Patents

Literature

118 results about "Thermal network model" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

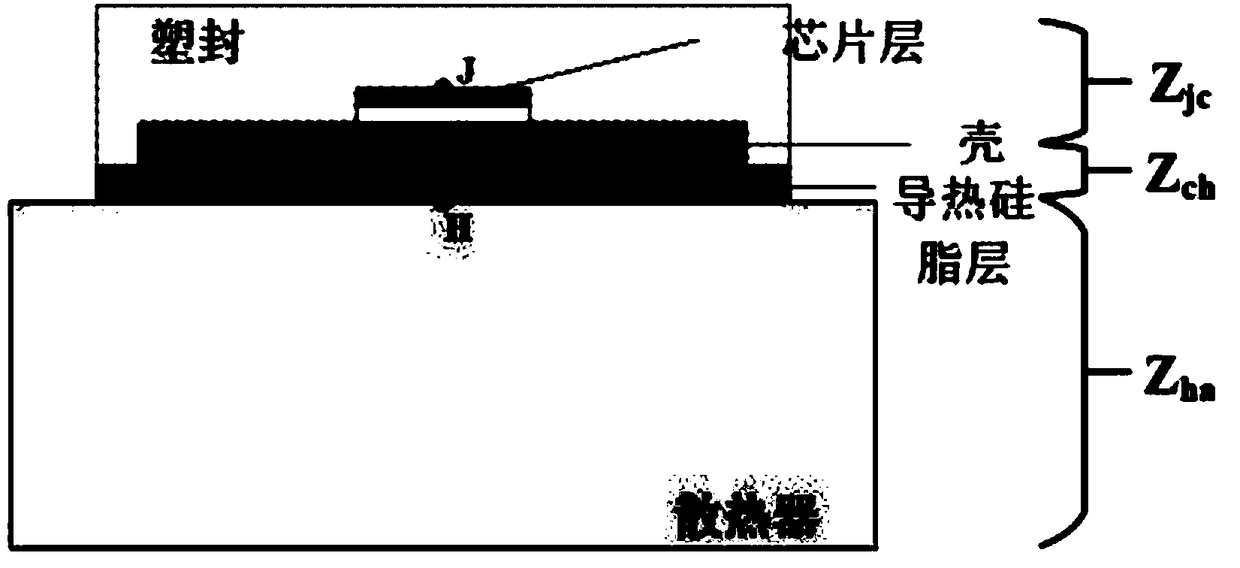

Electric-heat-aging junction temperature calculation model establishing method of IGBT module

ActiveCN106443400AImplement junction temperature prediction functionImproved thermal managementSemiconductor operation lifetime testingElectricityCoupling

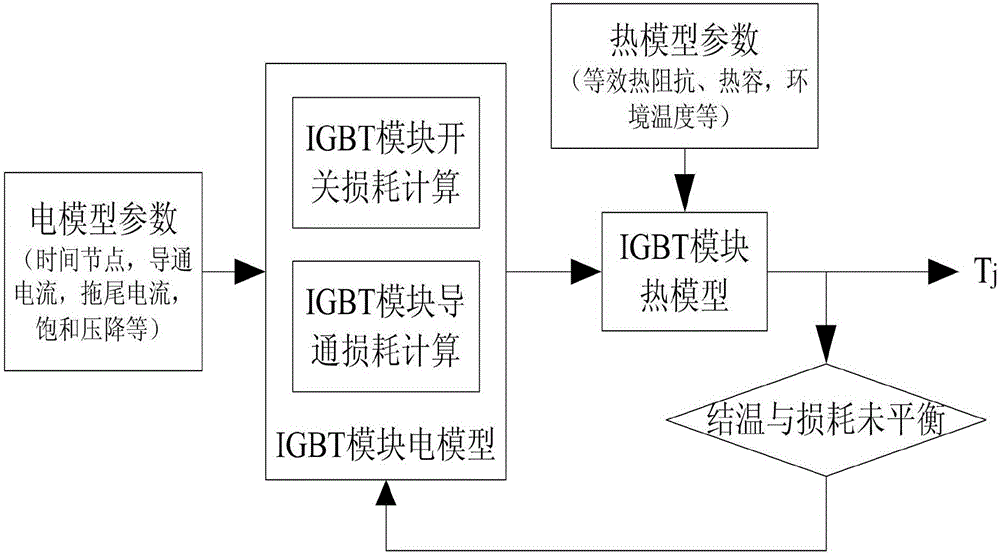

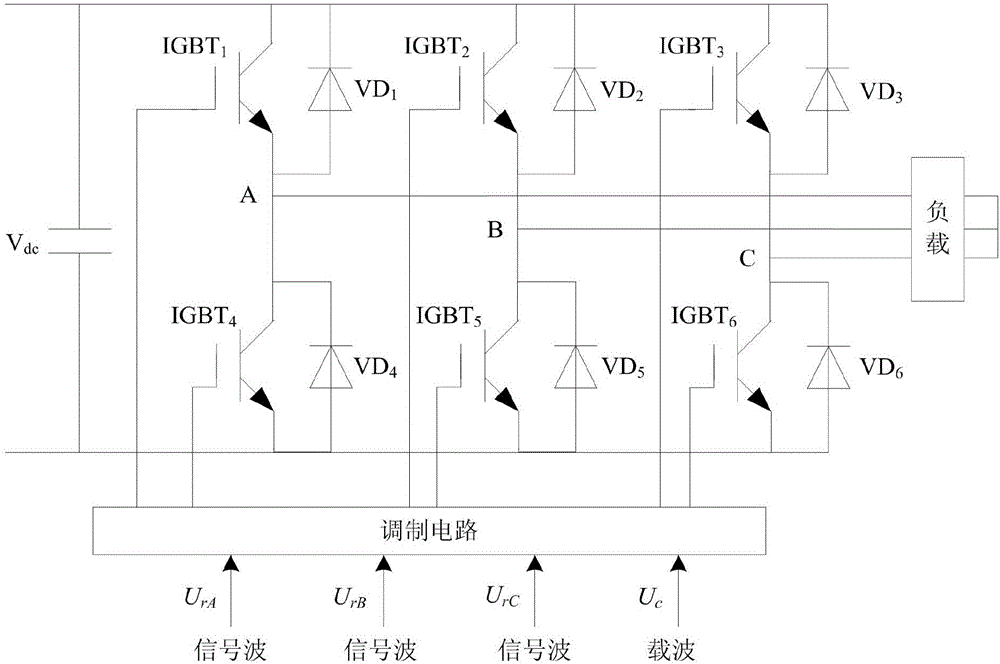

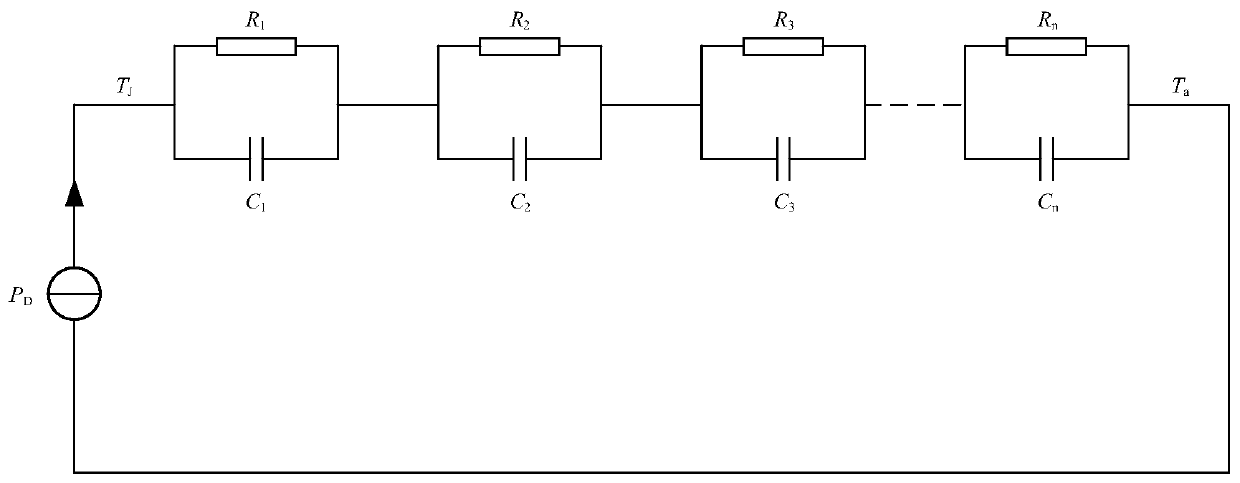

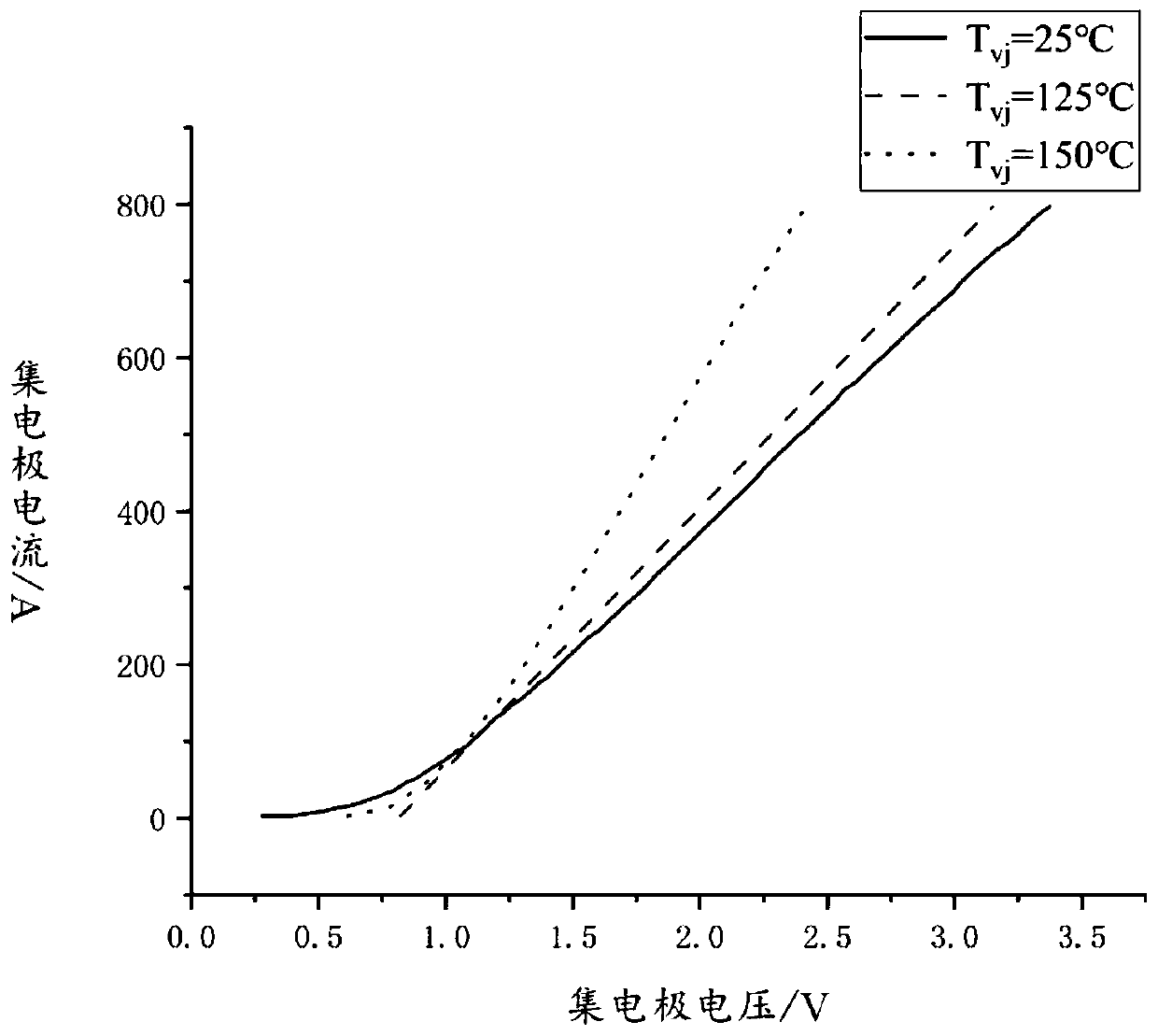

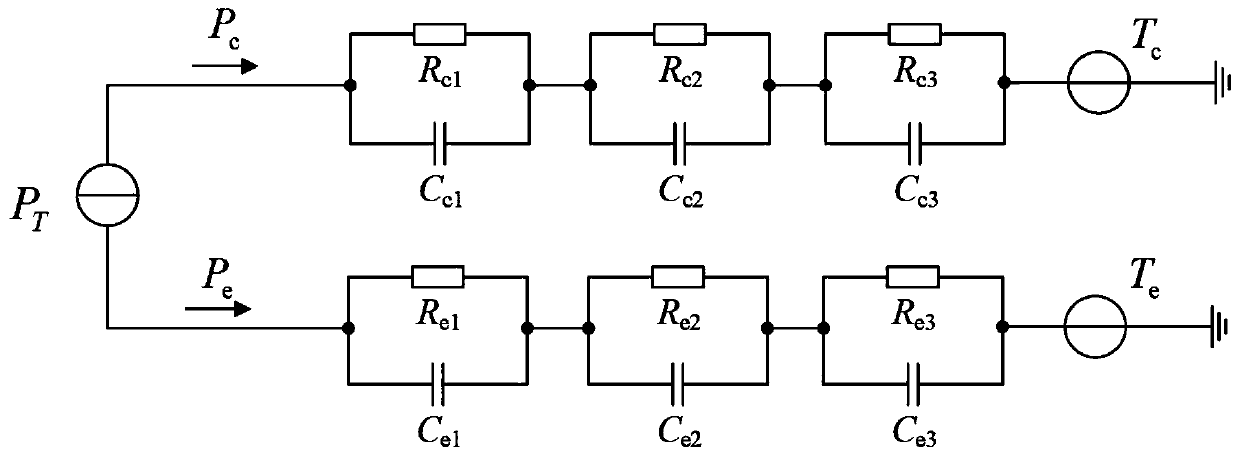

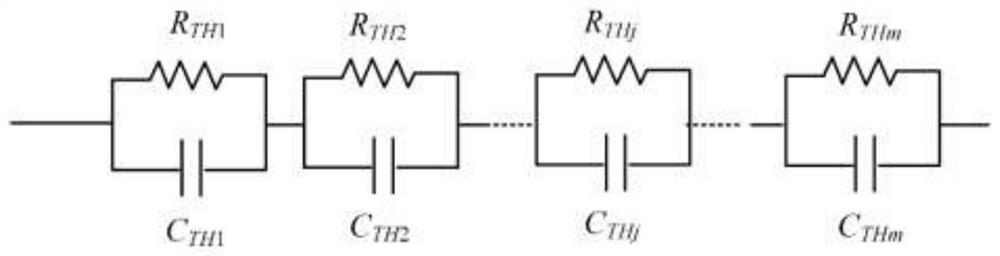

The invention relates to an electric-heat-aging junction temperature calculation model establishing method of an IGBT module. The method is technologically characterized by comprising the following steps of testing electric heating parameters of the IGBT module in different aging degrees, acquiring a three-dimensional relation curved surface and establishing an electric heating data sheet in different aging degrees; establishing an electric model of the IGBT module and a thermal network model of the IGBT module, inputting a power loss which is calculated through the electric model of the IGBT module into the thermal network model of the IGBT module in a current source manner, performing real-time feedback of the junction temperature which is calculated by the thermal network model to the electric model, and finishing establishment of an electric-heat coupling model of the IGBT module; performing aging state evaluation on the IGBT module; and performing junction temperature calculation on the IGBT module. According to the electric-heat-aging junction temperature calculation model establishing method, the corresponding electric heating parameters for different aging processes are acquired and furthermore the electric heating parameters are input into the electric-heat coupling model for performing junction temperature calculation, namely the parameter of the electric-heat coupling model is dynamically changed in real time according to the aging degree of the model, thereby realizing a junction temperature prediction function for the module aging degree.

Owner:HEBEI UNIV OF TECH

method for estimating the junction temperature of an IGBT power module on line

InactiveCN109871591AHigh measurement accuracyHigh simulationThermometers using electric/magnetic elementsUsing electrical meansJunction temperatureEngineering

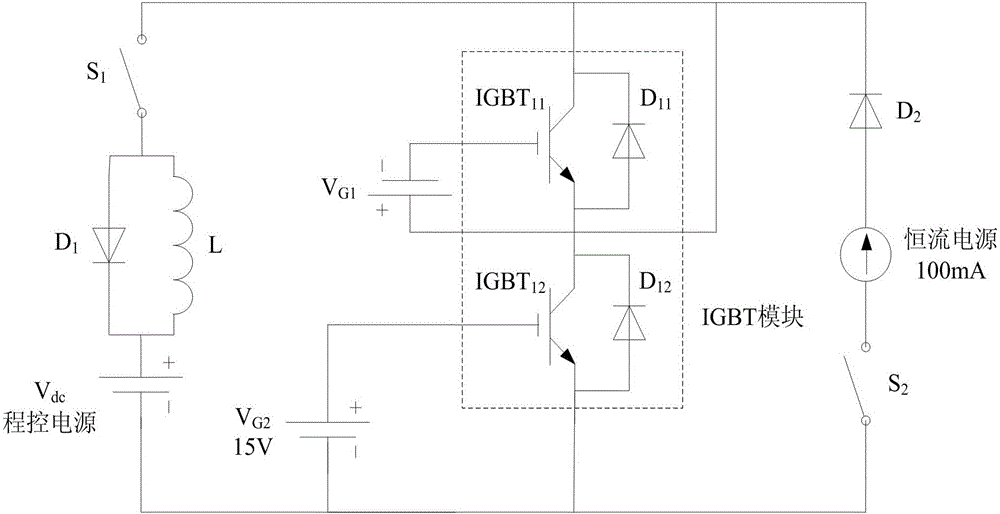

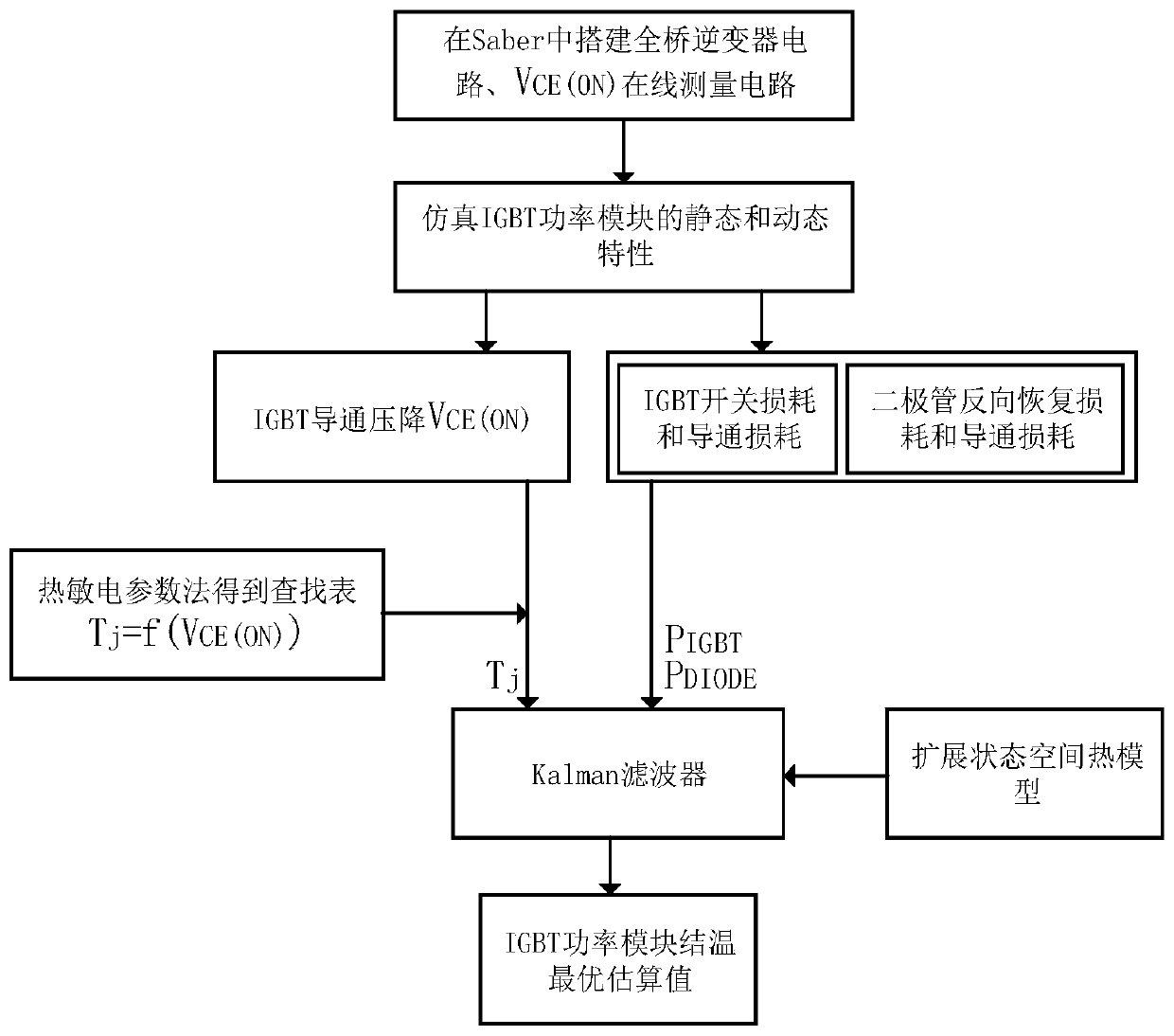

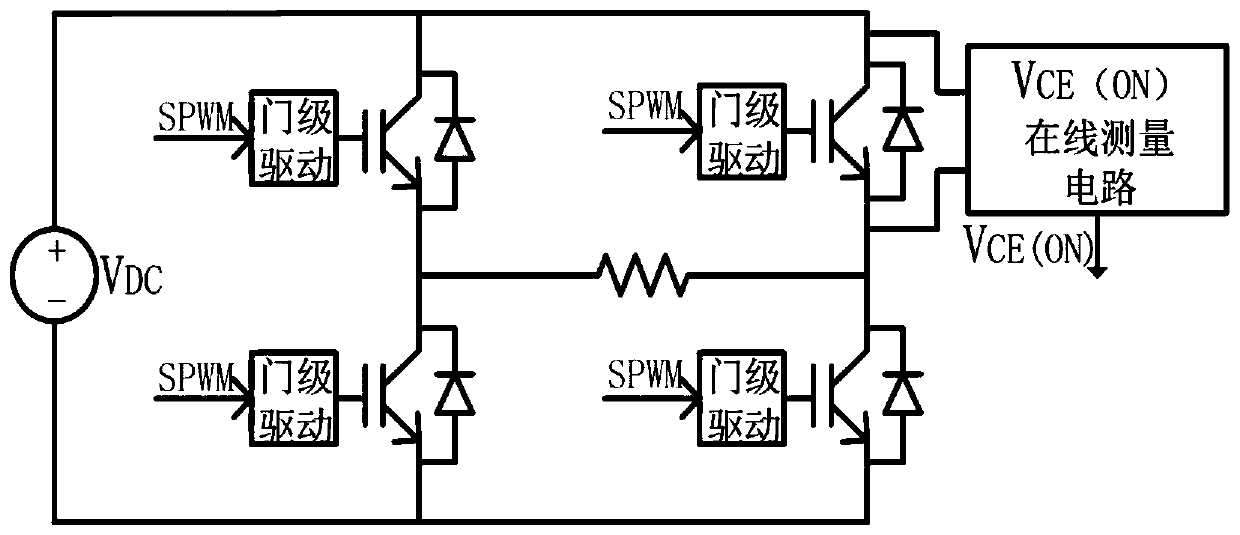

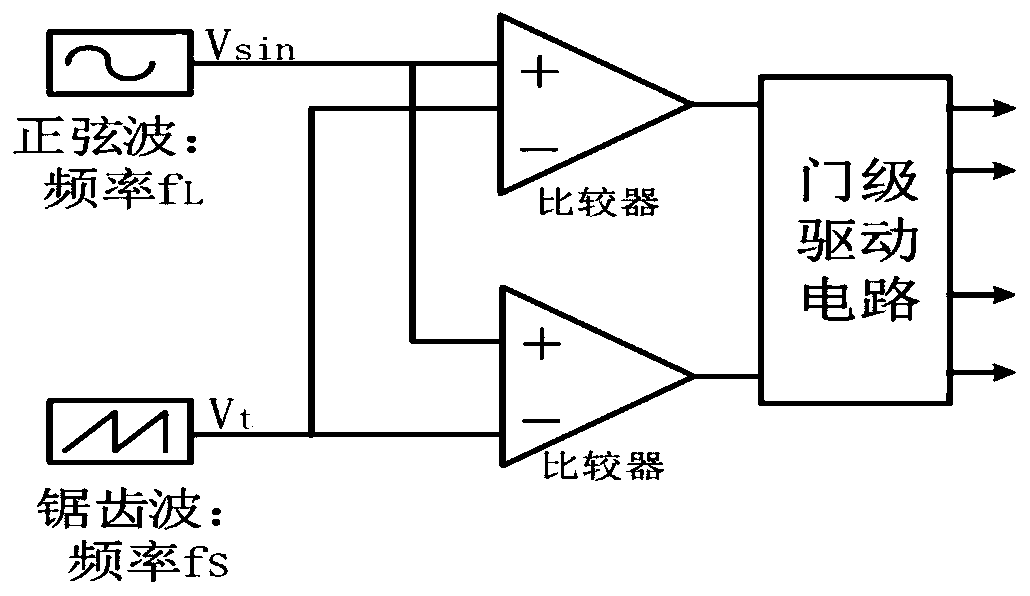

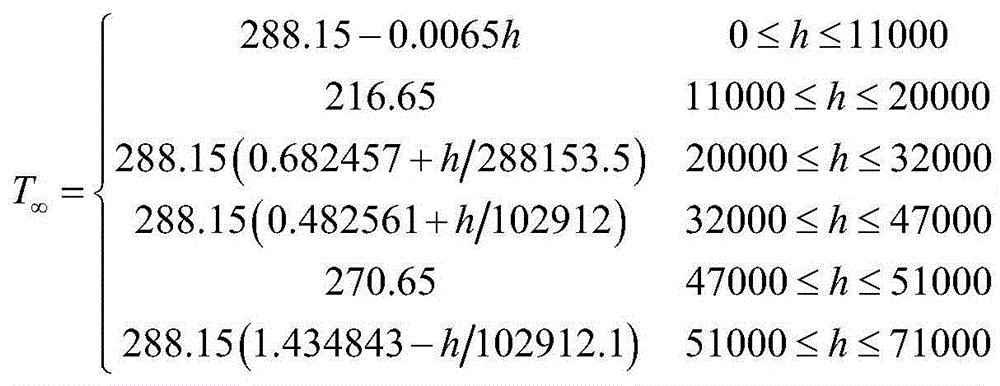

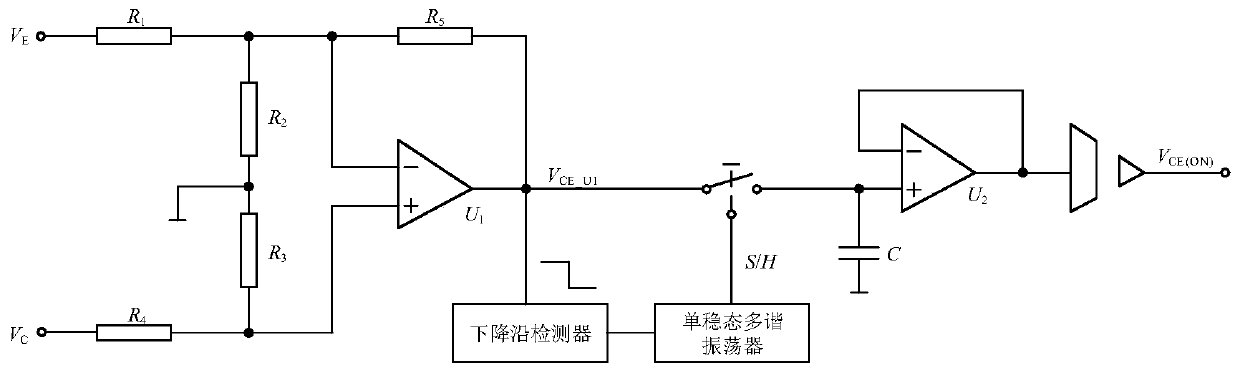

The invention discloses a method for estimating junction temperature on line by an IGBT (Insulated Gate Bipolar Transistor) power module. The method comprises the following steps: estimating the junction temperature by using a thermo-sensitive electrical parameter method; establishing an extended state space thermal model; and applying a Kalman filter in junction temperature estimation. The thermosensitive electrical parameter method can estimate the junction temperature of an IGBT power module in real time, an IGBT conduction voltage drop VCE (ON) is selected as a thermosensitive electrical parameter, and a VCE (ON) online measurement circuit is provided. On the basis of a Foster thermal network model, the influence of diode coupling is considered, and an extended state space thermal model comprising self-heating and coupling heat is provided; And taking the power loss of the diode and the IGBT and the junction temperature estimation value obtained by using the thermosensitive electrical parameter method as the input of the Kalman filter, and considering the measurement noise and the process noise, thereby obtaining the optimal junction temperature estimation value. According to the method, electrical insulation is achieved, measurement is carried out without changing a control strategy of the power converter, noise is reduced, the intermittent influence of voltage measurementis eliminated, and the junction temperature measurement precision is improved.

Owner:WUHAN UNIV

Discretized square wave extraction method and apparatus for IGBT coupling thermal impedance

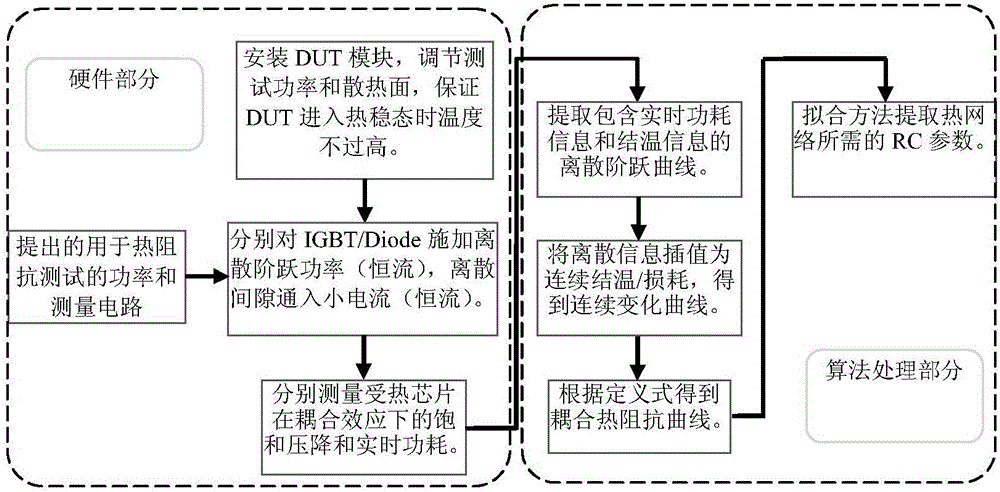

ActiveCN105699775ARealize measurementAccurate measurementResistance/reactance/impedenceSquare waveformJunction temperature

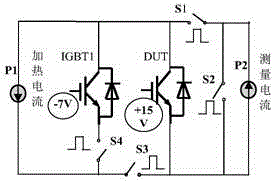

The invention provides a discretized square wave extraction method for an IGBT coupling thermal impedance. The method comprises: an IGBT is heated a conductive voltage drop of an FWD under a small current density is measured; the FWD is heated and a saturation voltage drop of the IGBT under the small current density is measured; according to the conductive voltage drop of the FWD and the saturation voltage drop of the IGBT under the small current density, junction temperature changing curves of the IGBT and the FWD are obtained indirectly and calculation is carried out to obtain a continuously-changing coupling thermal impedance curve; and fitting is carried out on the coupling thermal impedance curve to obtain coupling thermal impedance information of the IGBT and the FWD is obtained. According to the invention, with a simple method, the coupling thermal impedance of the IGBT module is extracted by measuring an end electrical feature quantity and then a perfect IGBT integrated thermal network model is established. The IGBT module is viewed as a black box and the internal packaging structure is ignored; under the circumstance that module packaging is not damaged, measurement of the coupling thermal impedance is realized based on discretized square wave measurement according to a principle of measuring thermal impedance by using an existing thermal sensitive parameter method. Moreover, the method has advantages of simpleness, effectiveness, fast response, and accurate measurement.

Owner:CHONGQING UNIV

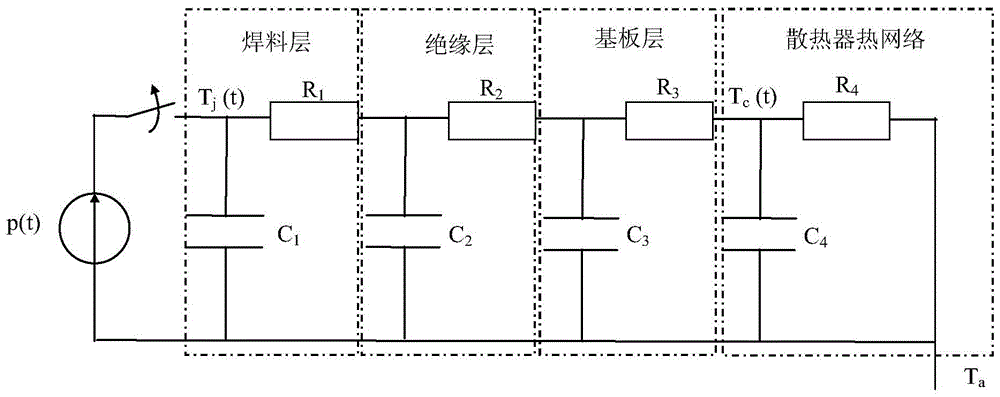

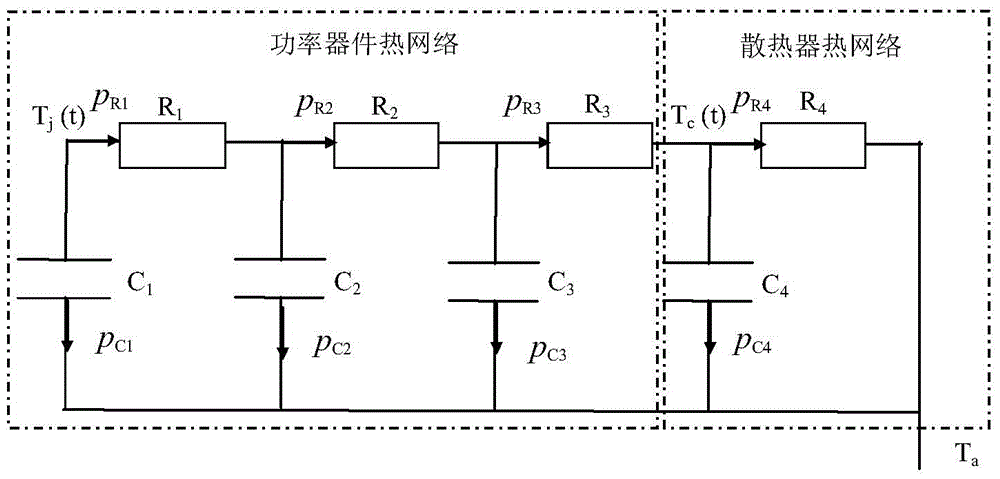

Thermal-network parameter identification method based on IGBT junction temperature information

ActiveCN105718694AGuaranteed safe operationAccurate identificationSpecial data processing applicationsJunction temperatureSafe operation

The invention provides a thermal-network parameter identification method based on IGBT junction temperature information.The thermal-network parameter identification method includes the steps that an equivalent thermal-network model is built according to the performance parameter of an IGBT module and the performance parameter of a radiator; according to the equivalent thermal-network model, any one pair of measurable thermal resistance and thermal capacity in a thermal network is changed, and constraint equations of two sets of different IGBT thermal-network parameters are built; two lowered temperature curves of the thermal resistance and thermal capacity before and after changes in the equivalent zero-input state are measured respectively; the lowered temperature curves are fitted, the two sets of corresponding time constants are obtained, and the IGBT thermal-network parameters are obtained through the constraint equations of the IGBT thermal-network parameters according to the measurable thermal resistance and thermal capacity.The thermal-network parameter identification method can be applied to the equivalent zero-input input state such as normal machine switching during working of a power conversion device, the thermal-network parameters of an IGBT can be accurately, effectively and simply identified without disassembling the IGBT module, the IGBT aging state is monitored, the service life is estimated, safe operation of the power conversion device is guaranteed, and operation and maintenance cost is reduced.

Owner:CHONGQING UNIV

Method for determining temperature field distribution of cabin of carrier rocket in flight phase in atmospheric layer

ActiveCN104820748AIncrease structural weightReliable design basisSpecial data processing applicationsEngineeringRocket

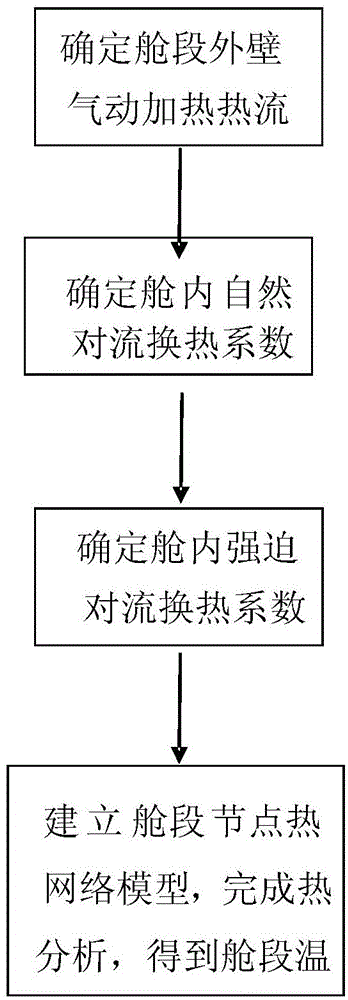

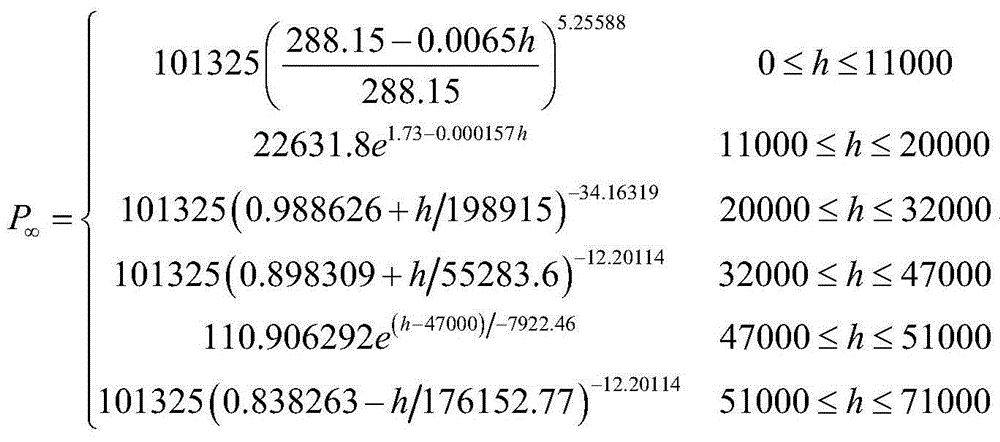

The invention relates to a method for determining temperature field distribution of a cabin of a carrier rocket in a flight phase in an atmospheric layer. The method comprises a first step of determining an aerodynamic heating thermal flow qh changing along with the flight height and acting on the outer wall of the cabin; a second step of determining an average natural convection heat transfer coefficient alpha n of the shell surface of an instrument in a closed cavity of the cabin changing along with the flight height; a third step of determining a forced convection heat transfer coefficient alpha f of interior of the cabin caused by flight accelerated speed and constant leakage of gas in the cabin; and a fourth step of building a cabin node thermal network model, finishing thermal coupling analysis, and obtaining the cabin temperature field distribution. The method comprehensively considers the impact of aerodynamic heating outside the cabin, air natural convection in the cabin and forced convection on the cabin thermal environment, thereby effectively solving the problem of determination of temperature field distribution of the cabin of the carrier rocket in the flight phase in the atmospheric layer.

Owner:BEIJING INST OF ASTRONAUTICAL SYST ENG +1

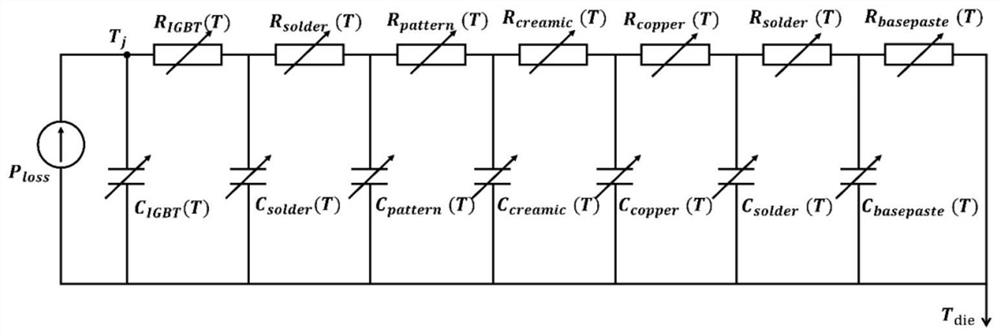

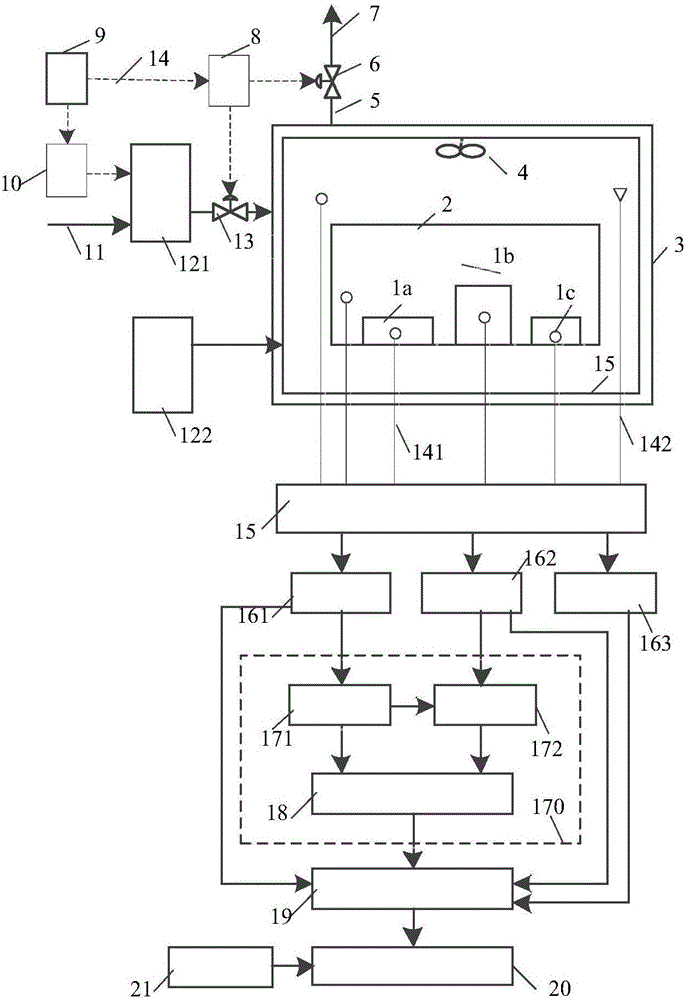

IGBT module junction temperature online estimation circuit system and method

InactiveCN110988641AImprove estimation accuracyImprove accuracyIndividual semiconductor device testingThermodynamicsJunction temperature

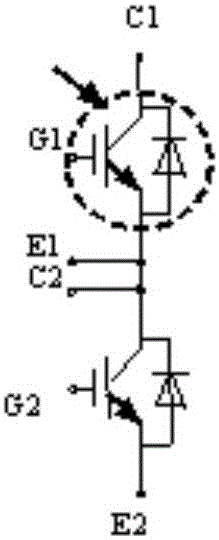

The invention discloses an IGBT module junction temperature online estimation circuit system and method, and the method comprises the following steps: 1, carrying out the online measurement of the IGBT on-state voltage drop VCE(ON) of an IGBT power module, and building an IGBT junction temperature Tj lookup table; 2, calculating the power loss of an IGBT and a diode in the IGBT power module; 3, periodically and timely updating the IGBT equivalent thermal network model by adopting a thermal network updating strategy considering the fatigue accumulation effect of the solder layer; 4, establishing a state space model by taking the junction temperature Tj and the IGBT and diode power loss as state variables according to the IGBT equivalent thermal network model, and updating the state space model; and 5, designing an adaptive Kalman filtering algorithm program according to the state space model to obtain an IGBT junction temperature Tj estimated value. The method integrates the advantagesof model estimation and online measurement, overcomes the defect that on-state voltage drop VCE (ON) measurement is inaccurate, keeps signal continuity, reduces noise interference, is high in estimation precision, and can estimate the IGBT module junction temperature in real time in a non-intervention mode.

Owner:WUHAN UNIV

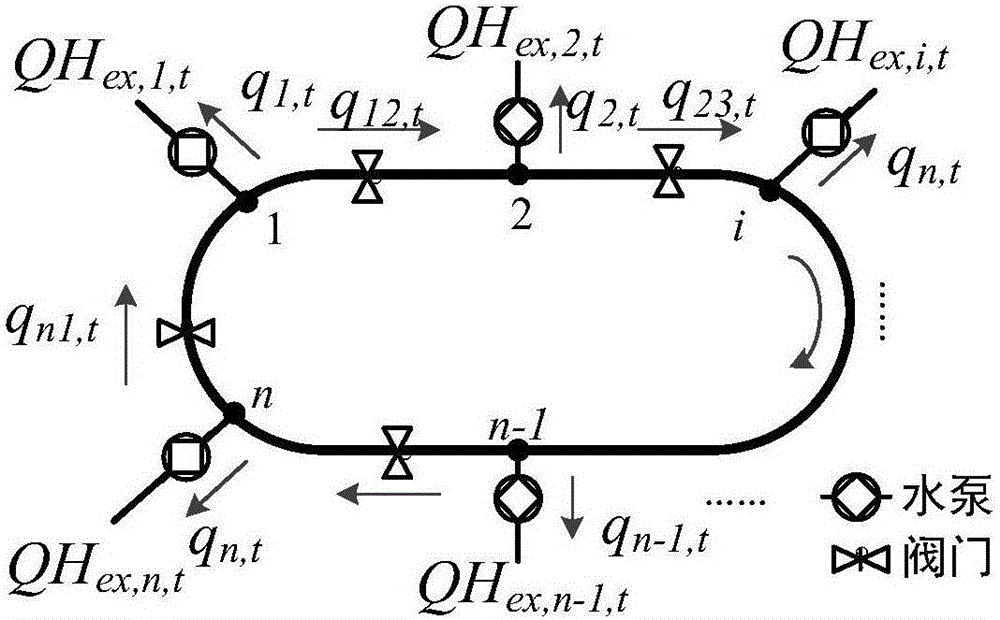

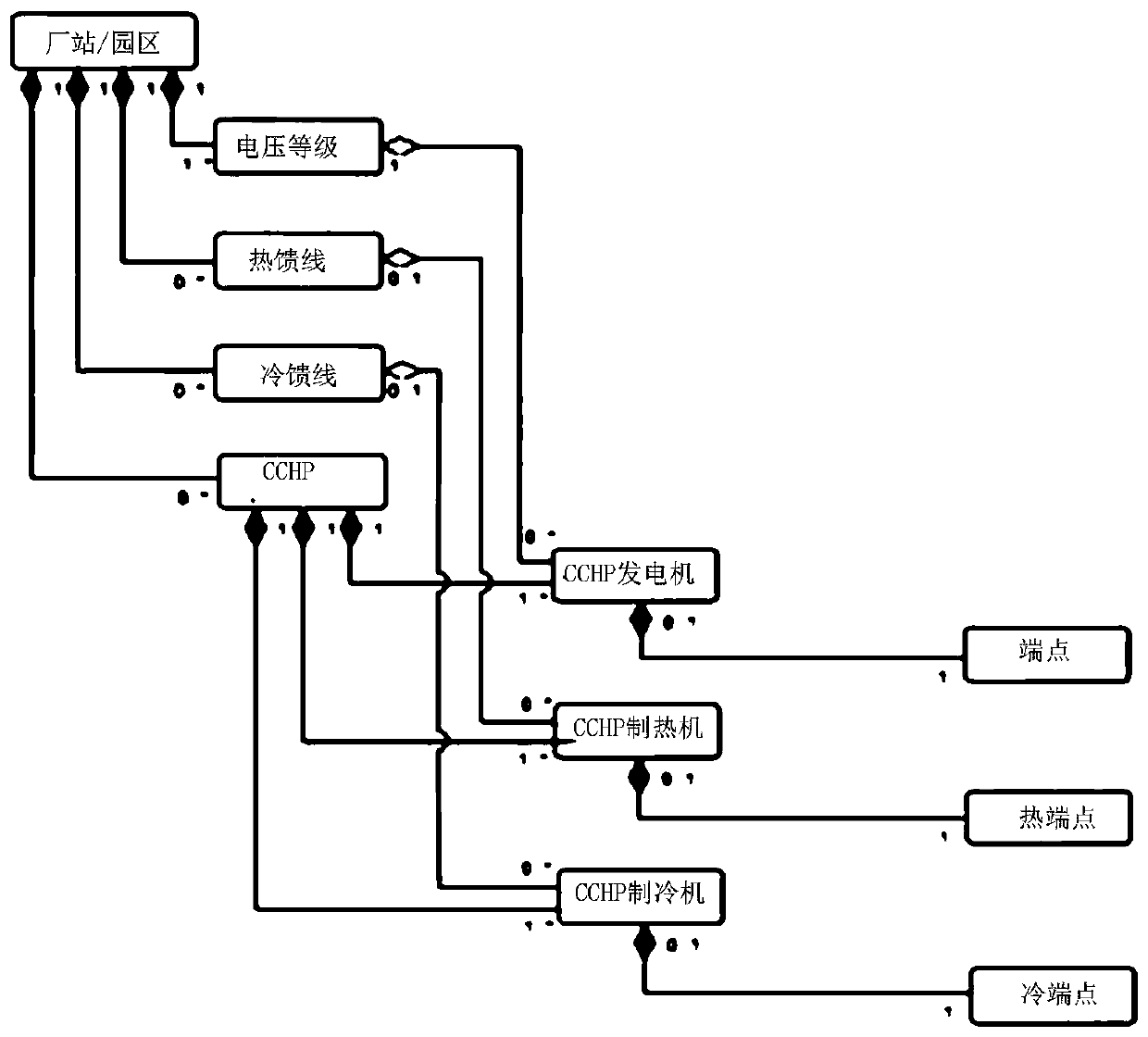

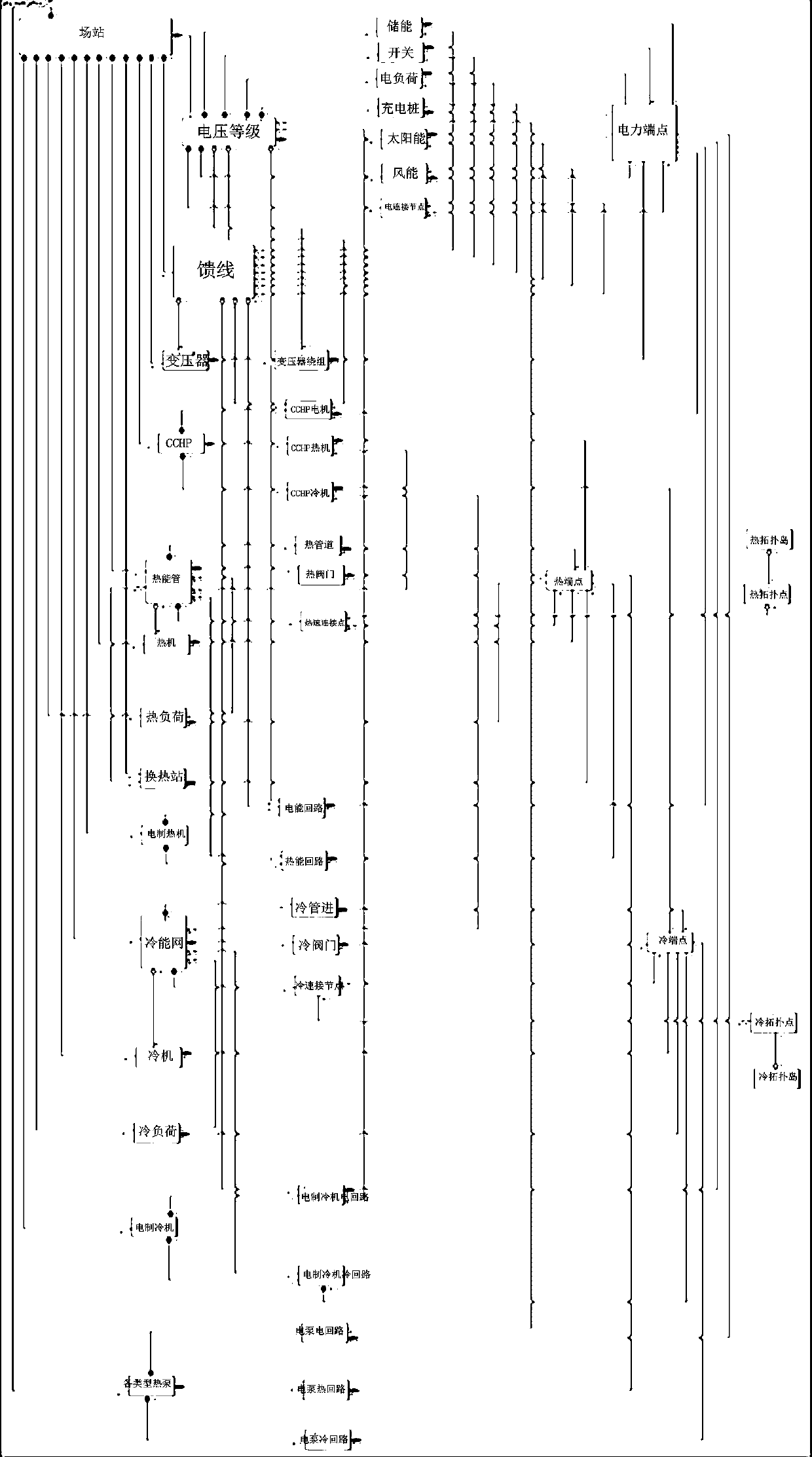

Establishment method of configuration model of multi-regional comprehensive energy system in combination with thermal network model

ActiveCN106055773AHigh annual investment costLow running costForecastingMulti-objective optimisationCost effectivenessCapacity provisioning

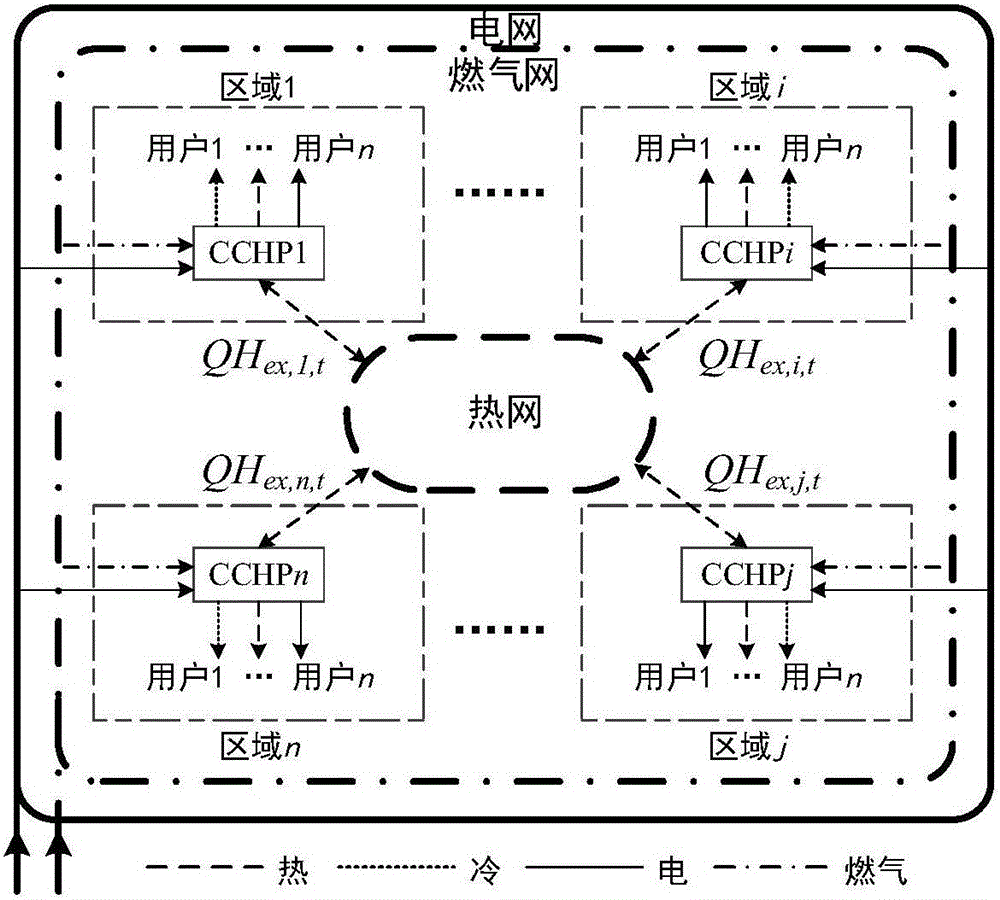

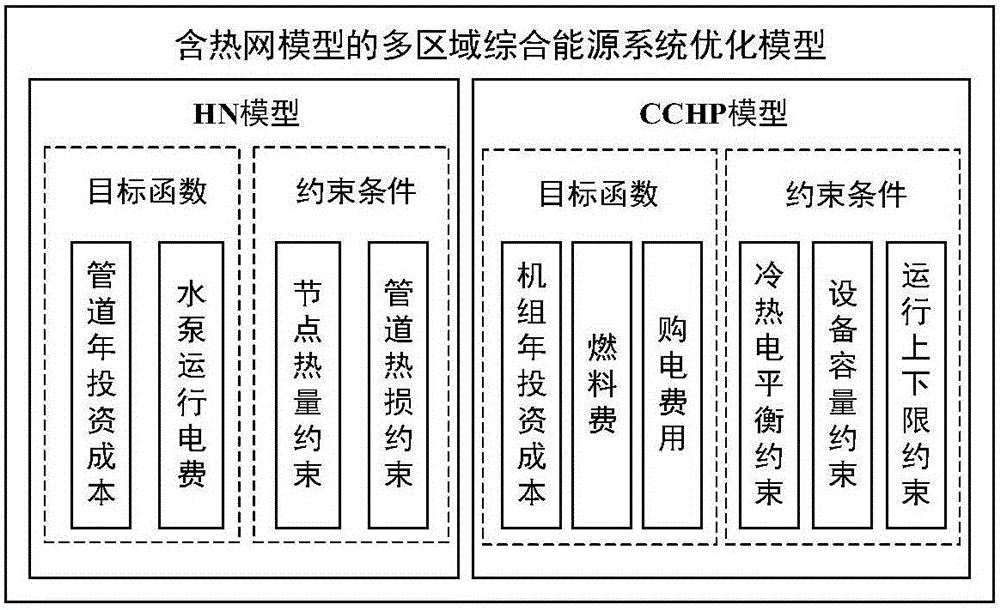

The invention discloses an establishment method of a configuration model of a multi-regional comprehensive energy system in combination with a thermal network model. The method comprises following steps: step 10), respectively establishing the Establishment method of configuration model of multi-regional comprehensive energy system in combination with the thermal network model and a CCHP model; step 20), combining the thermal network model and the CCHP model established to establish the configuration model. The method is capable of well utilizing obvious peak valley alternating occurrences existing cooling heating and power loads in all regions in order to achieve supply-demand complementarities of multiple energies and reducing capacity configuration. The problems such as configuration waste and low utilization rate of equipment during independent planning are solved. Overall cost-effectiveness of the system is effectively improved.

Owner:SOUTHEAST UNIV

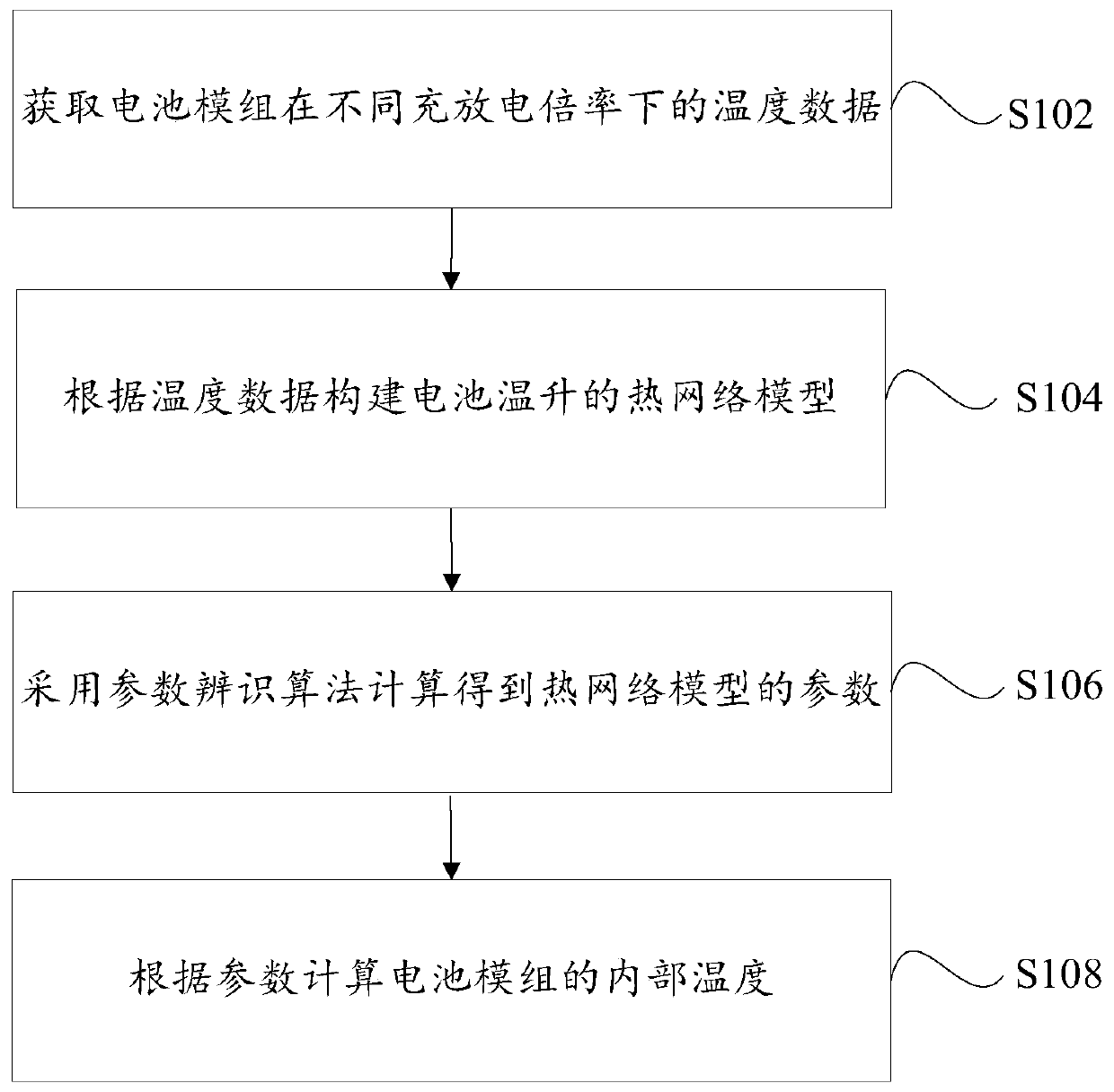

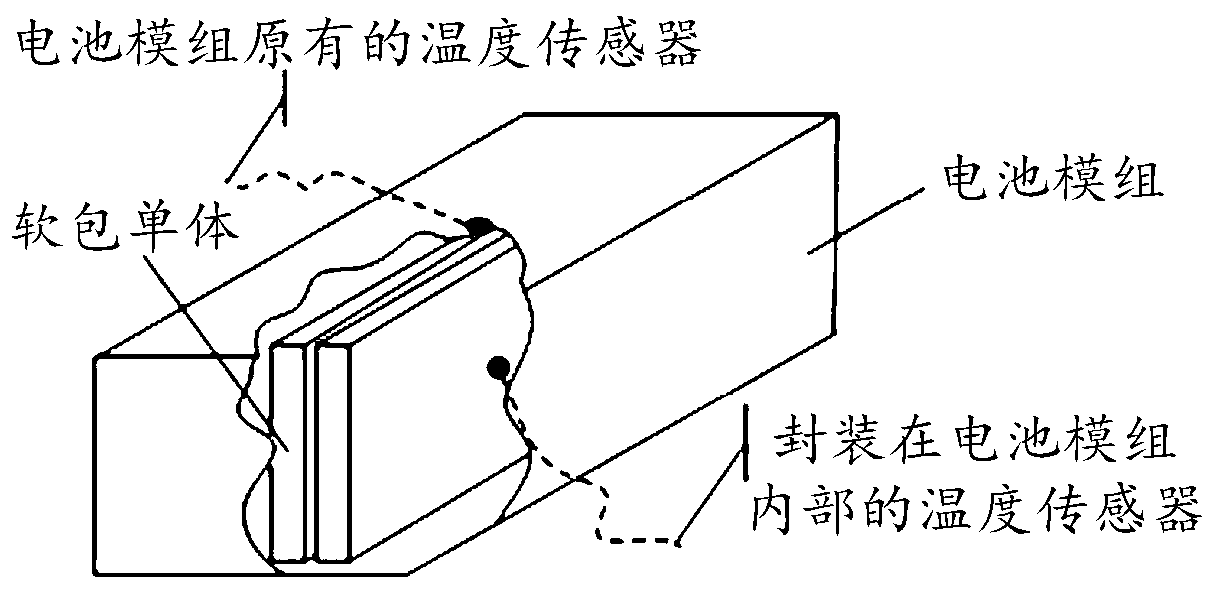

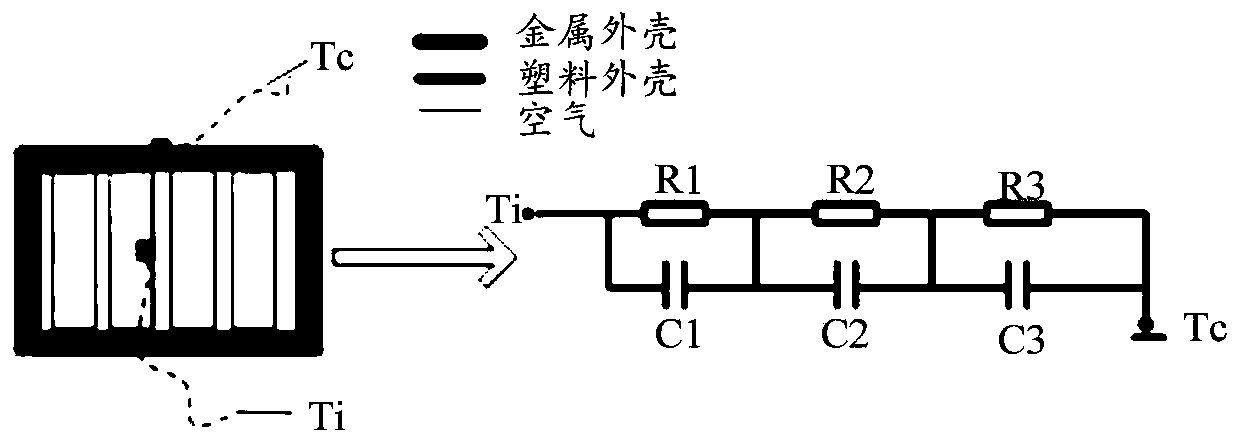

Method and device for determining internal temperature of battery module and intelligent terminal

InactiveCN110118617AImprove accuracyThermometer detailsElectrical testingEngineeringInternal temperature

The invention provides a method and a device for determining internal temperature of a battery module and an intelligent terminal, and relates to the technical field of temperature acquisition. The method comprises steps of acquiring the temperature data of a battery module at different charge and discharge rates; constructing a thermal network model of the battery temperature rise according to the temperature data; calculating the parameters of the thermal network model by using a parameter identification algorithm; calculating the internal temperature of the battery module according to the parameters. The method of the invention can effectively improve the accuracy for determining the internal temperature of the battery module.

Owner:上海元城汽车技术有限公司

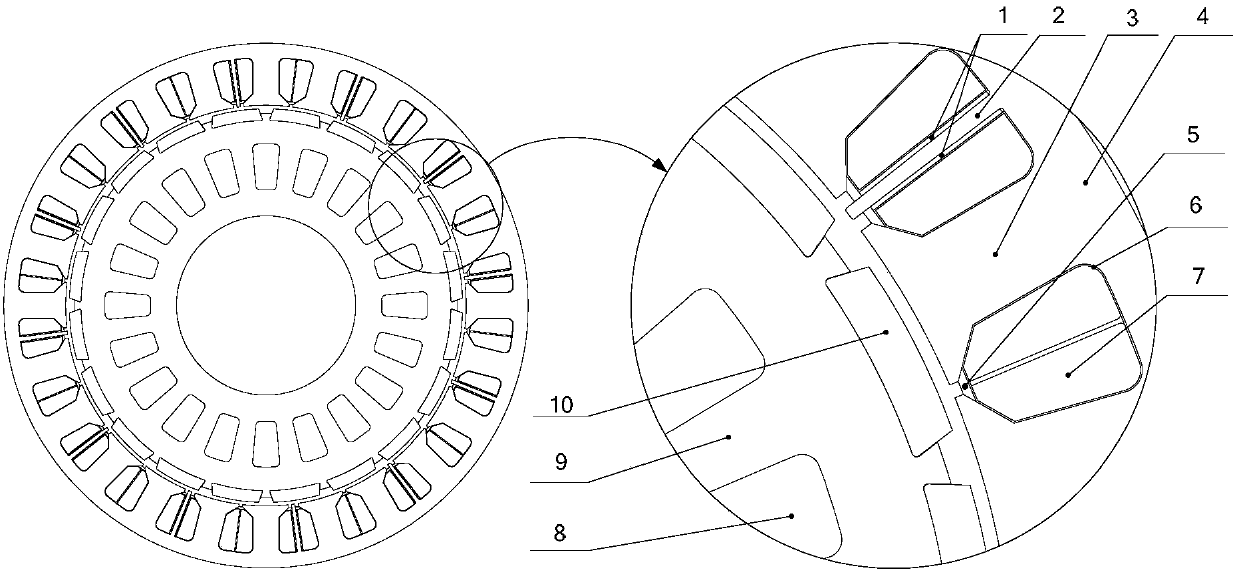

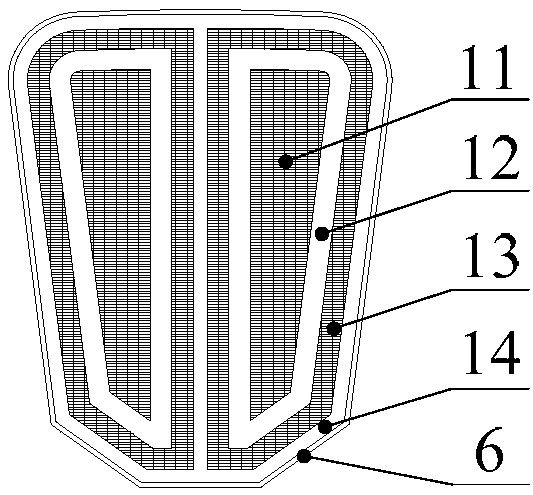

Dual-redundancy permanent magnet synchronous motor temperature rise calculation method based on equivalent thermal network model

ActiveCN107391884AThe temperature field takes less timeShort timeDesign optimisation/simulationSpecial data processing applicationsElectrical conductorPermanent magnet synchronous motor

The invention discloses a dual-redundancy permanent magnet synchronous motor temperature rise calculation method based on an equivalent thermal network model. The method includes: building the three-dimensional equivalent thermal network model, solving heat resistance and heat sources, building a thermal balance equation, and solving to obtain the temperature rise of each temperature rise node of a motor. The method has the advantages that the special small-tooth structure of a dual-redundancy permanent magnet synchronous motor with low-heat coupling and without electromagnetic coupling among various phases of windings is considered in modeling, the windings in grooves adopt a double-layer equivalent model with two layers of conductors and two layers of insulators being arranged in a contacted and spaced manner, the temperature rise nodes are built at other solid part nodes and fluid area nodes, contacted different nodes are connected through equivalent resistors, parts contacting with external environment nodes are connected with the external environment nodes through convection radiating resistors, and the heat sources are distributed at active nodes; when the method is used for calculating the temperature rise, calculation quantity is moderate, time consumption is low, accuracy is high. And the obtained temperature rise result can be used for guiding the determination of the motor insulating level and the configuration of a cooling manner.

Owner:TIANJIN UNIV

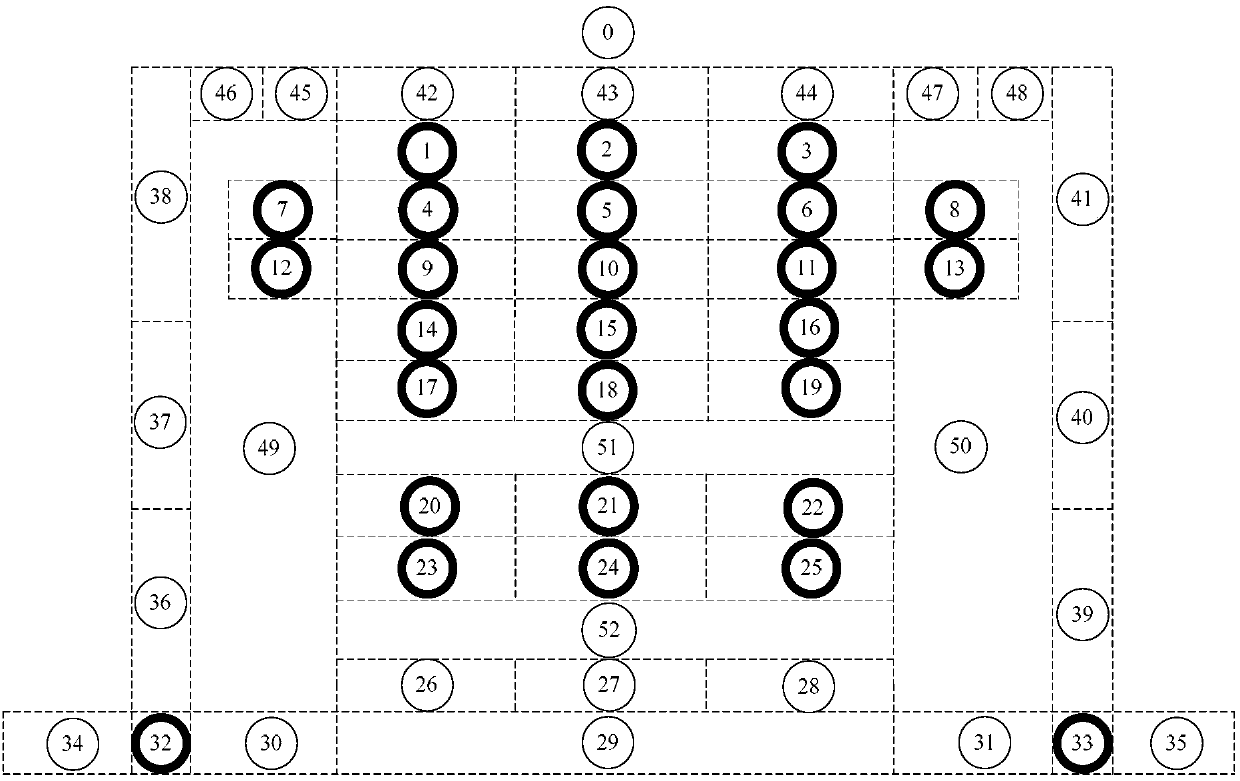

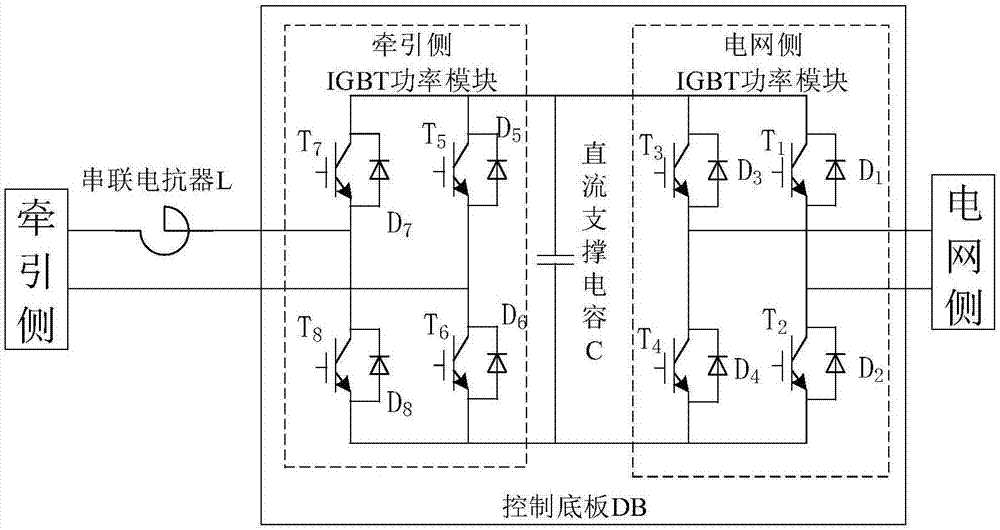

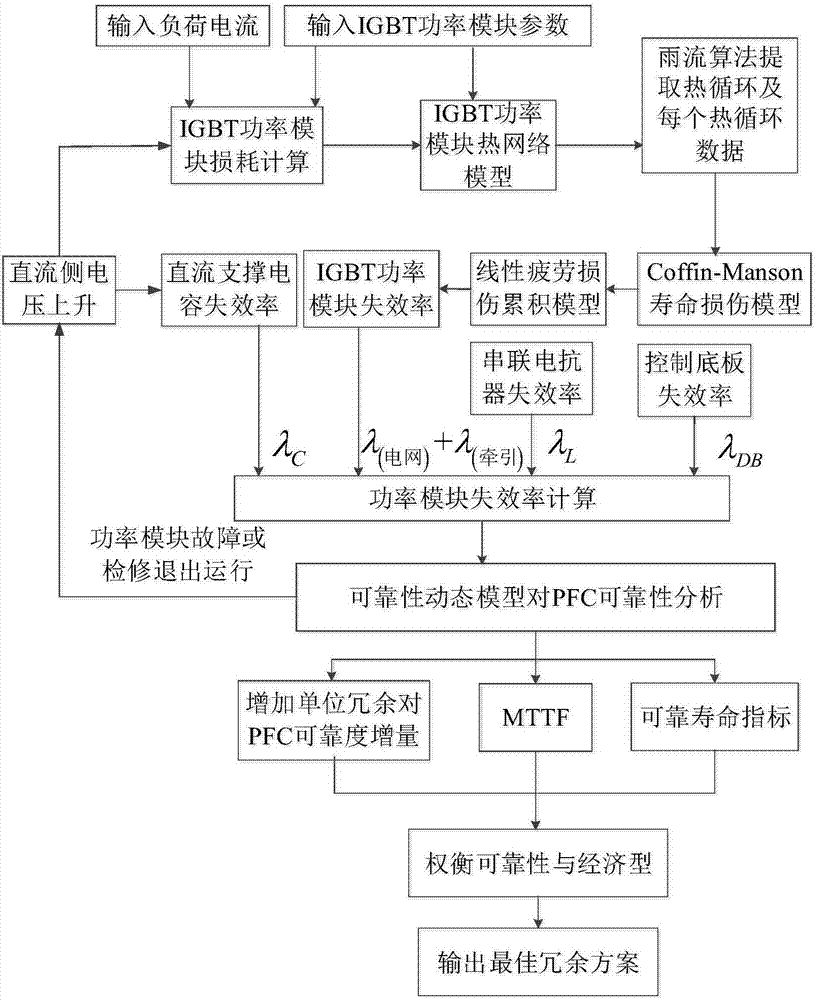

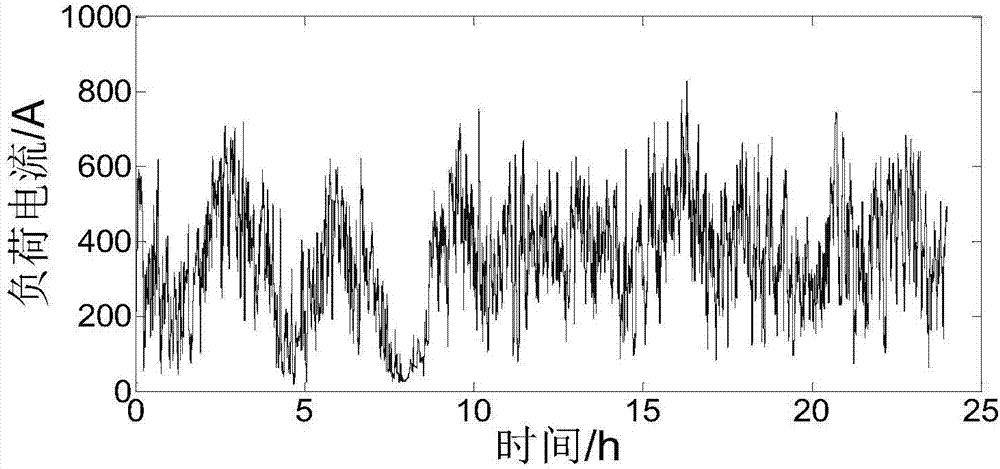

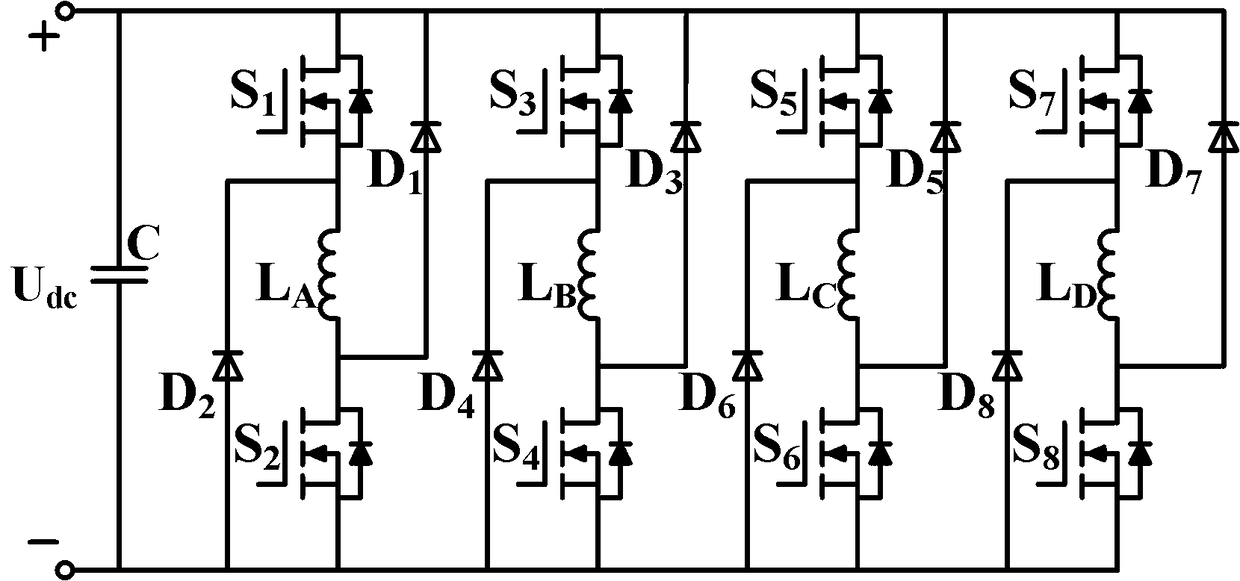

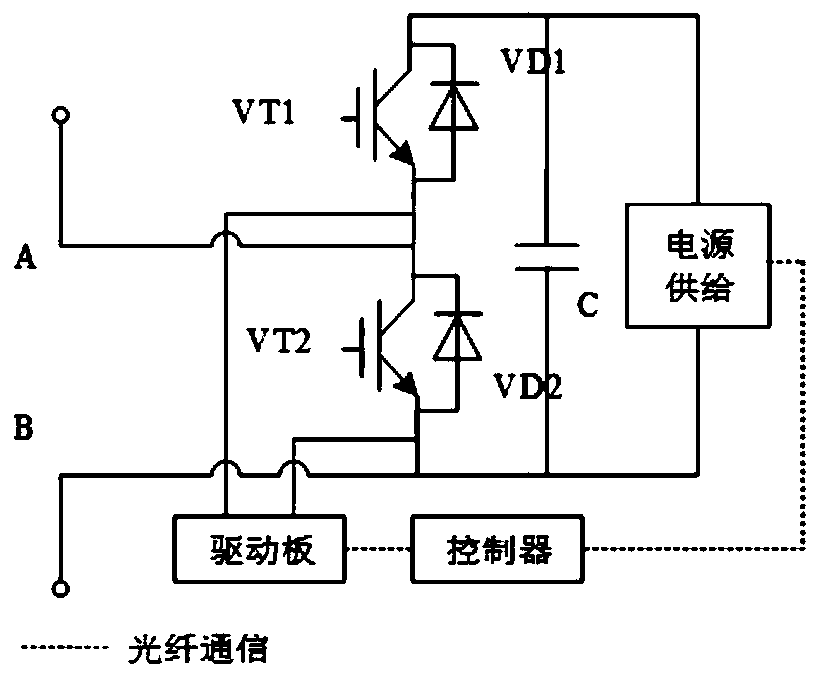

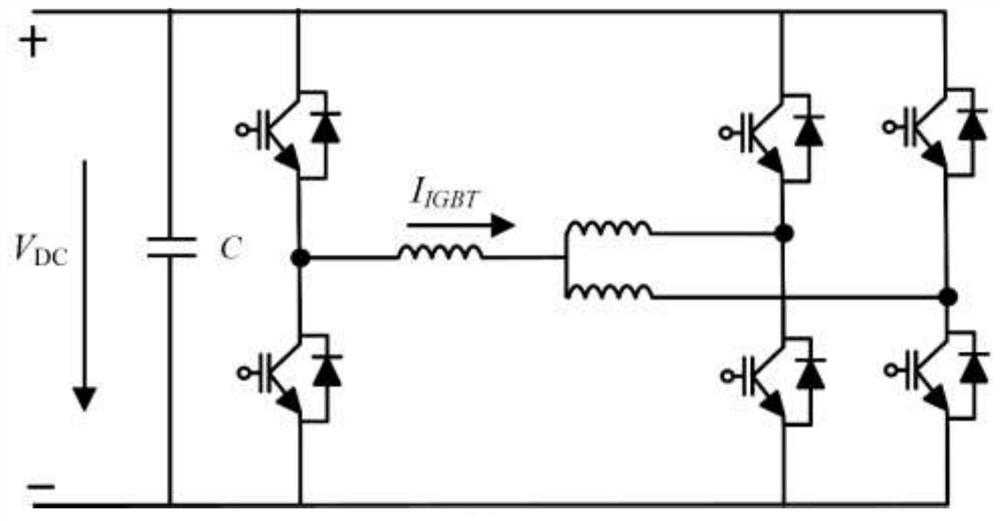

Cophase power supply system flow controller dynamic reliability evaluating method

ActiveCN107508281AEffectively quantify the degree of impactThe assessment results are accurateData processing applicationsAc networks with different sources same frequencyFatigue damageFailure rate

The invention discloses a cophase power supply system flow controller dynamic reliability evaluating method. The influence of the actual traction load randomness and impact on the junction temperature fluctuation of a power element is taken into account. Power loss and a thermal network model are used to calculate the junction temperature of the power element. A physical model based on a failure mechanism and a linear fatigue damage cumulative model are combined to calculate the power module failure rate of a flow controller. The PFC reliability is analyzed by using a dynamic reliability assessment method which takes into account the variation of the element failure rate. According to the invention, the redundancy of a power module is analyzed; the number of cascaded modules of the flow controller is optimized; and a necessary basis is provided for engineering design and operation maintenance of a cophase power supply system.

Owner:SOUTHWEST JIAOTONG UNIV

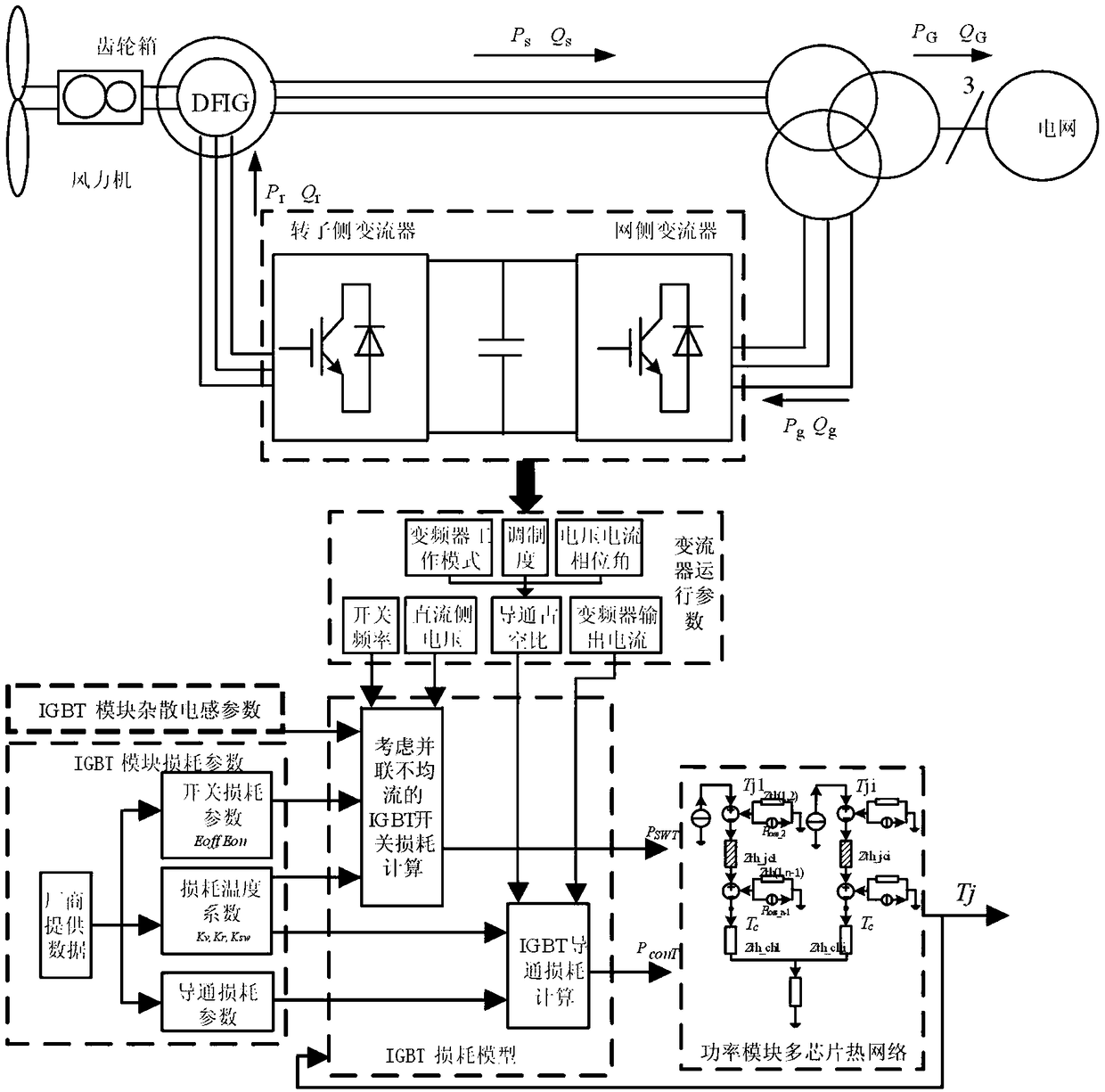

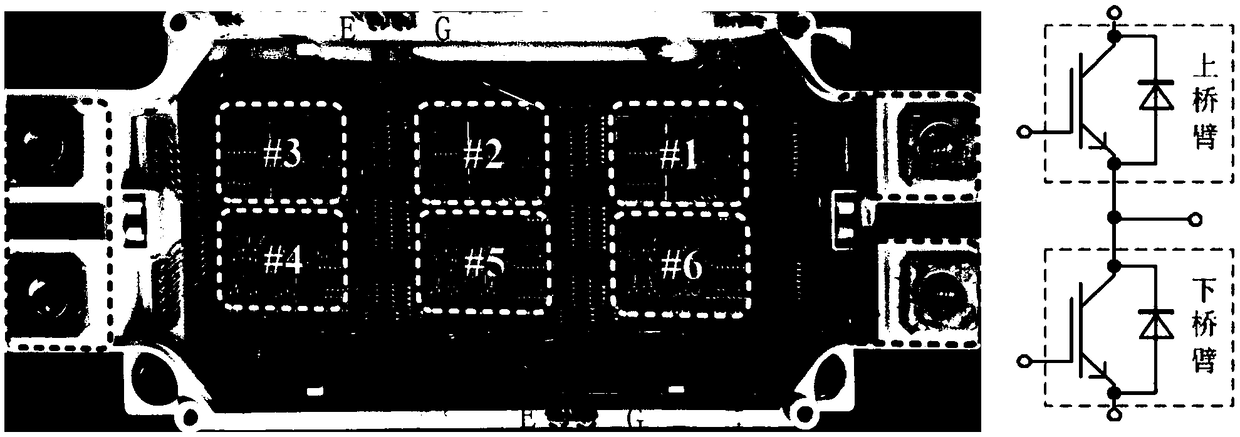

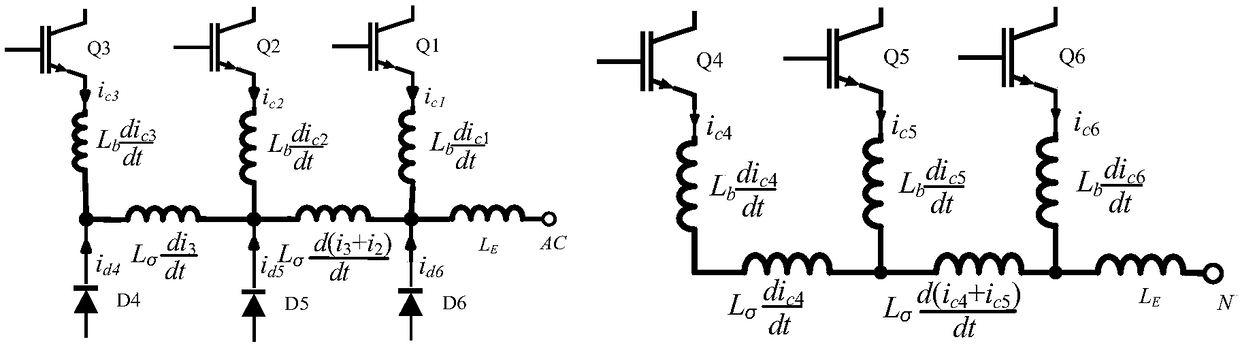

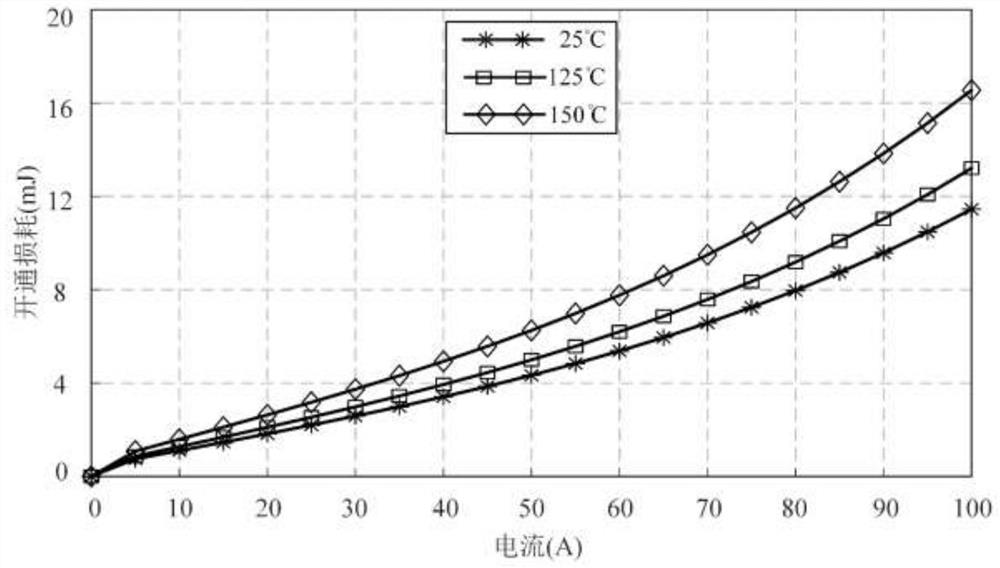

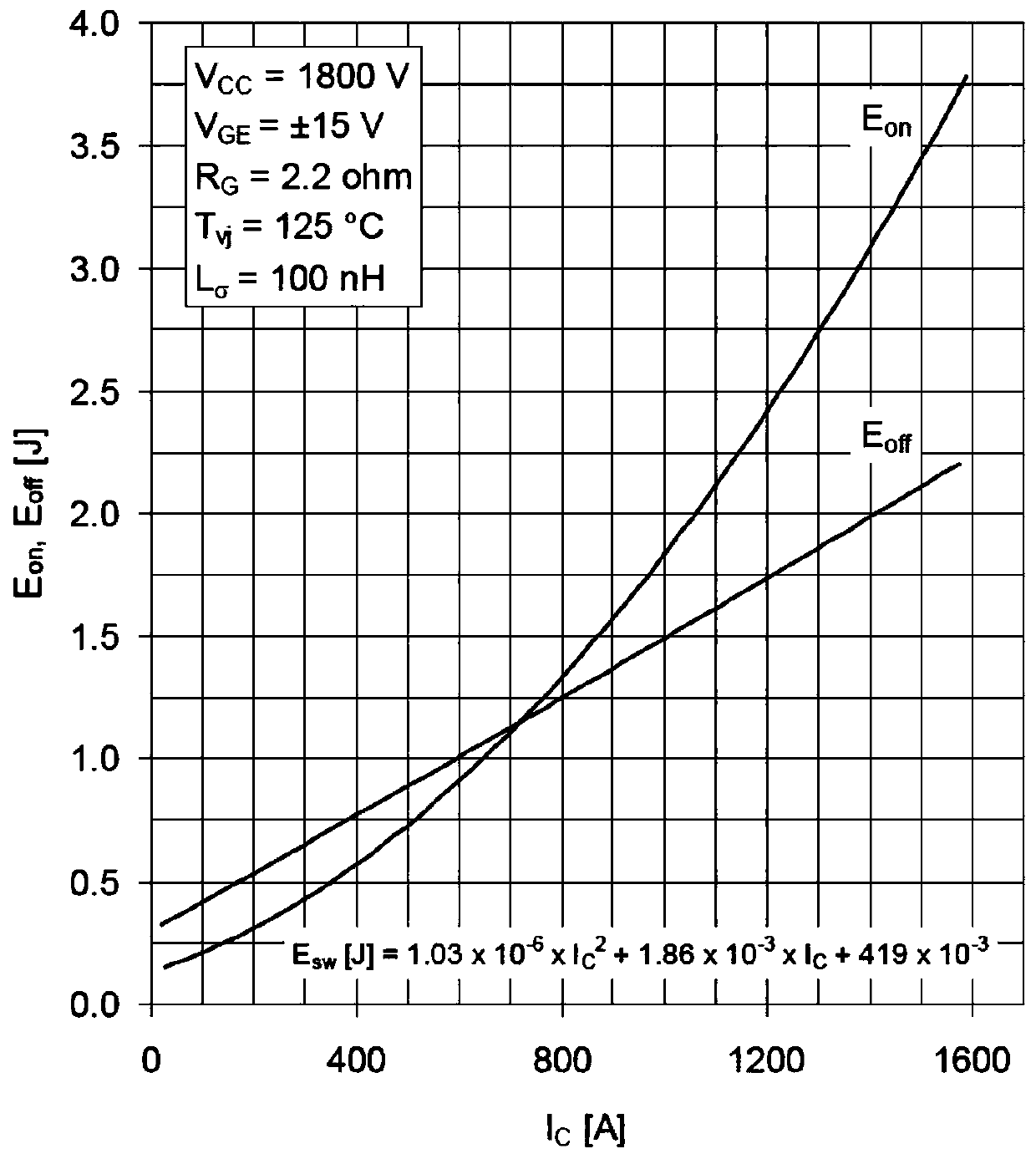

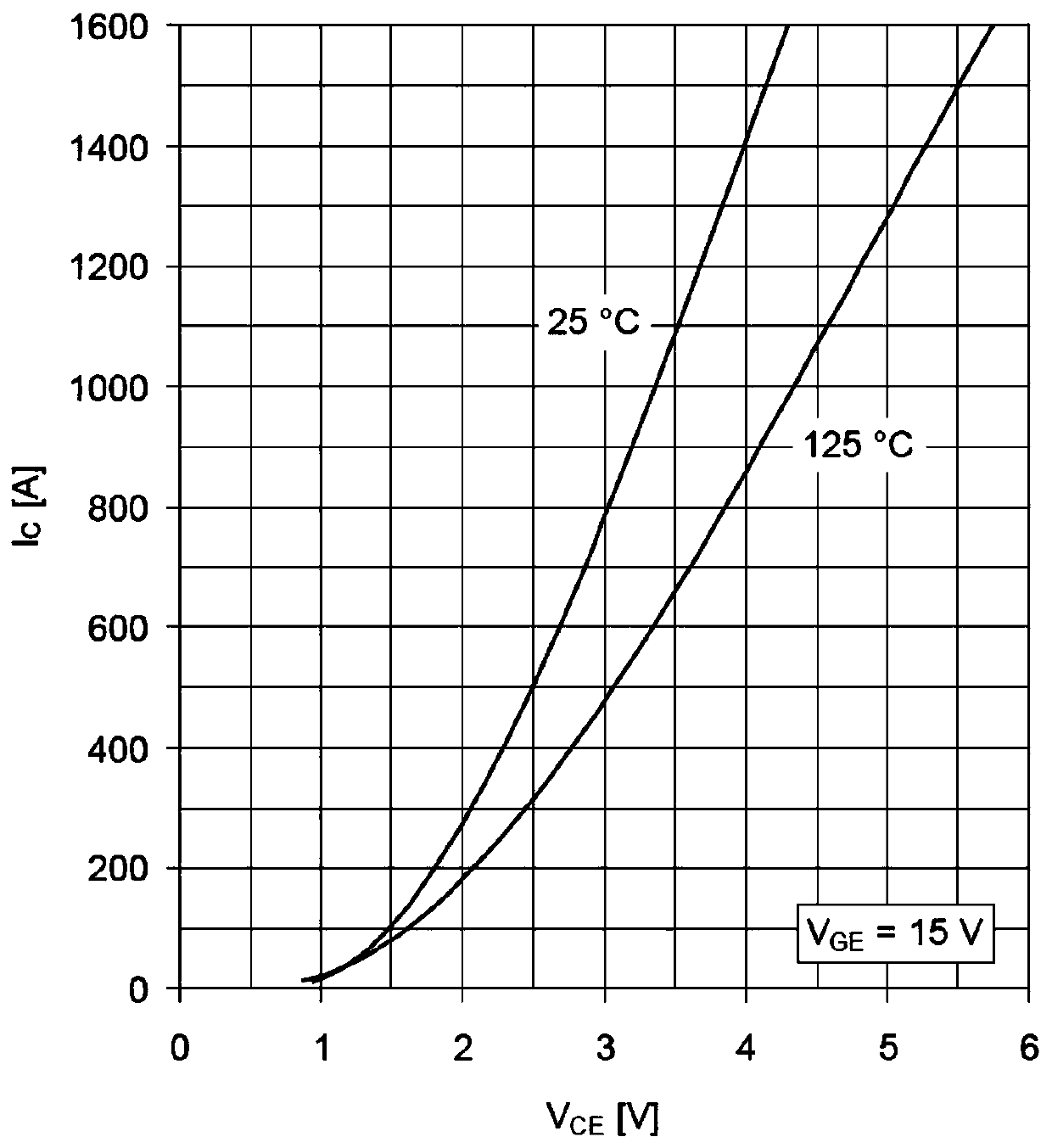

Dynamic junction temperature calculation method of IGBT power module of wind power converter considering the influence of stray inductance

ActiveCN109274255AImproved Thermal Management Control StrategiesAccurately reflectSingle network parallel feeding arrangementsWind energy generationNew energyStray inductance

The invention relates to a method for calculating the dynamic junction temperature of an IGBT power module of a wind power converter considering the influence of stray inductance, The invention belongs to the technical field of high-power power electronic device reliability for new energy power generation. The method comprises the following steps: S1, establishing an equivalent circuit model of anIGBT module according to the dynamic uneven current between parallel multi-chips caused by stray inductors; S2: deriving The mathematical relationship between the stray inductance parameters and theswitching-on loss; S3: Introducing the equivalent thermal coupling impedance to establish the thermal network model considering the thermal coupling between chips; 4, establishing a dynamic junction temperature calculation model of that IGBT module, feeding the junction temperature distribution result back to a mathematical relation model of los, and iteratively obtaining the dynamic junction temperature distribution among chips in the IGBT module. The invention can accurately reflect the dynamic heat distribution inside the IGBT power module, effectively characterize the heat weak links inside the module, and improve the heat management control strategy of the wind power converter, thereby improving the reliability thereof.

Owner:重庆平创半导体研究院有限责任公司

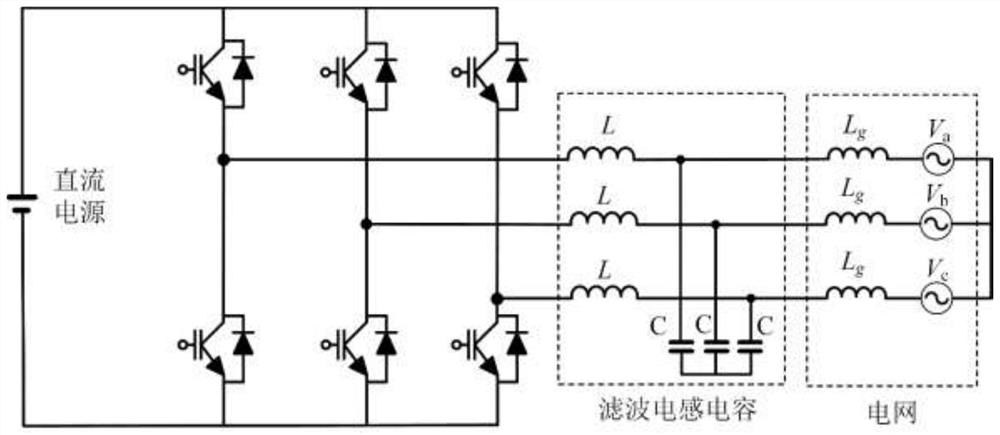

Calculation method for IGBT junction temperature fluctuation of power electronic converter

ActiveCN112464443APower loss calculationThe calculation result is accurateDesign optimisation/simulationCAD numerical modellingThermodynamicsJunction temperature

The invention discloses a calculation method for IGBT junction temperature fluctuation of a power electronic converter, and the method specifically comprises the steps of collecting a converter-levelvariable needed by the calculation of power loss, carrying out the Fourier decomposition of an output current at an AC side, and obtaining a current expression flowing through an analyzed IGBT; calculating switching loss and conduction loss corresponding to the alternating current side current peak value respectively, and then obtaining the analyzed power loss of the IGBT in the whole fundamentalwave period; deducing a junction temperature fluctuation expression in a fundamental wave period in combination with a Foster thermal network model, and deriving the junction temperature fluctuation expression to obtain maximum and minimum junction temperature generation time points; and calculating the maximum junction temperature value, the minimum junction temperature value, the junction temperature value at the moment corresponding to the current peak value and the component value of junction temperature fluctuation at the end of the fundamental cycle according to the obtained time points.According to the invention, the IGBT junction temperature fluctuation can be quickly calculated, and the calculation result is accurate, comprehensive and reliable.

Owner:SOUTHWEST JIAOTONG UNIV

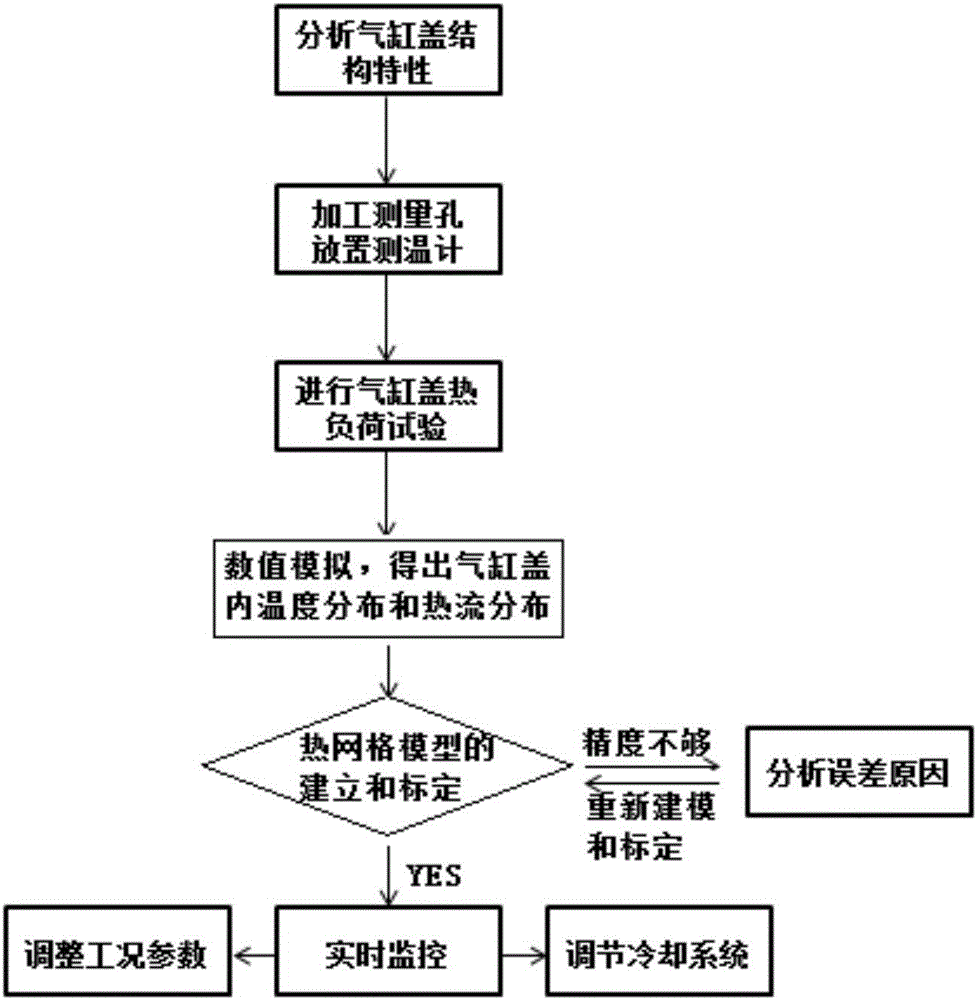

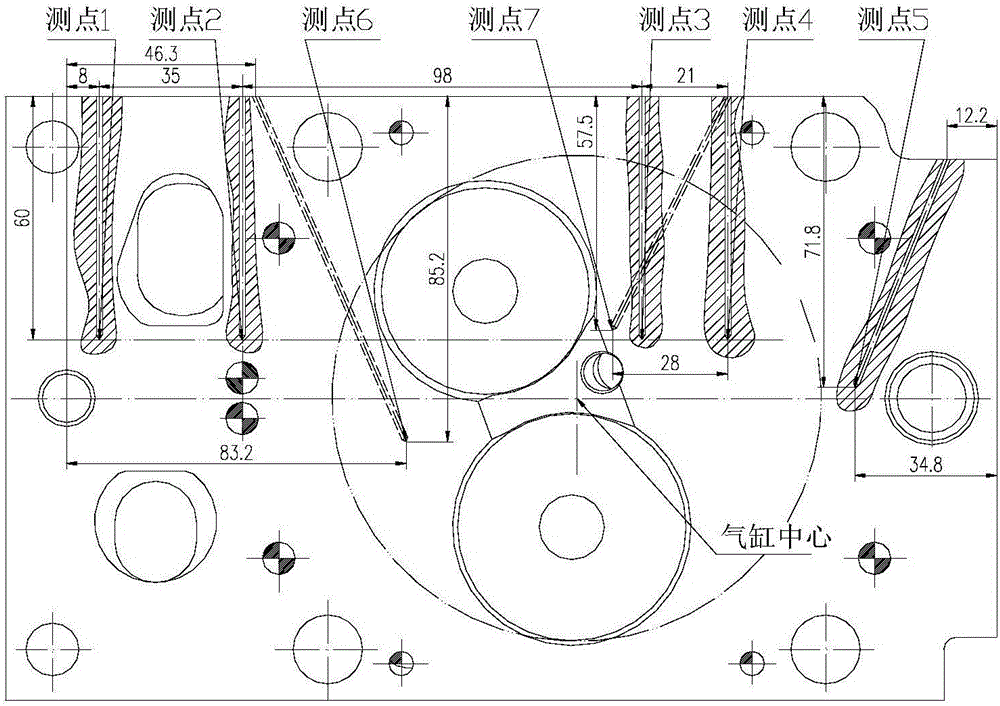

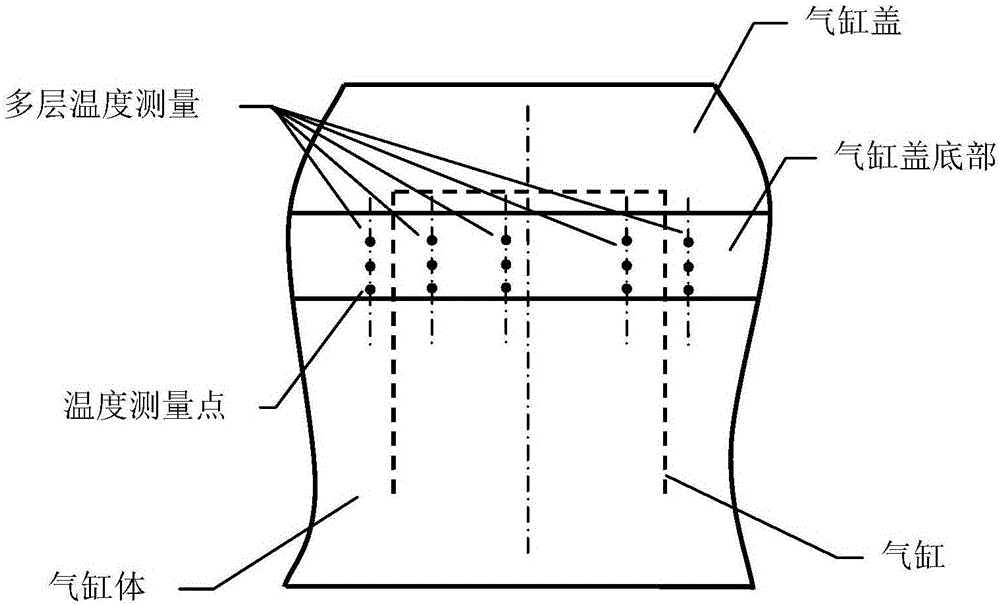

Real-time monitoring method for highest temperature in cylinder head of internal combustion engine

ActiveCN106368814AMaximum temperature real-time monitoringGuaranteed reliabilityMachines/enginesEngine componentsHeat flowCylinder head

The invention discloses a real-time monitoring method for the highest temperature in a cylinder head of an internal combustion engine. The real-time monitoring method includes the steps that (1) a temperature measuring experiment for the cylinder head of the internal combustion engine is conducted, and numerical simulation of a cylinder head temperature field is conducted, so that the highest temperature, temperature distribution and heat flow distribution in the cylinder head are obtained; (2) numerical simulation of external flow of the internal combustion engine is carried out, and the position of a peripheral temperature measuring point on the cylinder head is obtained; (3) a correlation model for the highest temperature in the cylinder head and the temperature at the peripheral temperature measuring point is determined by means of results of the highest temperature, temperature distribution and heat flow distribution; and (4) during actual work of the internal combustion engine, by measuring the temperature of the peripheral temperature measuring point of the cylinder head in real time with the peripheral temperature measuring point as a temperature measuring point and utilizing a calibrated thermal network model, the highest temperature in the cylinder head can be obtained in real time through inverse estimation. By means of the real-time monitoring method, real-time monitoring on the highest temperature of high-temperature parts which cannot be directly measured or are not suitable for being directly measured for a long time can be achieved, and the reliability of the parts is ensured.

Owner:HUAZHONG UNIV OF SCI & TECH

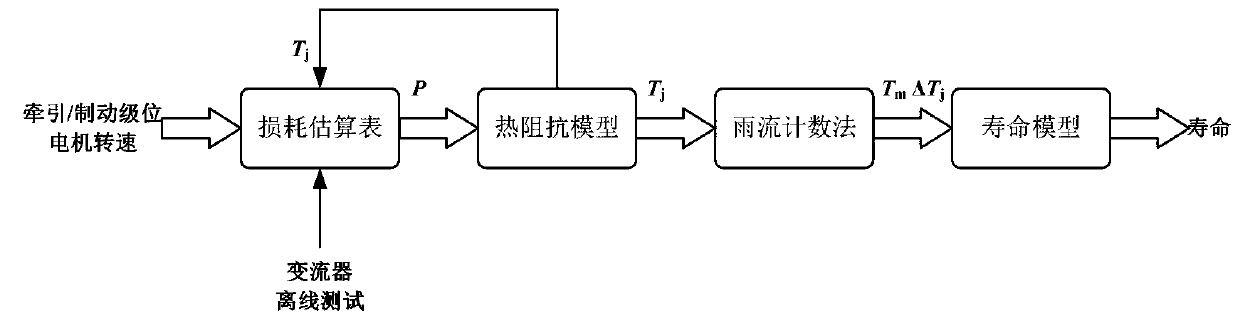

Method for predicting service life of IGBT module of traction transmission system of metro vehicle

InactiveCN110514979ALife PredictionEffective calculation of lifeSemiconductor operation lifetime testingMotor speedJunction temperature

The invention relates to the field of power electronic reliability, in particular to a method for predicting the service life of an IGBT module of a traction transmission system of a metro vehicle. The method comprises the following steps of 1, building a traction transmission system IGBT loss estimation model according to the traction level / the braking level and the motor speed n of the metro vehicle; 2, building a traction transmission system IGBT junction temperature estimation model on the basis of a Foster equivalent thermal network model and IGBT loss; and 3, building a traction transmission system IGBT life prediction model based on a rain-flow counting method and a Miner linear damage accumulation theory. According to the actual traction level / braking level and motor speed n of themetro vehicle, the IGBT loss is obtained by a lookup method to predict the service life of the IGBT module; and the accumulated damage degree of the IGBT module can be effectively calculated and theservice life of the IGBT module can be predicted, so that the damage early warning can be carried out on the IGBT module, the occurrence of faults is effectively prevented, the safety risk is reduced,and the economic loss is reduced.

Owner:重庆中涪科瑞工业技术研究院有限公司

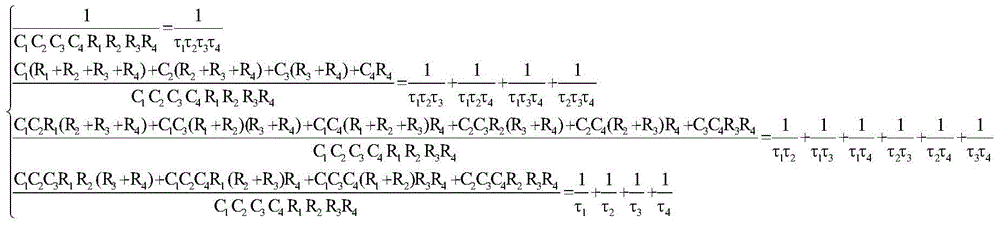

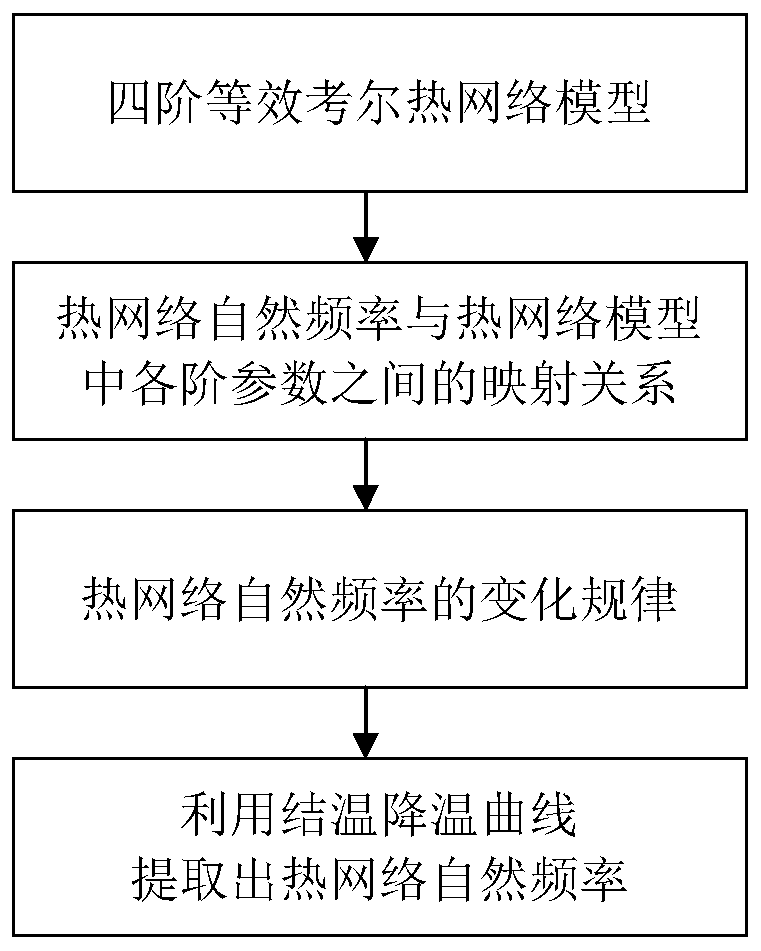

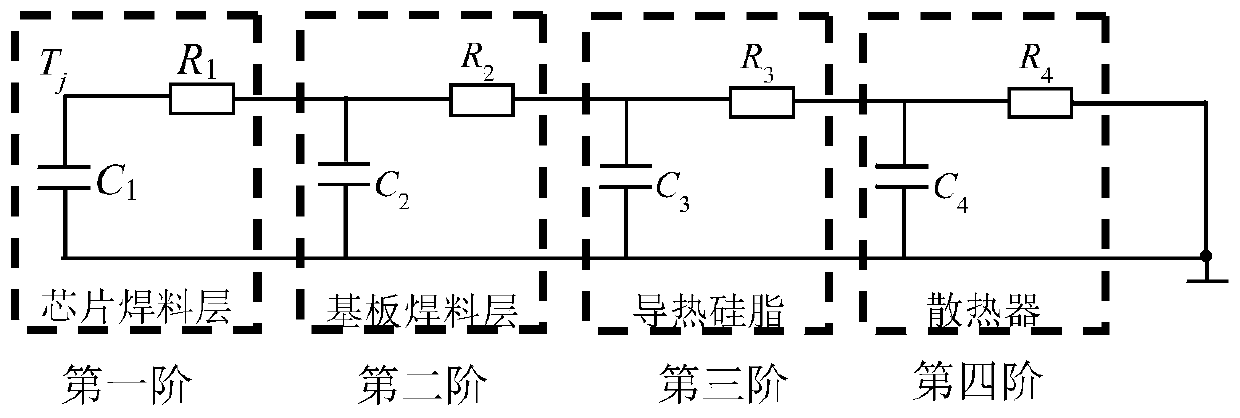

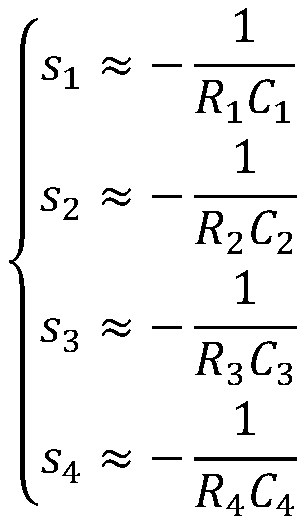

IGBT module health state monitoring method based on natural frequency of thermal network

InactiveCN111060797ALow costReduce operational complexitySemiconductor operation lifetime testingJunction temperatureComputer science

The invention discloses an IGBT module health state monitoring method based on a natural frequency of a thermal network. The IGBT module health state monitoring method comprises the steps of: establishing a fourth-order equivalent Cauer thermal network model according to physical performance parameters of an IGBT module and a radiator; establishing a mapping relationship between the natural frequency of the thermal network and parameters of each order in the thermal network model according to an order-of-magnitude difference between the thermal parameters of each order; fitting a measured junction temperature cooling curve of the IGBT module to obtain the natural frequency of the thermal network; and monitoring a health state of the IGBT module according to the natural frequency. The IGBTmodule health state monitoring method can monitor the aging degree of the IGBT module under the condition that the power loss of the IGBT module is not measured.

Owner:HOHAI UNIV

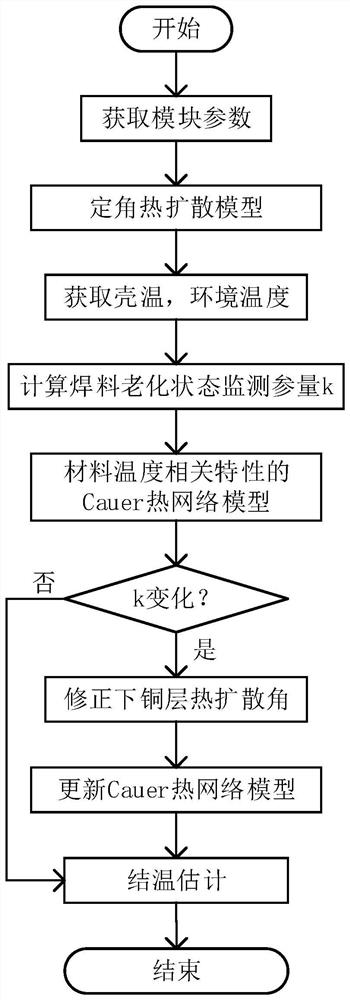

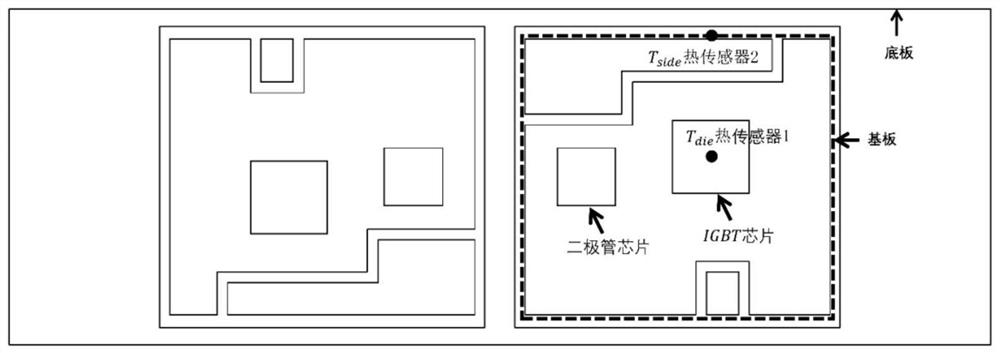

IGBT module junction temperature estimation method in solder aging state

ActiveCN111931402AResolving Heat Transfer Path Offset IssuesHigh precisionDesign optimisation/simulationSpecial data processing applicationsJunction temperatureProcess engineering

The invention relates to a method for estimating the junction temperature of an IGBT module in a solder aging state. The method comprises the steps that 1, geometric structure parameters and materialcharacteristic parameters of the IGBT module are acquired; 2, establishing a constant-angle thermal diffusion model based on the geometric parameters and the heat transfer performance; 3, collecting environment information of the IGBT module; 4, obtaining solder aging state monitoring parameters according to the environment information of the IGBT module; step 5, establishing a Caler thermal network model of IGBT module material temperature related characteristics; 6, quantifying the influence of solder aging on an internal heat transfer path through the aging monitoring parameters to obtain an actual heat transfer area, and updating the parameters of the thermal network model; and step 7, estimating the junction temperature of the IGBT module in real time based on the Cauer thermal network model and the feedback junction temperature. Compared with the prior art, the method has the advantages of being high in junction temperature estimation result precision, effectively improving evaluation precision and strategy rationality and the like.

Owner:SHANGHAI UNIVERSITY OF ELECTRIC POWER

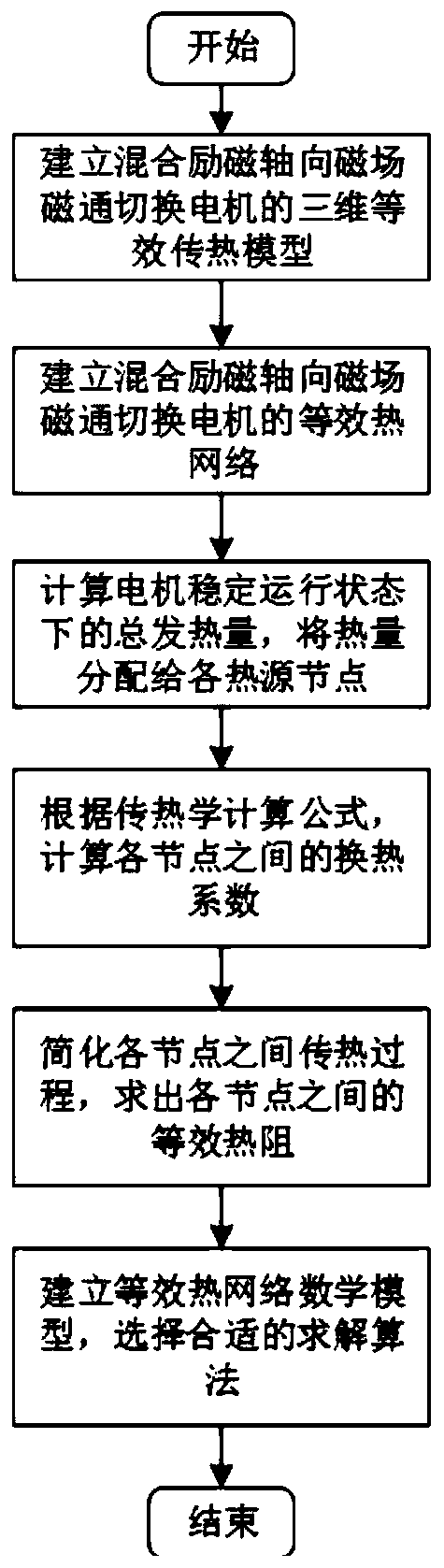

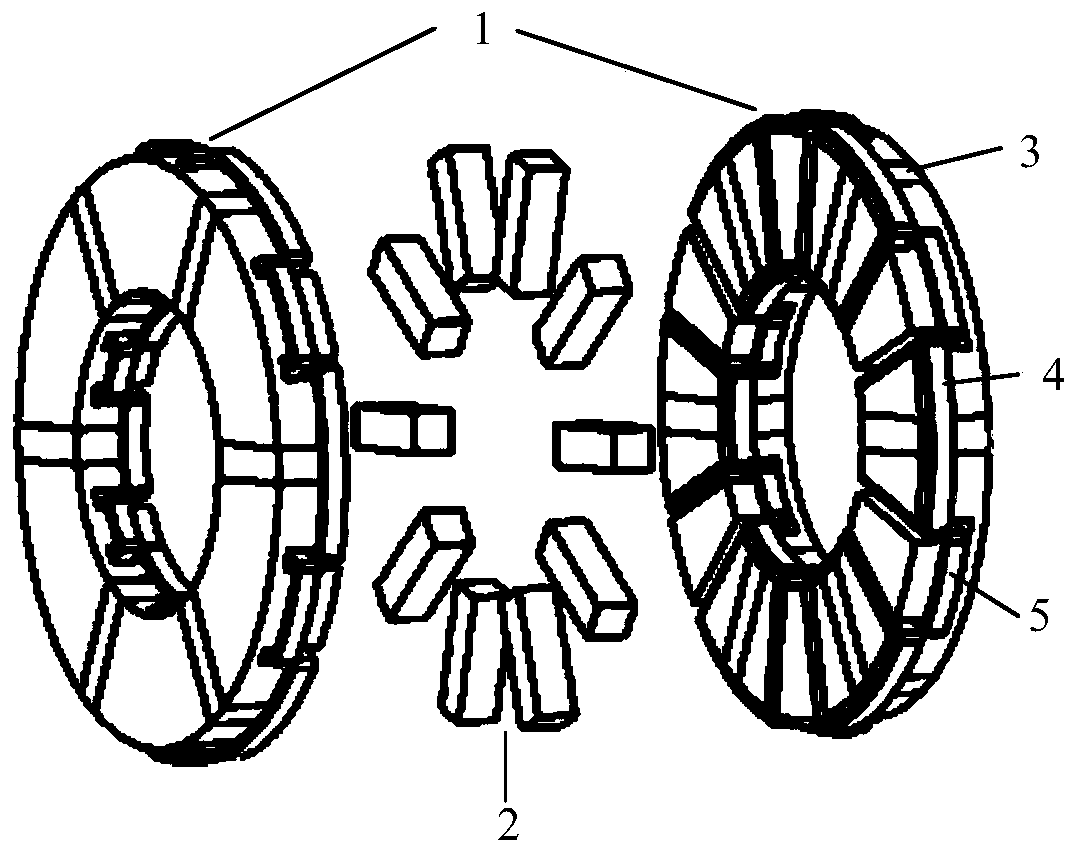

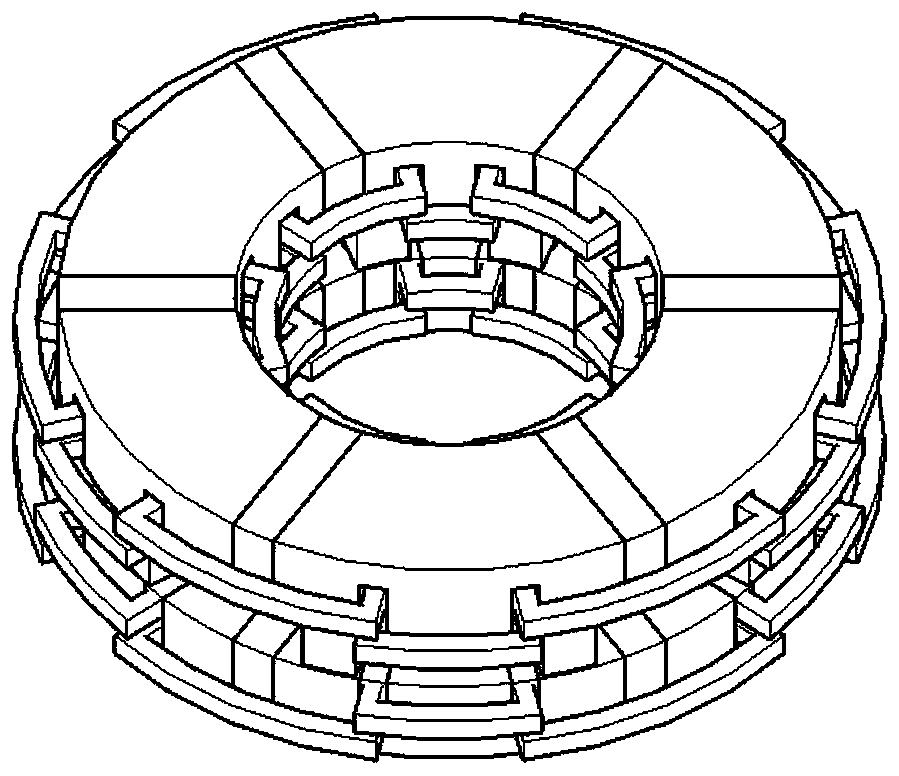

Equivalent thermal network modeling method of hybrid excitation axial magnetic field flux switching motor

ActiveCN110414074AAccurate calculationCalculation speedSpecial data processing applicationsMathematical modelElectric machinery

The invention discloses an equivalent thermal network modeling method of a hybrid excitation axial magnetic field flux switching motor. The method comprises the following steps: firstly, establishinga three-dimensional heat transfer model of a motor and an equivalent thermal network model of the motor; then, calculating the total heat productivity of the motor, distributing the heat to the heat source nodes, and calculating the heat transfer coefficient between the nodes according to the heat transfer empirical formula under different heat dissipation conditions; then equalizing the heat transfer between the nodes to the heat transfer between the simple geometries, and solving the equivalent thermal resistance between the nodes; and finally, establishing a mathematical model, and selecting a proper solving algorithm to solve the temperature rise of each node. The method reduces the difficulty of solving the temperature of the internal parts of the motor, is simple and quick, and is high in accuracy.

Owner:NANJING UNIV OF SCI & TECH

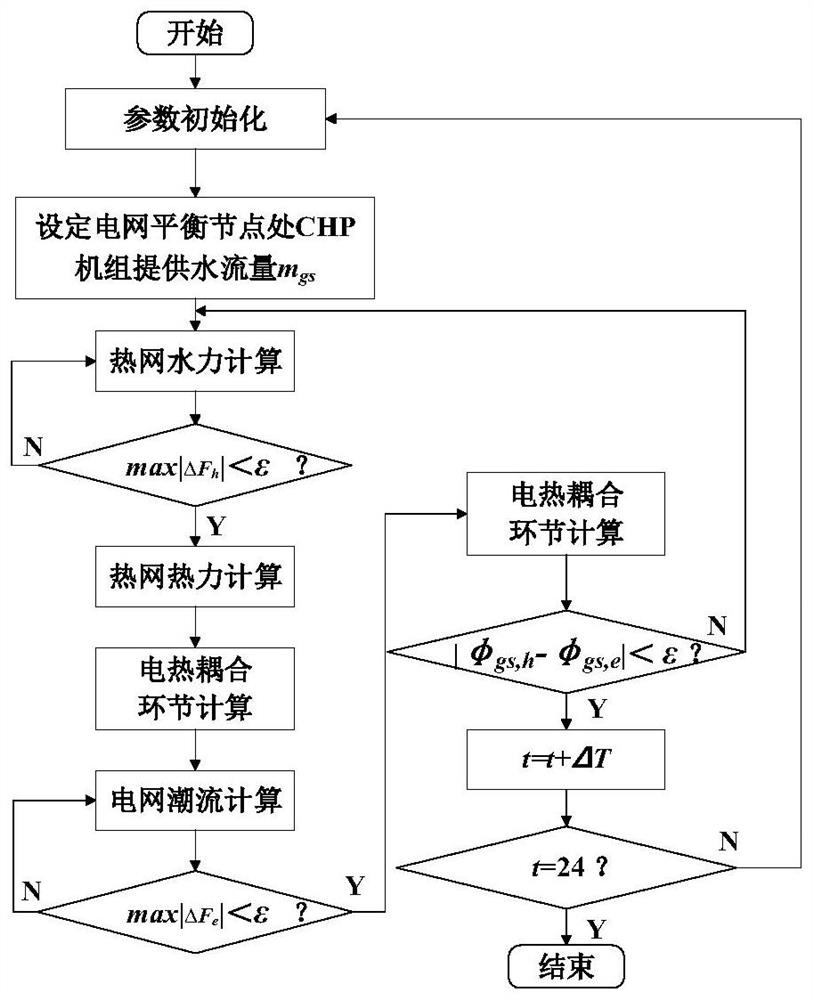

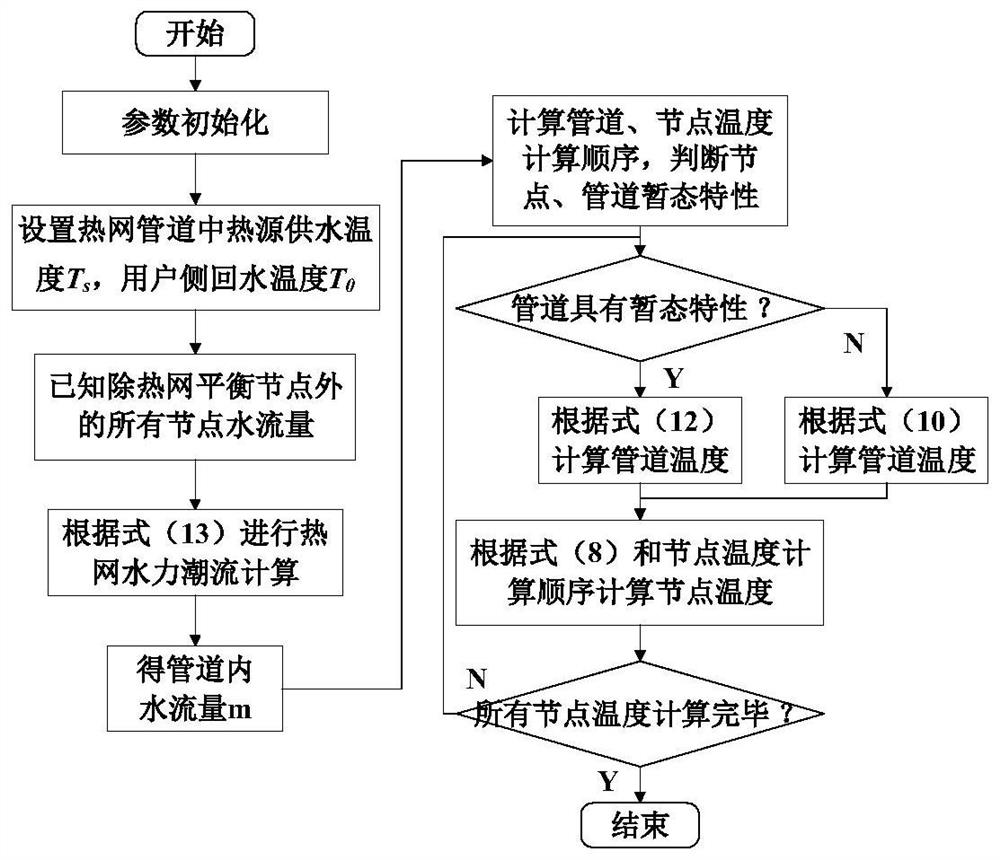

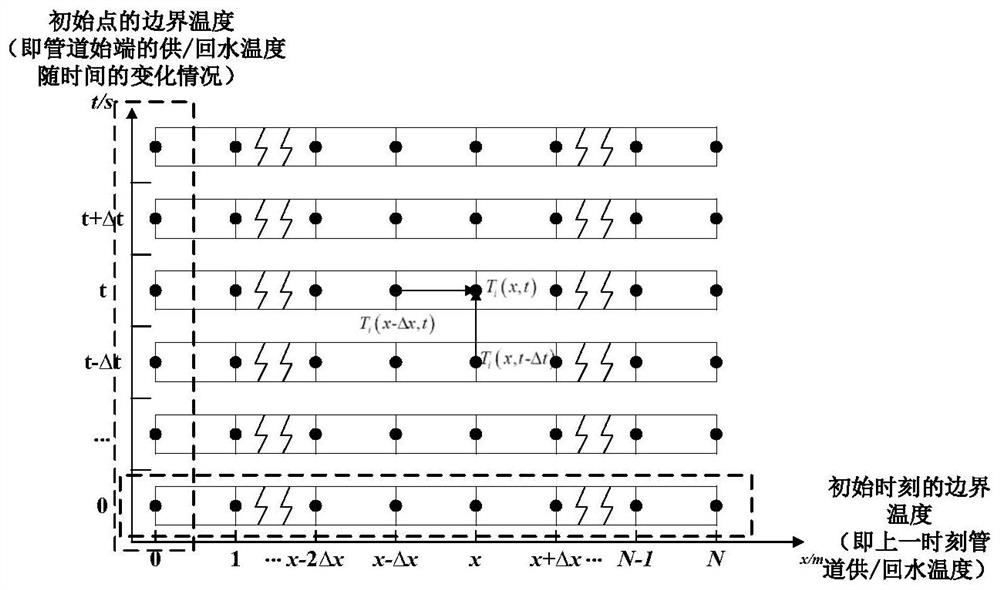

Electric heating comprehensive energy system optimal scheduling method considering refined heat supply network model

ActiveCN111815042ASmall pressure lossReduce mistakesForecastingTechnology managementOperation schedulingIntegrated energy system

The invention discloses an electric heating comprehensive energy system optimal scheduling method considering a refined heat supply network model. The method comprises the following steps: constructing a heat supply network hydraulic model considering refined resistance; constructing a thermodynamic model considering the dynamic characteristics of the heat supply network; time sequence load flow calculation of the electric heating comprehensive energy system is carried out; and optimal scheduling of the electric heating comprehensive energy system is carried out. The method can be used for transient analysis of the electric heating comprehensive energy system; the energy interaction process of different energy networks is analyzed, the economical efficiency of system operation scheduling is improved, the operation development of the comprehensive energy system is promoted, the method is suitable for determining the system operation state of the electric heating comprehensive energy system, and analysis means and other work are provided for system scheduling operation and planning construction.

Owner:TIANJIN UNIV

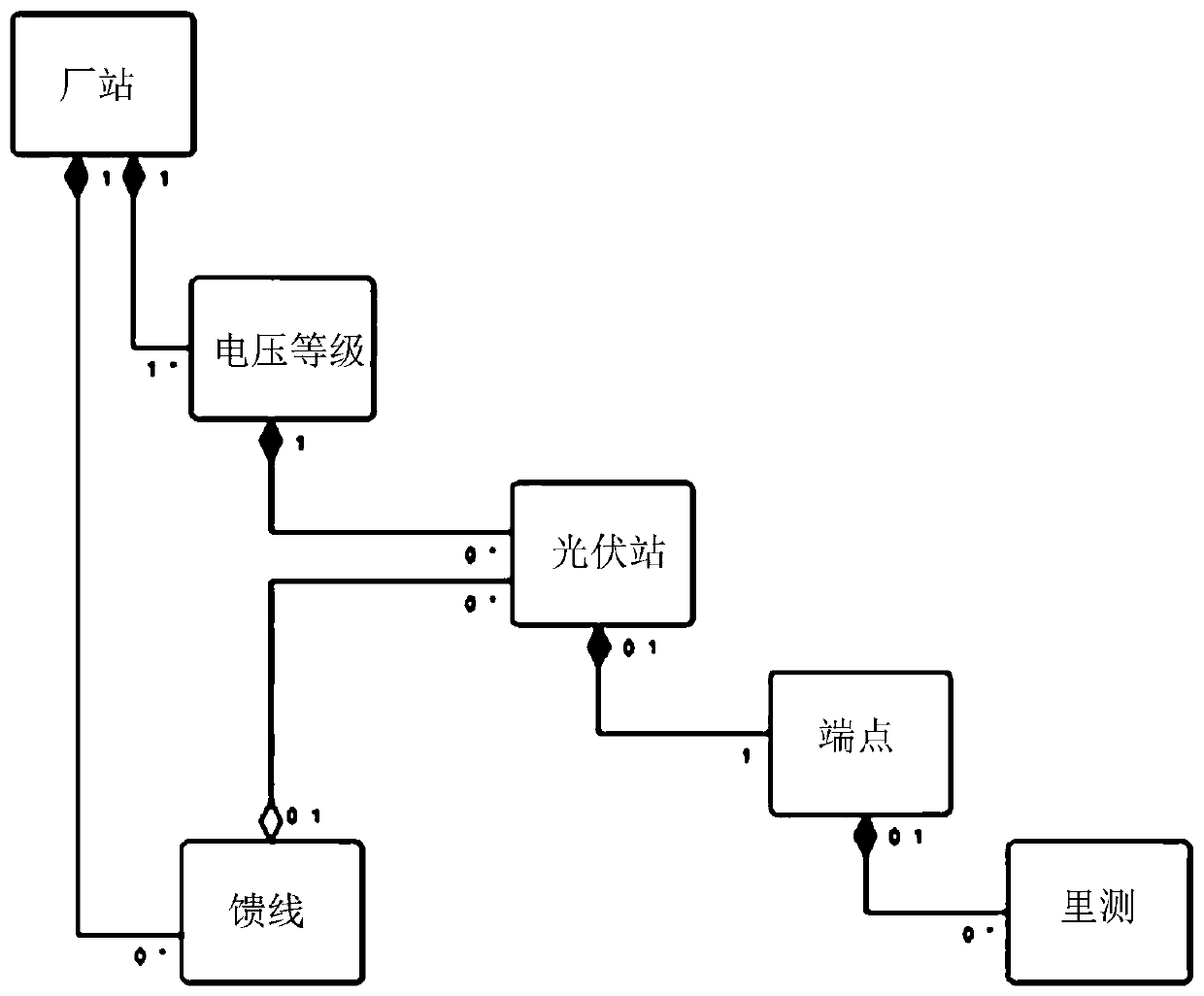

Optimized power flow calculation method based on multi-energy coupling model

ActiveCN110175311AEasy to calculateEasy to operateForecastingSystems intergating technologiesPower flowThe Internet

The invention discloses an optimized power flow calculation method based on a multi-energy coupling model. The method comprises the following steps of establishing a multi-energy coupling model covering a power grid model, a heat supply network model and a cold network model based on CIM standard model expansion; determining optimal operation conditions of the electric energy equipment, the heat energy equipment and the cold energy equipment under different operation scheme modes to serve as input for optimizing load flow calculation; and determining the output of each source end device and the energy flow distribution of each energy network through the optimized power flow calculation. According to the method, the multi-energy complementary energy internet model is constructed, complementation of different energy sources is achieved through modeling of the multi-energy coupling equipment, and the method is easy and convenient to calculate, high in operability and high in practical application value.

Owner:常州天合智慧能源工程有限公司

A fast junction temperature prediction method for asymmetric half-bridge power converters

PendingCN109214124AJunction Temperature Prediction AchievedDesign optimisation/simulationSpecial data processing applicationsElement modelPredictive methods

A method for predicting the junction temperature of three-dimensional resistance-capacitance thermal network of asymmetric half-bridge power convert features that the junction temperature of the three-dimensional resistance-capacitance thermal network is predicted by using the junction temperature of the three-dimensional resistance-capacitance thermal network of asymmetric half-bridge power converter. In this method, the junction temperature of power devices in asymmetric half-bridge power converters under different loads is predicted. The junction temperature coupling and boundary conditiondecoupling are taken into account, and a three-dimensional resistance-capacitance thermal network model is established to realize the effective junction temperature prediction of power devices. Firstly, the transient loss distributions under different load conditions are obtained in asymmetric half-bridge power converters. Secondly, the finite element model of asymmetric half-bridge power converter is established, and the coupling thermal impedance and boundary decoupling thermal impedance are extracted according to the finite element thermal stress simulation with the transient loss as the input of thermal load. Then, the expressions of coupled thermal impedance and heat dissipation boundary conditions are obtained by means of electrothermal analogy theory and curve fitting. Finally, a three-dimensional resistive-capacitive thermal network model is constructed to predict the junction temperature of the power device by using the controlled voltage source to represent the thermal coupling impedance relationship and the sub-radiator thermal impedance to represent the different thermal boundary conditions.

Owner:CHINA UNIV OF MINING & TECH

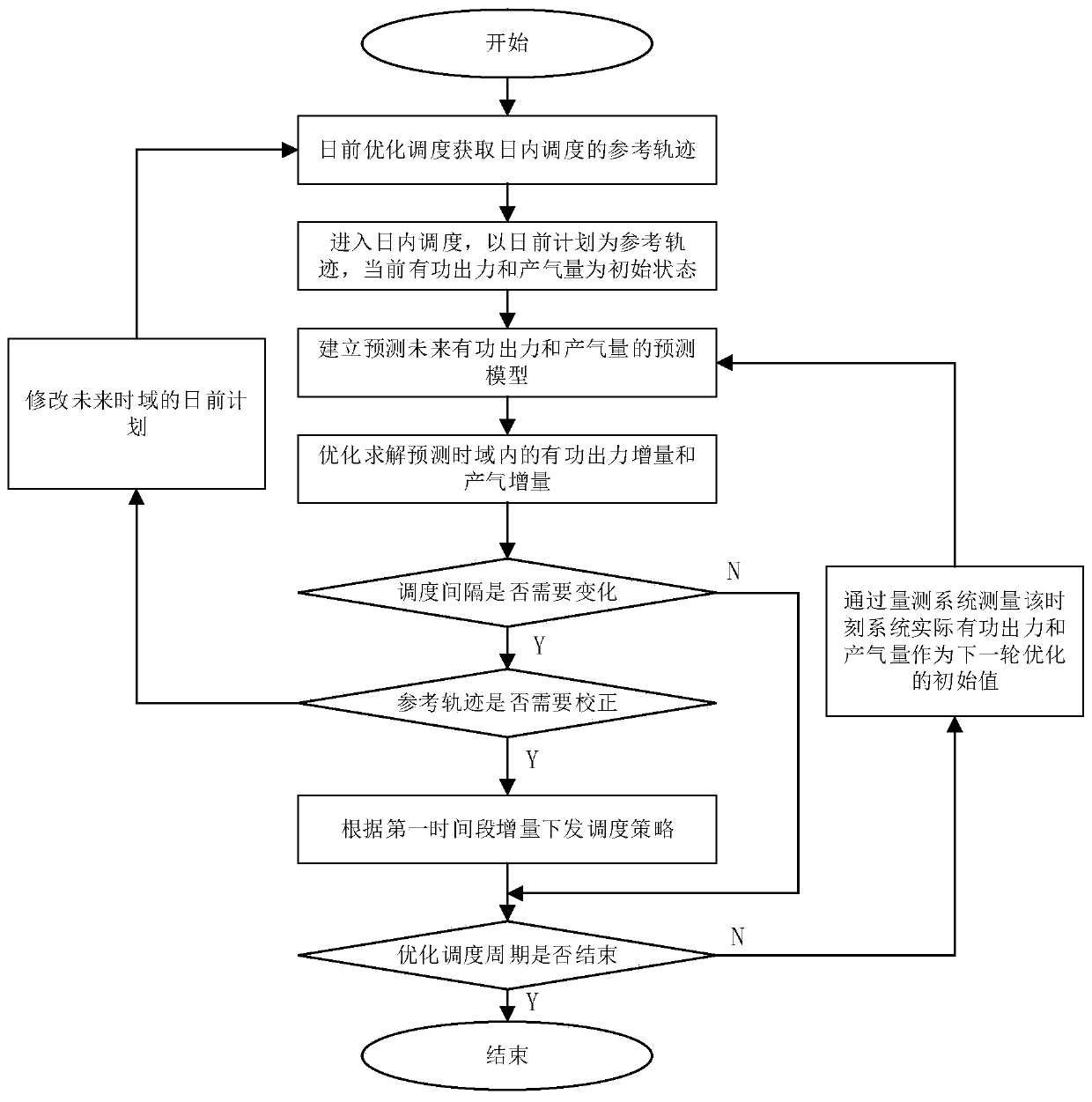

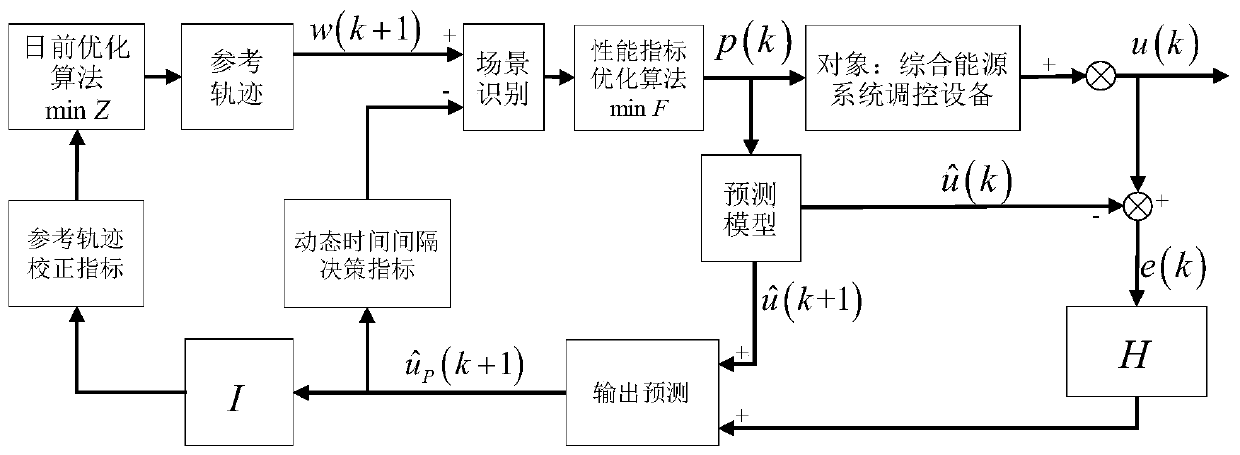

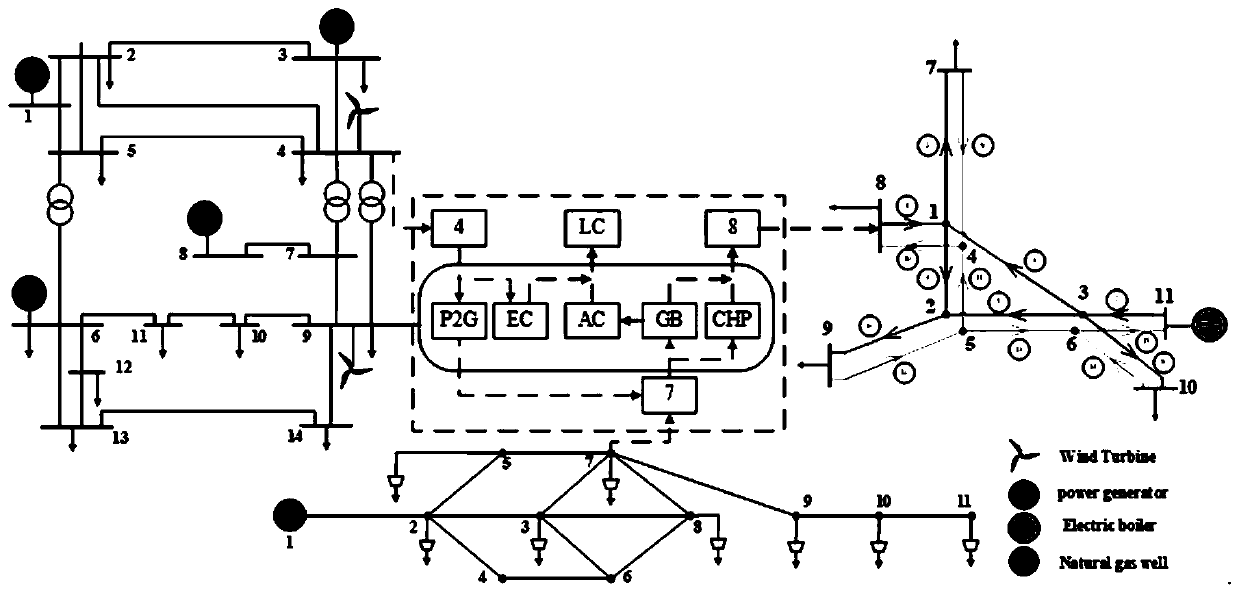

Comprehensive energy system scheduling method of dynamic time interval

ActiveCN110516951AEnough adjustable marginIncrease reflectionResourcesScheduling instructionsEnergy control

The invention discloses a comprehensive energy system scheduling method for a dynamic time interval, and the method comprises the following steps: establishing a comprehensive energy system schedulingframework based on the prediction control of a dynamic time interval model; establishing a comprehensive energy system day-ahead scheduling model; establishing an intra-day scheduling 'track deviation-control energy-control cost ' performance index based on model prediction control; establishing a dynamic time interval decision index; and establishing an energy conversion unit, a heat supply network model, a gas network model and a power grid model. The comprehensive energy system scheduling method has the beneficial effects that the dynamic time interval comprehensive energy system scheduling method taking trajectory deviation-control energy-control cost as a performance index is considered, so that the performance index has enough adjustable margin, and different scene requirements aremet; the dynamic time interval decision index is considered, the real state that the system is about to generate or even has a large error can be reflected, and the decision index is provided for judging whether the system needs to issue a scheduling instruction.

Owner:NANJING UNIV OF TECH

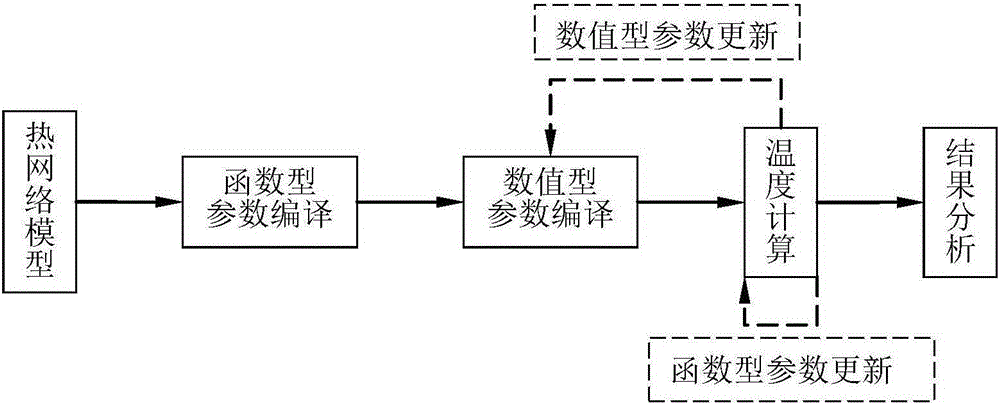

System-grade thermal performance representation method of self-adaptive thermal control technology

InactiveCN105159348ASolve the problem of not being able to pass simple thermal performance parametersSolutionTemperature control using electric meansReal representationEngineering

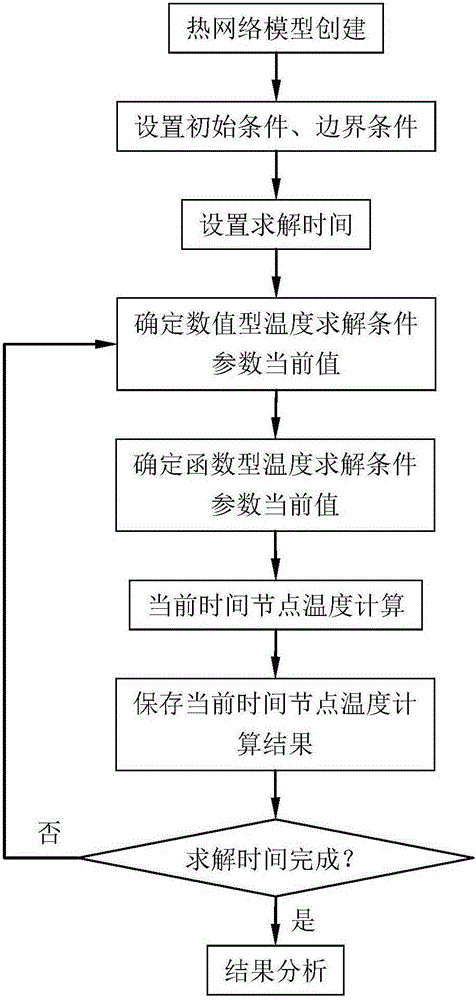

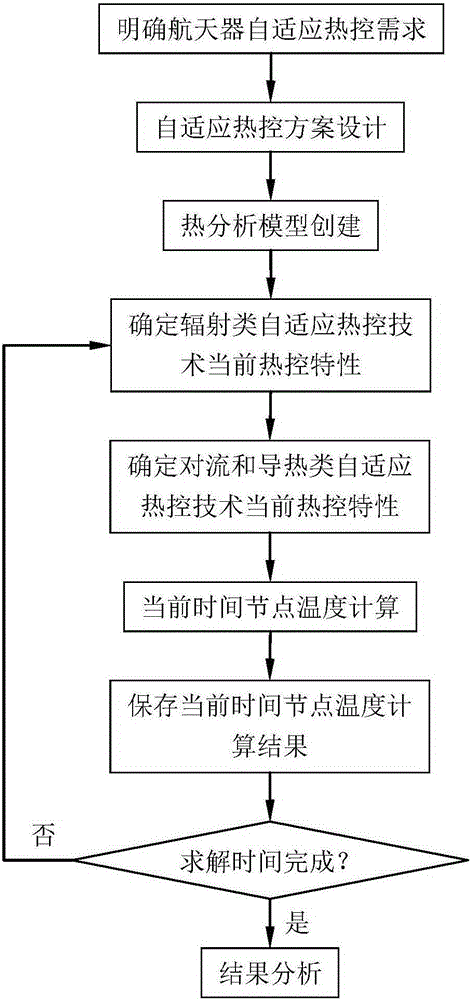

The invention discloses a system-grade thermal performance representation method of a self-adaptive thermal control technology. The method comprises the following steps: step one, creating a thermal network model; step two, arranging an initial condition and a boundary condition; step three, arranging a solution time; step four, determining a value type temperature solution condition parameter current value; step five, determining a function type temperature solution condition parameter current value; step six, calculating a current time node temperature; step seven, storing a current time node temperature calculation result; step eight, determining whether solution time is finished; and step nine, analyzing the result. The method provided by the invention solves the problem of incapability of real representation of a system-grade thermal performance through simple thermal performance parameters or a functional equivalent approximate processing method by use of the self-adaptive thermal control technology and fills the research blank in the field of application of the self-adaptive thermal control technology.

Owner:SHANGHAI SATELLITE ENG INST

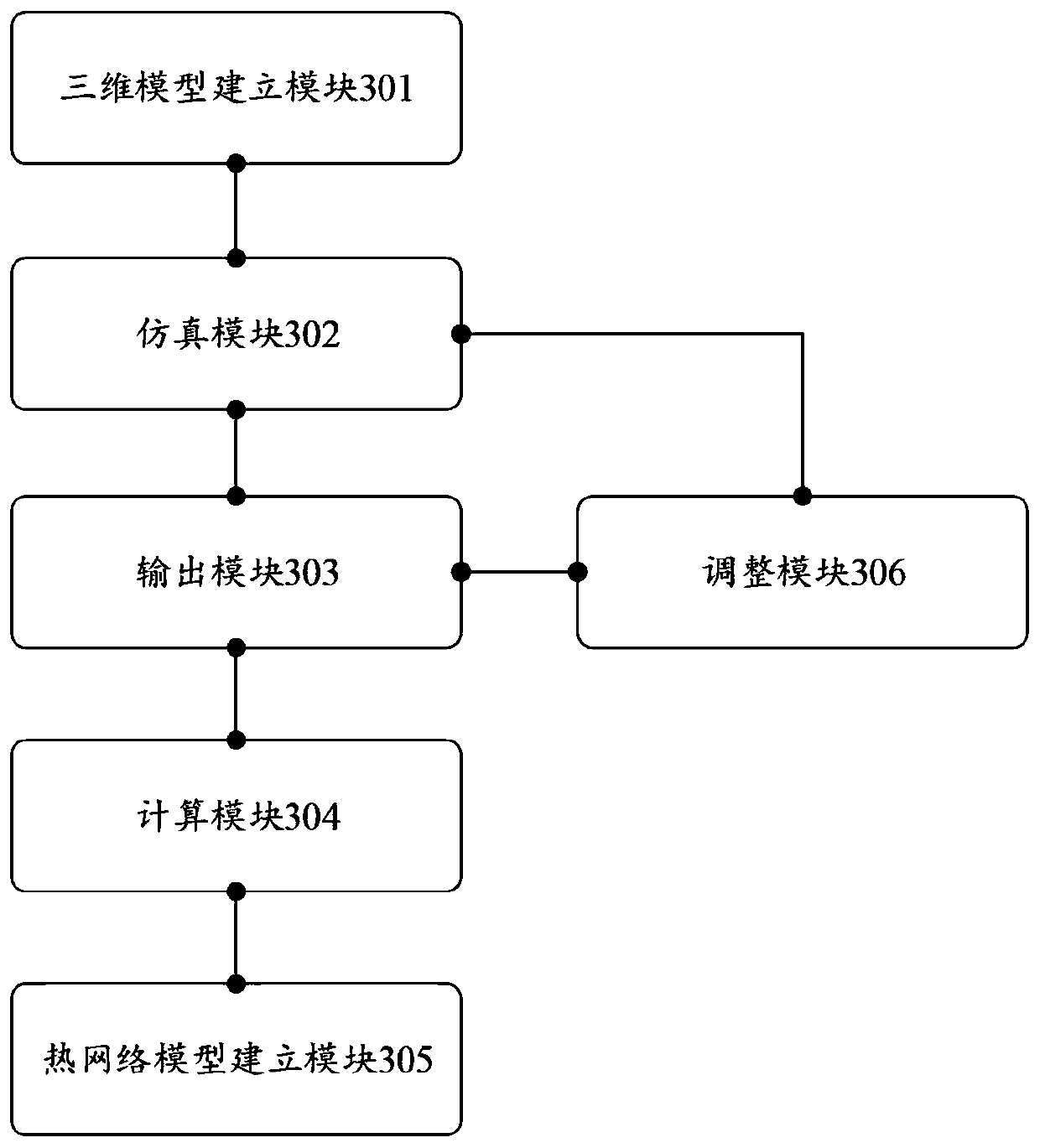

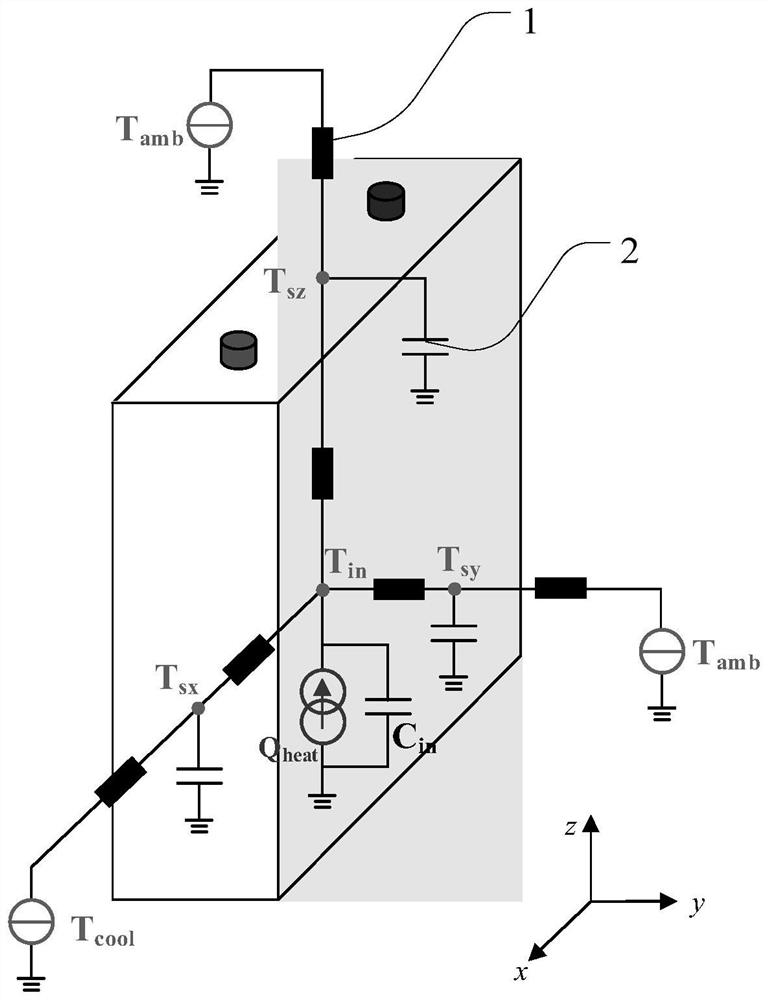

Crimping type IGBT thermal network model modeling method and related device

ActiveCN111125947AImprove calculation accuracyGuaranteed accuracyDesign optimisation/simulationCAD numerical modellingJunction temperatureEngineering

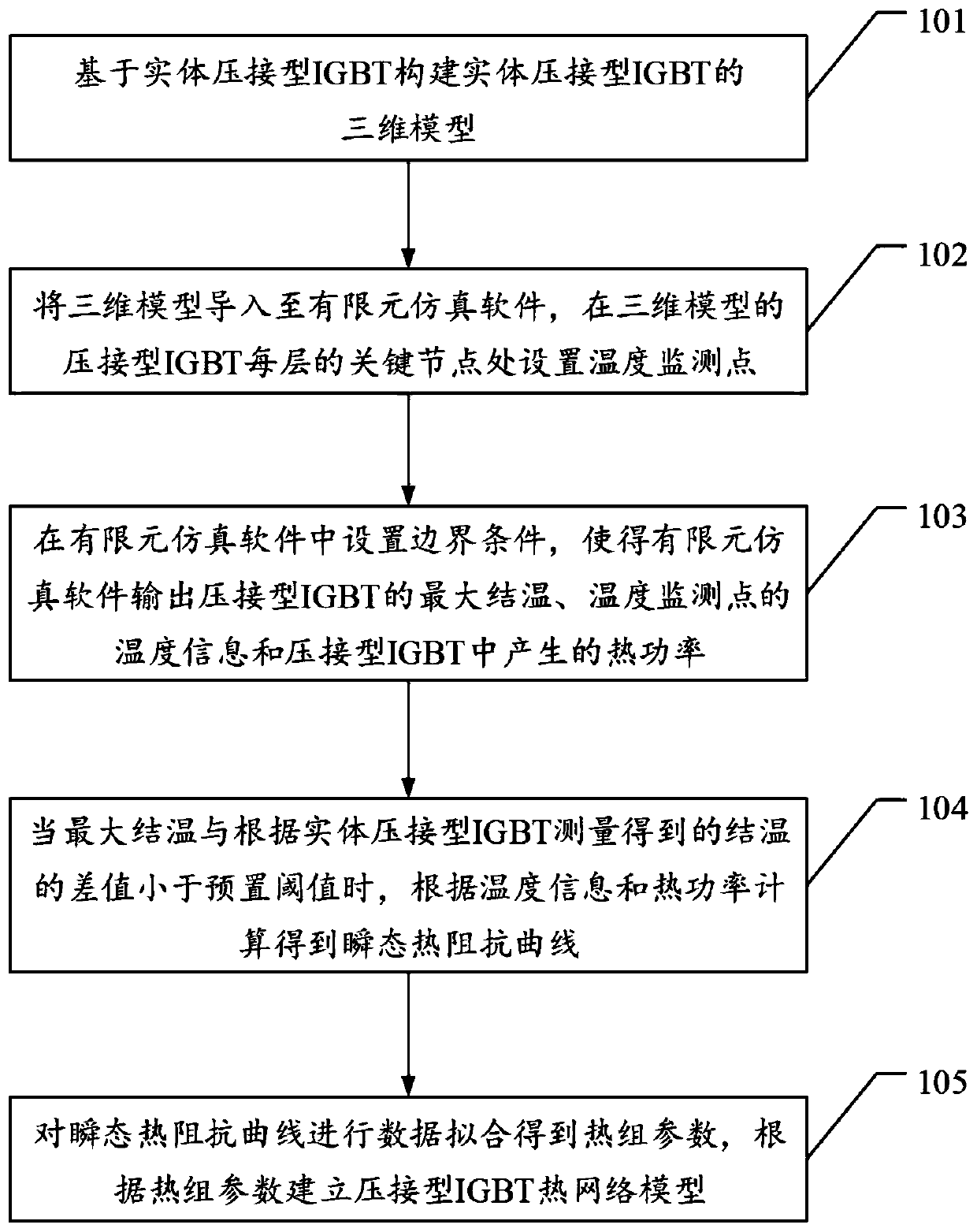

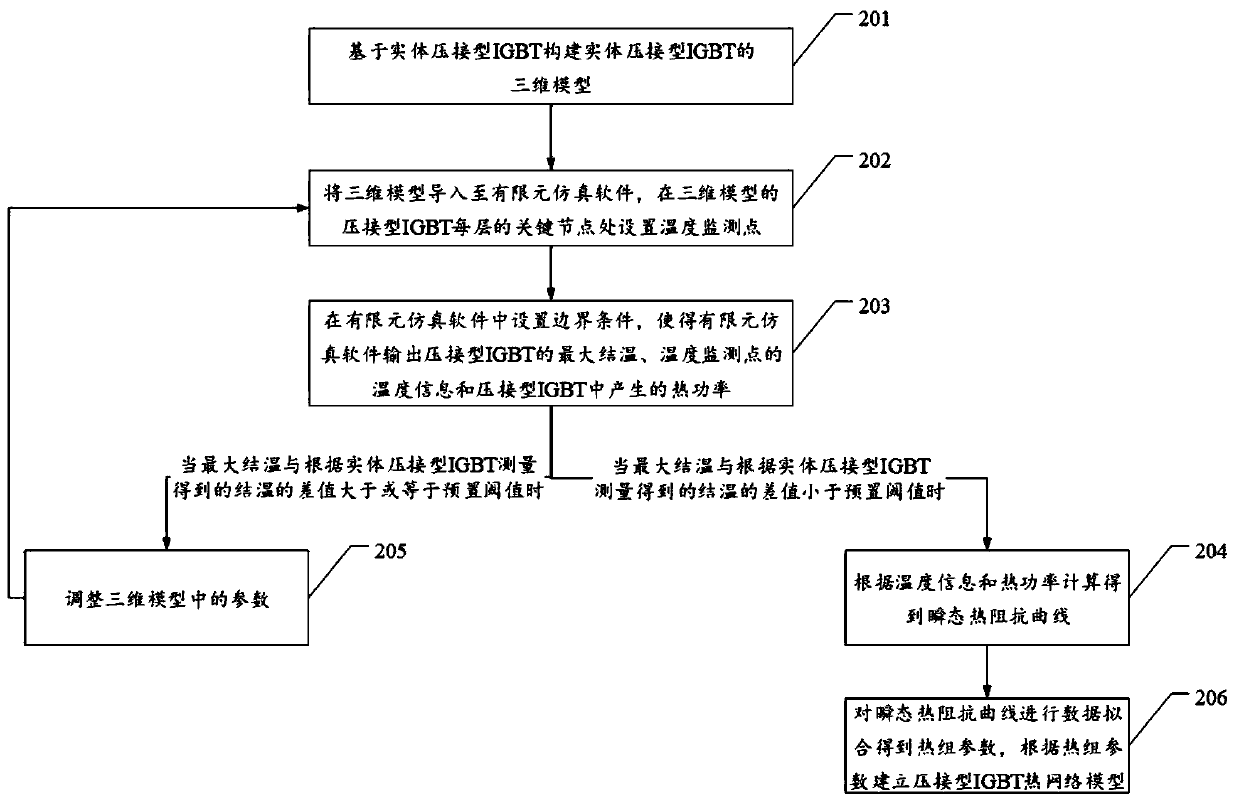

The invention discloses a crimping type IGBT thermal network model modeling method and a related device. The method includes: constructing a three-dimensional model based on the entity crimping type IGBT, importing the three-dimensional model into finite element simulation software, setting temperature monitoring points at key nodes of each layer of the crimping type IGBT of the three-dimensionalmodel, setting boundary conditions in the finite element simulation software, and enabling the finite element simulation software to output maximum junction temperature, temperature information of thetemperature monitoring points and thermal power; when the difference value between the maximum junction temperature and the junction temperature measured according to the entity crimping type IGBT issmaller than a preset threshold value, calculating and obtaining a transient thermal impedance curve according to the temperature information and the thermal power; carrying out data fitting on the curve to obtain heat group parameters; and establishing the crimping type IGBT thermal network model. The technical problems that in the prior art, the IGBT thermal network model is established throughthe thermal group parameters of the data manual, so that the IGBT thermal network model cannot calculate the temperature distribution information of each layer of the IGBT, and the calculation precision is not high are solved.

Owner:GUANGDONG POWER GRID CO LTD +1

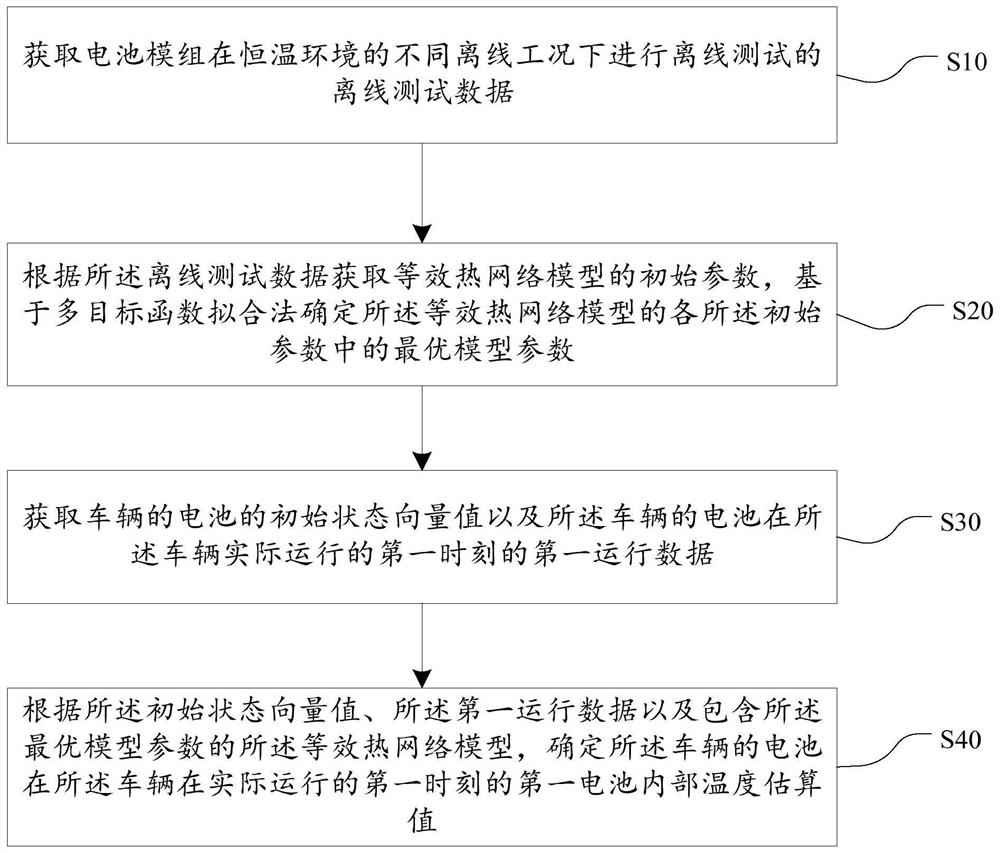

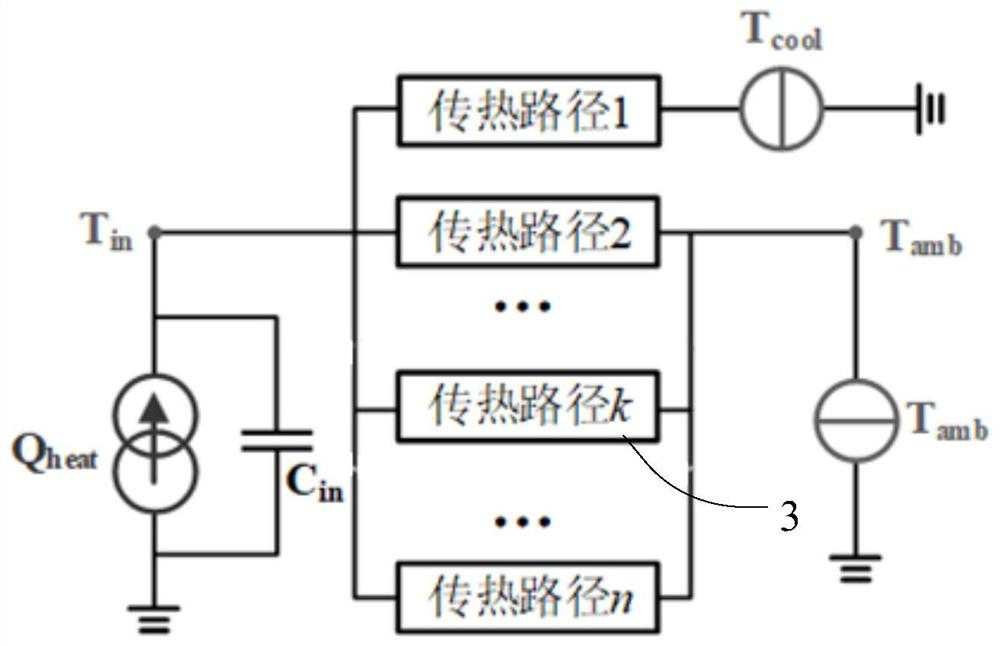

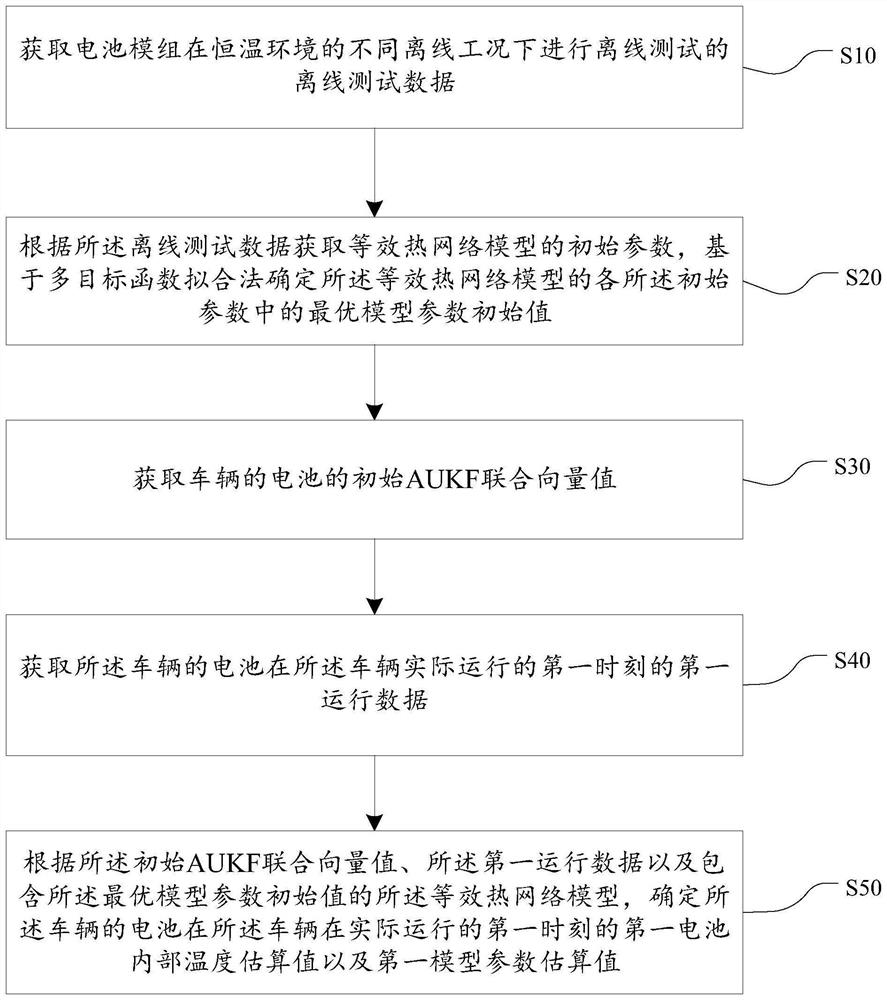

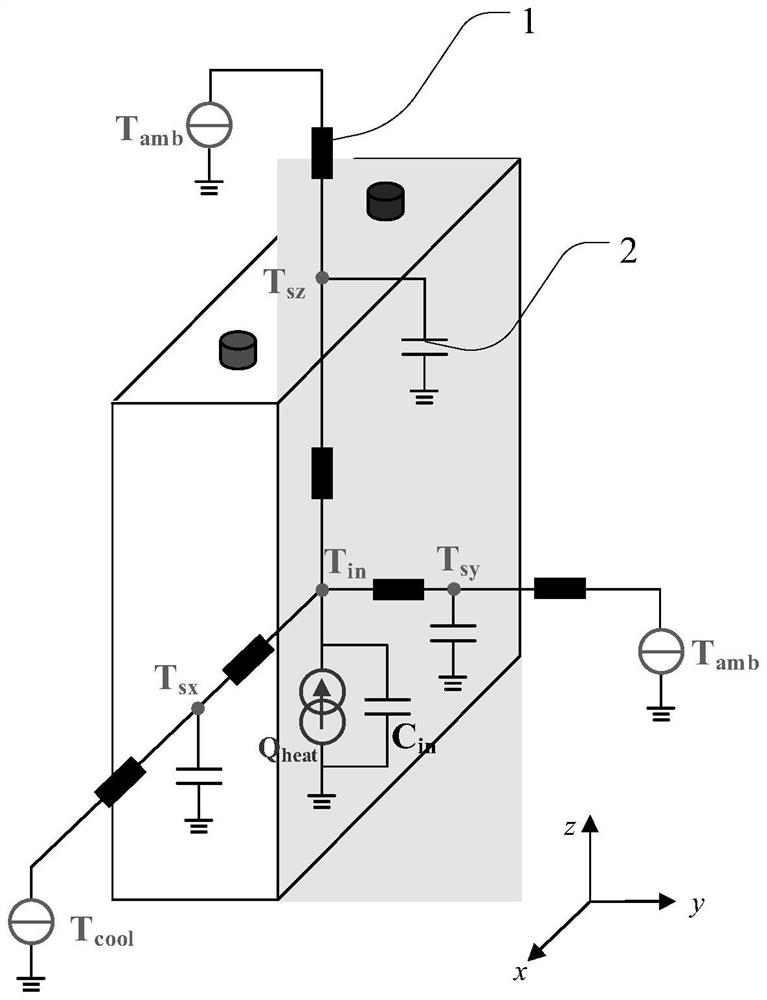

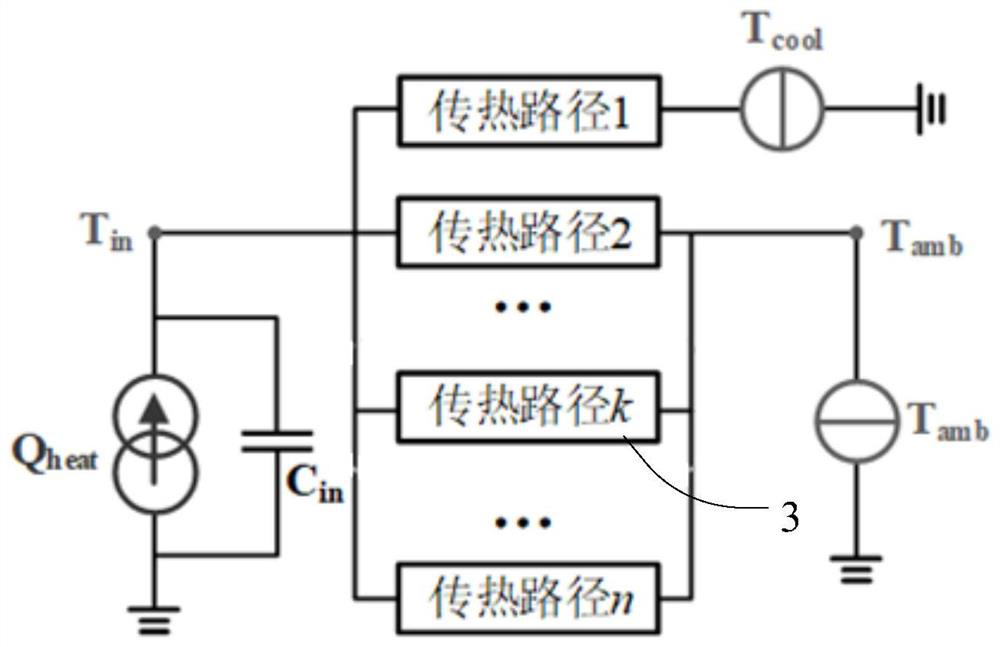

Battery internal temperature information processing method, computer equipment and storage medium

ActiveCN112964991AImprove working conditionsImprove securityElectrical testingSecondary cellsInformation processingSimulation

The invention discloses a battery internal temperature information processing method, computer equipment and a storage medium. The method comprises the following steps of: constructing an equivalent thermal network model according to off-line test data of an off-line test of a battery module, and determining optimal model parameters of the equivalent thermal network model based on a multi-objective function fitting method; and determining a first battery internal temperature estimated value of the battery of a vehicle at the first moment of actual operation of the vehicle according to the obtained initial state vector value of the battery of the vehicle, the first operation data at the first moment of actual operation of the vehicle and the equivalent thermal network model containing the optimal model parameters. According to the battery internal temperature information processing method, the computer equipment and the storage medium of the invention, the internal temperature of the battery can be accurately estimated in real time, so that the working condition of the battery can be optimized according to the internal temperature of the battery which is accurately estimated in real time, and the safety of the battery is improved.

Owner:BYD CO LTD

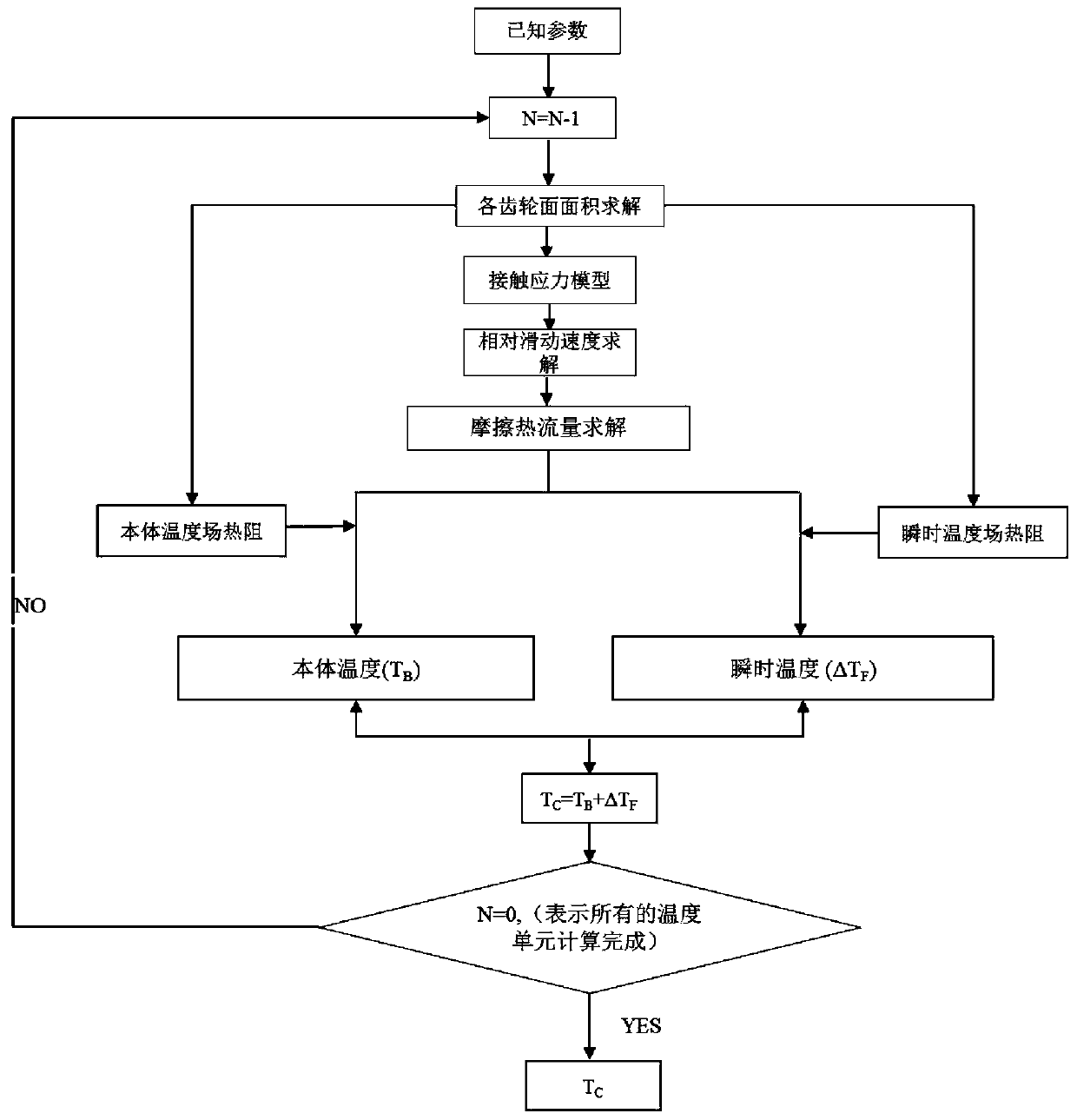

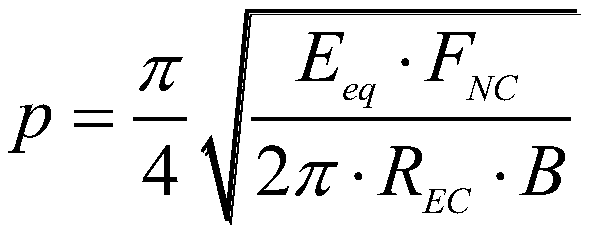

Straight gear temperature field prediction method based on thermal network model

ActiveCN110738348ASimplify calculation stepsShort calculation timeGeometric CADForecastingThermodynamicsGear wheel

The invention discloses a straight gear temperature field prediction method based on a thermal network model. According to the method, the calculation steps are simple, the calculation time is short,the occupied memory is small, the temperature value of each point can be independently solved, the meshing rule of a gear pair is considered when the instantaneous temperature is calculated, and compared with a Blok flash temperature formula, the method is closer to the actual meshing condition of the gear; in the process of analyzing the gear temperature field, the meshing rule of the gear pair in the meshing process is considered, the influence of the gear structure on the gear temperature field is also considered, and prediction is more accurate.

Owner:HUNAN UNIV

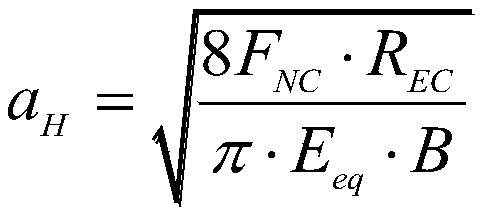

Iterative calculation method for junction temperature of IGBT module and related device

The invention discloses an IGBT module junction temperature iterative calculation method and a related device. The method comprises the steps: inputting the first power loss of each point of an obtained first power loss curve into an established Foster thermal network model, obtaining a first junction temperature, and generating a first junction temperature curve; inputting the second power loss of each point of the second power loss curve updated according to the first junction temperature curve into a model to generate a second junction temperature curve; calculating junction temperature difference values of the first junction temperature curve and the second junction temperature curve at the same moment; when the maximum junction temperature difference value is smaller than a preset threshold value, outputting a second junction temperature curve; when the maximum junction temperature difference value is not smaller than a preset threshold value; and taking the second junction temperature curve as a new first junction temperature curve, and returning to the step of updating the first power loss curve according to the first junction temperature curve to obtain the second power loss curve, thereby solving the problem of low junction temperature result accuracy caused by the fact that the relation between junction temperature and power loss is not considered in the junction temperature curve obtained by calculation in the prior art.

Owner:GUANGDONG POWER GRID CO LTD +1

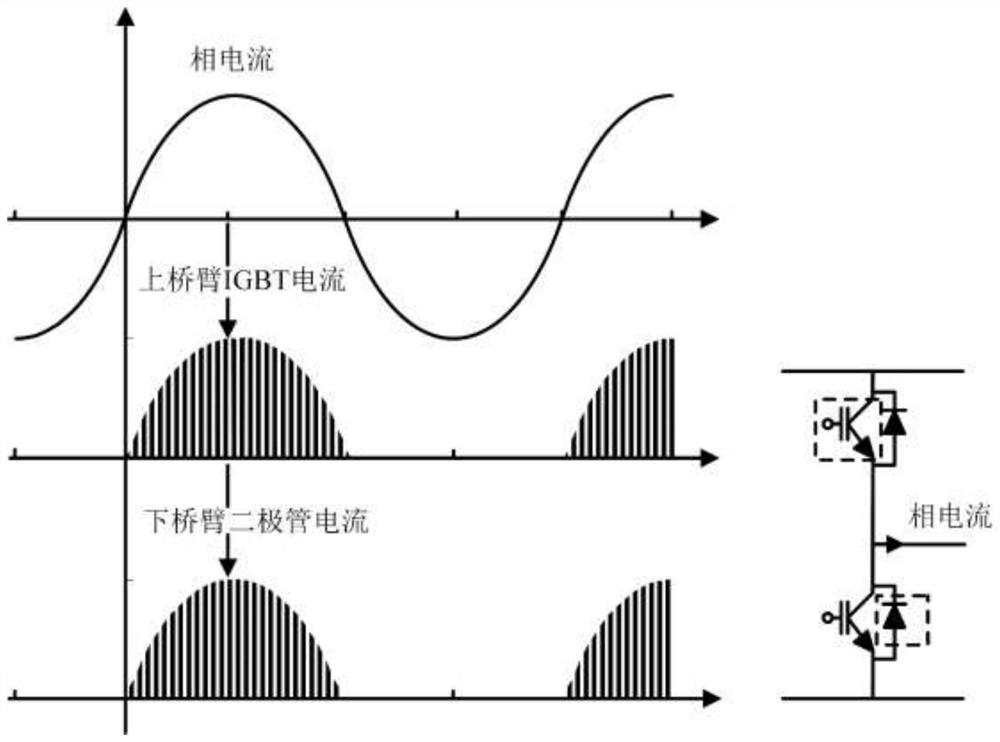

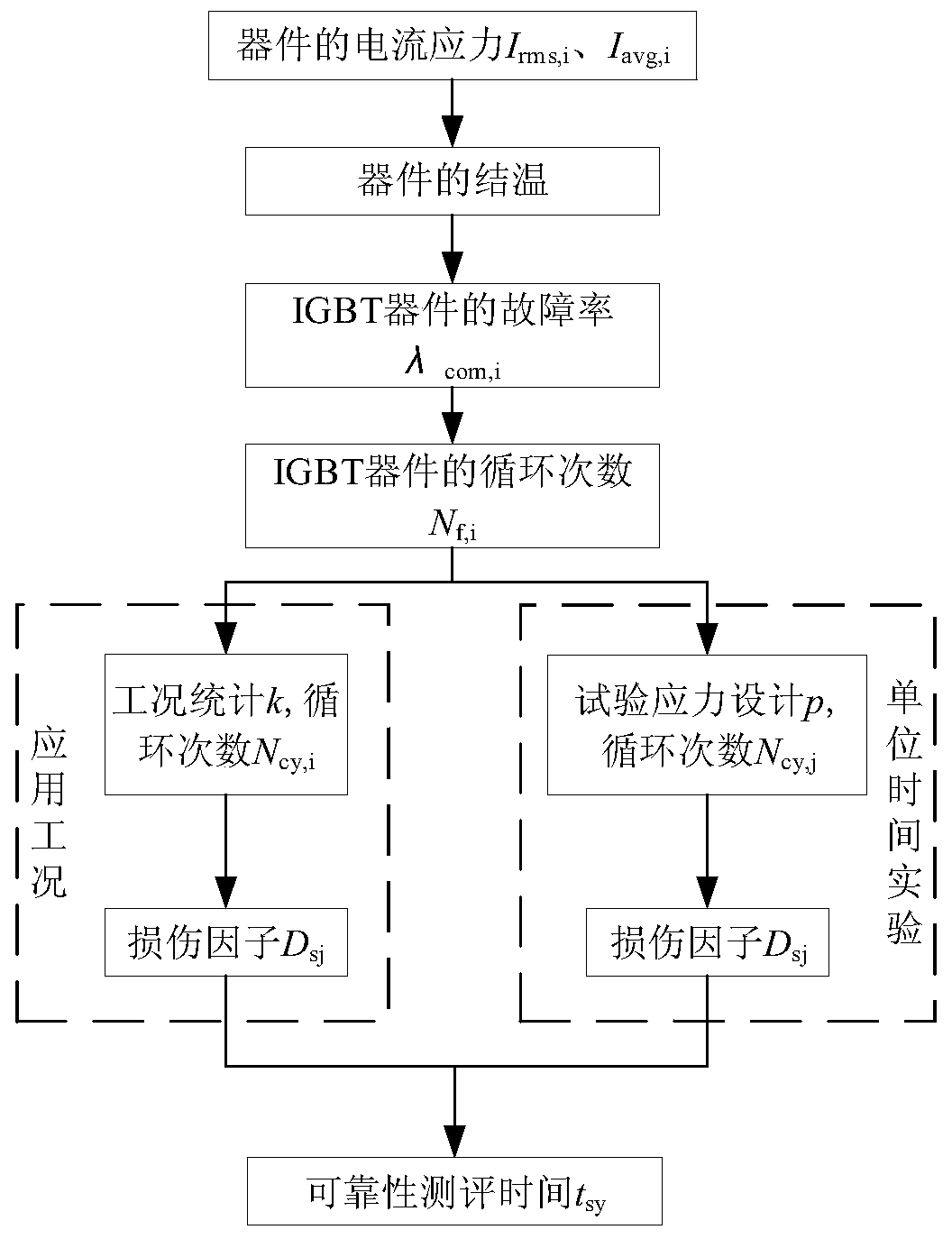

IGBT device power cycle evaluation method based on application condition of MMC converter valve

ActiveCN110133464AImprove accuracyReliability impactIndividual semiconductor device testingFailure ratePower cycle

The invention relates to an IGBT device power cycle evaluation method based on the application condition of an MMC converter valve, and belongs to the technical field of high-voltage direct current transmission. The method comprises the following steps: firstly, obtaining conduction loss and switching loss of a device based on a loss model of IGBT and a diode, and extracting average junction temperature and junction temperature fluctuation amplitude of the IGBT device and the diode according to a thermal network model of the IGBT device; secondly, considering the running condition of the MMC converter valve, providing a device failure rate calculation model, and acquiring the failure rate and the cycle times of the device; and finally, performing reliability evaluation modeling on the IGBTdevice based on a Miner rule and an equal damage rule, and acquiring a change rule of the reliability index of the IGBT device under different additional test conditions to form a reliability evaluation scheme. According to the invention, the IGBT device reliability evaluation method is formed, and has important significance for accurately evaluating the reliability of the IGBT device for the MMCconverter valve.

Owner:CHONGQING UNIV

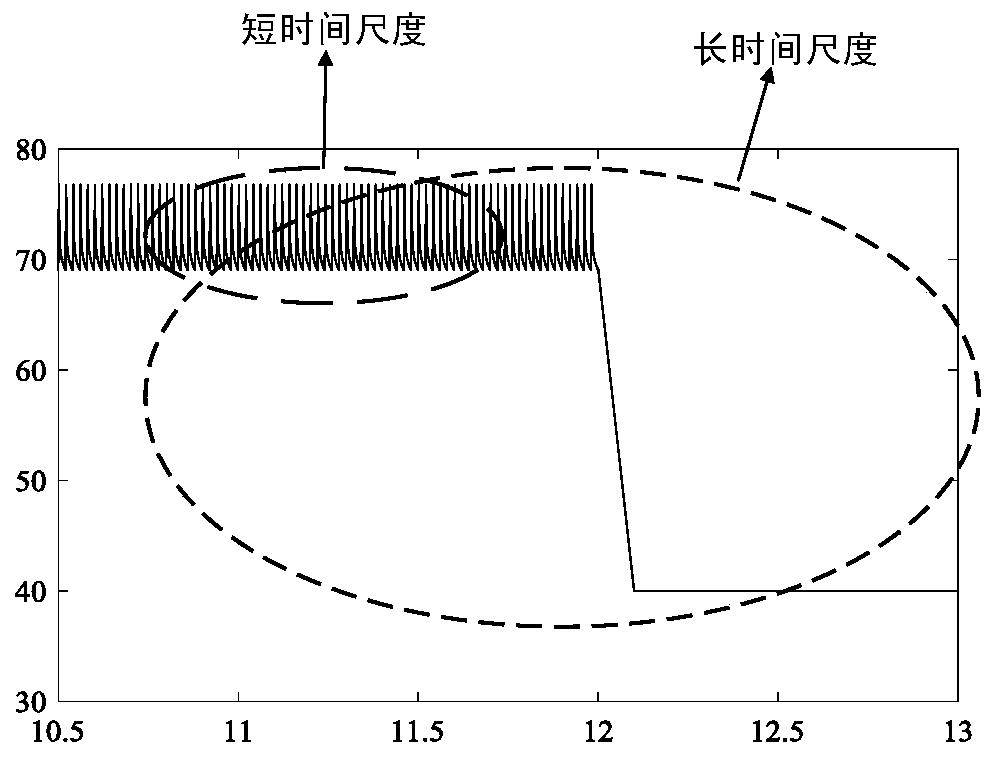

Battery internal temperature information processing method based on AUKF, equipment and medium

ActiveCN112964992AImprove working conditionsImprove securityInternal combustion piston enginesElectrical testingSimulationBattery cell

The invention discloses a battery internal temperature information processing method based on an AUKF, equipment and a medium. The method comprises the following steps of: acquiring initial parameters of an equivalent thermal network model according to offline test data of an offline test of a battery module, and determining an optimal model parameter initial value in the initial parameters based on a multi-objective function fitting method; and determining a first battery internal temperature estimated value and a first model parameter estimated value of the battery of a vehicle at a first moment of actual operation according to the initial AUKF joint vector value of the battery of the vehicle, the first operation data of the battery of the vehicle and the equivalent thermal network model containing the optimal model parameter initial value. According to the battery internal temperature information processing method based on the AUKF, the equipment and the medium, the model parameters of the equivalent thermal network model can be optimized while the internal temperature of the battery is accurately estimated in real time, so that the internal temperature of the battery can be more accurately estimated according to the optimized model parameters, the working condition of the battery is optimized according to the internal temperature of the battery accurately estimated in real time, and the working efficiency of the battery is improved, and the safety of the battery is improved.

Owner:BYD CO LTD

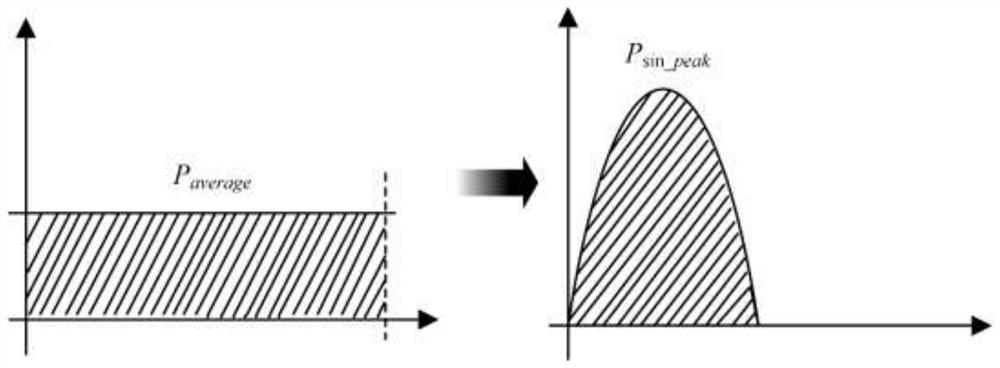

Optimized power loss equivalent modeling method for IGBT junction temperature estimation

ActiveCN112329244AReduce the scale of iterative calculationsSmall amount of calculationDesign optimisation/simulationSpecial data processing applicationsThermodynamicsJunction temperature

The invention discloses an optimized power loss equivalent modeling method for IGBT junction temperature estimation, and the method specifically comprises the steps: collecting an external variable needed by the calculation of power loss, calculating the average loss in a single fundamental wave period, and converting the average loss into half-sine loss; performing first-order square wave equivalence on the half-sine loss curve, and calculating an initial junction temperature value of a steady-state fundamental wave period in combination with a thermal network model; discretizing the half-sine loss curve, and deriving a junction temperature expression at any time point in a single steady-state fundamental wave period in combination with the thermal network model and the initial junction temperature value; deriving the junction temperature expression to obtain the maximum junction temperature time point and the minimum junction temperature time point, and performing discrete equivalence on the half-sine loss based on an equal-area rule; and calculating a discretized rectangular pulse loss value, substituting the discretized rectangular pulse loss value into the thermal network model, and calculating the junction temperature of the IGBT. According to the method, the discretization of power loss is more reasonable, the estimated junction temperature is more accurate, and meanwhile, the calculated amount in junction temperature estimation can be effectively reduced.

Owner:SOUTHWEST JIAOTONG UNIV

Thermal characteristic simulation and emulation prediction system and method of stratospheric airship load cabin electronic equipment

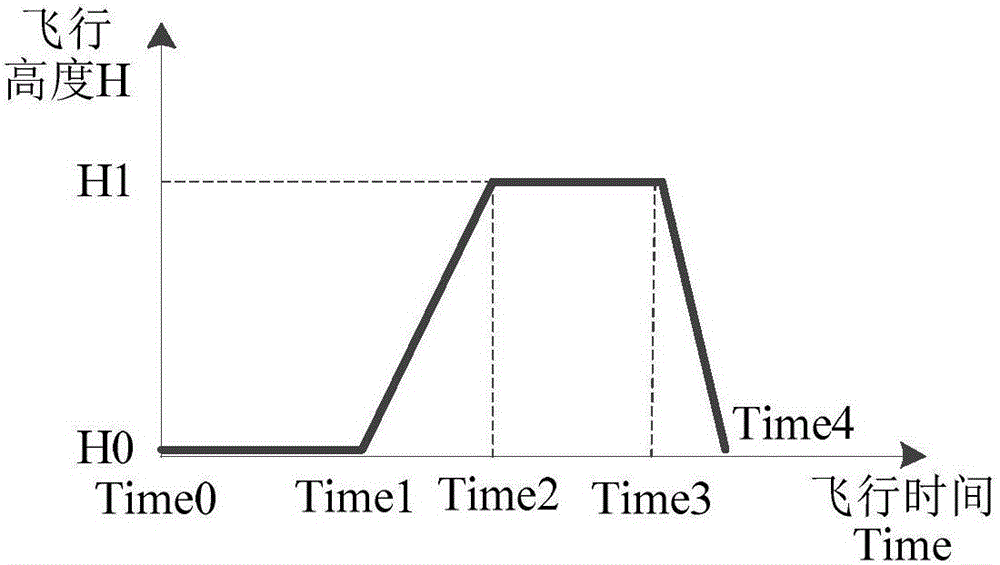

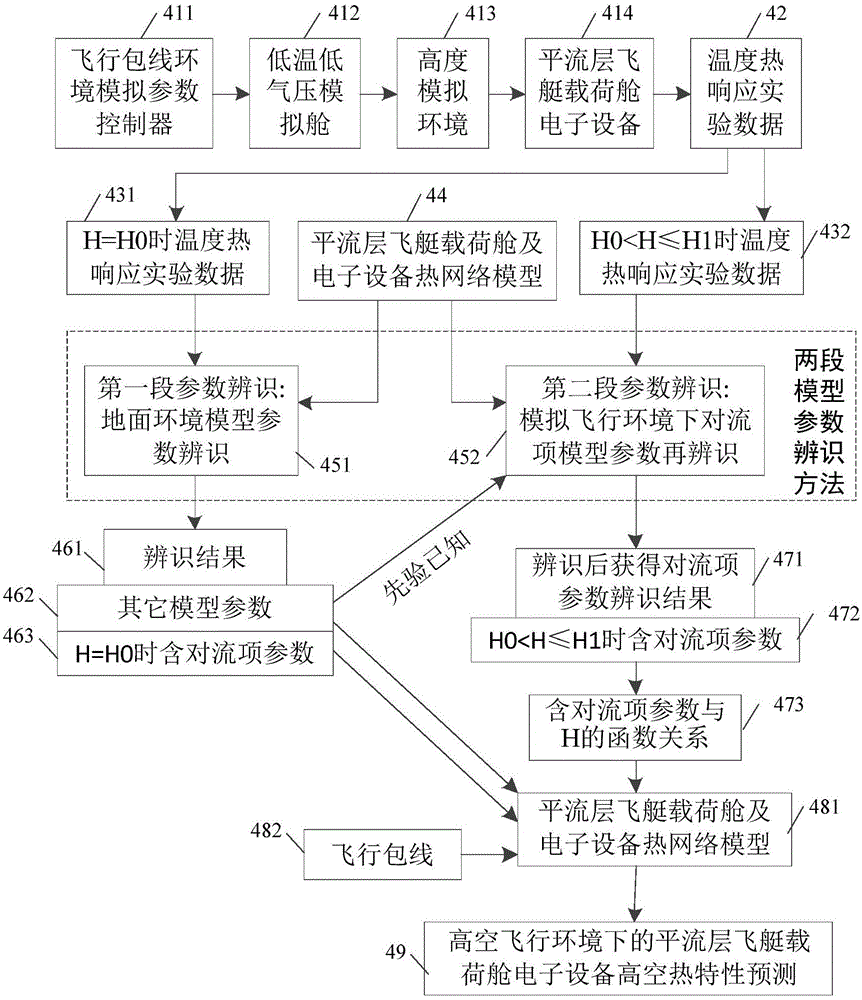

InactiveCN106227060ARealize dynamic change simulationEasy inputSimulator controlFlight heightEquipment temperature

The invention provides a thermal characteristic simulation and emulation prediction system and method of stratospheric airship load cabin electronic equipment. A low-temperature and low-pressure chamber is combined with a flight envelope environment simulation parameter control operator controller; dynamic change simulation of an external atmospheric environment during a whole flight phase of a stratospheric airship can be extremely conveniently realized according to input of a flight envelope; unknown parameters of a stratospheric airship load cabin thermal network model are divided into relatively fixed parameters and parameters changed along flight heights H, and two-stage type model parameter identification is carried out; identification convergence and identification precision of an identification result are improved; a relatively fixed parameter identification result is used as priori knowledge of the next identification process, so that the precision of the later stage of parameter identification is remarkably improved. An identification result of convective term parameters of the second stage of parameters is fitted into a function relation of the flight heights H so that the predication precision of equipment temperature under different flight profiles is effectively improved; aiming at the parameter identification with a single equation cycle, the identification convergence of the parameters and the parameter identification accuracy are greatly improved.

Owner:SCI RES TRAINING CENT FOR CHINESE ASTRONAUTS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com