Patents

Literature

231 results about "Thermal network" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A thermal network model was applied to simulate a transient temperature rise in small-size multichip modules. The heat transfer process by natural convection and thermal radiation was also adopted in this model in addition to the thermal diffusion by thermal conduction.

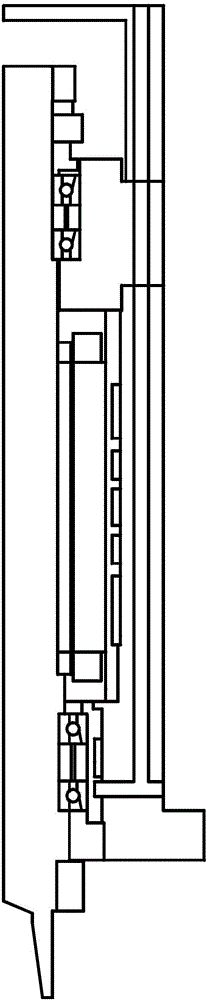

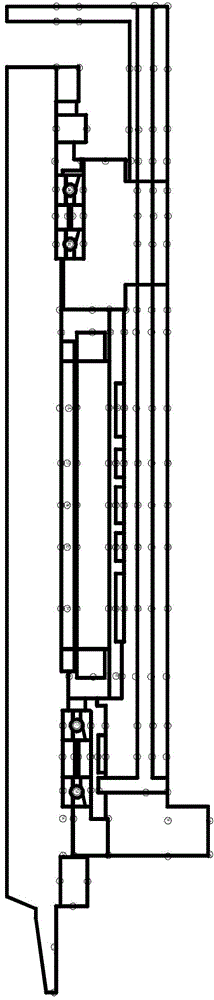

Thermal network modeling method applied to electric spindle steady temperature field

ActiveCN102867088AA Method for Accurate Thermal Boundary Condition DescriptionAccurate calculationAerodynamics improvementSpecial data processing applicationsMathematical modelPhysical model

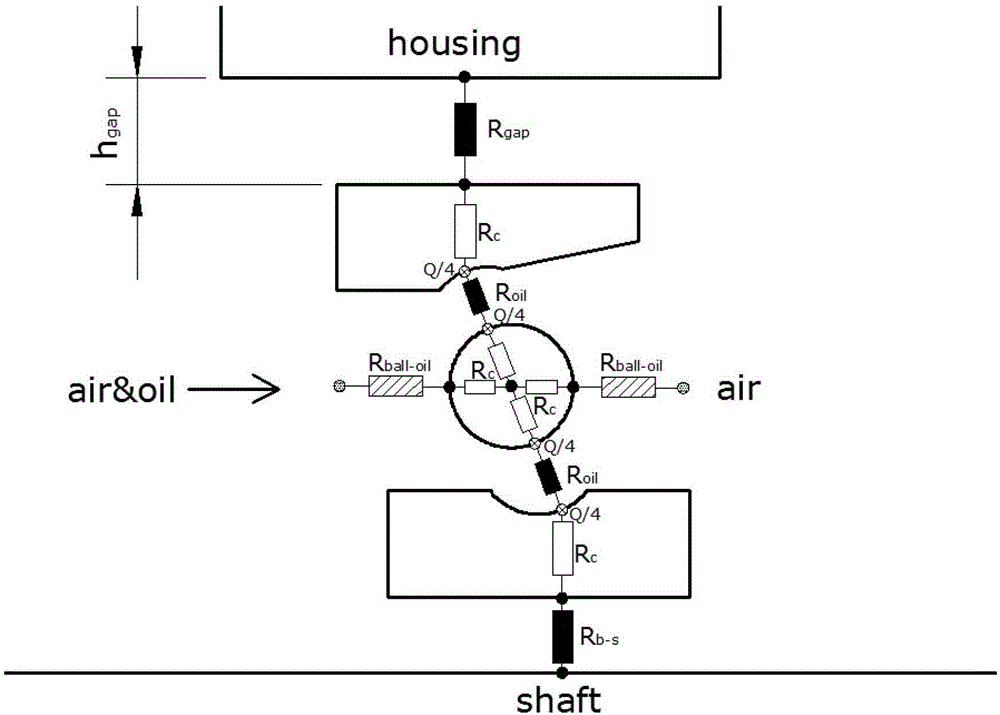

The invention discloses a thermal network modeling method applied to an electric spindle steady temperature field. The method comprises the following steps of (1) building an electric spindle axisymmetric two-dimensional model; (2) building an equivalent thermal network of an axis; (3) calculating the overall heating value of a bearing and a motor, and distributing the heat to heating nodes; (4) according to heat transfer theory empirical formulas under different radiation conditions, calculating a convective heat transfer coefficient for heat exchange between a boundary node and fluid; (5) equalizing heat transfer between the nodes into ideal geometric heat transfer, obtaining conduction heat resistance of each part and boundary thermal-convection resistance, and building a heat transfer physical model; and (6) building a mathematical model and selecting a solution algorithm. A thermal network method is applied to a high-speed main shaft system with two heat sources, i.e. the bearing and the motor, and a complex convective heat exchange boundary, so that the difficulty in solving the characteristic temperature of each part of a complex assembling body of the main shaft is reduced. Compared with the method of solving a heat transfer differential equation, the thermal network modeling method is a quick and accurate steady temperature field calculation method.

Owner:XI AN JIAOTONG UNIV

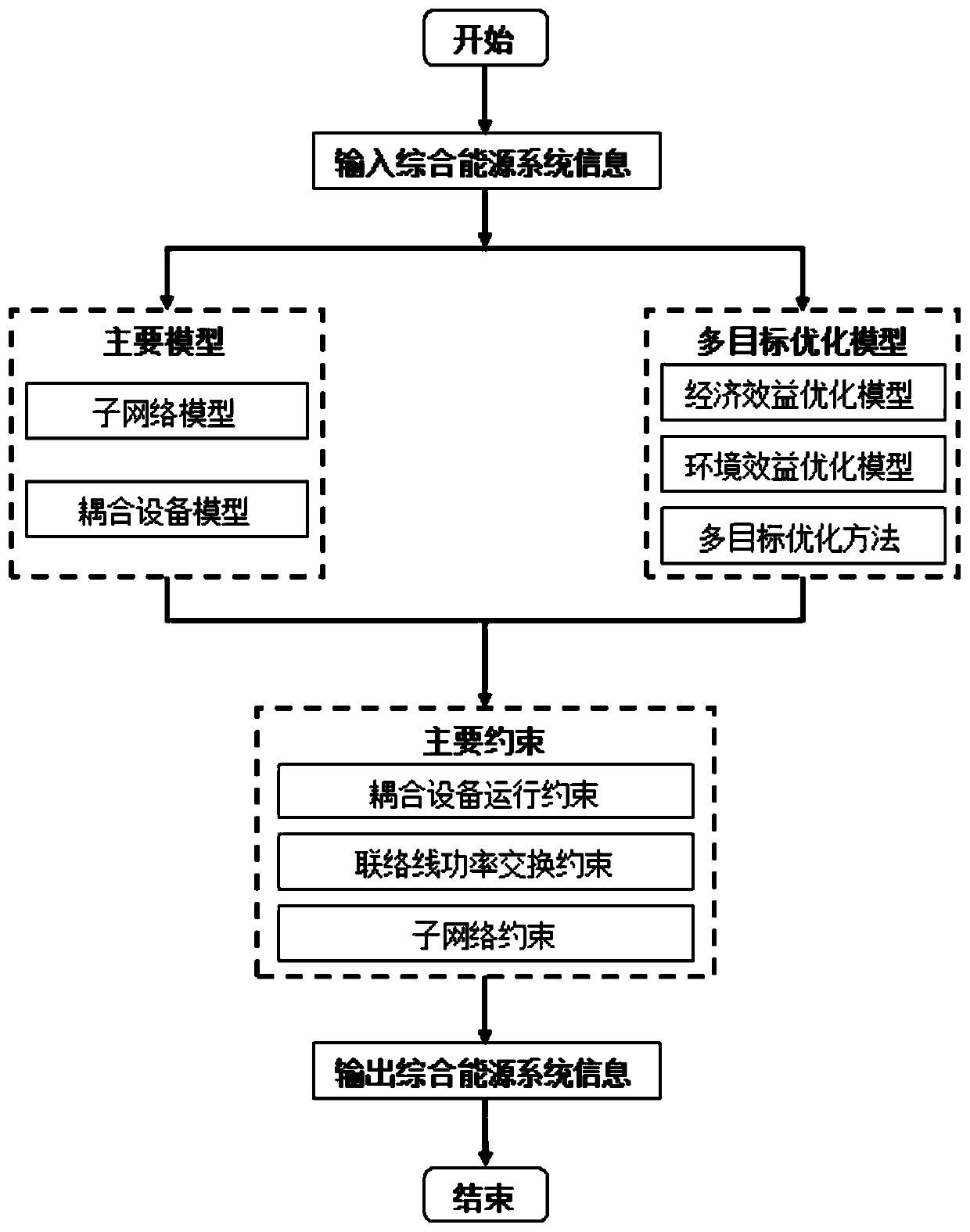

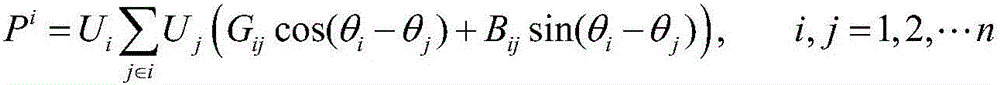

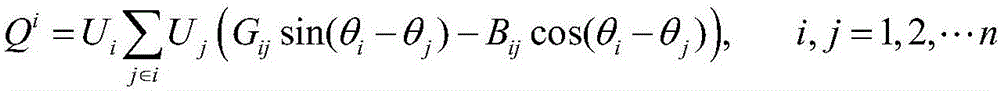

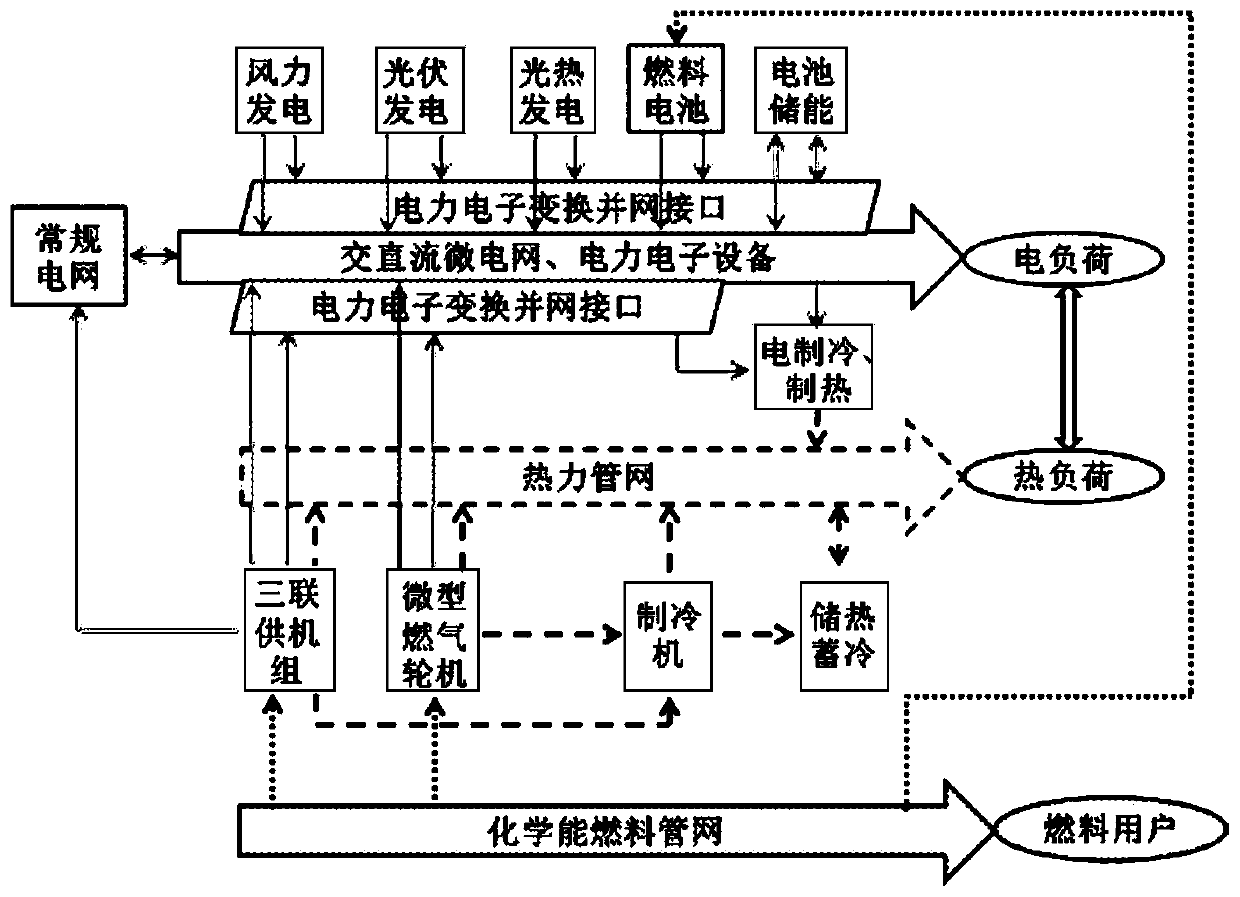

Comprehensive energy system multi-objective operation optimization method considering electric heating gas network

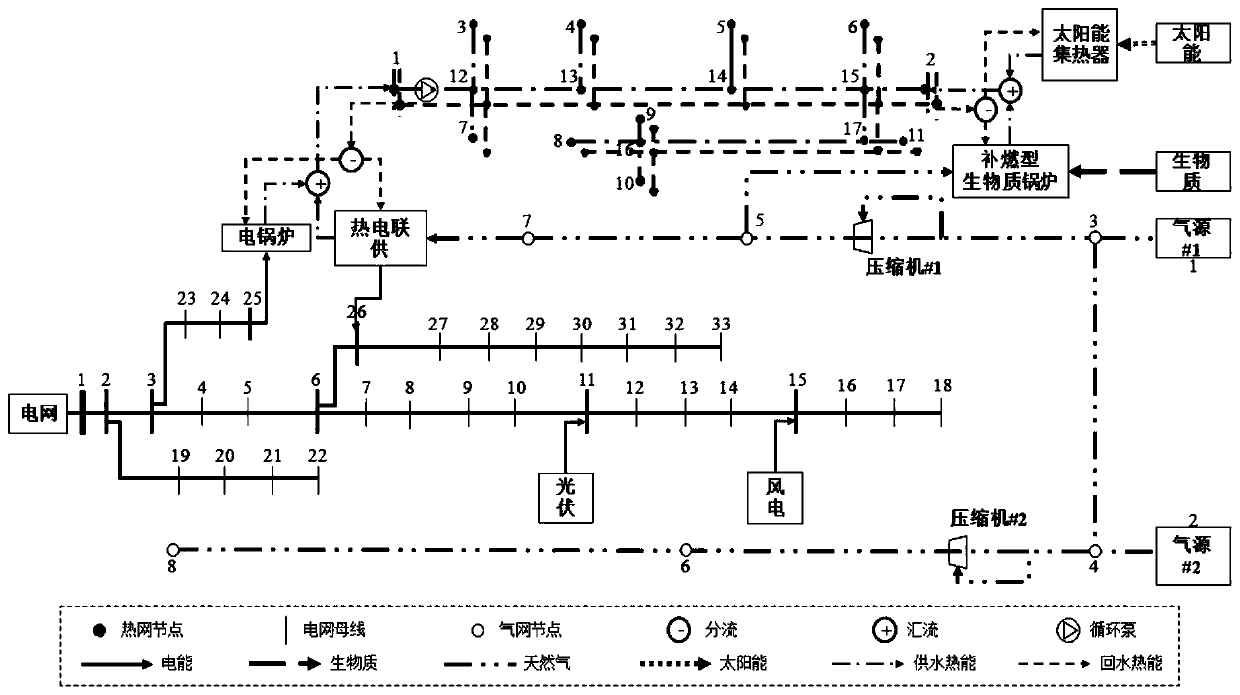

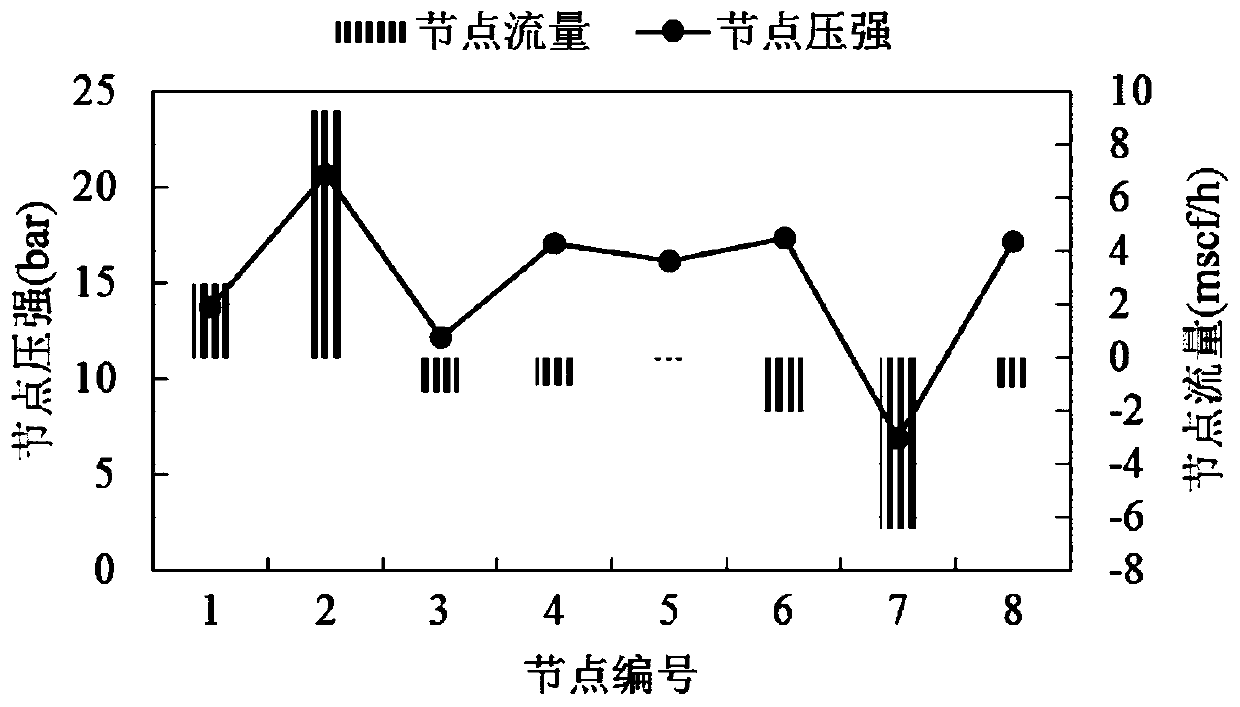

The invention provides a comprehensive energy system multi-objective operation optimization method considering an electric heating gas network. The comprehensive energy system multi-objective operation optimization method comprises the steps that a comprehensive energy system sub-network model comprising a natural gas network, a power network and a thermal network is established according to the obtained comprehensive energy system main information; then, an integrated energy system typical coupling equipment model comprising an electric boiler, a combined heat and power system, an afterburning type biomass boiler and a solar heat collector is established; secondly, on the basis of the maximization of the economic benefits and the environmental benefits, a multi-objective operation optimization model is established, and the comprehensive energy system operation constraint conditions including the coupling equipment operation constraints, the tie line power exchange constraints and thesub-network operation constraints, are set; and finally, the multi-objective operation optimization model is solved, and the main information of the comprehensive energy system is outputted. Accordingto the method, the effectiveness of the model and the method on the comprehensive energy system operation optimization is verified through the example analysis, and the reference can be provided forthe multi-objective operation optimization of the comprehensive energy system.

Owner:HOHAI UNIV

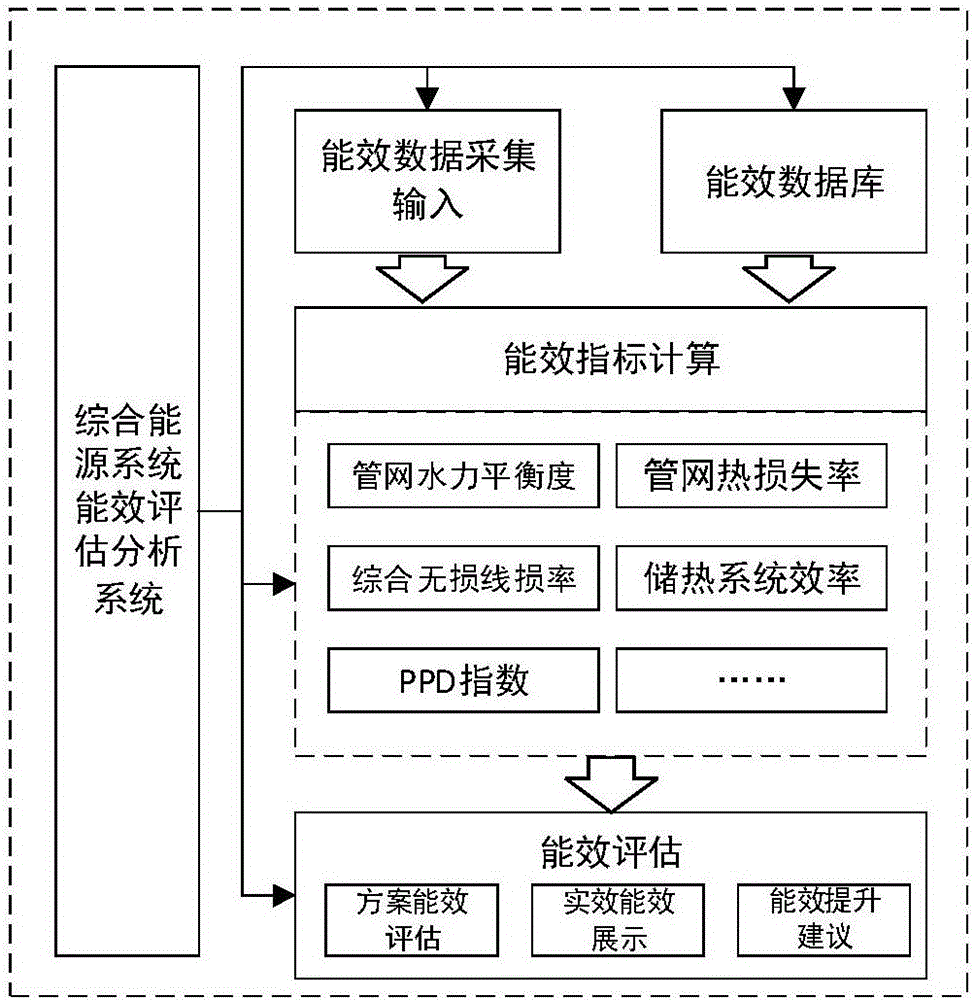

Evaluation method for evaluating energy efficiency of integrated energy system

InactiveCN106600104AFully reflectScientific reflectionTechnology managementResourcesWeight coefficientIntegrated energy system

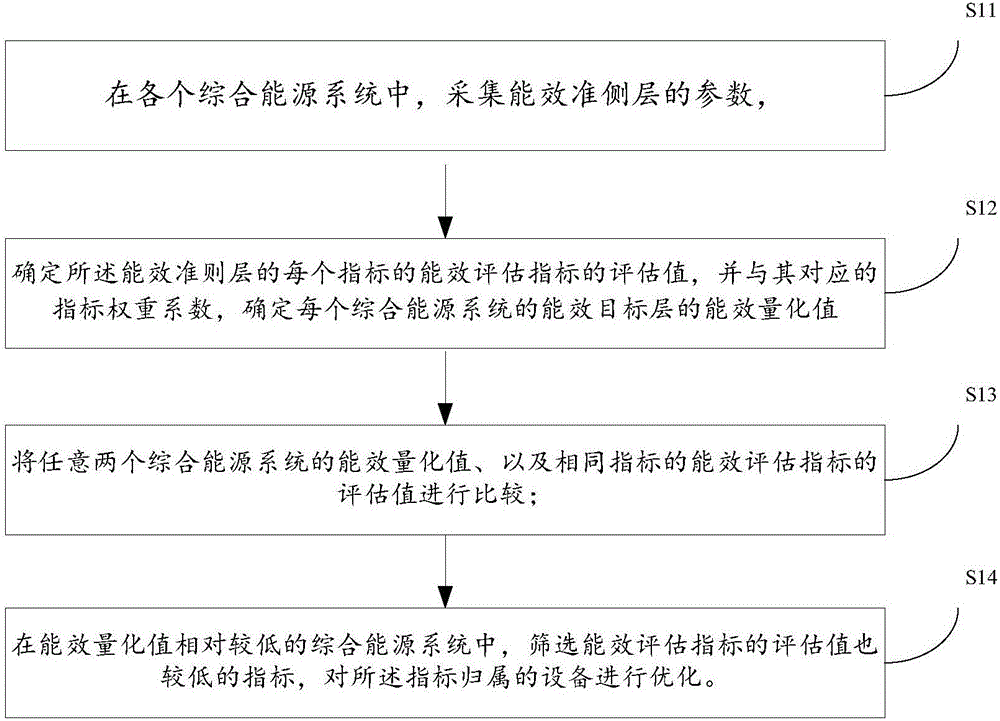

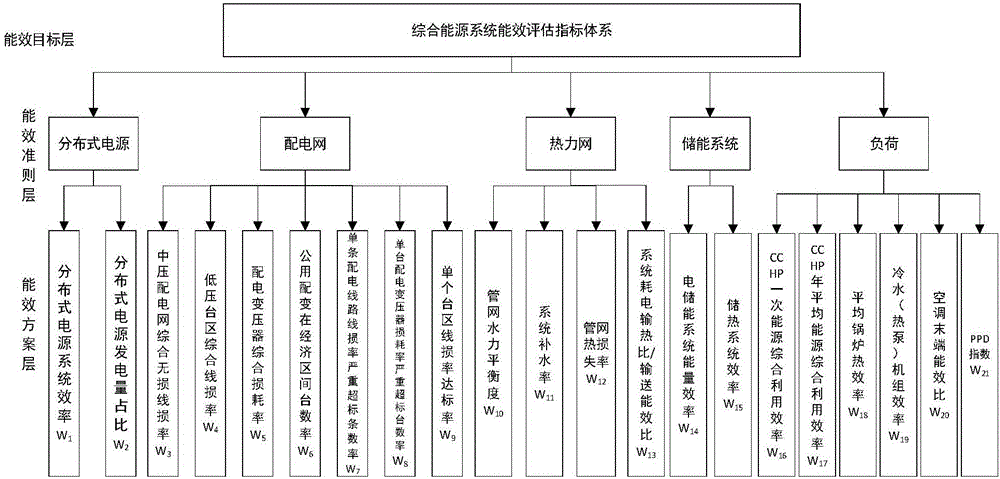

The invention provides an evaluation method for evaluating the energy efficiency of an integrated energy system. The method comprises the steps of in each of various integrated energy systems, collecting the parameters of an energy efficiency criterion layer, wherein the equipment of the energy efficiency criterion layer is composed of a distributed power supply, a power distribution network, a thermal network, an energy storage system and a load device, and each device includes at least one indicator; determining the evaluated value Ei of each energy efficiency evaluation index of the energy efficiency criterion layer, determining an index weight coefficient Wi corresponding to each evaluated value Ei, and determining the energy efficiency quantized value E=sigma (Wi*Ei) of an energy efficiency target layer of each integrated energy system, wherein i is a positive integer; comparing the energy efficiency quantized values E of any two integrated energy systems, and the evaluated values Ei of identical energy efficiency evaluation indexes; in an integrated energy system relatively low in energy efficiency quantized value E, screening out an index relatively low in the evaluated value Ei of an energy efficiency evaluation index, and optimizing the equipment having the above energy efficiency evaluation index.

Owner:JIANGSU ELECTRIC POWER CO +1

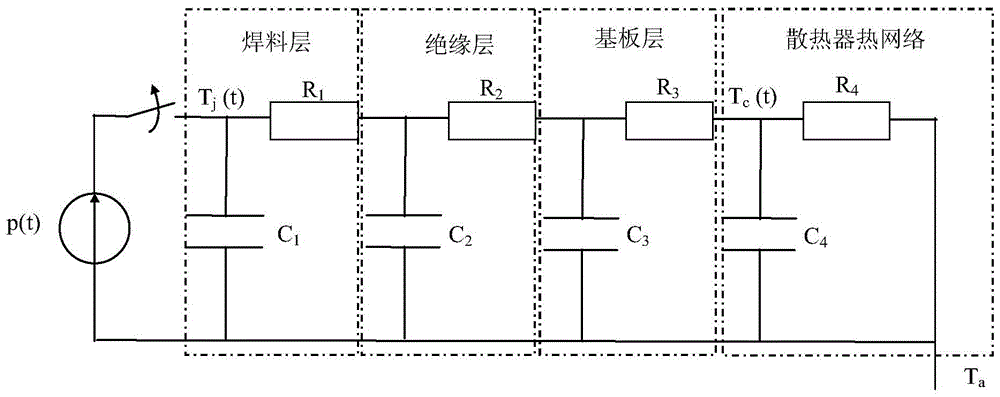

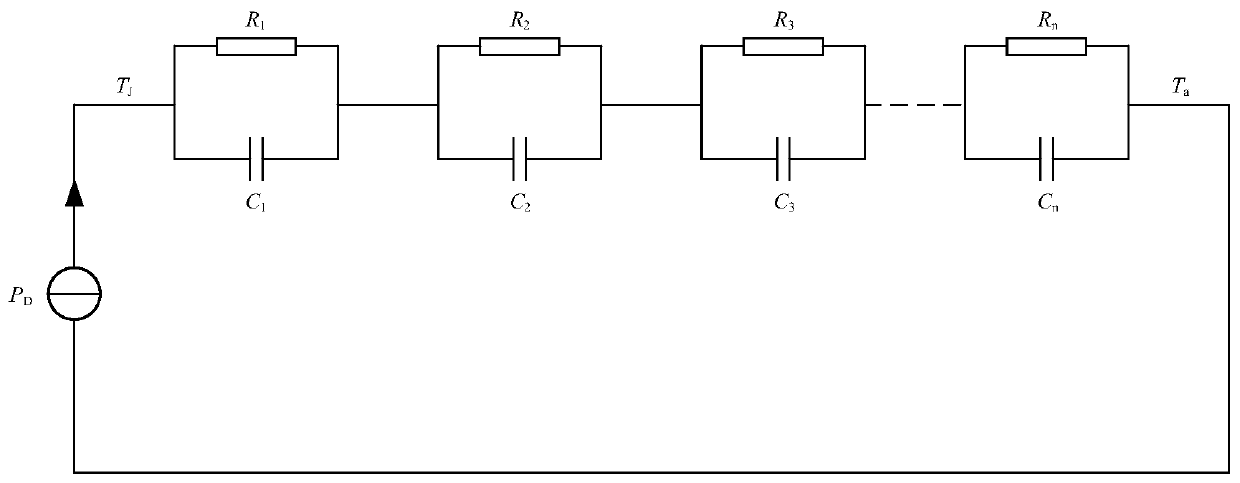

Thermal-network parameter identification method based on IGBT junction temperature information

ActiveCN105718694AGuaranteed safe operationAccurate identificationSpecial data processing applicationsJunction temperatureSafe operation

The invention provides a thermal-network parameter identification method based on IGBT junction temperature information.The thermal-network parameter identification method includes the steps that an equivalent thermal-network model is built according to the performance parameter of an IGBT module and the performance parameter of a radiator; according to the equivalent thermal-network model, any one pair of measurable thermal resistance and thermal capacity in a thermal network is changed, and constraint equations of two sets of different IGBT thermal-network parameters are built; two lowered temperature curves of the thermal resistance and thermal capacity before and after changes in the equivalent zero-input state are measured respectively; the lowered temperature curves are fitted, the two sets of corresponding time constants are obtained, and the IGBT thermal-network parameters are obtained through the constraint equations of the IGBT thermal-network parameters according to the measurable thermal resistance and thermal capacity.The thermal-network parameter identification method can be applied to the equivalent zero-input input state such as normal machine switching during working of a power conversion device, the thermal-network parameters of an IGBT can be accurately, effectively and simply identified without disassembling the IGBT module, the IGBT aging state is monitored, the service life is estimated, safe operation of the power conversion device is guaranteed, and operation and maintenance cost is reduced.

Owner:CHONGQING UNIV

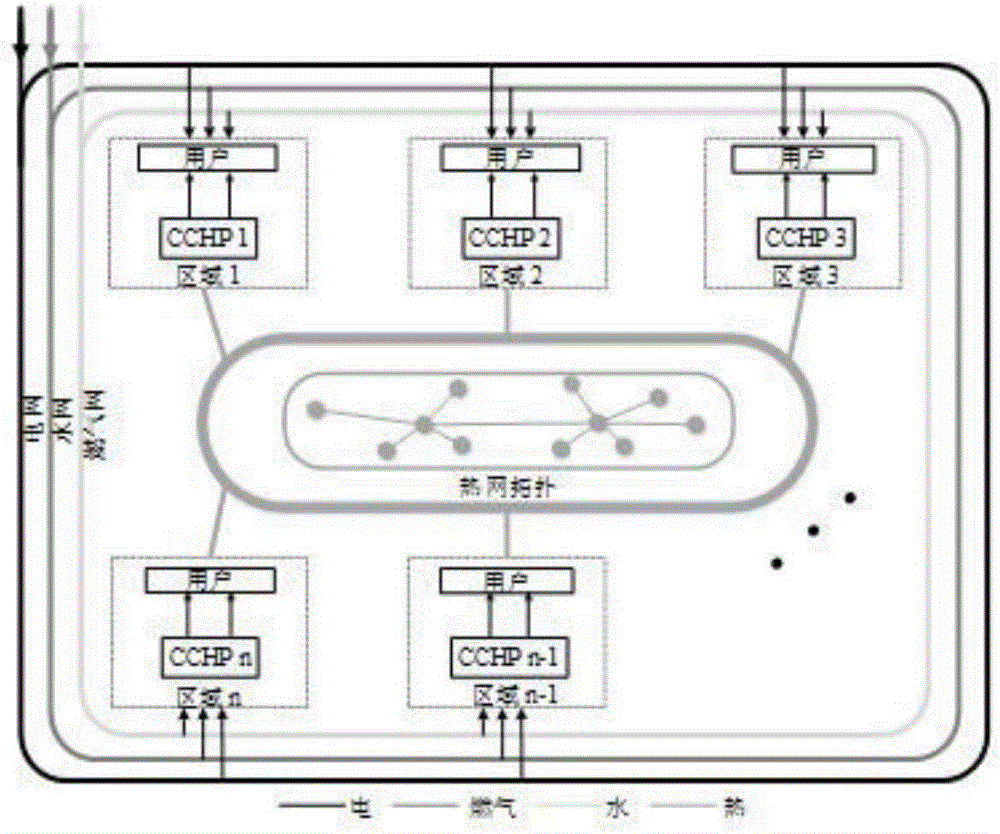

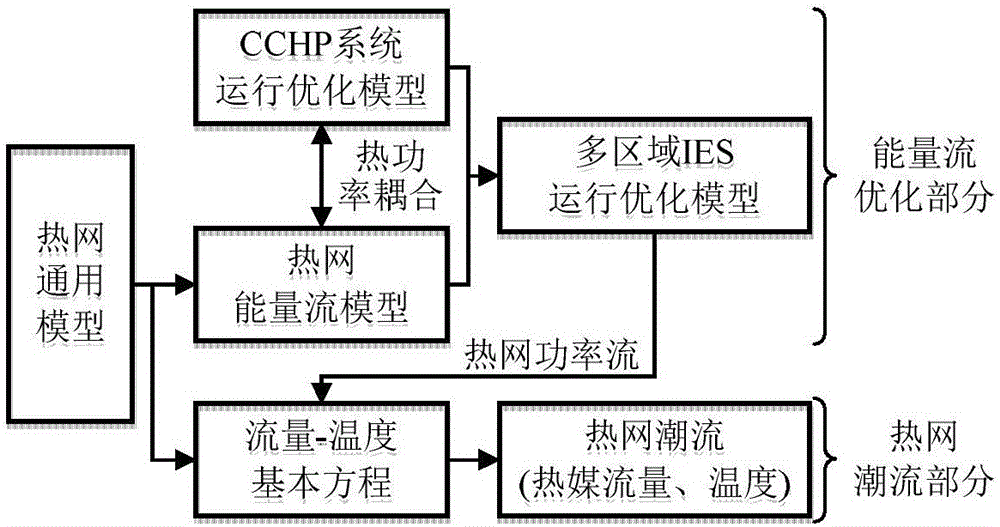

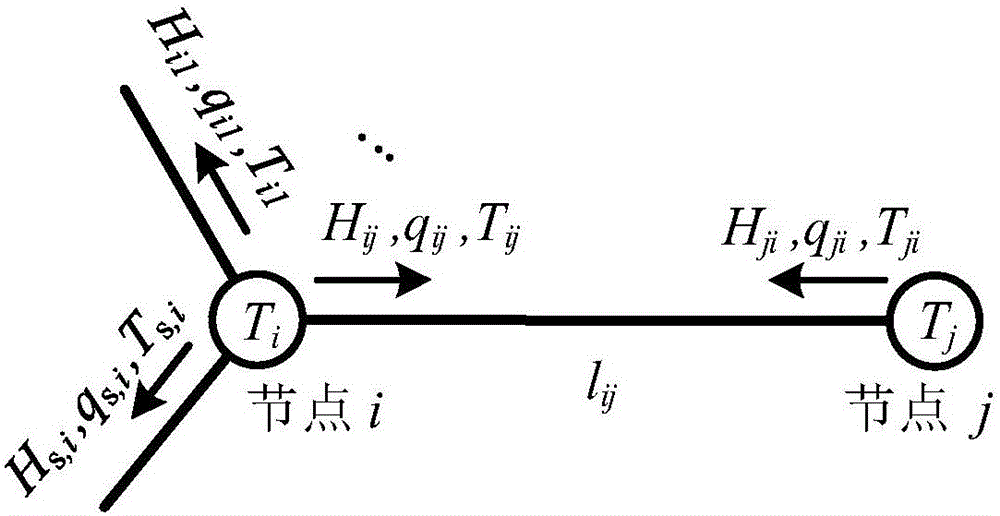

Multi-region integrated energy system operation method based on operation optimization model

ActiveCN106447113AOptimal Energy ManagementEasy to solveForecastingSystems intergating technologiesThermal energyIntegrated energy system

The invention discloses a multi-region integrated energy system operation method based on an operation optimization model. The method comprises the steps that 10) a thermal network energy transmission general model is established and simplified into a thermal network energy flow model and a thermal network flow- temperature equation, and a thermal network operation cost model is established; 20) based on a CCHP operation optimization model, the thermal network energy flow model is combined to establish a multi-region integrated energy system operation optimization model; and 30) a multi-region integrated energy system operates according to the operation optimization model established in the step 20). The method can realize thermal energy exchange in different regions, realizes unified scheduling of equipment in different regions, enables the equipment to work in the best condition as much as possible, realizes the optimal work coordination, and improves the energy system economy.

Owner:SOUTHEAST UNIV

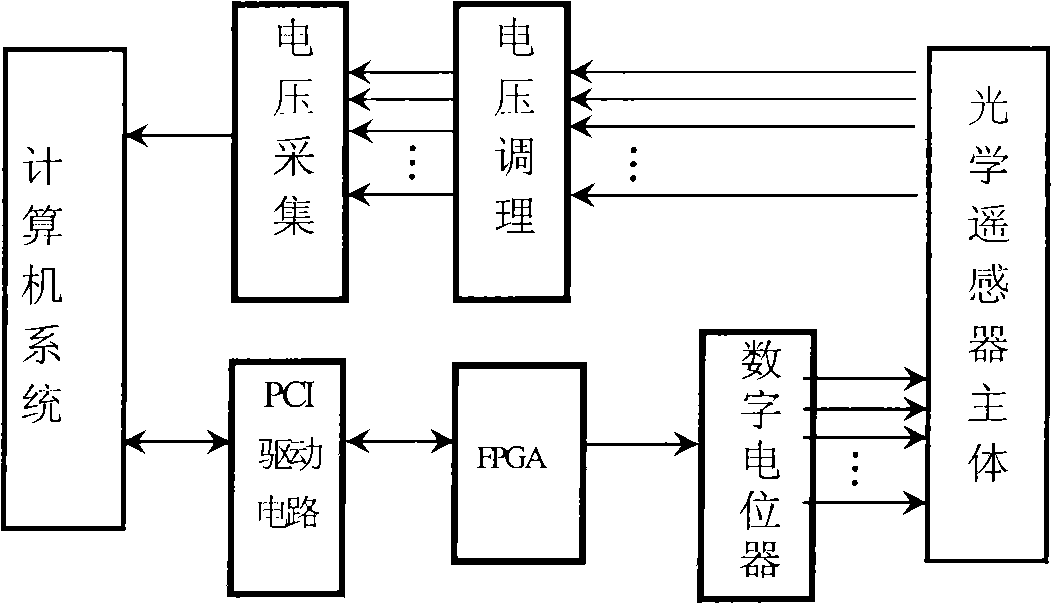

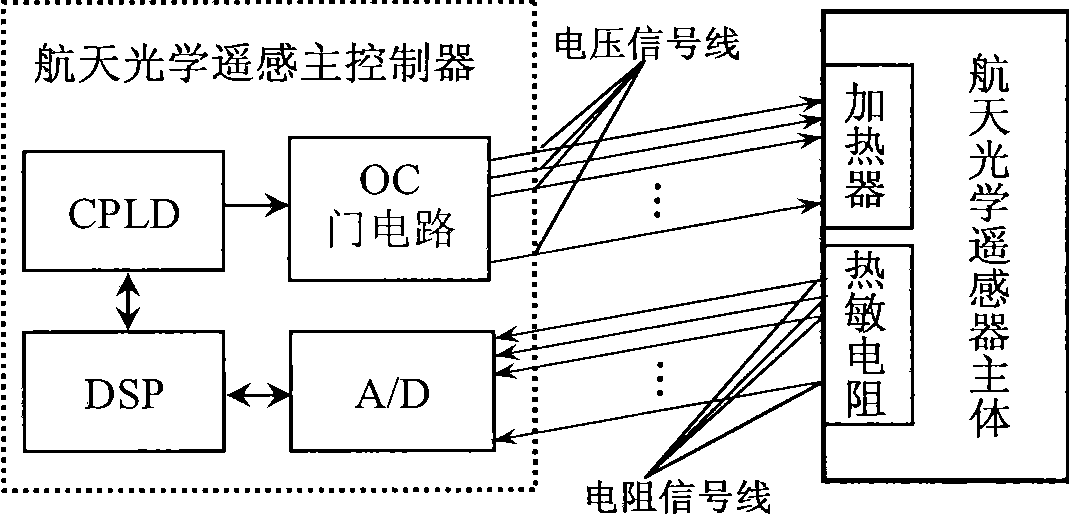

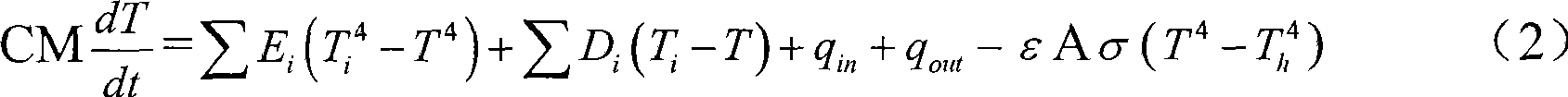

Emulation test method for active thermal-control circuit of aerospace optical remote sensor

InactiveCN101498937ASolve simulationResolve detectionElectric testing/monitoringMathematical modelEngineering

The invention relates to a simulation test method for the active thermal control circuit of a space optical remote sensor. A test system consisting of a voltage conditioning circuit, an analog to digital conversion circuit, a computer PCI bus driving circuit, an FPGA, a digital potentiometer synthesis conversion processing circuit and a microcomputer is connected to the active thermal control circuit of the optical remote sensor being tested, which forms an optical remote sensor active thermal control circuit closed loop simulation test system and realizes the aim of simulation test. At first, the heating information of a control circuit is collected, the validity of the information is judged, and then according to a pre-constructed thermal network mathematical model, temperature information after changing is fed back to the active thermal control circuit, therefore, the effect of maintaining heating is simulated. The test method can satisfy the long-term, rapid, convenient and clear test and monitor need of the active thermal control circuit of the optical remote sensor.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

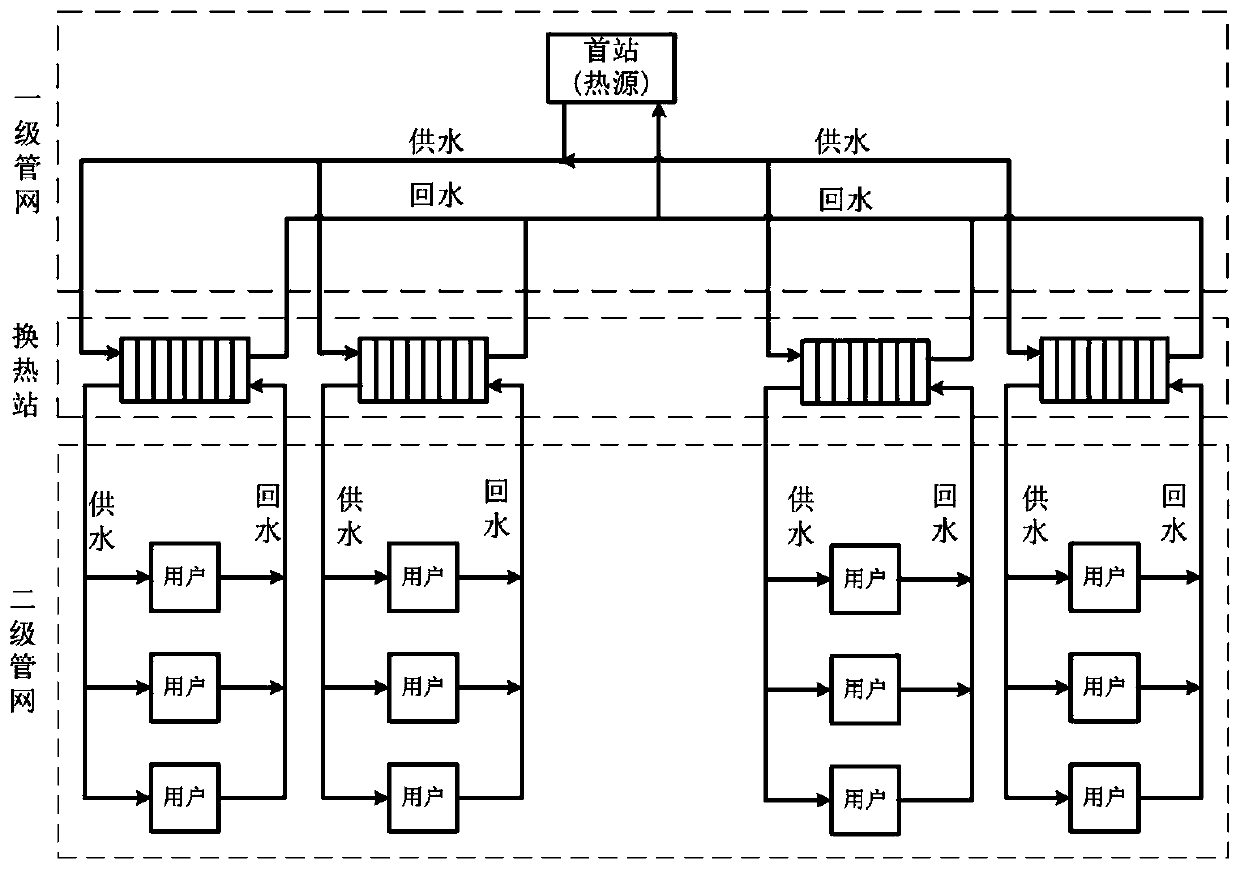

Interval power flow calculating method of heat supply network in electrical-thermal coupled system

ActiveCN106056478AImprove securityAvoid errorsData processing applicationsSingle network parallel feeding arrangementsEngineeringOperation safety

The invention relates to an interval power flow calculating method of a heat supply network in an electrical-thermal coupled system, and belongs to the technical field of operation safety analysis of a multi-energy-flow coupled system. On one hand, the method, by adopting an interval power flow analysis method, provides basis for safe and stable control of the coupled energy system or pipeline planning with the influence of wind power uncertainty on steady operation of other energy networks (thermal network) being taken into consideration under development tendency of coupled operation of a plurality of energy systems; and on the other hand, the method prevents a lot of data statistics and complex mathematic model and calculation, and meanwhile, the method only needs interval information and does not need to estimate membership information and the like, thereby preventing errors due to artificial hypothesis subjectivity. The method can be applied to energy management of the electrical-thermal coupled multi-energy-flow system; and when the system has a safety problem or a potential risk, a safety warning is given, thereby facilitating improving safety of the operation of the electrical-thermal coupled multi-energy-flow system.

Owner:北京清源智慧科技有限公司

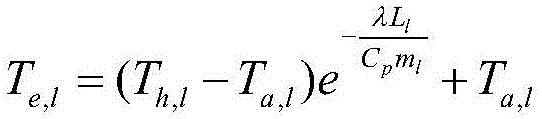

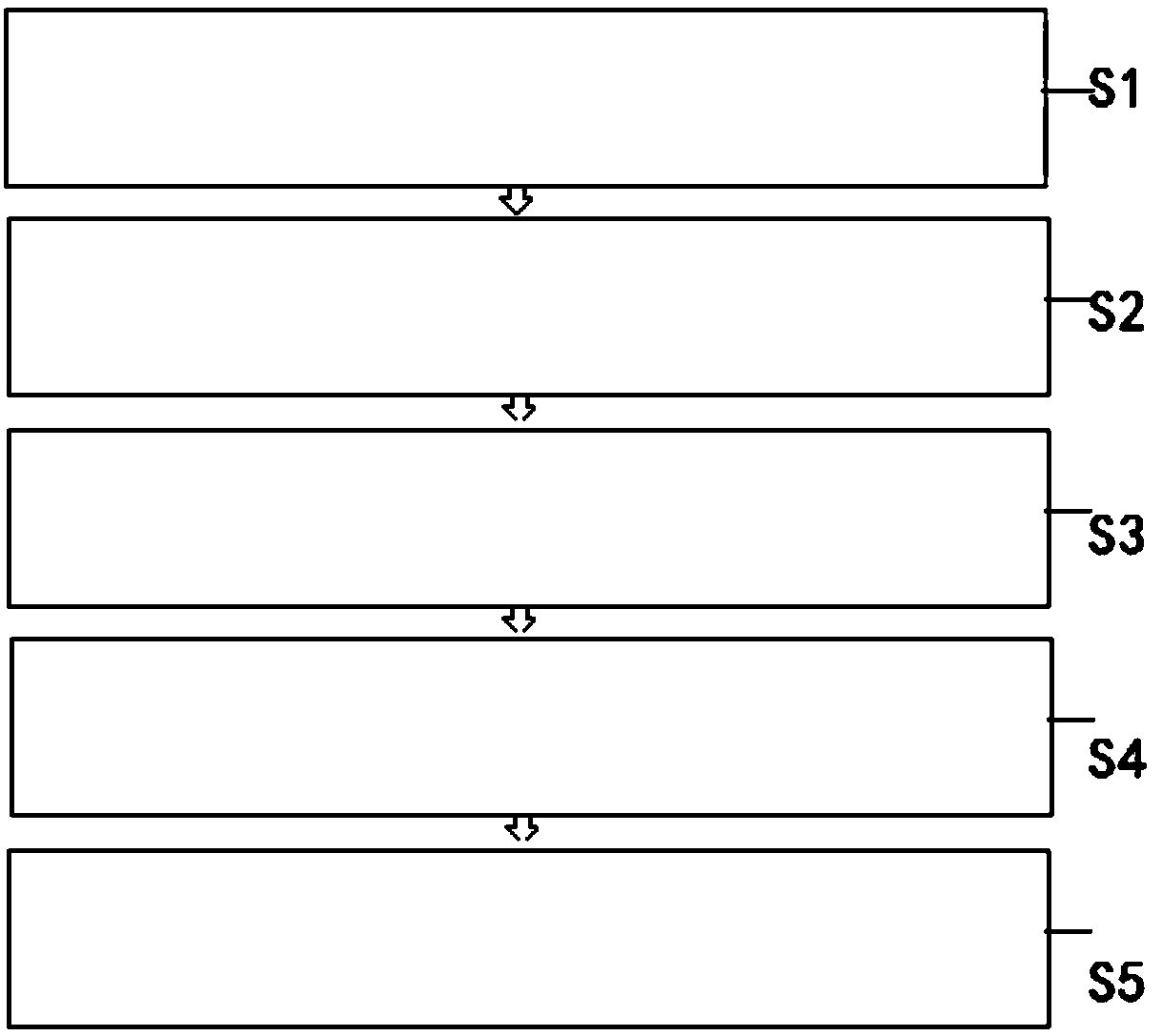

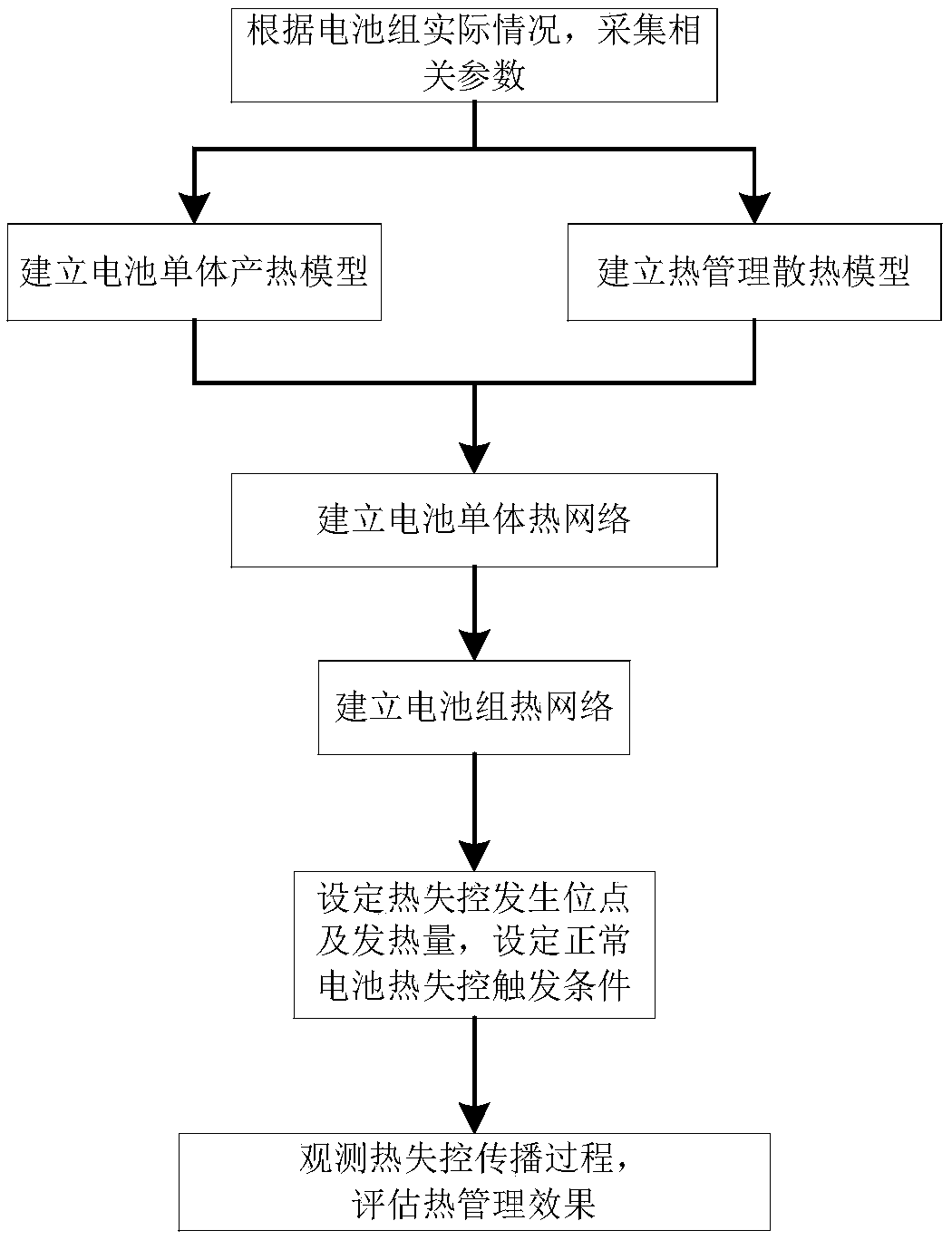

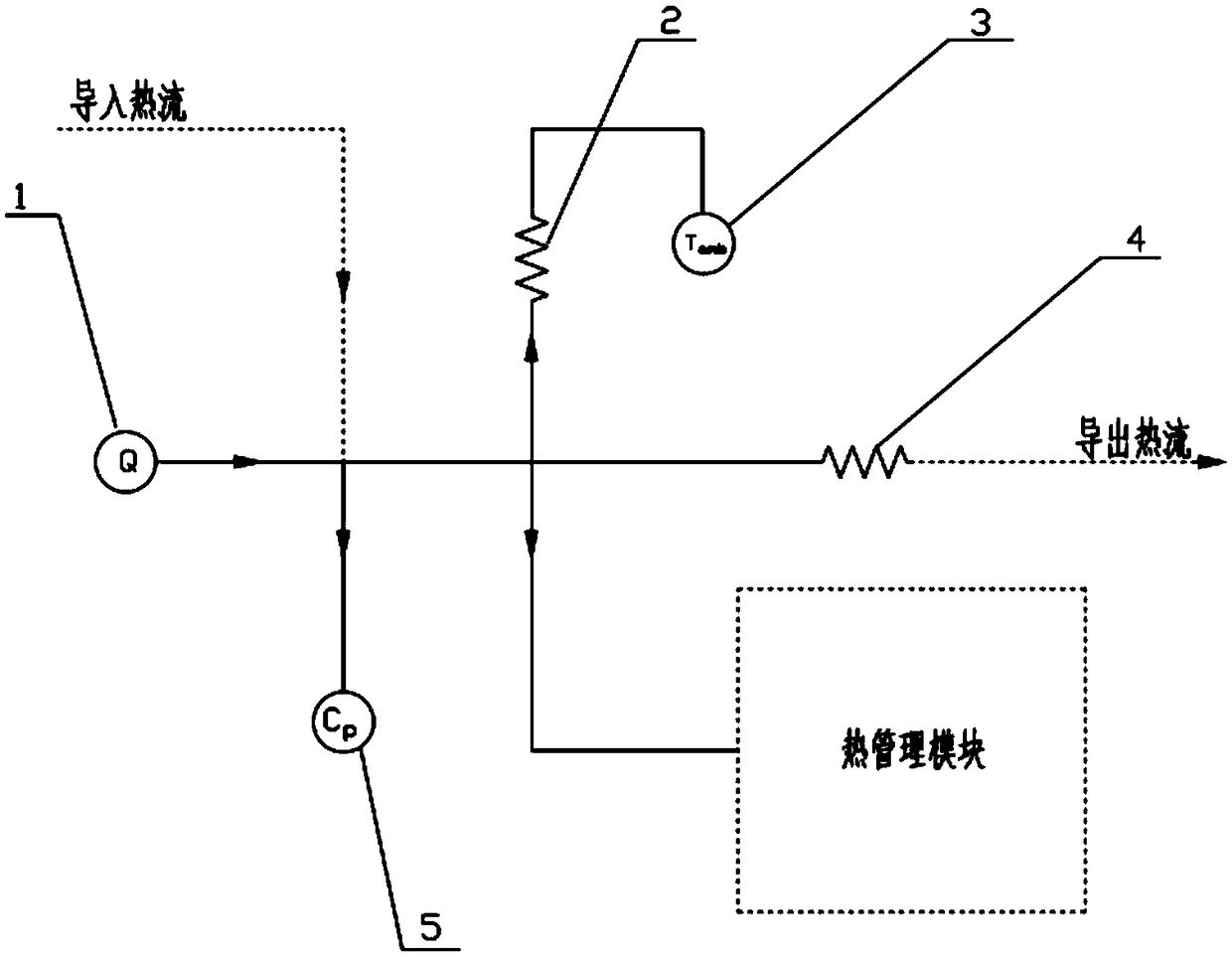

Battery thermal-runaway prediction method based on thermal-resistance network model

ActiveCN108647432AThe technical means are clearDesign optimisation/simulationSpecial data processing applicationsSimulationNetwork model

The invention discloses a battery thermal-runaway prediction method based on a thermal-resistance network model. According to the method, battery single-bodies in a large battery pack are simplified into thermal network nodes, convection, thermal-conduction and radiation processes in a battery pack system are simplified into thermal resistance, and a circuit solving method is utilized to realize fast calculation of battery pack thermal-transfer processes. In addition, different cooling manners are simplified into corresponding thermal-resistance modules to be embedded into a battery pack thermal-resistance network, and effectiveness of the cooling manners on thermal-runaway protection can be evaluated. A thermal-runaway prediction process includes: establishing a single-body thermal-resistance network on the basis of thermal-transfer feature parameters of the battery single-bodies; calculating battery steady-state thermal-generation quantity, setting corresponding thermal-management schemes, and obtaining battery single-body thermal-generation features of a thermal-runaway process through experiment; establishing the battery pack thermal-resistance network; giving a thermal-runawayoccurrence position, and setting a normal battery thermal-runaway temperature lower-limit; and recording predicted battery pack damage progress and damage time, and assessing protection effects of the different thermal-management measures.

Owner:XI AN JIAOTONG UNIV

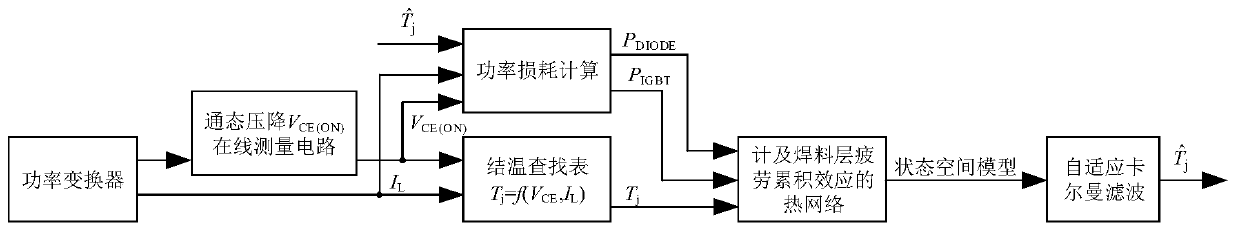

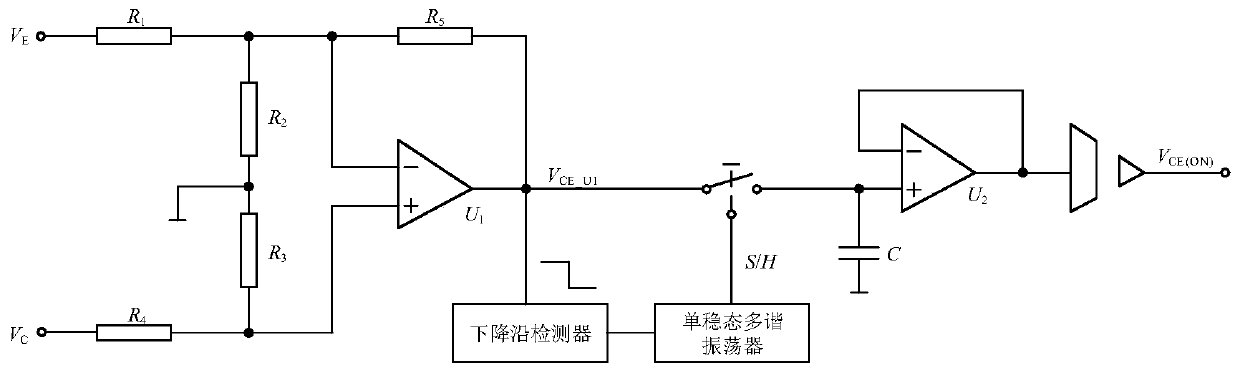

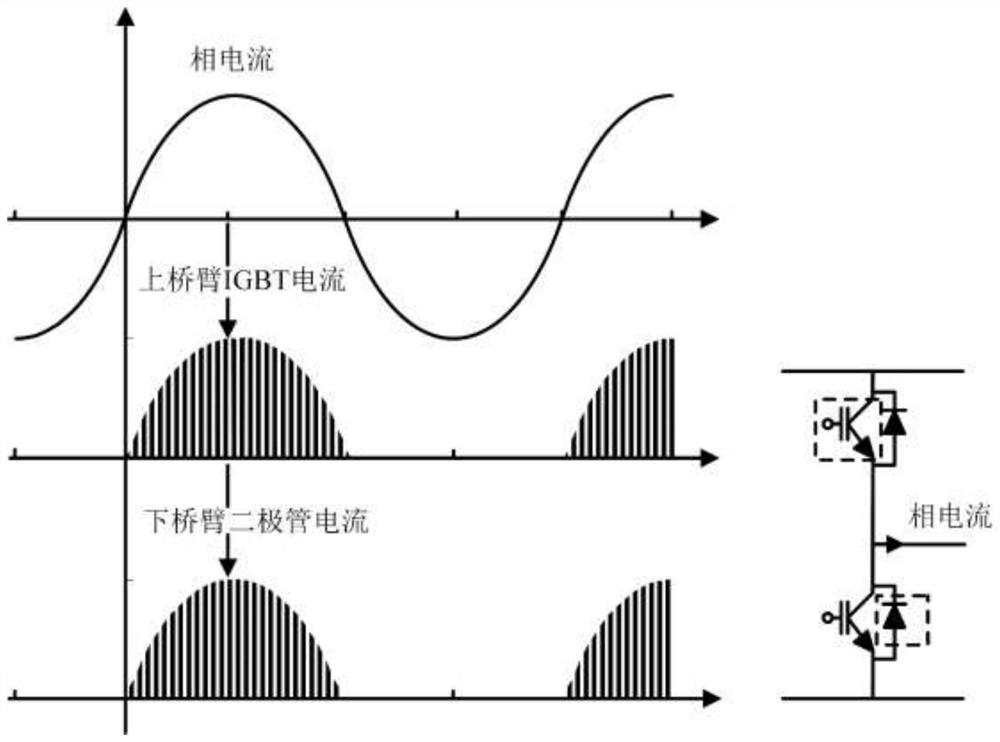

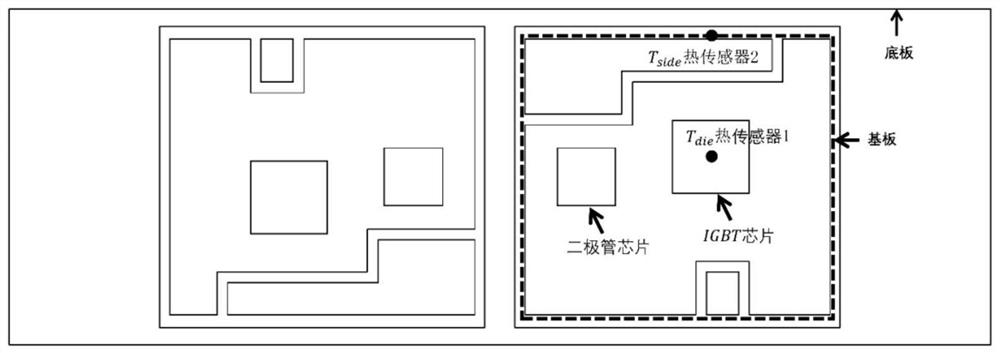

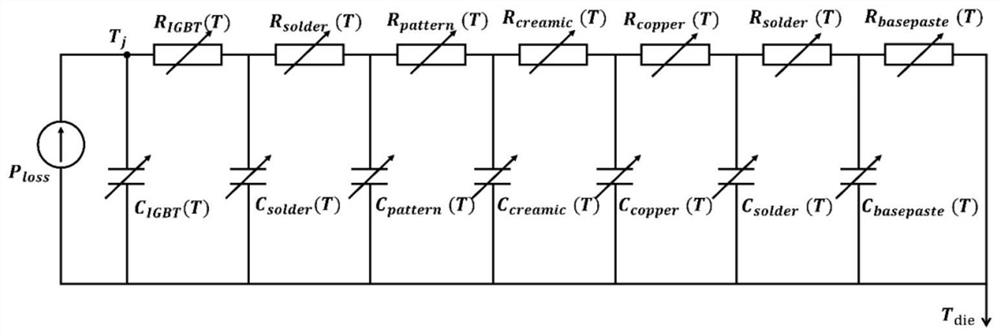

IGBT module junction temperature online estimation circuit system and method

InactiveCN110988641AImprove estimation accuracyImprove accuracyIndividual semiconductor device testingThermodynamicsJunction temperature

The invention discloses an IGBT module junction temperature online estimation circuit system and method, and the method comprises the following steps: 1, carrying out the online measurement of the IGBT on-state voltage drop VCE(ON) of an IGBT power module, and building an IGBT junction temperature Tj lookup table; 2, calculating the power loss of an IGBT and a diode in the IGBT power module; 3, periodically and timely updating the IGBT equivalent thermal network model by adopting a thermal network updating strategy considering the fatigue accumulation effect of the solder layer; 4, establishing a state space model by taking the junction temperature Tj and the IGBT and diode power loss as state variables according to the IGBT equivalent thermal network model, and updating the state space model; and 5, designing an adaptive Kalman filtering algorithm program according to the state space model to obtain an IGBT junction temperature Tj estimated value. The method integrates the advantagesof model estimation and online measurement, overcomes the defect that on-state voltage drop VCE (ON) measurement is inaccurate, keeps signal continuity, reduces noise interference, is high in estimation precision, and can estimate the IGBT module junction temperature in real time in a non-intervention mode.

Owner:WUHAN UNIV

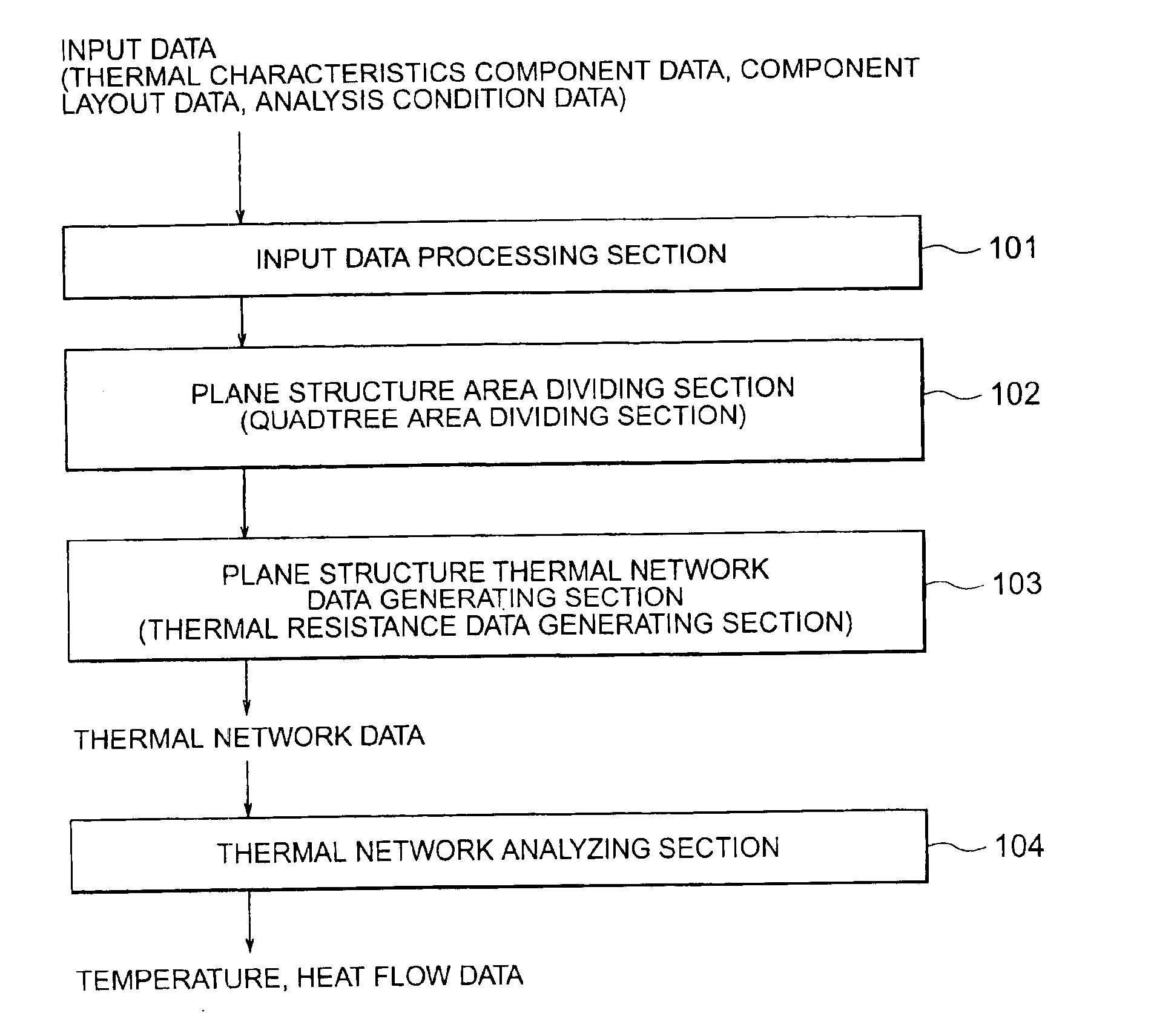

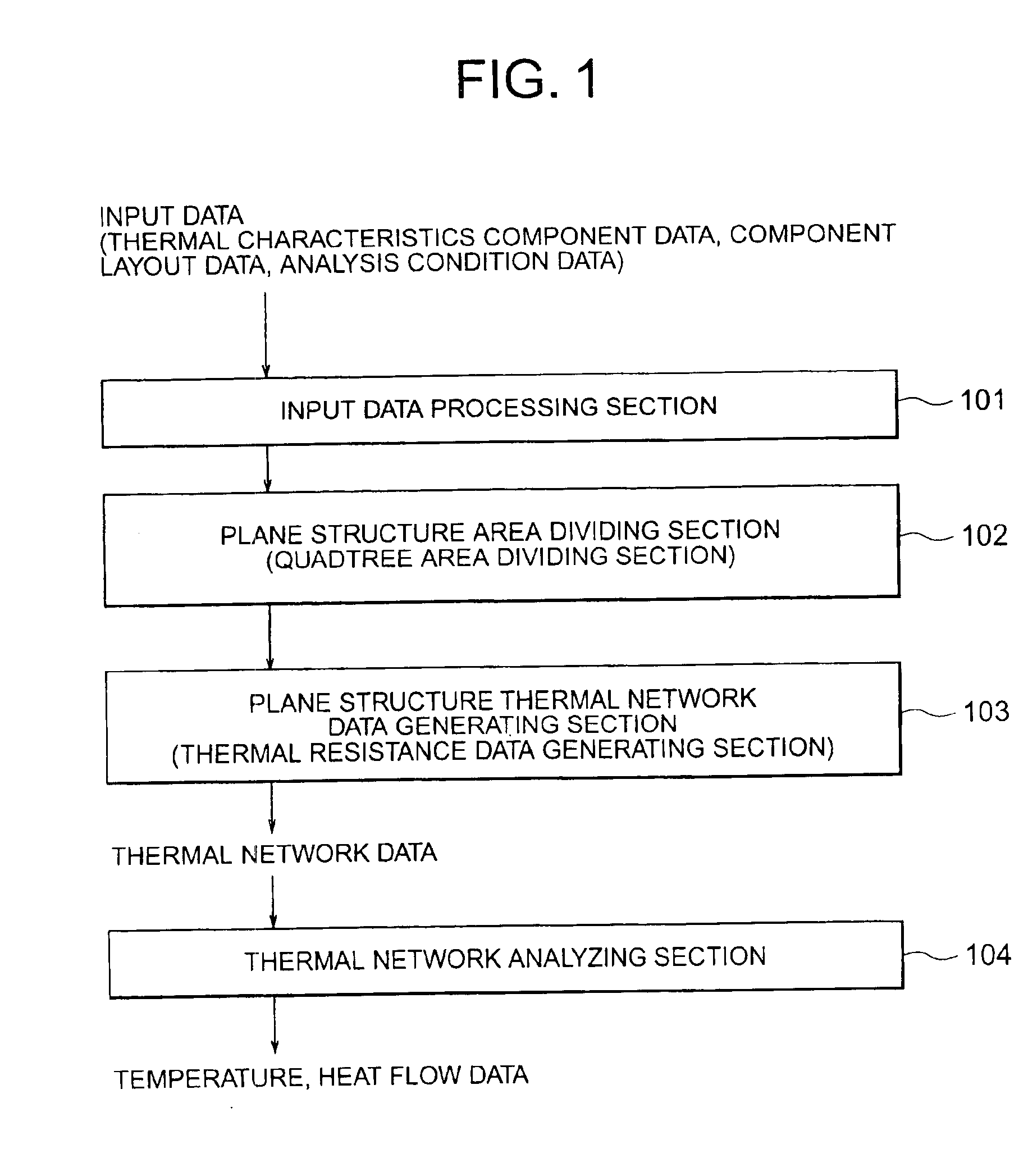

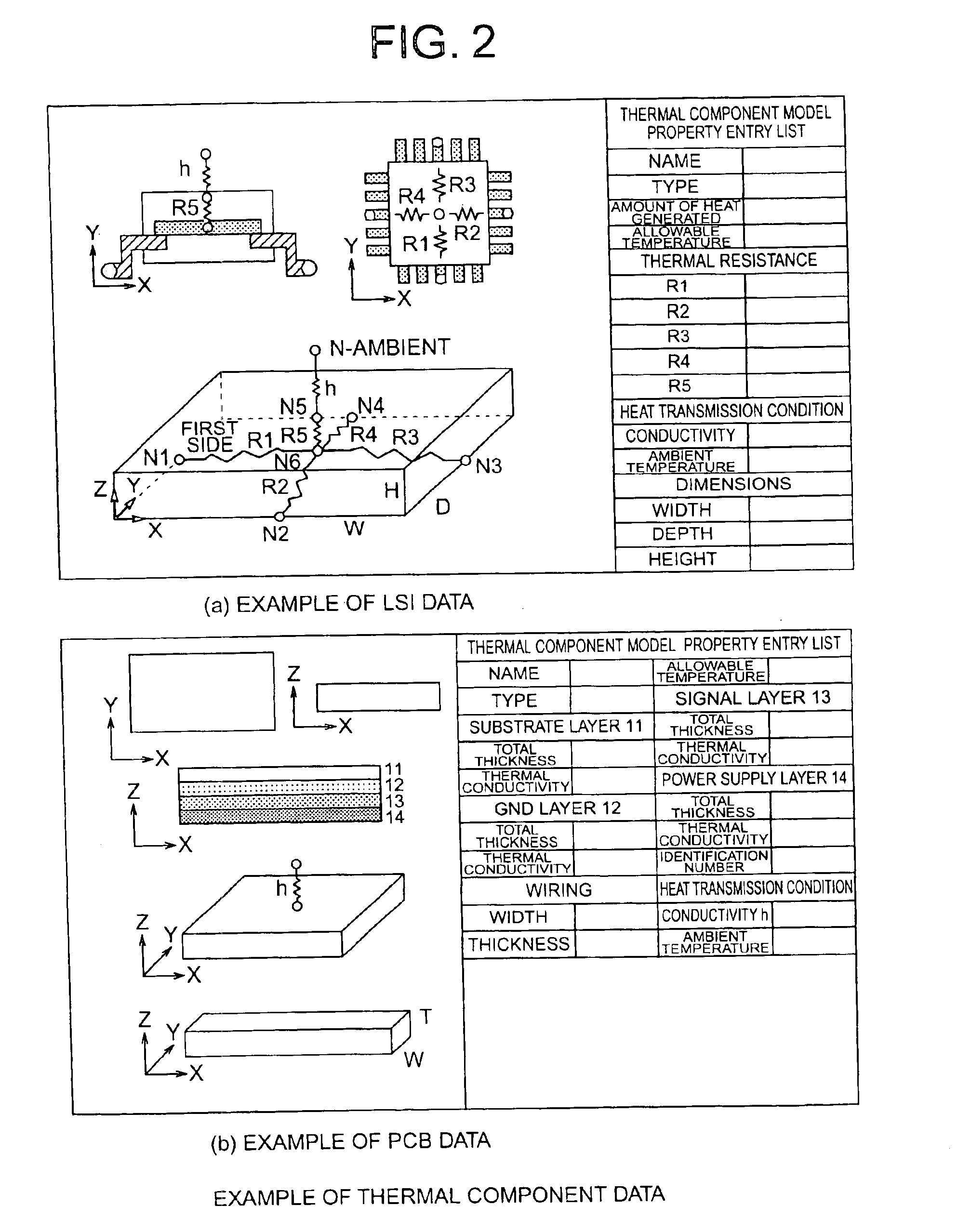

System and method for generating thermal network data and recording medium

InactiveUS6895354B2Practical calculation speedAnalyze moreDigital computer detailsDesign optimisation/simulationCouplingComputer science

A method for generating thermal network data for use in thermal analysis of a coupling structure of a large number of components. Depending on the density of nodes having a position defined by the structure, two-dimensional quadtree area division or three-dimensional octtree area division is performed. A node is provided in the center of the divided area and anode is determined using approximation to a node having a position defined by the structure. Alternatively, an area and a node are determined using Voronoi area division in case of area subdivision where a small area is assigned only to a defined node. Thermal network data is generated by inserting thermal resistances between respective nodes.

Owner:NEC CORP

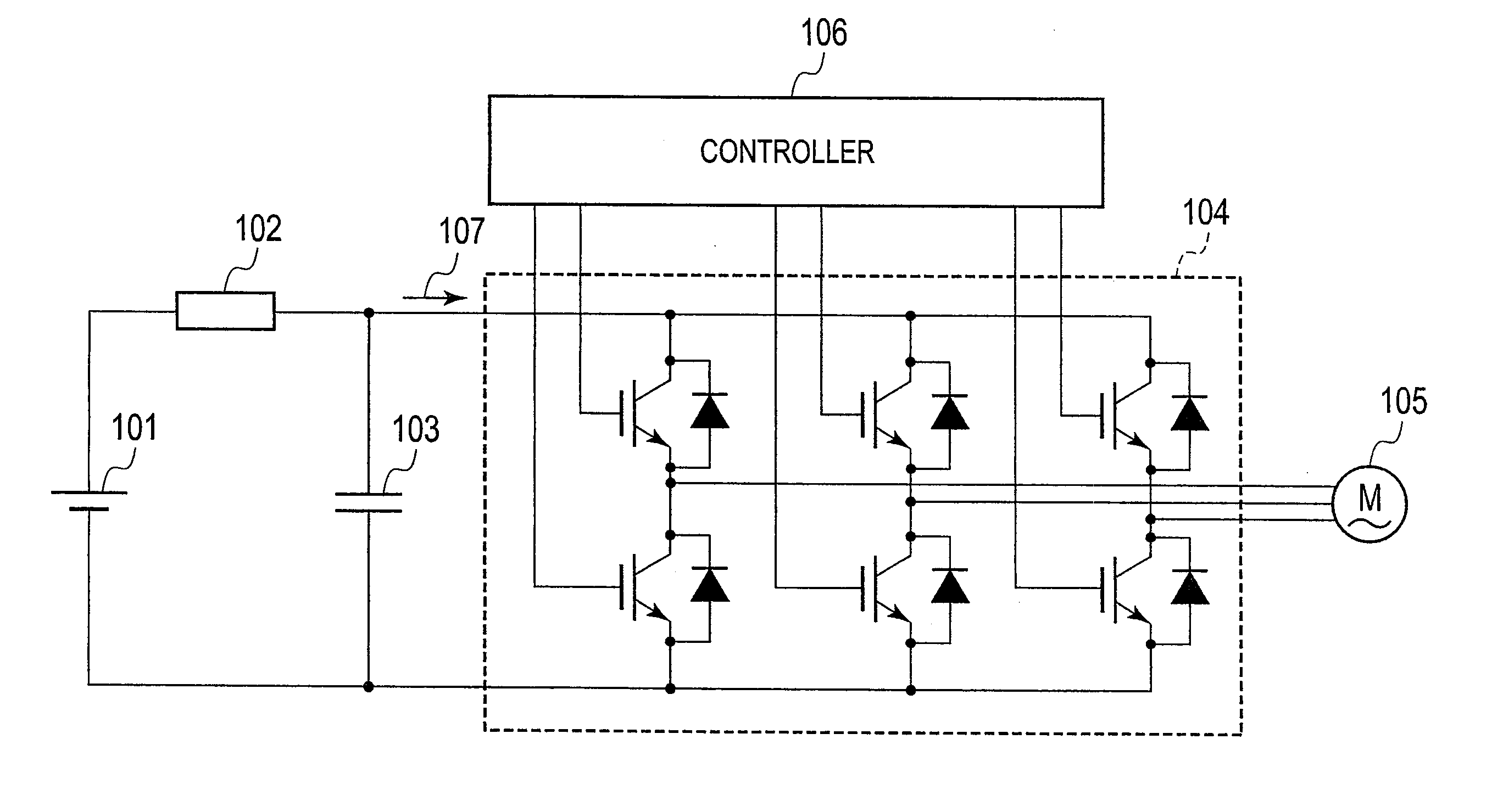

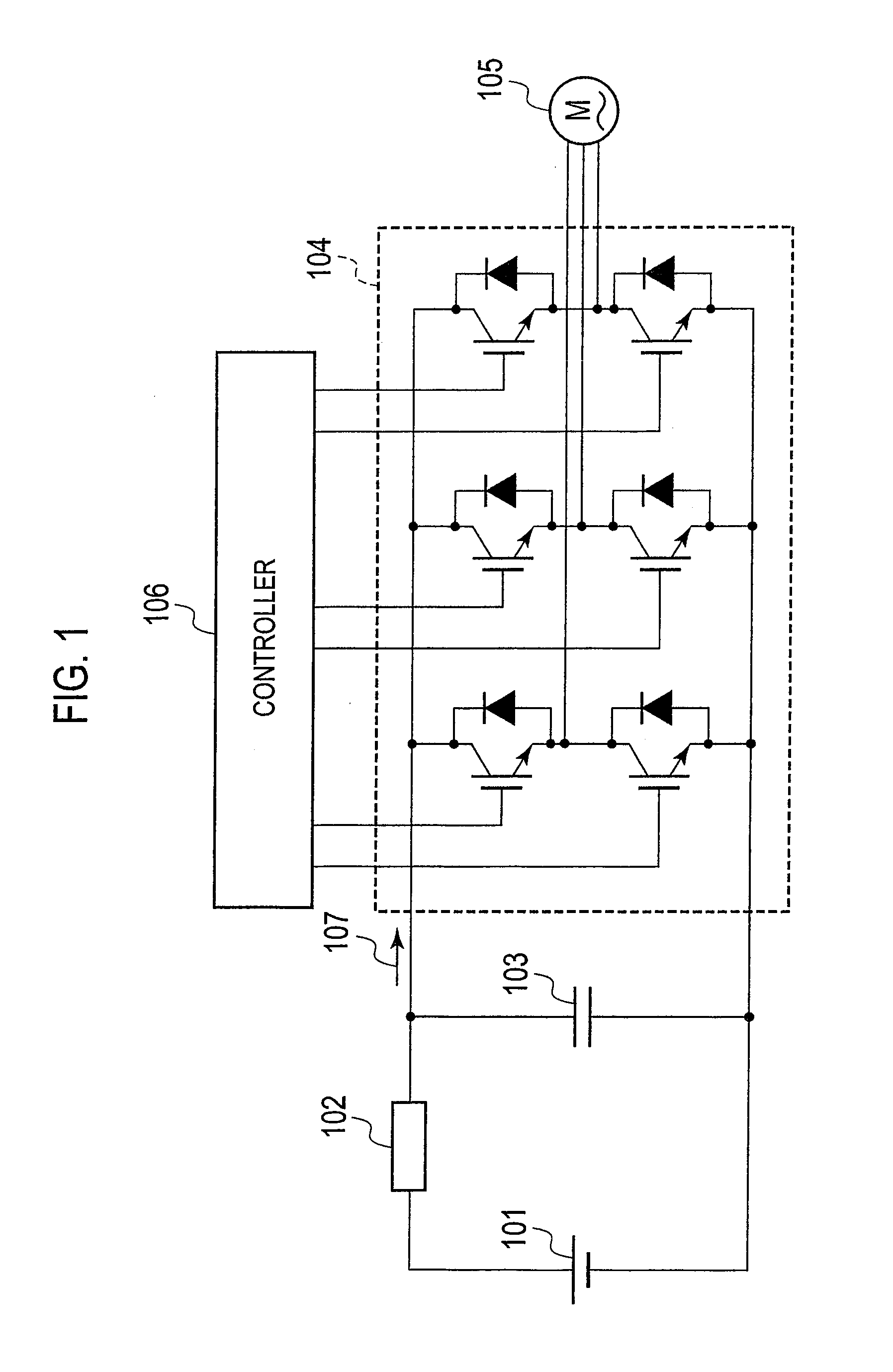

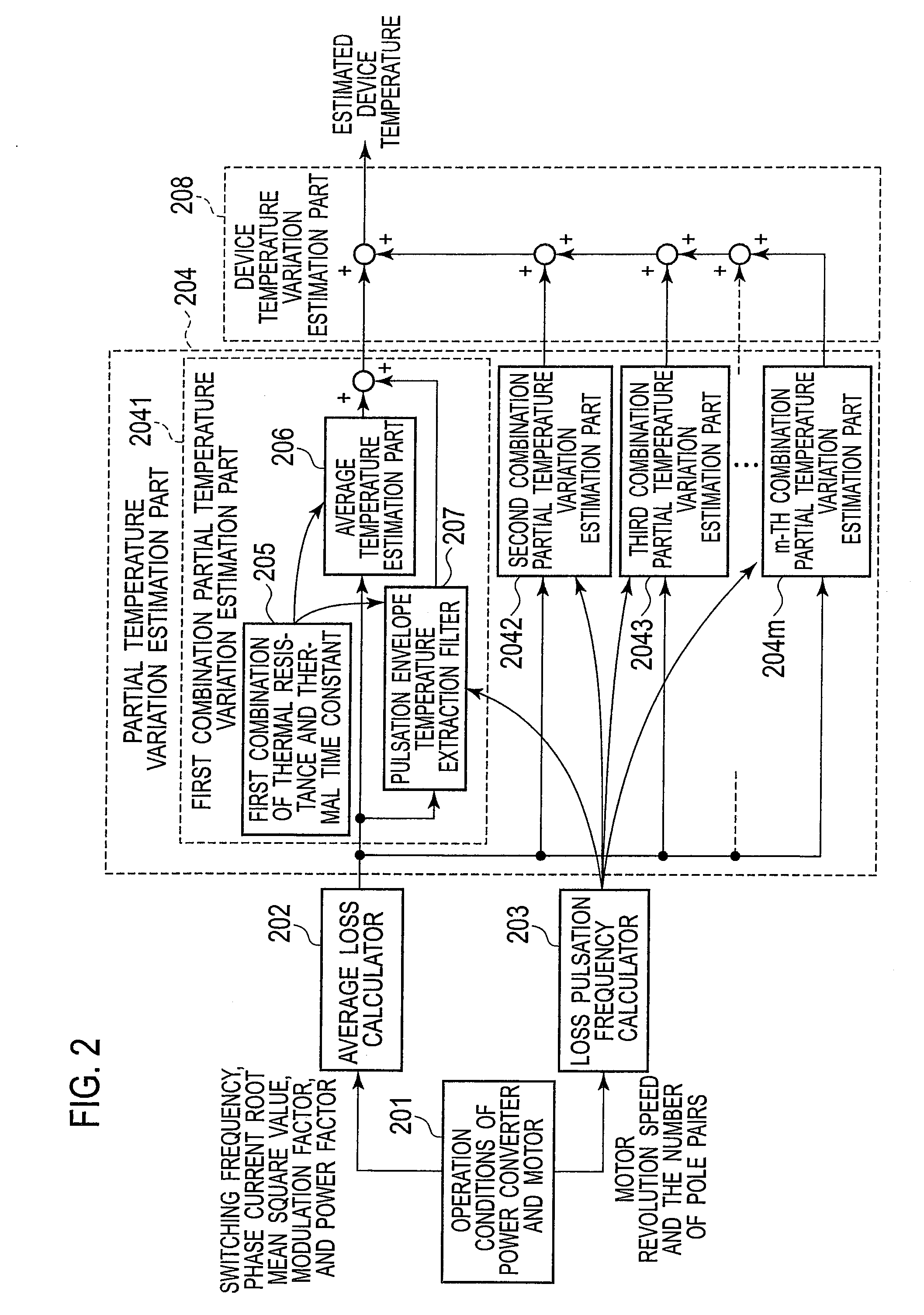

Controller of power converter

ActiveUS20130135906A1Effective protectionAvoid heatAC motor controlElectric motor controlEngineeringSemiconductor

A controller of a power converter has: an average loss calculator (202) calculating an average loss in a semiconductor device; and a partial temperature variation estimation part (204), while regarding the semiconductor device as a thermal network including at least one combination of a thermal resistance and a thermal time constant, estimating a partial temperature variation of the combination from a loss in the semiconductor device and the combination of the thermal resistance and the thermal time constant. The partial temperature variation estimation part (204) estimates an average temperature from the loss, the thermal resistance, and the thermal time constant; extracts a pulsation envelope temperature exceeding the maximum value of a pulsation temperature dependent on the average loss and the pulsation frequency; and estimates a temperature variation in the semiconductor device by adding the average temperature and the pulsation envelope temperature.

Owner:NISSAN MOTOR CO LTD

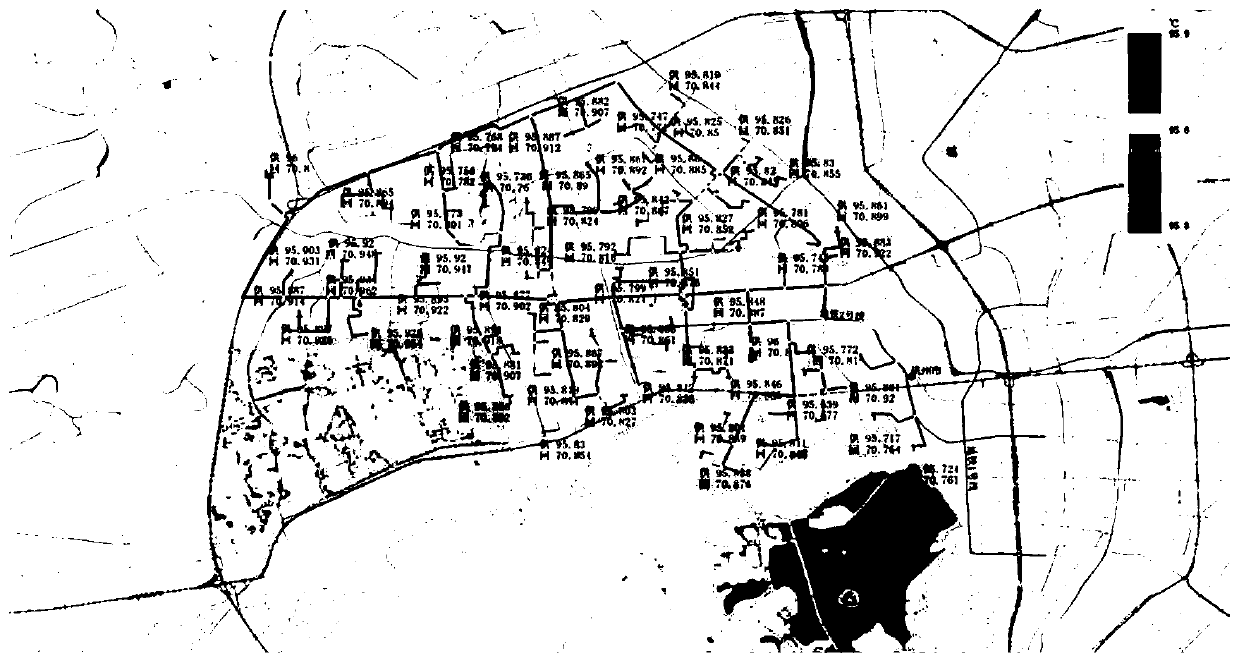

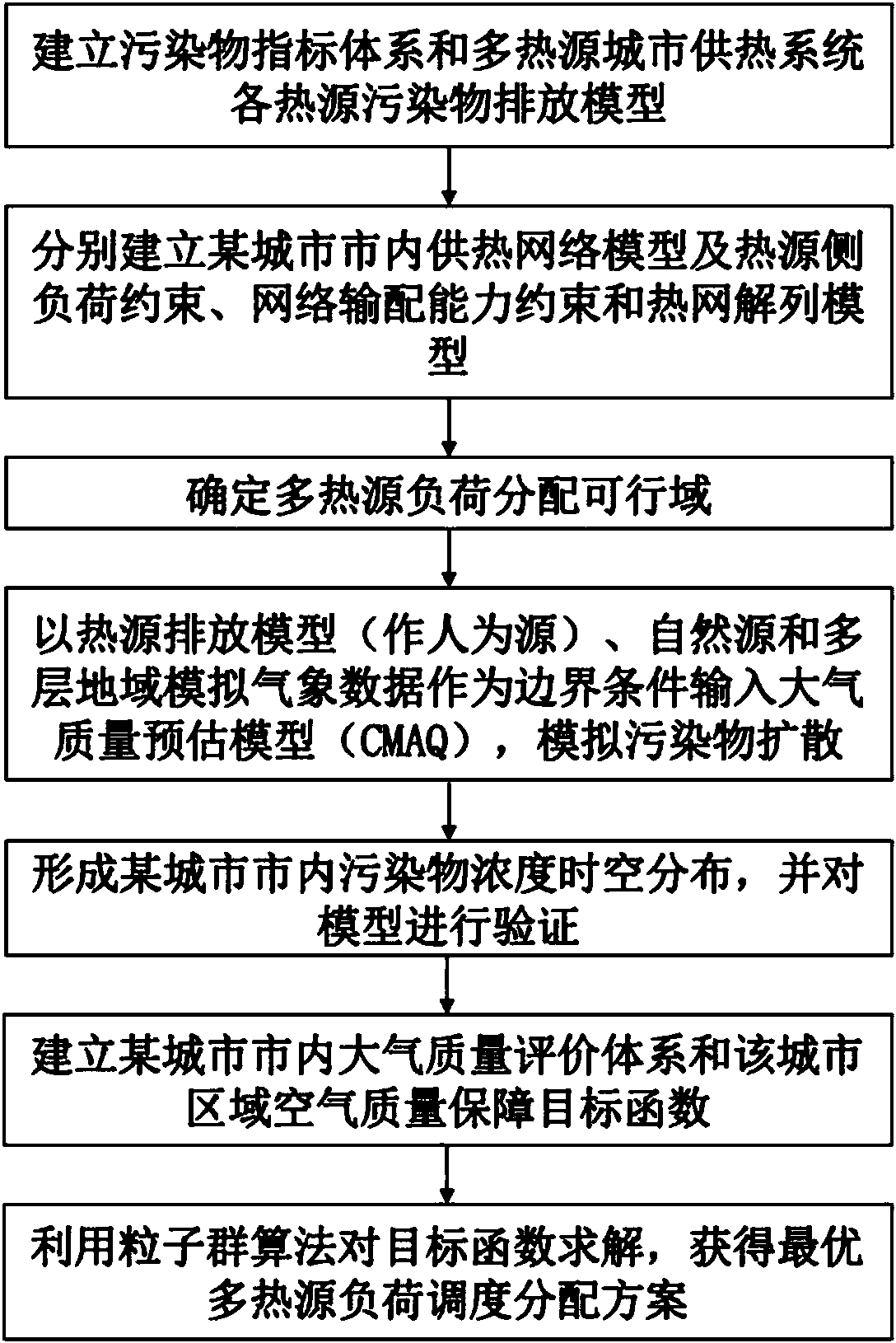

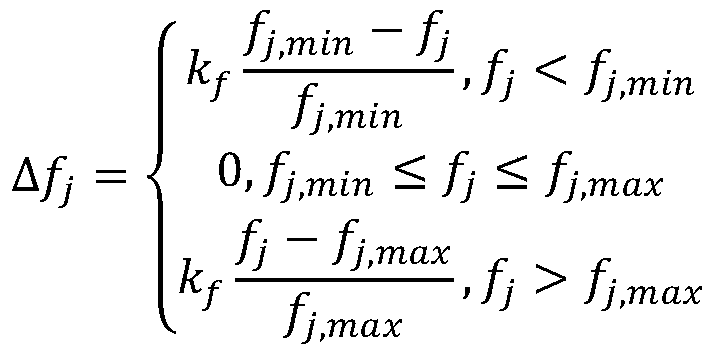

Multi-heat-source heat supply system load scheduling distribution method and system based on urban atmospheric diffusion process simulation prediction

ActiveCN111461439AQuality improvementAdd constraintsLighting and heating apparatusForecastingPollutant emissionsNetwork model

The invention relates to a multi-heat-source heat supply system load scheduling distribution method and system based on urban atmospheric diffusion process simulation prediction. The method comprisesthe following steps that S1, all heat source pollutant emission models are established; s2, establishing a heat supply network model, a heat source side load constraint, a heat supply network transmission and distribution capability constraint and a heat supply network splitting model, and determining a multi-heat-source load distribution feasible region; s3, importing the multi-layer regional simulation meteorological data and the pollutant list as boundary conditions into an atmospheric quality prediction model system, generating pollutant concentration space-time distribution, and verifyingthe model; s4, establishing an atmospheric quality evaluation system; and S5, constructing a target function of the lowest atmospheric pollution, and performing multi-scheme comparison on line to ensure that the atmospheric quality of the key region reaches the standard in a specific period and obtain an optimal multi-heat-source heat supply system load scheduling distribution scheme. The methodand the system provided by the invention can effectively solve the problem of air quality guarantee during major activities.

Owner:ZHEJIANG UNIV

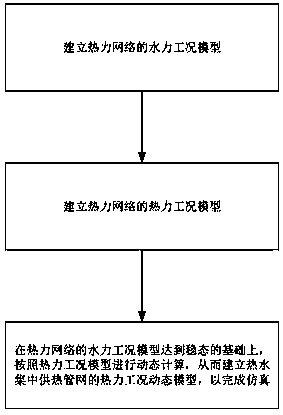

Thermal network dynamic simulation method and device

ActiveCN111222213AAccurate calculationReduce mistakesGeometric CADDesign optimisation/simulationEngineeringNetwork media

The invention relates to a thermal network dynamic simulation method and device, and belongs to the technical field of comprehensive energy service. The method comprises the steps: establishing a hydraulic working condition model and a thermal working condition model of a thermal network; in a pipeline characteristic equation of the hydraulic working condition model, enabling the density, which reflects the influence of the physical parameter, on the hydraulic working condition in the state that the temperature of a heat supply network medium changes, to serve as a variable for processing; inan energy equation of the thermal working condition model, taking the density and the specific heat capacity, which reflects the influence of the two physical property parameters on the thermal working condition in the state that the temperature of a heat supply network medium changes, as variables,. According to the invention, the temperature results calculated by the hydraulic working conditionmodel and the thermal working condition model are closer to the actual temperature, the error is small, and the reliability is high; through the specific heat capacity serving as the variable quantityin the energy equation, the energy storage effect of the stock working medium in the pipe network in the energy conveying process of the heat supply pipe network is fully considered, and the dynamiccharacteristics in the energy conveying process of the heat supply pipe network can be effectively reflected.

Owner:XUJI GRP +4

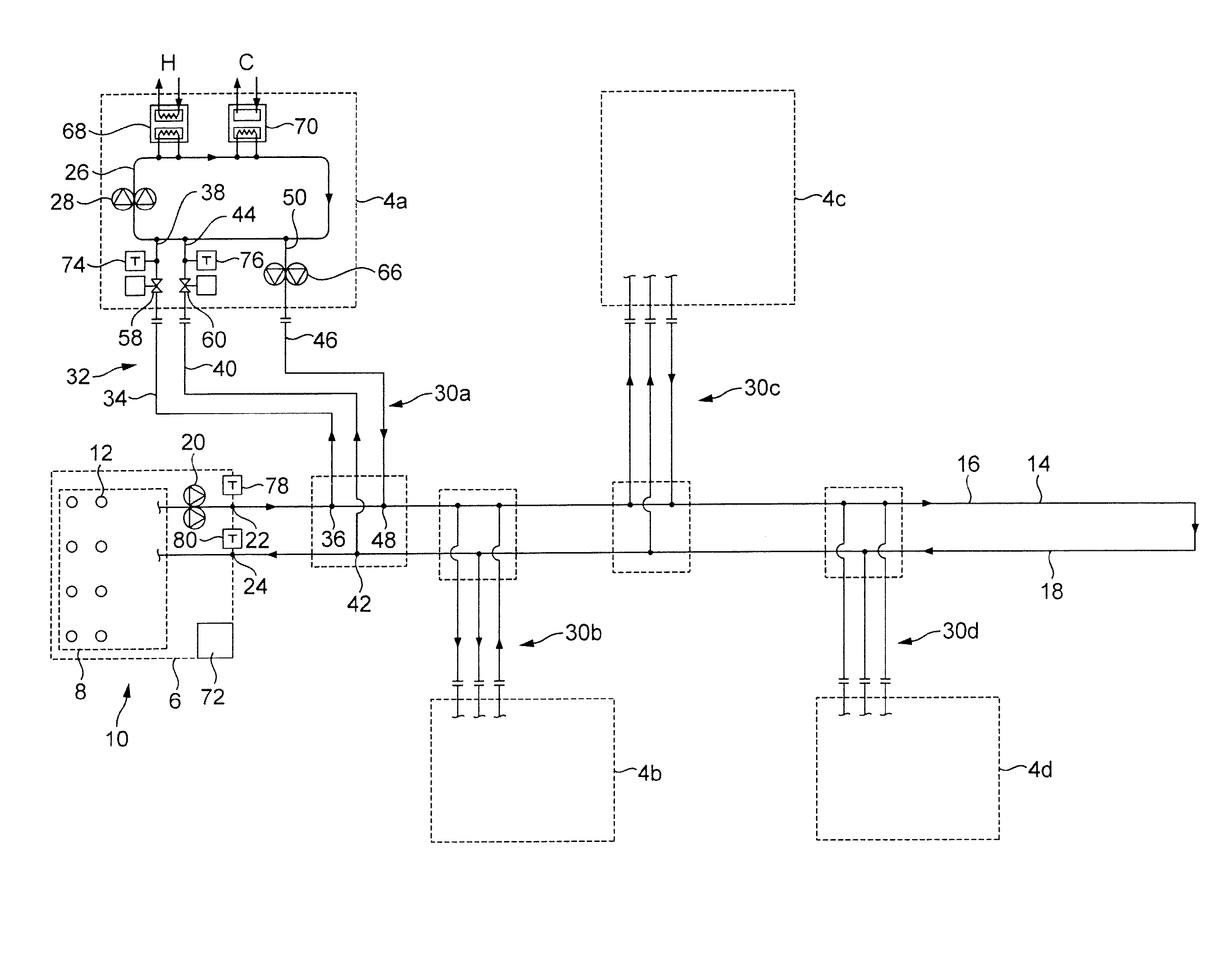

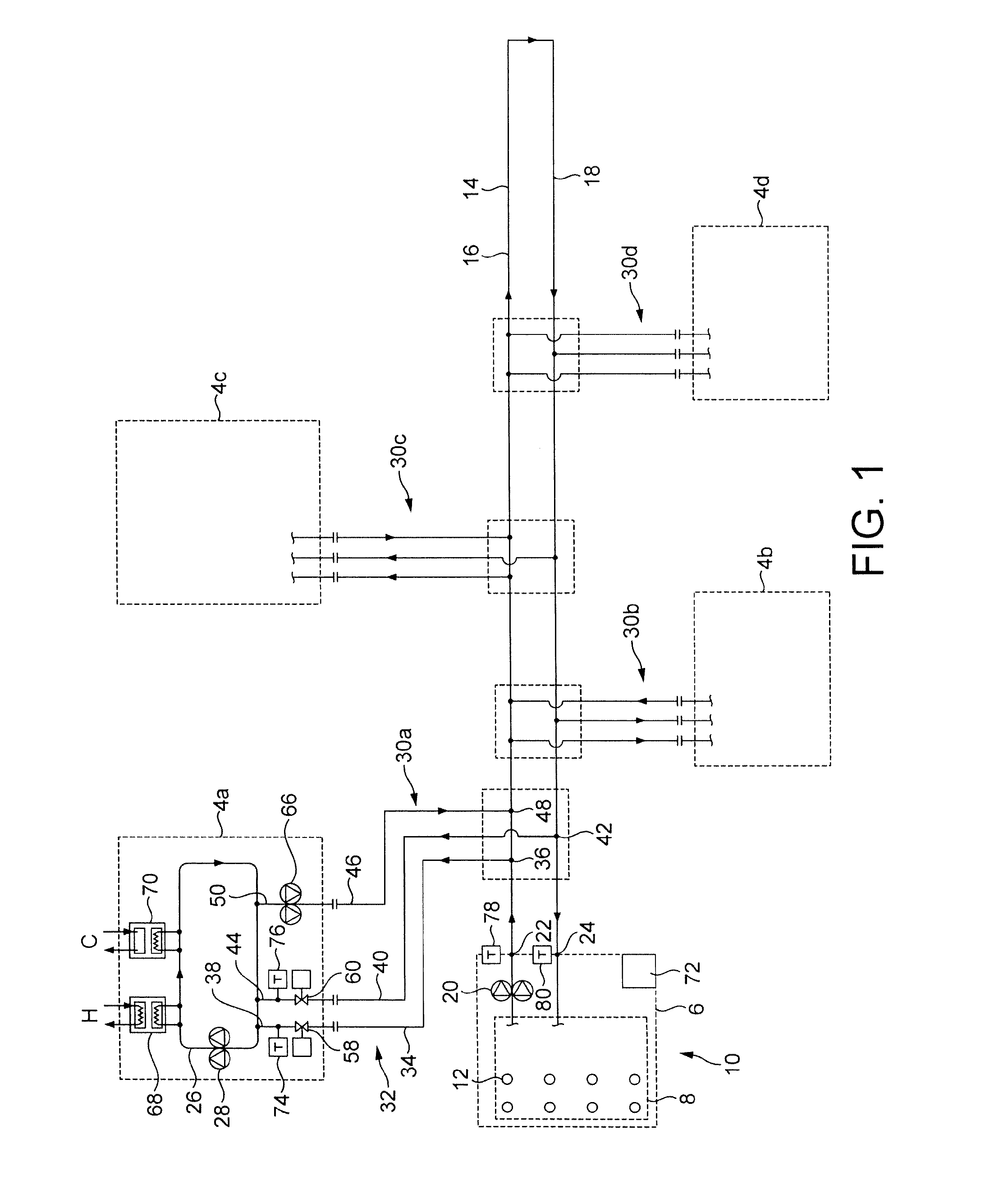

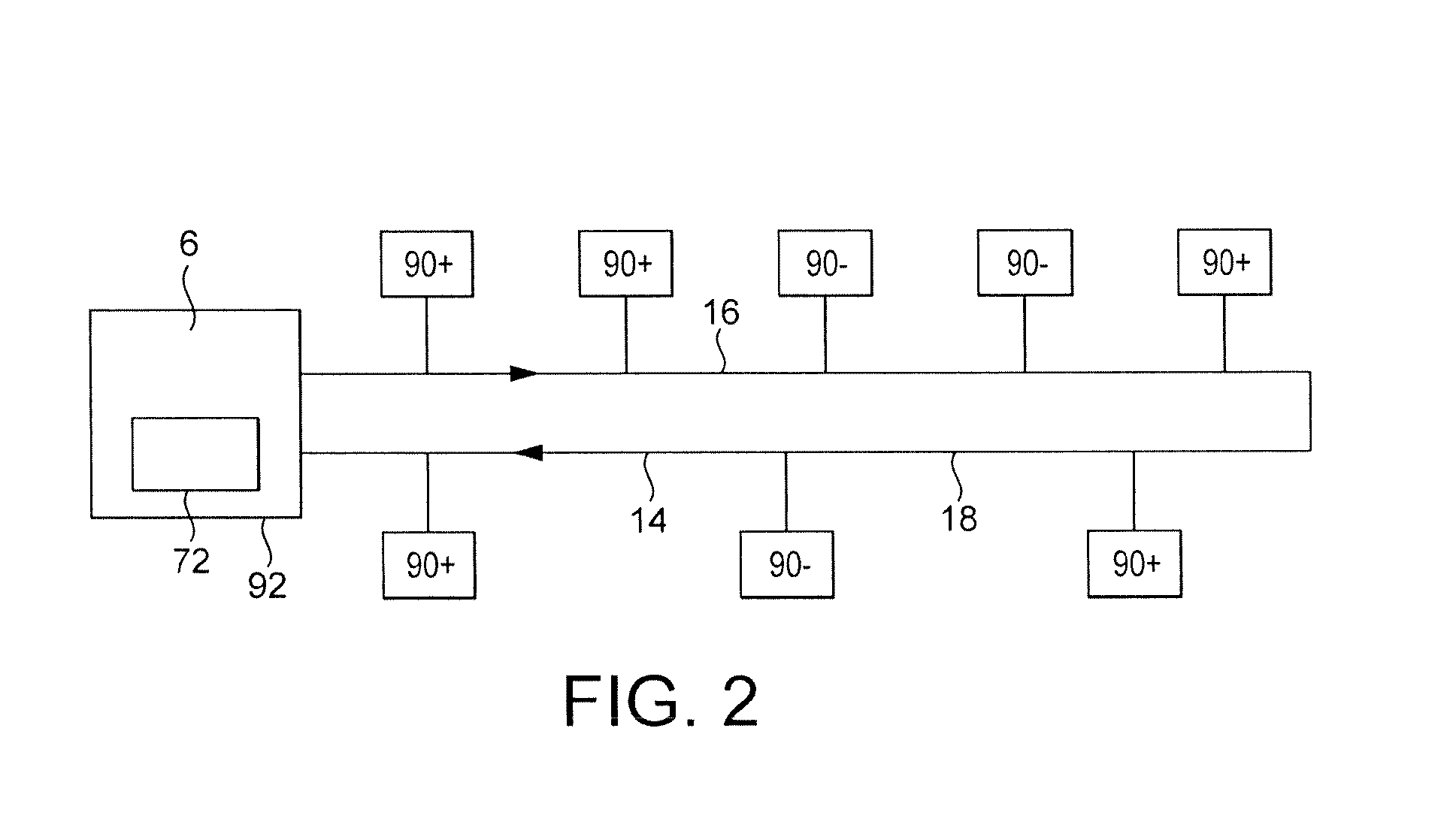

Thermal energy network

InactiveUS20160334116A1Increase heatDistrict heating systemLighting and heating apparatusThermal energyWorking fluid

A district energy network interconnecting a plurality of thermal loads and for redistributing thermal energy therebetween, the network comprising: a primary circuit loop for working fluid, at least two thermal loads thermally connected to the primary circuit loop, at least one of the thermal loads being capable of taking heat from the primary circuit loop and at least one of the thermal loads being capable of rejecting heat into the primary circuit loop, an energy centre connected to the loop and capable of acting as a heat source or a heat sink, and a control system adapted to provide to the primary circuit loop a positive or negative thermal input from the energy centre as a balancing thermal input to compensate for net thermal energy lost to or gained from the at least two thermal loads by the primary circuit loop.

Owner:GREENFIELD MASTER IPCO

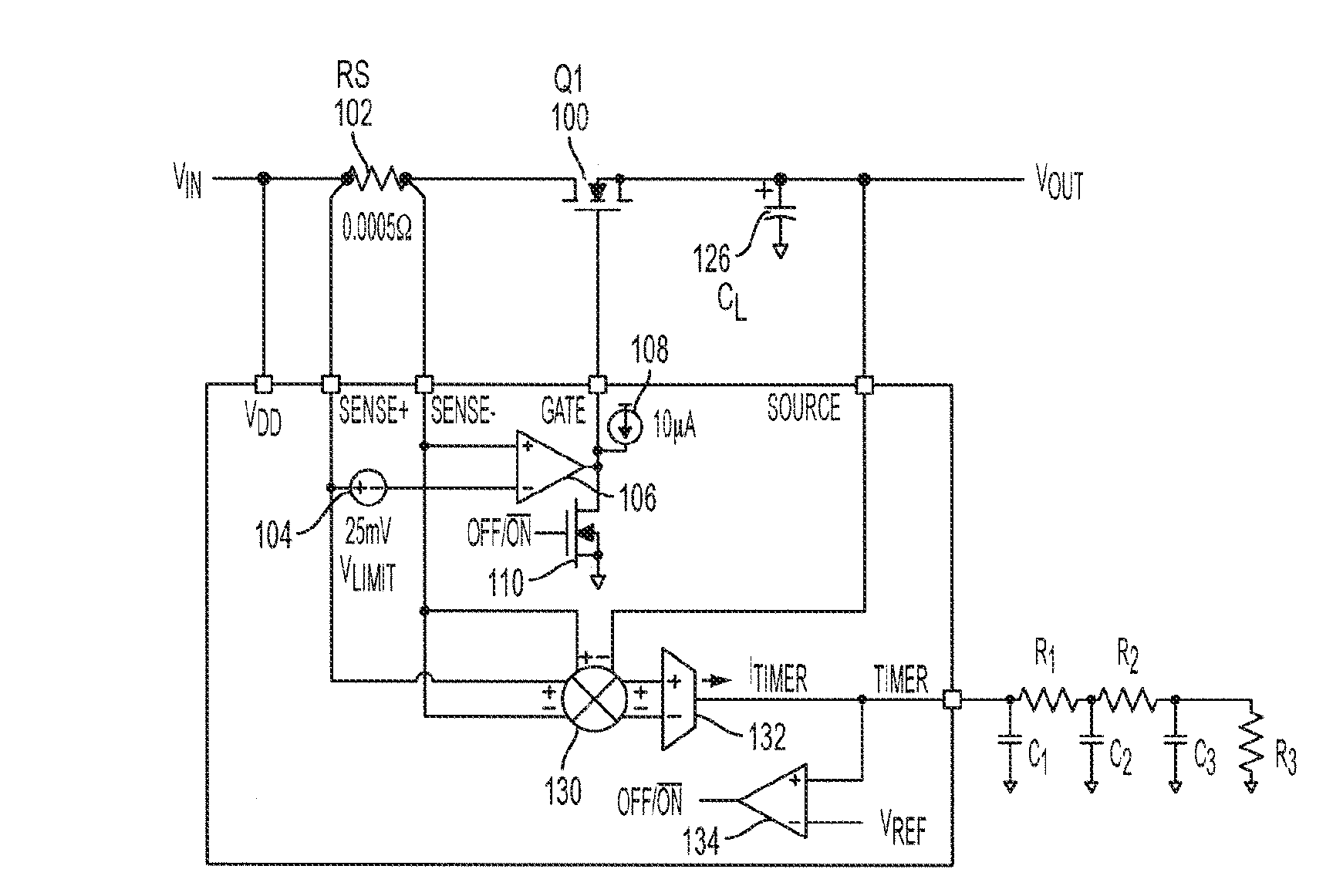

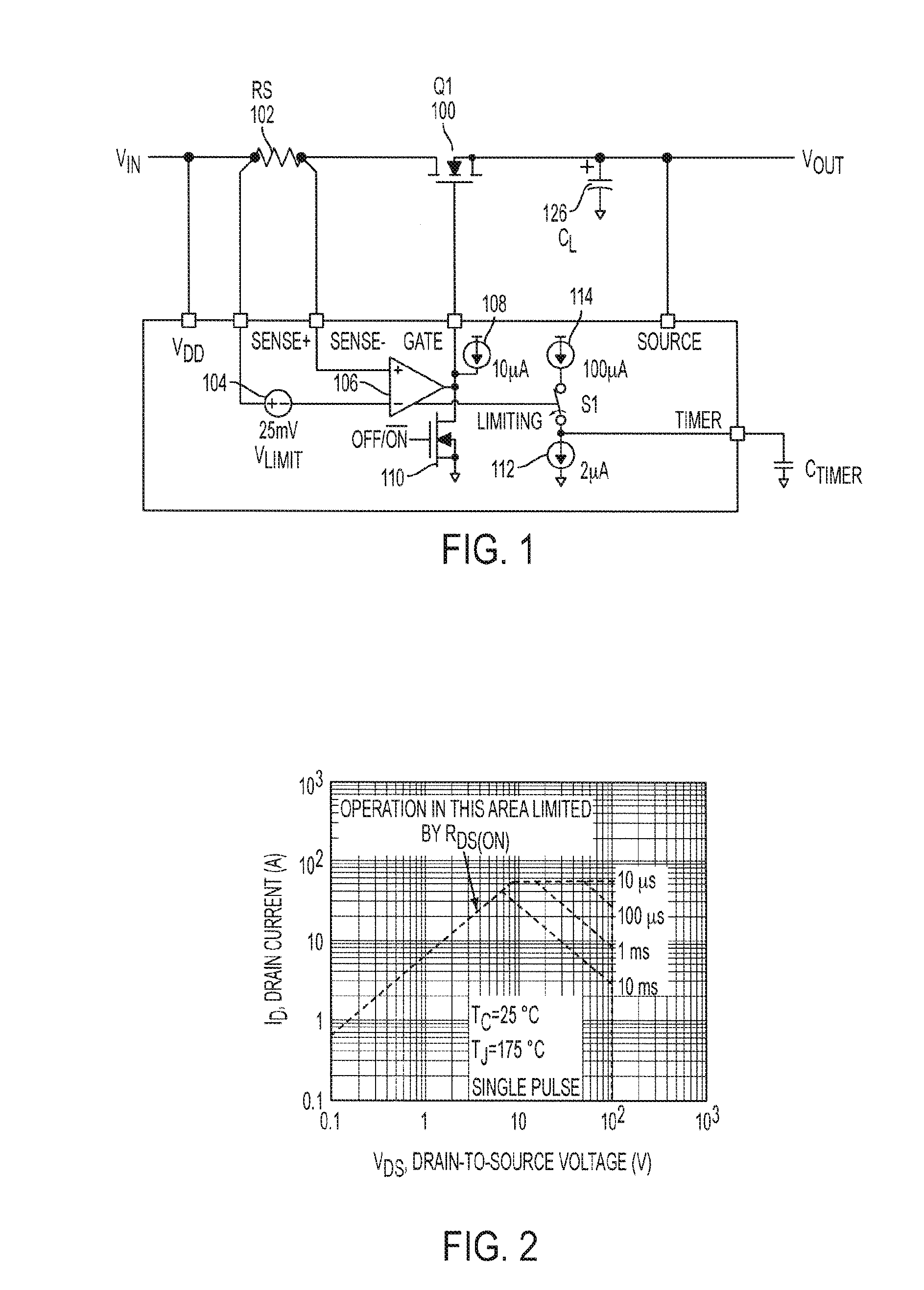

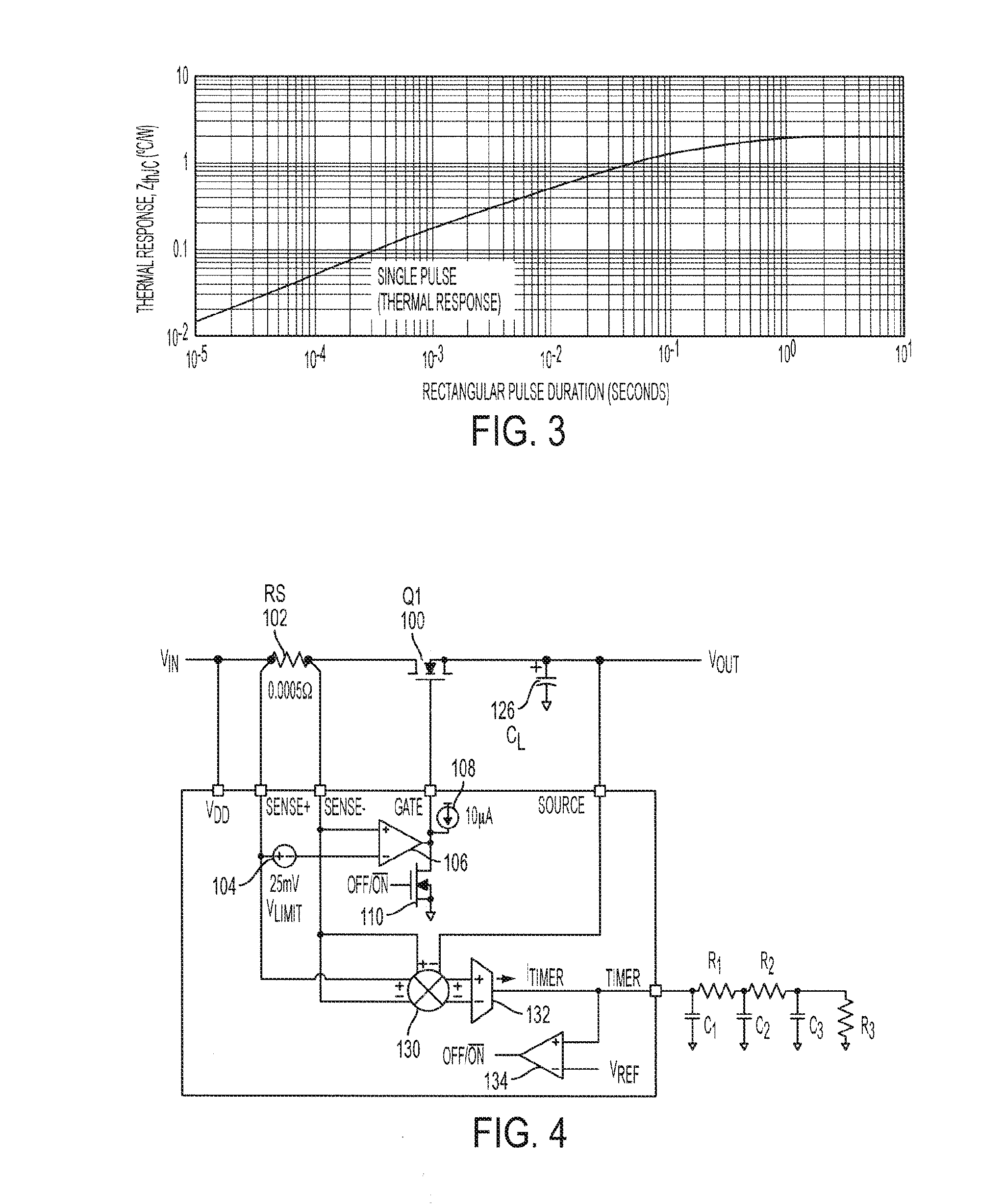

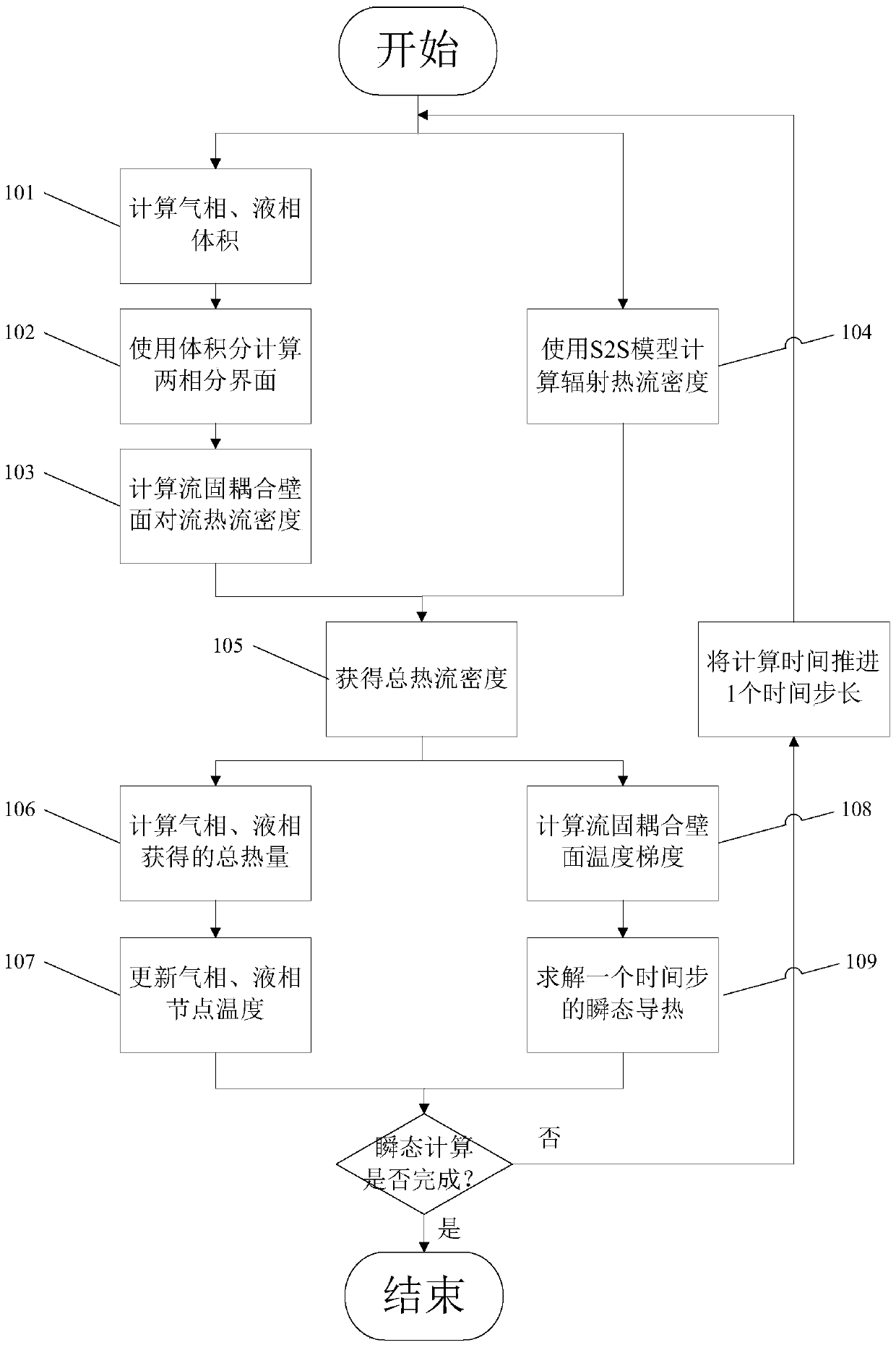

Mosfet protection using resistor-capacitor thermal network

ActiveUS20160218501A1Reduce in quantityTime can be short and longTransistorOther resistor networksMOSFETCapacitance

A circuit for protecting a semiconductor element is provided in a system for supplying power from an input node to an output node. The circuit has an analog multiplier responsive to a voltage across the semiconductor element and a current flowing through the semiconductor element to produce an output voltage. A transconductance amplifier is coupled to an output of the analog multiplier for receiving the output voltage of the analog multiplier to produce an output current. An analog RC circuit coupled to the output of the transconductance amplifier is configurable to include a selected number of resistive elements having selected resistance values and a selected number of capacitive elements having selected capacitance values. The configuration of the RC circuit is carried out to provide an RC thermal model that reproduces a desired thermal behavior of the semiconductor element. The RC circuit is responsive to the output current of the transconductance amplifier to produce an output voltage used to control the semiconductor element.

Owner:ANALOG DEVICES INT UNLTD

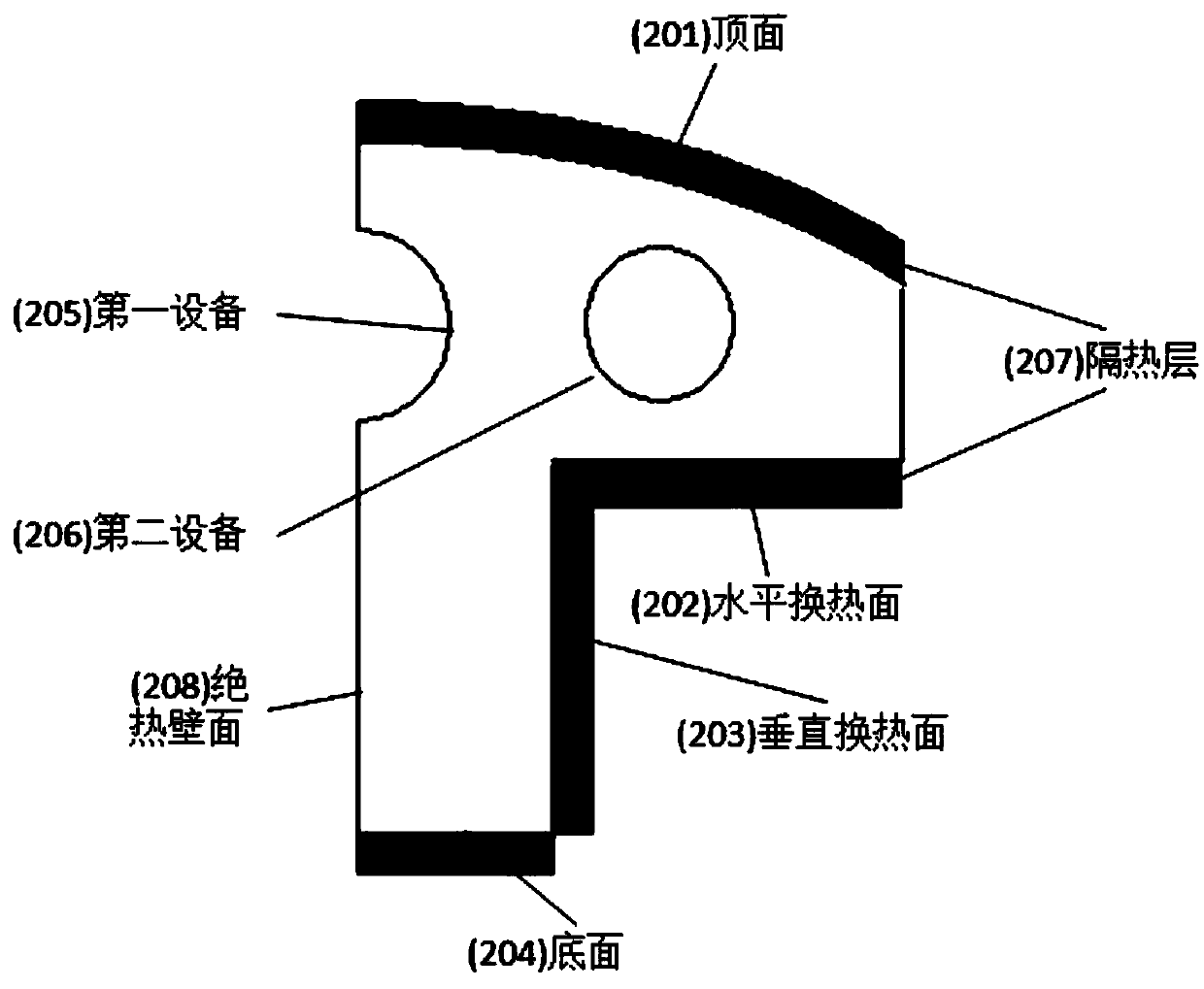

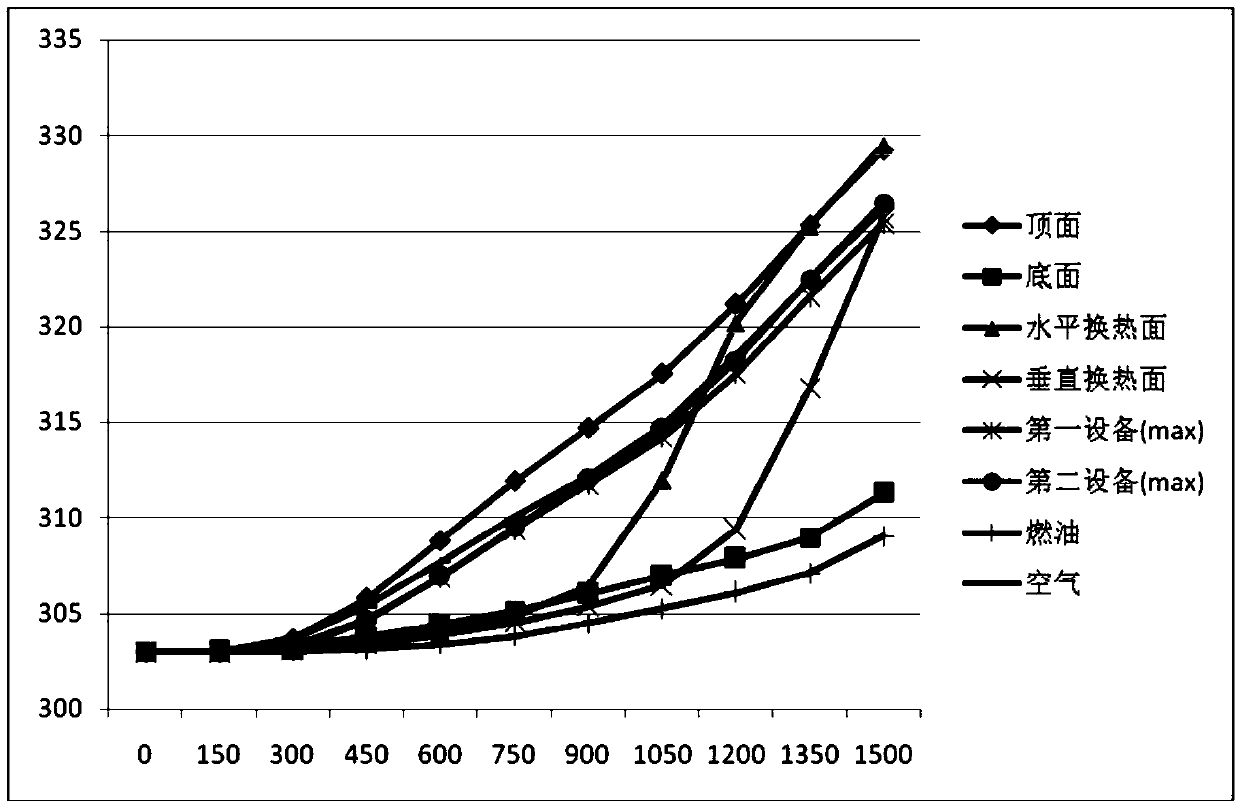

Fluid-solid node two-phase flow modeling method

ActiveCN105512433ADesign optimisation/simulationSpecial data processing applicationsGas phaseFuel tank

The invention discloses a fluid-solid node two-phase flow modeling method used for achieving gravity-driven fluid-structure interaction heat transfer of two-phase flow without phase change. The method is characterized in that accurate calculation of a flow field is ignored, and the two-phase flow is processed according to a node thermal network thought. The method specifically comprises the steps that A, a liquid phase and a gas phase are abstracted into nodes with certain mass, volume and temperature; B, a gravity direction volume integral is used for calculating the interface between the two phases; C, a surface radiation heat transfer model is used for calculating the radiation heat flux density of a fluid-structure interaction wall; D, the temperature of the gas phase and the temperature of the liquid phase are calculated according to the heat convection heat flux density of the fluid-structure interaction wall; E, solid transient heat conduction is calculated according to the total heat flux density of the fluid-structure interaction wall. Targeting the fluid-structure interaction heat transfer process of the two-phase flow in a typical fuel tank, compared with a calculated result obtained through a Fluent business software phase field method, the calculated result obtained through the modeling method better reflects the influence of the phase interface on heat transfer, calculation efficiency is improved by one order of magnitude, and the engineering calculation demand is met.

Owner:BEIHANG UNIV

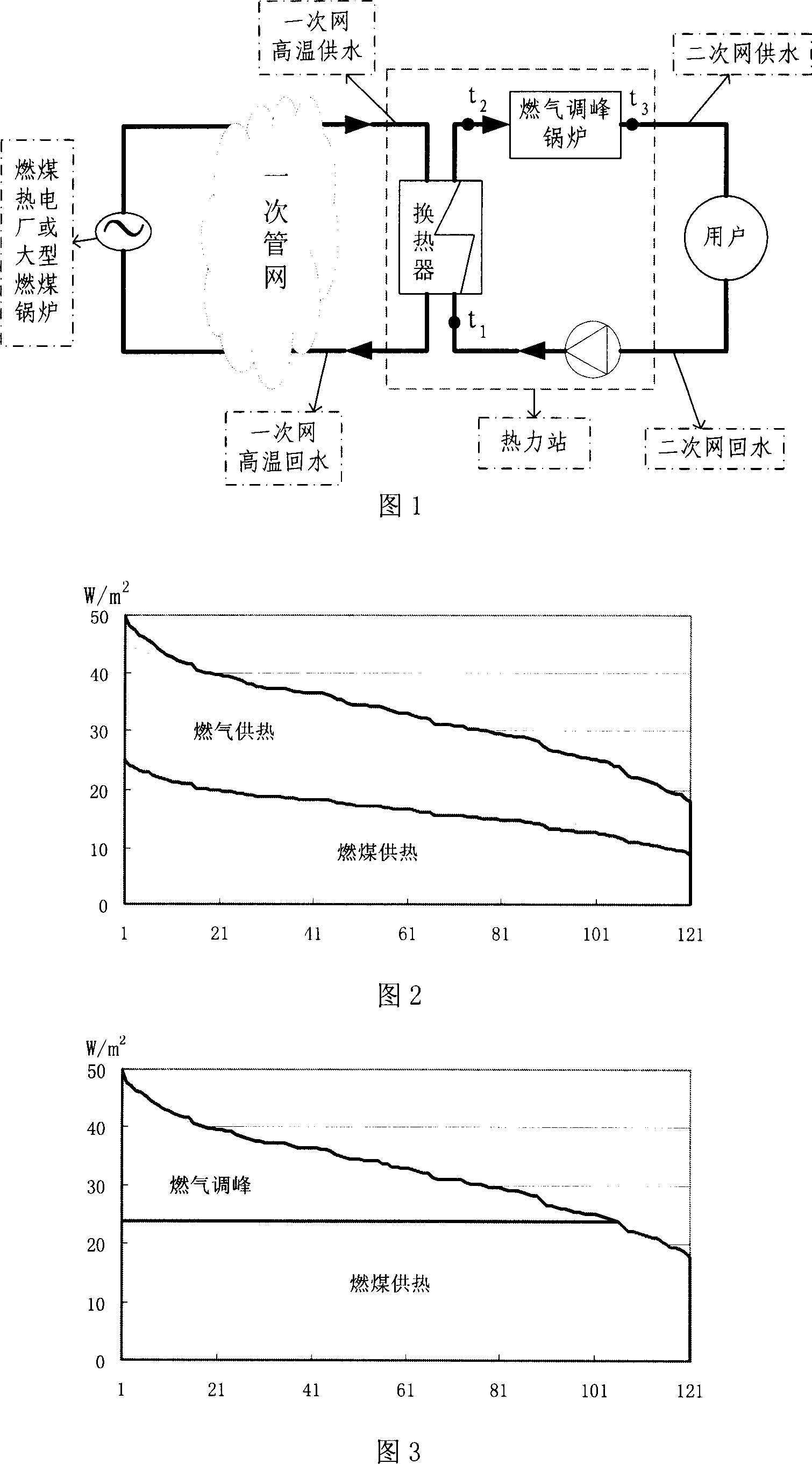

Fuel coal and fuel gas united heat supply method

ActiveCN1952493AImprove heating energy efficiencyReduce energy consumptionDistrict heating systemLighting and heating apparatusSmall peakCogeneration

The invention relates to a coal-gas combined heating supply method, belonging to HVAC area. The first step of said method is that small peak-shaving boiler with burning gas, as peak-shaving thermal source, running with the parallel of central heat network, is set in each thermal station of civil thermal network with the heat source, which is the boiler in the huge heat supply or coal-burning region. Said secondary backwater is that first heat exchanger obtains quantity of heat generated by the boiler of coal-burning thermal power station or huge coal-burning region and transmitted by the first pipe network, and then it is heated furthermore by small gas-burning peak-shaving boiler so that independent adjusting in time on each heat supply region is accomplished. Thermal resource only bears the basic load of heat supply and the lack of heat is compensated by small gas-burning peak-shaving boiler in each thermal power station. The heat value is changed as the relation of climate and requirement changes. Said first network also bears adjusting action.

Owner:BEIJING QINGJIAN ENERGY TECH CO LTD

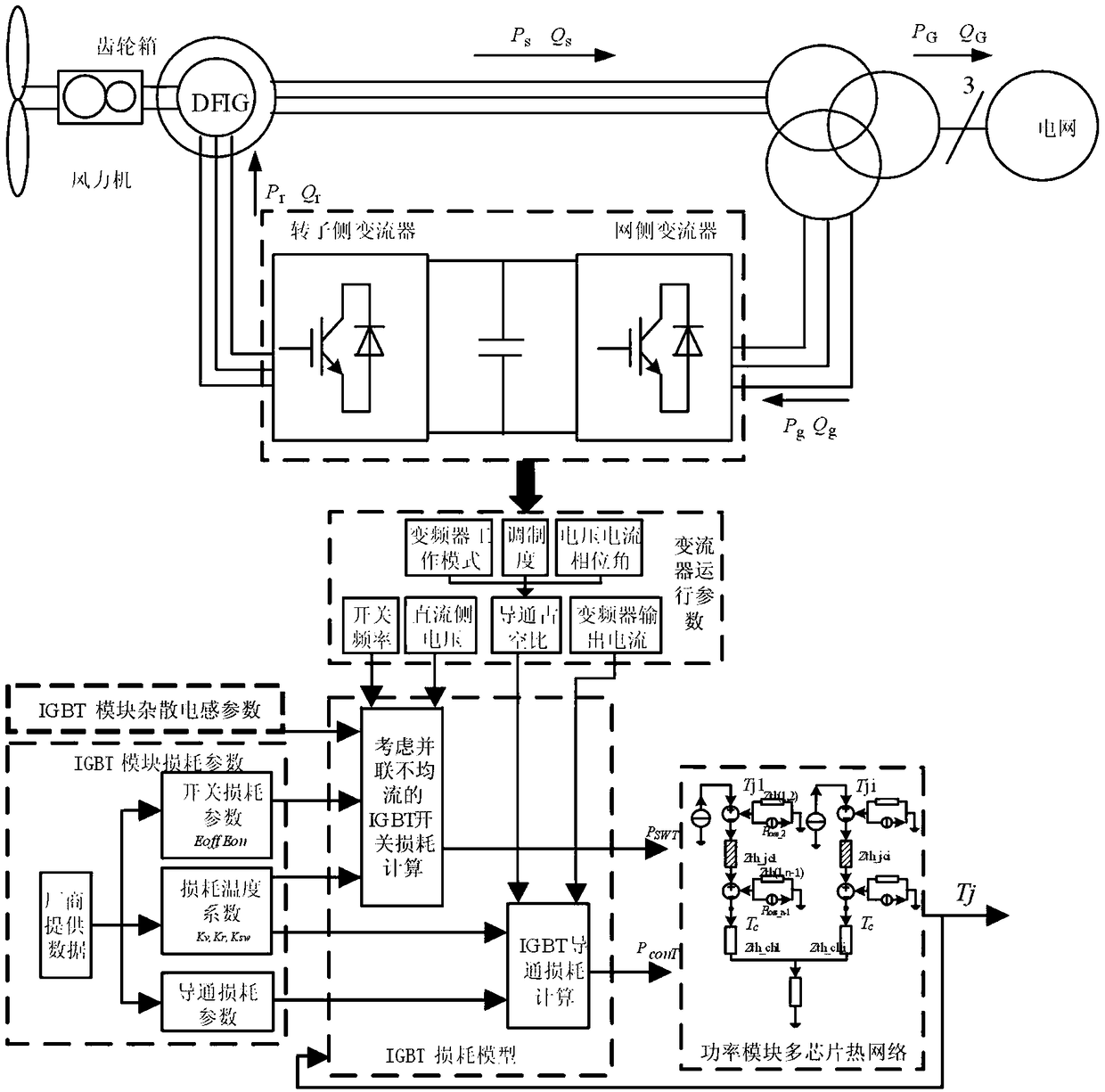

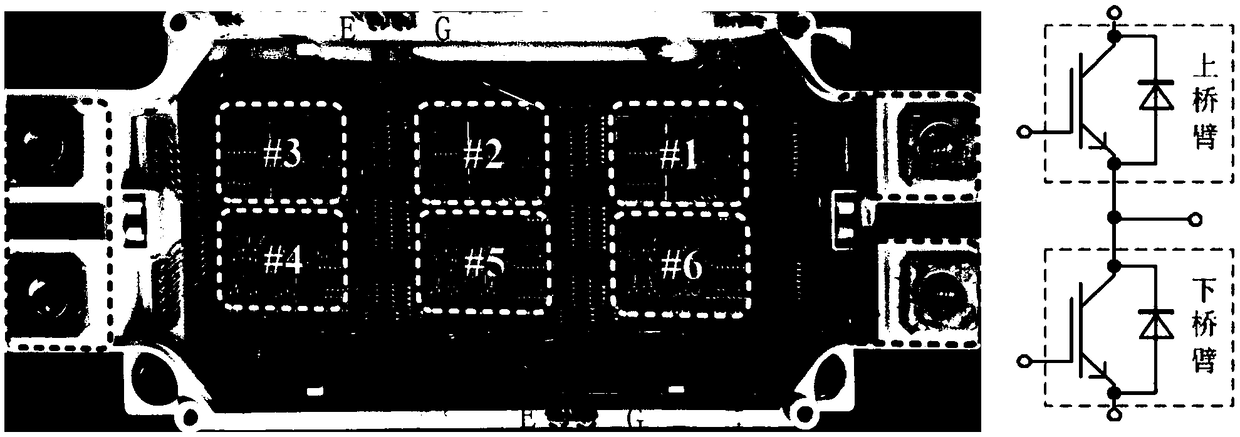

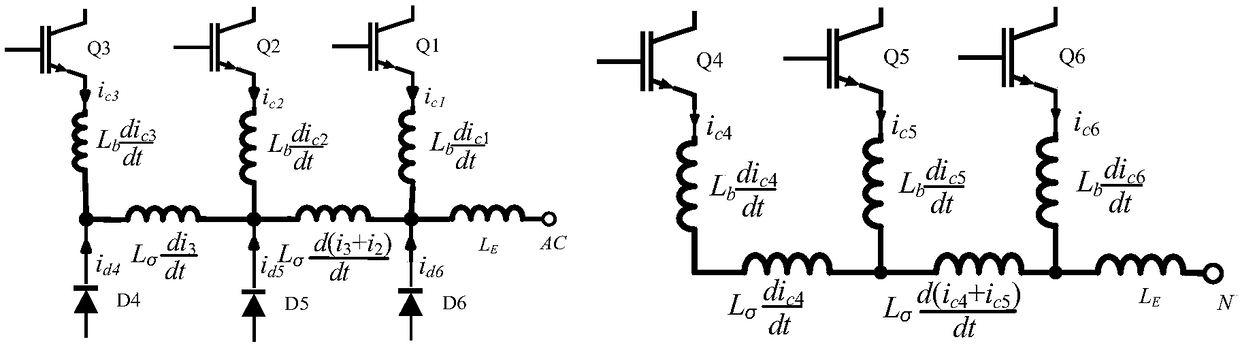

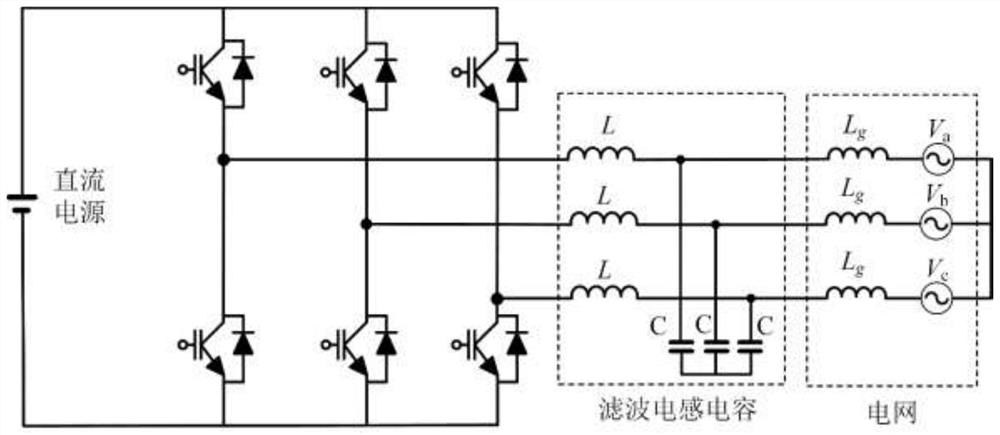

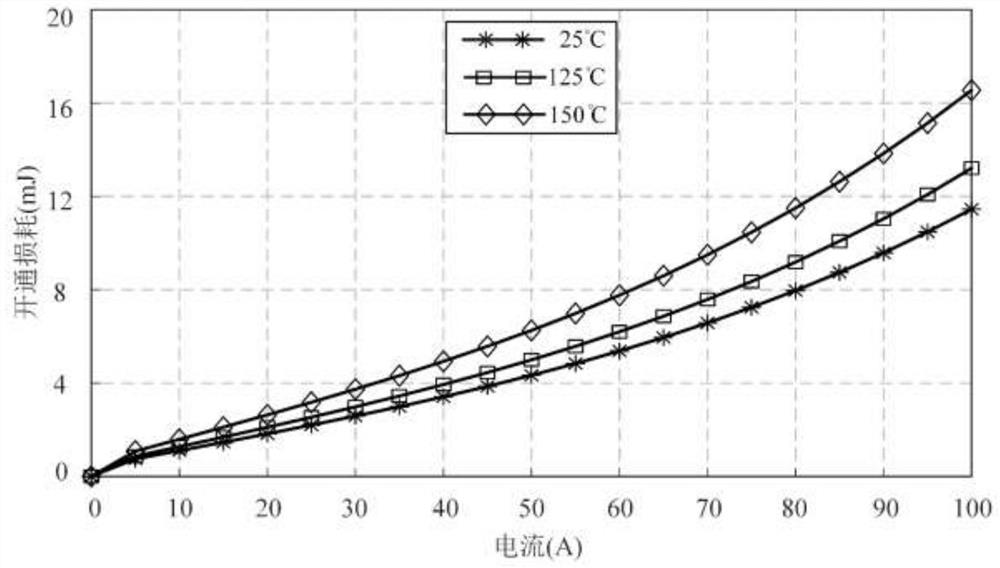

Dynamic junction temperature calculation method of IGBT power module of wind power converter considering the influence of stray inductance

ActiveCN109274255AImproved Thermal Management Control StrategiesAccurately reflectSingle network parallel feeding arrangementsWind energy generationNew energyStray inductance

The invention relates to a method for calculating the dynamic junction temperature of an IGBT power module of a wind power converter considering the influence of stray inductance, The invention belongs to the technical field of high-power power electronic device reliability for new energy power generation. The method comprises the following steps: S1, establishing an equivalent circuit model of anIGBT module according to the dynamic uneven current between parallel multi-chips caused by stray inductors; S2: deriving The mathematical relationship between the stray inductance parameters and theswitching-on loss; S3: Introducing the equivalent thermal coupling impedance to establish the thermal network model considering the thermal coupling between chips; 4, establishing a dynamic junction temperature calculation model of that IGBT module, feeding the junction temperature distribution result back to a mathematical relation model of los, and iteratively obtaining the dynamic junction temperature distribution among chips in the IGBT module. The invention can accurately reflect the dynamic heat distribution inside the IGBT power module, effectively characterize the heat weak links inside the module, and improve the heat management control strategy of the wind power converter, thereby improving the reliability thereof.

Owner:重庆平创半导体研究院有限责任公司

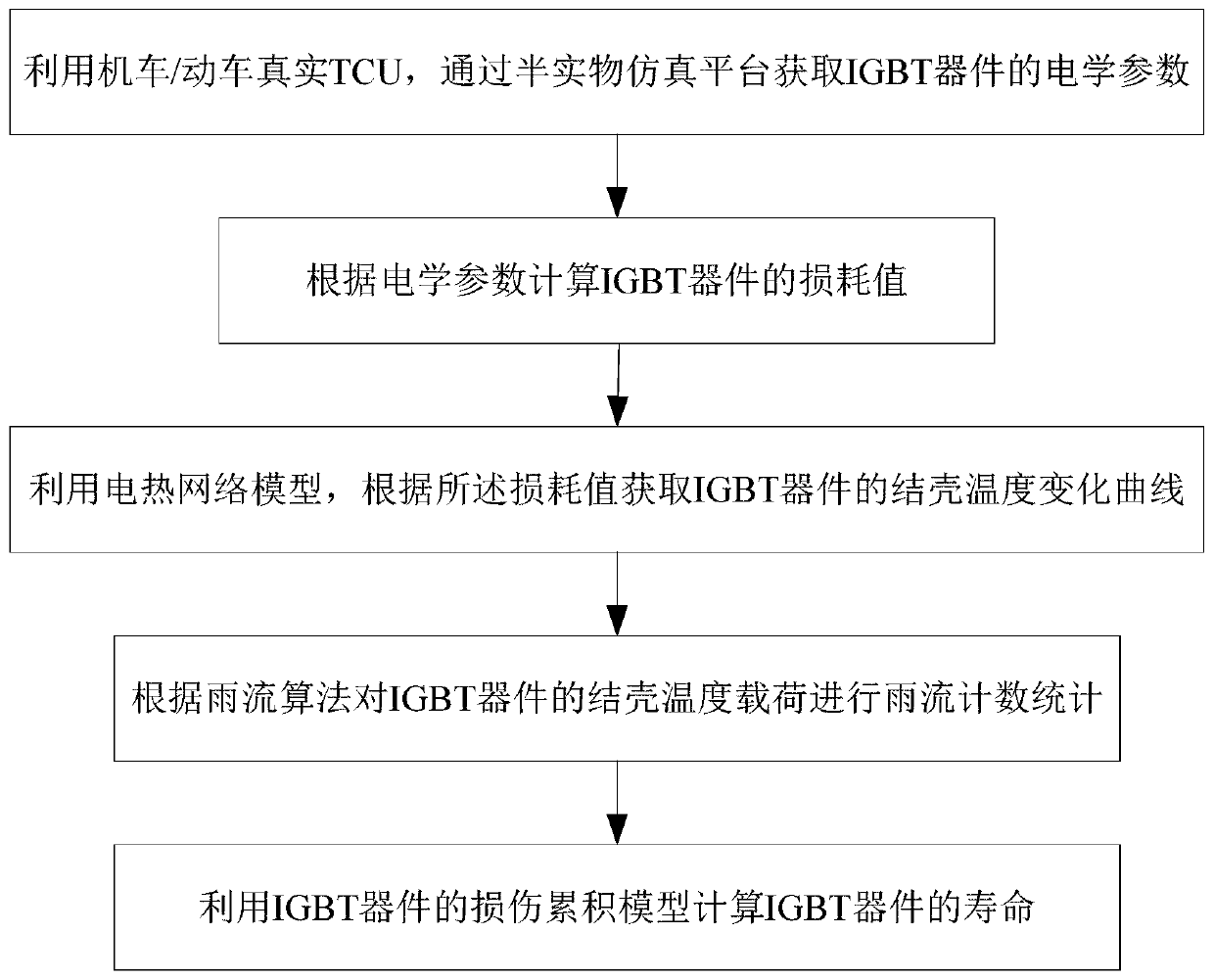

Life prediction method of IGBT device based on semi-physical simulation platform

ActiveCN110147578ARealize full lifecycle managementEquivalent AccuracyDesign optimisation/simulationSpecial data processing applicationsSimulationNetwork model

The invention belongs to the technical field of power electronic devices for rail transit, and particularly relates to an IGBT device service life prediction method based on a semi-physical simulationplatform, which comprises the following steps: obtaining electrical parameters of an IGBT device through the semi-physical simulation platform by using a locomotive / bullet train real TCU; calculatinga loss value of the IGBT device according to the electrical parameters; utilizing an electric heating network model to obtain a crusting temperature change curve of the IGBT device according to the loss value; performing rain current counting statistics on the crusting temperature load of the IGBT device according to a rain current algorithm; and calculating the service life of the IGBT device byusing the damage accumulation model of the IGBT device. According to the service life prediction method, current and voltage changes which are closer to actual working conditions are provided by using the real TCU of the bullet train / locomotive and are equivalent to the accuracy of on-site acquired data, so that a theoretical basis is provided for determining the replacement time of the IGBT device for rail transit and realizing the full-service life cycle management of the IGBT device.

Owner:XIAN YONGDIAN ELECTRIC

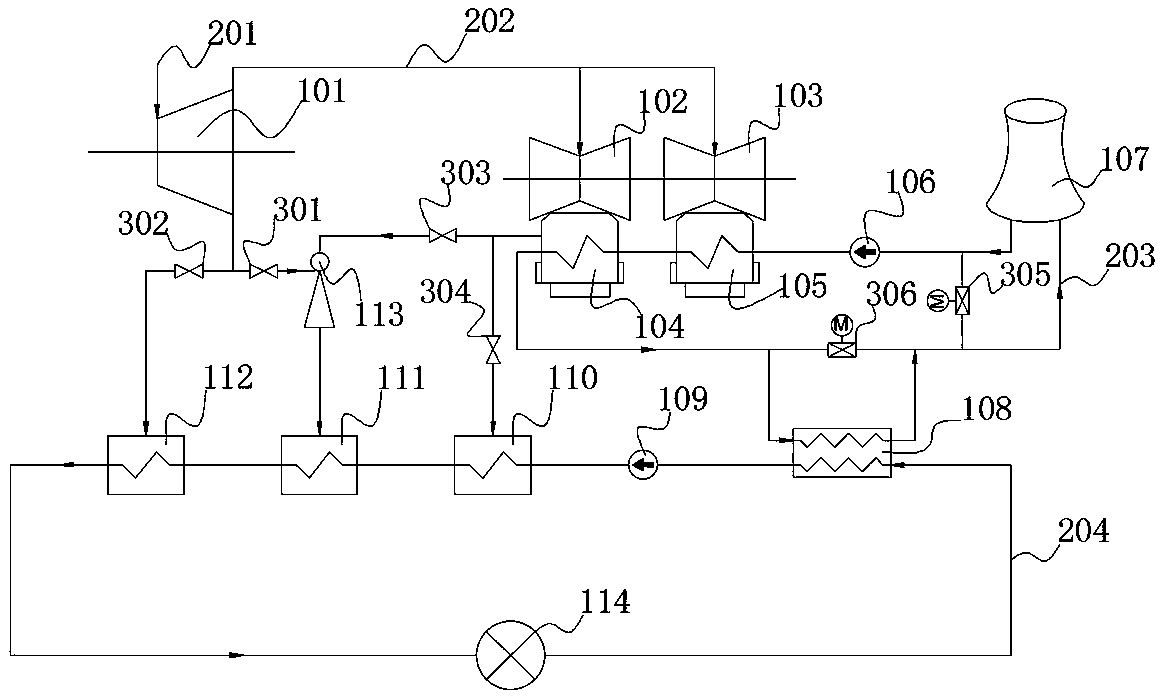

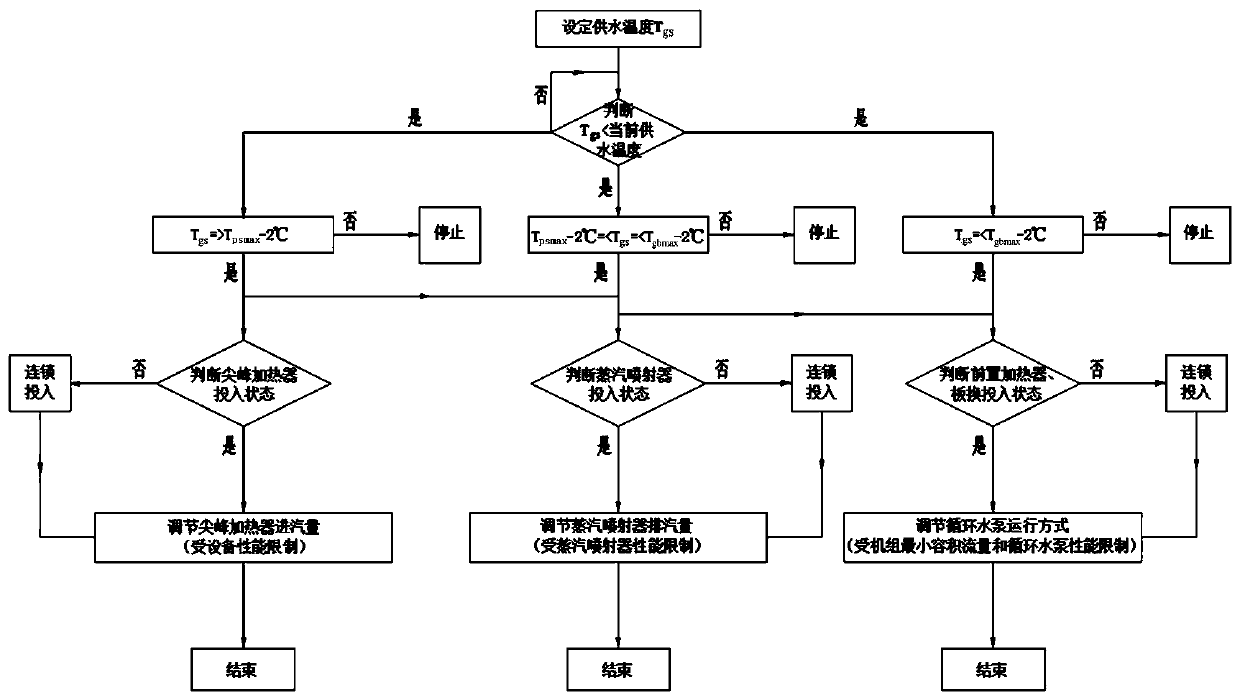

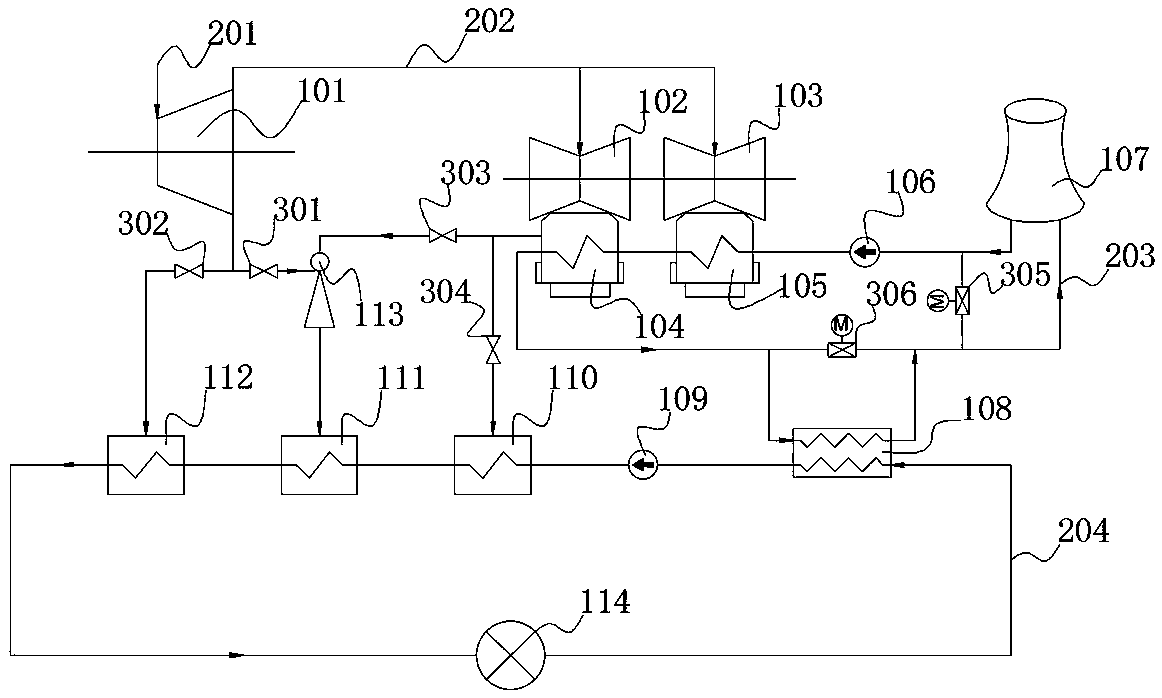

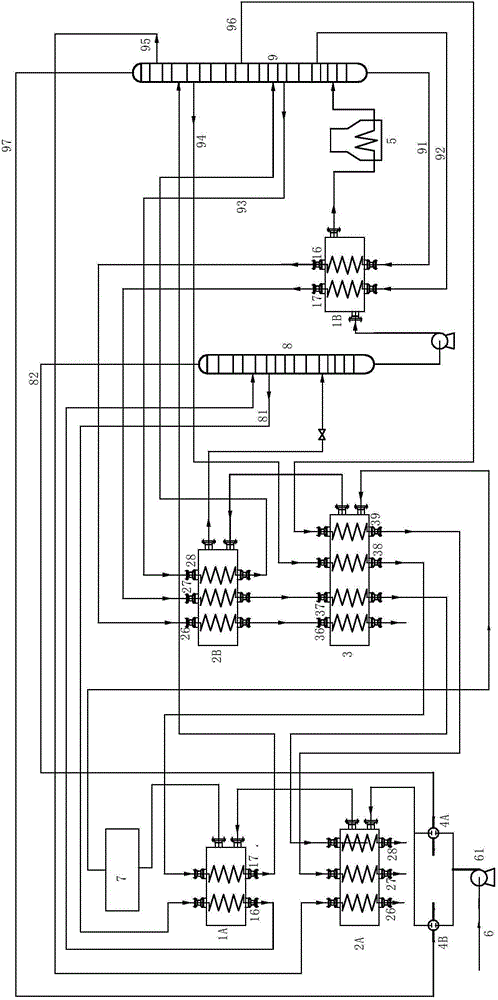

Indirect air cooling unit high back pressure heat supplying system and adjusting method

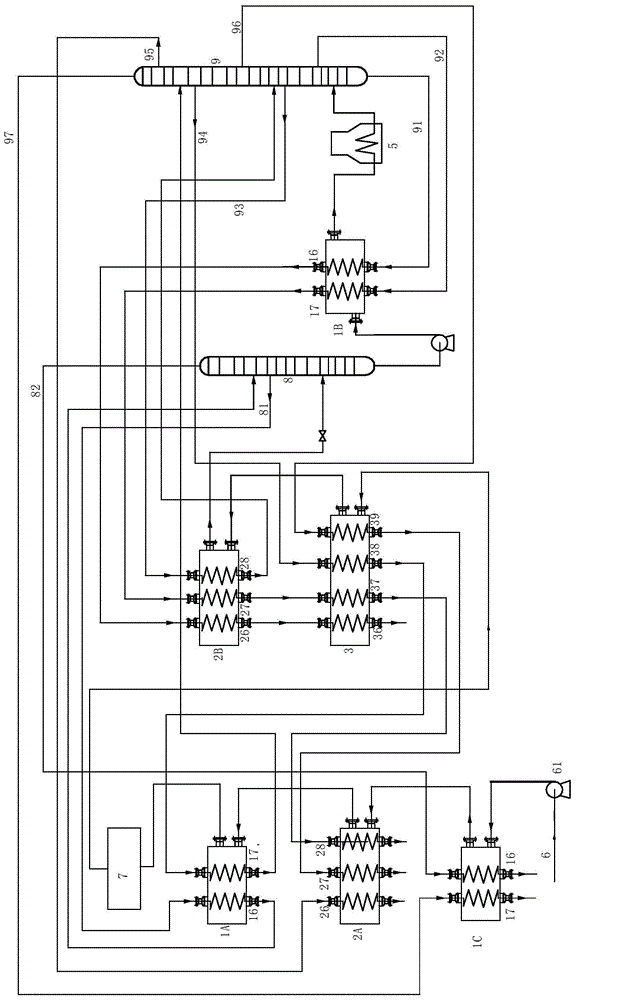

ActiveCN109990362AMake more use of heating capacityReduce heat transfer areaSteam/vapor condensersHot-water central heatingCooling towerRecuperator

The invention discloses an indirect air cooling unit high back pressure heat supplying system and an adjusting method. The system mainly comprises a steam turbine intermediate pressure cylinder, a steam turbine low pressure cylinder, a high back pressure steam condenser, a low back pressure steam condenser, a circulating water pump, an indirect air cooling tower, a thermal net plate type heat exchanging device, a thermal network circulating water pump, a front-mounted thermal net steam condenser, a steam jetting device steam condenser, a peak heating device, a vapour jetting device and the like. According to the system, first stage heating is conducted on thermal net back flowing water by using the thermal net plate type heat exchanging device, secondary heating is conducted on the thermalnet back flowing water by the front-mounted thermal net steam condenser, third-stage heating is conducted on the thermal net back flowing water by using the steam jetting device steam condenser, fourth-stage heating is conducted on the thermal net back flowing water by using the peak heating device, and the gradient utilization of the energy is achieved by four-stage heating of the whole system.The system has the advantages that the technological converting is simple, the cost is low, the converting on the steam turbine body is not needed, the defect of larger end difference of panel type heat exchanging device is overcome, compared with traditional indirect air cooling unit high back pressure heat supplying converting, the dead steam utilization rate of the unit after application is improved, and equipment initial investment is reduced.

Owner:晟源高科(北京)科技有限公司

High-thermal-conduction adhesive

InactiveCN105694787AImprove thermal conductivityGood adhesionNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesAdhesive cementPolymer science

A high-thermal-conduction adhesive includes a matrix, a thermal-conduction filler, a crosslinking agent, a plasticizer and the like, and is characterized in that the thermal-conduction filler contains a one-dimensional high-thermal-conduction insulation material; the one-dimensional material is overlapped mutually in the matrix to form a thermal-conductive network structure by using structure advantages, and the thermal conduction performance of the adhesive is greatly improved. The adhesive has good insulation performance and thermal conduction performance, and can be used in microelectronic packaging or LED illuminating industries.

Owner:FOSHAN BAIRUI NEW MATERIAL TECH CO LTD

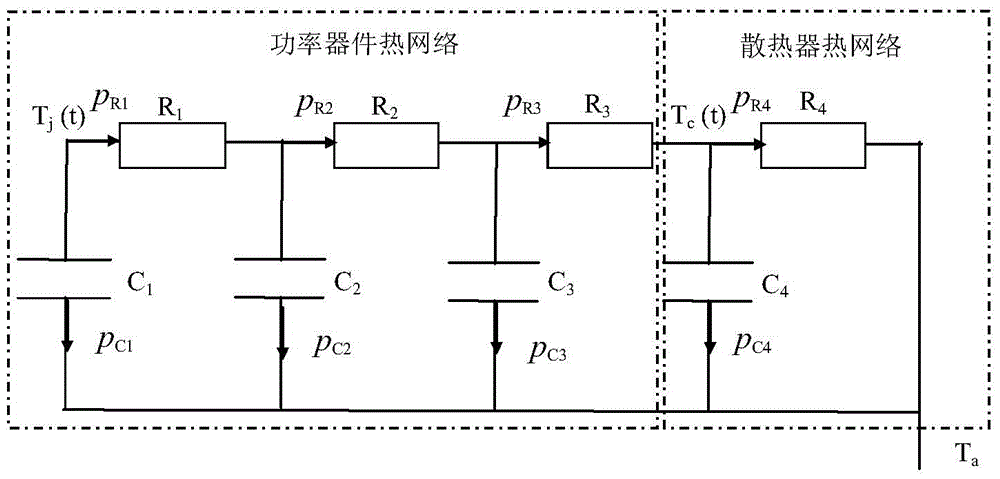

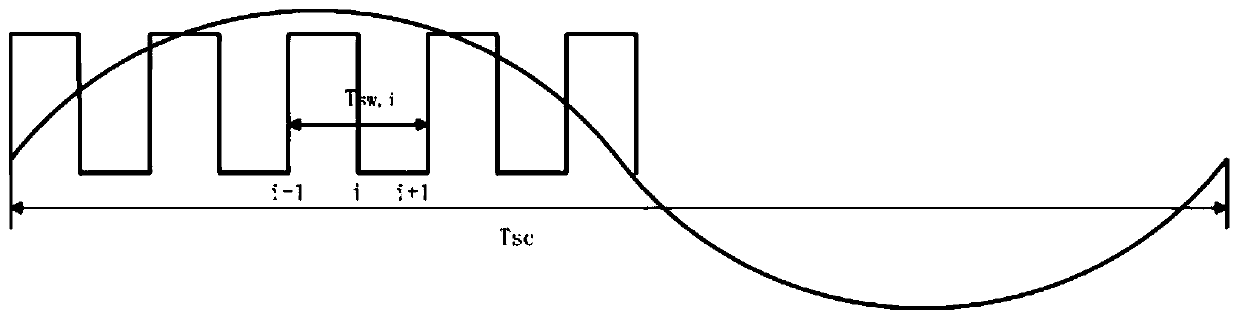

Calculation method for IGBT junction temperature fluctuation of power electronic converter

ActiveCN112464443APower loss calculationThe calculation result is accurateDesign optimisation/simulationCAD numerical modellingThermodynamicsJunction temperature

The invention discloses a calculation method for IGBT junction temperature fluctuation of a power electronic converter, and the method specifically comprises the steps of collecting a converter-levelvariable needed by the calculation of power loss, carrying out the Fourier decomposition of an output current at an AC side, and obtaining a current expression flowing through an analyzed IGBT; calculating switching loss and conduction loss corresponding to the alternating current side current peak value respectively, and then obtaining the analyzed power loss of the IGBT in the whole fundamentalwave period; deducing a junction temperature fluctuation expression in a fundamental wave period in combination with a Foster thermal network model, and deriving the junction temperature fluctuation expression to obtain maximum and minimum junction temperature generation time points; and calculating the maximum junction temperature value, the minimum junction temperature value, the junction temperature value at the moment corresponding to the current peak value and the component value of junction temperature fluctuation at the end of the fundamental cycle according to the obtained time points.According to the invention, the IGBT junction temperature fluctuation can be quickly calculated, and the calculation result is accurate, comprehensive and reliable.

Owner:SOUTHWEST JIAOTONG UNIV

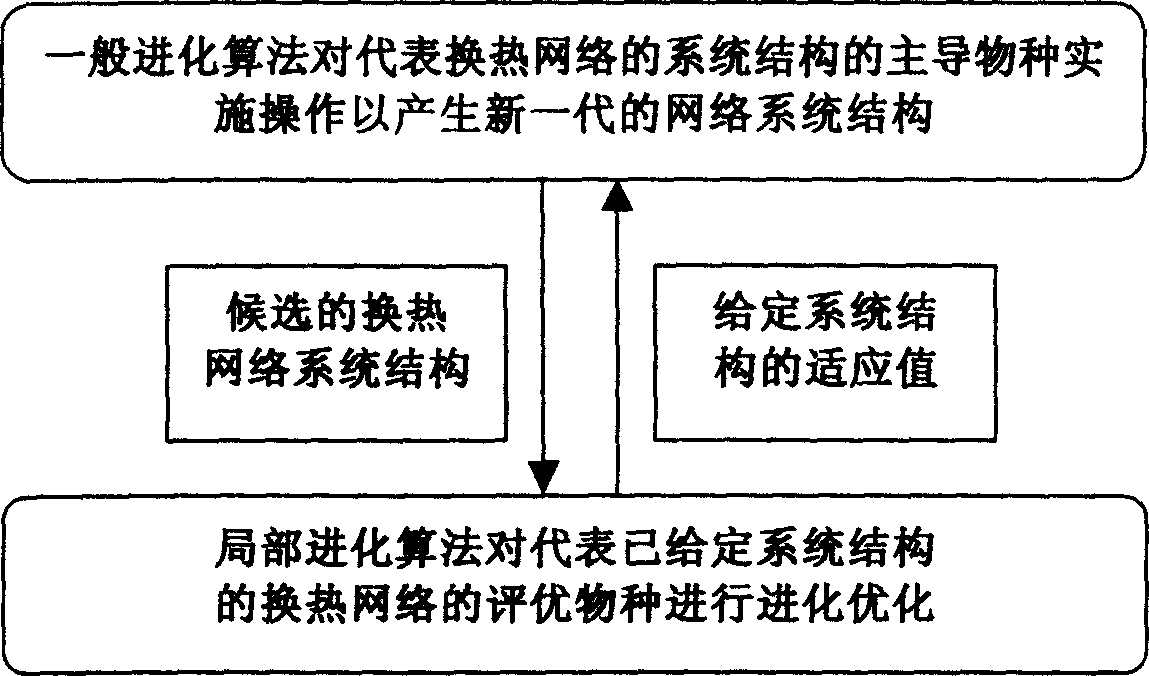

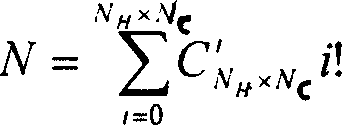

Intelligent optimizing method for optimal synthesis of heat exchange network

InactiveCN1554898ASolving the Optimal Synthesis ProblemLighting and heating apparatusHot-water central heatingInformation processingExchange network

The comprehensive optimizing method of heat exchange network belongs to the field of intelligent information processing technology. Based on system optimizing concept, the optimal synthesis problem of heat exchange network is equivalized into two parts of system structure and heat exchange unit, and the two parts are synergically optimized to obtain the optimal compromise of system structure and heat exchange unit ultimately. The proper optimizing scheme, including three steps of decomposing issue, synergic optimizing of network and selecting optimal optimizing, is adopted according to the practical conditions. The present invention solves the problem of optimal synthesis for large scale heat exchange network, and may be used in chemical, oil refining and other industrial process.

Owner:SHANGHAI JIAO TONG UNIV

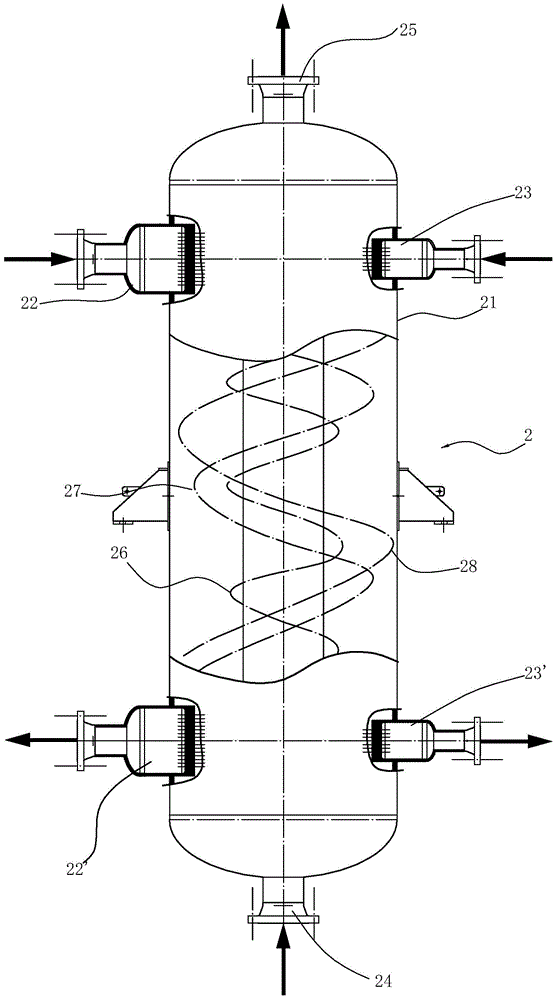

Heat exchange system and process of atmospheric and vacuum distillation unit

ActiveCN104479735AIncrease temperatureLess drag dropStationary tubular conduit assembliesHydrocarbon oils treatmentExchange networkEngineering

The invention relates to a heat exchange system and process of an atmospheric and vacuum distillation unit. Heat exchangers having special structures are adopted, multiple streams of material flow are simultaneously or sequentially subjected to heat exchange with material flow in shell pass, the resistance is reduced, the heat exchange efficiency is high, the temperature difference at a hot end is small, the operation is stable, the fouling resistance is good, the occupation area and investment of equipment are reduced, a heat exchange network is optimized, the temperature of a crude oil heat exchange terminal is increased, the crude oil heat exchange temperature can be increased by 4-5 DEG C under the condition that a heat exchange source is unchanged, and the energy saving and consumption reducing effects are very remarkable.

Owner:ZHENHAI PETROCHEM JIANAN ENG

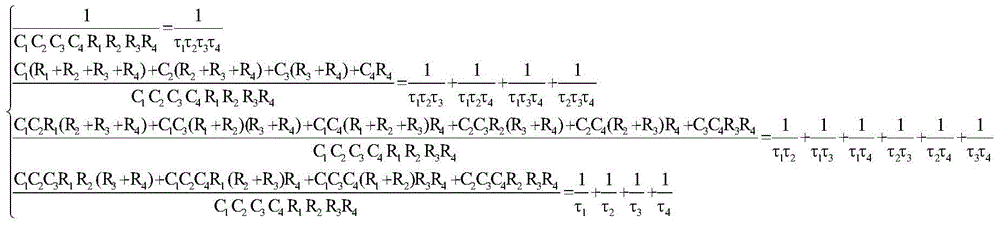

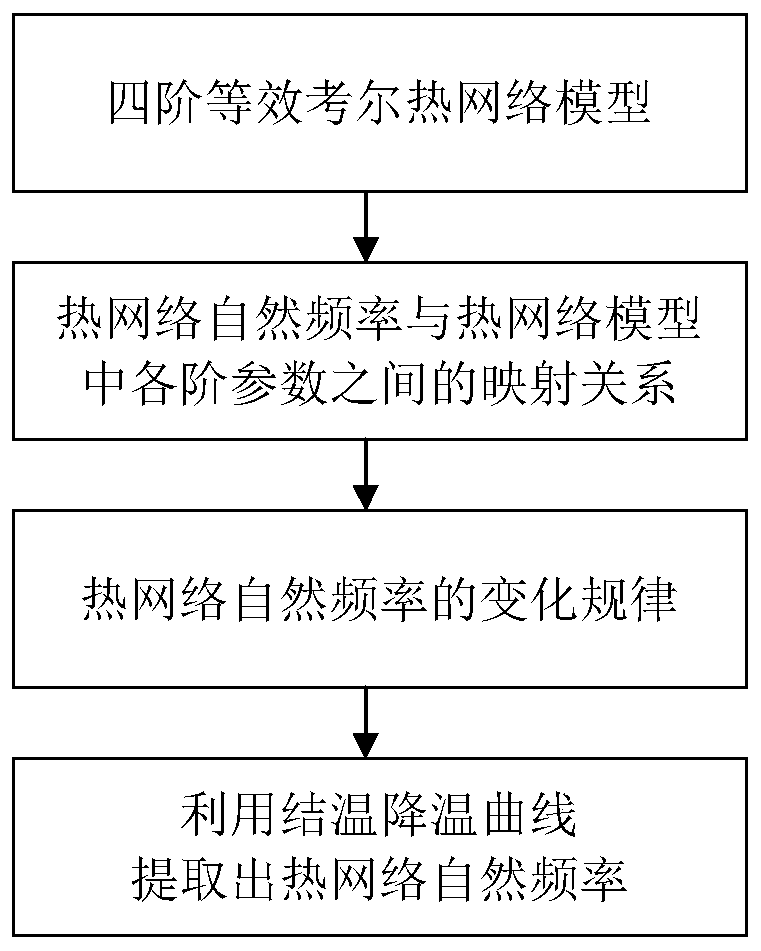

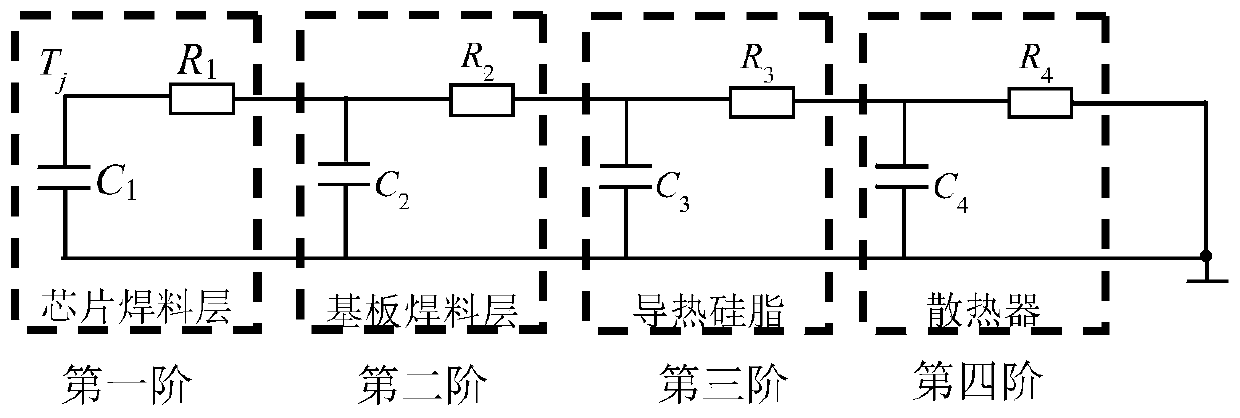

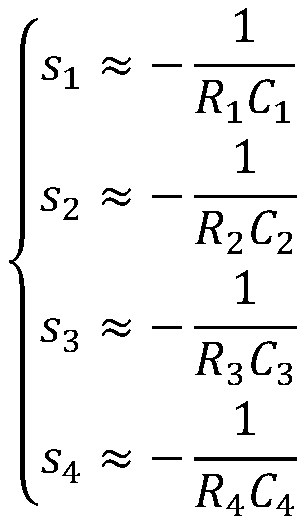

IGBT module health state monitoring method based on natural frequency of thermal network

InactiveCN111060797ALow costReduce operational complexitySemiconductor operation lifetime testingJunction temperatureComputer science

The invention discloses an IGBT module health state monitoring method based on a natural frequency of a thermal network. The IGBT module health state monitoring method comprises the steps of: establishing a fourth-order equivalent Cauer thermal network model according to physical performance parameters of an IGBT module and a radiator; establishing a mapping relationship between the natural frequency of the thermal network and parameters of each order in the thermal network model according to an order-of-magnitude difference between the thermal parameters of each order; fitting a measured junction temperature cooling curve of the IGBT module to obtain the natural frequency of the thermal network; and monitoring a health state of the IGBT module according to the natural frequency. The IGBTmodule health state monitoring method can monitor the aging degree of the IGBT module under the condition that the power loss of the IGBT module is not measured.

Owner:HOHAI UNIV

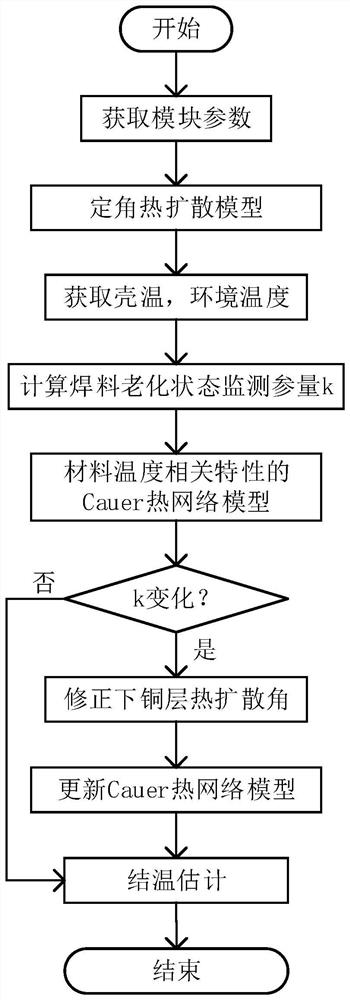

IGBT module junction temperature estimation method in solder aging state

ActiveCN111931402AResolving Heat Transfer Path Offset IssuesHigh precisionDesign optimisation/simulationSpecial data processing applicationsJunction temperatureProcess engineering

The invention relates to a method for estimating the junction temperature of an IGBT module in a solder aging state. The method comprises the steps that 1, geometric structure parameters and materialcharacteristic parameters of the IGBT module are acquired; 2, establishing a constant-angle thermal diffusion model based on the geometric parameters and the heat transfer performance; 3, collecting environment information of the IGBT module; 4, obtaining solder aging state monitoring parameters according to the environment information of the IGBT module; step 5, establishing a Caler thermal network model of IGBT module material temperature related characteristics; 6, quantifying the influence of solder aging on an internal heat transfer path through the aging monitoring parameters to obtain an actual heat transfer area, and updating the parameters of the thermal network model; and step 7, estimating the junction temperature of the IGBT module in real time based on the Cauer thermal network model and the feedback junction temperature. Compared with the prior art, the method has the advantages of being high in junction temperature estimation result precision, effectively improving evaluation precision and strategy rationality and the like.

Owner:SHANGHAI UNIVERSITY OF ELECTRIC POWER

Structure and preparation method of novel high-thermal-conductivity s electronic packaging base plate material

The invention discloses a structure and a preparation method of a novel high-thermal-conductivity electronic packaging base plate material. The method comprises: sintering by using an organic polyurethane foam impregnation method to obtain a net-shaped porous aluminum oxide ceramic as a heat conduction framework of an epoxy resin-based material; carrying out surface modification with a silane coupling agent, filling with an epoxy resin, and carrying out encapsulation; and carrying out high-temperature curing to form the ceramic / resin composite base plate material with good heat conduction performance. The invention belongs to the field of base plate materials for electronic packaging. In the prior art, the existing ceramic / resin composite material cannot form a heat conduction network under low filler content. According to the invention, based on the problem in the prior art, a net-shaped porous structure is constructed by an organic foam impregnation method, and a light composite baseplate material is prepared through surface modification, epoxy resin negative pressure impregnation and other technologies, so that the heat conductivity of the composite material is substantially improved and the thermal expansion coefficient is substantially reduced under the condition of the low ceramic volume fraction; and the method is easy to operate, low in cost, excellent in performance and suitable for large-area popularization.

Owner:NANJING ZHONGJIANG NEW MATERIAL TECH

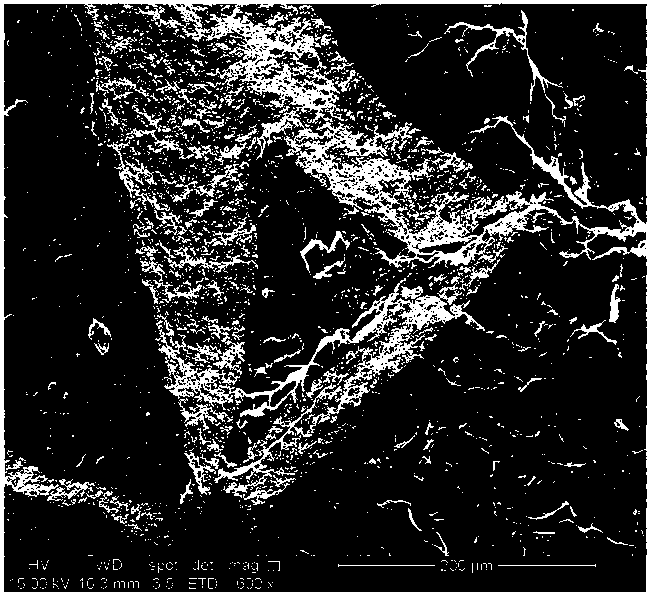

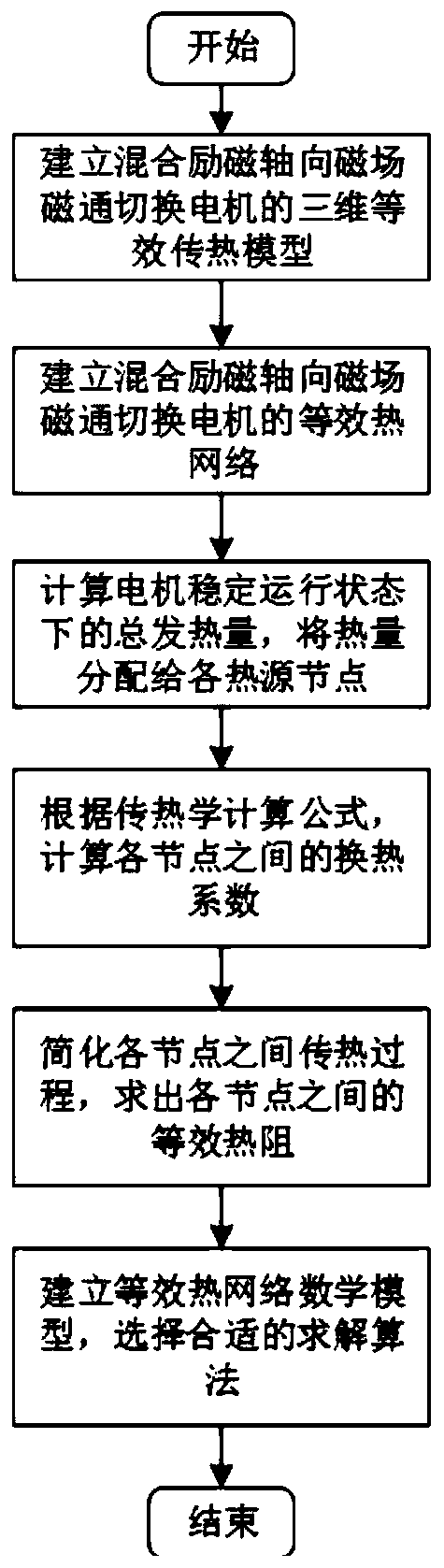

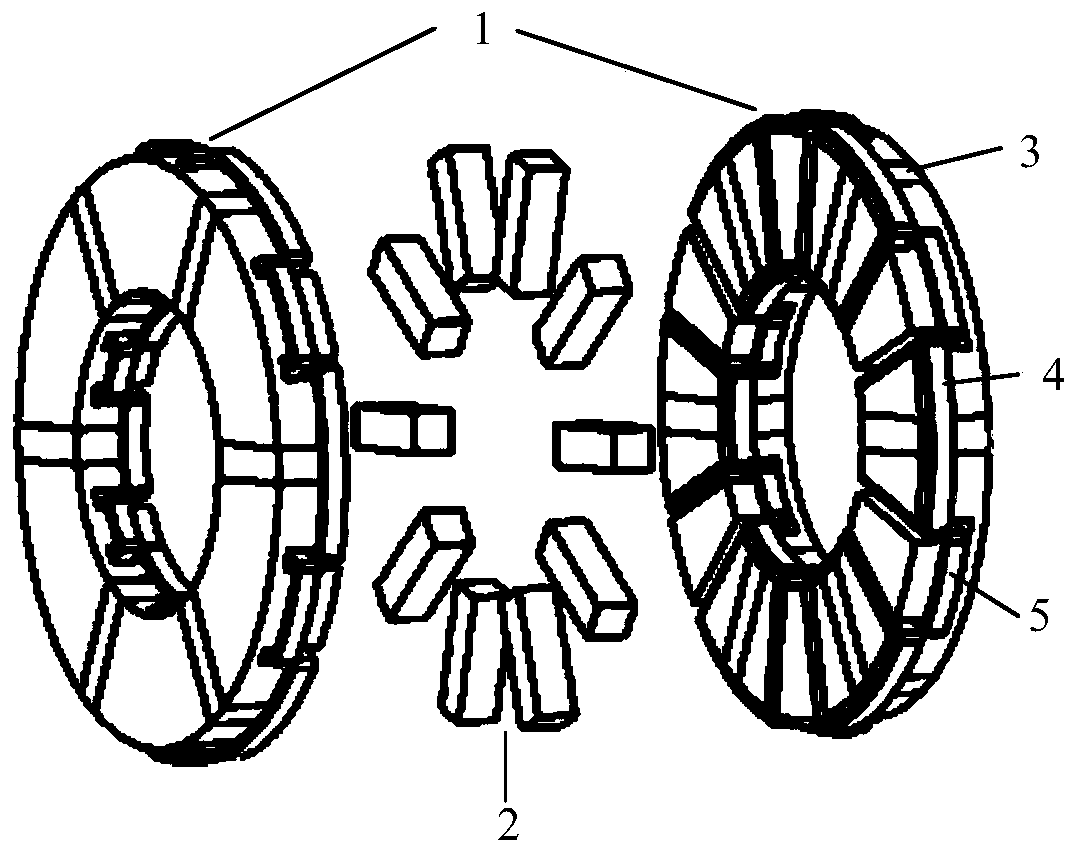

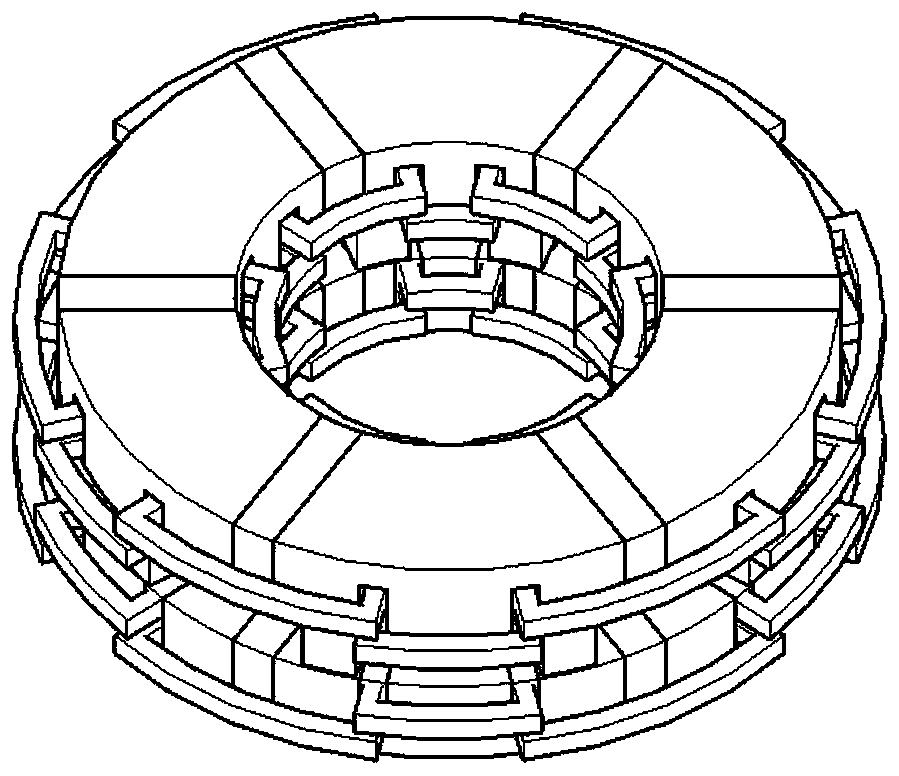

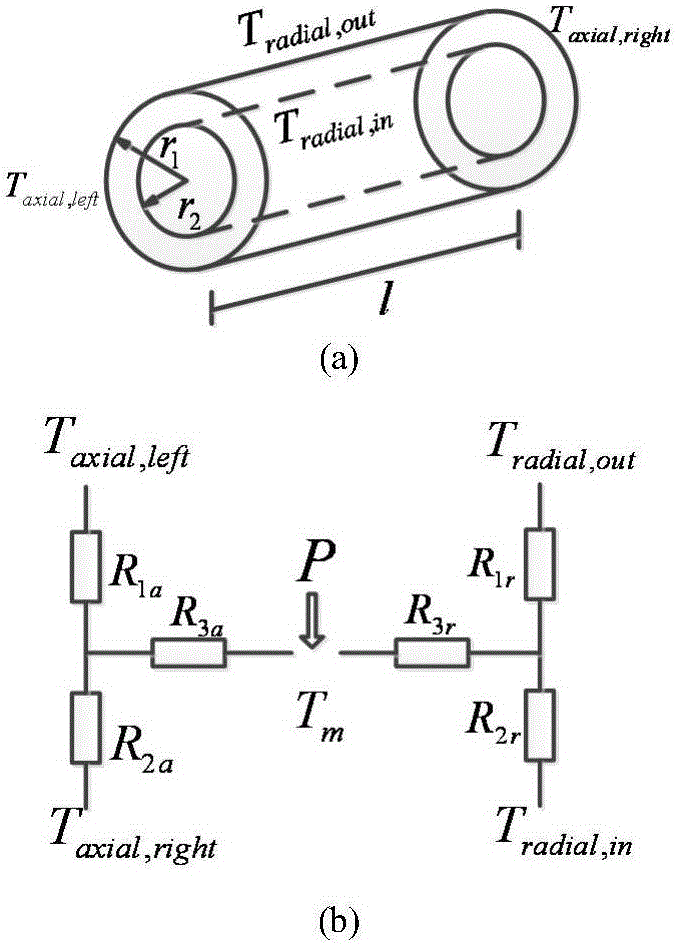

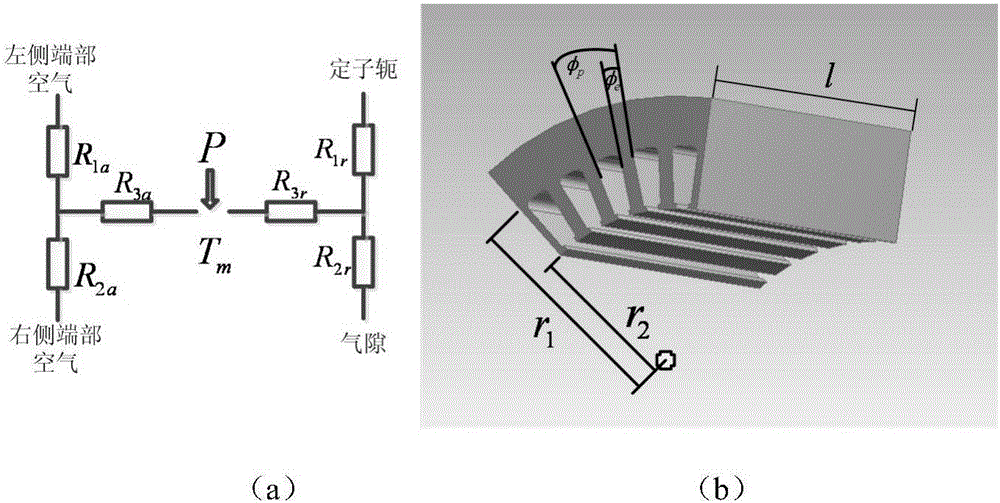

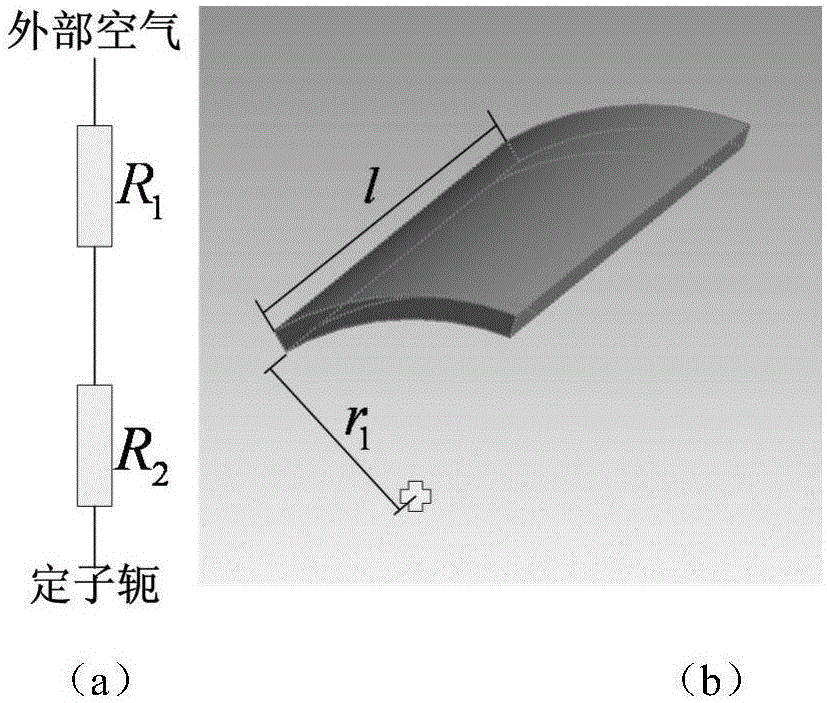

Equivalent thermal network modeling method of hybrid excitation axial magnetic field flux switching motor

ActiveCN110414074AAccurate calculationCalculation speedSpecial data processing applicationsMathematical modelElectric machinery

The invention discloses an equivalent thermal network modeling method of a hybrid excitation axial magnetic field flux switching motor. The method comprises the following steps: firstly, establishinga three-dimensional heat transfer model of a motor and an equivalent thermal network model of the motor; then, calculating the total heat productivity of the motor, distributing the heat to the heat source nodes, and calculating the heat transfer coefficient between the nodes according to the heat transfer empirical formula under different heat dissipation conditions; then equalizing the heat transfer between the nodes to the heat transfer between the simple geometries, and solving the equivalent thermal resistance between the nodes; and finally, establishing a mathematical model, and selecting a proper solving algorithm to solve the temperature rise of each node. The method reduces the difficulty of solving the temperature of the internal parts of the motor, is simple and quick, and is high in accuracy.

Owner:NANJING UNIV OF SCI & TECH

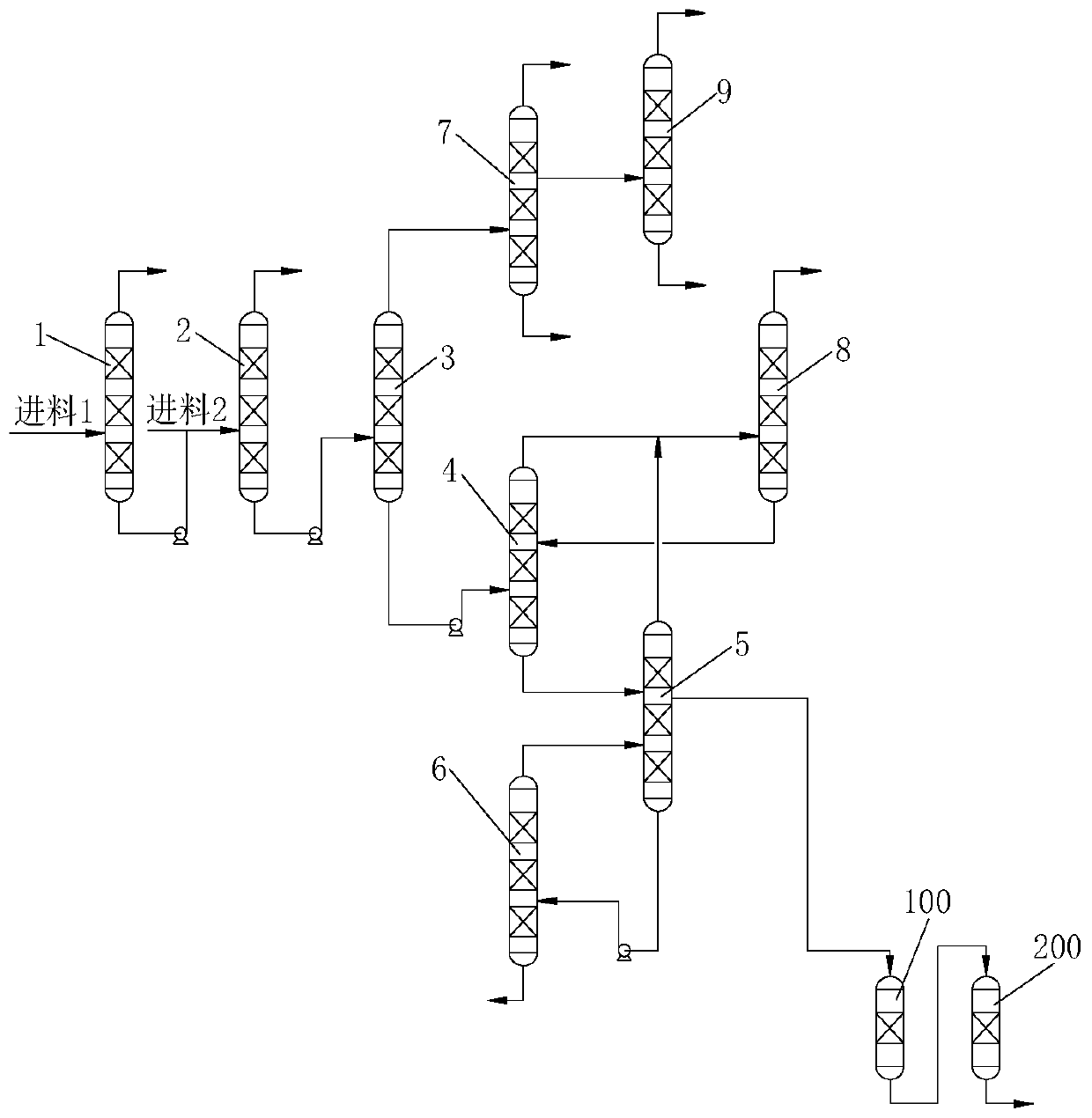

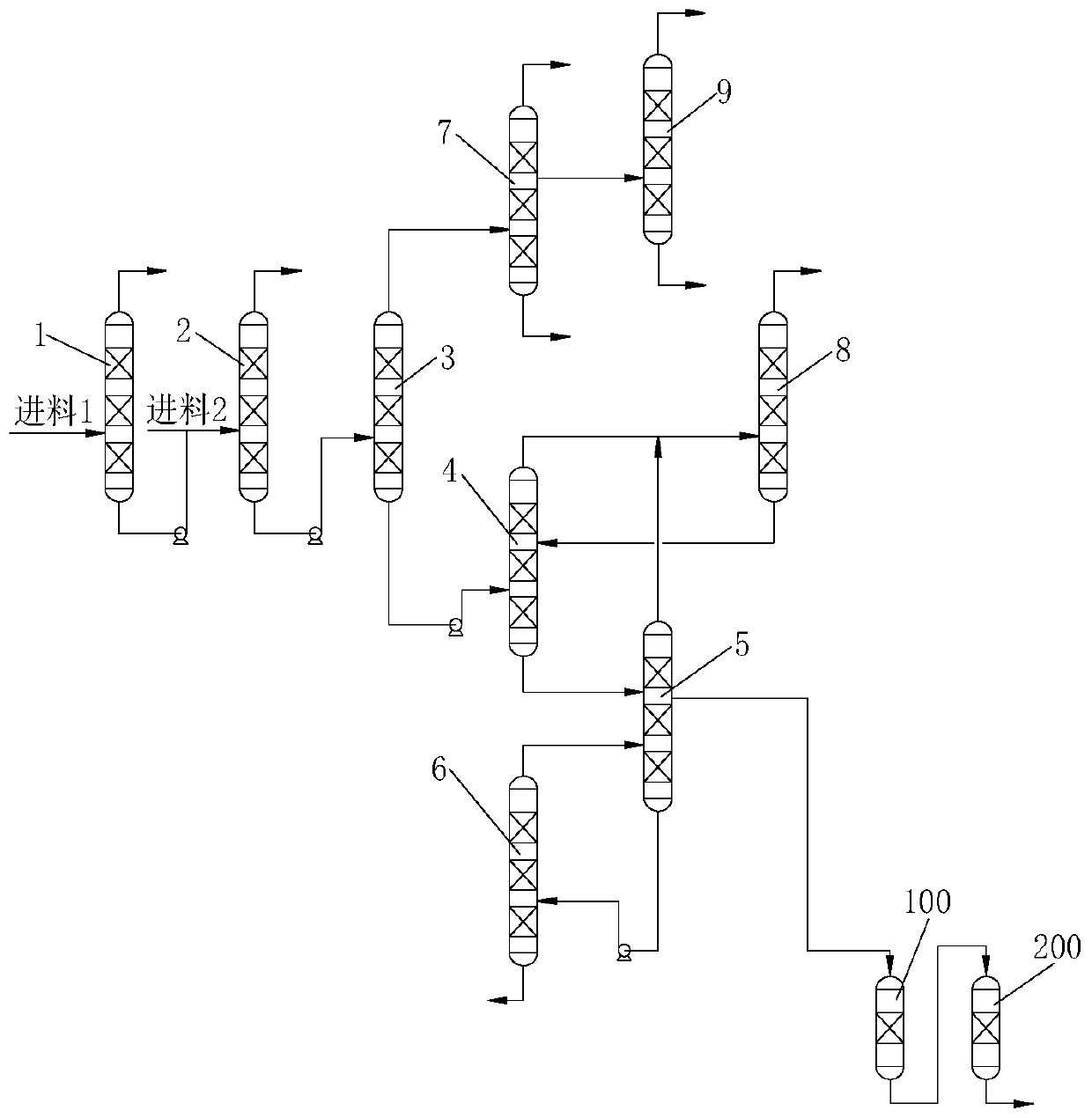

System and method for ethylene glycol rectification in production of ethylene glycol from syngas

ActiveCN109956851AHigh recovery rateQuality improvementChemical industryHydroxy compound separation/purificationSyngasPolymer science

The invention discloses a system and a method for ethylene glycol rectification in the production of ethylene glycol from syngas. The system comprises a methanol recovery tower A, a methanol recoverytower B, a light component removal tower, a dealcoholization tower, an ethylene glycol product tower, a heavy component removal tower, a light component recovery tower, an ethylene glycol recovery tower, an ethanol tower and a refining reactor. Rectification, adsorption and other diversified technologies are adopted to improve the recovery rate, quality and quality product rate of ethylene glycol;a thermal network is adopted to carry out energy saving optimization on the system, so the steam consumption is reduced; and all the components in crude ethylene glycol are finely cut and fully recovered to obtain high-quality methanol, ethanol and ethylene glycol and also obtain heavy diol and light diol byproducts.

Owner:NINGBO JINYUANDONG PETROCHEM ENG TECH

Axial ventilation permanent magnet synchronous motor temperature field calculating method

InactiveCN106096157AOmit hot connectionSimple modelComputer aided designSpecial data processing applicationsElectric machinePermanent magnet synchronous motor

The invention relates to an axial ventilation permanent magnet synchronous motor temperature field calculating method. The axial ventilation permanent magnet synchronous motor temperature field calculating method comprises the steps that heat networks of motor parts are respectively established based on heat transfer theory; the heat networks of the parts are mutually connected to form a hot network model of a whole motor structure; modeling is conducted on a cooling airflow in a motor, the cooling airflow is simulated into a hot pressing source controlled by the cooling airflow amount, the airflow temperatures are set to linearly change at the end and in a rotor ventilation hole, and the airflow temperatures at respective midpoint positions are regarded as average temperature rise of the airflow; the hot pressing source representing the cooling airflow is combined with the heat networks of the motor structure: nodal equations are listed to solve node temperatures. An accurate and reasonable motor temperature field can be obtained by adopting the axial ventilation permanent magnet synchronous motor temperature field calculating method.

Owner:TIANJIN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com