Method for making solder bump

A technology of solder bumps and fabrication methods, applied in the fields of semiconductor/solid-state device manufacturing, electrical components, electrical solid-state devices, etc., can solve problems such as the influence of solder bumps and the reliability of semiconductor devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

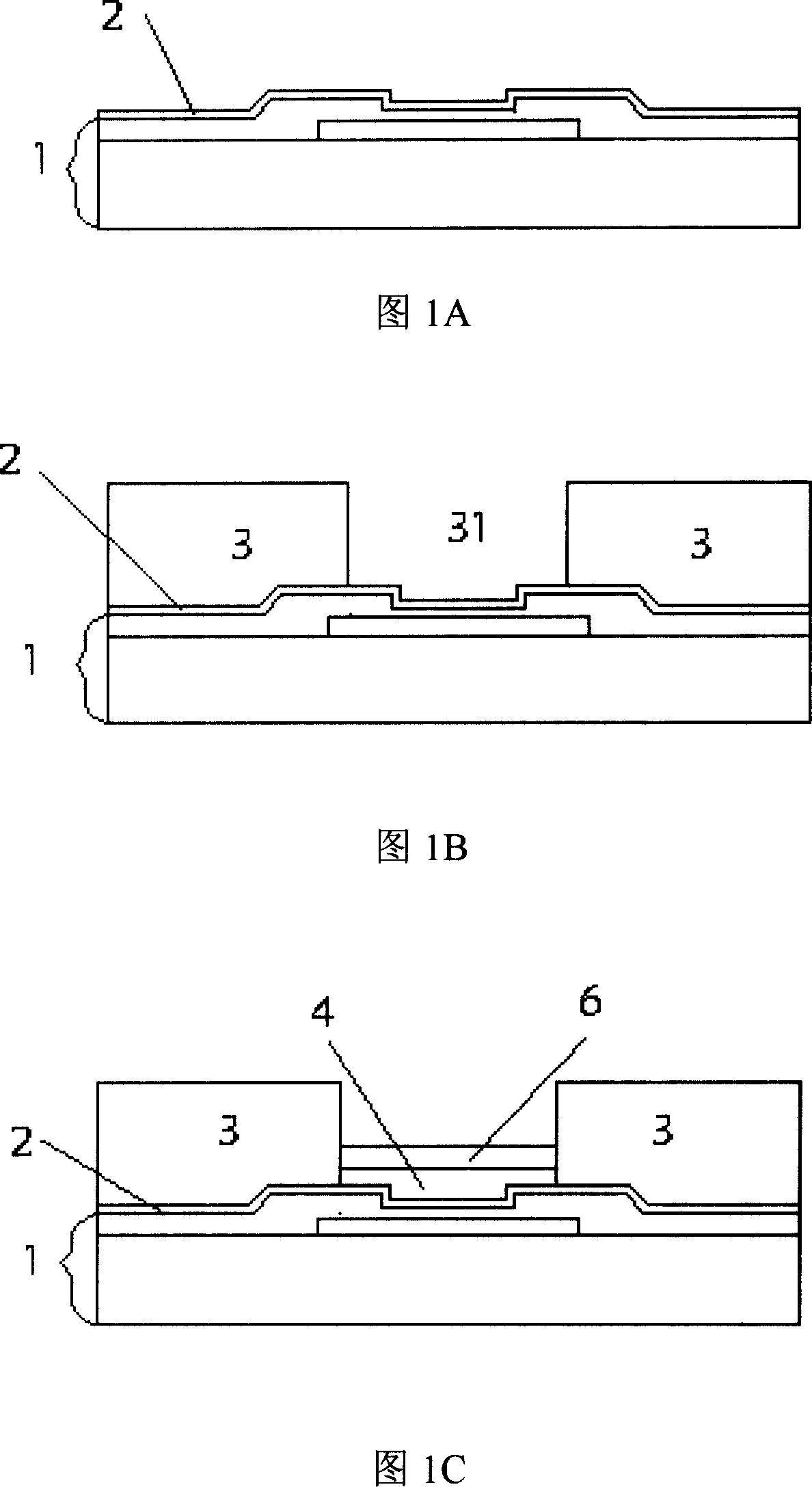

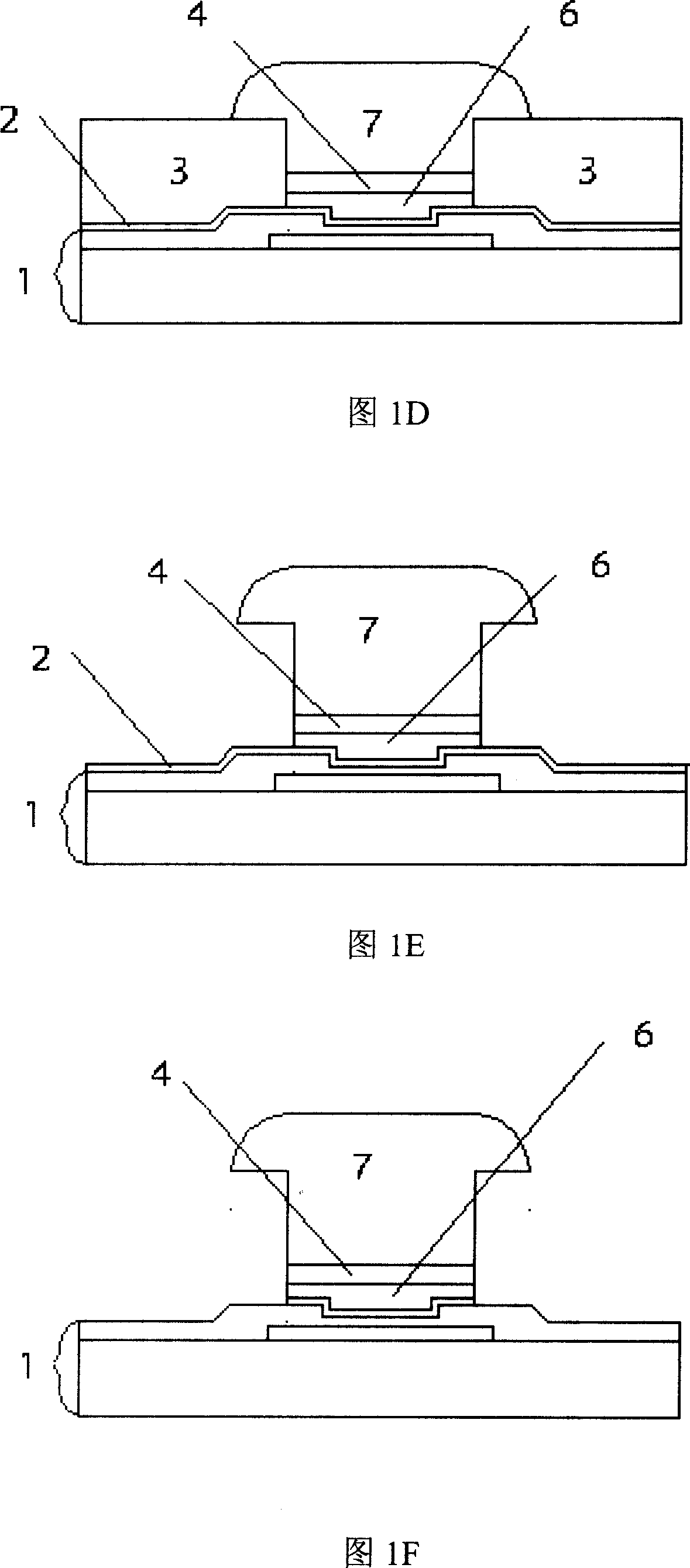

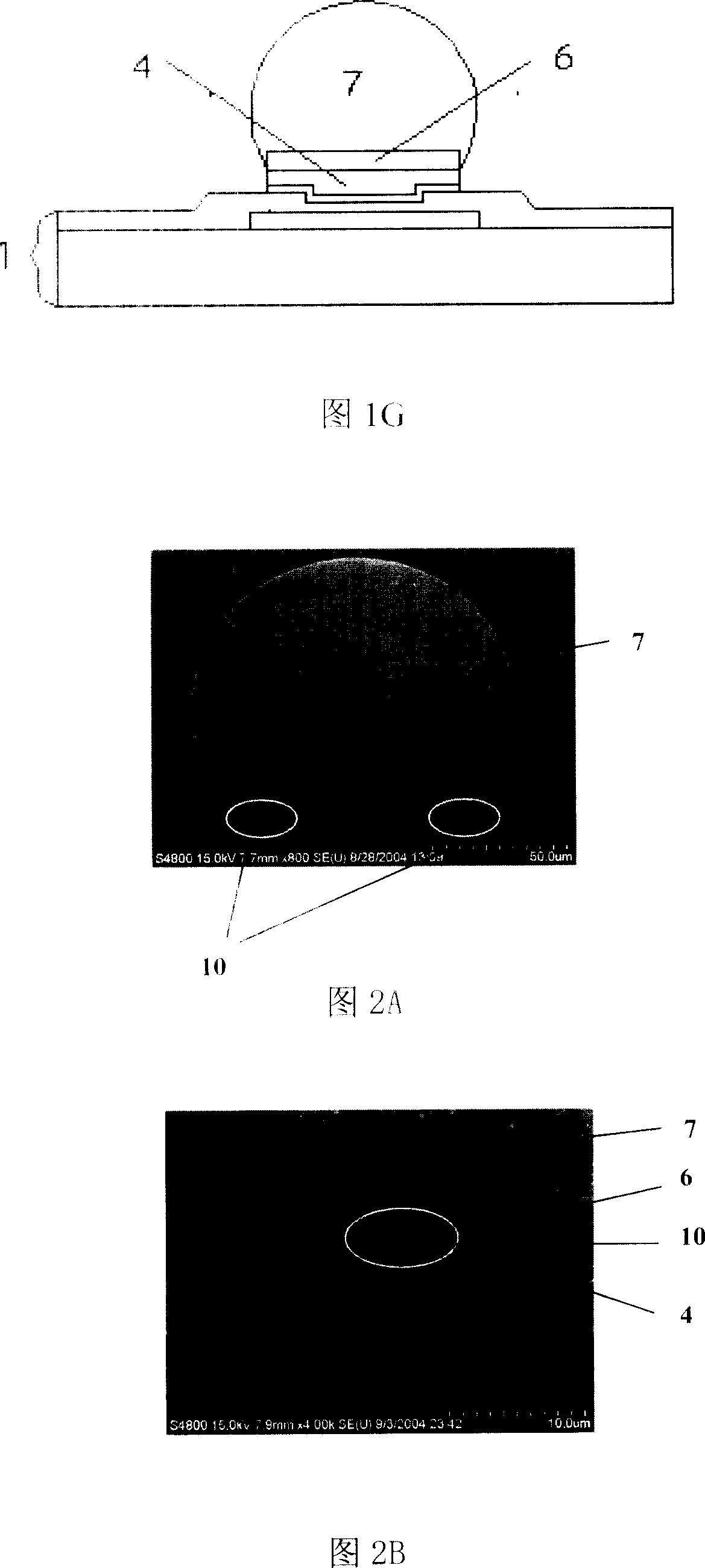

Method used

Image

Examples

Embodiment Construction

[0061] Below by embodiment, the present invention is described in more detail.

[0062] In the wafer level redistribution package (Wafer Level Contribution Package, WLCSP), first make the pads on the IC wafer and cover the passivation layer around the pads, generally as a prefabricated layer 21, as shown in FIG. 3A. A chrome-copper (Cr-Cu) layer 22 is then sputter deposited using conventional techniques around the pad area where the solder bump is to be formed. Wherein, first sputtering deposits a chromium (Cr) layer, the thickness of the chromium (Cr) layer is 1000±50 Ȧ; then sputtering deposits a copper (Cu) layer, the thickness of the copper (Cu) layer is 3000±100 Ȧ, The total thickness of the chromium-copper (Cr—Cu) layer 22 is 4000±150 Ȧ.

[0063] As shown in Figure 3B, the first photoresist (PR) layer 23 is coated on the above-mentioned chromium-copper (Cr-Cu) layer 22, and the thickness of the photoresist layer is 7 ± 0.5 μm, and photolithography is carried out accordi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com