Crystalline silicon solar cell resource classifying recycling method

A technology for sorting solar cells and resources, applied in the field of solid waste treatment, can solve the problems of increased difficulty in recycling aluminum flocculants, poor removal of n-type junctions, affecting the purity of polysilicon, etc., to achieve inhibition of formation and avoid excessive etching , good removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

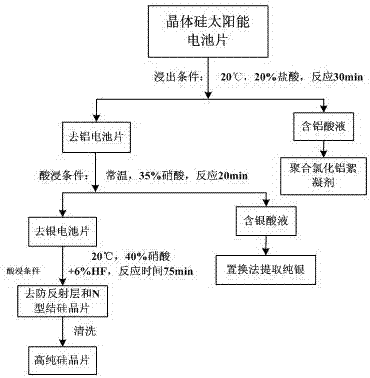

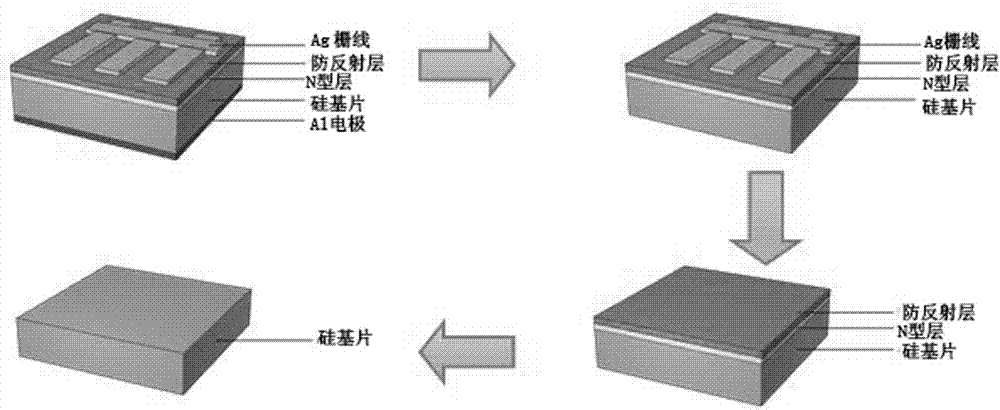

[0039] Such as figure 1 , 2 Shown, a kind of crystalline silicon solar cell piece resource classification recovery method, comprises the following steps:

[0040] 1) Clean the crystalline silicon solar cells with ultrasonic waves and rinse them with deionized water to obtain clean silicon wafers.

[0041] 2) Put the cleaned silicon wafer into the HCl solution with a volume fraction of 20%-40% at room temperature, and the reaction time is 30 minutes, and the aluminum coating on the back of the silicon wafer can be etched clean. When the volume fraction of HCl is less than 20%, the reagent concentration should be increased. When the aluminum mass concentration in the recycled solution system reaches 5%, the separated solution is filtered and used to make polyaluminum chloride products.

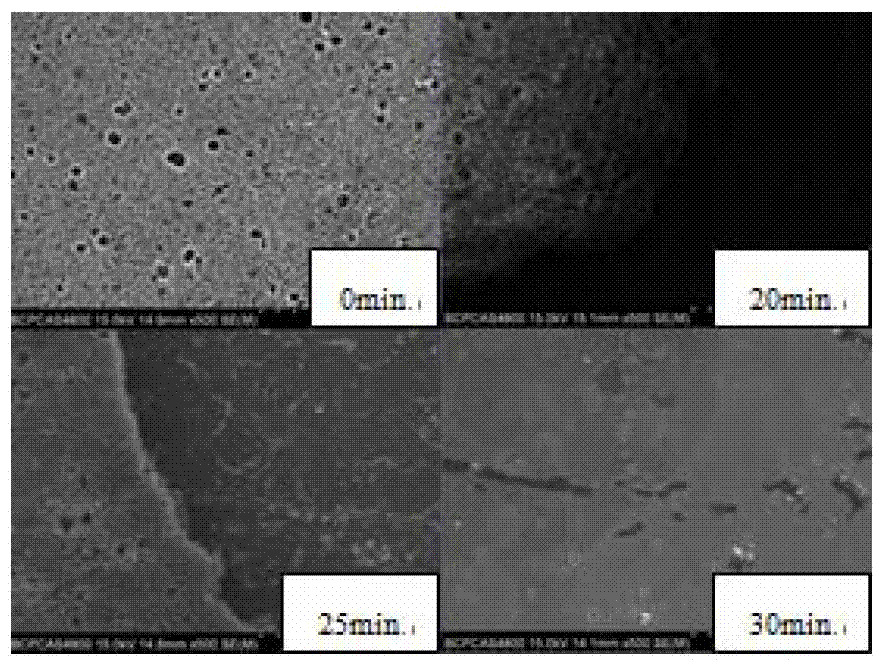

[0042] Adding fatty alcohol polyoxyethylene ether (JFC) W:V (mass to volume)=0.5g:1L, when the volume fraction of HCl solution is 20%, the etching reaction time of aluminum coating can be sho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com