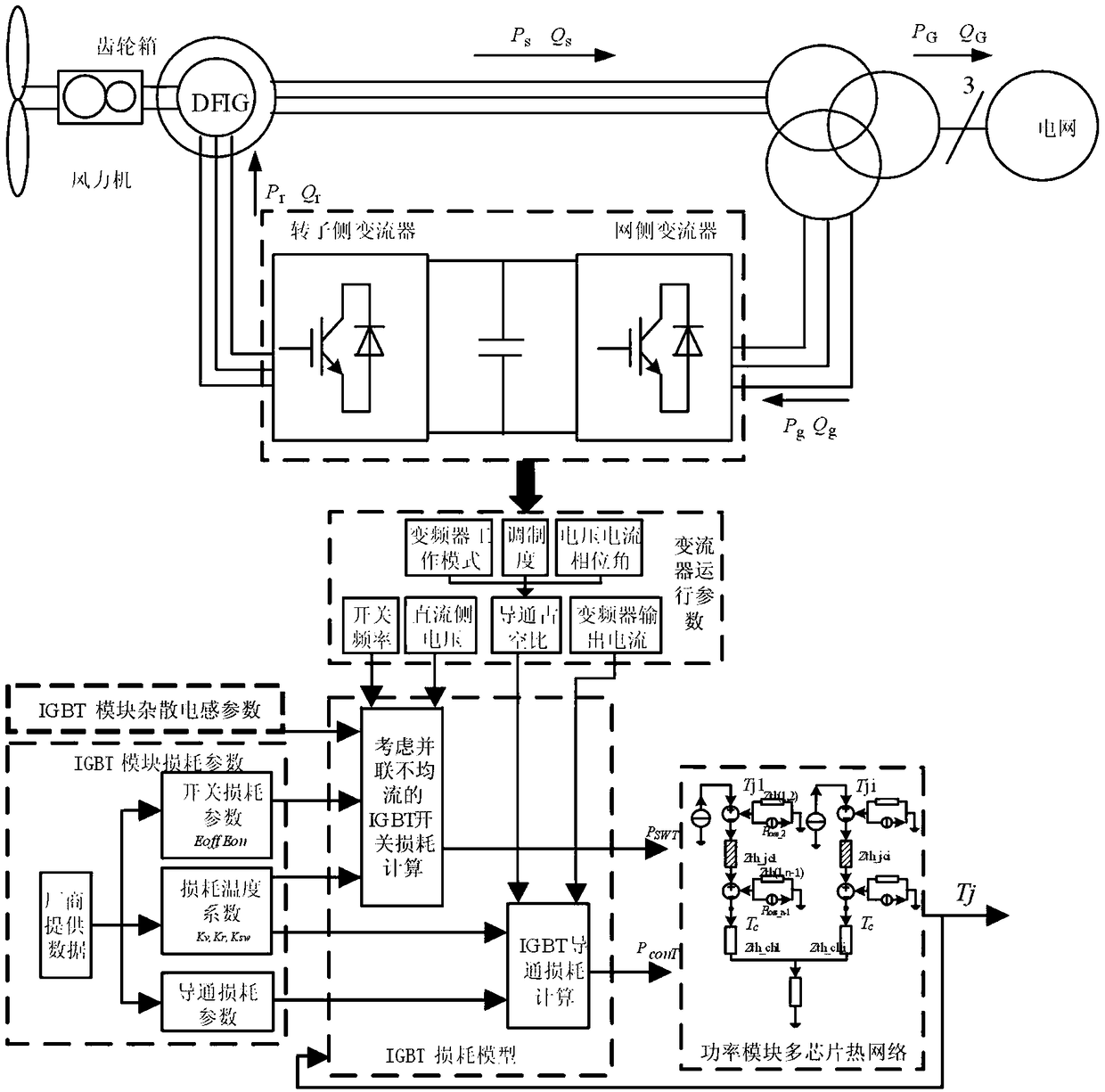

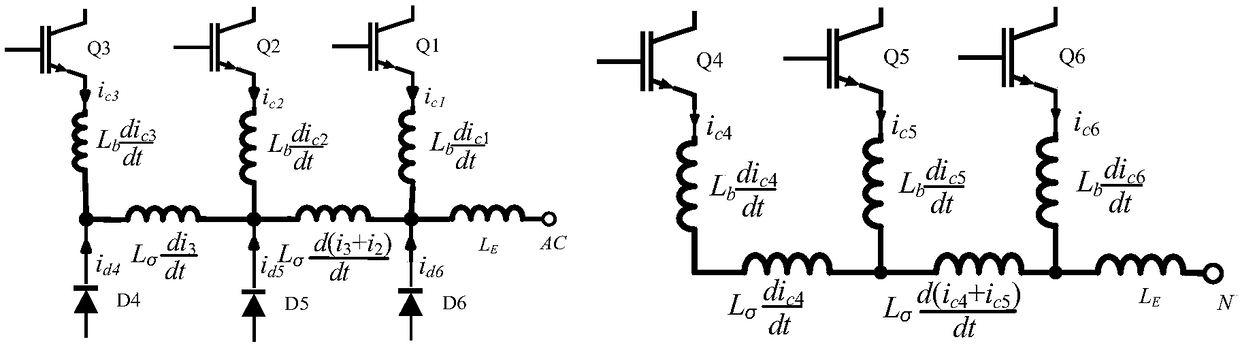

[0046] figure 1 Shown is the specific calculation model of the method of the present invention. The purpose of the present invention is to provide a method for calculating the dynamic junction temperature of the wind power converter IGBT power module considering the influence of stray inductance. The method takes into account the influence of stray inductance , combined with the thermal network model considering the thermal coupling between chips, using ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com