Patents

Literature

102results about How to "Reliability impact" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

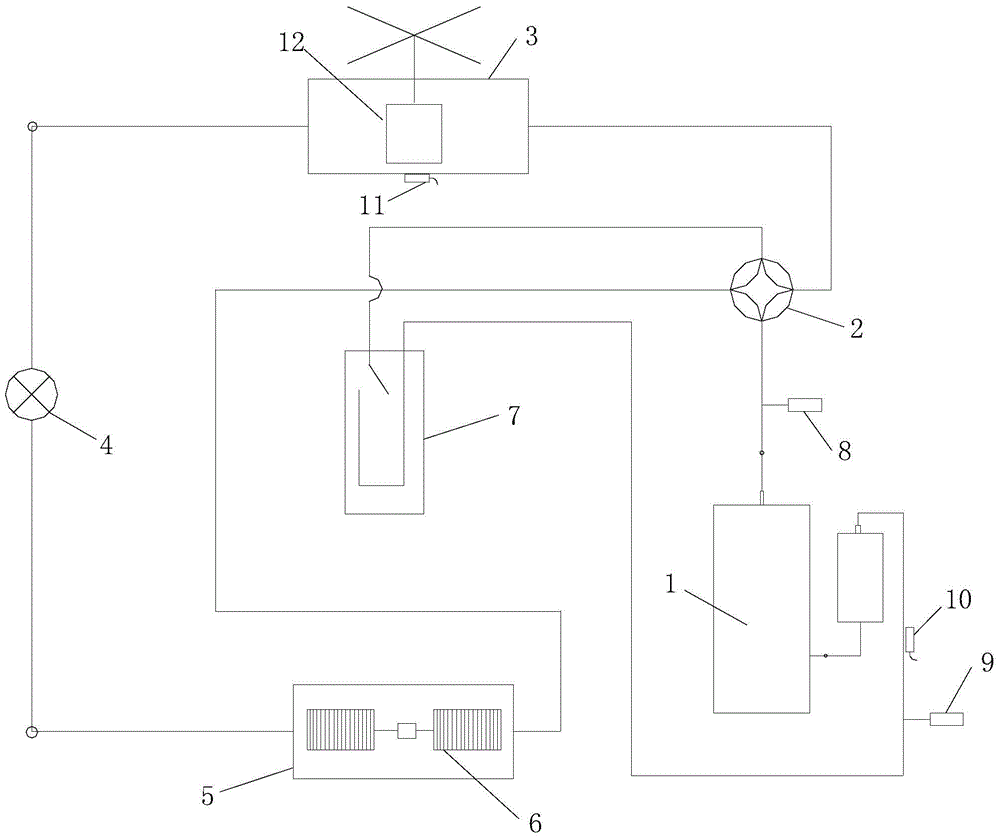

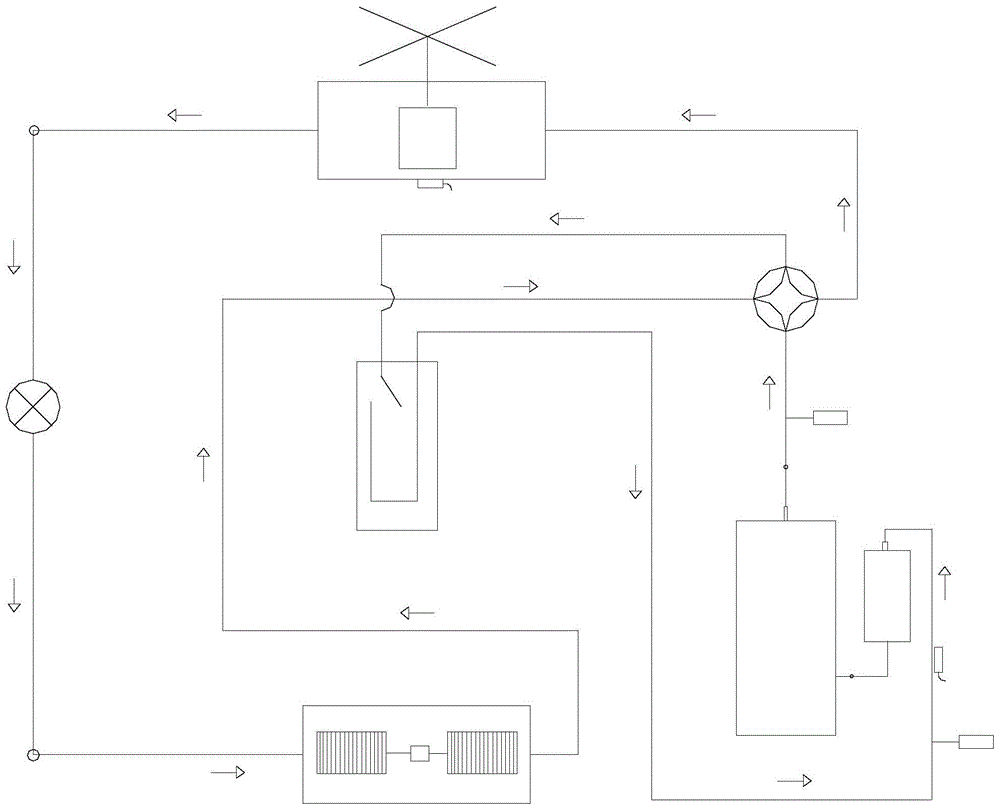

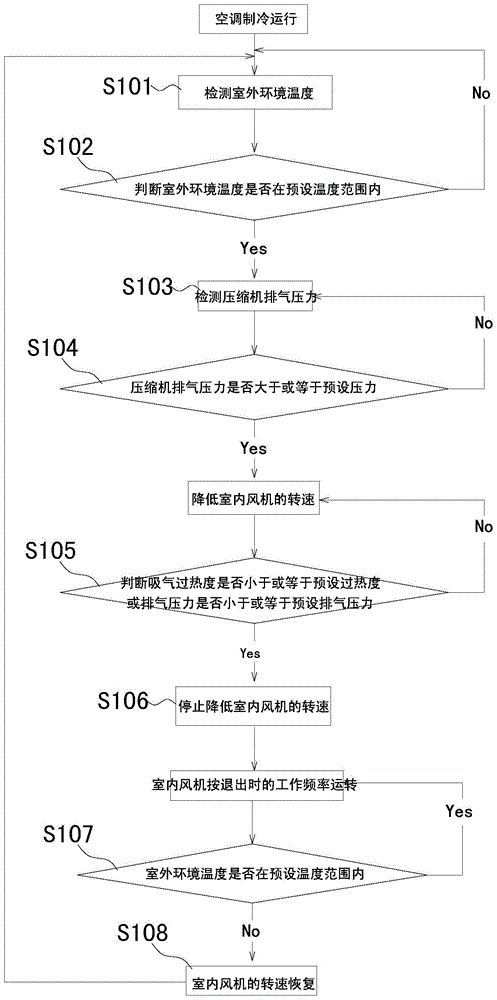

Pressure control method of air conditioning system

ActiveCN104697106AReduce exhaust pressureEffect of exhaust pressureMechanical apparatusSpace heating and ventilation safety systemsSystem pressureAir conditioning

Owner:GREE ELECTRIC APPLIANCES INC

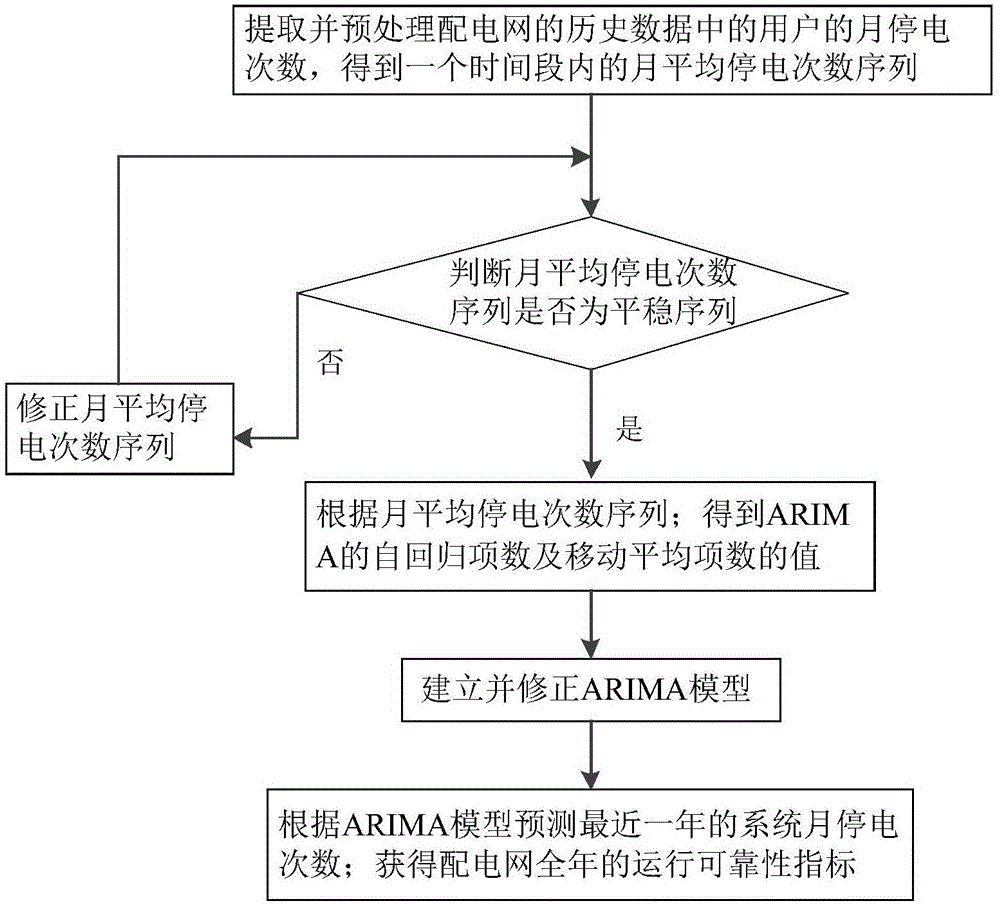

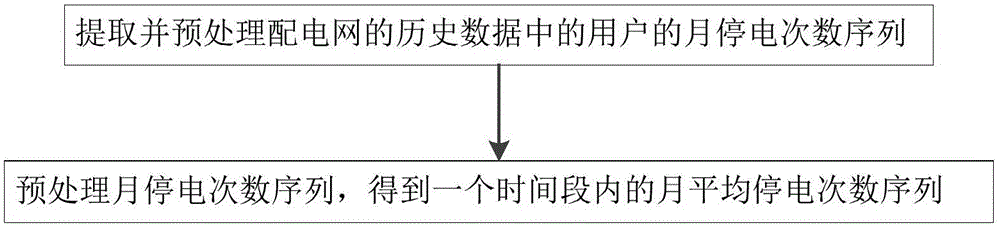

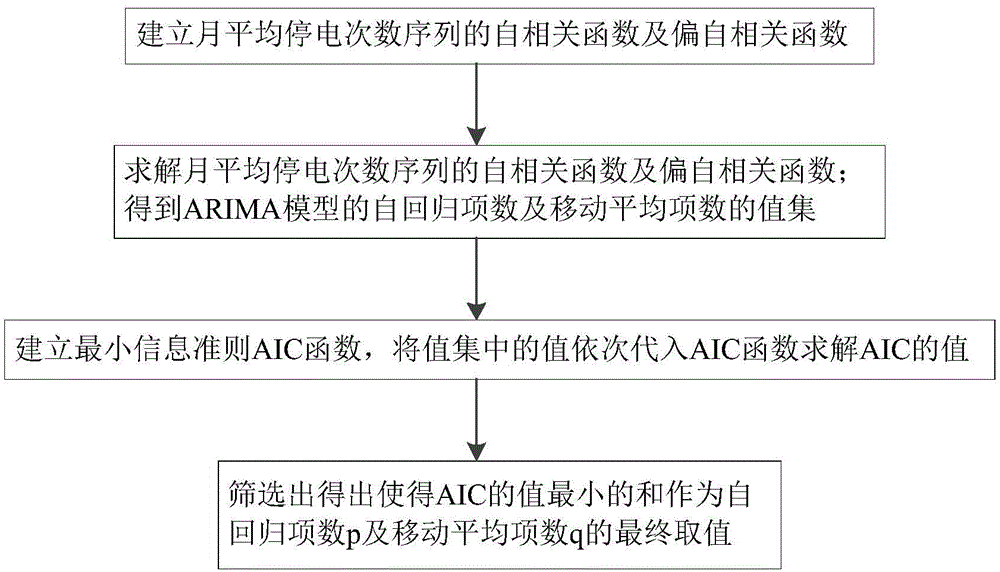

Method for predicting operational reliability of power distribution network based on ARIMA model

ActiveCN105069535AAccurate and Effective Predictive EvaluationImprove accuracyGeneration forecast in ac networkWeather condition predictionLoad following power plantTime sequence

The invention provides a method for predicting the operational reliability of a power distribution network based on an ARIMA model, and the method comprises the steps: predicting the number of times of monthly power failures of a user through building the ARIMA model; enabling an unstable element failure time sequence to be converted into a stable time sequence, and then carrying out the regression of the lagged value of a dependent variable and the present value and lagged value of a random error term to build a user monthly power failure time model; sampling a shutdown point according to the prediction results; considering real-time load operation conditions; building a fault mode impact table based on a TLOC rule and a PLOC rule; calculating the system recovery time for the shutdown of equipment at each time, and finally obtaining a yearly reliability index. The method proposed by the invention guides the planning, design, operation and maintenance of a future power grid effectively and accurately, improves the accuracy of prediction and estimation of the operational reliability of the power distribution network, achieves the stable operation of the power distribution network, reduces the frequency of power failures, and reduces the power failure range.

Owner:CHINA ELECTRIC POWER RES INST +3

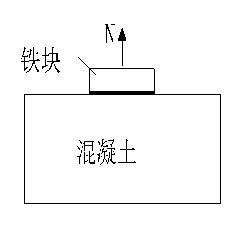

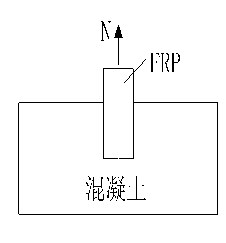

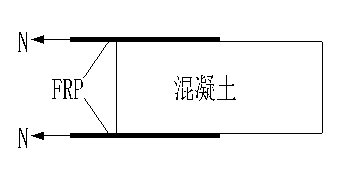

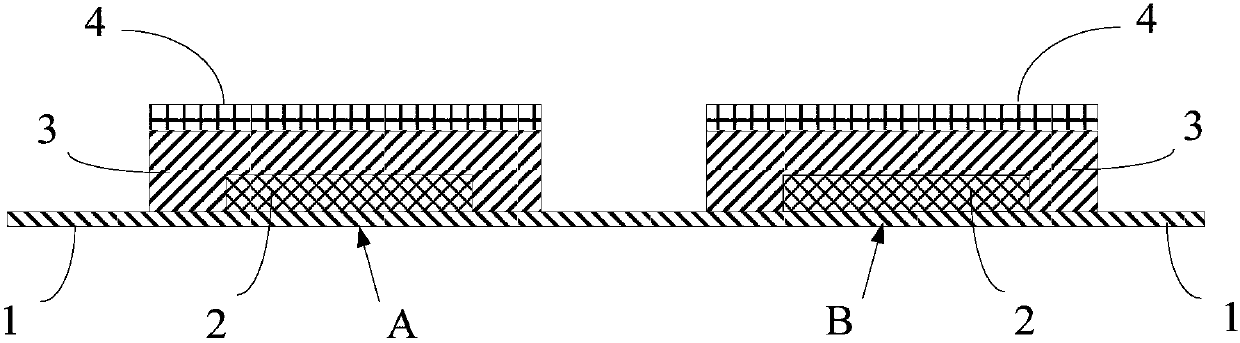

Method for testing interface bond behavior of CFRP (carbon fiber reinforced polymer) cloth-concrete based on beam specimen

InactiveCN103344560ATruly reflect the state of stressEasy to operateUsing mechanical meansMaterial analysisInverted-T shapeEngineering

The invention discloses a method for testing interface bond behavior of CFRP (carbon fiber reinforced polymer) cloth-concrete based on a beam specimen. The method comprises three steps of preparing a test specimen, arranging a test point and loading a test. The test specimen manufactured in the first step is the beam specimen and comprise two concrete test blocks, which are arranged at left and right and symmetric in shape; the two concrete test blocks are inverted T-shaped concrete test blocks; the upper parts in the middle of the two concrete test blocks are connected by a steel hinge; the steel hinge is divided into left and right halves; and the left and right halves are respectively adhered to the concrete test block at the corresponding side, and have the rotation ability. Compared with the traditional double shear test method for testing the interface bond behavior of the CFRP cloth-concrete, the effect of asymmetric loading on the data reliability is avoided; the method has a unique advantage of high accuracy of the test result; and the accuracy and the creditability of the detection result are improved.

Owner:ZHENGZHOU UNIV

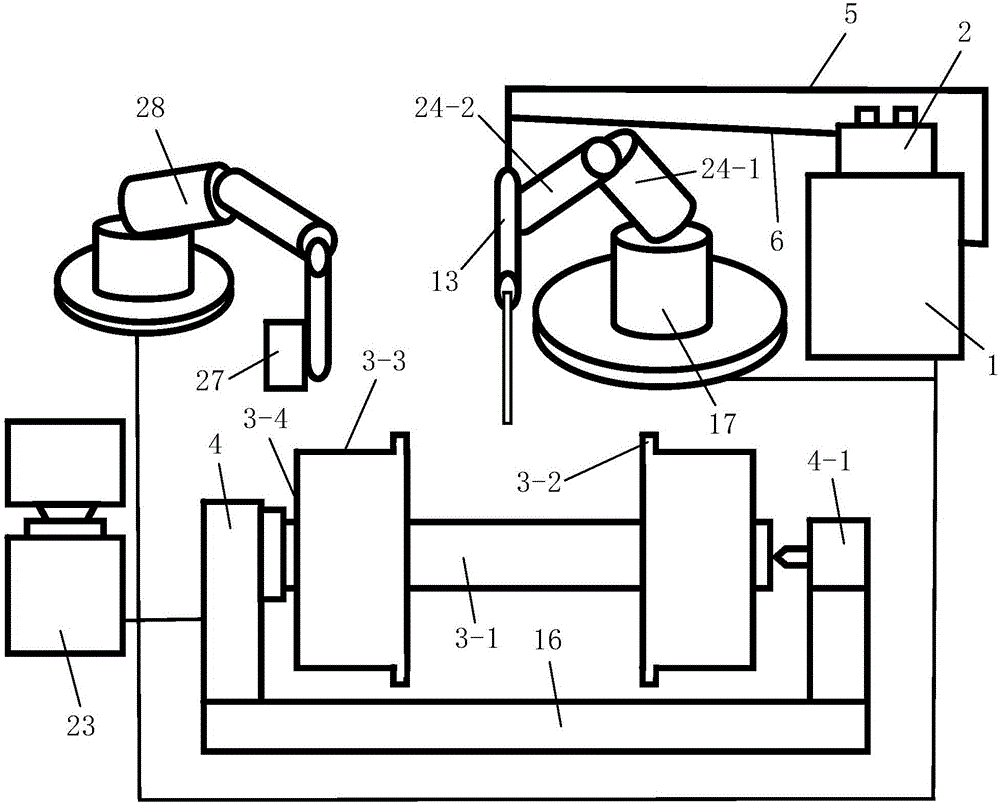

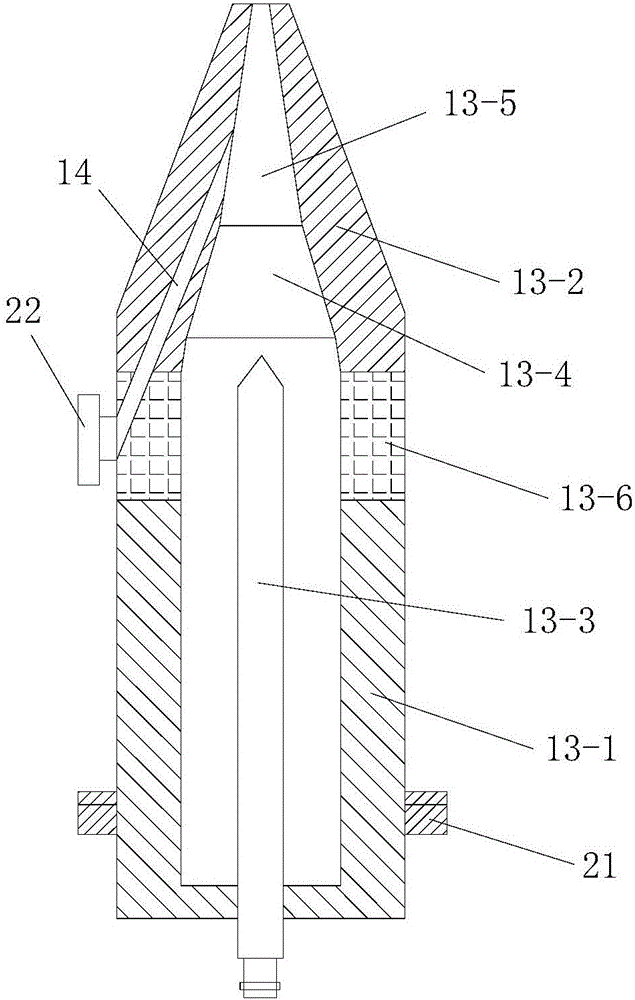

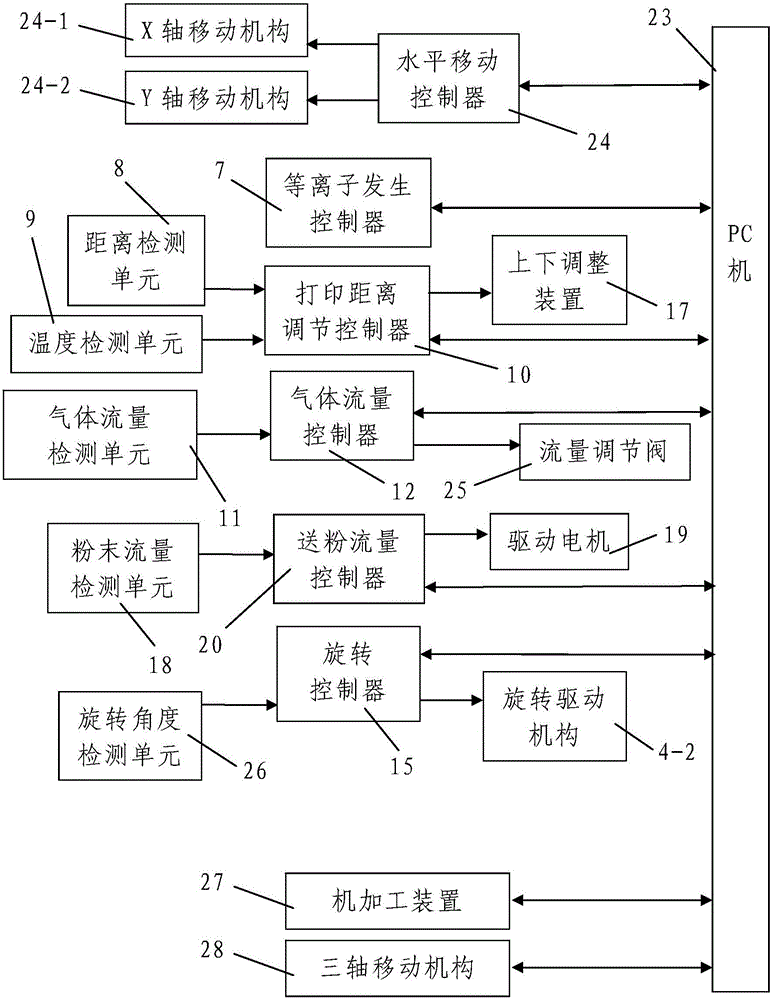

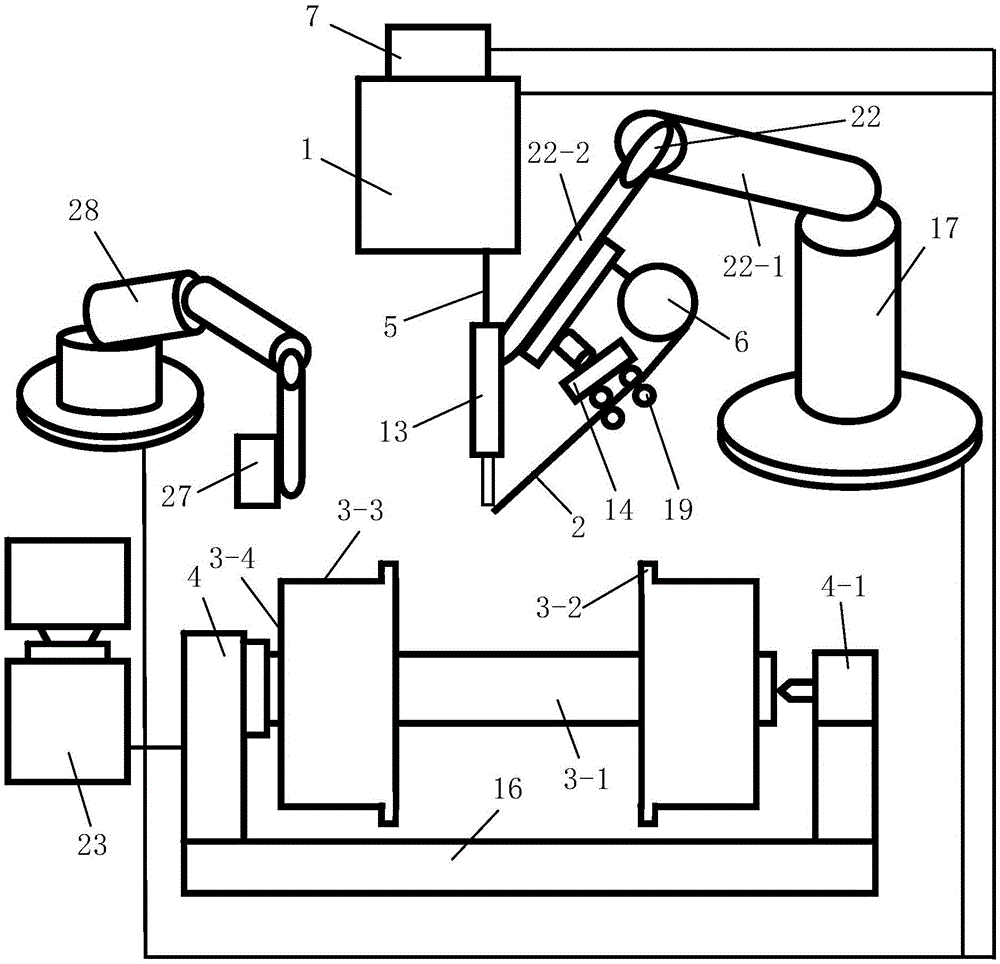

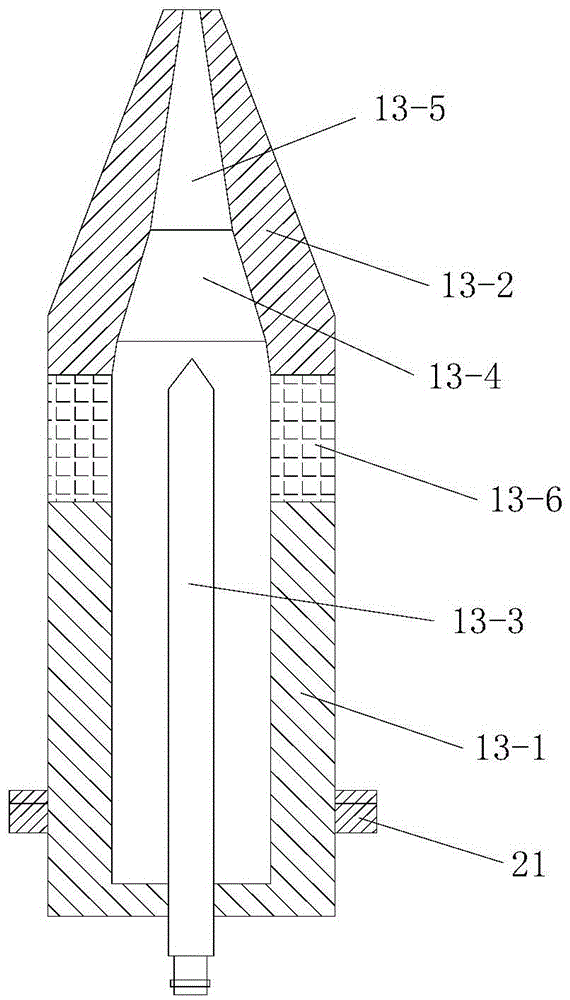

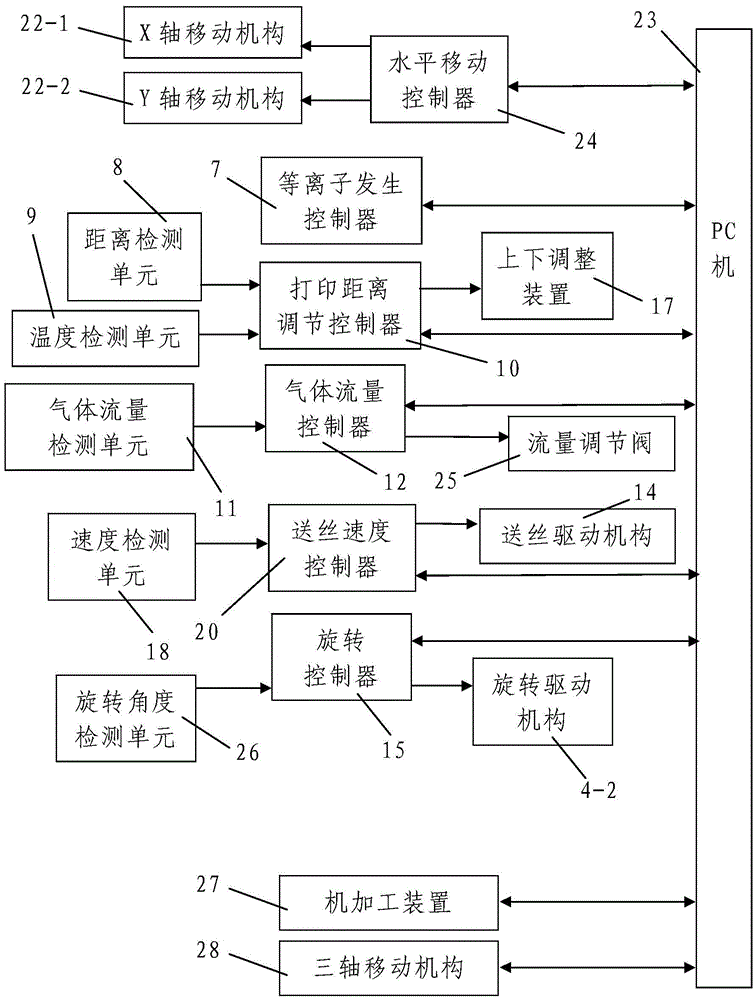

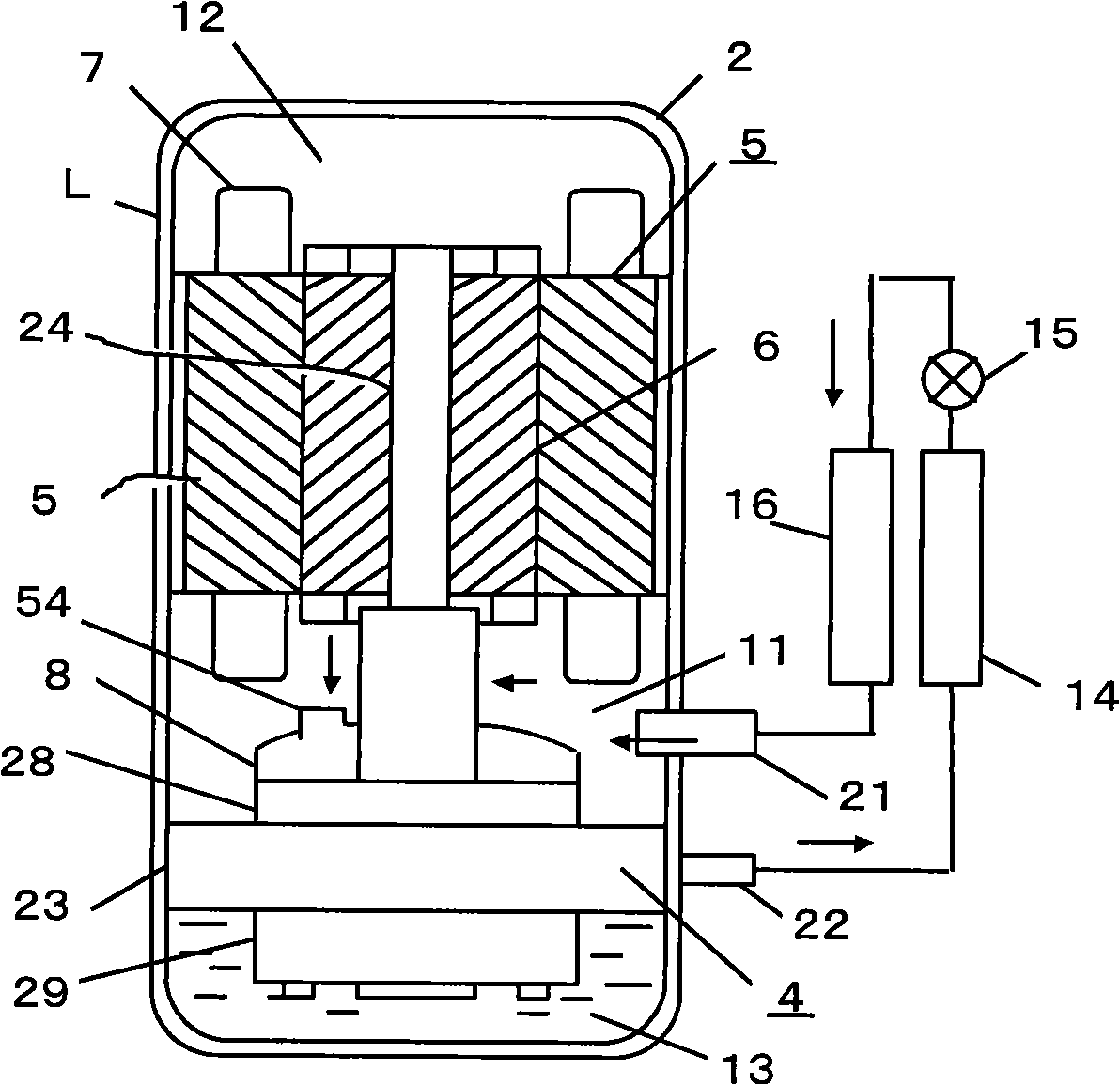

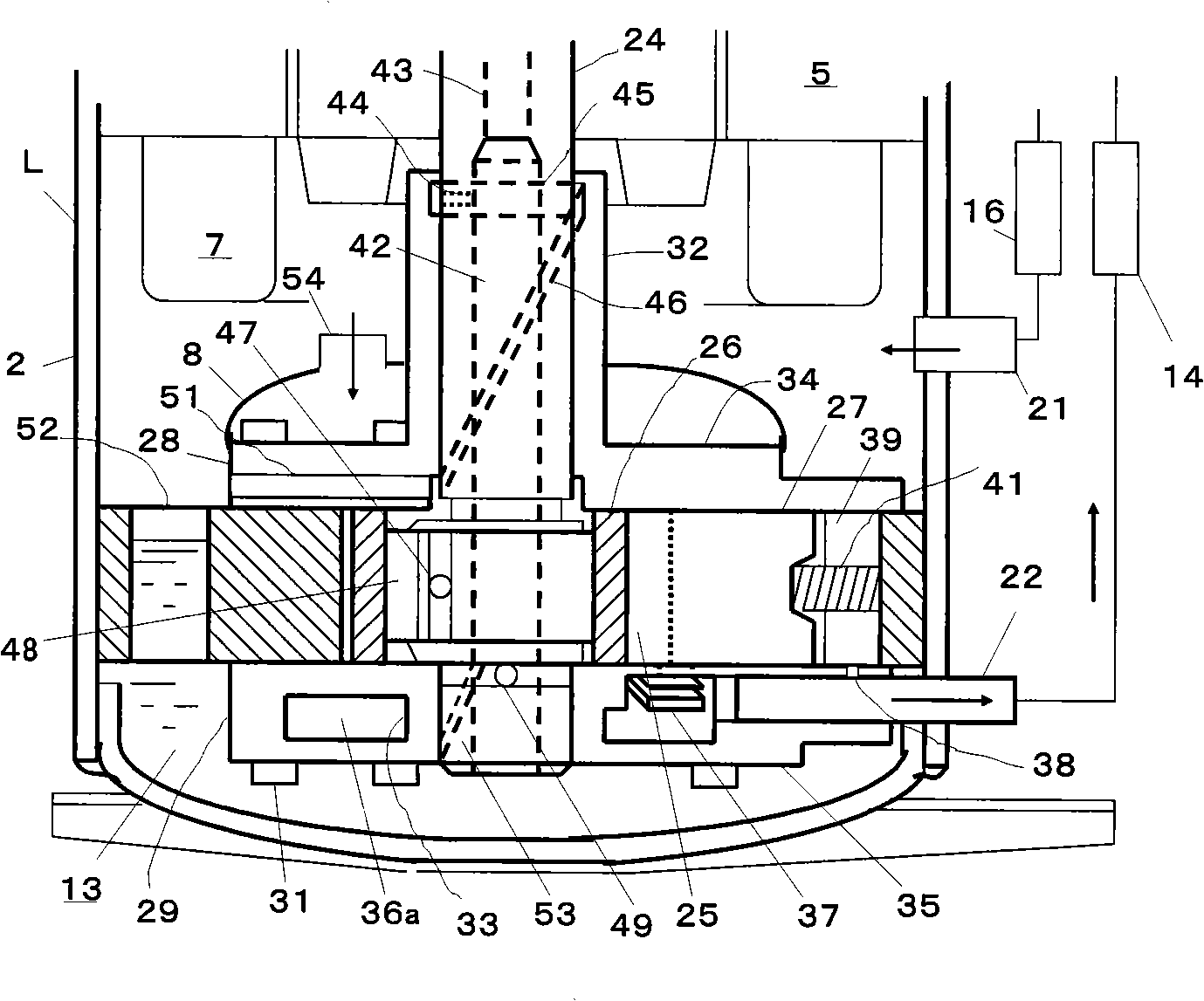

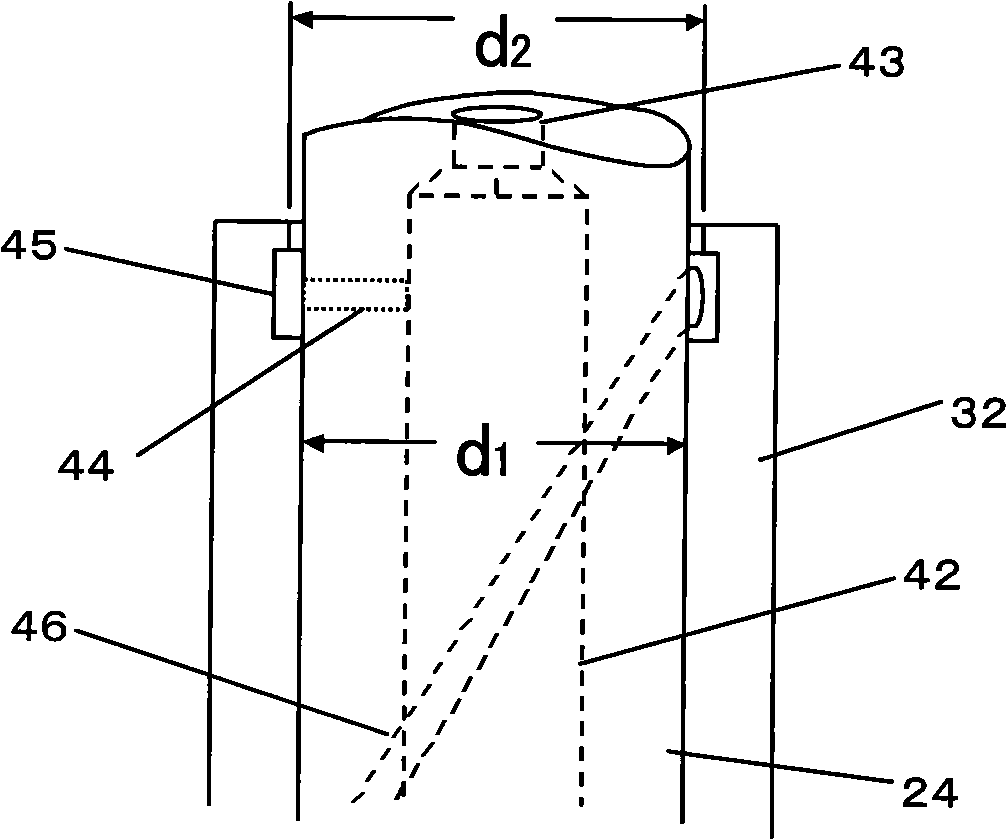

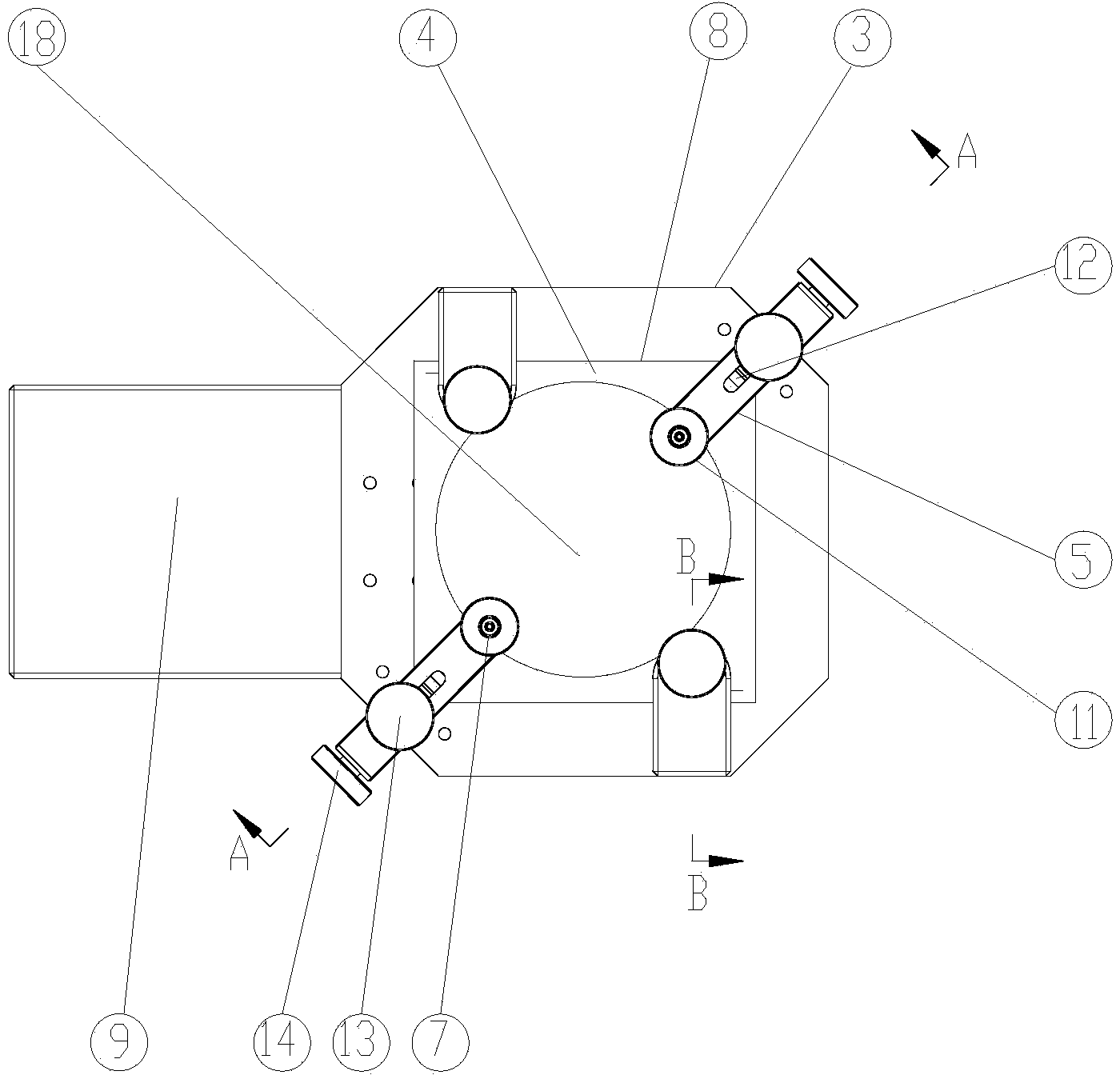

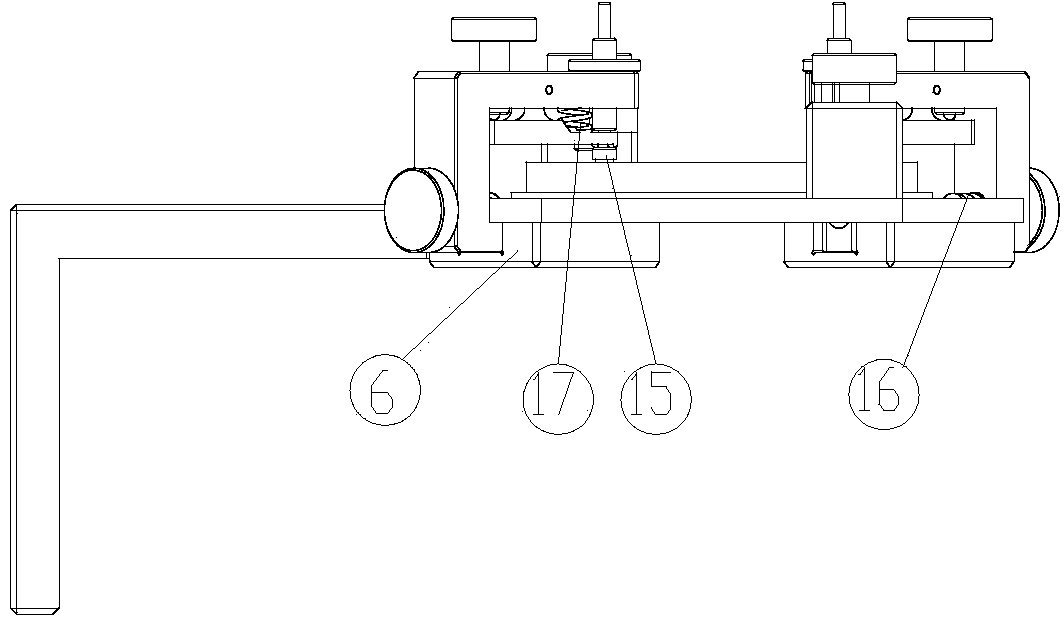

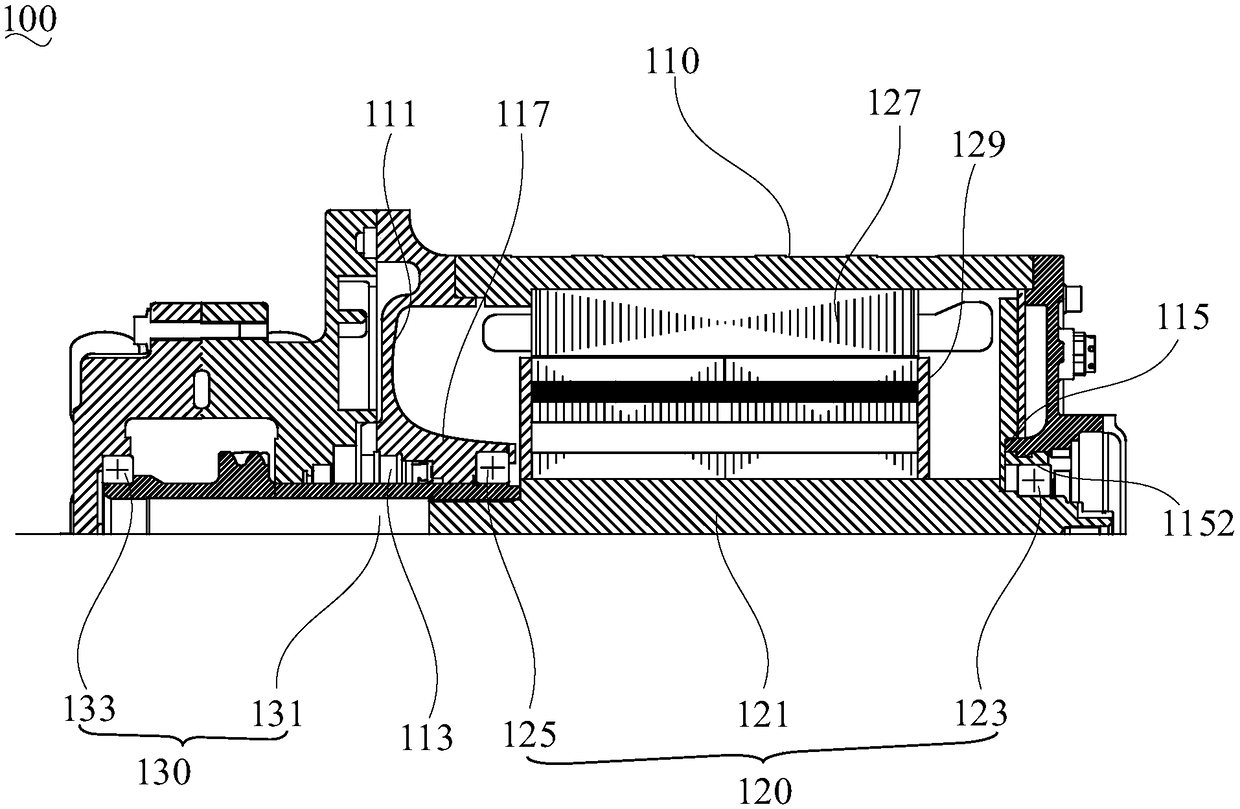

Plasma 3D printing remanufacturing equipment and method for train wheel

InactiveCN105710371ASimple structureReasonable designAdditive manufacturing apparatusIncreasing energy efficiencyDistance detectionPlasma beam

The invention discloses plasma 3D printing remanufacturing equipment and method for a train wheel. The plasma 3D printing remanufacturing equipment consists of a monitoring system, a plasma beam processing system, a machining device for machining a train wheel to be repaired, a triaxial moving mechanism used for driving the machining device to move and a horizontal printing platform used for placing the train wheel to be repaired, wherein the plasma beam processing system consists of a plasma generator, a printing position adjusting device, an air supply device and a powder feeder; and the monitoring system comprises a horizontal movement controller, a temperature detection unit, a distance detection unit, a printing distance adjustment controller and a rotation controller, and the temperature detection unit and the printing distance adjustment controller constitute a temperature adjustment and control device. The plasma 3D printing remanufacturing method comprises the following steps: firstly, detecting defects of the train wheel; and secondly, repairing the train wheel. The plasma 3D printing remanufacturing equipment is reasonable in design, simple and convenient to operate, high in efficiency and good in using effect, the repair process is directly carried out in the atmospheric environment without a closed molding room, the repaired train wheel is good in quality, and the repair efficiency is high.

Owner:SINOADDITIVE MFG EQUIP CO LTD

Plasma 3D fast forming and remanufacturing method and equipment of train wheels

InactiveCN105522155ASimple structureReasonable designAdditive manufacturing apparatusIncreasing energy efficiencyMonitoring systemPlasma generator

The invention discloses a plasma 3D fast forming and remanufacturing method and equipment of train wheels. The equipment comprises a monitoring system, a plasma beam machining system, a machining device for machining to-be-repaired train wheels, a three-axis moving mechanism for driving the machining device to move and a horizontal printing platform for placing the to-be-repaired train wheels. The plasma beam machining system comprises a plasma generator, a gas supply device, a feeding device and a printing positioning adjusting device. The monitoring system comprises a horizontal movement controller, a temperature detecting unit, a distance detecting unit, a printing distance adjusting controller and a rotation controller, wherein the temperature detecting unit and the printing distance adjusting controller form a temperature adjusting and control device. The method includes the steps of firstly, detecting train wheel defects; secondly, repairing the train wheels. The plasma 3D fast forming and remanufacturing method and equipment has the advantages that the equipment is reasonable in design, simple to operate, high in efficiency, good in use effect and high in repairing efficiency, a closed forming room is not needed, the repairing process is directly performed under an atmospheric environment, and the repaired train wheels are good in quality.

Owner:SINOADDITIVE MFG EQUIP CO LTD

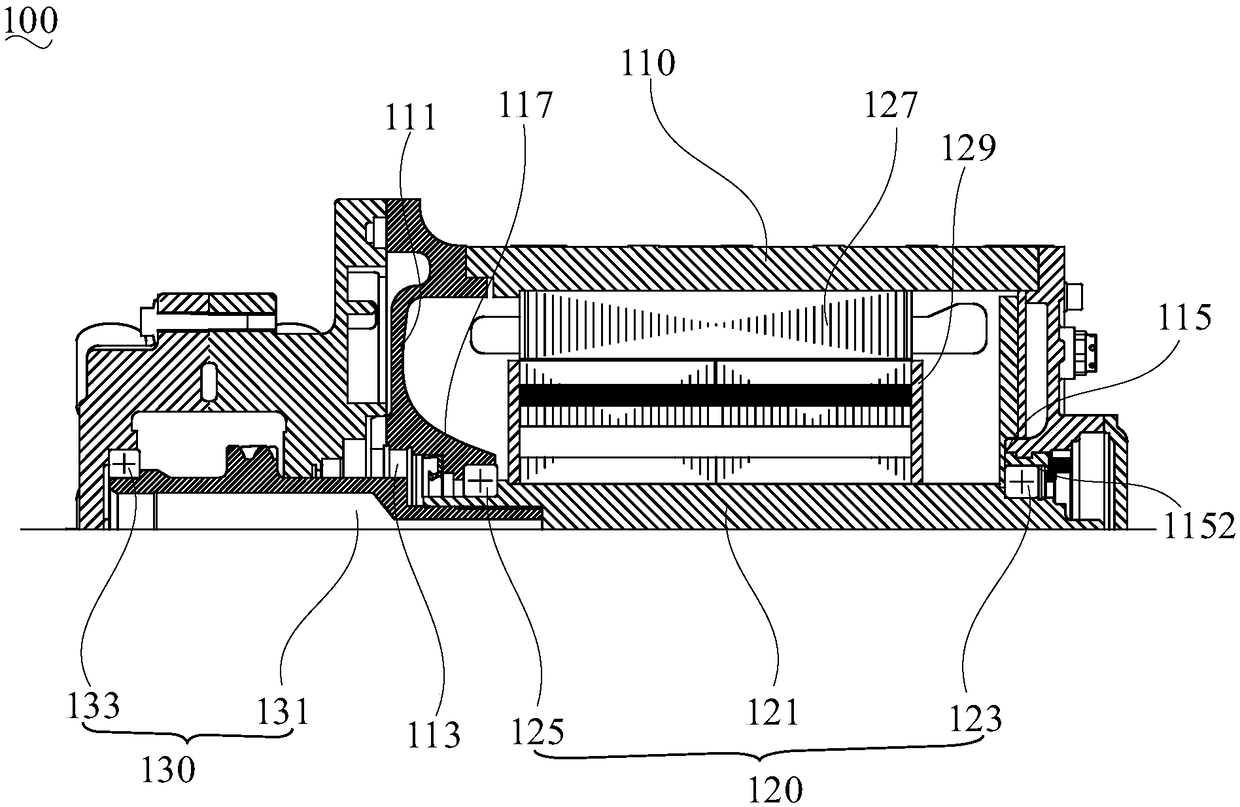

Control method for reducing oil-jetting apparatus of rotary compressor and uses thereof

InactiveCN101354042AReduce performanceReliability impactRotary piston pumpsRotary/oscillating piston pump componentsCrankshaftBleeding reduction

The invention relates to a control method for an oil bleeding reduction device of a rotary compressor and application thereof; the oil bleeding reduction device of the rotary compressor comprises a motor arranged in a shell body of the rotary compressor and a compression component connected with the motor, wherein, the compression component comprises a cylinder, a sliding vane, a crank shaft, a main bearing and a supplementary bearing; the main bearing and the supplementary bearing are used for supporting the crank shaft; the crank shaft is internally provided with a vertical core of an oil pool opening facing to the bottom of the rotary compressor; the vertical core comprises a lower crank shaft vertical core and an upper crank shaft vertical core connected with the lower crank shaft vertical core; the upper crank shaft vertical core is arranged at the upper end of the crank shaft; a long bearing sheathed with the crank shaft is arranged above the main bearing; an inner circular groove is arranged around the upper part of the long bearing circumferentially; the crank shaft arranged at the upper part of the lower crank shaft vertical core is provided with a first cross bore; one end of the first cross bore is open in the lower crank shaft vertical core, while the other end thereof is open in the position of the inner circular groove; the inner diameter of the top of the long bearing positioned above the inner circular groove is 10 microns to 20 microns larger than that of the long bearing.

Owner:GUANGDONG MEIZHI COMPRESSOR

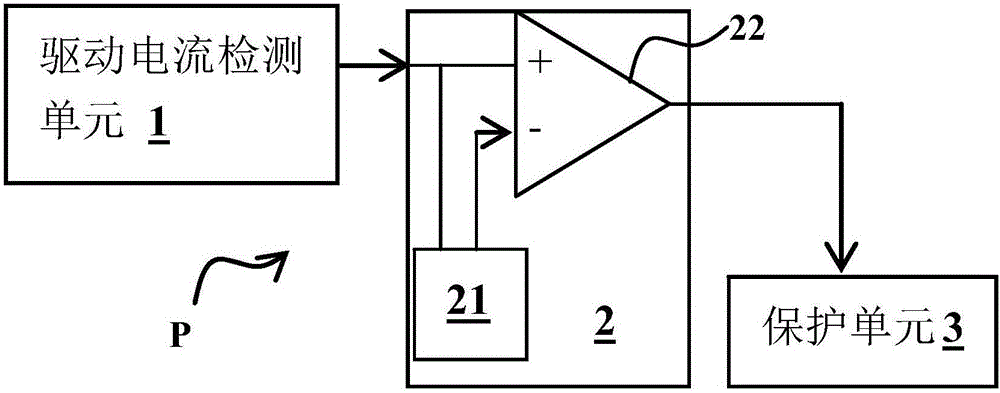

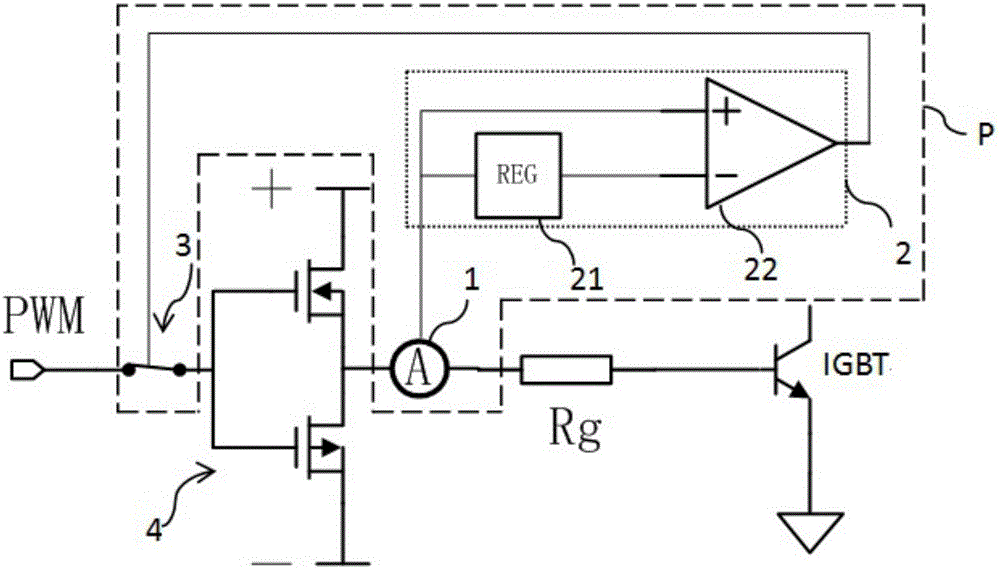

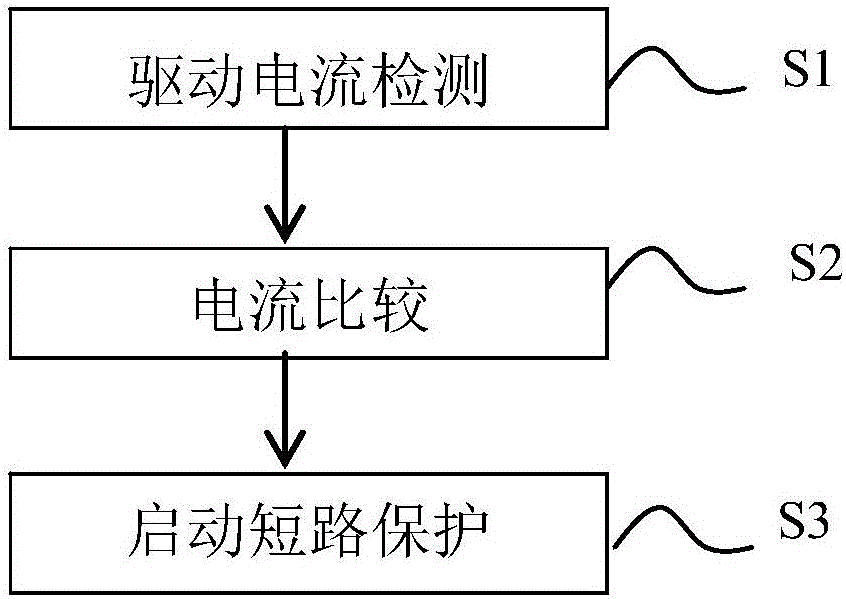

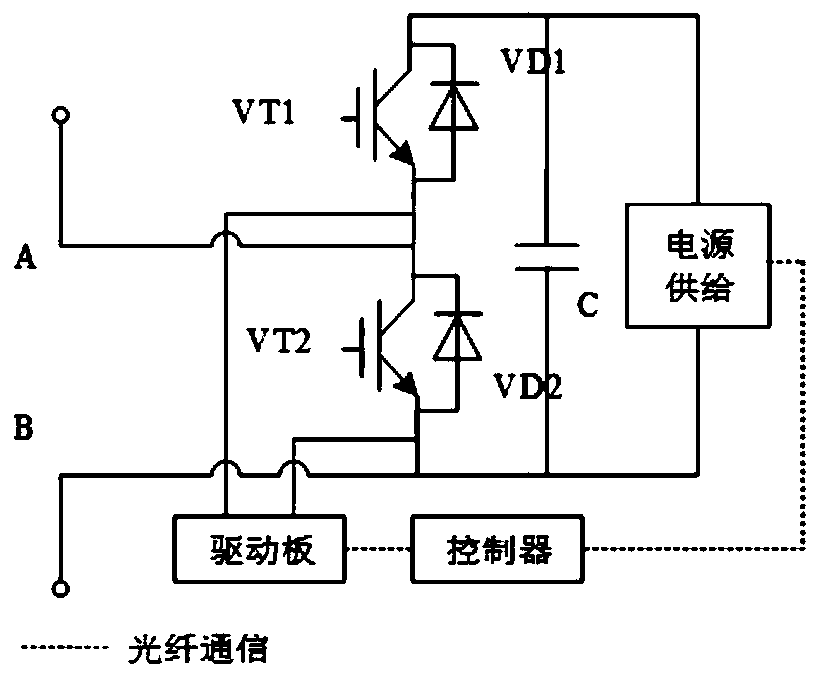

IGBT short circuit protection circuit and method, IGBT driver and IGBT circuit

InactiveCN106130520ARealize short circuit protectionReliability impactEmergency protective circuit arrangementsElectronic switchingDriving currentReference current

The invention provides an IGBT short circuit protection circuit and method, an IGBT driver and an IGBT circuit. The IGBT short circuit protection circuit comprises a drive current detection unit, used for detecting the drive current flowing through an IGBT gate; a comparison unit, used for comparing the drive current with reference current and outputting a comparison result; and a protection unit, used for determining whether to start short circuit protection of the IGBT according to the comparison result. According to the technical scheme, the drive current flowing through the IGBT is detected to control the self locking of the IGBT drive circuit, so as to improve the reliability of the short circuit protection of the IGBT.

Owner:GREE ELECTRIC APPLIANCES INC

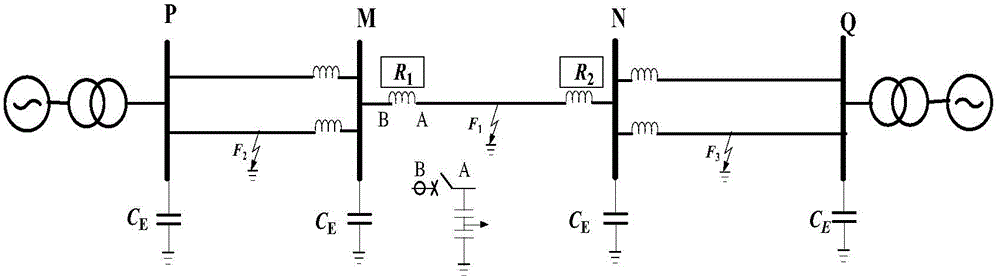

Fault phase selection method utilizing phase current gradient sums

ActiveCN104391221APhase selection criteria are simpleReliable electionFault locationPhase currentsElectrical resistance and conductance

The invention relates to a fault phase selection method utilizing phase current gradient sums and belongs to the power system relay protection technical field. The method comprises the following steps that: a measuring end obtains three-phase current and zero-mode current gradient sums after a power transmission line fault is calculated; after normalization is performed on the three-phase current and zero-mode current gradient sums, the three-phase current gradient sums are sorted into an order of s1, s2 and s3; and whether the fault is a grounding fault is determined according to the zero-mode current gradient sums, if the fault is a non-grounding fault, the absolute value of s1-s2 is larger than a set threshold value, and the fault is a three-phase short-circuiting fault, otherwise, the fault is a phase-to-phase fault, and phases corresponding to s1 and s2 are fault phases; if the fault is a grounding fault, s1 / s2 is greater than the set threshold value, the fault is a single-phase grounding fault, and a phase corresponding to s1 is a fault phase, otherwise, the fault is a two-phase grounding fault, and phases corresponding to s1 and s2 are fault phases. As indicated by a large quantity of simulation analysis, the fault phase selection method utilizing the phase current gradient sums can reliably select fault phases. The reliability of the fault phase selection method is not affected by fault positions, transition resistance and small fault angles, and therefore, the fault phase selection method has excellent effects.

Owner:KUNMING UNIV OF SCI & TECH

Etching liquid, etching method and surface roughening method for GaP layer of LED chip

ActiveCN103966605ASimple compositionEasy to operateSemiconductor devicesPhosphoric acidSurface roughening

The invention discloses an etching liquid, an etching method and a surface roughening method for a GaP layer of an LED chip, belonging to the field of surface roughening. The etching liquid comprises hydrochloric acid, phosphoric acid, sulfuric acid and hydrogen peroxide. The surface roughening method of the LED chip combines a plasma etching process with a wet etching process, so that etching holes are bowl-shaped, the total reflection of emergent light can be effectively reduced, and the light emergent efficiency of the LED chip is improved. The surface roughening method has the advantages of simple process, reasonable design and easiness and convenience in operation, the rise of surface contact voltage of the LED chip cannot be caused, and the product reliability cannot be influenced.

Owner:马鞍山太时芯光科技有限公司

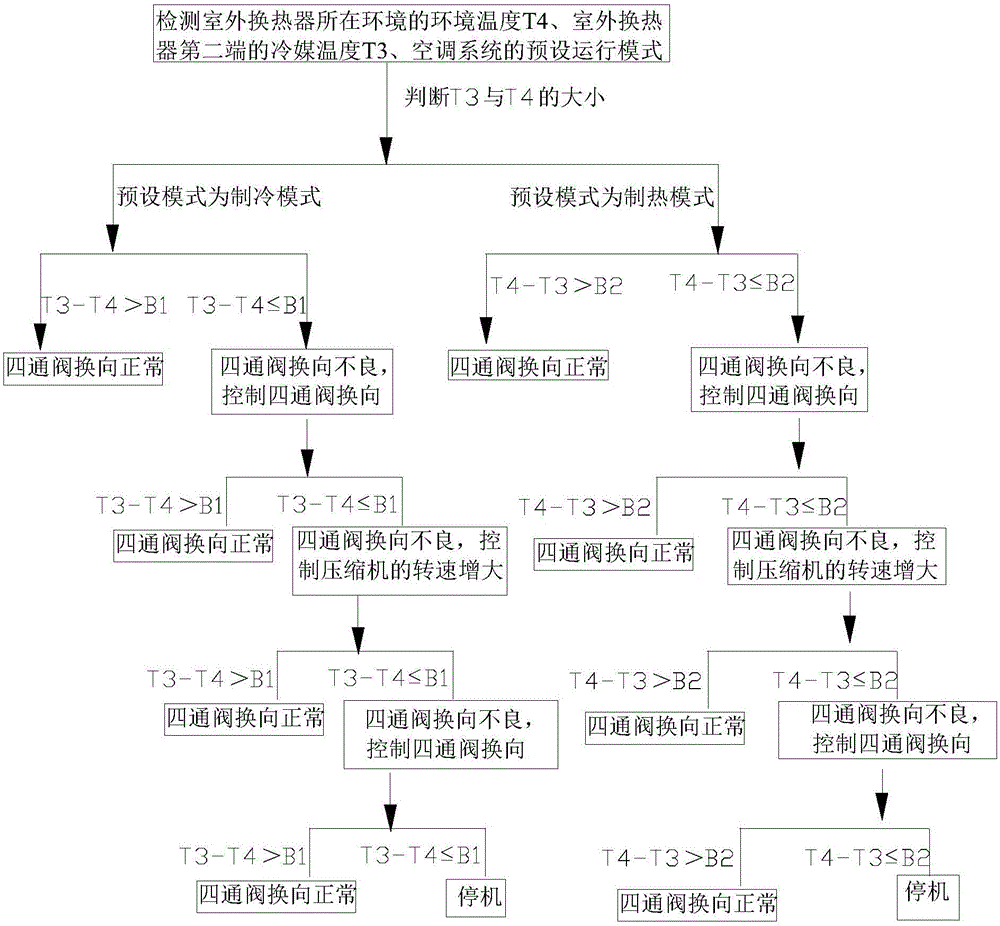

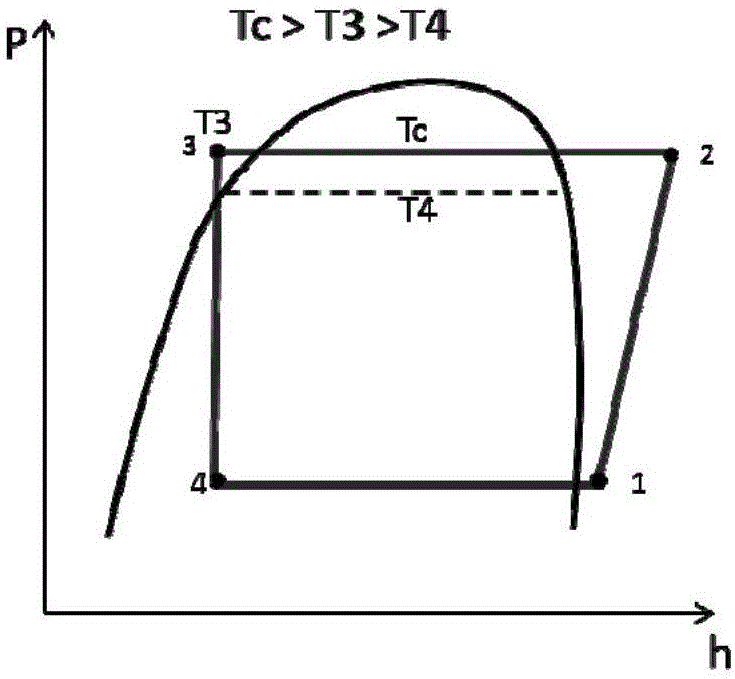

Control method of air conditioning system

InactiveCN106500420AReliability impactLow costMechanical apparatusSpace heating and ventilation safety systemsFour-way valveCoolant flow

The invention discloses a control method of an air conditioning system. The control method comprises the following steps of measuring the environment temperature T4 of the environment where an outdoor heat exchanger is located, and the coolant temperature at the second end of the outdoor heat exchanger or the coolant temperature T3 of the coolant flow path between the second end and the second valve port of the outdoor heat exchanger, and detecting the preset operation mode, chosen by a user, of the air conditioning system after the air conditioning system is started up; judging which is larger between T3 and T4 when the preset operation mode is the cooling mode, determining that a four-way valve is poorly reversing if T3 minus T4 is equal to or less than the first preset value B1, and controlling the four-way valve to reverse to make the actual operation mode of an air conditioner be the cooling mode; and judging which is larger between T3 and T4 when the preset operation mode is the heating mode, and determining that the four-way valve is poorly reversing if T4 minus T3 is equal to or less than the second preset value B2, and controlling the four-way valve to reverse to make the actual operation mode of the air conditioner be the heating mode. According to the control method of the air conditioning system, the cost can be reduced.

Owner:GD MIDEA HEATING & VENTILATING EQUIP CO LTD +1

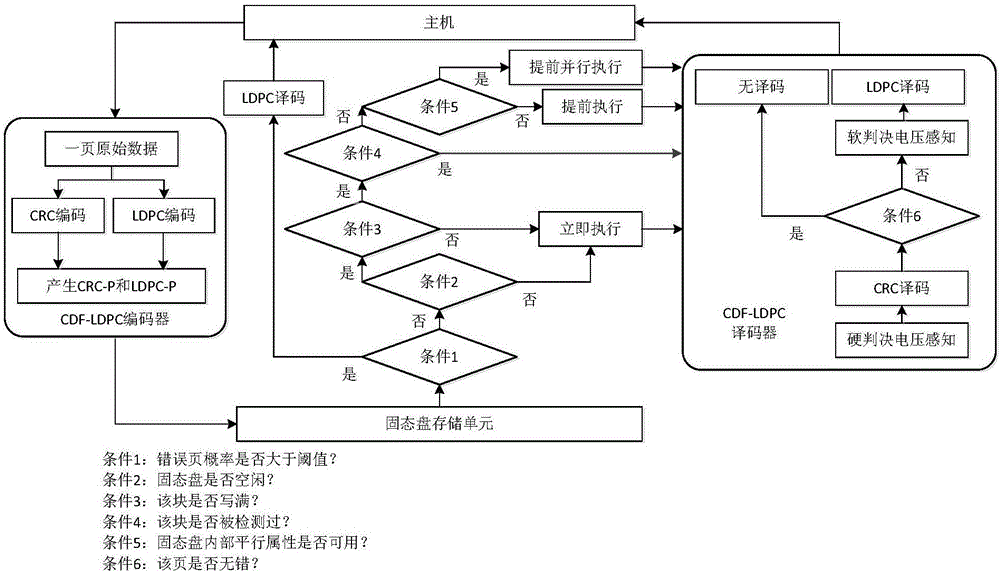

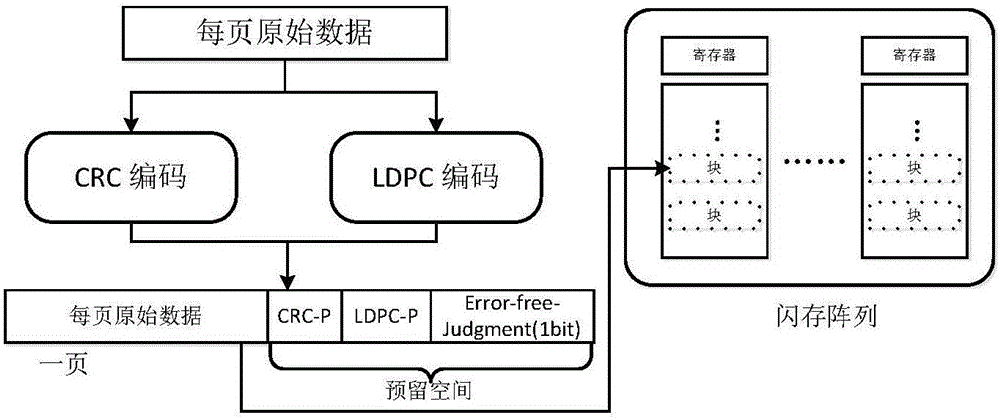

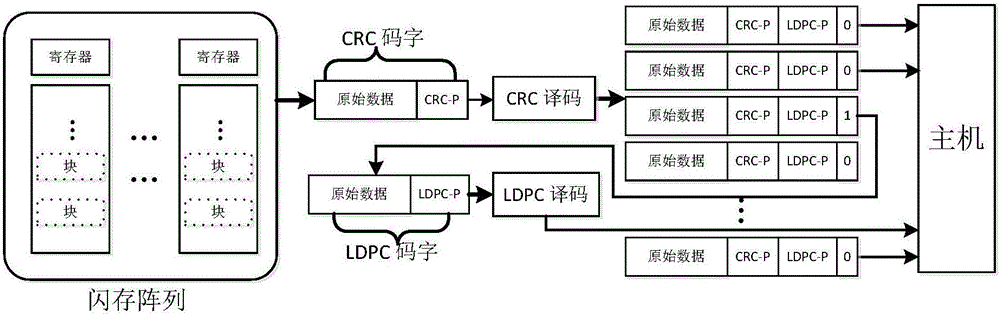

Solid-state disk error correction method combining error detection code with error correction code

InactiveCN106601305AImprove read performanceReliability is not compromised in any wayError correction/detection using multiple parity bitsCode conversionOriginal dataCorrection method

The invention discloses a solid-state disk error correction method combining an error detection code with an error correction code. The method comprises the following steps of (1) before data is written in a solid-state disk, encoding original data of flash pages, and storing the data in a storage unit of the solid-state disk; and (2) detecting error states of the flash pages in the storage unit by using error detection code decoding operation, directly reading the flash pages without errors, and performing error correction on the flash pages with errors by using low-density parity-check code (LDPC) decoding operation. According to the method, the flash pages can be subjected to error detection by using error detection code cyclic redundancy check (CRC) firstly when the error rates of the flash pages are very low in an early use stage of the solid-state disk; the detected pages without the errors are directly read without being subjected to the LDPC decoding process; and the detected pages with the errors are subjected to LDPC decoding-based error correction.

Owner:HUAZHONG UNIV OF SCI & TECH

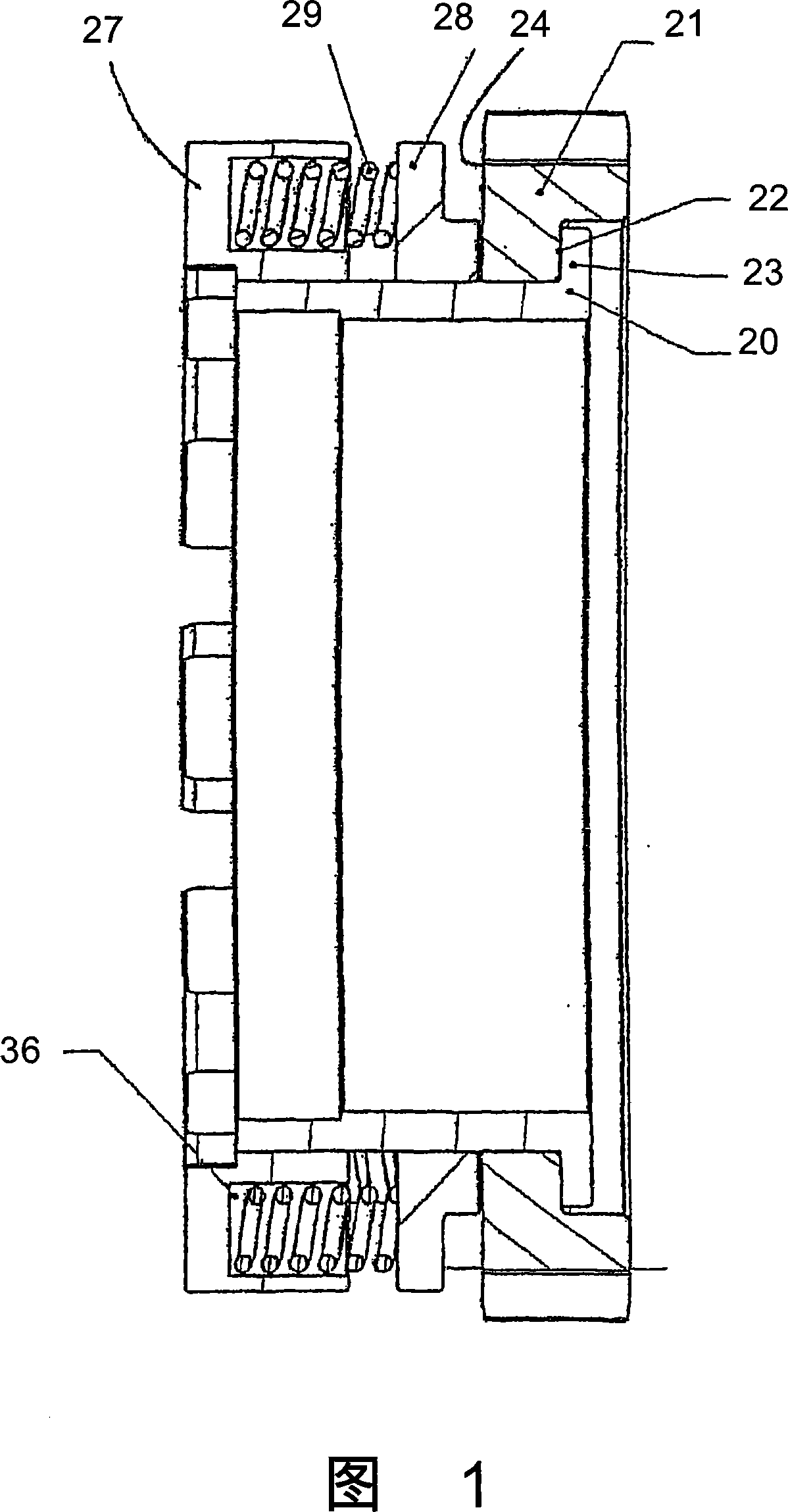

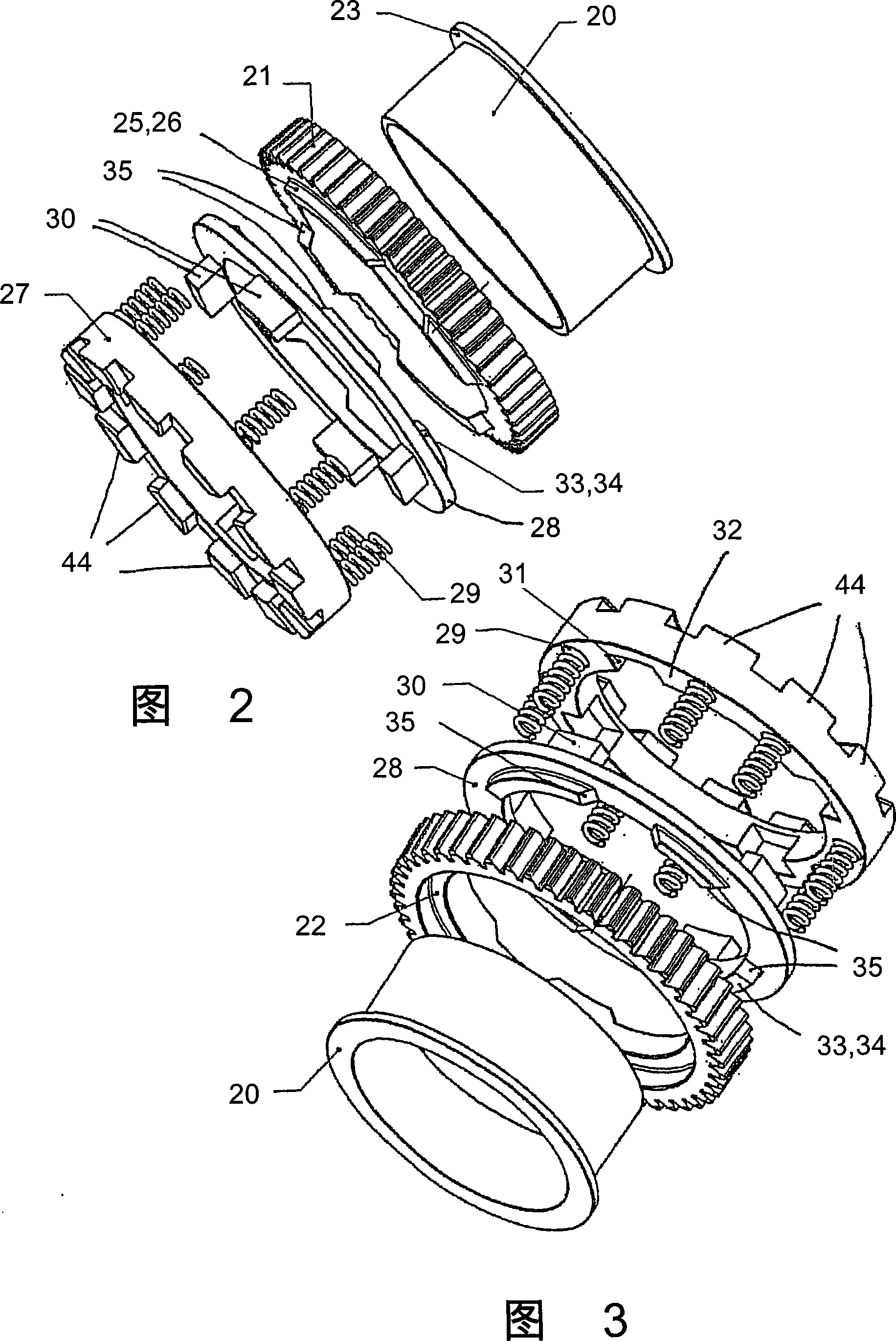

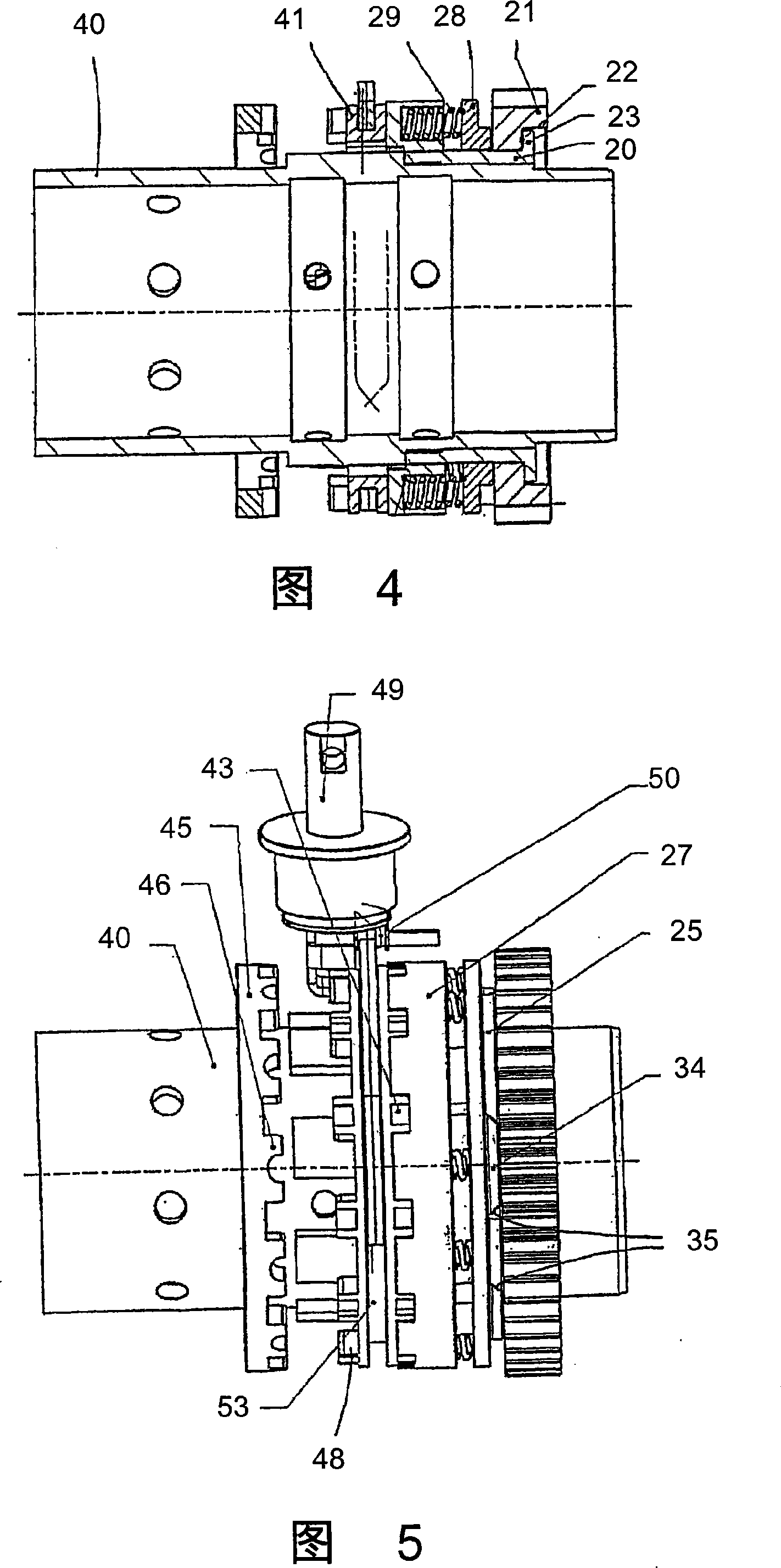

Percussion hammer and/or drill hammer comprising a safety coupling

InactiveCN1997489AAvoid wear and tearAvoid interlocking problemsPortable percussive toolsSpannersCouplingEngineering

Disclosed is a safety coupling in a percussion hammer and / or drill hammer, comprising a basic sleeve (20), a driven toothed wheel (21) that is rotatably mounted on the basic sleeve (20) and can be driven by a drive unit, a closing ring (27) which is fastened to the basic sleeve (20), and a locking ring (28) located between the driven toothed wheel (21) and the closing ring (27). Said locking ring is fixed in a torsion-proof manner relative to the closing ring (27) while being movable relative to the closing ring (27) in an axial direction, counter to the effect of a spring mechanism (29). The locking ring (28) is axially displaced while the driven toothed wheel (21) remains in the axial position thereof when a threshold torque is exceeded.

Owner:WACKER NEUSON SE

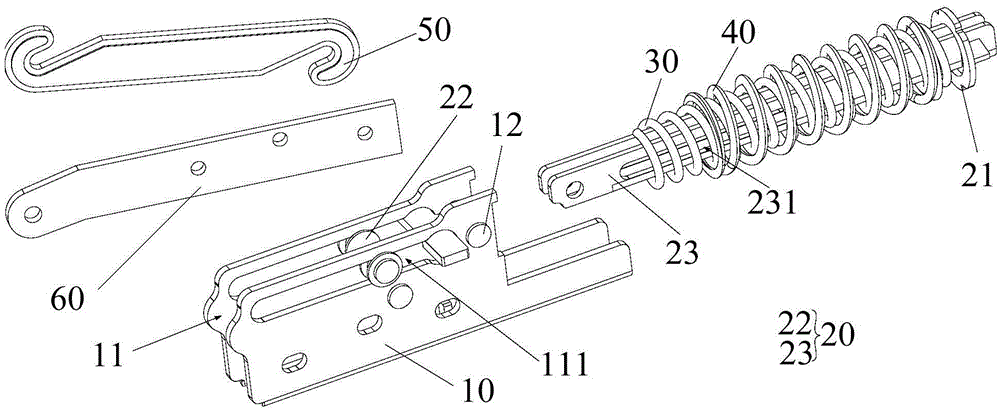

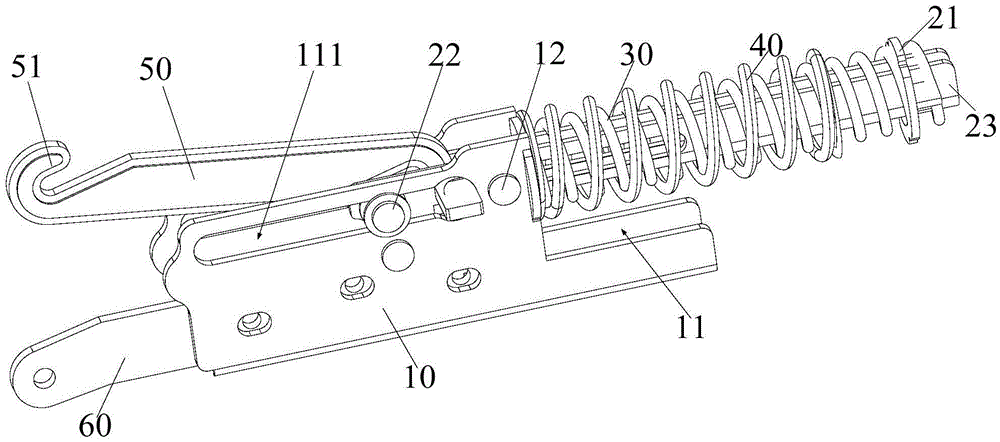

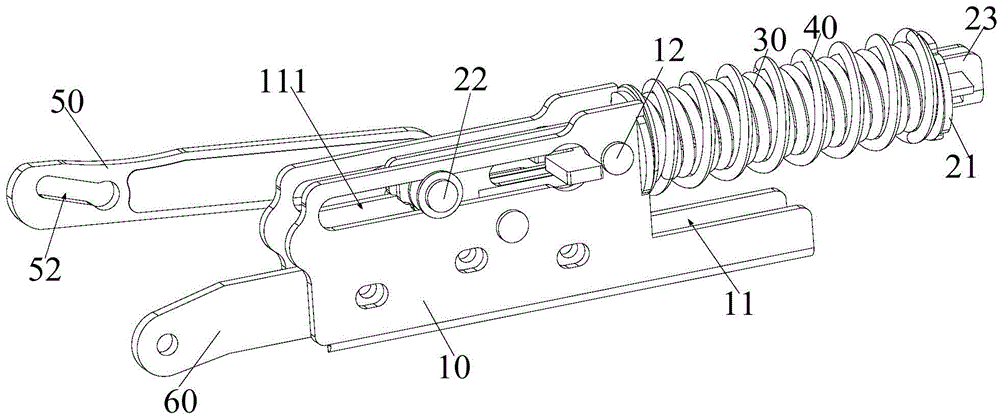

Hinge and cooking device

InactiveCN105534276AIncrease resistanceGuaranteed stabilitySteam cooking vesselsRoasters/grillsPull forceHinge angle

The invention provides a hinge and a cooking device. The hinge comprises a base, a central shaft, a first spring, a second spring and a first connecting rod, wherein the base is fixed on a box body, a guiding slot is formed in the base; one end of the central shaft is mounted in the guiding slot in a sliding manner, and a position limiting part is arranged on the other end of the central shaft; the first spring and the second spring are arranged on the central shaft in a sleeving manner, can move along the axis of the central shaft, and are supported between the base and the position limiting part; the first connecting rod is connected with each of a door body and the central shaft. According to the hinge provided by the invention, the first spring and the second spring are arranged on the central shaft, when the door body is opened, the central shaft on the hinge slides in the guiding slot in the base, the first spring is compressed by the position limiting part, and the second spring is compressed when the door body is opened to a certain angle, so that the resistance for opening the door body is increased, the door body can be prevented from dropping quickly, meanwhile, the door body can be avoided from being quickly closed due to the pull force of the first spring, and the application reliability of the cooking device can be ensured.

Owner:GUANGDONG MIDEA KITCHEN APPLIANCES MFG CO LTD +1

Method for making solder bump

InactiveCN101071778AAvoid over etchingDoes not reduce interfacial resistanceSolid-state devicesSemiconductor/solid-state device manufacturingIsolation layerCopper

The invention provides a new solder bump making method, able to prevent metal layers under solder bumps from being over etched. And it is characterized in: separately forming plated copper layers under solder bumps and nickel isolation layers on the plated copper layers and making the nickel isolation layers completely cover the plated copper layers under them to prevent the plated copper layers from being etched in the following isotropic etching and forming bottom cut, i.e. concave cut, in all plated copper layers. Thus, it can prevent the conductivity of the formed solder bumps from decreasing and improves reliability of solder bumps and semiconductor devices.

Owner:SEMICON MFG INT (SHANGHAI) CORP

Electronic equipment and an electronic equipment control method

ActiveCN109862159AReliability impactReduce the impact on the screen ratioDigital data processing detailsDevices with sensorDistance detectionEngineering

The invention provides electronic equipment and an electronic equipment control method, the electronic equipment comprises a first side and a second side which are arranged back to back, and a frame is arranged between the first side and the second side; A display module is arranged on the first side, at least part of the display module can transmit light, and a gap is formed between the display module and the frame; A first light emitting device, a second light emitting device and a light receiving device are arranged in the electronic device., The first light emitting device and the light receiving device are both arranged below the display module and arranged corresponding to the light-transmitting display area of the display module, the first light emitting device emits light signals outwards through the light-transmitting display area, and the second light emitting device emits light signals outwards through the gap. According to the electronic equipment provided by the invention,the influence of distance detection on the screen reliability and the influence on the screen-to-body ratio can be reduced.

Owner:VIVO MOBILE COMM CO LTD

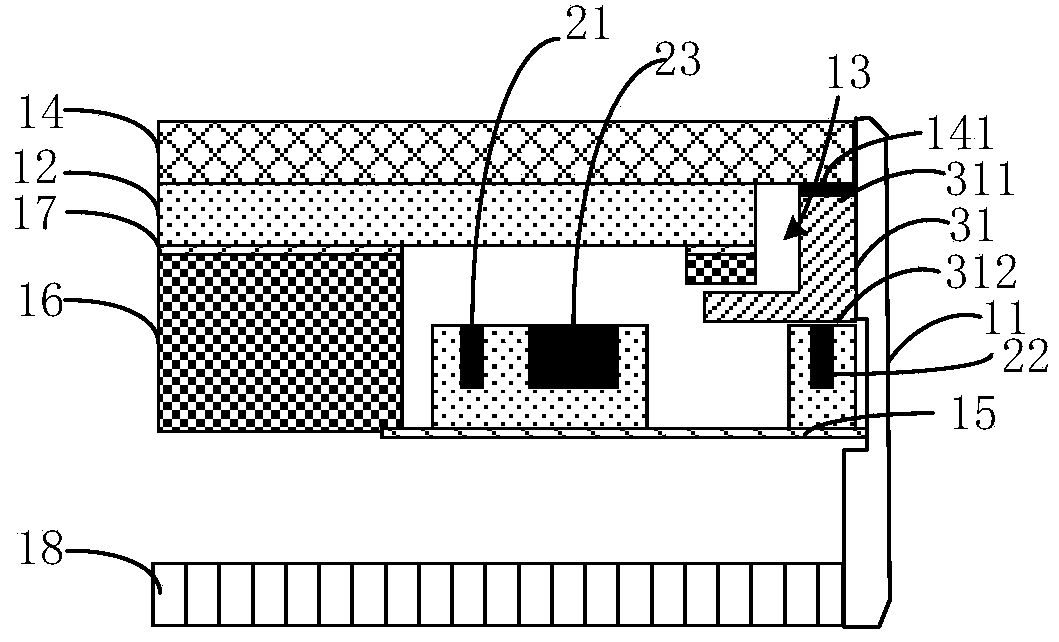

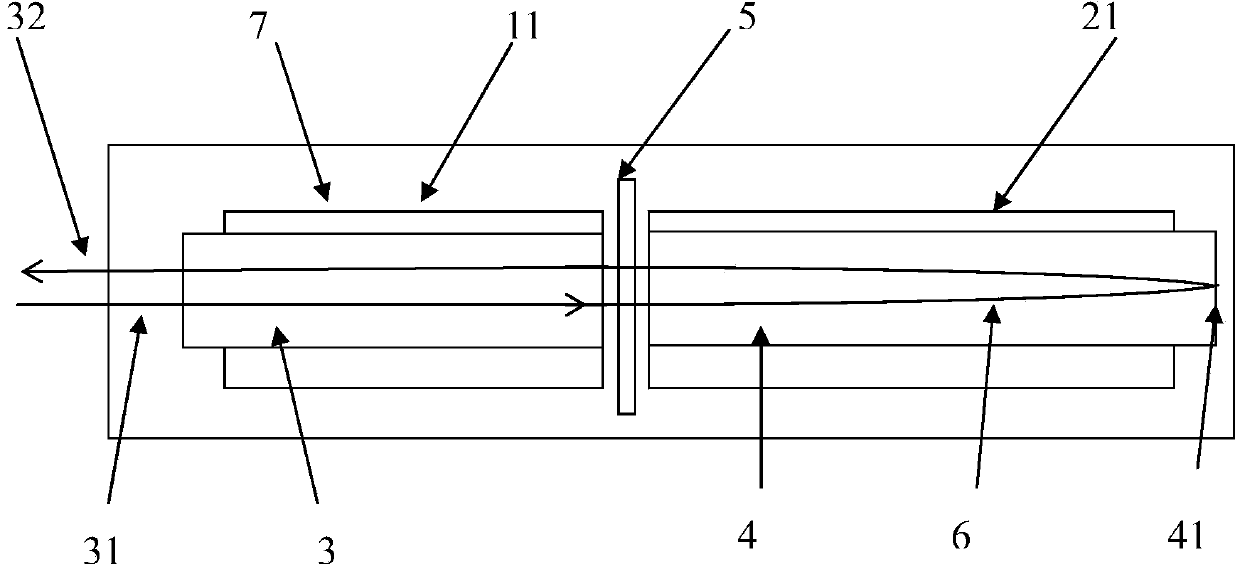

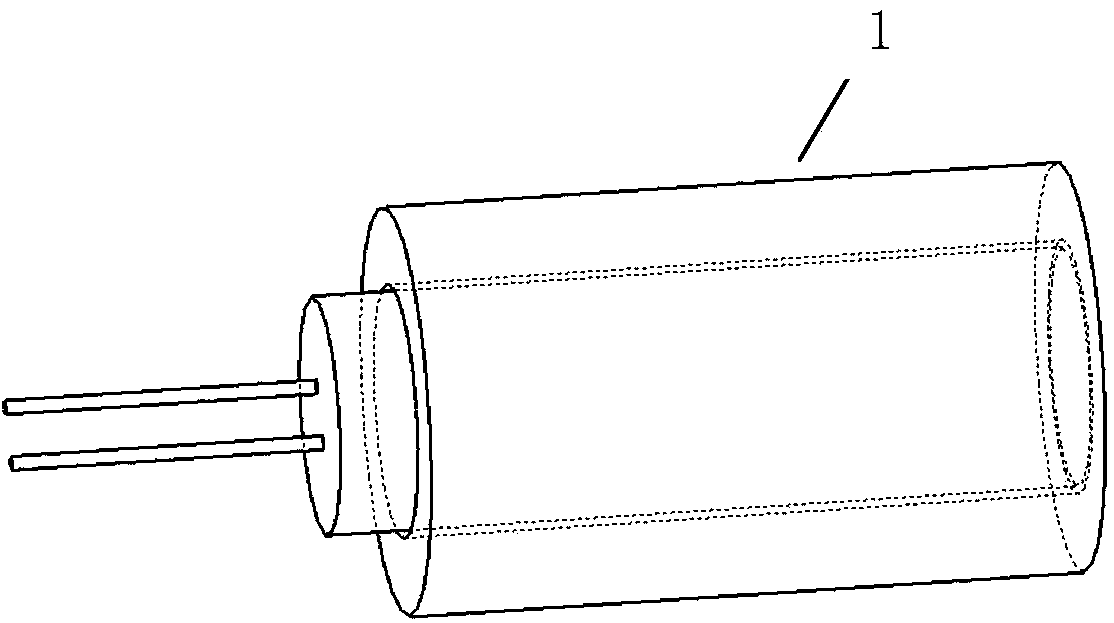

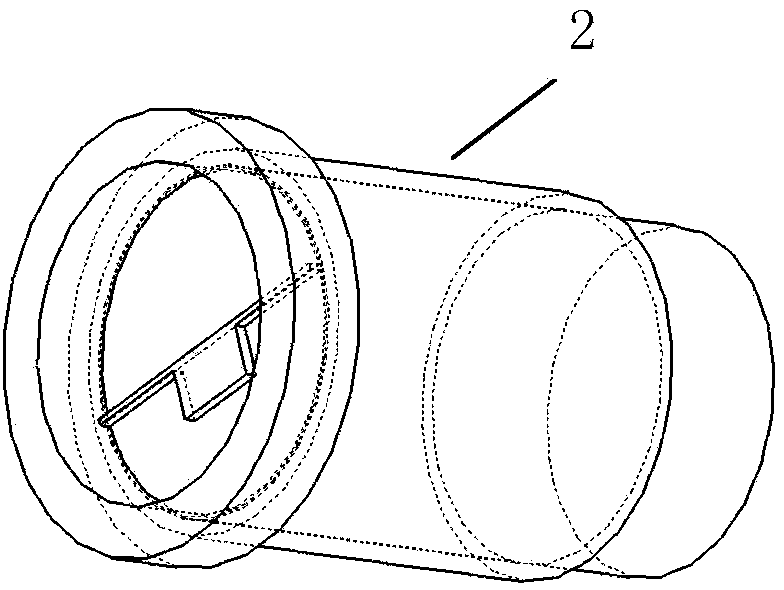

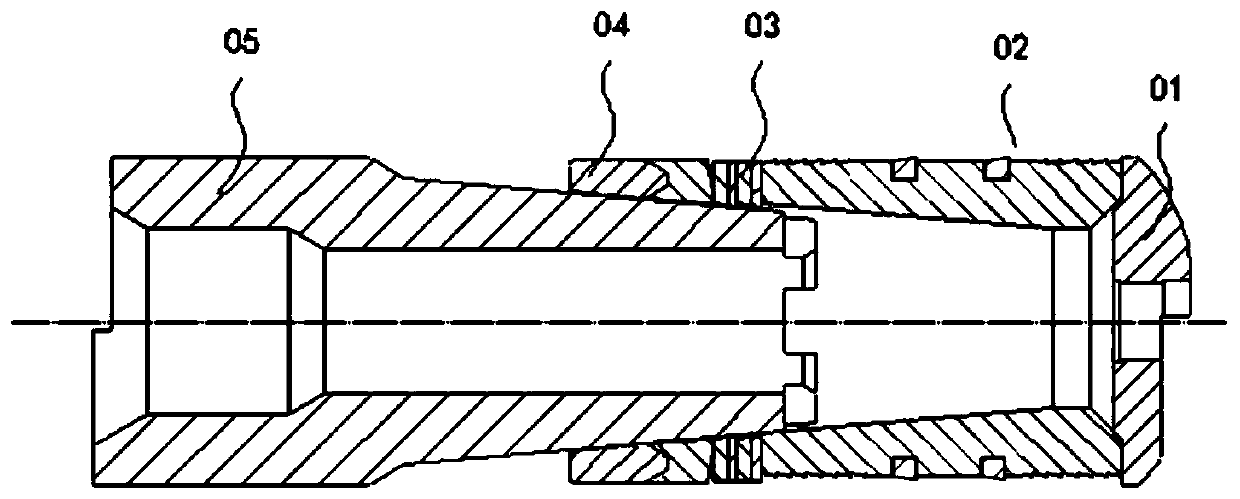

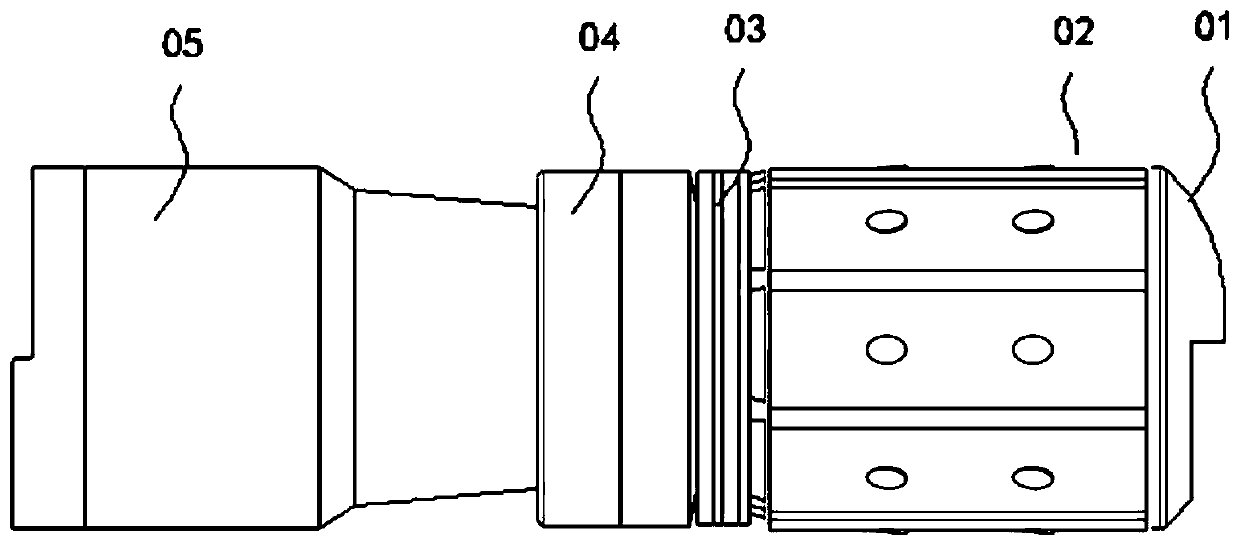

Encapsulation structure and encapsulation method for MEMS (micro-electromechanical system) variable optical attenuator

The invention relates to an encapsulation structure for an MEMS (micro-electromechanical system) variable optical attenuator. The encapsulation structure comprises a focusing lens, a tail fiber sleeve and an optical chip, wherein the optical chip is manufactured by adopting the MEMS, the tail fiber sleeve is fixedly arranged in a hollow cylindrical magnet through bonding glue for forming a magnetic assembly 1, one end of the focusing lens is a light signal incident surface, the other end of the focusing lens is provided with a light reflecting surface, the focusing lens is fixedly arranged in the other hollow cylindrical magnet through bonding agents, the optical chip is fixedly arranged on the end part, used for being sucked with the magnetic assembly 1, on the hollow cylindrical magnet through bonding agents, and a magnetic assembly 2 is formed; the magnetic assembly 1 and the magnetic assembly 2 which are in a mutual magnetic suction state and are reinforced through the bonding agents form a variable optical attenuator assembly, the optical attenuator assembly is arranged in a hollow external protecting sleeve, in addition, two ends of the external protecting sleeve are filled and encapsulated by bonding agents, and the variable optical attenuator is formed. The invention aims at providing the encapsulation structure and an encapsulation method for the MEMS with the advantages of miniaturization, low cost and high reliability.

Owner:苏州盛维新电子科技有限公司

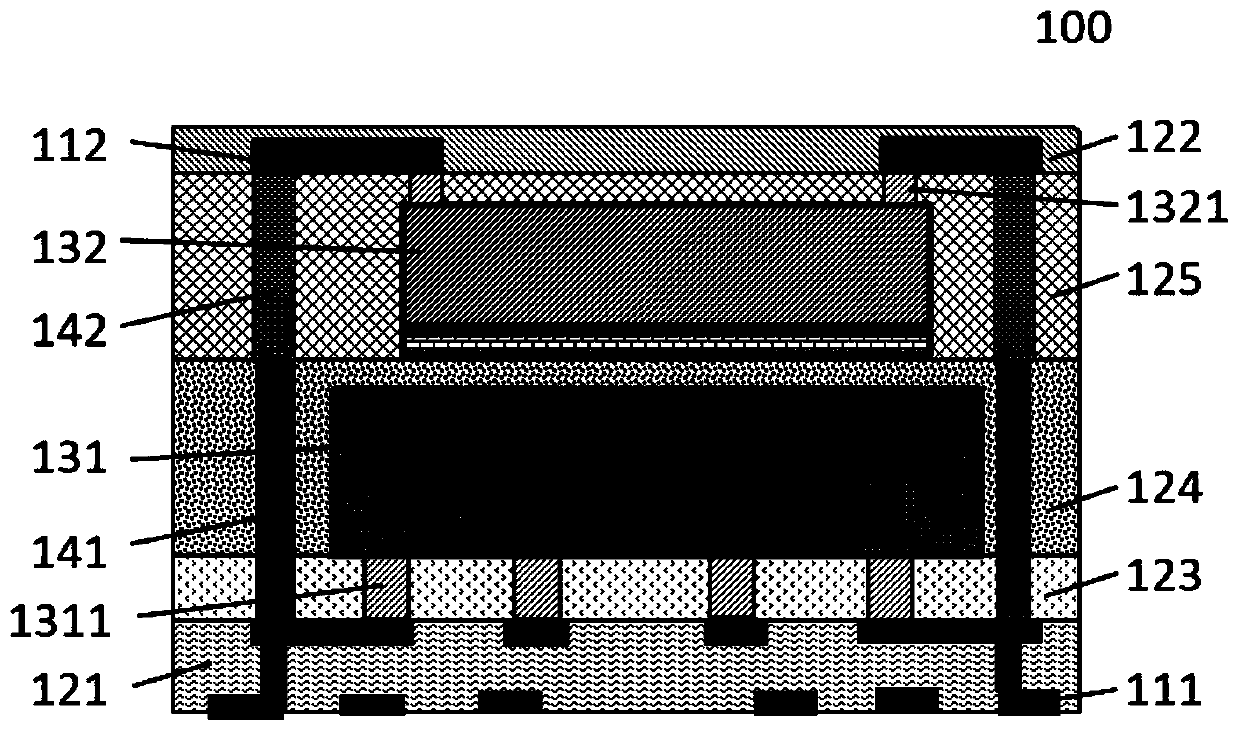

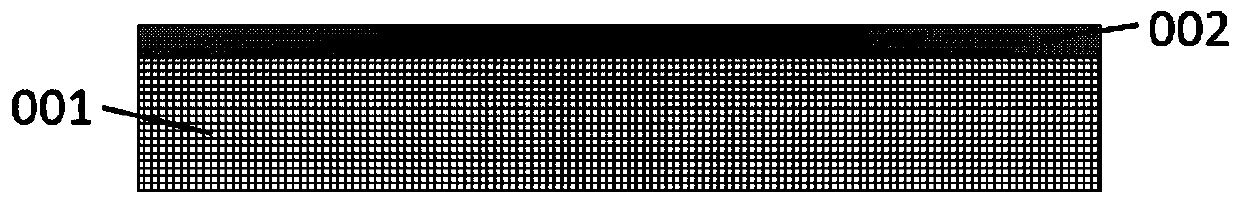

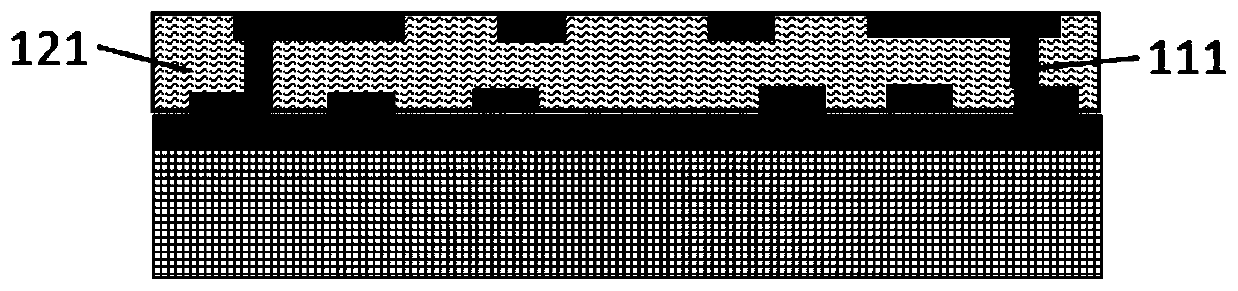

Stacked packaging structure and preparation method thereof

InactiveCN110970397AReliability impactSemiconductor/solid-state device detailsSolid-state devicesRedistribution layerElectrical connection

The invention discloses a stacked packaging structure, which comprises: a first chip, wherein the first chip is inversely attached to the first rewiring layer, and a welding pad of the first chip is provided with a bump; a bottom layer filling film covering the front surface of the first chip; a first conductive channel disposed around the first chip; a first plastic package layer wrapping the first chip and the upper part of the first conductive channel; the first rewiring layer which is formed on the back surface of the bottom layer filling film and is electrically connected to the first chip and the first conductive channel; a first dielectric layer covering the surface and a gap of the first rewiring layer; a second chip right attached to the surface of the first plastic package layer;a second conductive channel disposed around the second chip; a second plastic package layer wrapping the second chip and the second conductive channel; a second rewiring layer formed on the surface of the second plastic package layer and electrically connected to the second chip and the second conductive channel; and a second dielectric layer covering the surface and a gap of the second redistribution layer.

Owner:江苏中科智芯集成科技有限公司

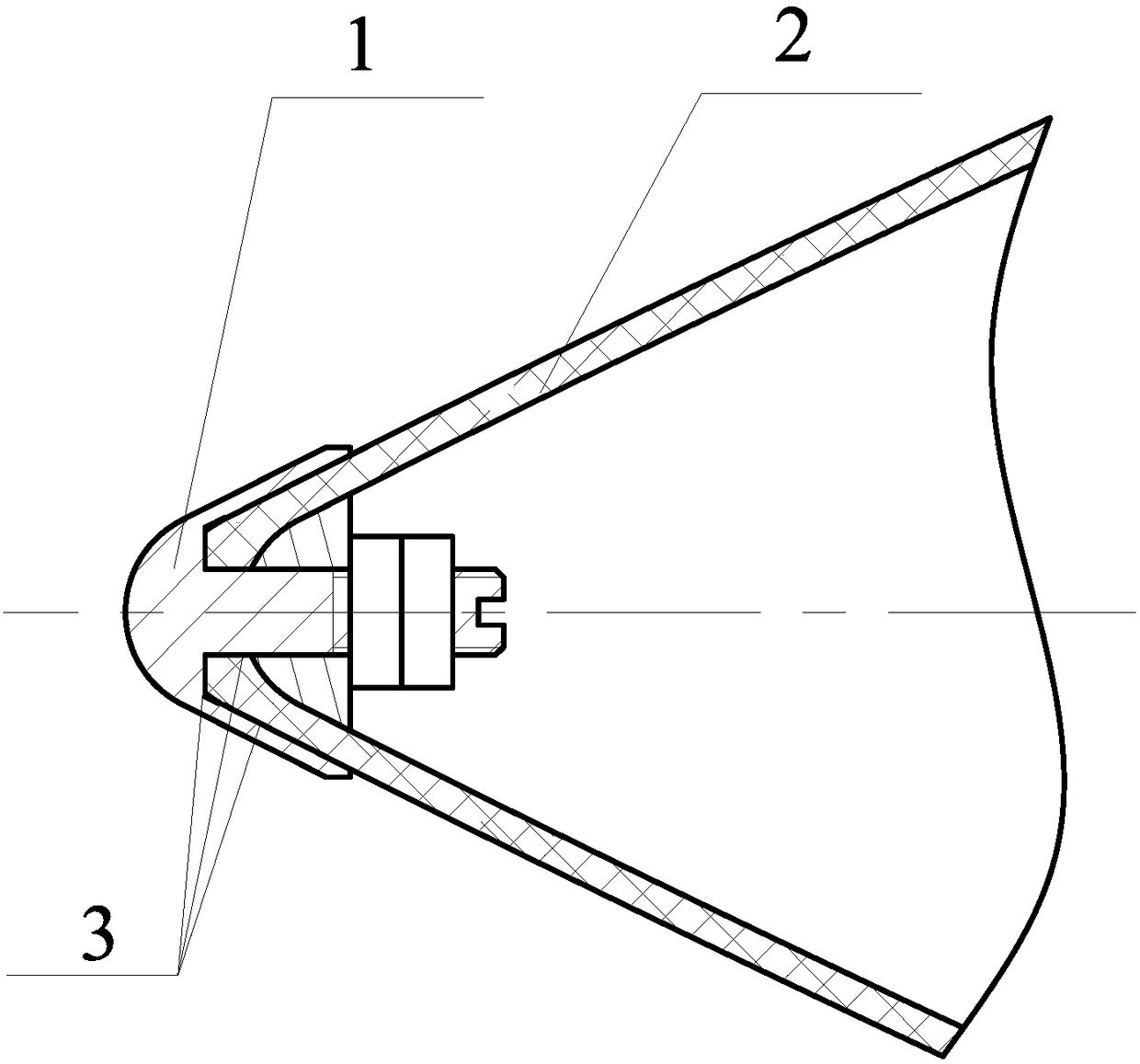

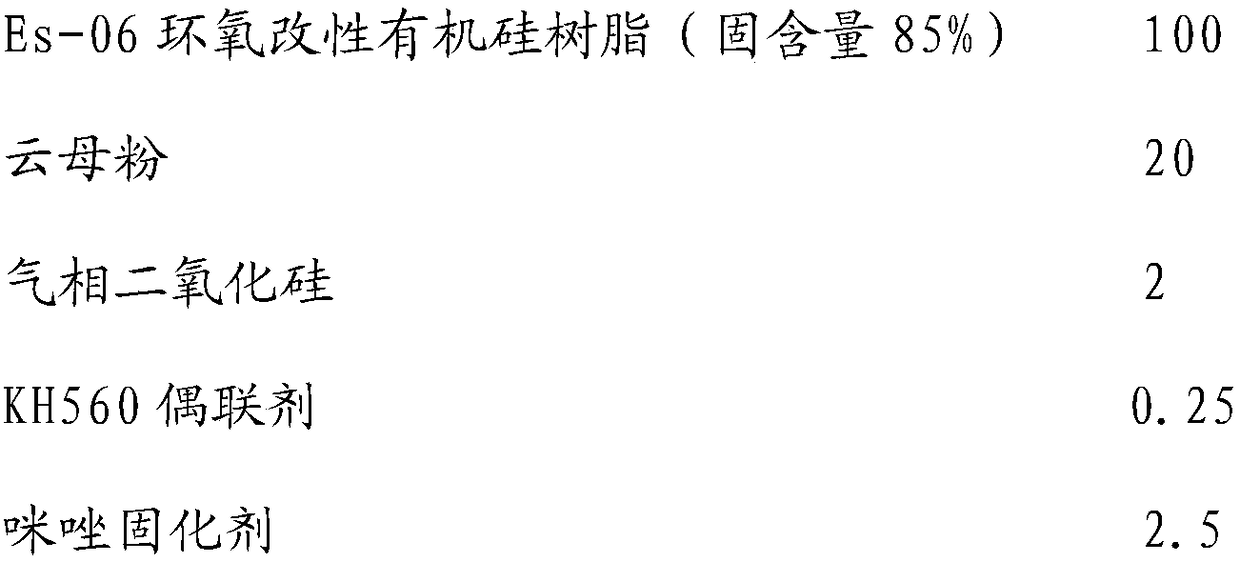

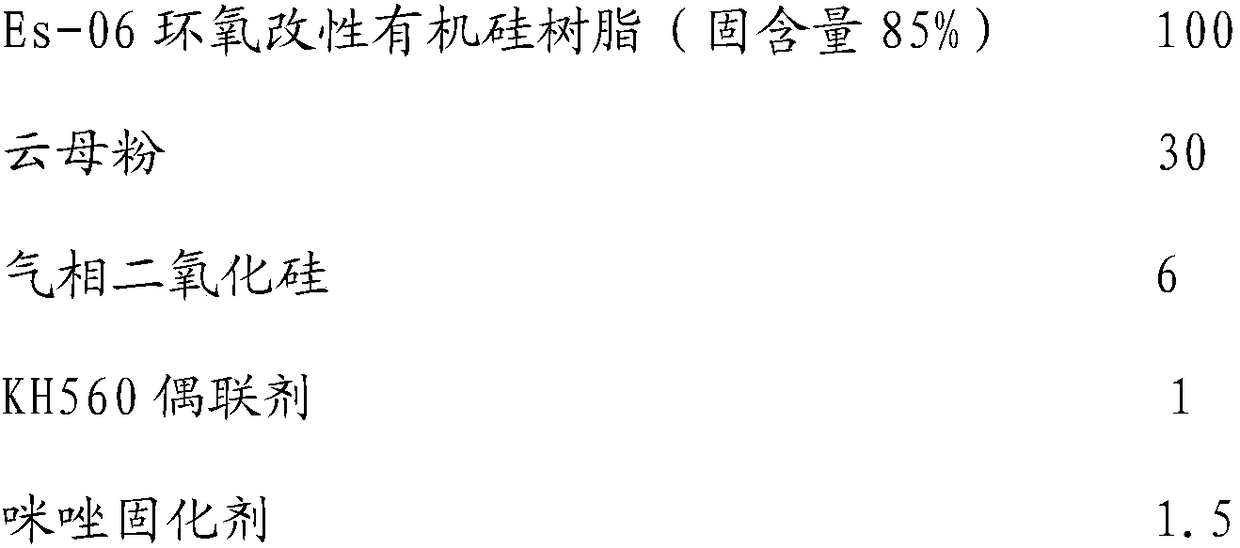

High-temperature-resistant and rainfall-erosion-resistant wave transmission antenna housing and preparation method thereof

ActiveCN108148548ASolve temperature resistanceAchieving adhesionNon-macromolecular adhesive additivesRadiating element housingsEpoxyAdhesive

The invention provides a high-temperature-resistant and rainfall-erosion-resistant wave transmission antenna housing and a preparation method thereof. The high-temperature-resistant and rainfall-erosion-resistant wave transmission antenna housing comprises an antenna housing body and a rainfall-erosion head, wherein the rainfall-erosion head is connected to the antenna housing body through a high-temperature-resistant wave transmission adhesive; the high-temperature-resistant wave transmission adhesive comprises epoxy-modified organic resin, mica powder, fumed silica, a silane coupling agent and an imidazole curing agent; the mica powder, the fumed silica, the silane coupling agent and the imidazole curing agent are sequentially added to the epoxy-modified organic resin. According to the high-temperature-resistant and rainfall-erosion-resistant wave transmission antenna housing, a special intermediate-temperature normal-pressure curing type high-temperature-resistant wave transmissionadhesive is adopted, so that the rainfall erosion head and the housing body can be adhered in high temperature environment; the temperature resistance and reliability of the rainfall erosion head andthe housing body in connection are ensured; and the influence of the mounted rainfall erosion head on the electric performance of a wideband antenna housing can be overcome.

Owner:AEROSPACE INST OF ADVANCED MATERIALS & PROCESSING TECH

Lightweight ball seat

PendingCN109944571AShorten the overall lengthImprove drilling efficiencyFluid removalWell/borehole valve arrangementsHardnessEngineering

The invention provides a lightweight ball seat. The seat comprises a lower joint, a slip, a sealing member and a central tube, the central tube is in a truncated cone shape, the sealing member and theslip sequentially sleeve the outer side of one end with a smaller outer diameter of the central tube in a direction in which the outer diameter of the central tube is reduced, one end of the sealingmember abuts the one end of the slip, and the end of the one end with a smaller outer diameter of the central tube is located in the slip; the end of the lower joint abuts the other end of the slip, and the lower joint is internally provided with a sealing tool connecting structure; the sealing member adopts a two-stage structure, and the hardness of the first-stage sealing member is smaller thanthe hardness of the second-stage sealing member. The ball seat is provided with the two-stage sealing member, and improves the reliability of the sealing during work, the design of the ball seat is compact and short, the material is a lightweight magnesium-lithium alloy material, the drilling efficiency is improved, after the work is finished, it is easy to return out, and the risk of clogging a wellbore is eliminated.

Owner:VERTECHS OIL & GAS TECH CO LTD

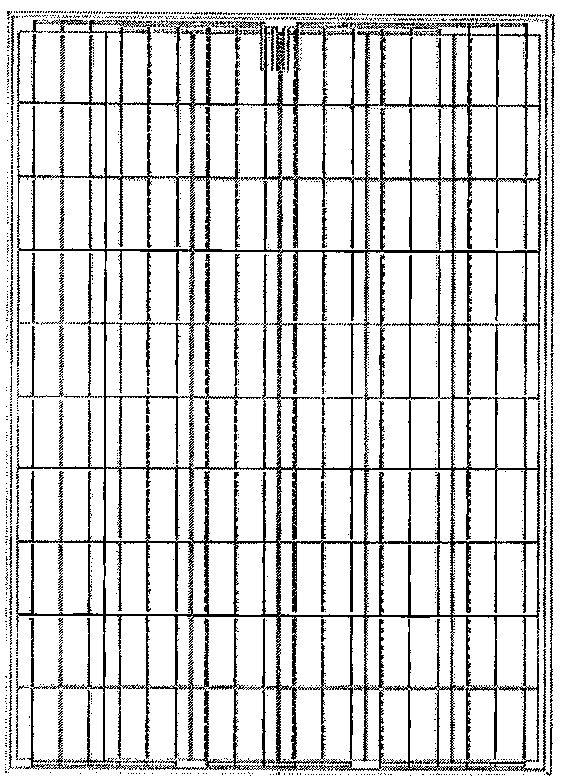

Anti-dirt dustproof transparence-enhancing solar photovoltaic module and manufacturing method thereof

InactiveCN103474495AEasy to processStrong anti-dirty abilityFinal product manufactureGlass/slag layered productsHeat stabilityMolecular materials

The invention discloses an anti-dirt dustproof transparence-enhancing solar photovoltaic module. A manufacturing method of the anti-dirt dustproof transparence-enhancing solar photovoltaic module comprises the steps that the common processes of single welding, series welding, stacking, lamination and the like are conducted on the module, fluorocarbon resin is compounded on a stacked coated glass coating layer, and the fluorocarbon resin is a C-F high molecular material which has the anti-dirt dustproof transparence-enhancing function and meanwhile good in high-temperature resistance and heat stability.

Owner:HANWHA SOLARONE QIDONG

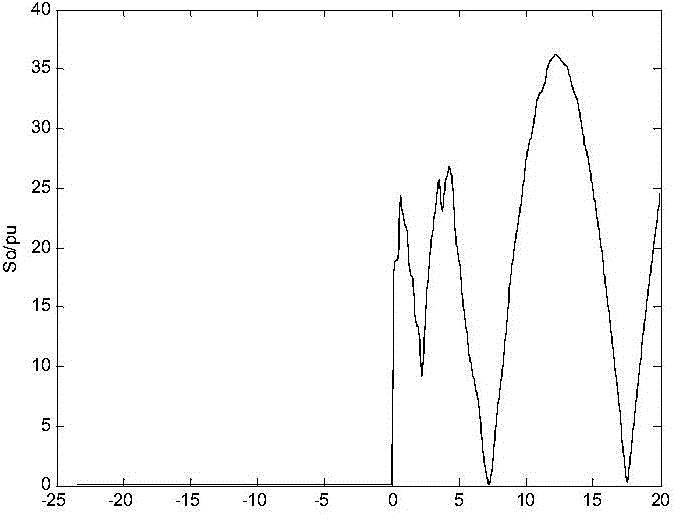

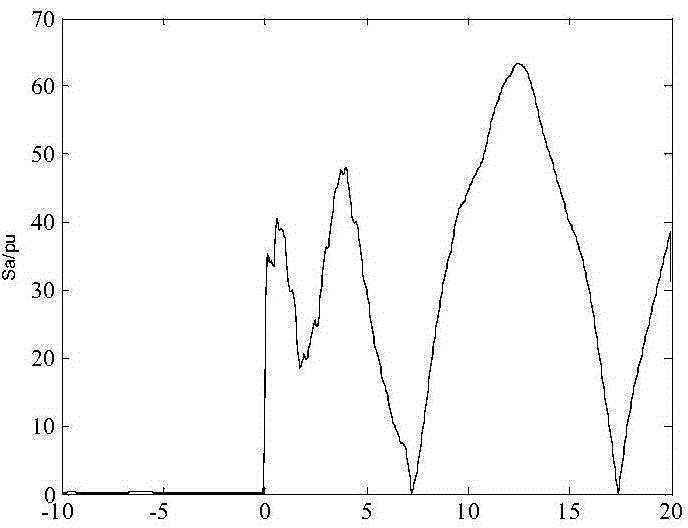

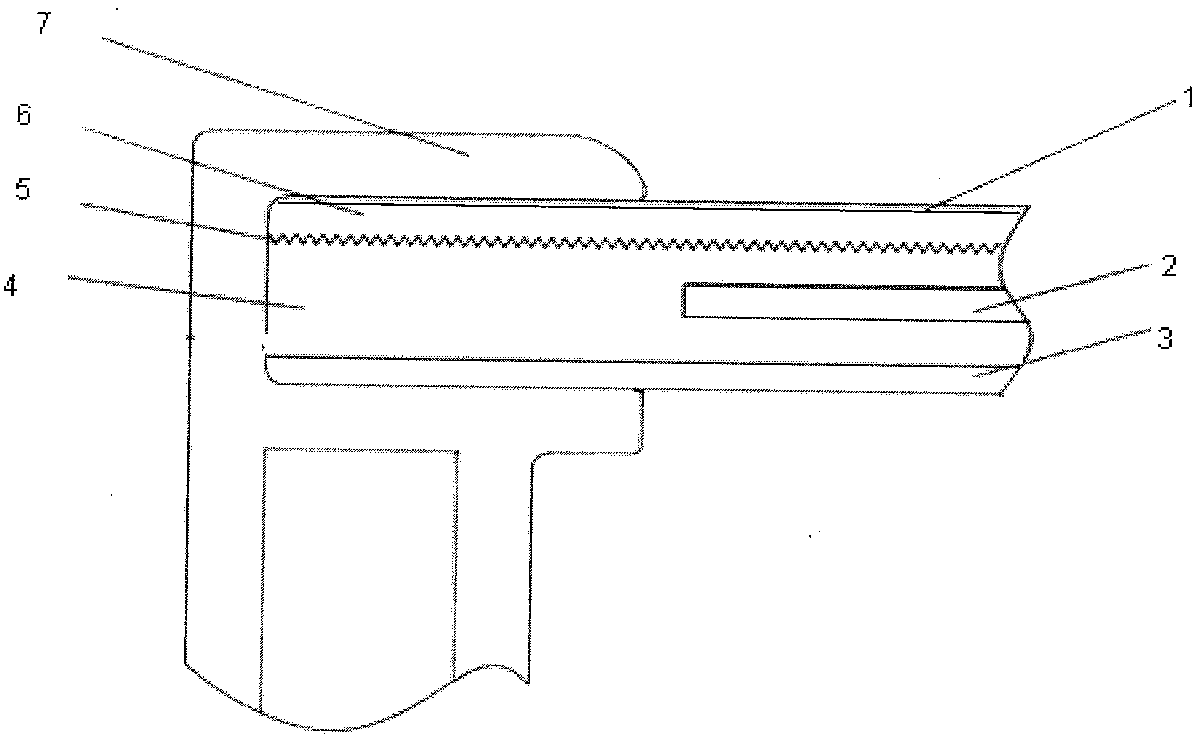

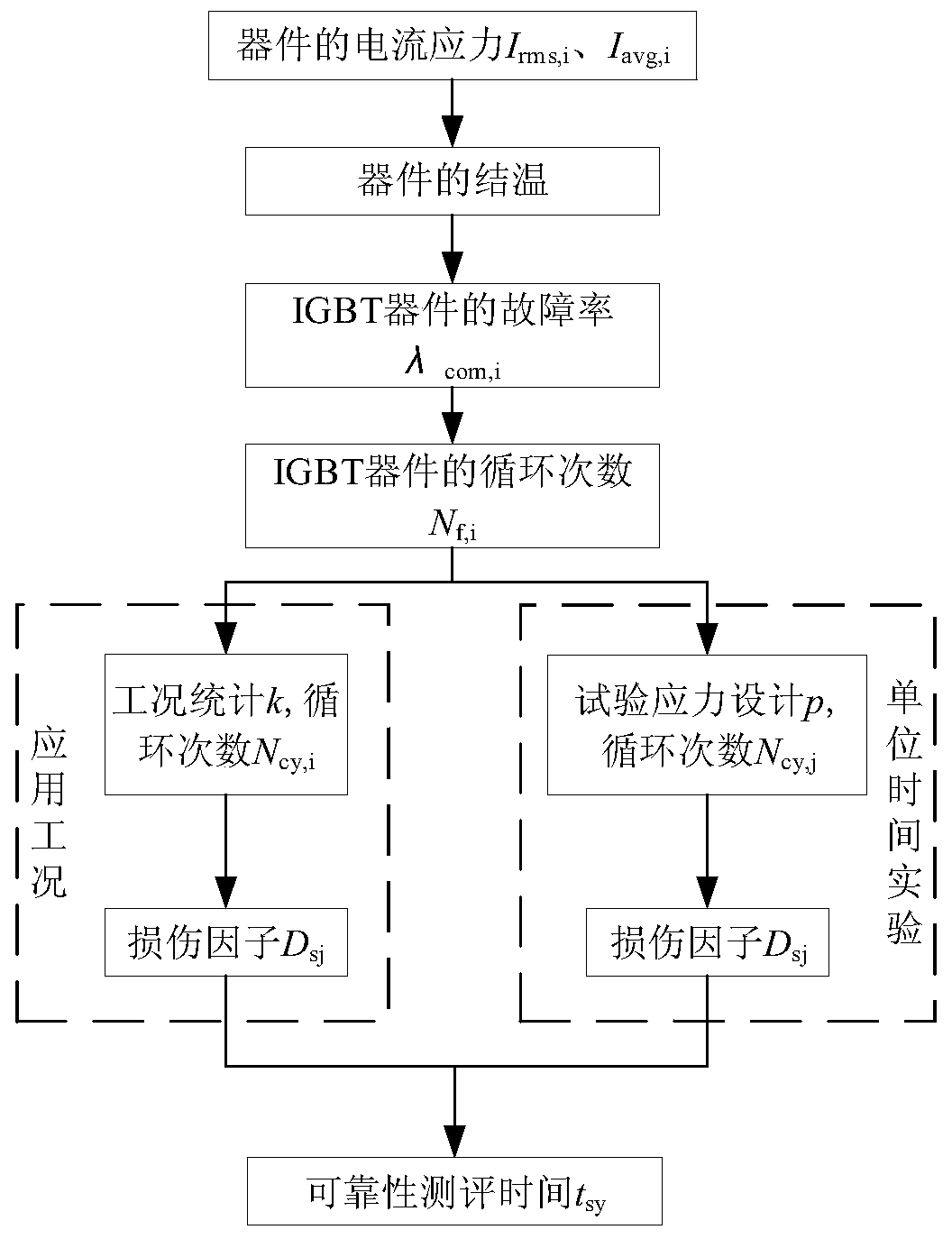

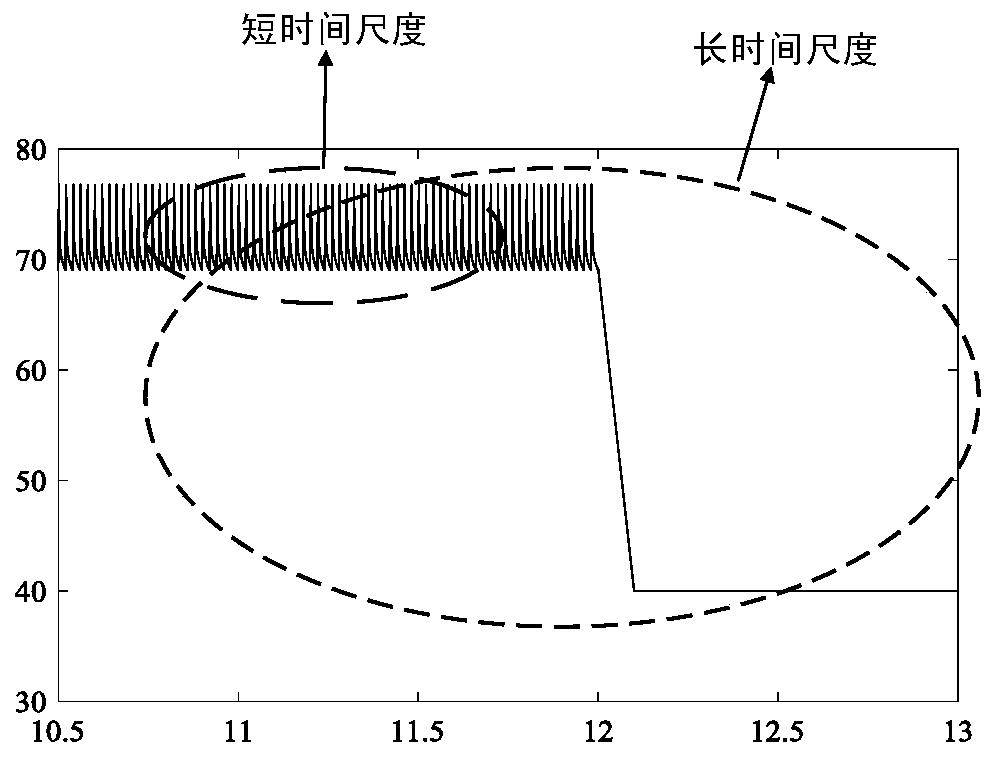

IGBT device power cycle evaluation method based on application condition of MMC converter valve

ActiveCN110133464AImprove accuracyReliability impactIndividual semiconductor device testingFailure ratePower cycle

The invention relates to an IGBT device power cycle evaluation method based on the application condition of an MMC converter valve, and belongs to the technical field of high-voltage direct current transmission. The method comprises the following steps: firstly, obtaining conduction loss and switching loss of a device based on a loss model of IGBT and a diode, and extracting average junction temperature and junction temperature fluctuation amplitude of the IGBT device and the diode according to a thermal network model of the IGBT device; secondly, considering the running condition of the MMC converter valve, providing a device failure rate calculation model, and acquiring the failure rate and the cycle times of the device; and finally, performing reliability evaluation modeling on the IGBTdevice based on a Miner rule and an equal damage rule, and acquiring a change rule of the reliability index of the IGBT device under different additional test conditions to form a reliability evaluation scheme. According to the invention, the IGBT device reliability evaluation method is formed, and has important significance for accurately evaluating the reliability of the IGBT device for the MMCconverter valve.

Owner:CHONGQING UNIV

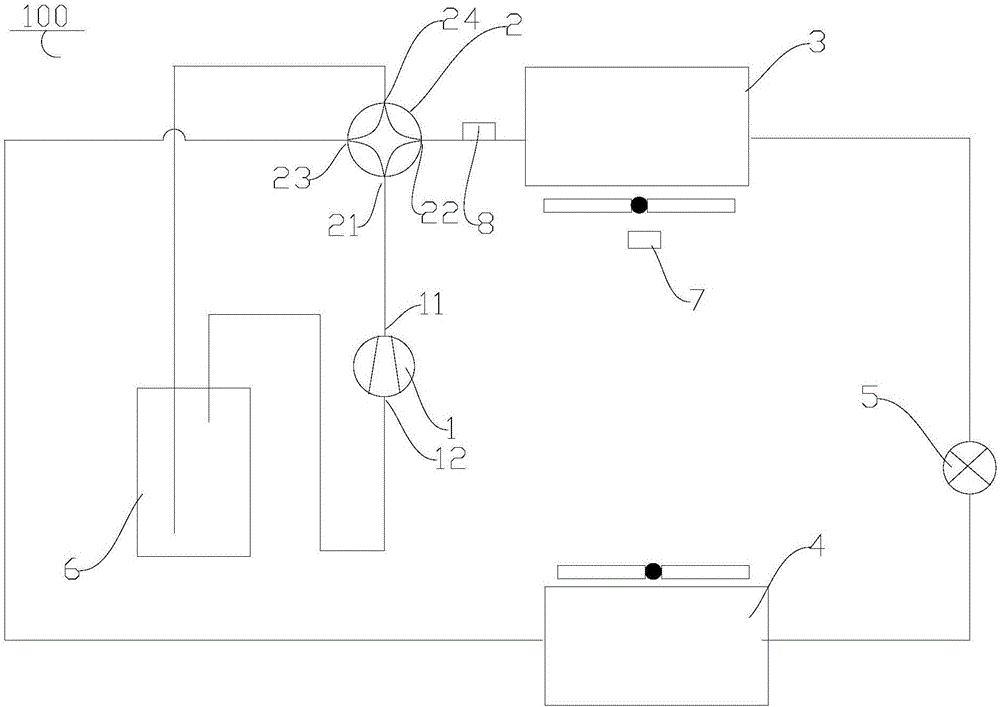

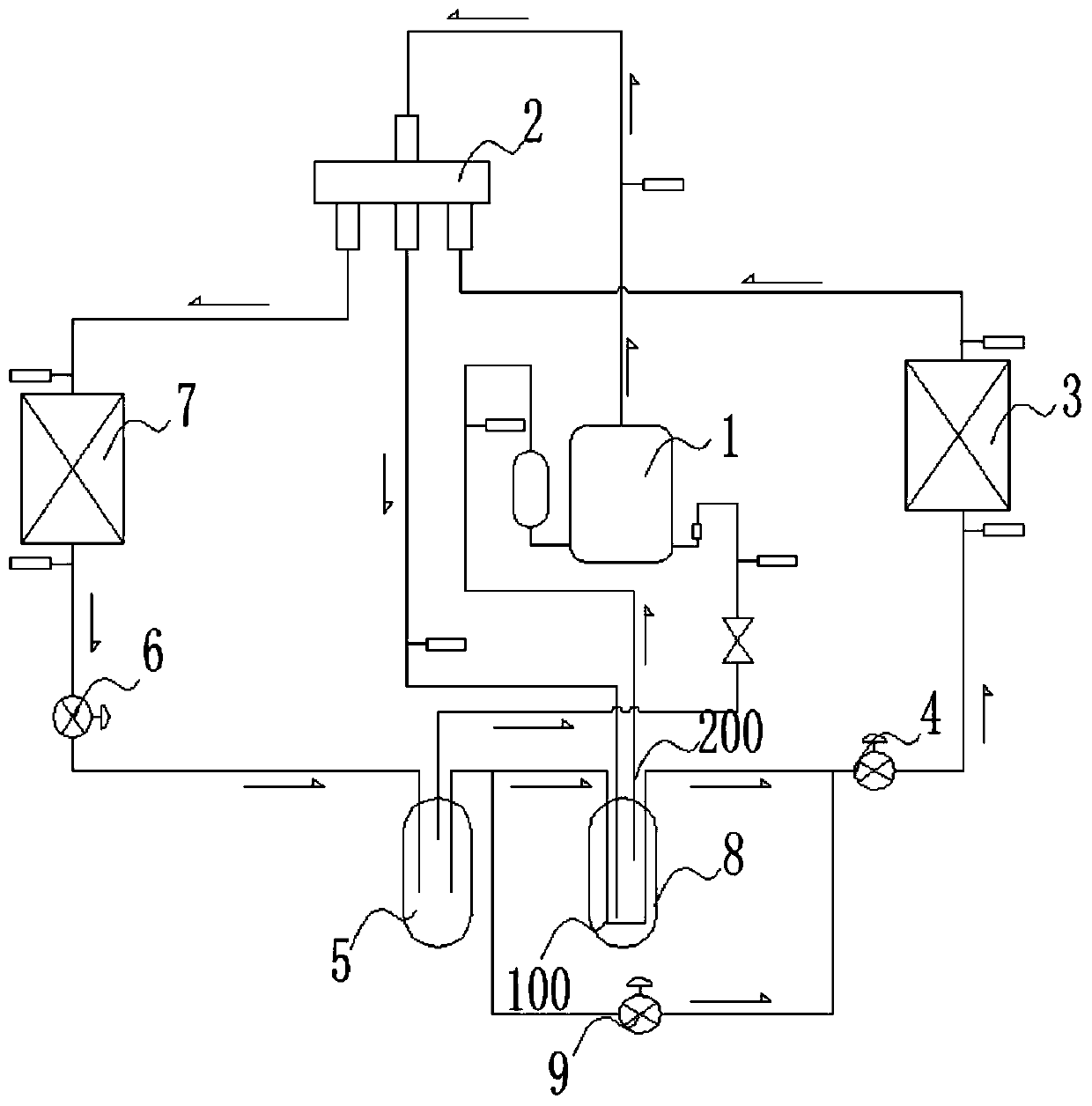

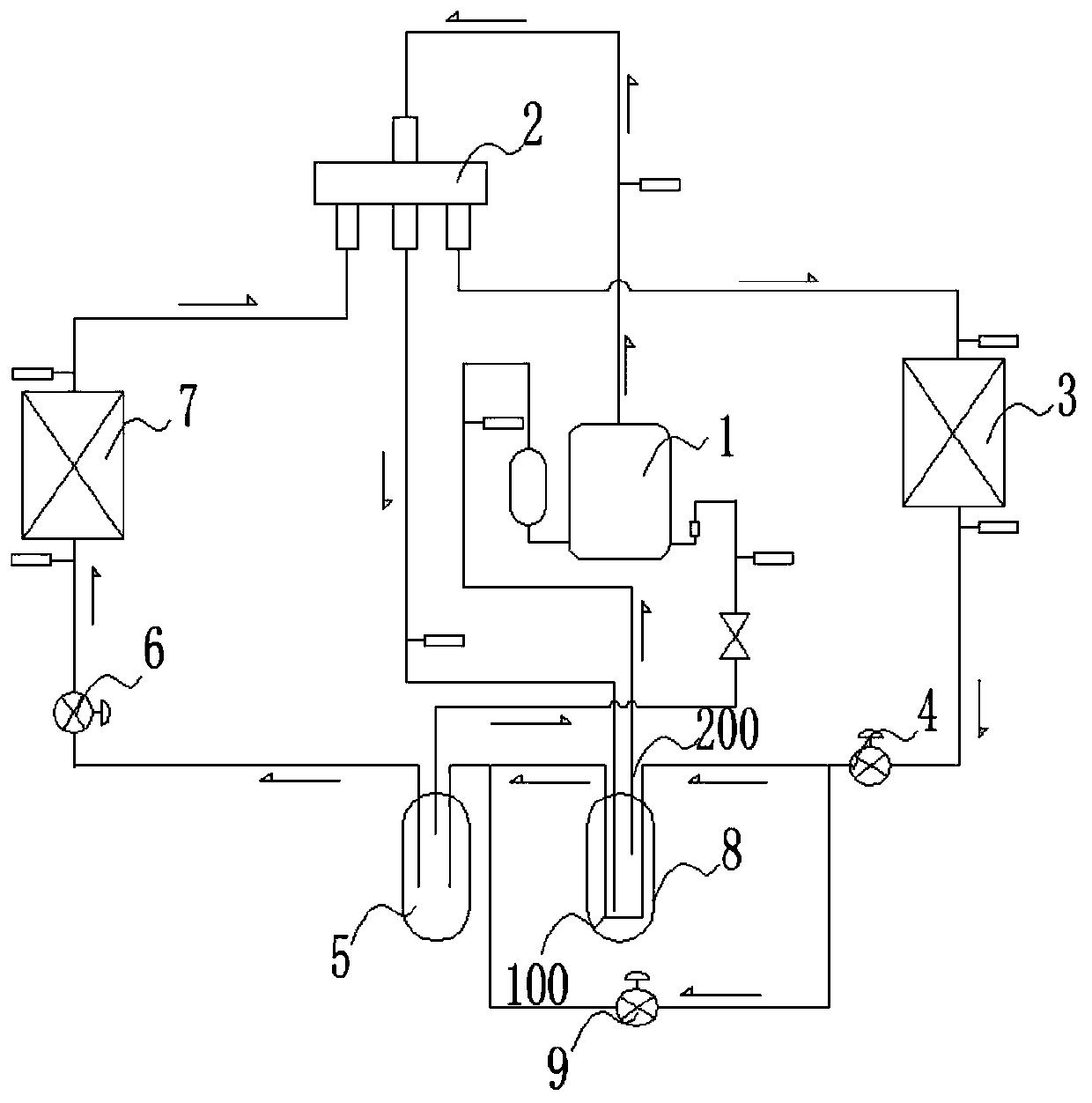

Heat pump system, gas suction overheating degree control method, and gas-liquid separator accumulated-liquid evaporation control method

ActiveCN109869941AImprove performanceAvoid frostMechanical apparatusFluid circulation arrangementVapor–liquid separatorEvaporation

The invention provides a heat pump system, a gas suction overheating degree control method, and a gas-liquid separator accumulated-liquid evaporation control method. The heat pump system comprises a compressor, a reversing element, an outdoor heat exchanger, a first throttle element, a flash evaporator, a second throttle element, an indoor heat exchanger and a gas-liquid separator which are connected through pipelines to form a gas supply and enthalpy-increasing air conditioning cycle, and the first pipeline between the first throttle element and the flash evaporator is located in the gas-liquid separator so as to transfer heat of a refrigerant in the first pipeline to a gas outlet pipe of the gas-liquid separator. According to the heat pump system, the gas suction overheating degree control method, and the gas-liquid separator accumulated-liquid evaporation control method, the gas exhaust temperature of the compressor is decreased while the gas suction regenerative overheating degreeof the compressor is increased, and the operation reliability of the compressor is ensured while the performance of the heat pump system is improved.

Owner:GREE ELECTRIC APPLIANCES INC

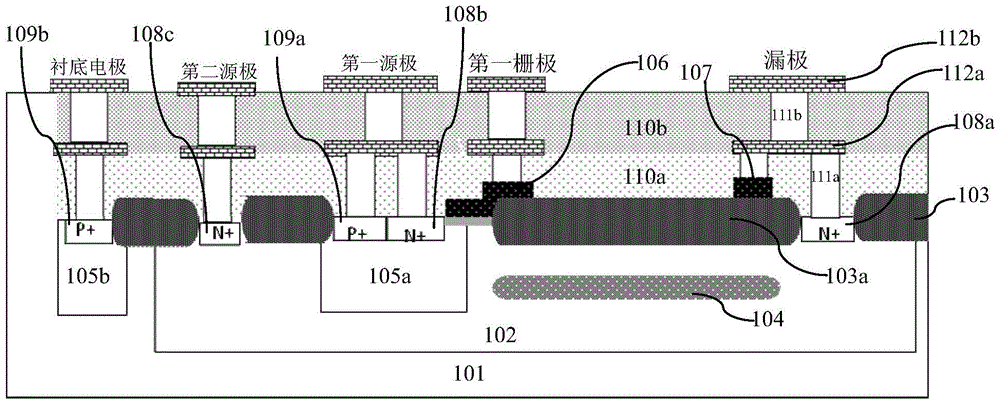

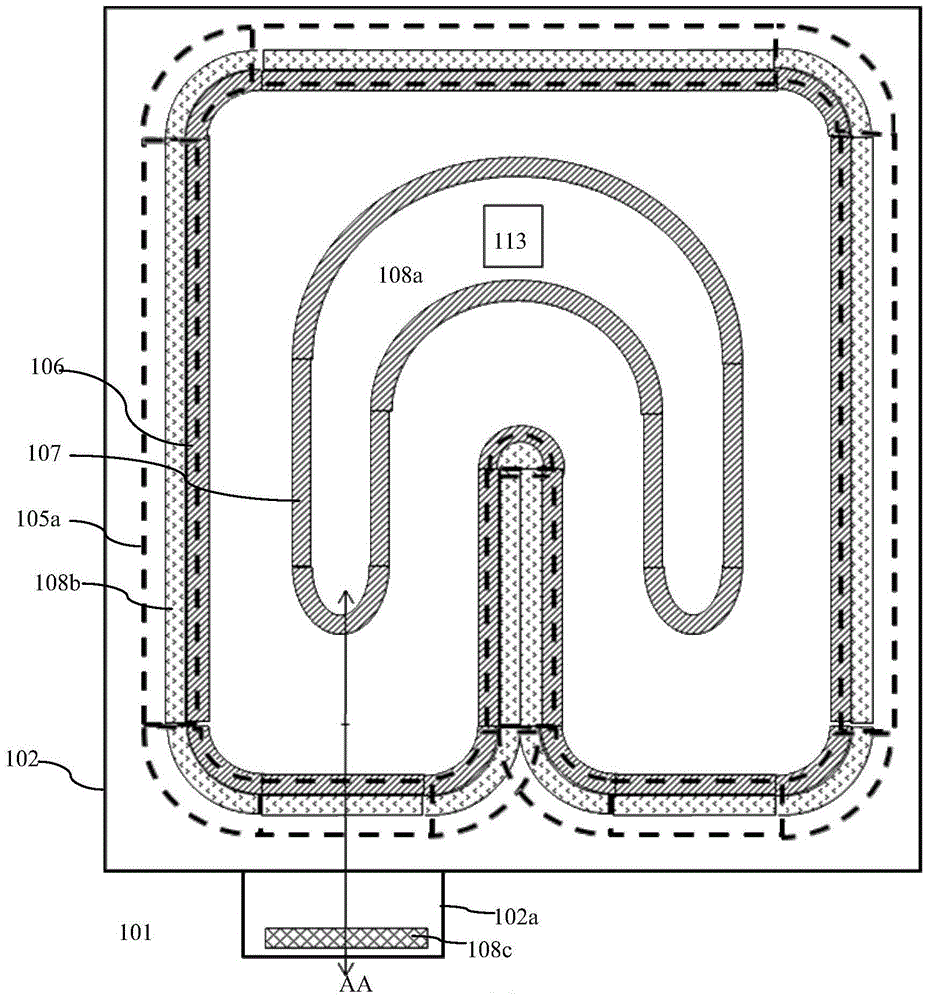

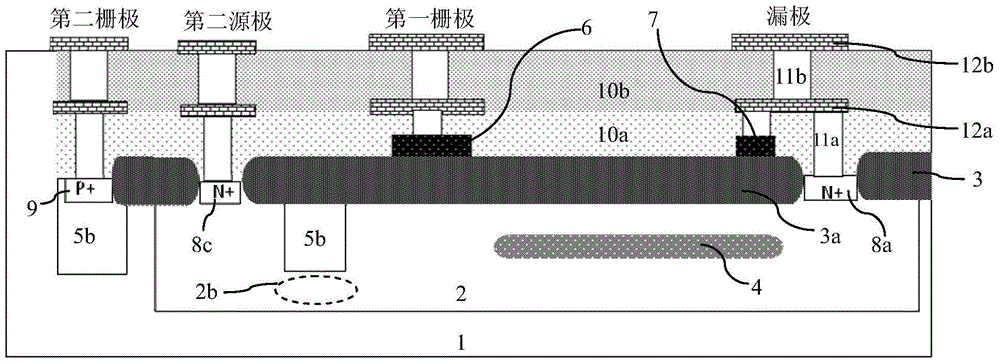

An integrated structure of an LDMOS and a JFET and a manufacturing method thereof

ActiveCN105702678AImprove pressure resistanceAchieve high withstand voltageSolid-state devicesSemiconductor/solid-state device manufacturingLDMOSJFET

The invention discloses an integrated structure of an LDMOS and a JFET and a manufacturing method thereof. The JFET uses a drift region and a drain region, which are also the drift region and the drain region of the LDMOS. A first polysilicon layer is connected in an end to end mode to form a closed first polysilicon encircling structure. A source region and a channel region of the LDMOS respectively circle around the outer side of the first polysilicon layer to form a source region encircling structure with an opening. A gate electrode region and a source region of the JFET form in a deep N-well outside an opening position, so that a gate electrode region of the JFET and the channel region of the LDMOS are separated. The invention also discloses a manufacturing method for the integrated structure of the LDMOS and the JFET. According to the invention, high-voltage resistance of the JFET can be realized; meanwhile, the reliability of the LDMOS device can be raised; and relatively low cost is realized.

Owner:SHANGHAI HUAHONG GRACE SEMICON MFG CORP

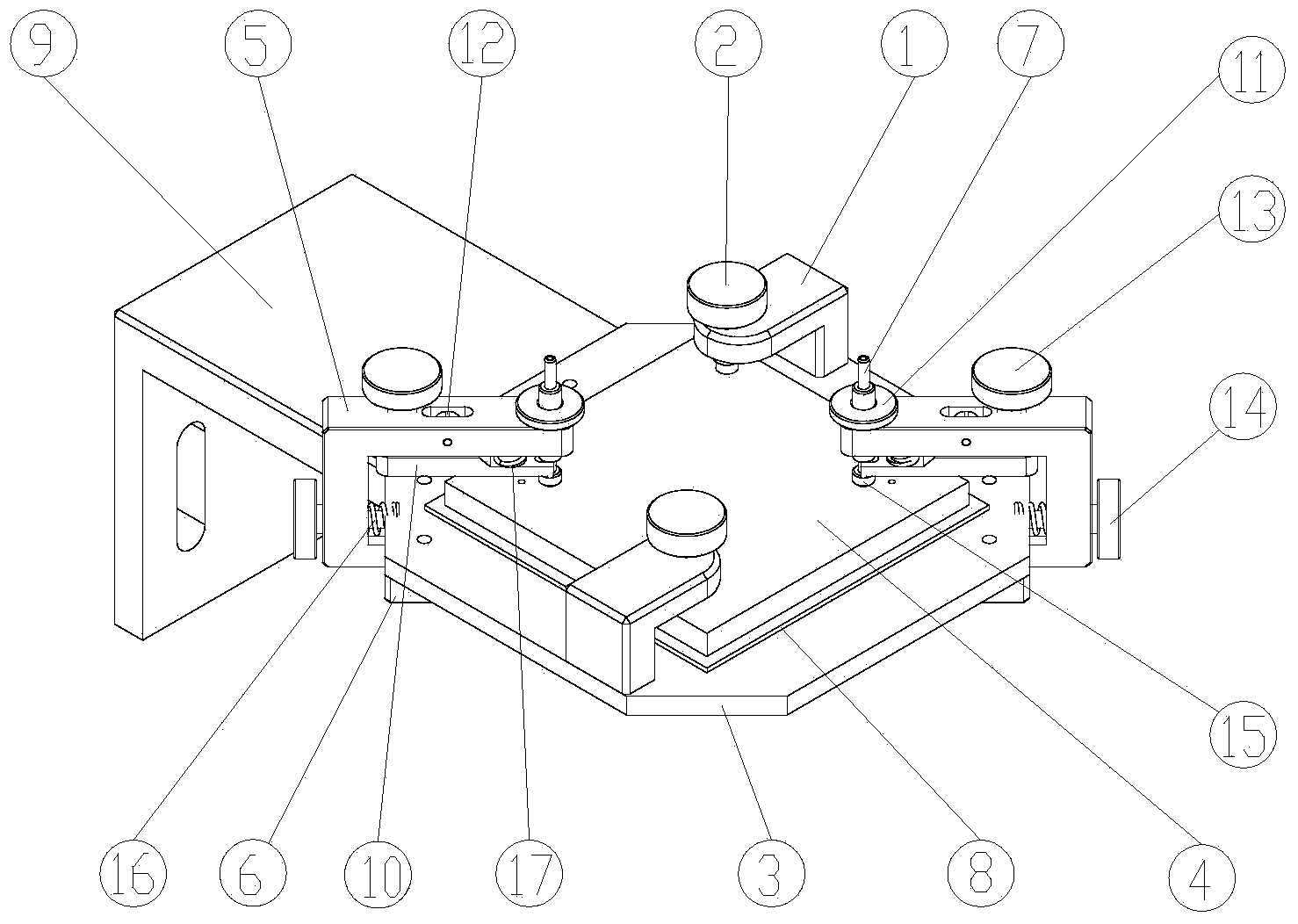

Sheet clamp

ActiveCN103921229AReliability impactAccurate analysisWork holdersPermeability/surface area analysisImaging analysisEngineering

The invention discloses a sheet clamp which comprises a clamp substrate and a clamp supporting frame. The clamp substrate is arranged on the clamp supporting frame. The sheet clamp is further composed of two holders arranged on the clamp substrate. The two holders are respectively provided with a detachable liquid connector, the clamp substrate is provided with multiple glass pressing bases, and the glass pressing bases are provided with glass pressing screws. The detachable liquid connectors arranged on the holders can be replaced according to different displacing fluid, influences of residual liquid on reliability of displacement experiment data are prevented, meanwhile, a glass sheet is fixed through the glass pressing bases and the glass pressing screws arranged on the glass pressing bases so that the situation that images collected at different displacement time periods move and rotate substantially due to the fact that the sheet moves when a displacing fluid guide pipe is replaced can be avoided, and accordingly later image analysis can be more accurate.

Owner:CHENGDU WESTIMAGE TECH

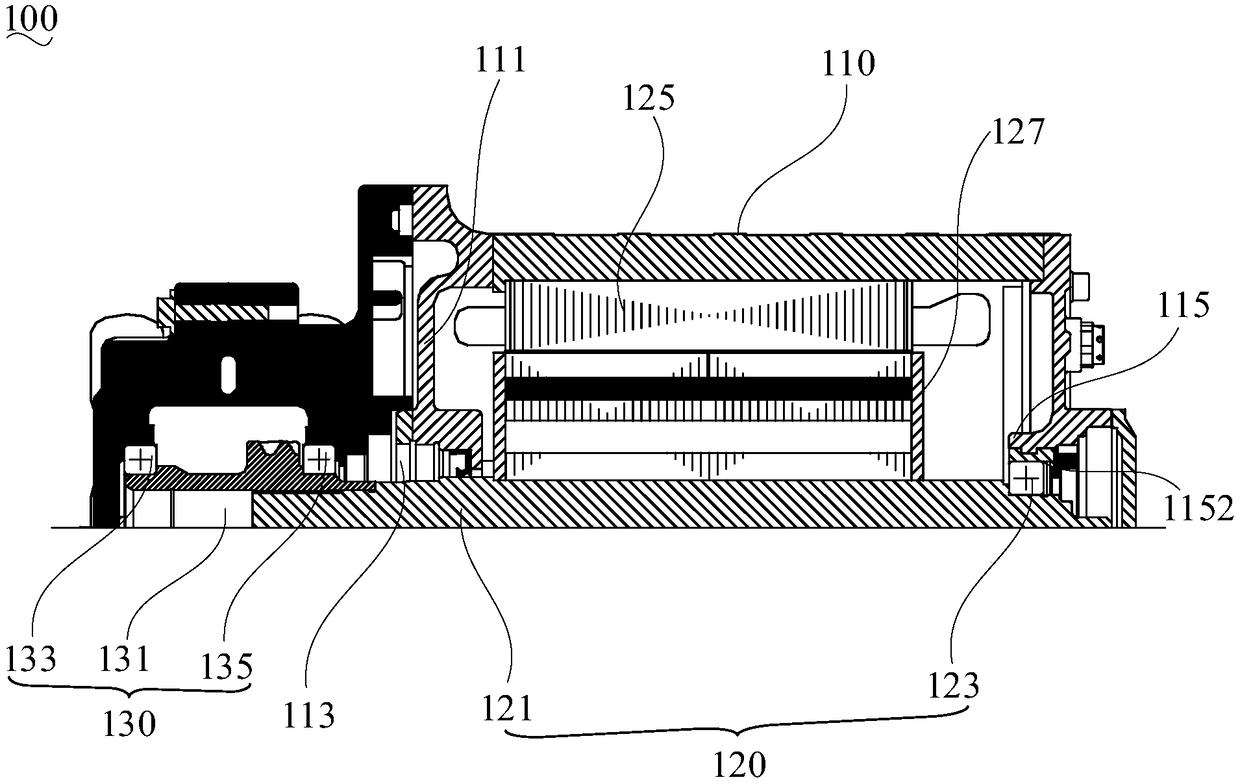

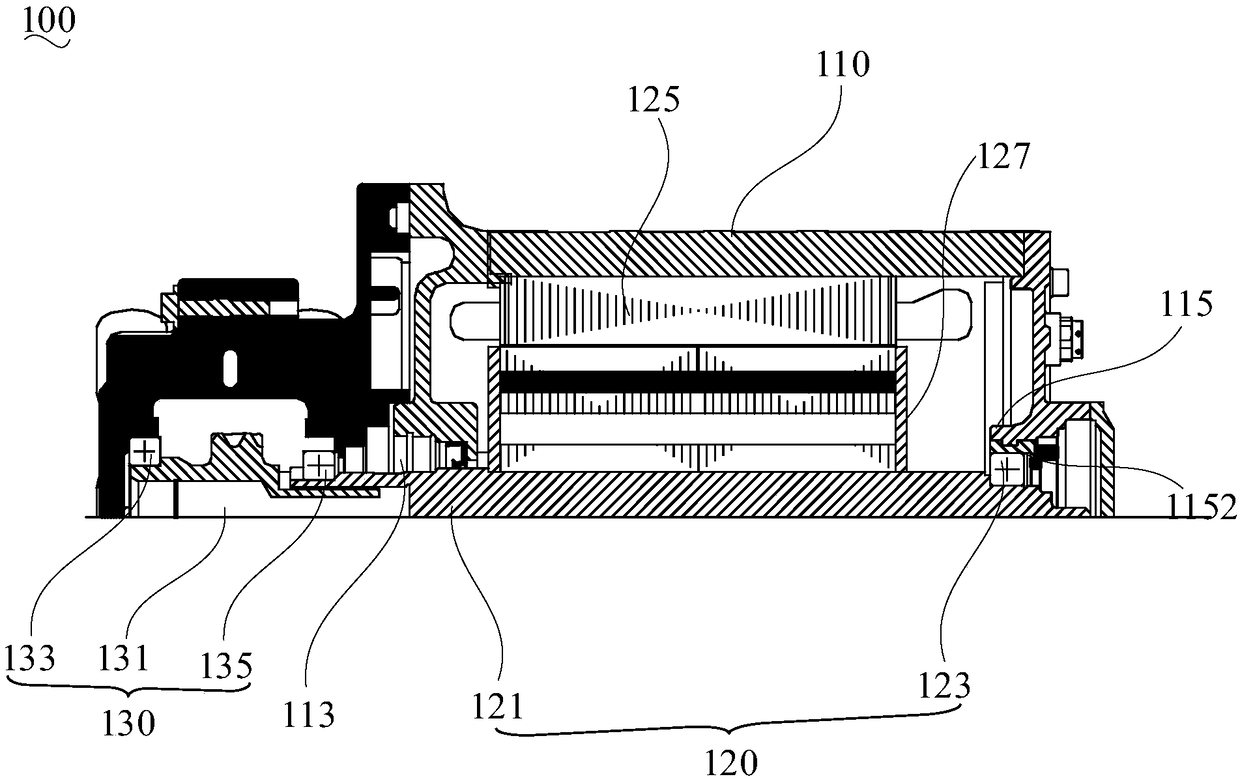

Electric vehicles and - integrated powertrain thereof

PendingCN108944394AReduce the number of bearingsSimple structureElectric propulsion mountingControl devicesElectric vehiclePowertrain

The invention relates to an electric vehicle and an integrated powertrain thereof, wherein an end of an output shaft of a motor away from an output bearing is not mounted on an inner wall of a motor cavity through a bearing, so that the number of bearings can be reduced compared with the powertrain in the prior art, thereby simplifying a structure and reducing a cost. In addition, one end of the motor output shaft extends into the reducer chamber and is splined with the reducer input shaft. In one aspect, since the second input bearing is proximate to the motor output shaft, the second input bearing may provide support to the motor output shaft while supporting the reducer input shaft. On the other hand, since the motor output shaft and the reducer input shaft are splined to transmit torque, and the splined connection has a strong radial limiting effect, the motor output shaft and the reducer input shaft can also support each other. Therefore, the reliability of the transmission process will not be affected. It can be seen that the electric vehicle and the integrated powertrain thereof not only reduce the cost, but also take into account the higher reliability.

Owner:ZHUZHOU GEAR CO LTD

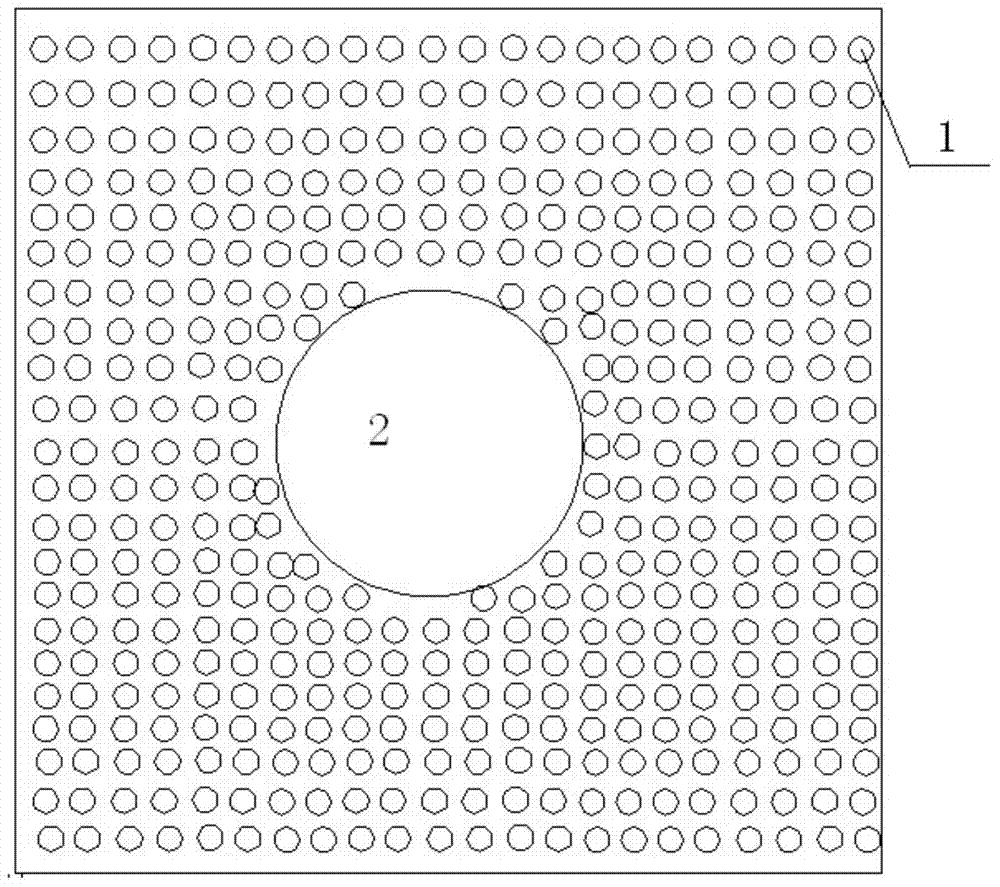

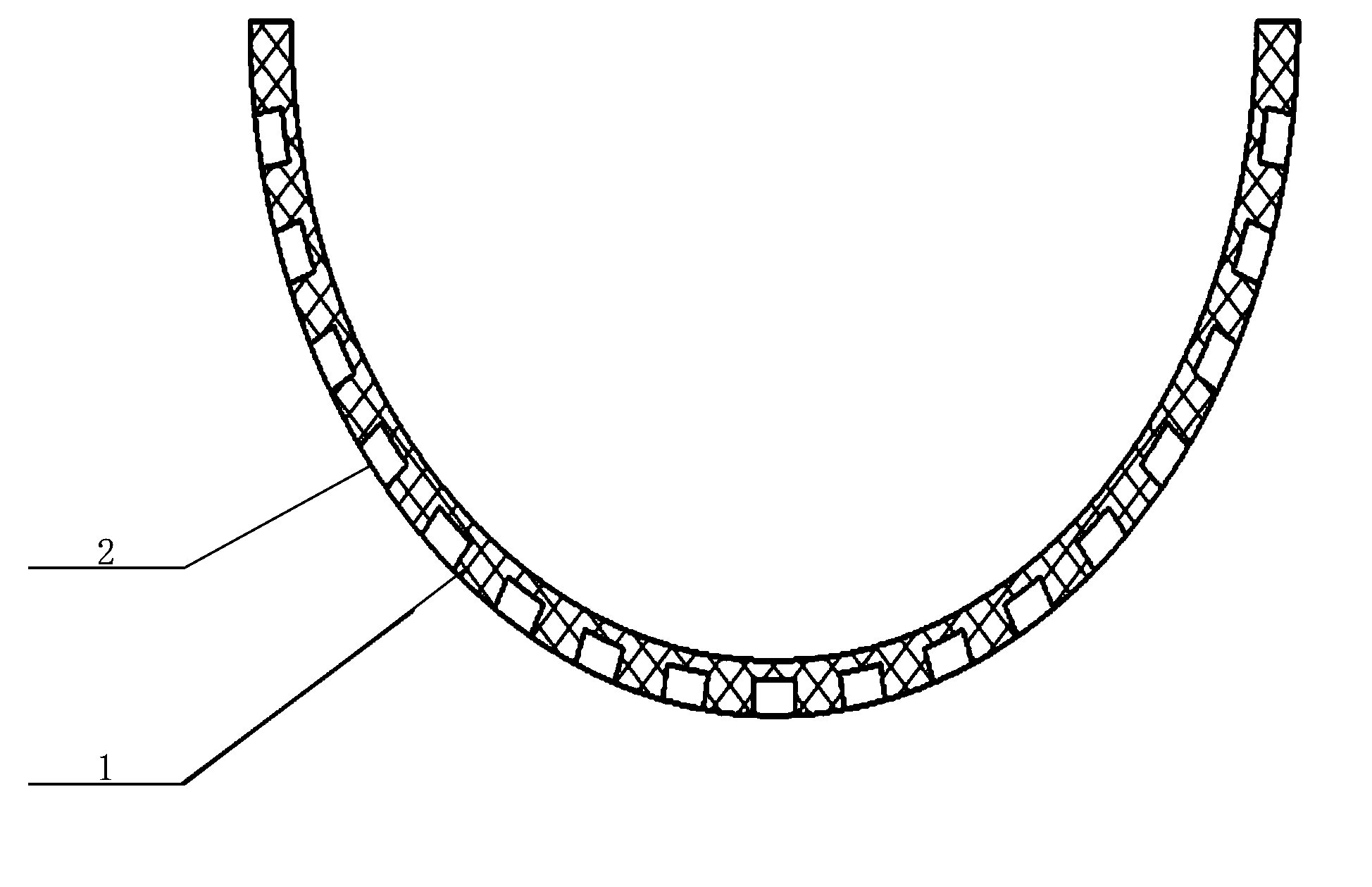

Damping sleeve for metal pipe vibration and noise reduction and coating method

InactiveCN103411089AIncrease the damping areaMeet different application environmentsSpringsPipe elementsRubber materialEngineering

The invention discloses a damping sleeve for metal pipe vibration and noise reduction and a coating method. The damping sleeve (1) with the thickness of T is in a more-than-one-half cylinder shape and made of rubber materials. A plurality of cavity holes (2) are formed in the outer surface of the damping sleeve (1). Redundant parts of the two damping sleeves (1) are cut off in the 45-degree direction of the axis to enable the two damping sleeves (1) to define a whole circle and form a pairing damping sleeve. The inner wall of the paring damping sleeve and the outer wall of a metal pipe are evenly painted with glue, the pairing damping sleeve coats the outer wall of the metal pipe, joint closing is carried out on the pairing damping sleeve in the 45-degree included angle direction, then the pairing damping sleeve is wound and tightly tied up through woven belts, and the woven belts are removed after the glue is completely solidified. The thick pairing damping sleeve coats the metal pipe, the impedance sudden change is formed between the metal pipe and the pairing damping sleeve, therefore, vibration energy can be absorbed through the cavity holes in the pairing damping sleeve when vibration is generated on the metal pipe, and the vibration noise of the metal pipe is reduced.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

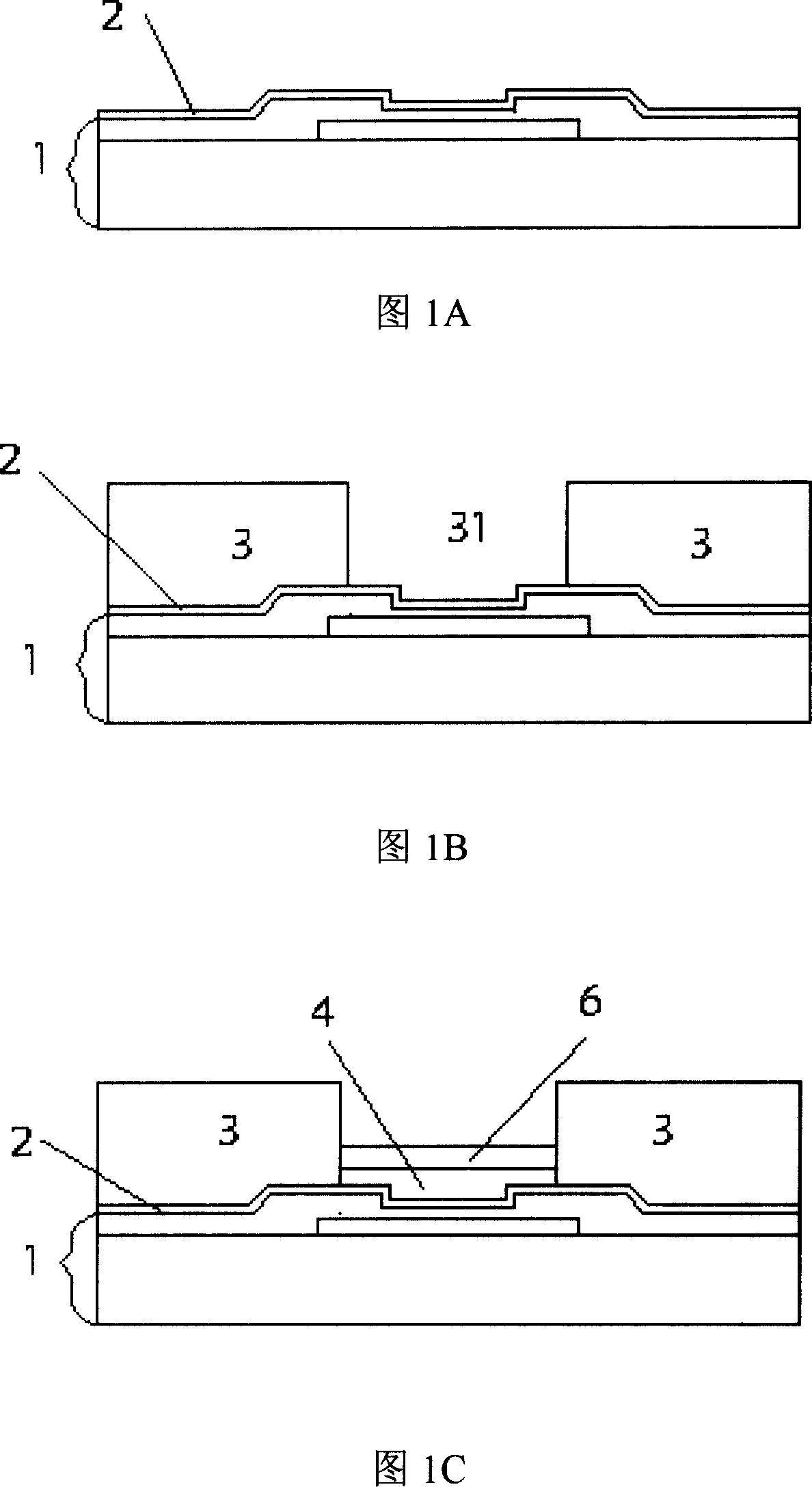

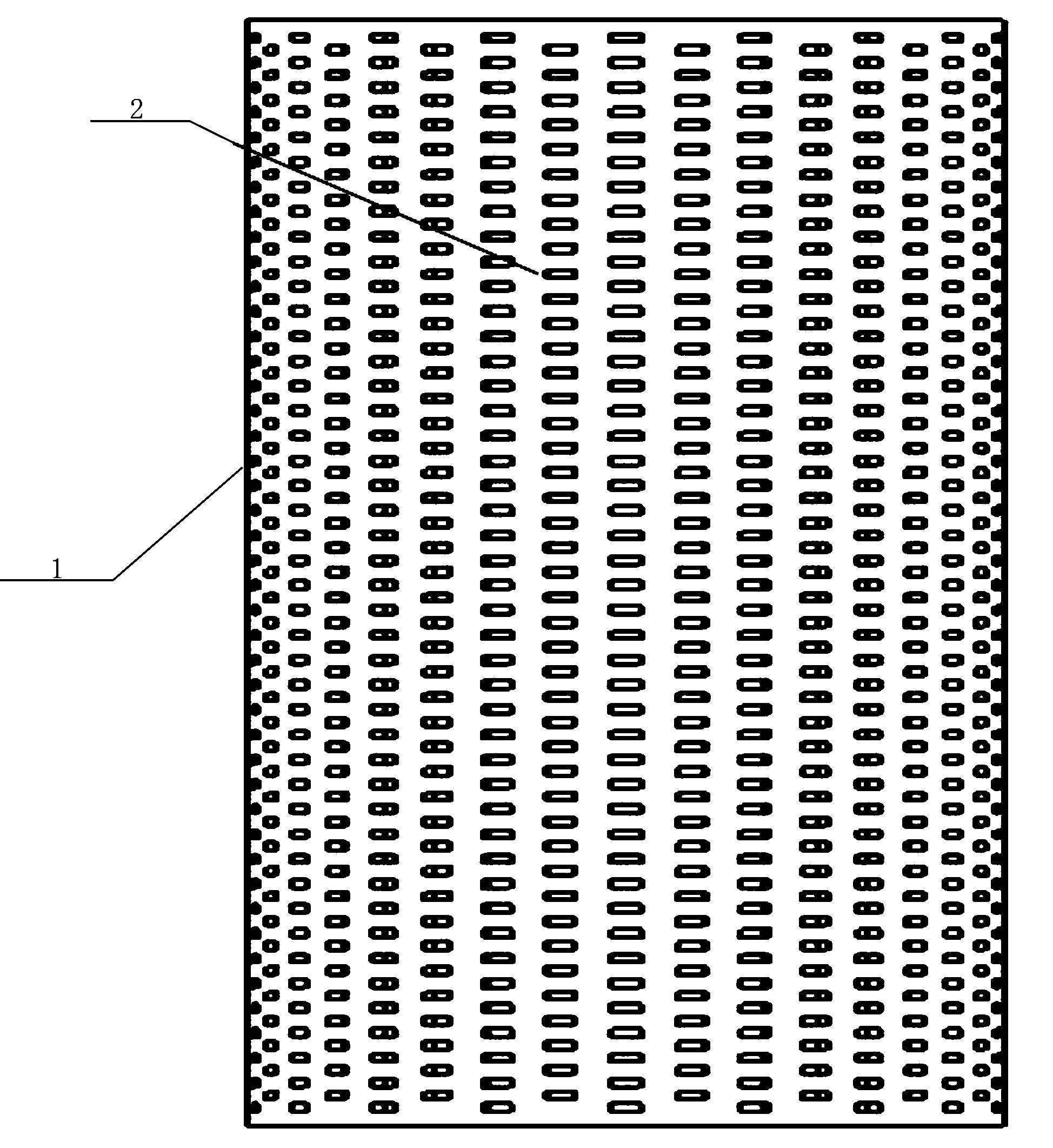

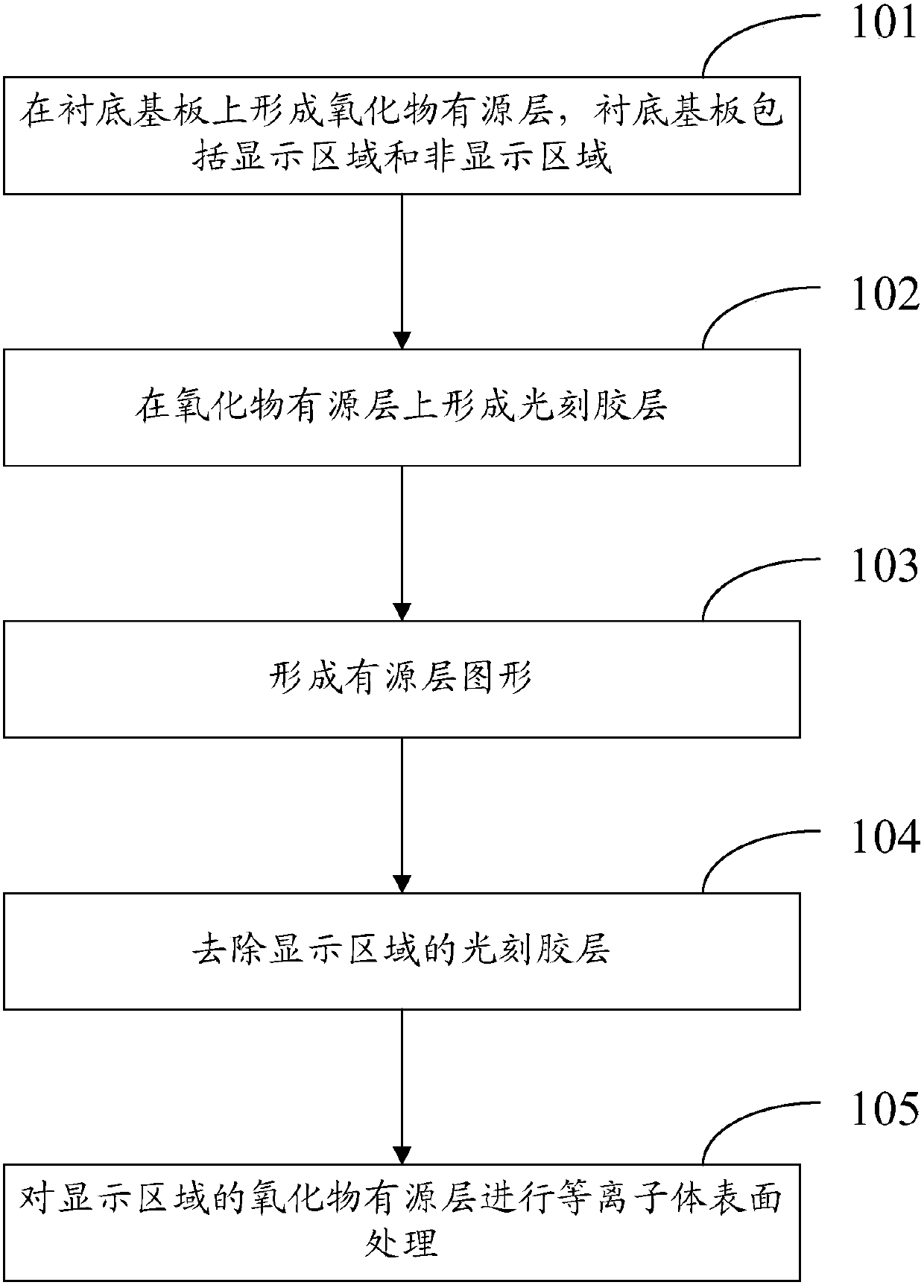

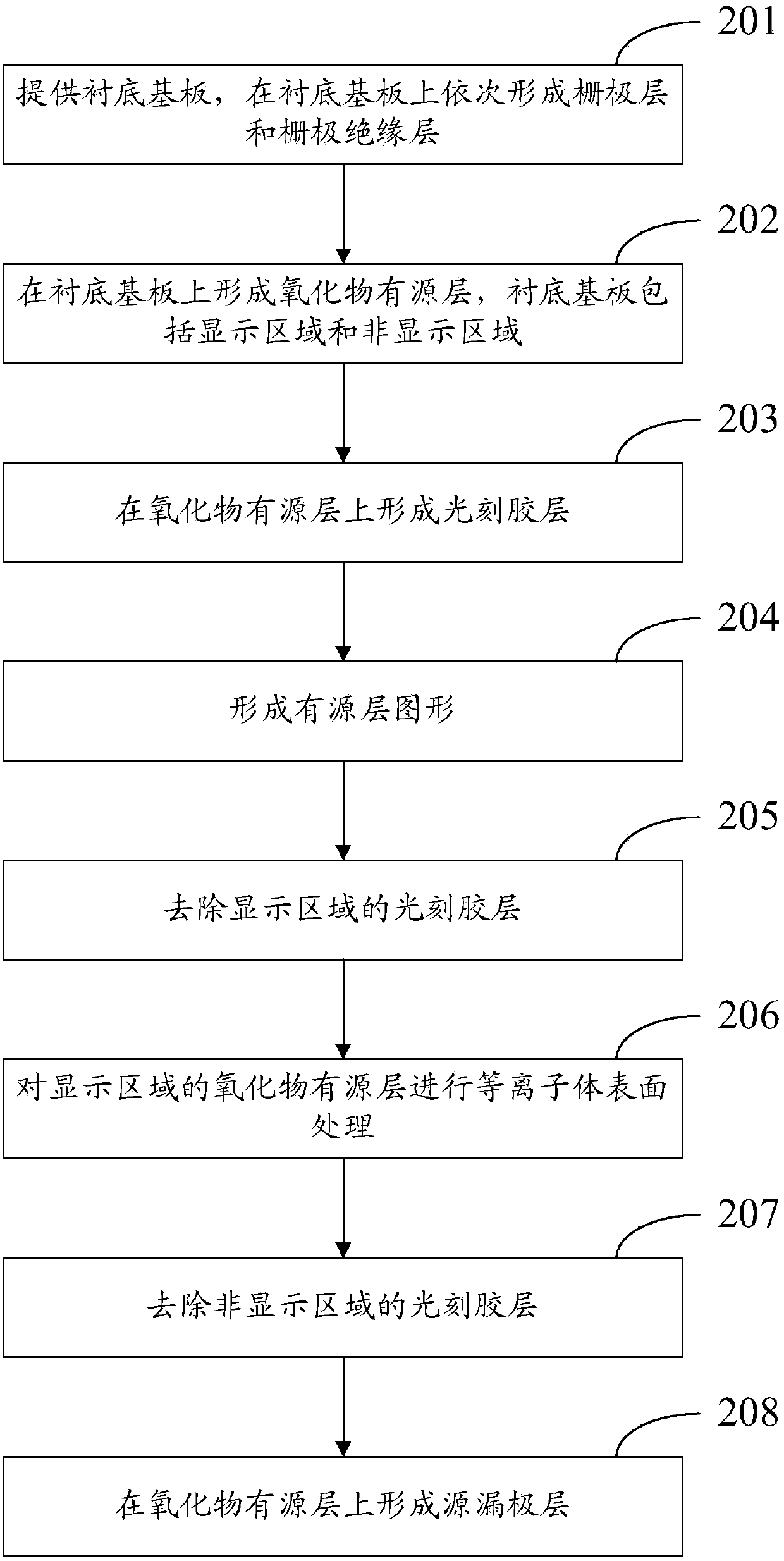

Array substrate manufacturing method, array substrate and display device

InactiveCN105957872AImproved negative bias stress toleranceReduced positive bias stress toleranceSolid-state devicesSemiconductor/solid-state device manufacturingOxideOptoelectronics

The invention discloses an array substrate manufacturing method, an array substrate and a display device, belonging to the technical field of display. The manufacturing method comprises steps: forming an oxide active layer on an underlayment substrate, wherein the underlayment substrate comprises a display region and a non-display region; forming a photoresist layer on the oxide active layer; forming an active layer pattern; removing the photoresist layer of the display region; performing plasma surface treatment for the oxide active layer of the display region to increase oxygen content of the oxide active layer of the display region. According to the invention, reliability of thin film transistors of the display region and the non-display region can be guaranteed at the same time.

Owner:BOE TECH GRP CO LTD

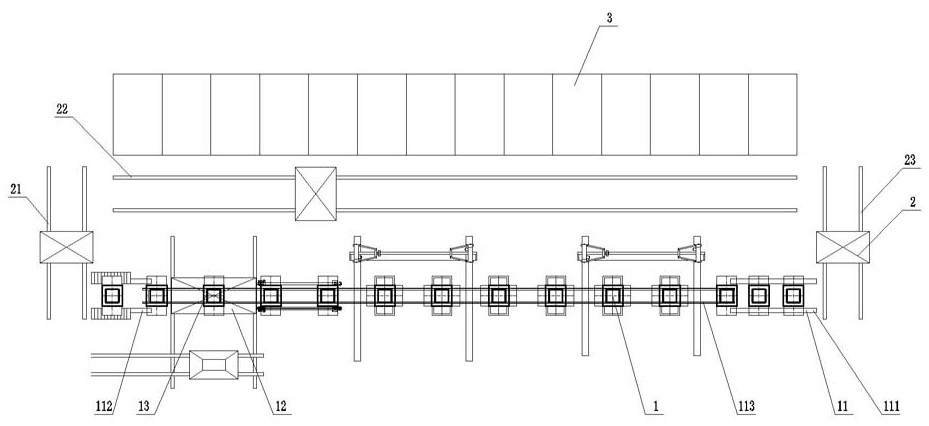

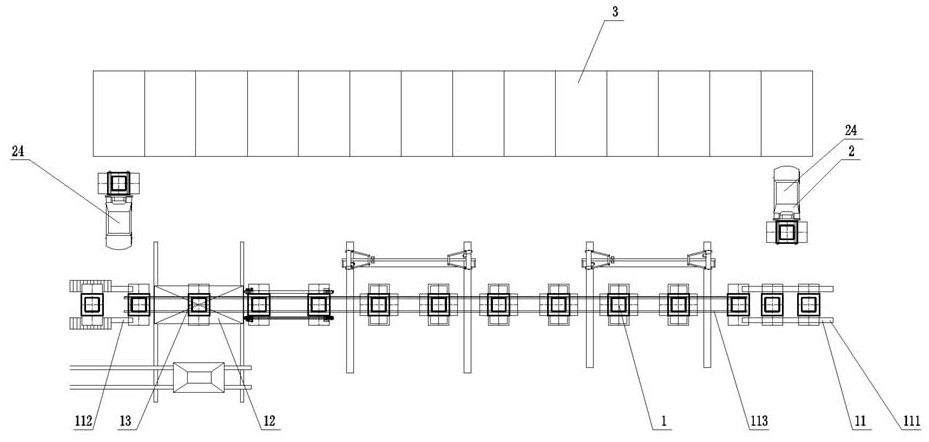

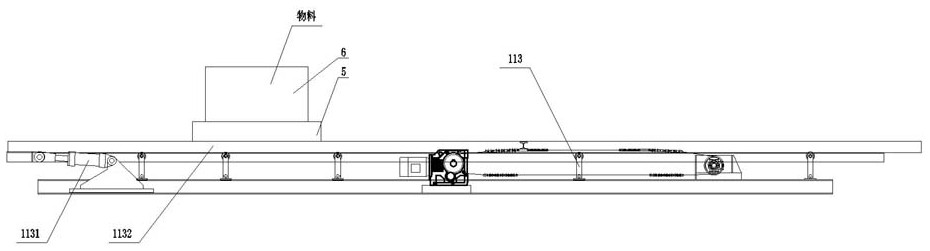

Prefabricated concrete component production line

PendingCN114179210AReliability impactSimple structureCeramic shaping plantsFeeding arrangmentsTransport systemChain type

The precast concrete component production line comprises an operation system, a ferry system and a maintenance system, and materials flow between the operation system and the maintenance system through the ferry system; the operation system comprises a conveying system, a material distribution system and a vibration system; the conveying system comprises a front-end chain type conveying system, a tail-end chain type conveying system and a stepping conveying system; the stepping conveying system comprises a lifting mechanism and a transmission bracket; the front-end chain type conveying system and the tail-end chain type conveying system are each provided with a deviation rectifying device. The production line has the beneficial effects of simple structure, small investment and flexible production; production capacity and production efficiency of a production line can be improved, and labor intensity of workers is reduced; the pouring efficiency and the pouring quality can be improved; the U-shaped prefabricated part ensures the flatness in the foundation pit and improves the installation precision of the operation line. And the deviation rectifying device timely adjusts to ensure the accuracy of the mold position and ensure the mold assembly line working procedure.

Owner:JIANHUA CONSTR MATERIALS (JIANGSU) CO LTD

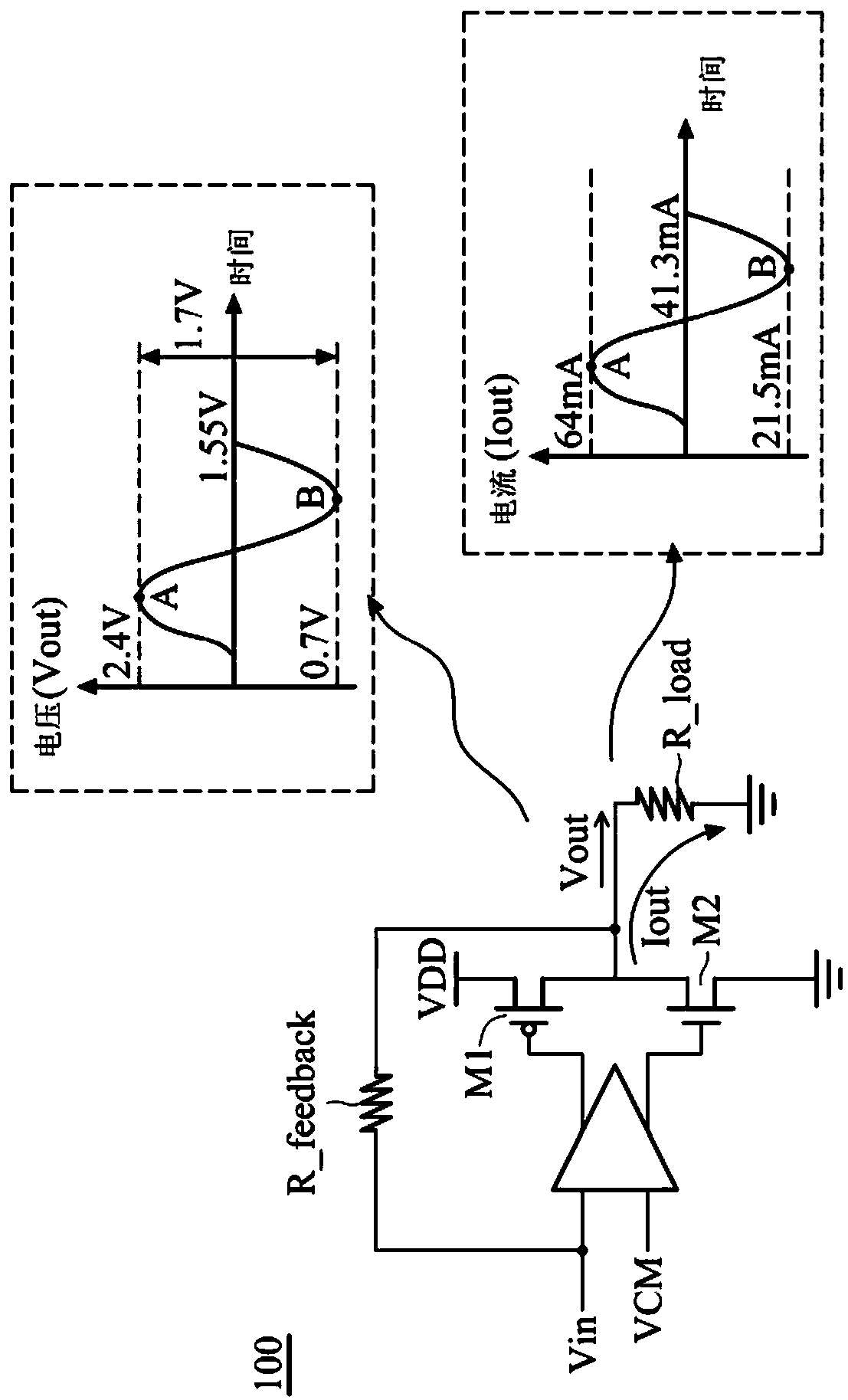

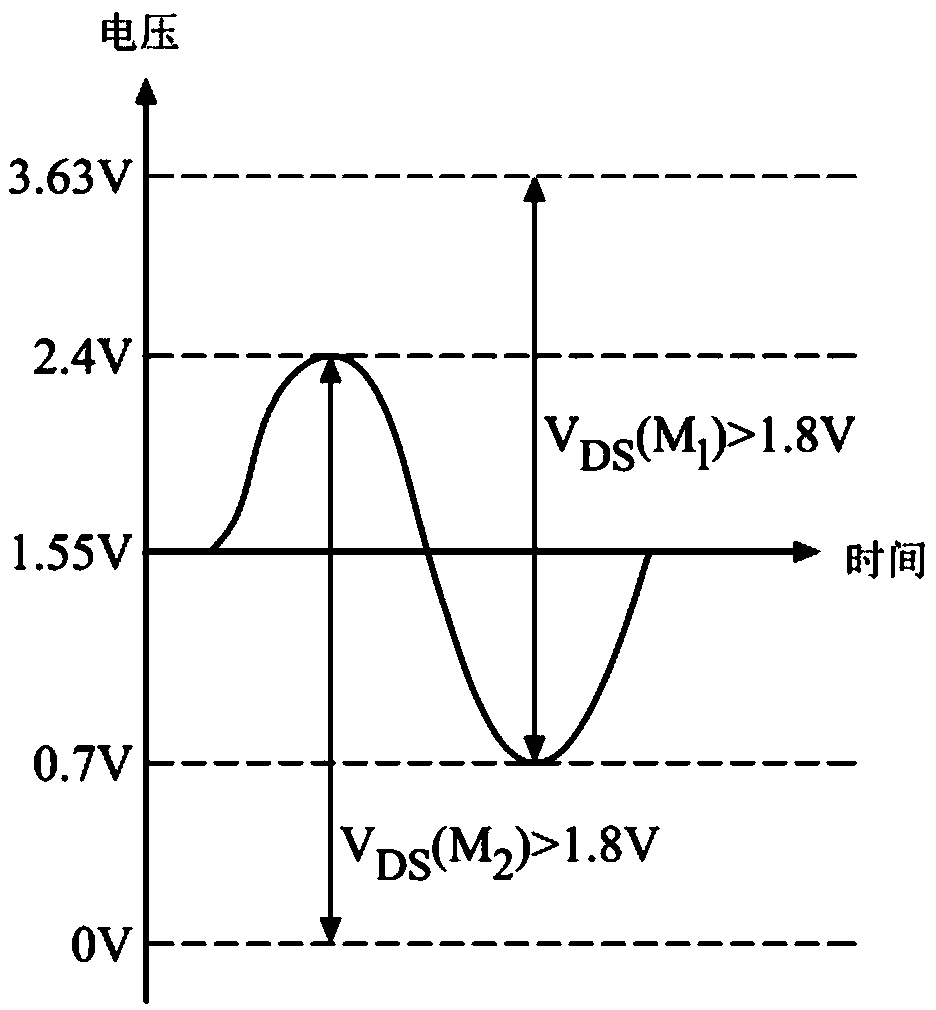

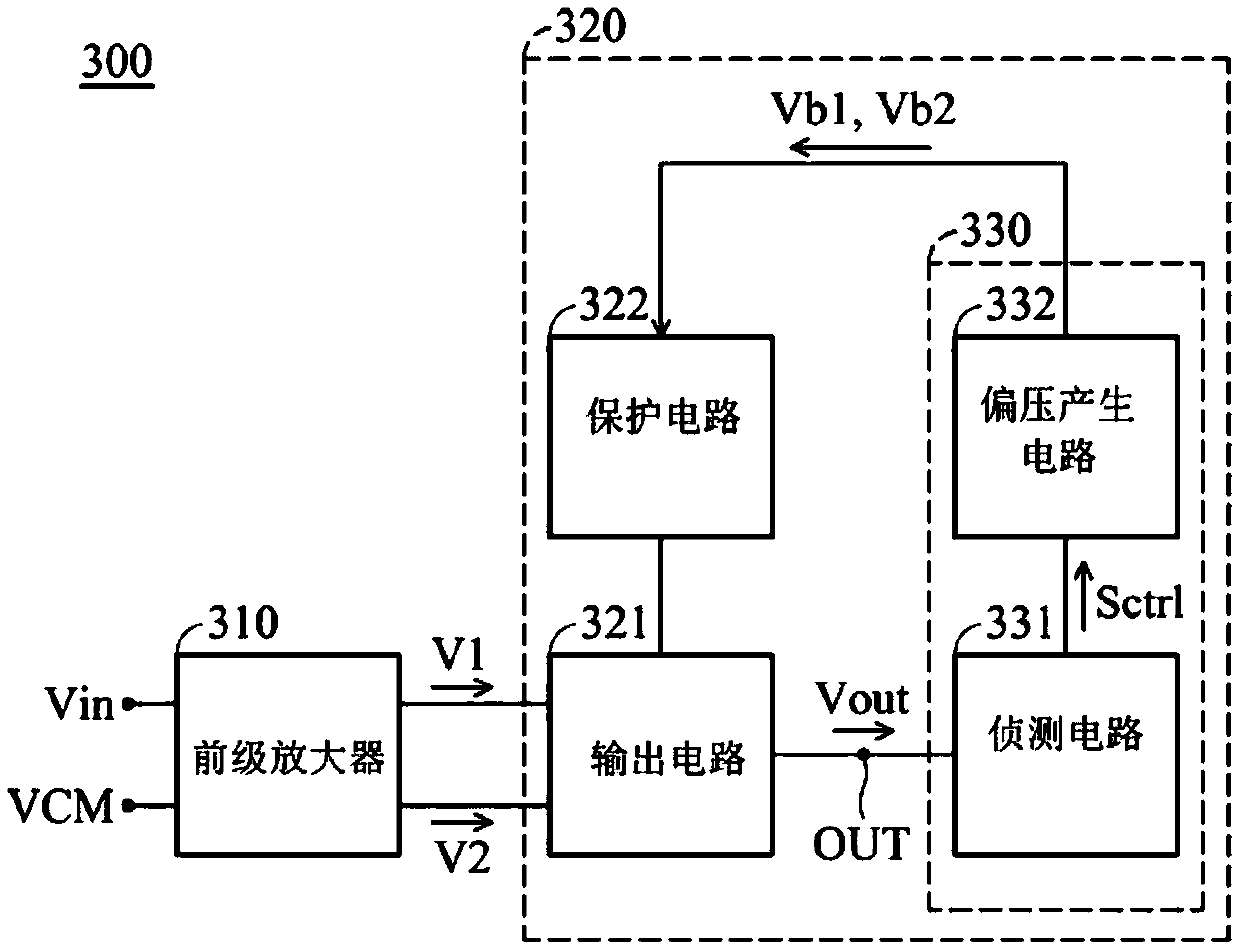

Amplifier circuit and output drive circuit thereof

InactiveCN110323942AReliability impactReduce areaDc-dc conversionElectric variable regulationAudio power amplifierEngineering

The invention provides an amplifier circuit and an output drive circuit thereof. The output drive circuit is used for receiving and driving a first input signal and a second input signal and comprisesan output circuit, a protection circuit and a bias control circuit. The output circuit is used for generating an output voltage at the signal output end according to the first input signal and the second input signal. The protection circuit is coupled to the output circuit and used for adjusting the voltage across two terminals of at least one electronic component of the output circuit accordingto the first bias voltage and the second bias voltage, so that the voltage across the two terminals is smaller than a predetermined voltage value. The bias control circuit is coupled to the signal output terminal, and is used for detecting the voltage level of the output voltage and dynamically adjusting the first bias voltage and the second bias voltage according to the voltage level of the output voltage.

Owner:MEDIATEK SINGAPORE PTE LTD SINGAPORE

Electric vehicles and their integrated powertrain

PendingCN108973631AReduce in quantityStrong radial limit actionElectric propulsion mountingControl devicesReduction driveReducer

The invention relates to an electric vehicle and an integrated powertrain thereof, wherein an end of a reducer input shaft remote from an input bearing is not mounted on an inner wall of a reducer chamber through a bearing, so that the number of bearings can be reduced relative to the powertrain in the prior art, thereby simplifying a structure and reducing a cost. In addition, one end of the reducer input shaft extends into the motor cavity and is splined with the motor output shaft. In one aspect, since the second output bearing is proximate to the reducer input shaft, the second output bearing may provide support to the reducer input shaft while supporting the motor output shaft. On the other hand, since the motor output shaft and the reducer input shaft are splined to transmit torque,and the splined connection has a strong radial limiting effect, the motor output shaft and the reducer input shaft can also support each other. Therefore, reliability of the transmission process is not affected. Accordingly, the electric vehicle and its integrated powertrain not only reduce the cost, but also take into account the higher reliability.

Owner:ZHUZHOU GEAR CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com