Patents

Literature

464results about How to "Shorten the overall length" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

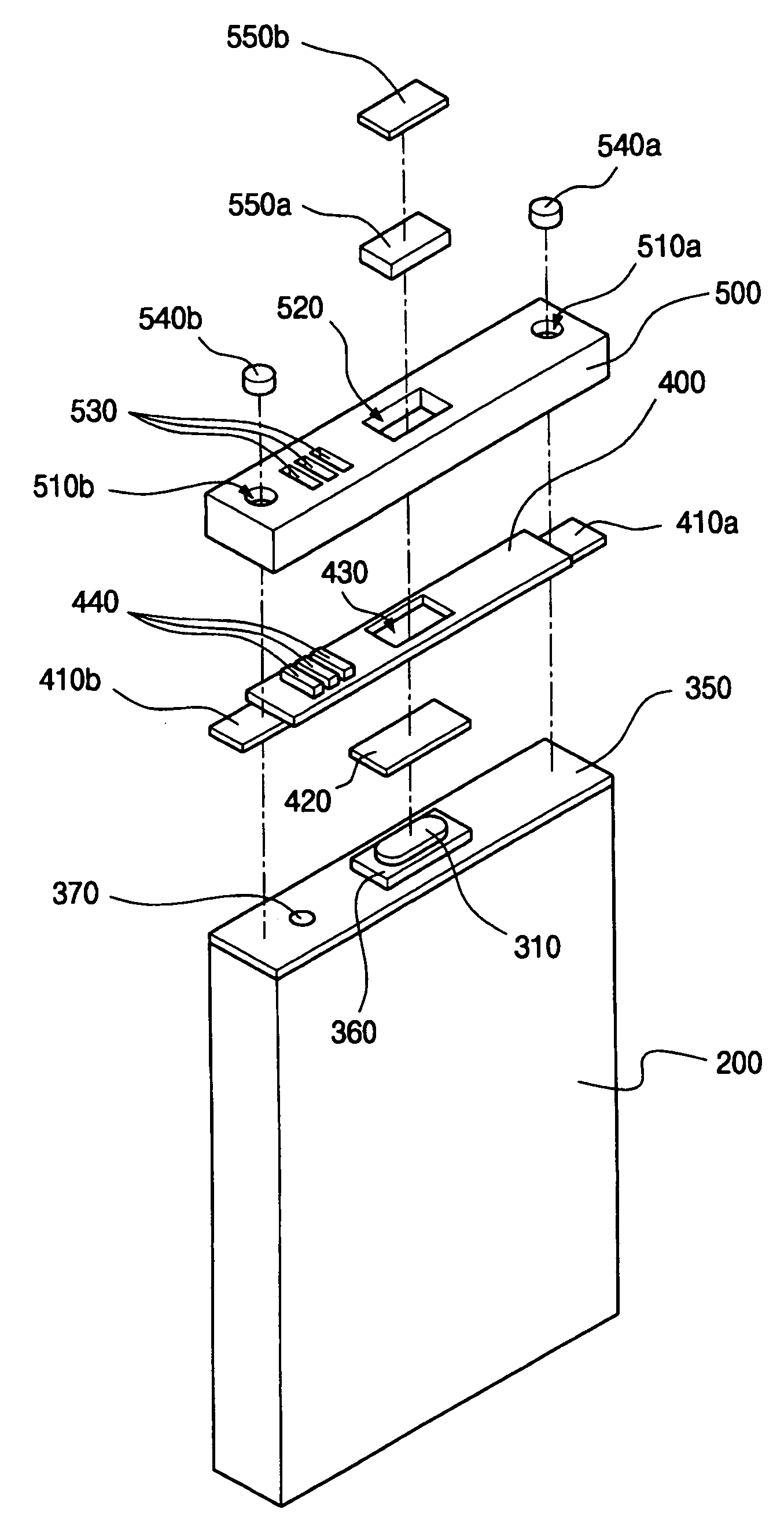

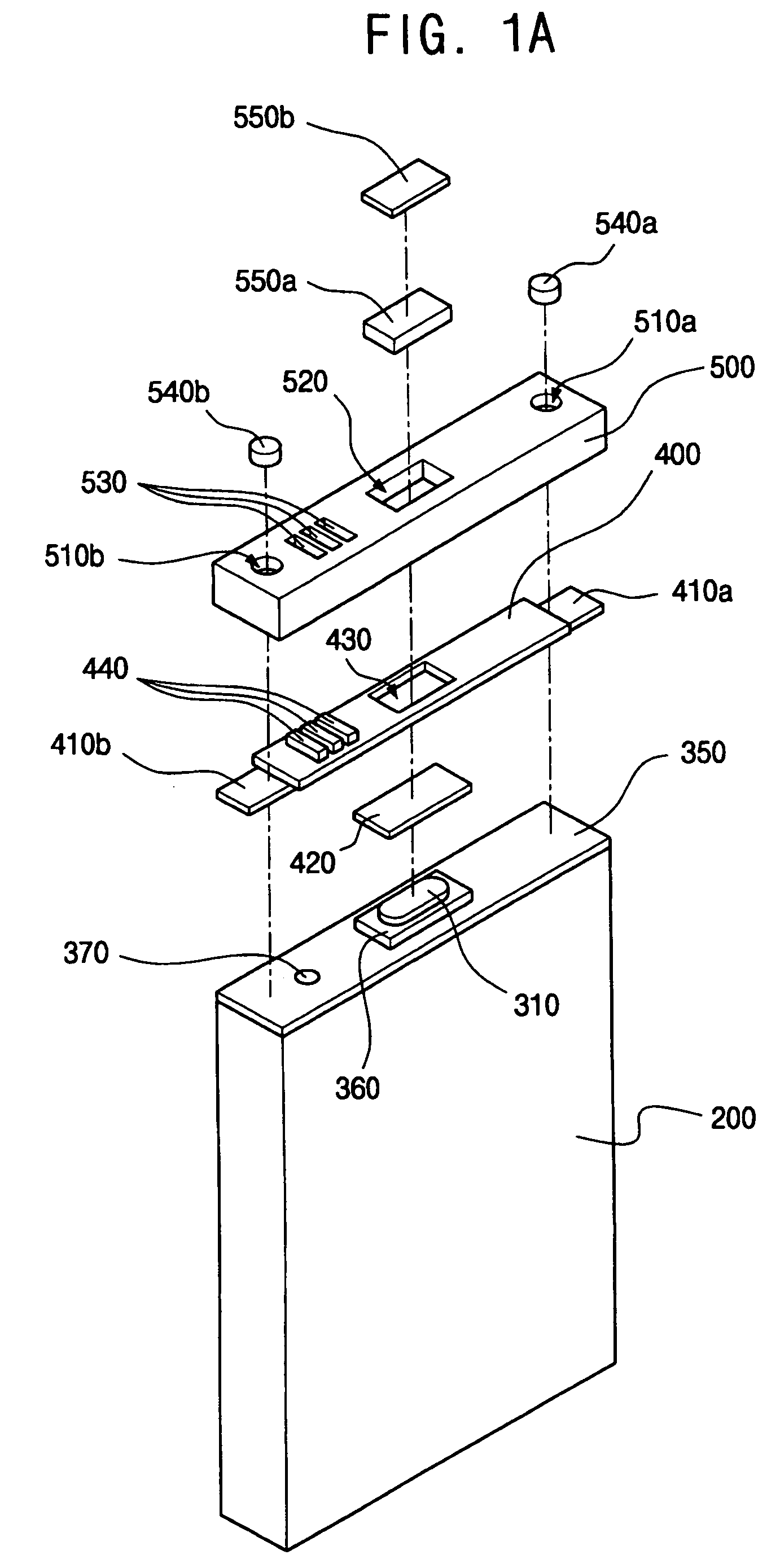

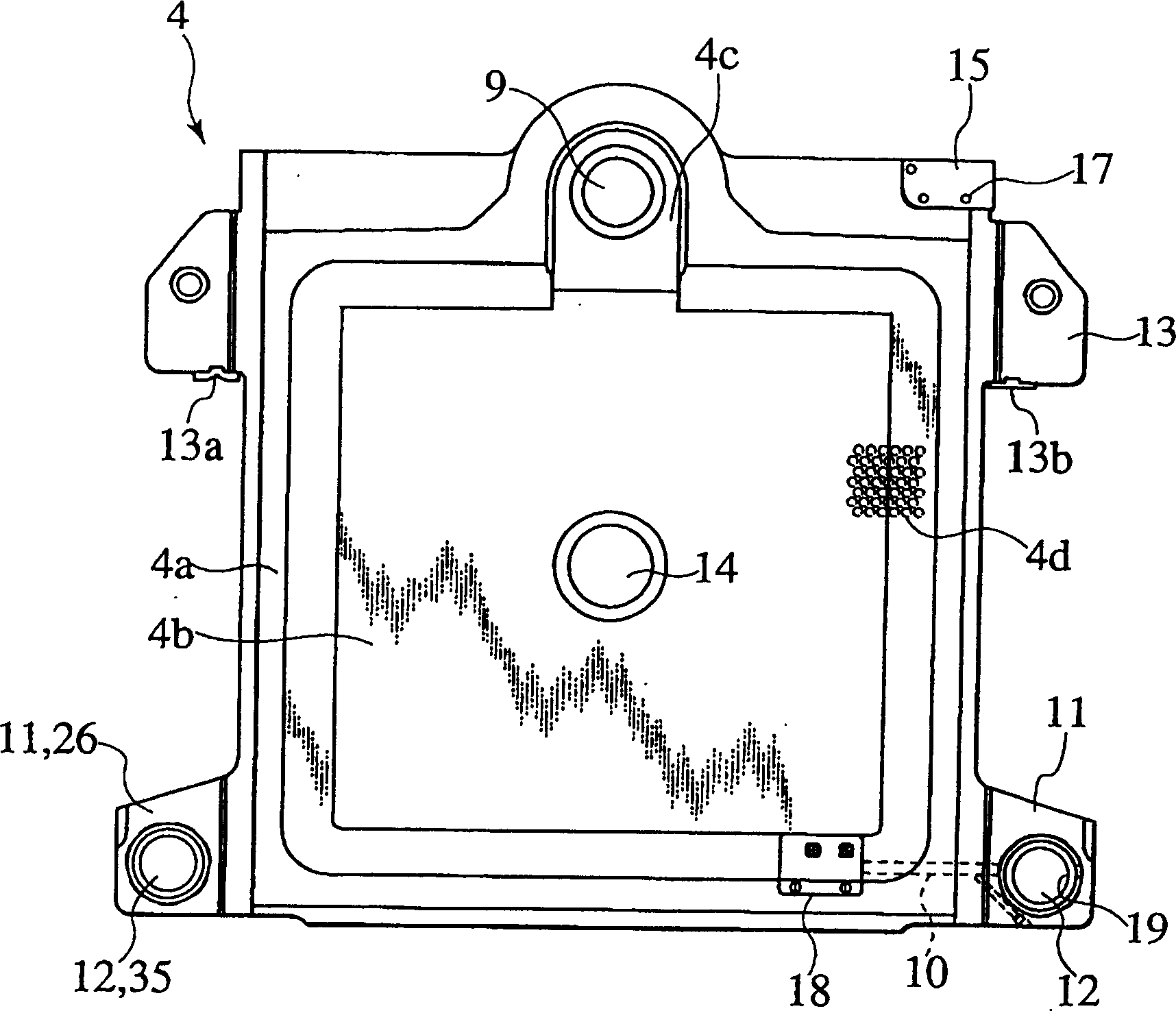

Battery pack and method of fabricating the same

InactiveUS20090098418A1Reducing entire lengthShorten the overall lengthBatteries circuit arrangementsFinal product manufactureEngineeringElectrical and Electronics engineering

A battery pack and a method of fabricating the same. The battery pack includes a bare cell including an electrode terminal, a protection circuit board electrically connected to the bare cell, the protection circuit board including a plurality of metal tabs arranged at opposite ends thereof, and a case surrounding the protection circuit board, the case being perforated by a plurality of first apertures arranged at locations that correspond to ones of the plurality of metal tabs. The method includes arranging a bare cell having a cap plate and an electrode terminal passing through a terminal aperture in the cap plate, electrically connecting a protection circuit board to the bare cell, the protection circuit board having metal tabs arranged at both ends thereof and arranging a case to surround the protection circuit board, the case being perforated by a plurality of first apertures that are arranged at locations that correspond to ones of the metal tabs.

Owner:SAMSUNG SDI CO LTD

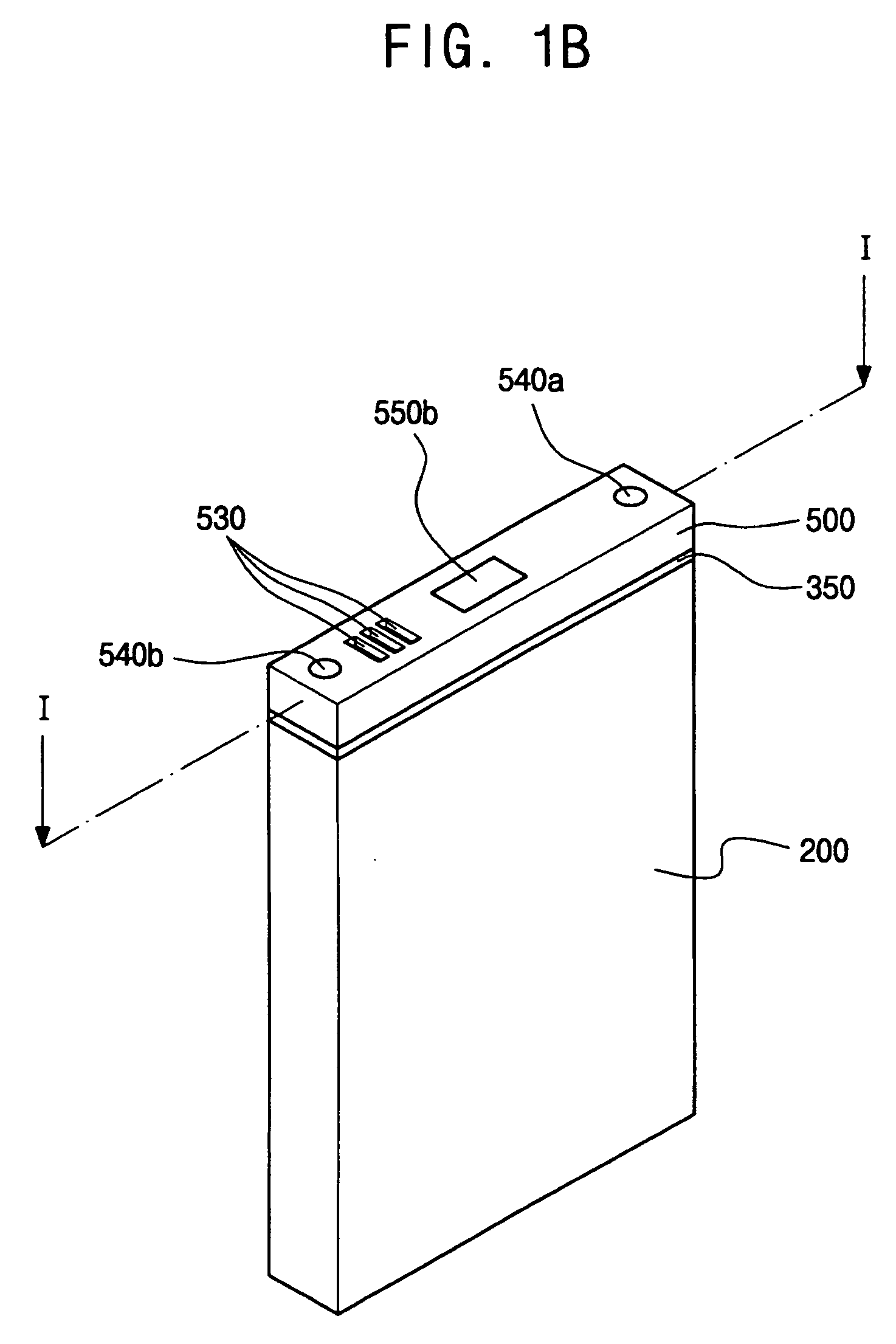

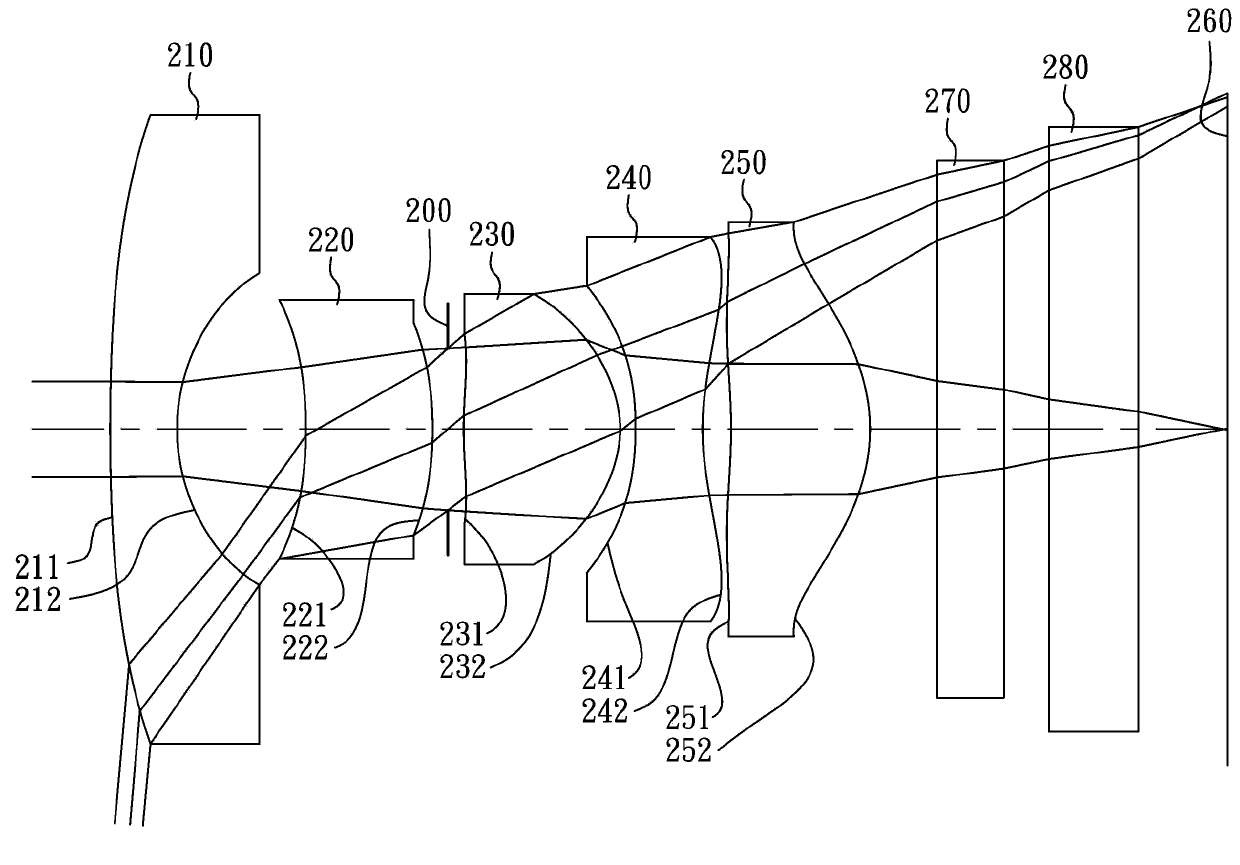

Wide-angle image capturing lens assembly

A wide-angle image capturing lens assembly includes, in order from an object side to an image side, a first lens element, a second lens element, a third lens element, a fourth lens element and a fifth lens element and each of the first through fifth lens elements is single and non-cemented. The first lens element with negative refractive power has a concave image-side surface. The second lens element with refractive power has a concave object-side surface and a convex image-side surface. The third lens element has positive refractive power. The fourth lens element has negative refractive power, wherein at least one of an object-side surface and an image-side surface of the fourth lens element is aspheric. The fifth lens element with positive refractive power has a convex image-side surface, wherein at least one of an object-side surface and the image-side surface of the fifth lens element is aspheric.

Owner:LARGAN PRECISION

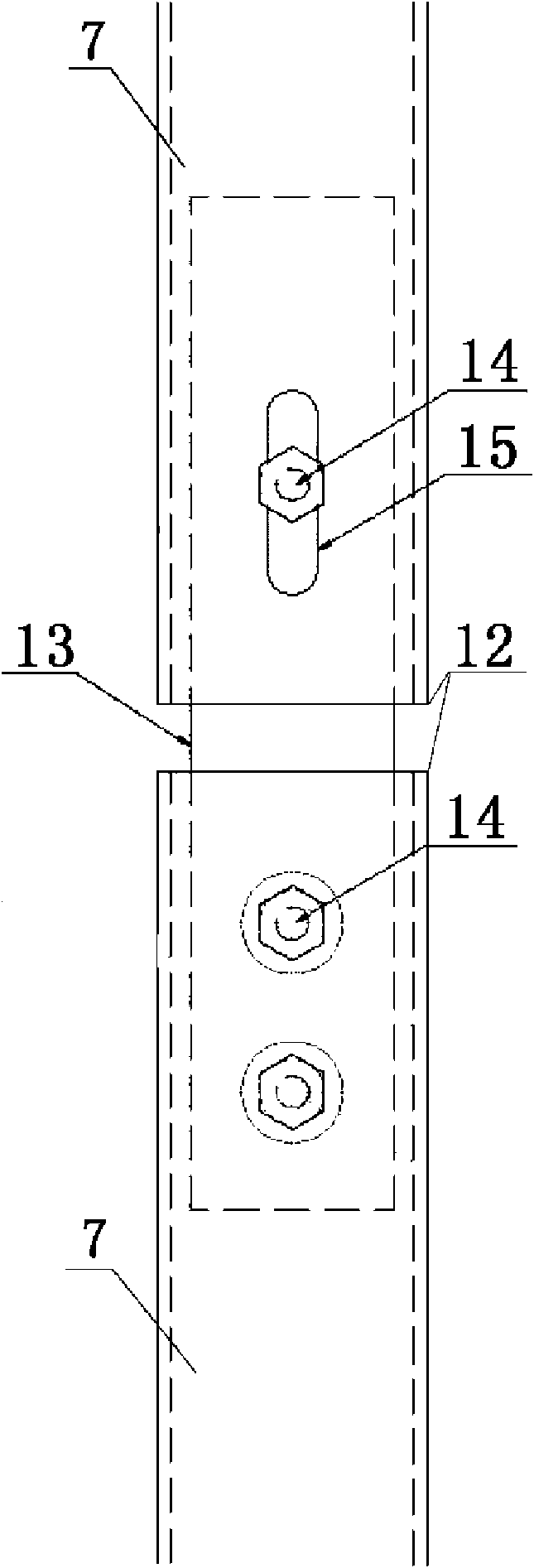

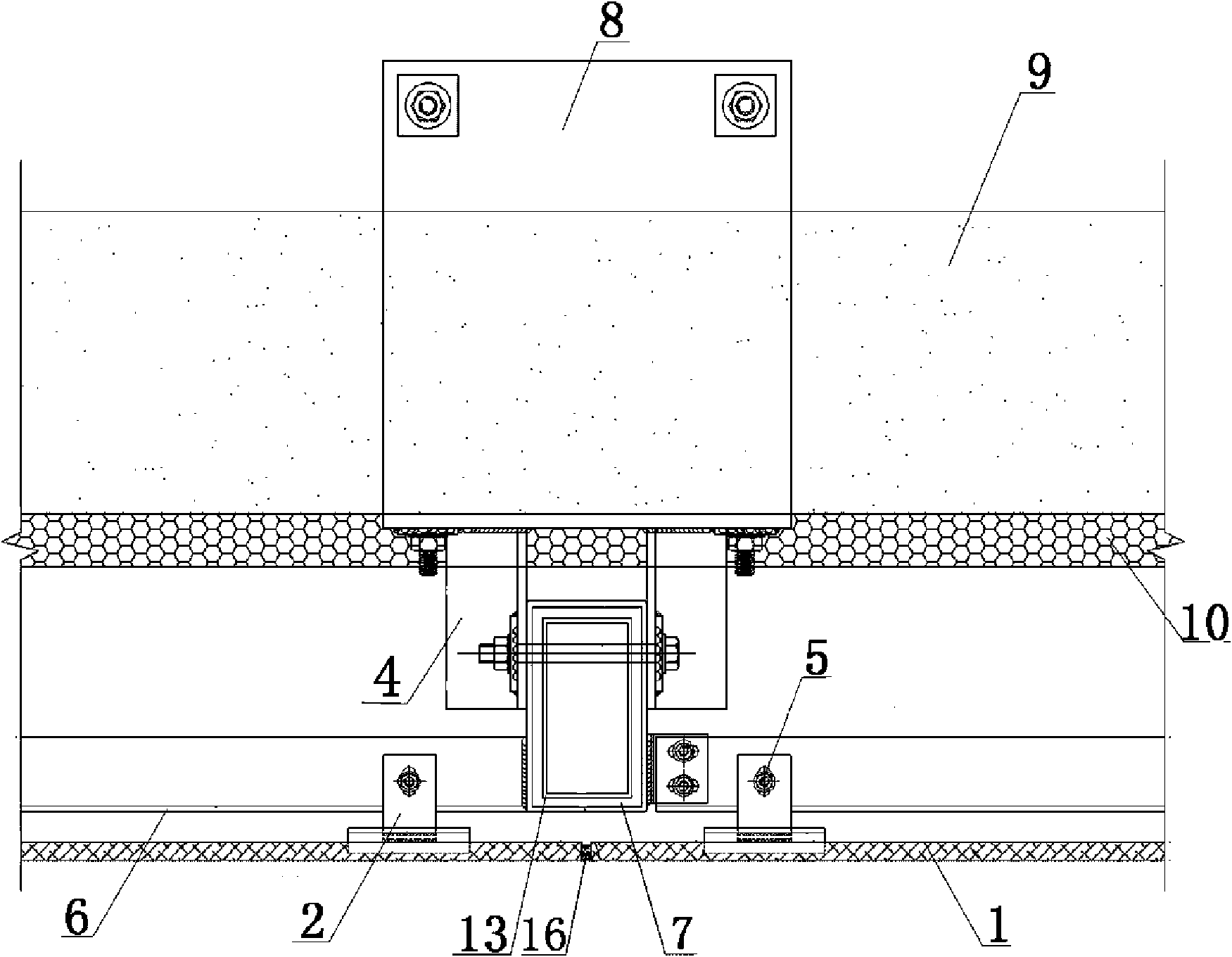

Drily hung vitrolite wall surface decoration system and construction method thereof

InactiveCN101824895ASatisfy self-expanding deformationFulfil requirementsCovering/liningsWallsKeelHigh rise

The invention relates to a drily hung vitrolite wall surface decoration system and a construction method thereof. A main building wall body is connected with a preembedded piece; the preembedded piece is connected with vertical keels through floor connecting pieces; the vertical keels are vertically connected with a transverse keel; the transverse keel is provided with a dilatation joint at each floor; a steel lock pin is inserted between the two vertical keels of the upper part and the lower part of the dilatation joint, one end of the steel lock pin is fixedly connected with a vertical keel through bolts, and the other end is in flexible connection with an oblong hole of the other vertical keel; the back of the vitrolite is provided with at least a pair of dovetail grooves; the dovetail grooves are connected with anchoring pieces in an embedded mode; the heads of the anchoring pieces are clamped into the dovetail grooves at the back of the vitrolite; a cavity for penetrating and anchoring the head of a T-shaped hanging piece is formed between an anchoring plate and the back of the vitrolite; the head of the T-shaped hanging piece extends to the cavity; the cavity is filled with epoxide resin anchoring glue; and a pectoral plate of the T-shaped hanging piece is fixedly connected with the transverse keel through a stainless steel bolt. The invention solves the problem of dry hanging vitrolite wall surface decoration systems on high rise buildings.

Owner:BEIJING CONSTR ENG GRP CO LTD

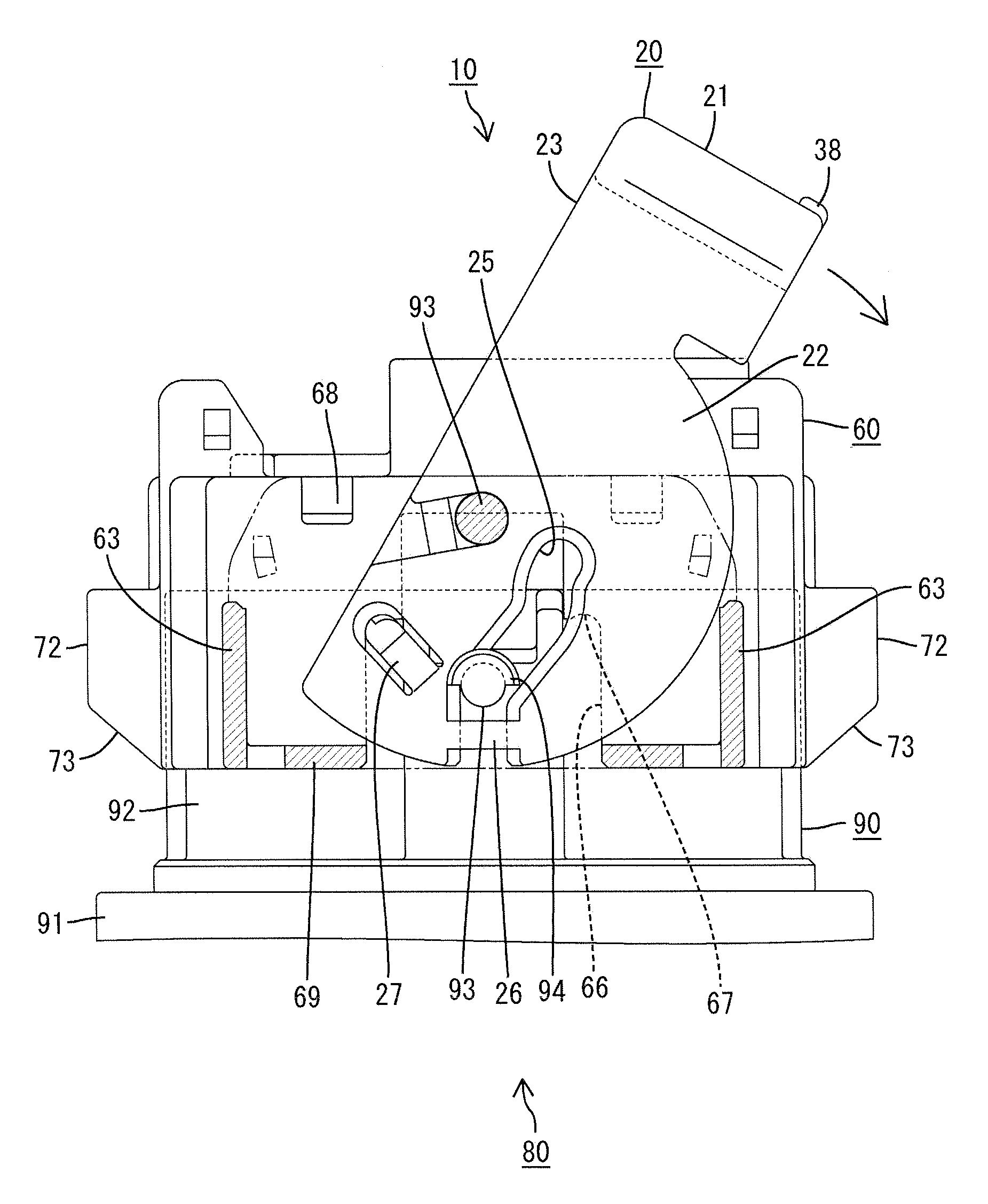

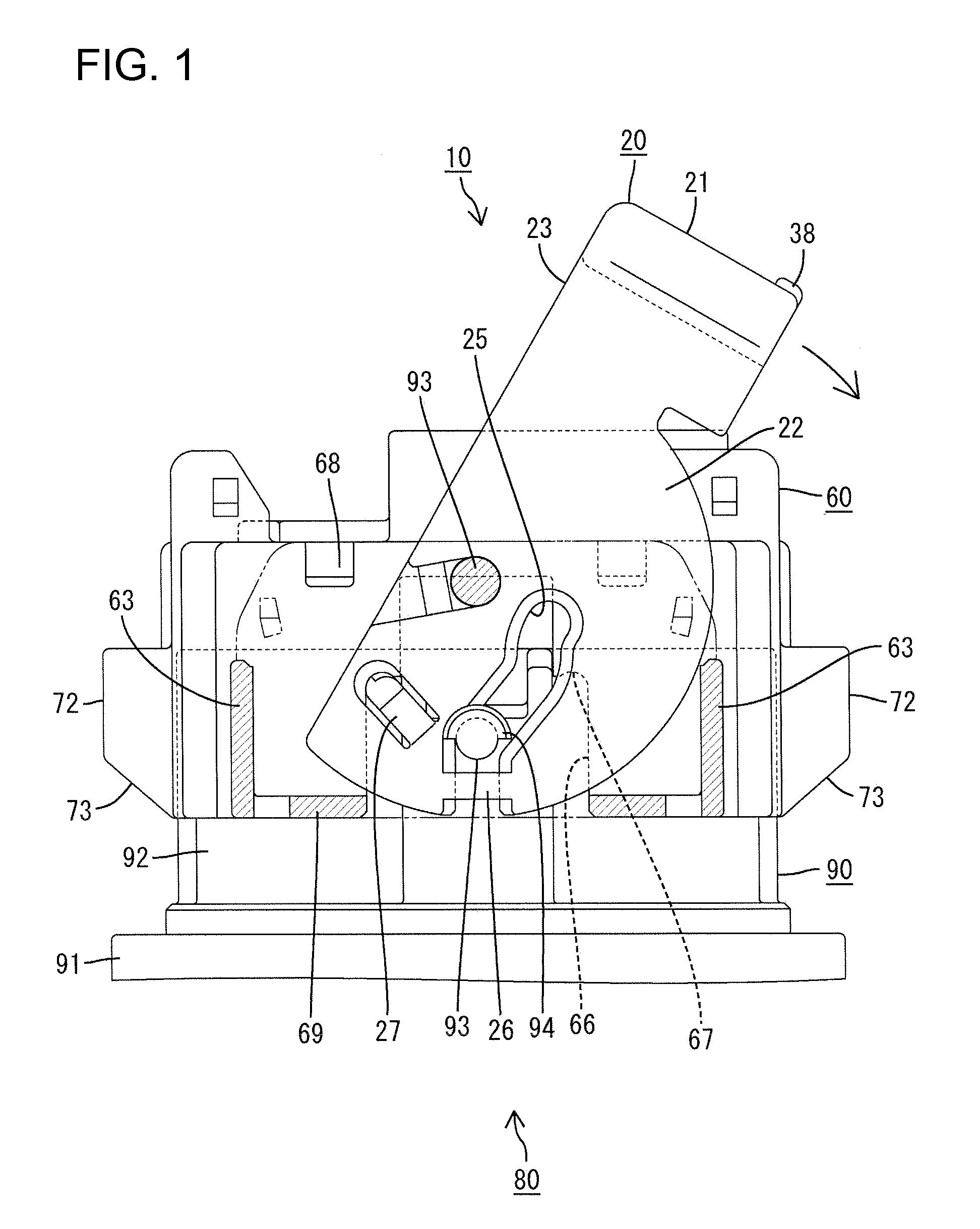

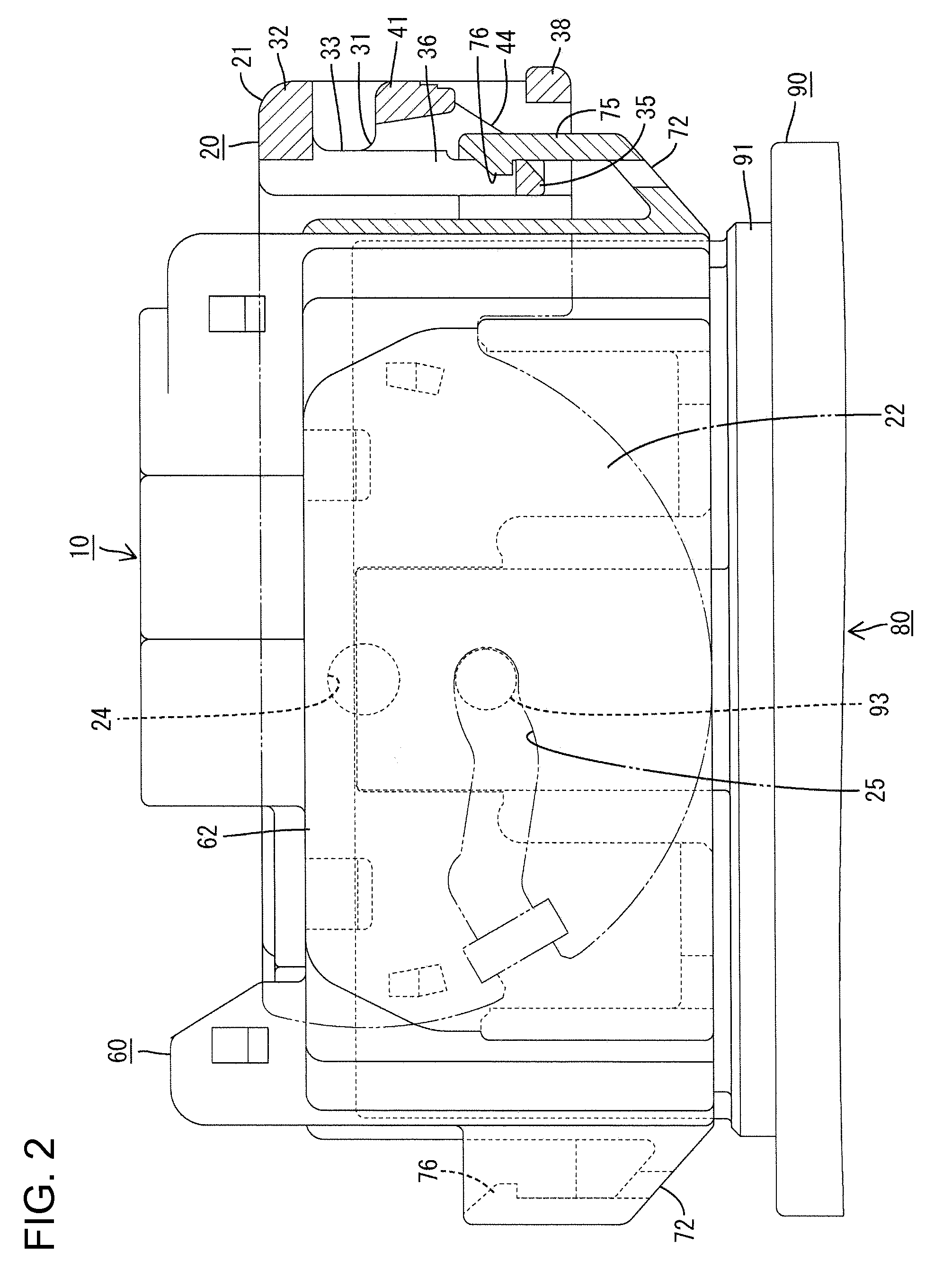

Lever-type connector

ActiveUS20090023317A1Shorten the overall lengthSufficient flexure amountEngagement/disengagement of coupling partsEngineeringMechanical engineering

A lever-type connector (10) has a housing (60) for engaging a mating connector (80). A lever (20) is supported rotatably by the housing (60) and is configured for assisting connection of the connectors (10, 80). The lever (20) has a lever-locking part (31) with a deformable elastic piece (33). A lock (35) on the elastic piece (33) engages a receiving portion (72) on the housing (60) for holding the lever (20) in a rotation-prevented state. A release portion (41) formed separately from the lever-locking part (31) can be pressed to displace the elastic piece (33) in a direction for separating the lock (35) from the receiving portion (72).

Owner:SUMITOMO WIRING SYST LTD

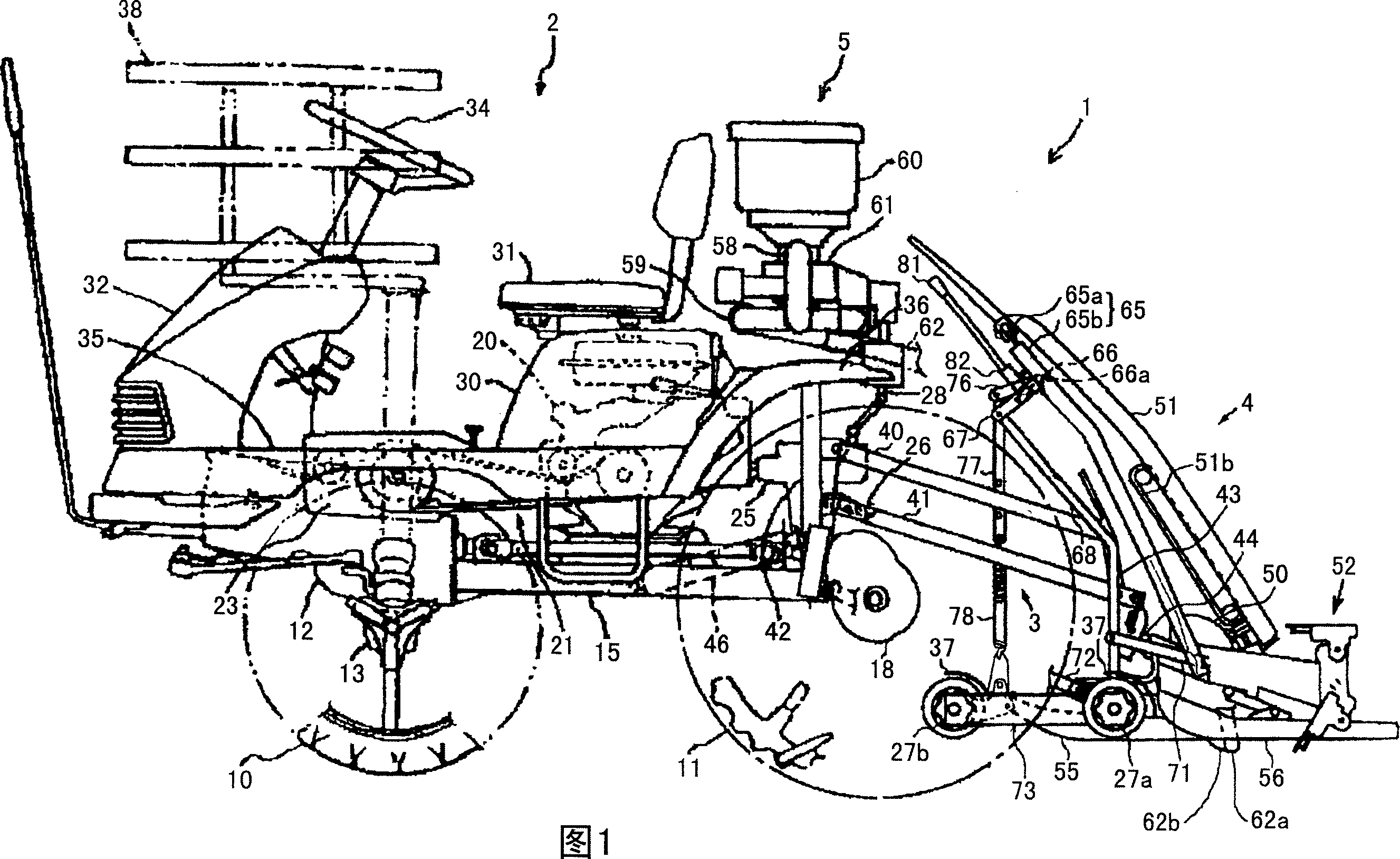

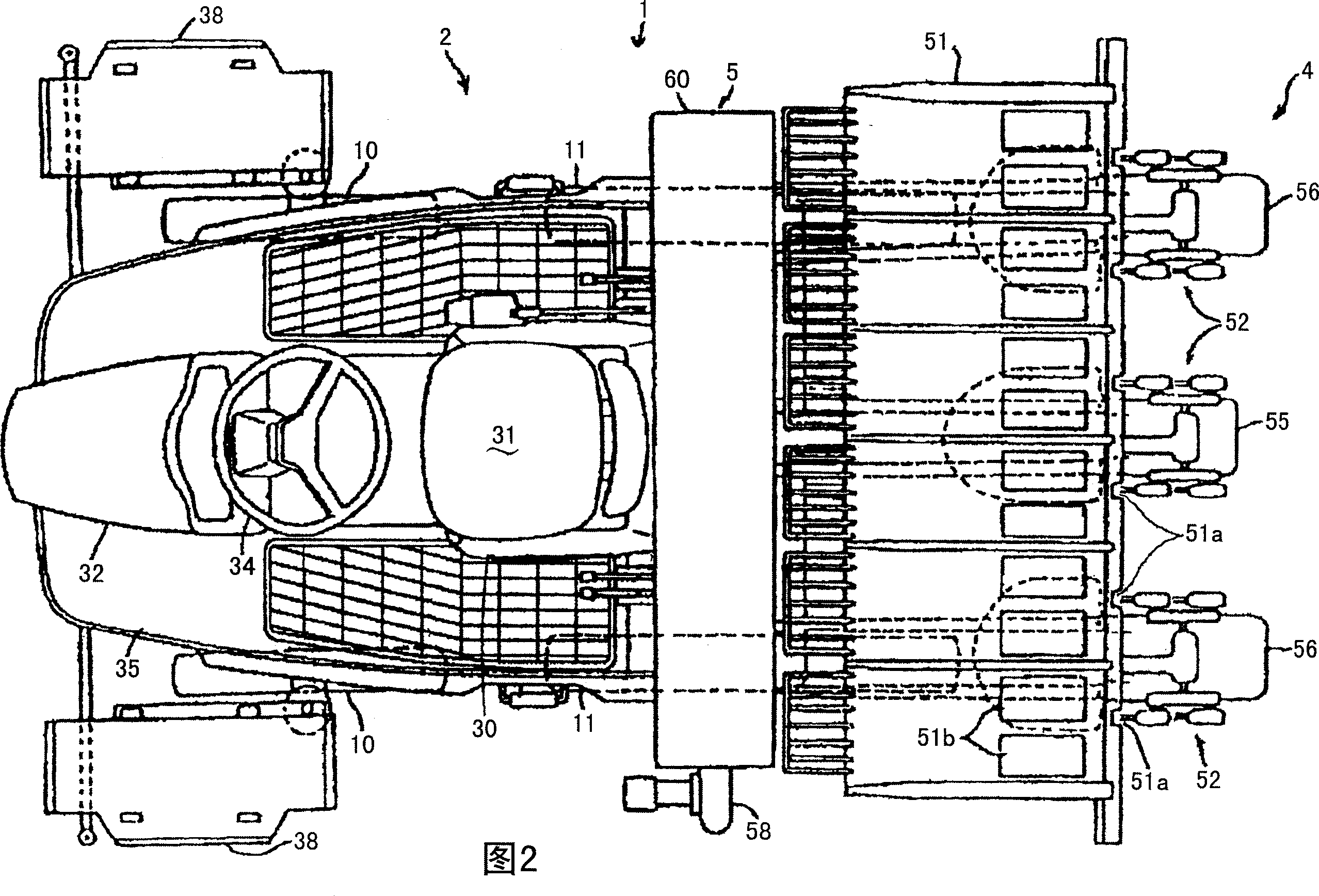

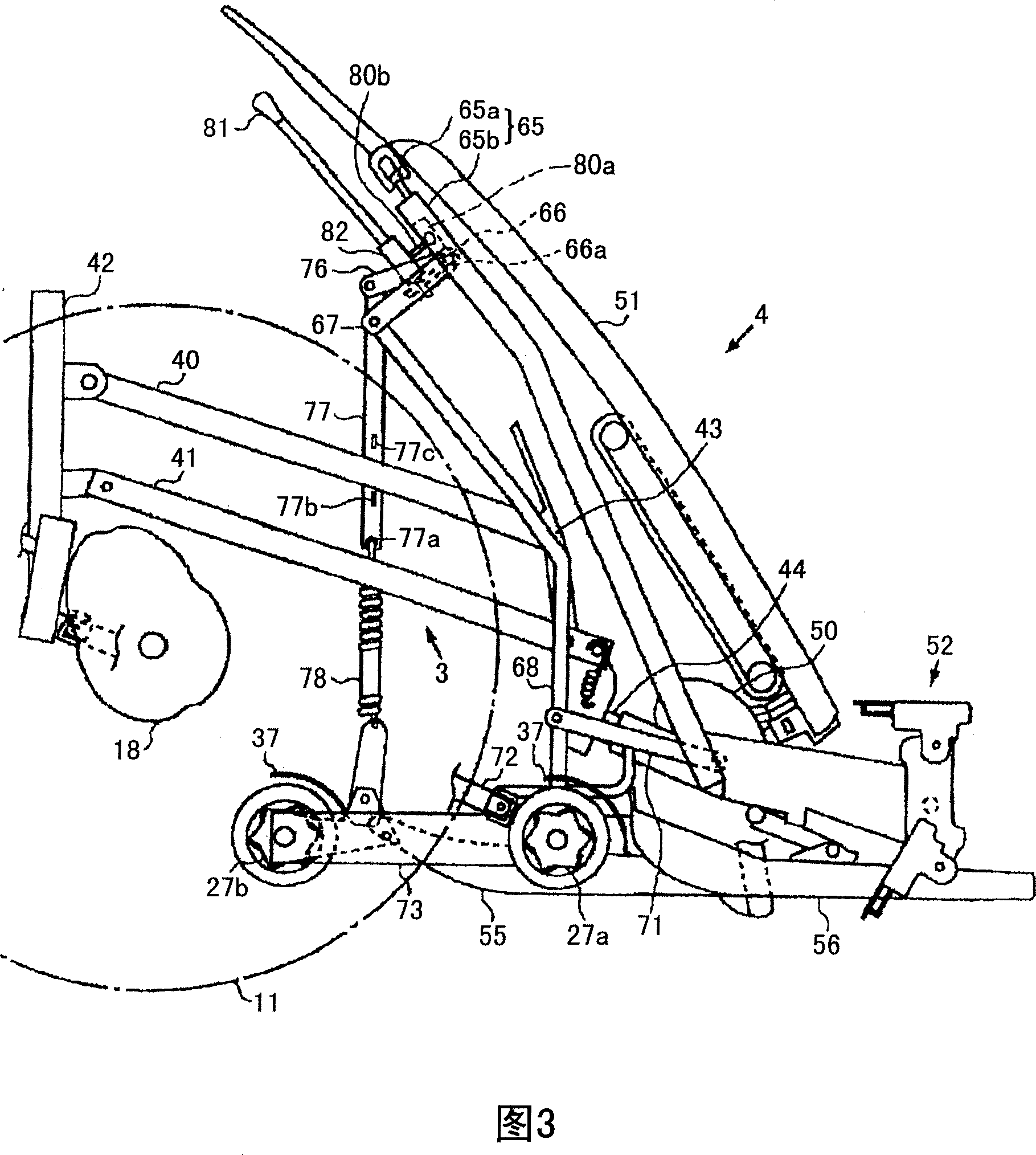

Seedling transplanter

InactiveCN101027958AReduce weightImprove work efficiencyAgricultural vehiclesAgriculture and animal husbandary industryAgricultural landEarth surface

According to an existing seedling transplanter, a rotor used for right and left leveling earth surfaces and a rotor used for centrally leveling earth surface are mounted respectively at a seedling planting mechanism to constitute a complicated structure wherein the rotors for leveling earth surfaces are very heavy, then the seedling planting constructional properties for agricultural land task become worse. The seedling transplanter in accordance with the present invention, in which a seedling planting part is mounted at back side of a walking car body equipped with right and left back wheels by aid of an elevation and subsidence connecting rod mechanism, is characterized in that a central earth surface leveling task mechanism is mounted at the seedling planting part, which locates in front of the central floating body between the right and left back wheels and between the right and left back wheels at the bolt body in the confrontation; a right and left earth surface leveling task mechanism is mounted at back of the right and left back wheesl or in front of the outer side floating body, which locates at back of the right and left back wheels at the bolt body in side-glance. The central earth surface leveling task mechanism is configured more upwards than the right and left earth surface leveling task mechanism, at the same time, the central earth surface leveling task mechanism and the right and left earth surface leveling task mechanism are connected integrally into an integral structure and are set to be capable of freely regulating the up and down positions.

Owner:ISEKI & CO LTD

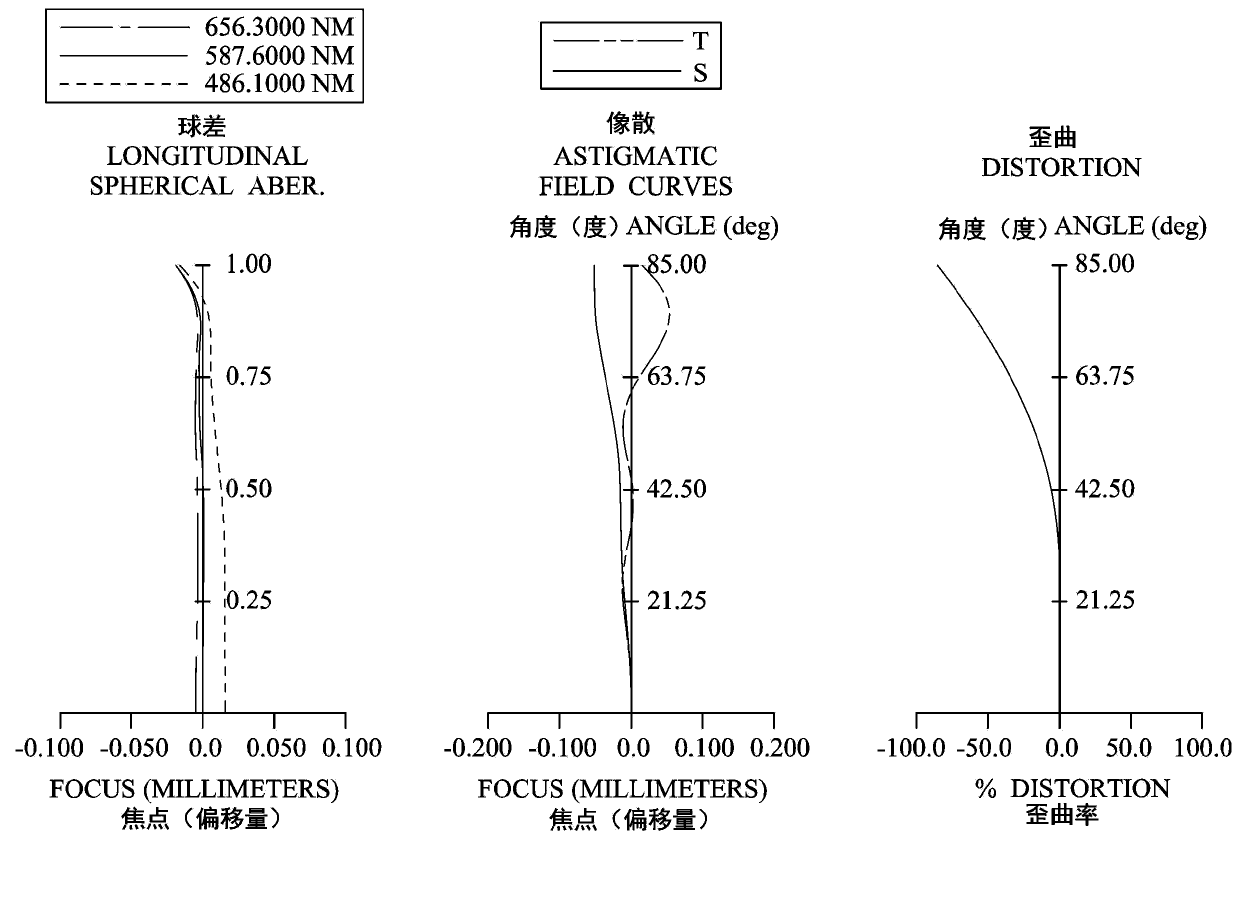

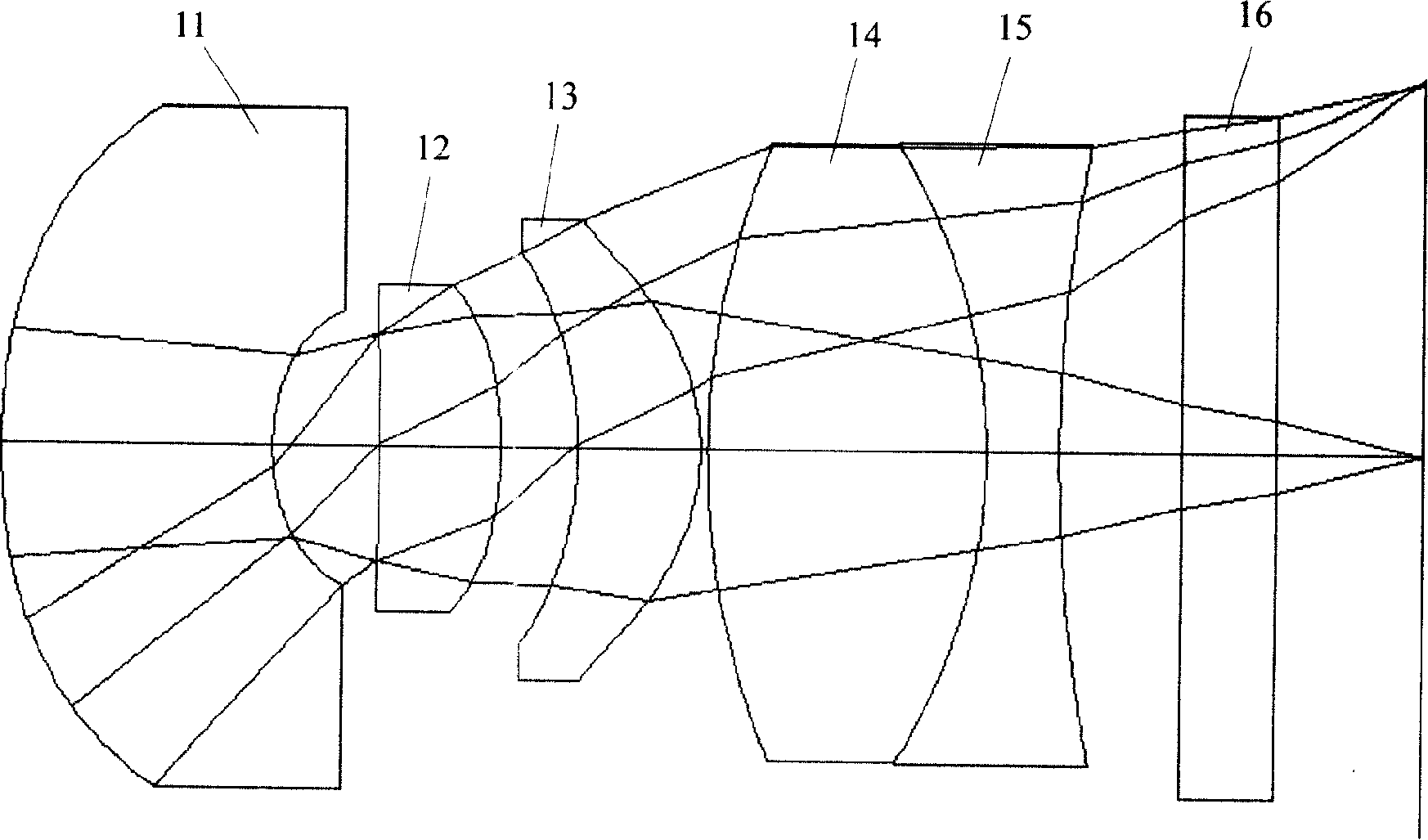

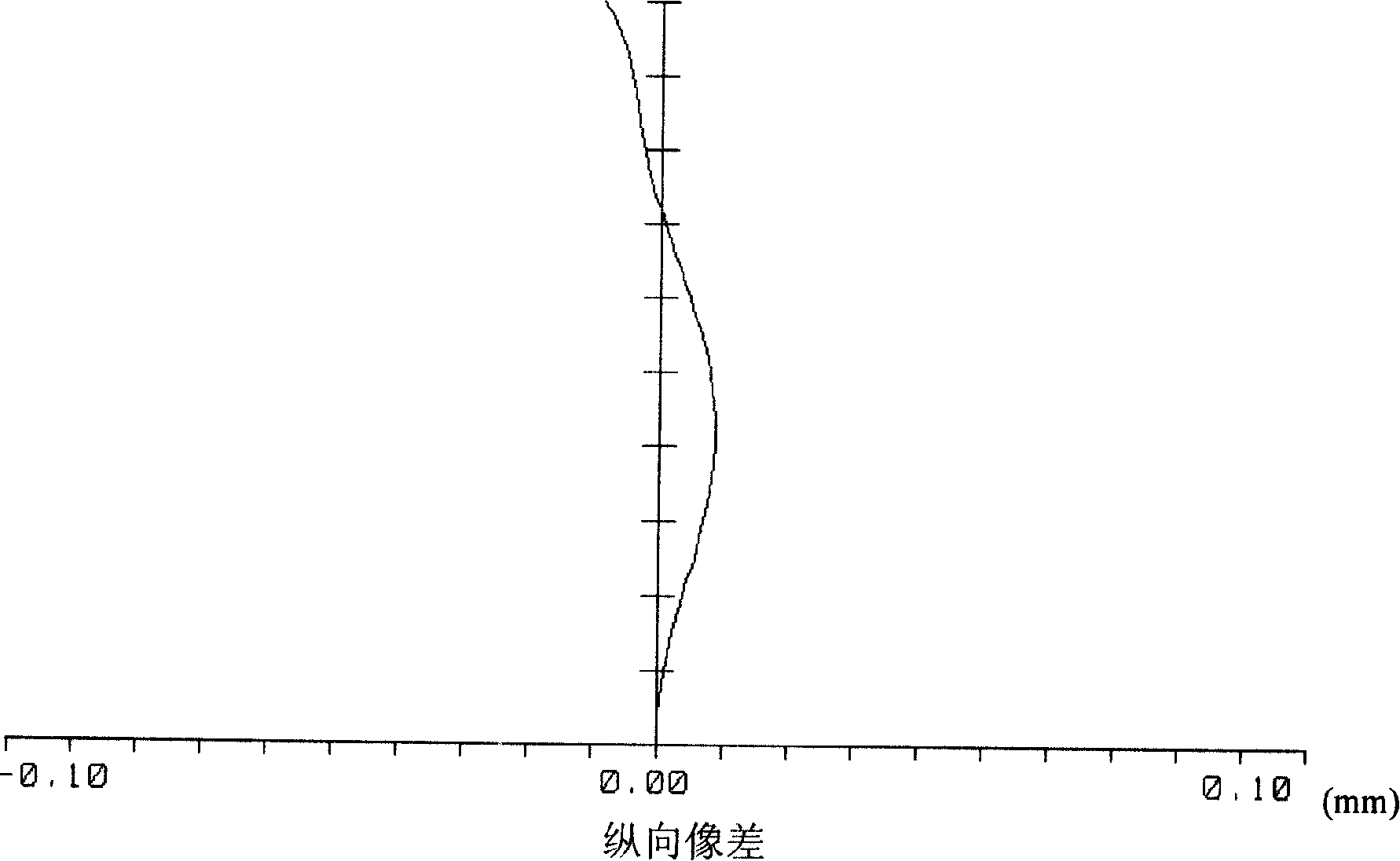

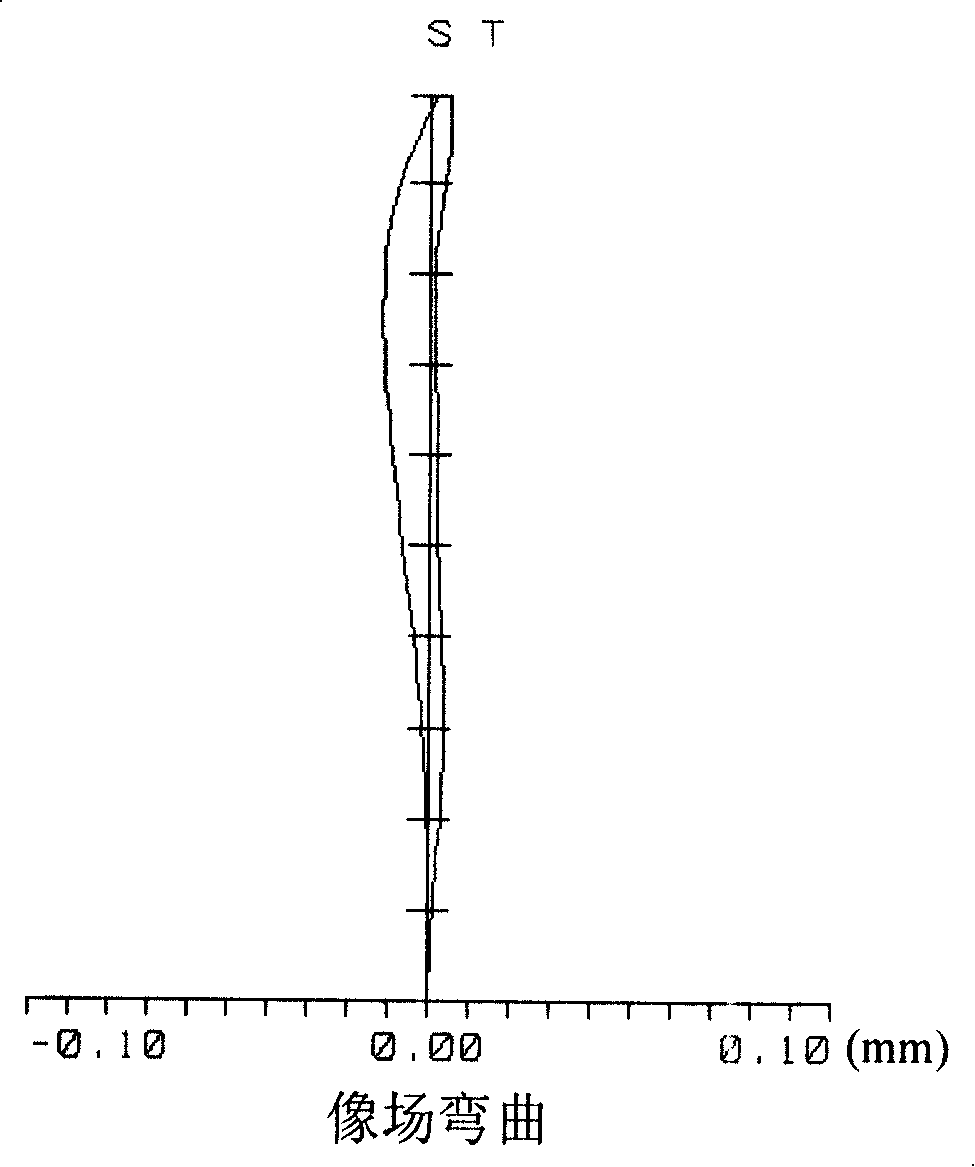

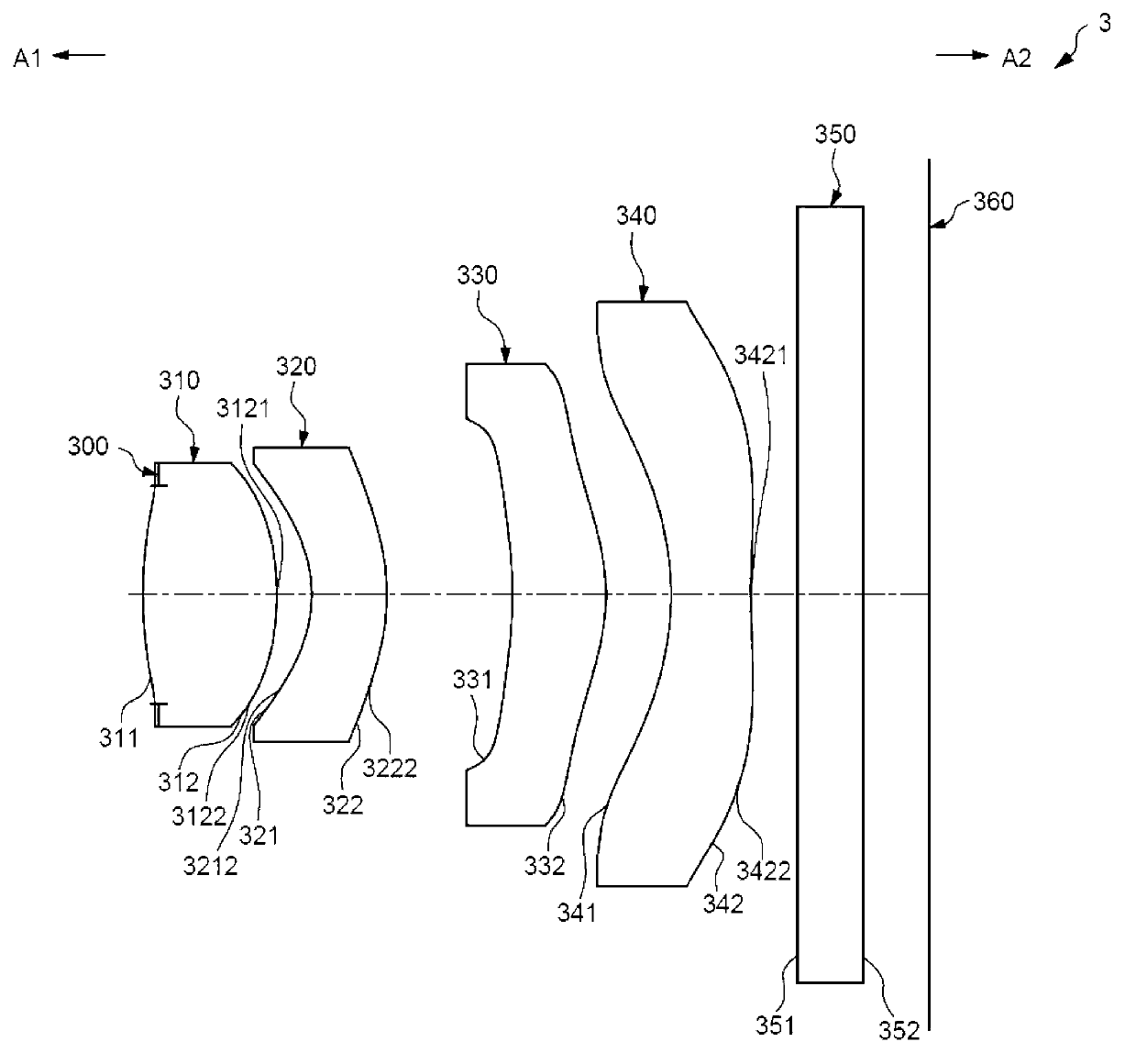

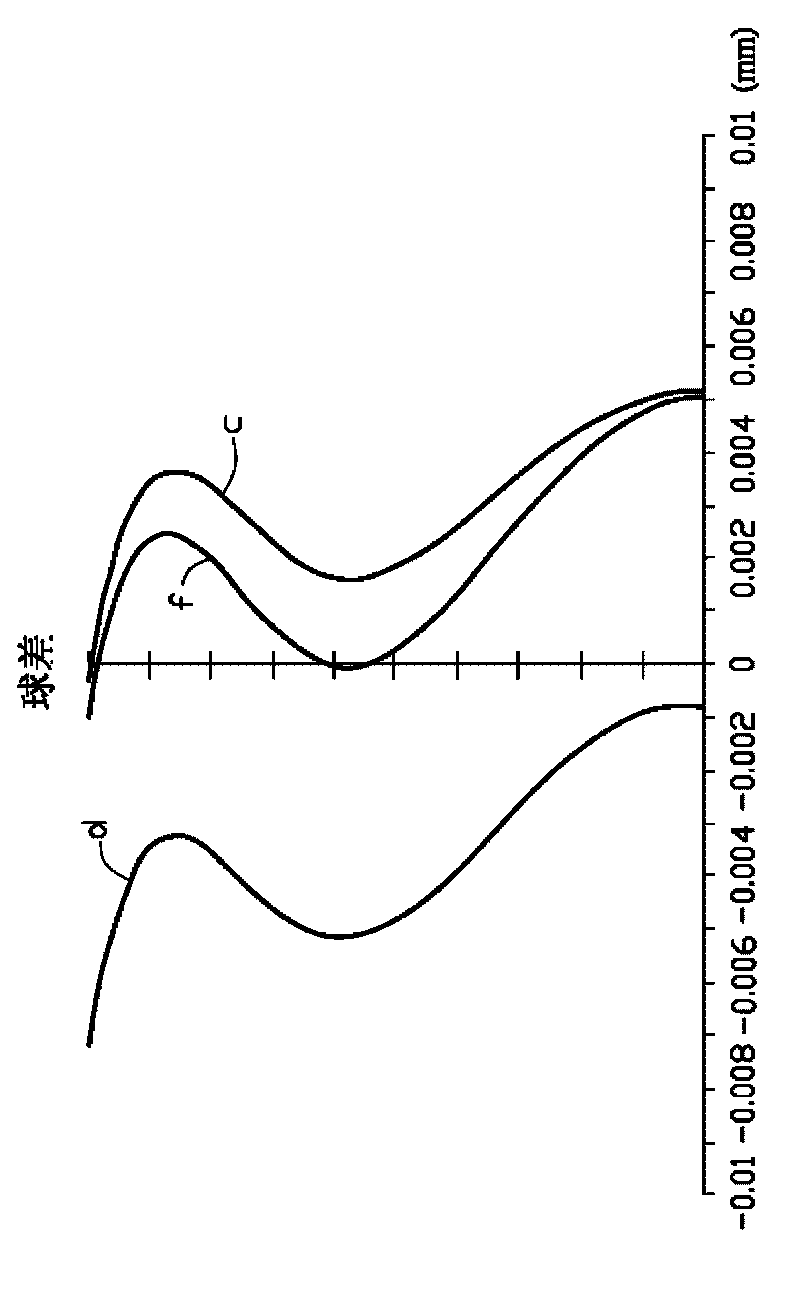

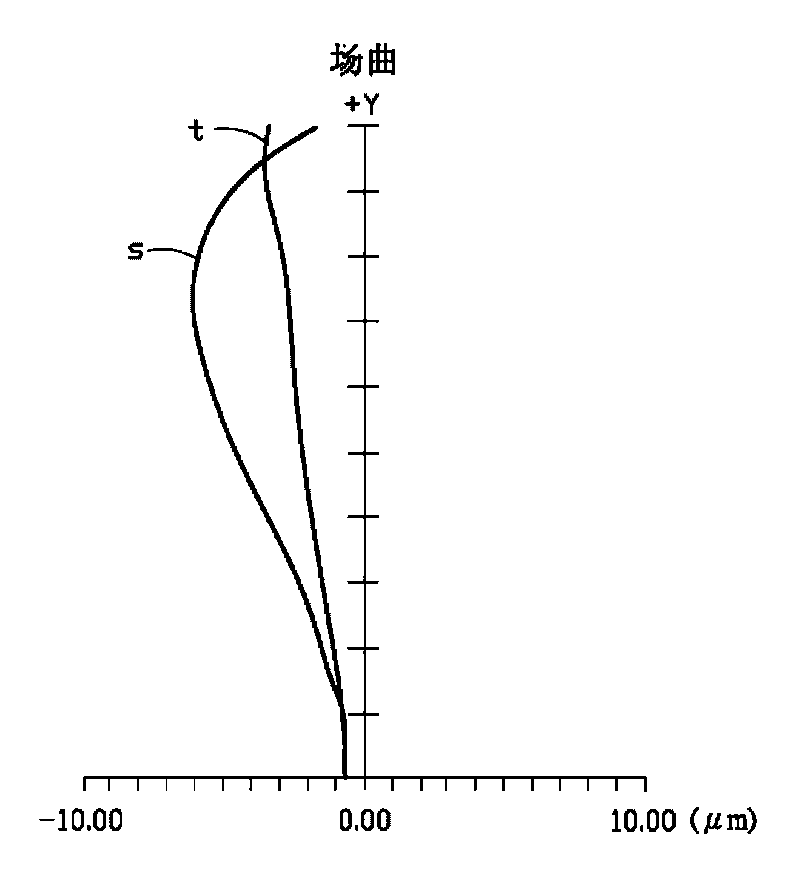

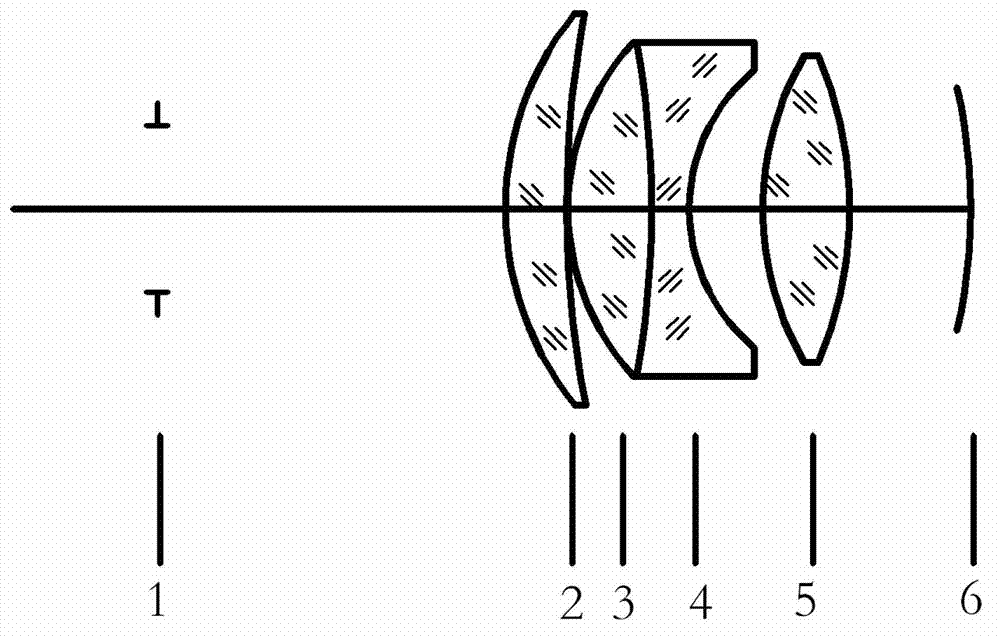

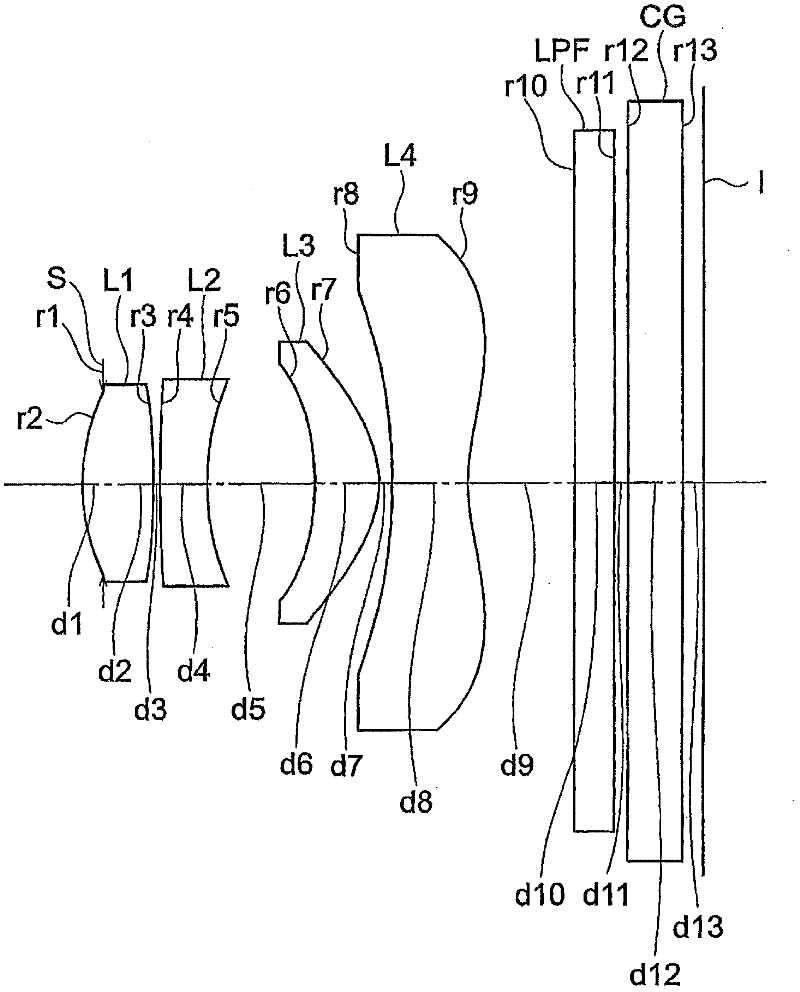

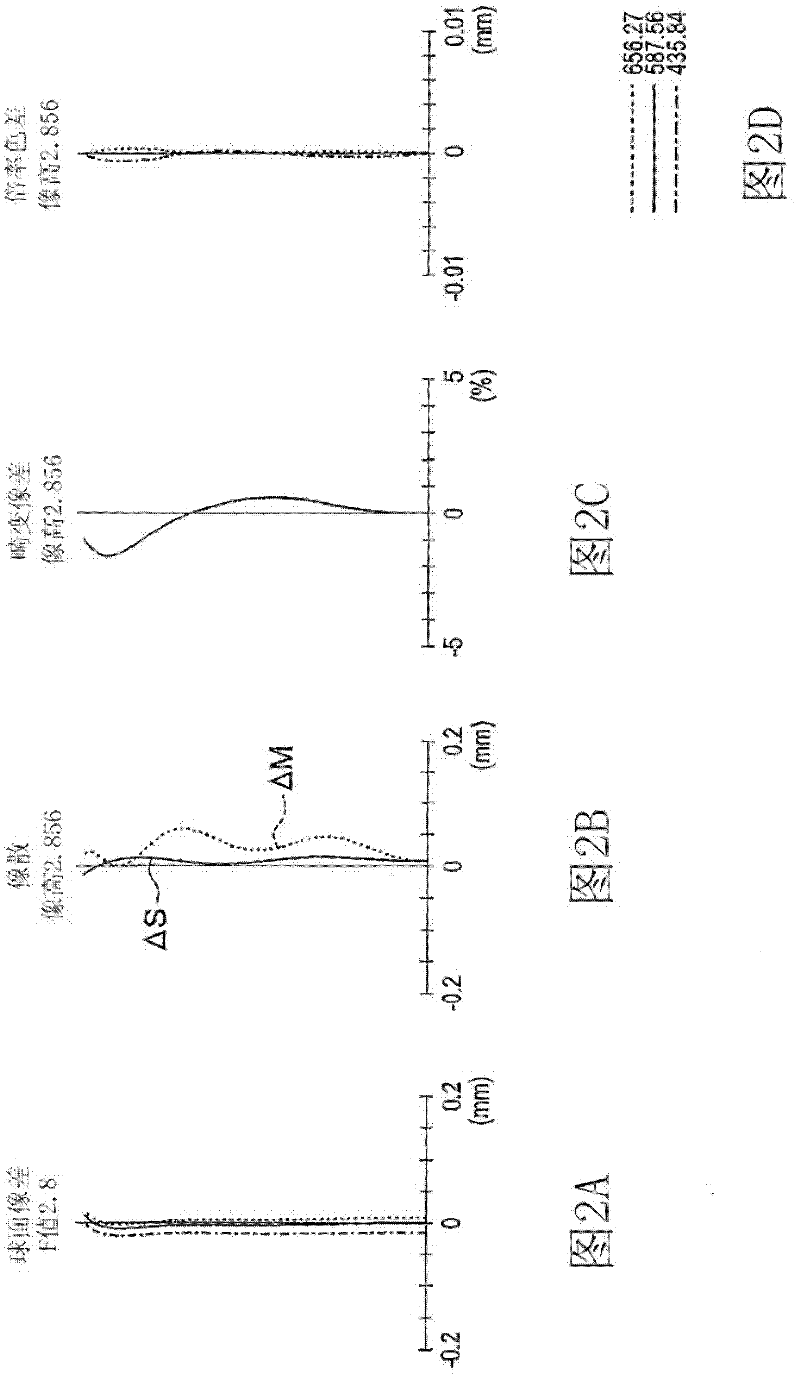

Wide-angle lens

ActiveCN101162290AShorten the overall lengthImprove optical performanceOptical elementsCamera lensPhysics

The invention discloses a wide-angle lens with a larger hole diameter and a 80 degrees wide vision angle; the wide-angle lens comprises the following elements from the object to the image: a first lens, a second lens, a third lens and a balsaming lens, wherein, the first lens is a negative lens with high refractive index, the first surface of the first lens located at the side of the object is a convexity facing to the object, and the first surface also adopts a non-spherical design; the second lens is a crescent positive lens which is arranged behind an iris(not shown in the figure) and faces to the object, the crescent positive lens is provided with at least one non-spherical face; the third lens is also a crescent positive lens which is provided with at least one non-spherical face; the balsaming lens is made by gluing a fourth lens and a fifth lens and is of plus power. The wide-angle lens satisfies a particular condition, so the whole length of the lens can be more effectively shortened and the product is compacter.

Owner:ASIA OPTICAL CO INC

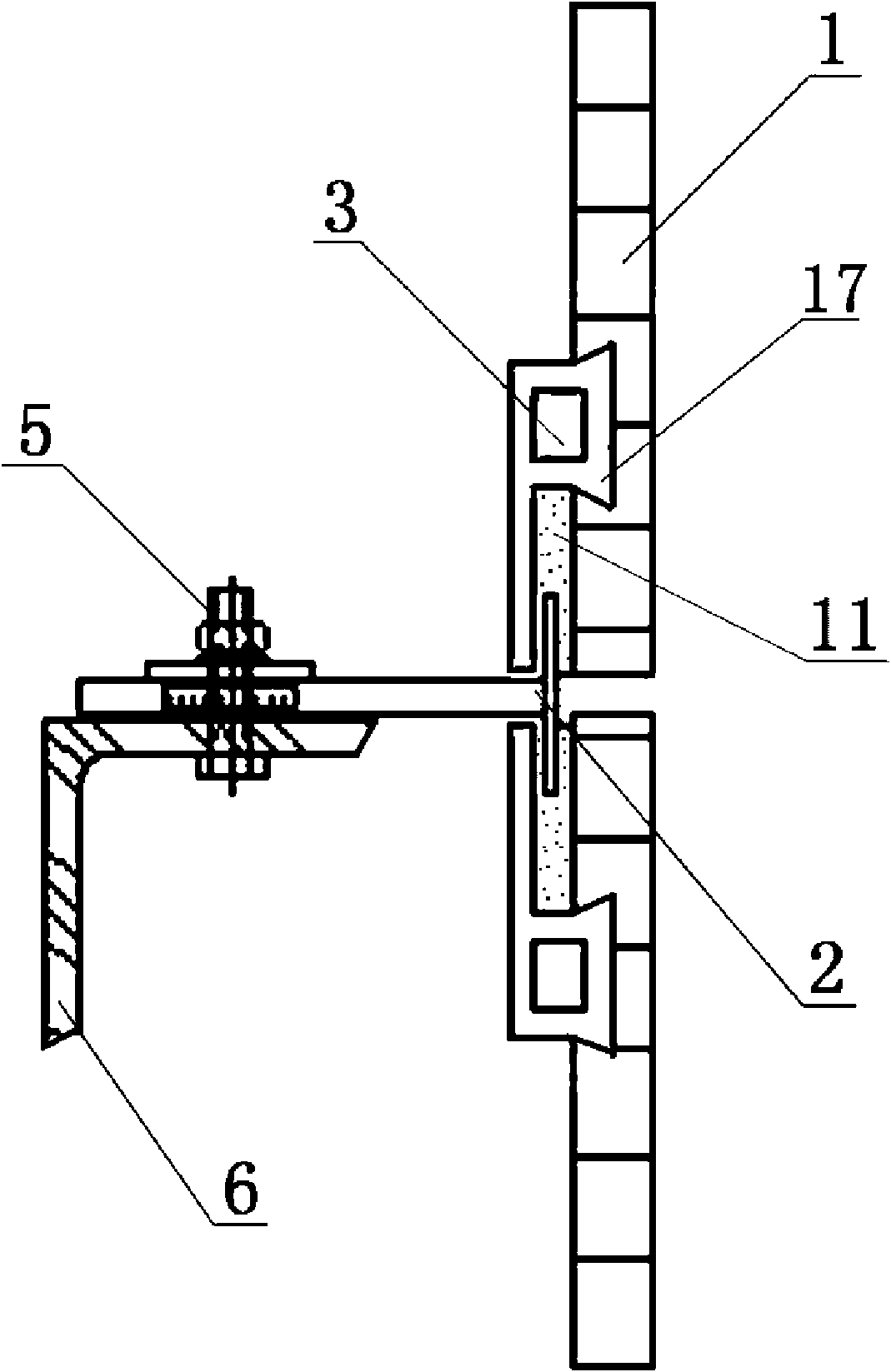

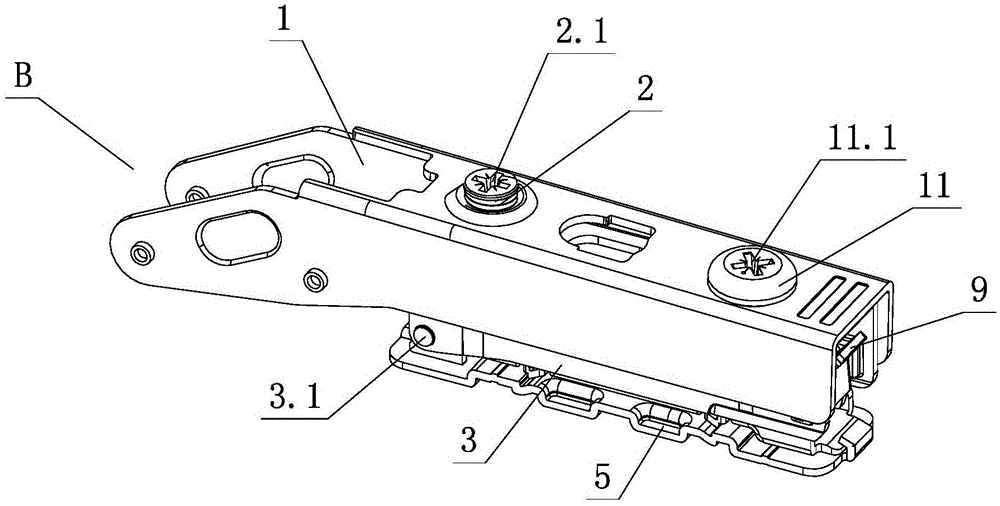

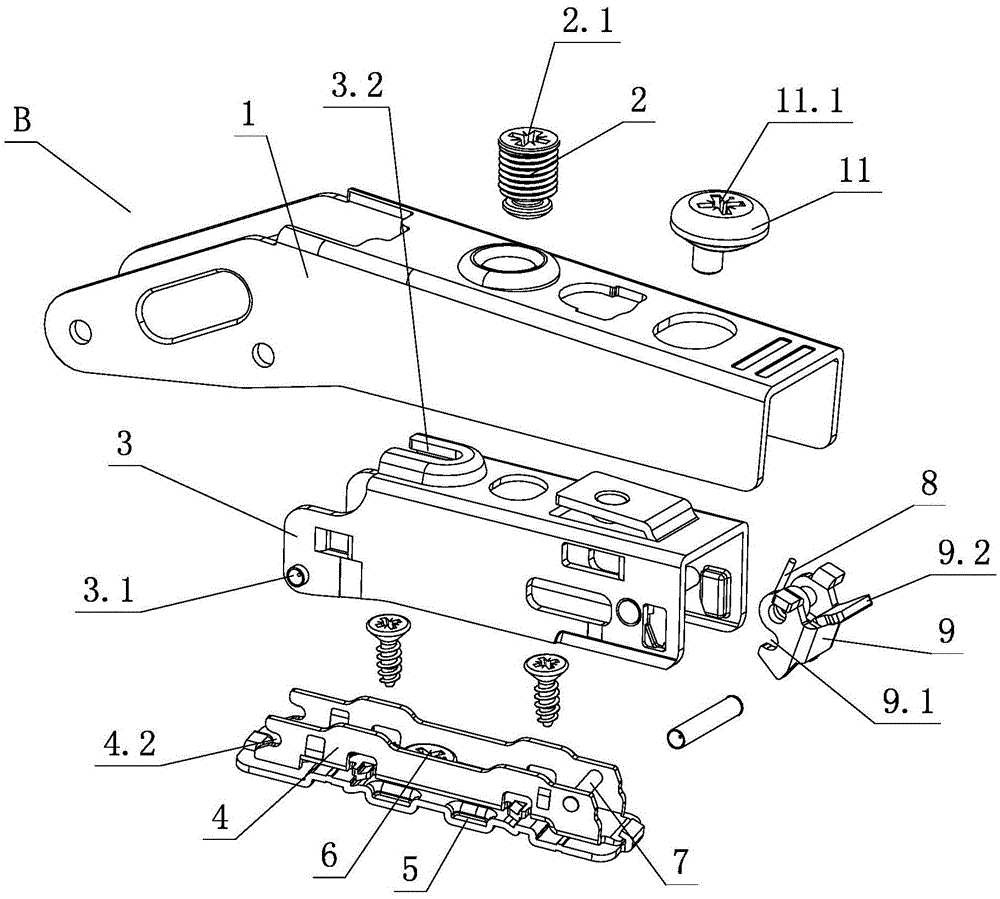

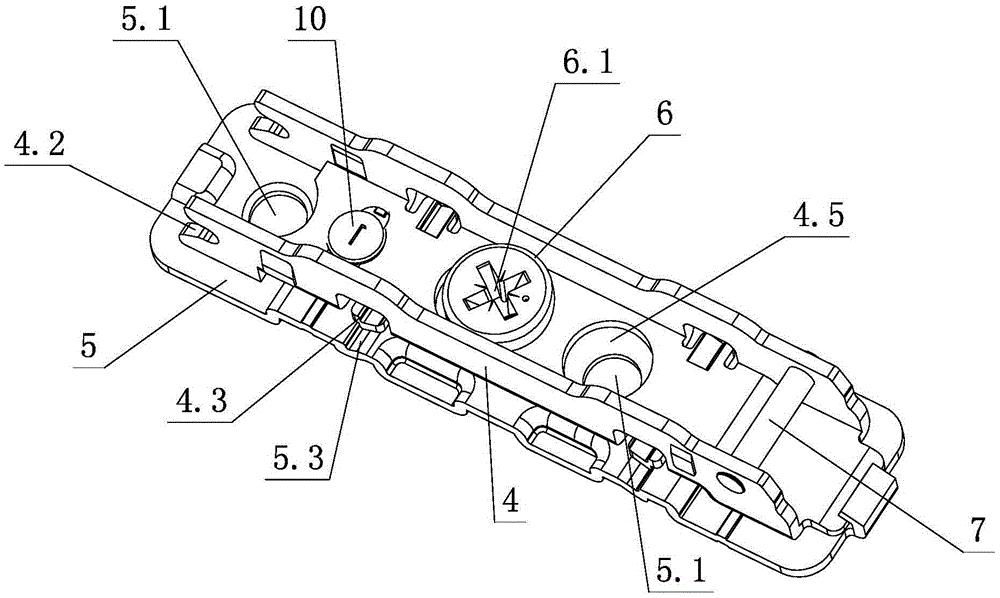

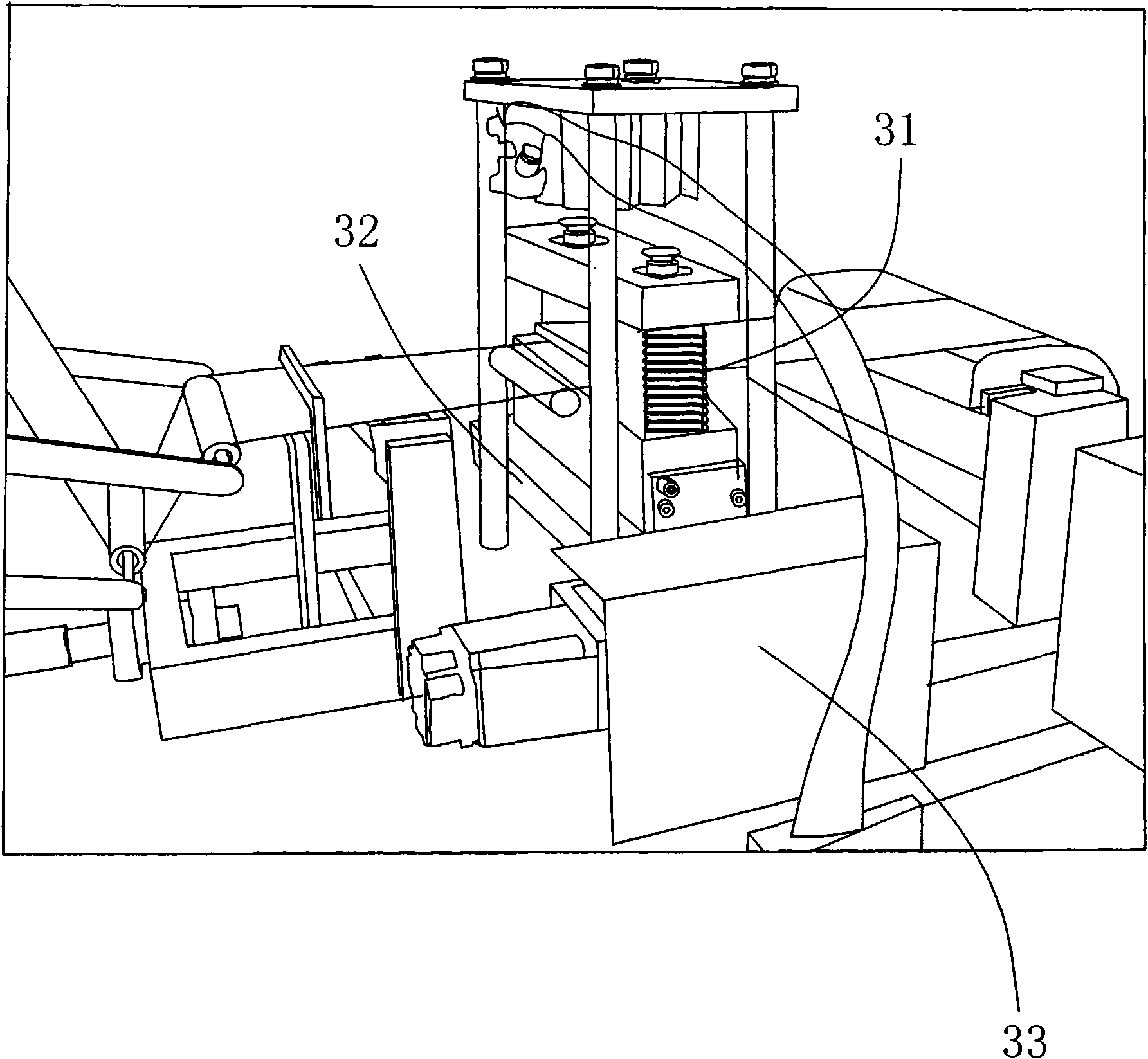

Detachable regulating mechanism of furniture hinge

InactiveCN105604421AShorten the overall lengthExquisite appearanceWing accessoriesHingesEngineeringMechanical engineering

A detachable regulating mechanism of a furniture hinge comprises a fixed base device and a fixed support device mutually hinged through a transmission arm, the fixed base device comprises a regulating seat and a base component, the regulating seat is provided with a middle member through a screw regulator, the base component comprises a locking element, a base element and an eccentric element, the locking element is U shaped, a locking mating portion is arranged between the front end of the locking member and the front end of the middle member, the rear end of the locking element is transversely provided with a fastening shaft in a positioned manner that is locked to and separated from an elastic fastening component on the middle member in a detachable manner, the middle of the locking element is provided with a connecting notch, the front and rear ends of the base element are provided with fixing portions, respectively, the middle of the base element is provided with a connecting hole, one end of the eccentric element acts on the connecting hole, the middle of the eccentric element acts on the connecting notch, the other end of the eccentric element is provided with an eccentric acting portion, a sliding guide portion is disposed between the locking element and the base element in a mutual sliding fit manner, and the eccentric acting portion is activated through a tool or manually to adjust left-right positions of the locking element and the base element.

Owner:伍志勇

Method for optimizing connection of workpiece detection flow line by aid of transfer cases which are used as carriers

ActiveCN103600969AShorten the overall lengthFlexible schedulingConveyor partsMechanical conveyorsTransfer caseEngineering

Owner:STATE GRID CORP OF CHINA +2

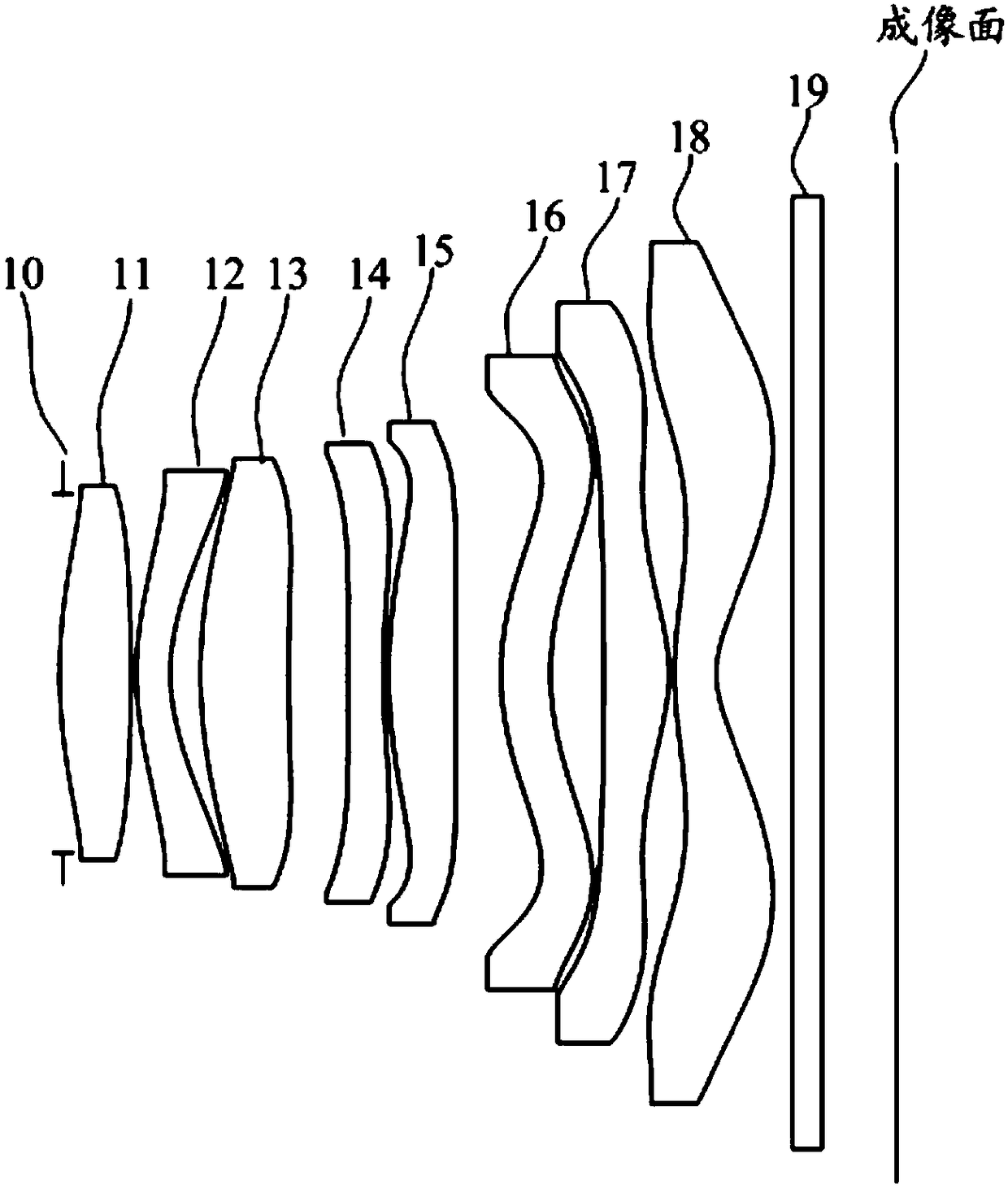

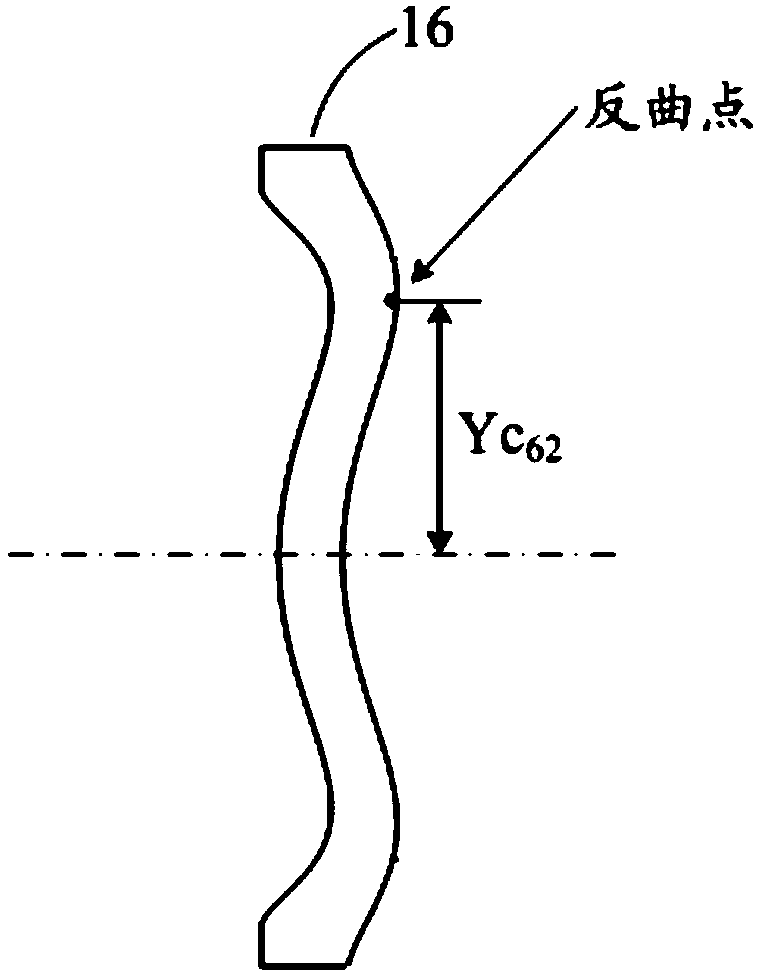

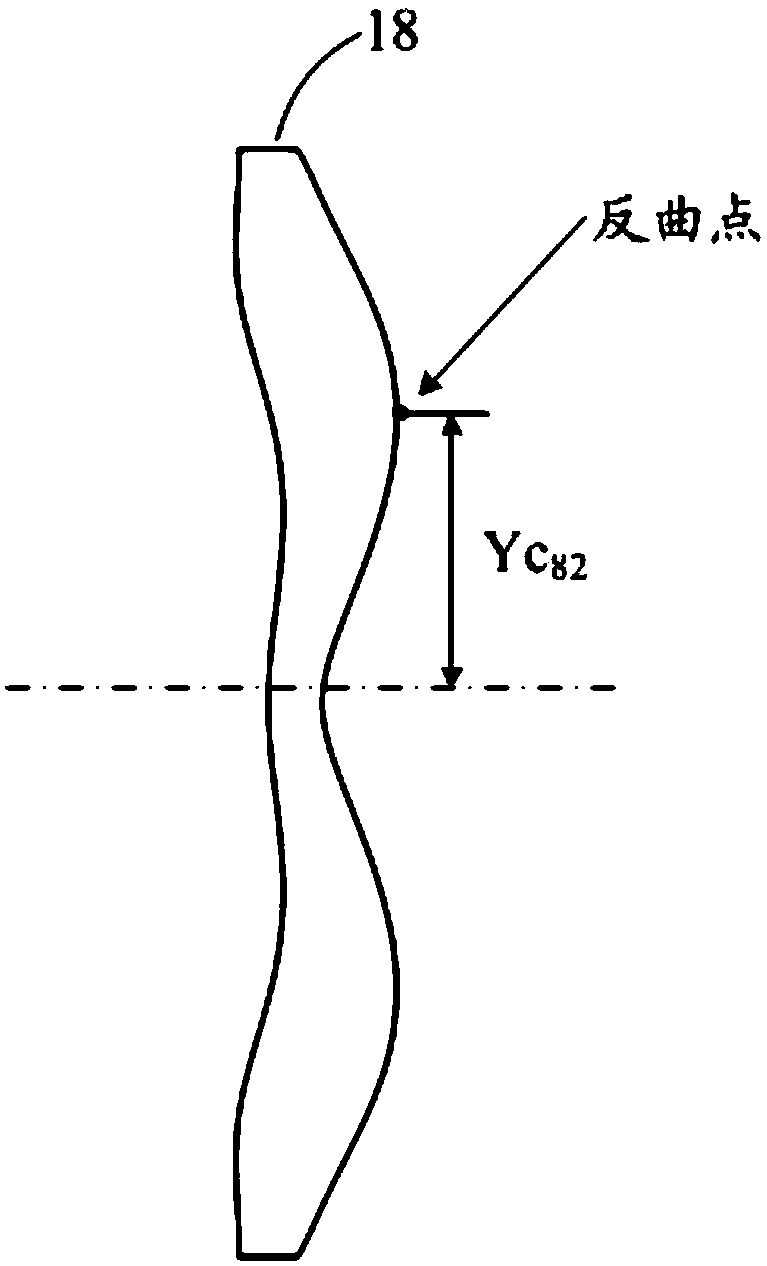

Optical imaging lens and electronic equipment

ActiveCN109061838AShorten the overall lengthRaise the light heightOptical elementsPhysicsCamera lens

The invention discloses an optical imaging lens. The optical imaging lens comprises a first lens, a second lens, a third lens, a fourth lens, a fifth lens, a sixth lens, a seventh lens and an eighth lens, wherein the first lens has positive refractive power, an imaging side surface of the first lens is a convex surface at a near optical axis, the second lens has negative refractive power, the third lens has refractive power, the fourth lens has refractive power, an object side surface of the fourth lens is a convex surface at an optical axis, an imaging side surface of the fourth lens is a concave surface at a near optical axis, the fifth lens has refractive power, the sixth lens has refractive power, an object side surface of the sixth lens is a convex surface at a near optical axis, an imaging side surface of the sixth lens is a concave surface at a near optical axis and is provided at least one inflexion point, the seventh lens has refractive power, the eighth lens has refractive power, and an imaging side surface of the eighth lens is provided with at least one inflexion point. The optical imaging lens is relatively short in lens length, has large optical aperture and excellentvisual field angle, favorable imaging quality can be achieved, and the application requirement can be met. The invention also provides electronic equipment.

Owner:GUANGDONG XUYE OPTOELECTRONICS TECH

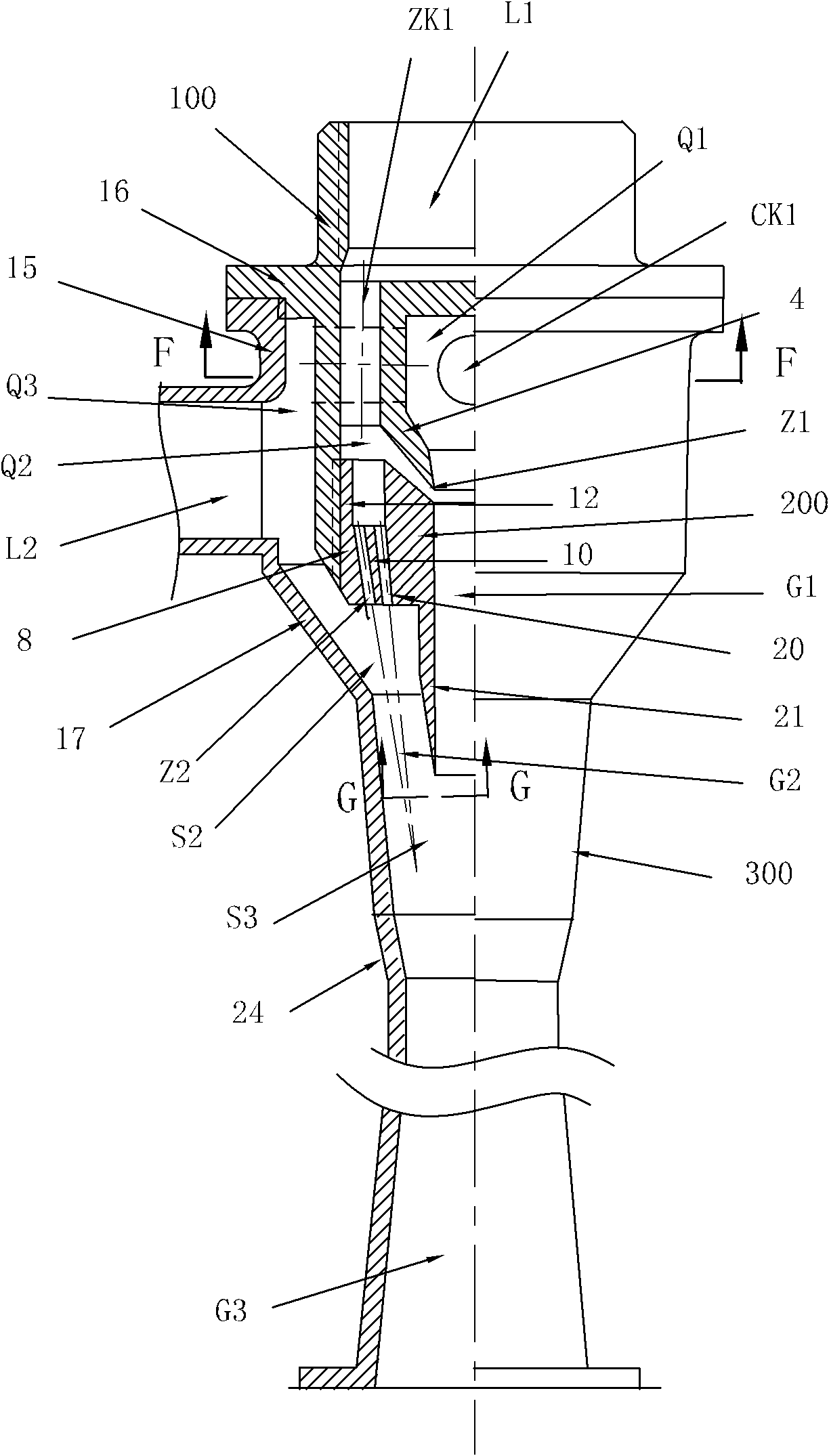

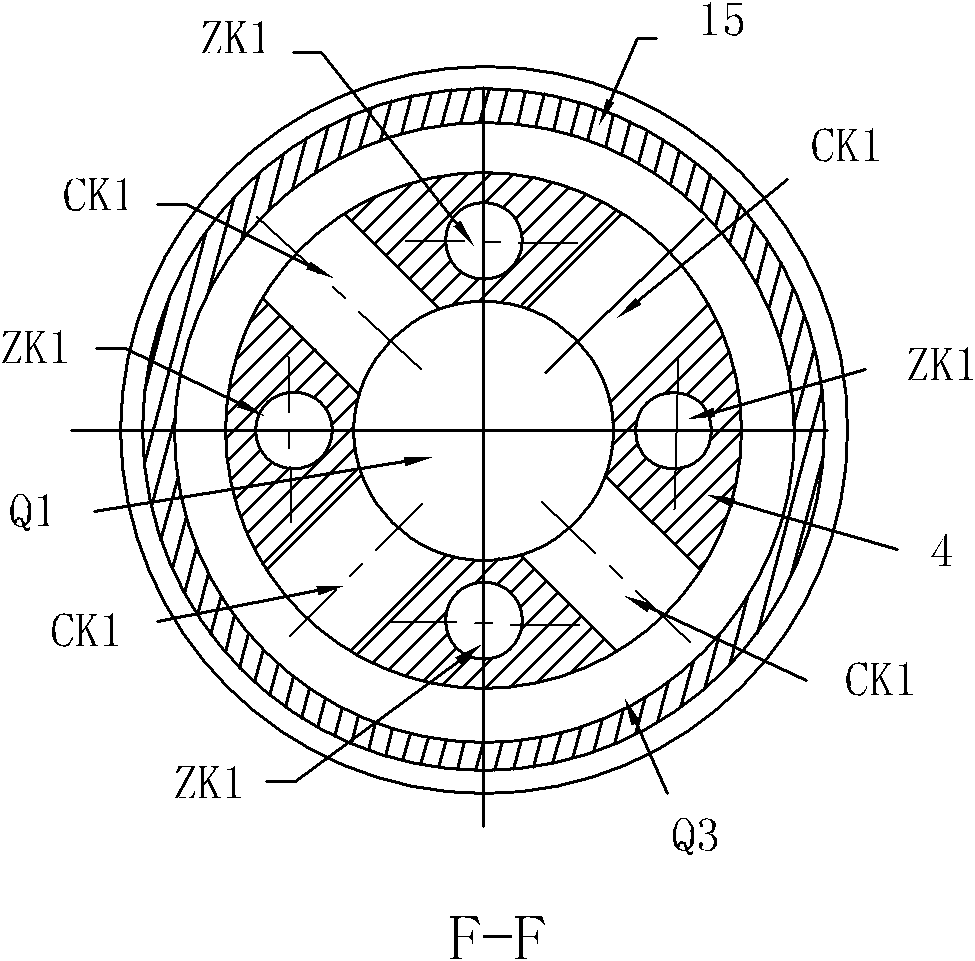

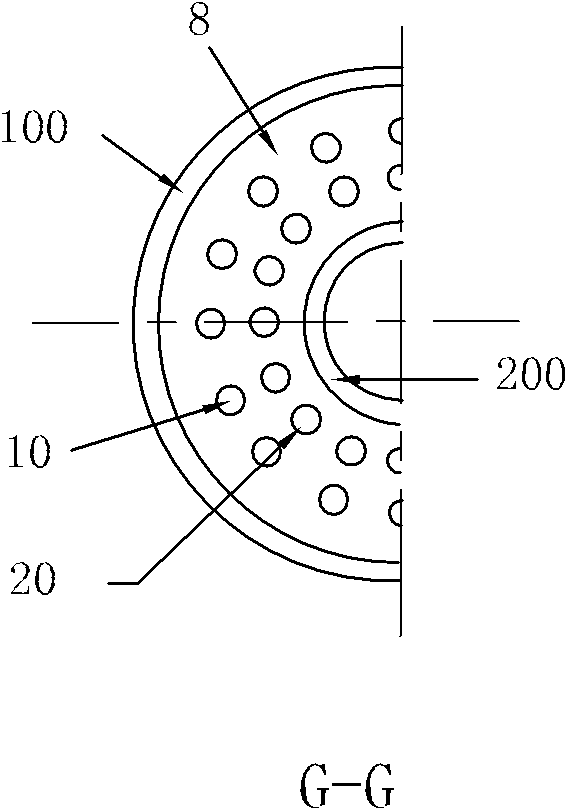

Jet pump

InactiveCN102654145ANovel structureUnique structureJet pumpsMachines/enginesSuction forceEngineering

The invention provides a jet pump, and relates to a mixed flow jet apparatus. The jet pump is composed of a current distributing assembly, an inner pipe assembly and an outer sleeve assembly which have a same shaft core, wherein the current distributing assembly and the inner pipe assembly are fixedly connected in series, thereby forming a blind top centre cavity and a centre mixing tube; the outer sleeve assembly is sleeved outside the current distributing assembly and the inner pipe assembly, thereby forming an annular mixing chamber, an annular mixing pipe, a total mixing chamber and a total mixing output pipe; an internal ring nozzle and an external ring nozzle are arranged between the current distributing assembly and the inner pipe assembly, a mainstream body sprayed by the internal ring nozzle carries out jet-suction on a secondary fluid of the blind top centre cavity so as to spray to the centre mixing tube, and the secondary fluid is mixed in the centre mixing tube so as to output a centre mixed flow; a mainstream body sprayed by the external ring nozzle carries out jet-suction on a secondary fluid of the blind top centre cavity so as to spray to the annular mixing pipe, and the secondary fluid is mixed in the annular mixing pipe so as to output an annular mixed flow; and the two mixed flows are mutually injected to enter the total mixing chamber and the total mixing output pipe so as to further output in an isotrope voltage-sharing manner. The jet pump provided by the invention has the advantages of smaller weight and axial direction size, high injection rate, great suction force and good property in large flow.

Owner:韩铁夫

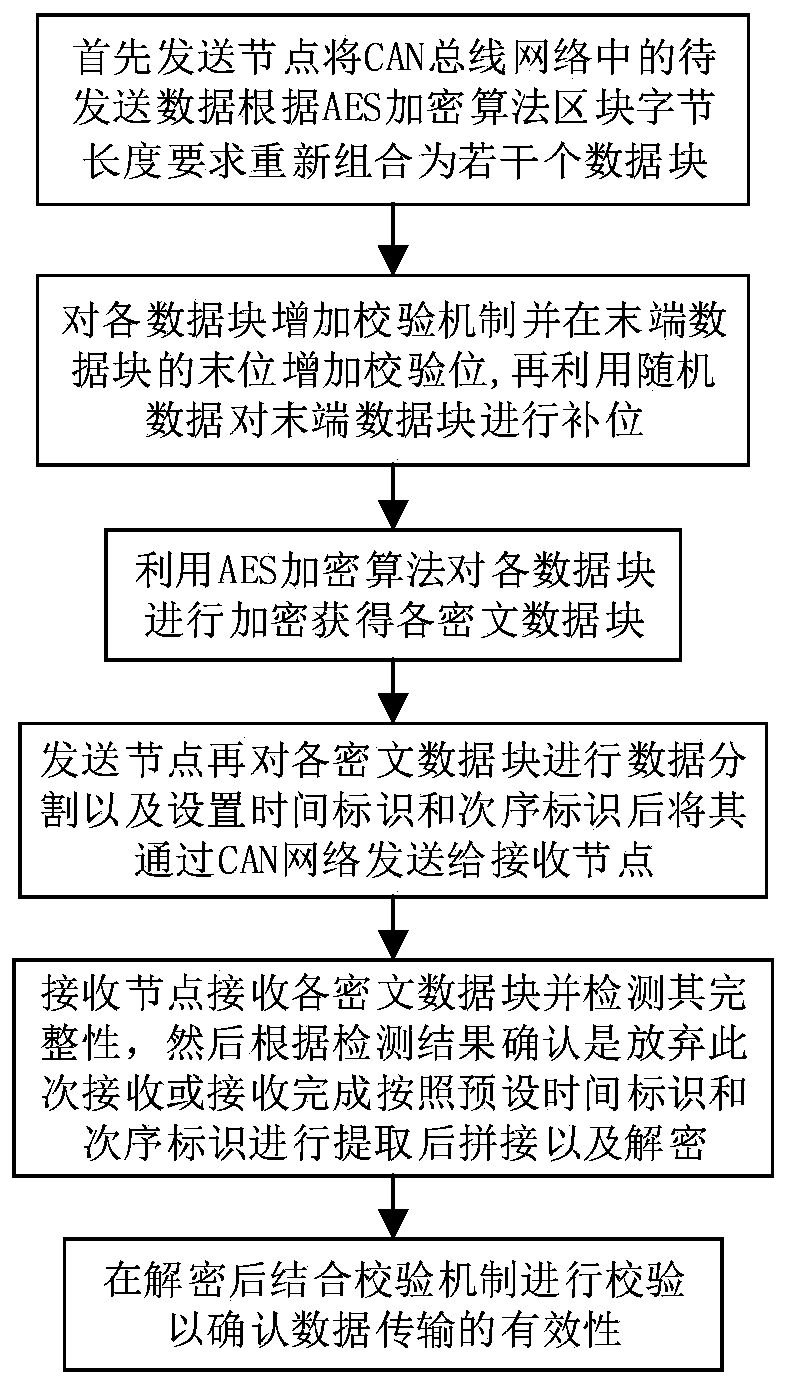

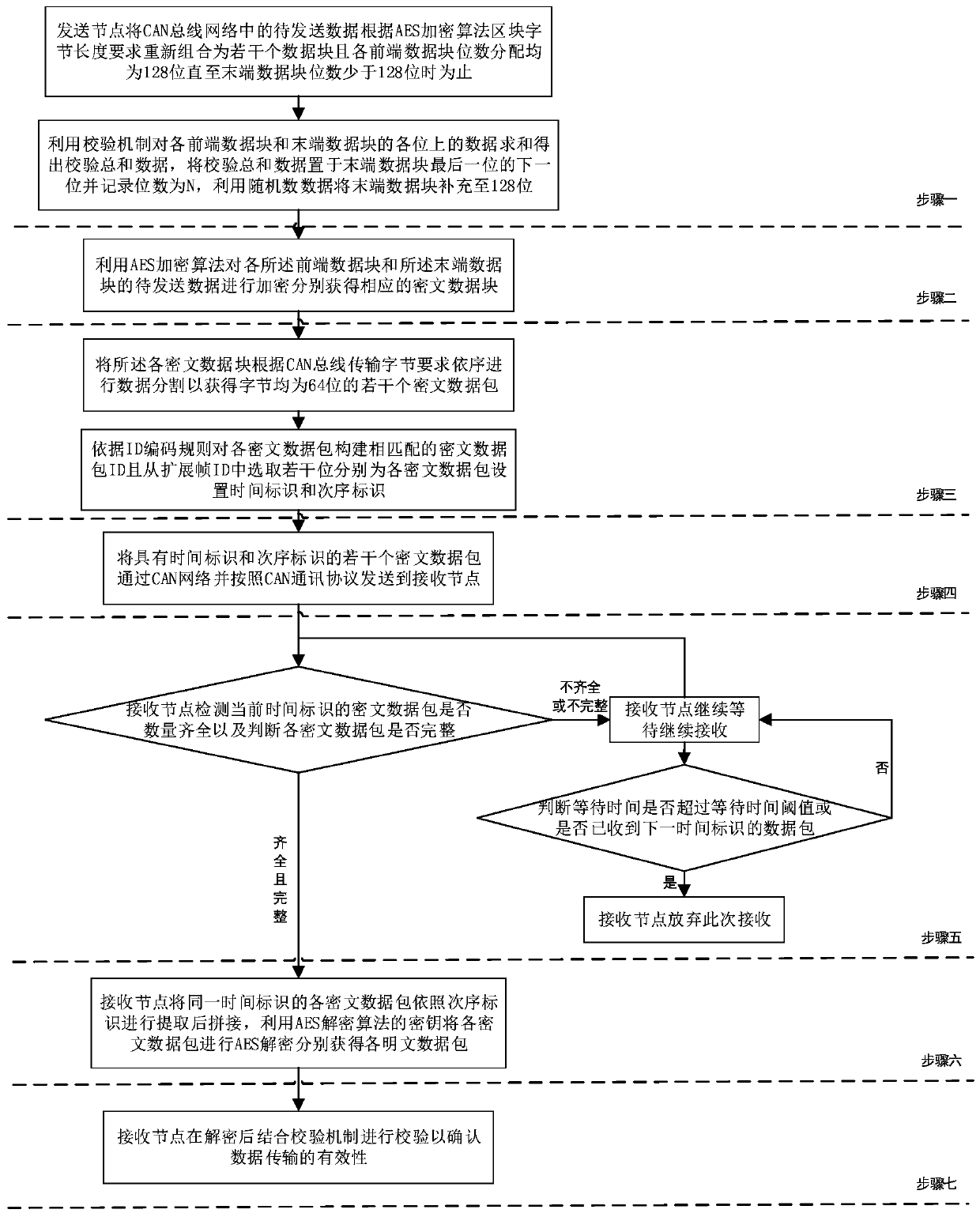

Automobile CAN bus encryption method

ActiveCN110545257AEnsure safetyReduce communication loadEncryption apparatus with shift registers/memoriesBus networksCiphertextData information

The invention relates to an automobile CAN bus encryption method. The method includes: firstly enabling a sending node to recombine to-be-sent data in a CAN bus network into a plurality of data blocksaccording to an AES encryption algorithm block byte length requirement; adding a check mechanism to each data block and adding a check bit to the tail of the tail end data block; carrying out bit compensation on the tail end data block by utilizing random data; encrypting each data block by using an AES encryption algorithm to obtain each ciphertext data block; enabling the sending node to perform data segmentation on each ciphertext data block, set a time identifier and an order identifier and send the ciphertext data blocks to the receiving node through the CAN network; enabling the receiving node to receive each ciphertext data block and detect the integrity of each ciphertext data block; according to the detection result, confirming that that it is discarded that this time of receiving is completed or splicing and decryption are conducted after extraction is conducted according to the preset time identifier and the sequence identifier, carrying out verification in combination witha verification mechanism after decryption to confirm the effectiveness of data transmission. The data transmission efficiency is improved, and the safety of data information transmission on an automobile is guaranteed.

Owner:BEIJING HANGSHENG NEW ENERGY TECH CO LTD

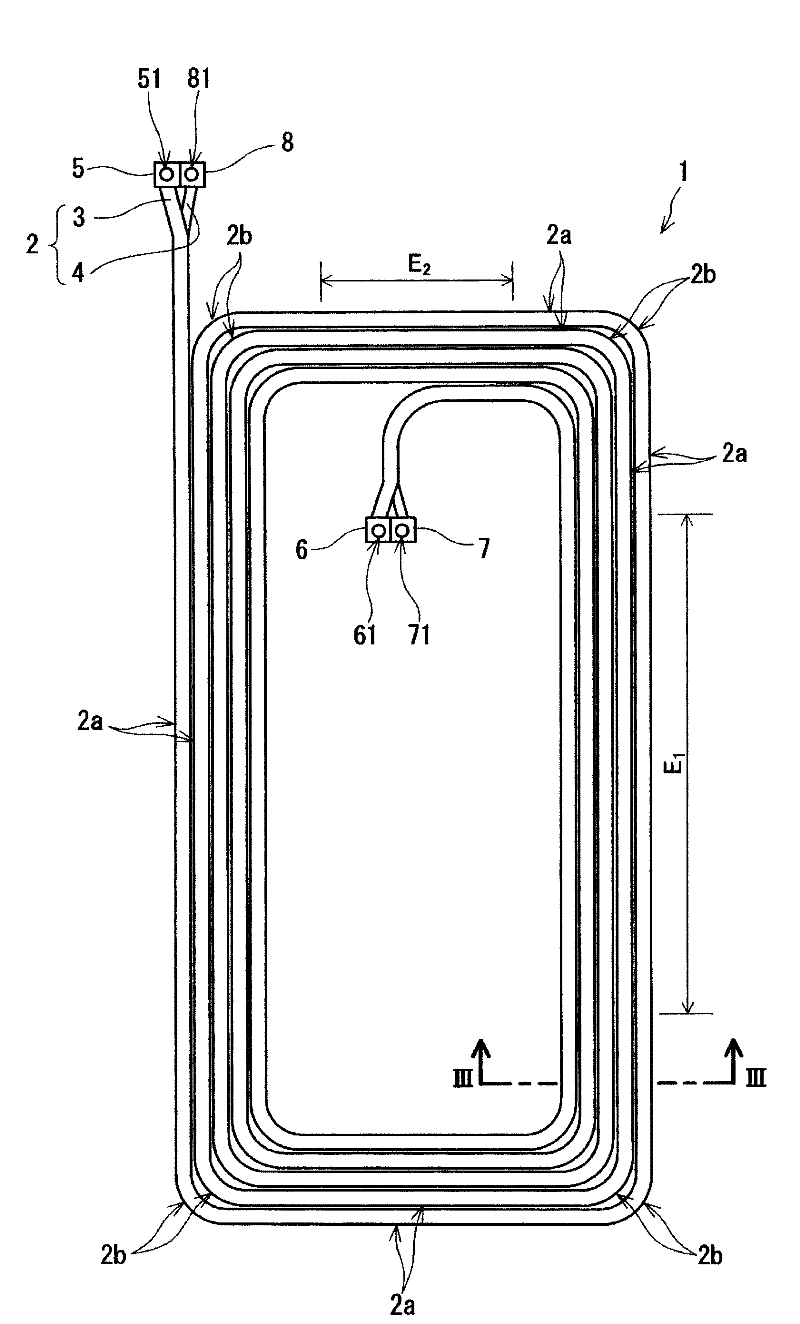

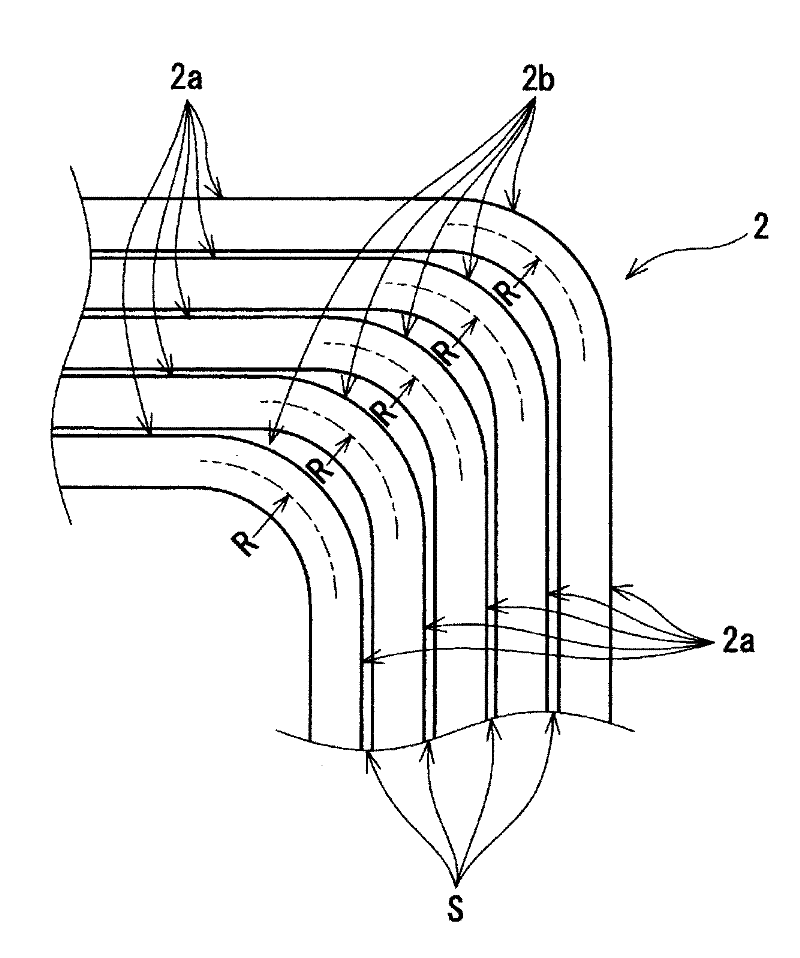

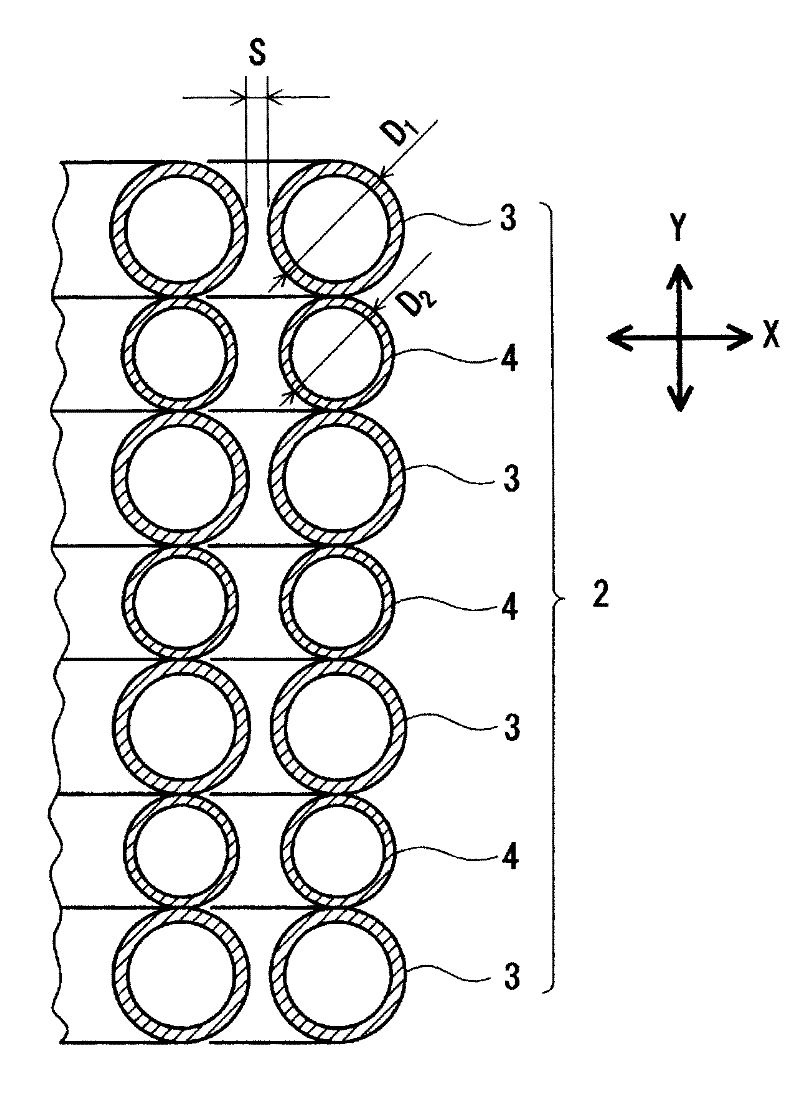

heat exchanger

InactiveCN102301197AImprove temperature uniformityImprove heat exchange efficiencyFluid heatersHeating fuelEngineeringHeat transfer tube

A heat exchanger includes a heat transfer tube group in which a plurality of first heat transfer tubes (3) through which a first fluid flows and a plurality of second heat transfer tubes (4) through which a second fluid that exchanges heat with the first fluid flows are arranged alternately while being in contact with each other. The heat transfer tube group is formed in a spiral shape by being wound in X direction perpendicular to Y direction in which the first heat transfer tubes (3) and the second heat transfer tubes (4) are arranged. A plurality of concave portions (3a) are provided on both sides, in the X direction, of an outer circumferential surface (31) of each of the first heat transfer tubes (3), along an extending direction of the first heat transfer tube (3). The plurality of concave portions (3a) form convex portions on an inner circumferential surface of the first heat transfer tube (3).

Owner:PANASONIC CORP

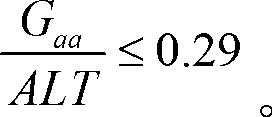

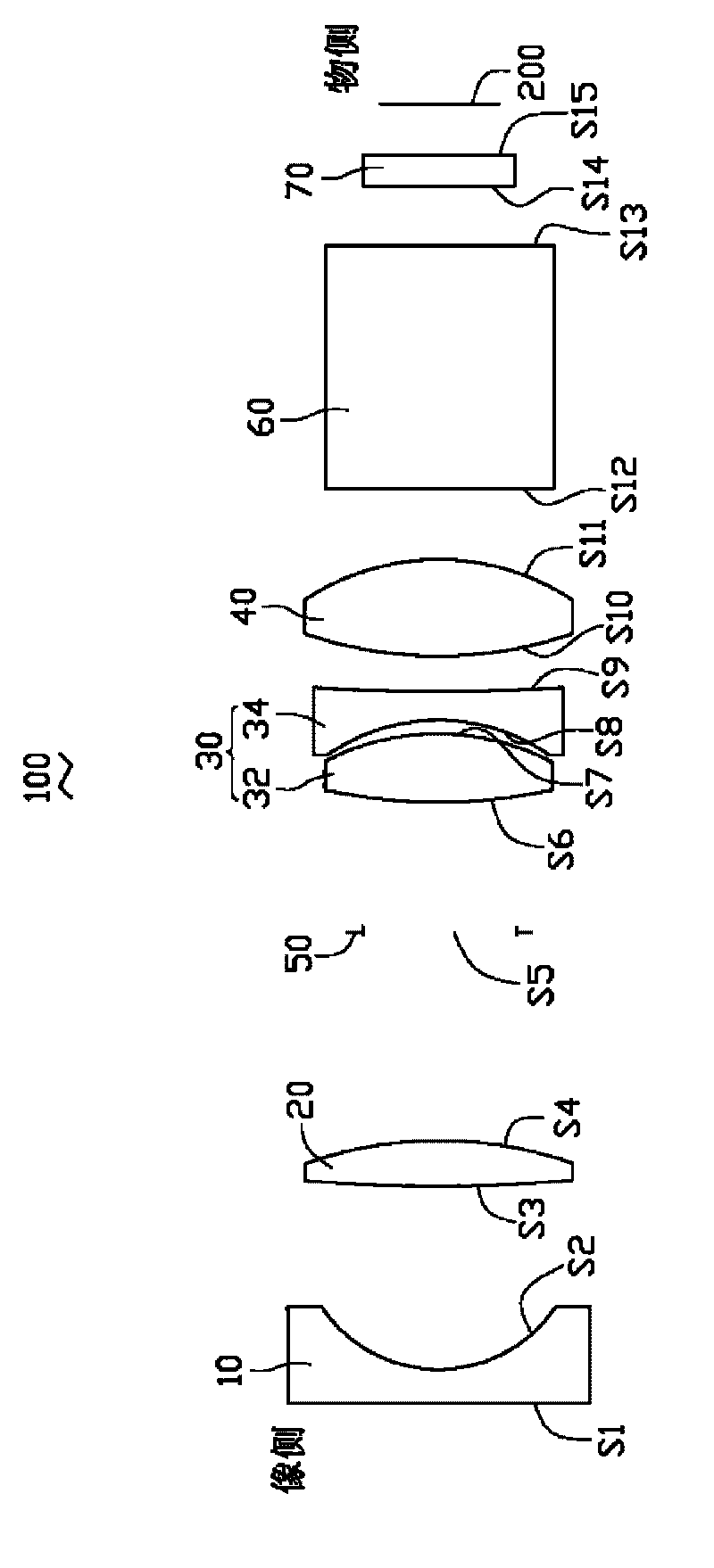

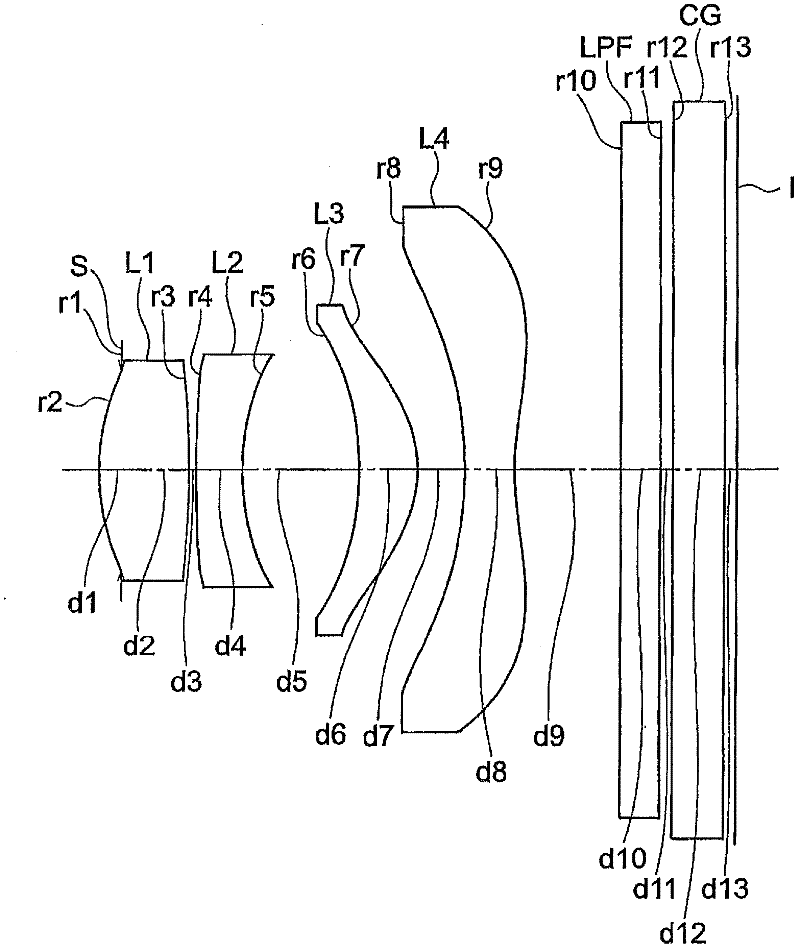

Portable electronic device and optical imaging lens thereof

ActiveCN103185958AGood optical performanceShorten the overall lengthMountingsCamera body detailsCamera lensOptical axis

The invention provides a portable electronic device and an optical imaging lens thereof. The optical imaging lens comprises four lenses from an object side to an image side sequentially, wherein the sum of three air gaps in an optical axis from the first lens to the fourth lens is Gaa, and the air interval in the optical axis from the third lens to the fourth lens is G34; and the Gaa and the G34 can fulfill the condition expression that Gaa / G34 is smaller than or equal to 6.0. The portable electronic device comprises a frame and an imaging module arranged in the frame, wherein the imaging module comprises an optical imaging lens, a lens cone, a module pedestal unit and an image sensor. According to the portable electronic device and the optical imaging lens thereof, the total length of the system can be shortened under a condition that the excellent optical performance and the system performance can be maintained by controlling the concave and convex curve arrangement, the conditional expression of the ratio of phototropism and opticity and / or parameter and other characteristics of each lens.

Owner:GENIUS ELECTRONICS OPTICAL XIAMEN

Projection lens

InactiveCN101726833AReduce in quantityShorten the overall length of the lensOptical elementsCamera lensProjection lens

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

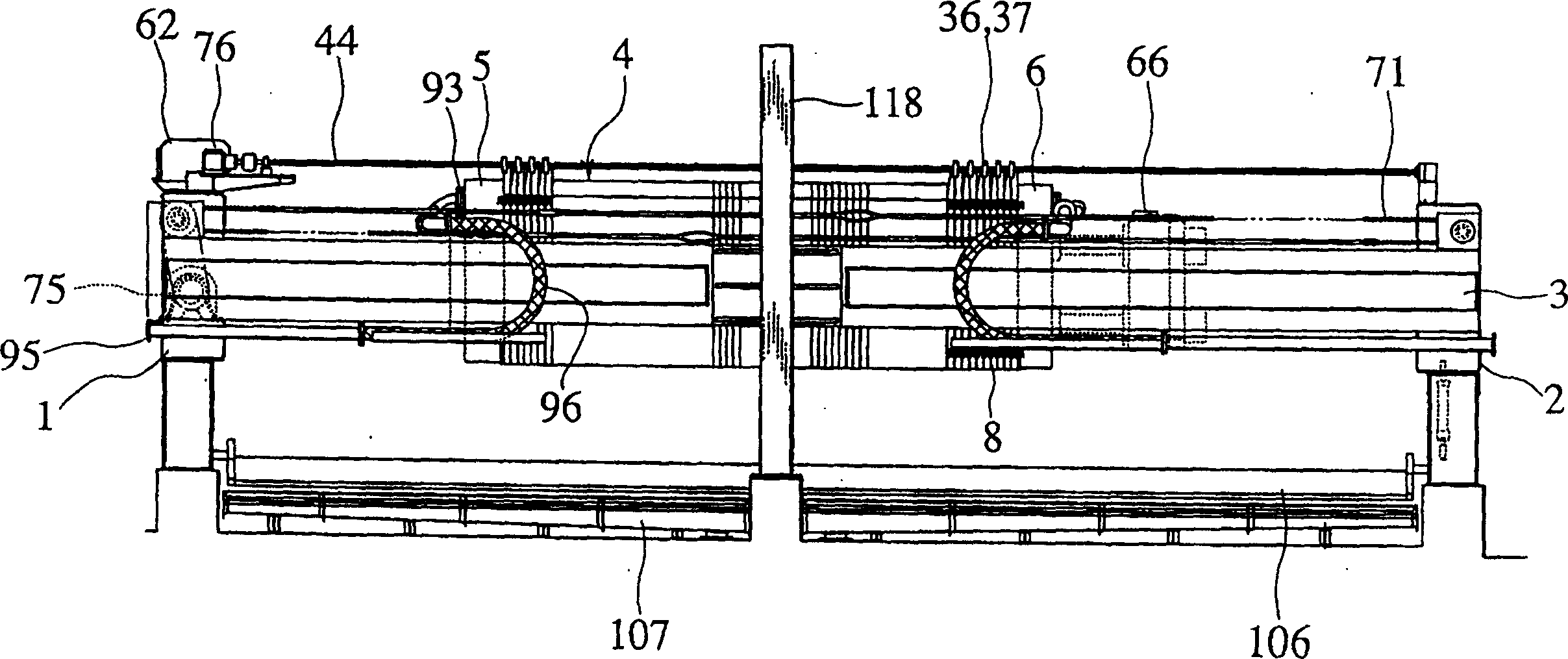

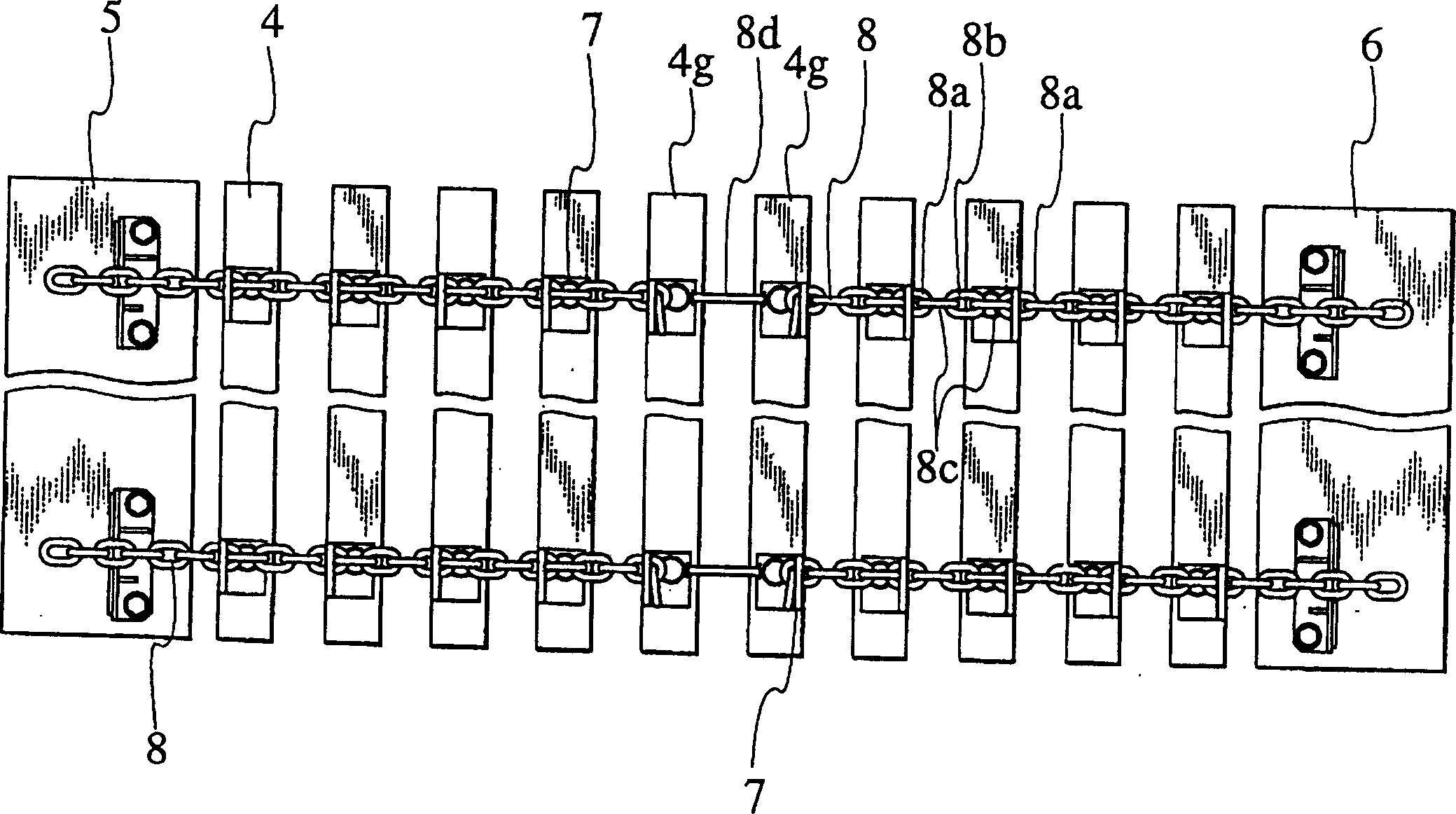

Filter press

InactiveCN1511610AImprove filtration efficiencyShorten the overall lengthFiltration separationFilter cakeFilter press

The present invention relates to press filter and is especially one press filter with several filter boards capable of being opened simultaneously to move filter cloths simultaneously to drain filter cakes and clean filter cloths. The press filter has two, one front and one back, supports, filter boards set on the steel tracks between the two supports, filter cloths set on the filter boards to form filtering chamber and connected via moving chains for opening and closing freely, upper and lower filter cloth fixing metal cores with original liquid passing hole in proper position.

Owner:ISHIGAKI CO LTD

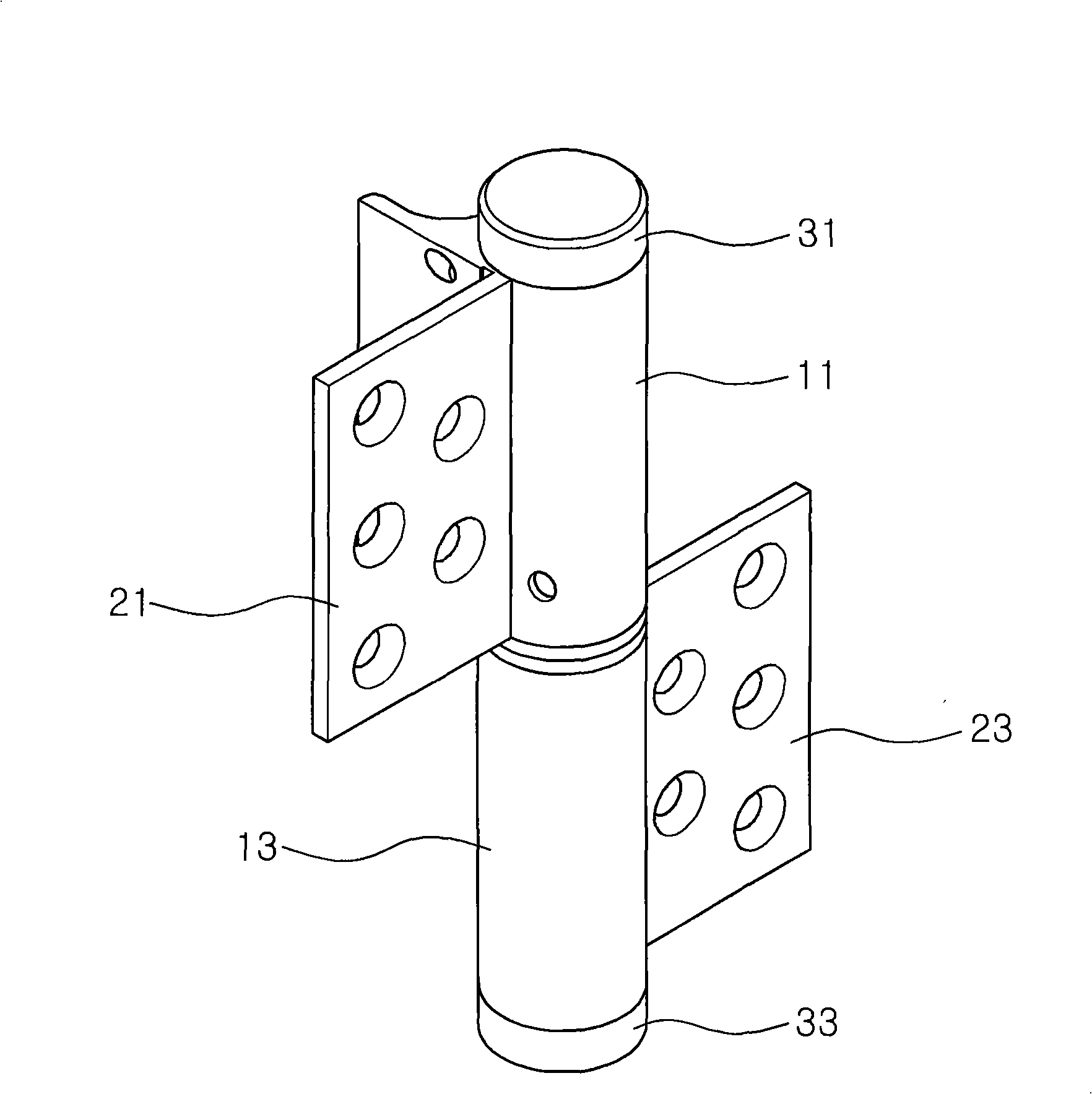

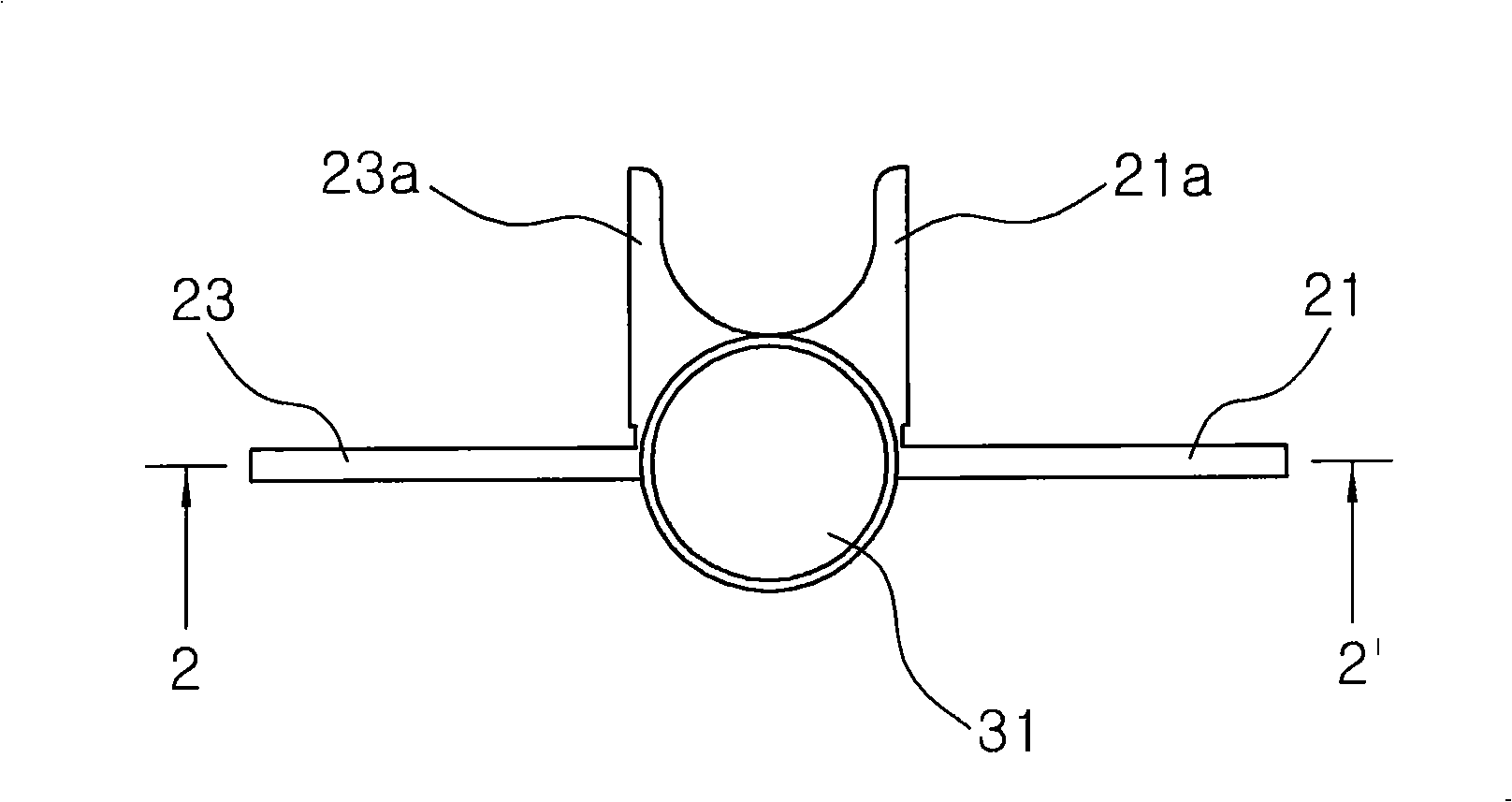

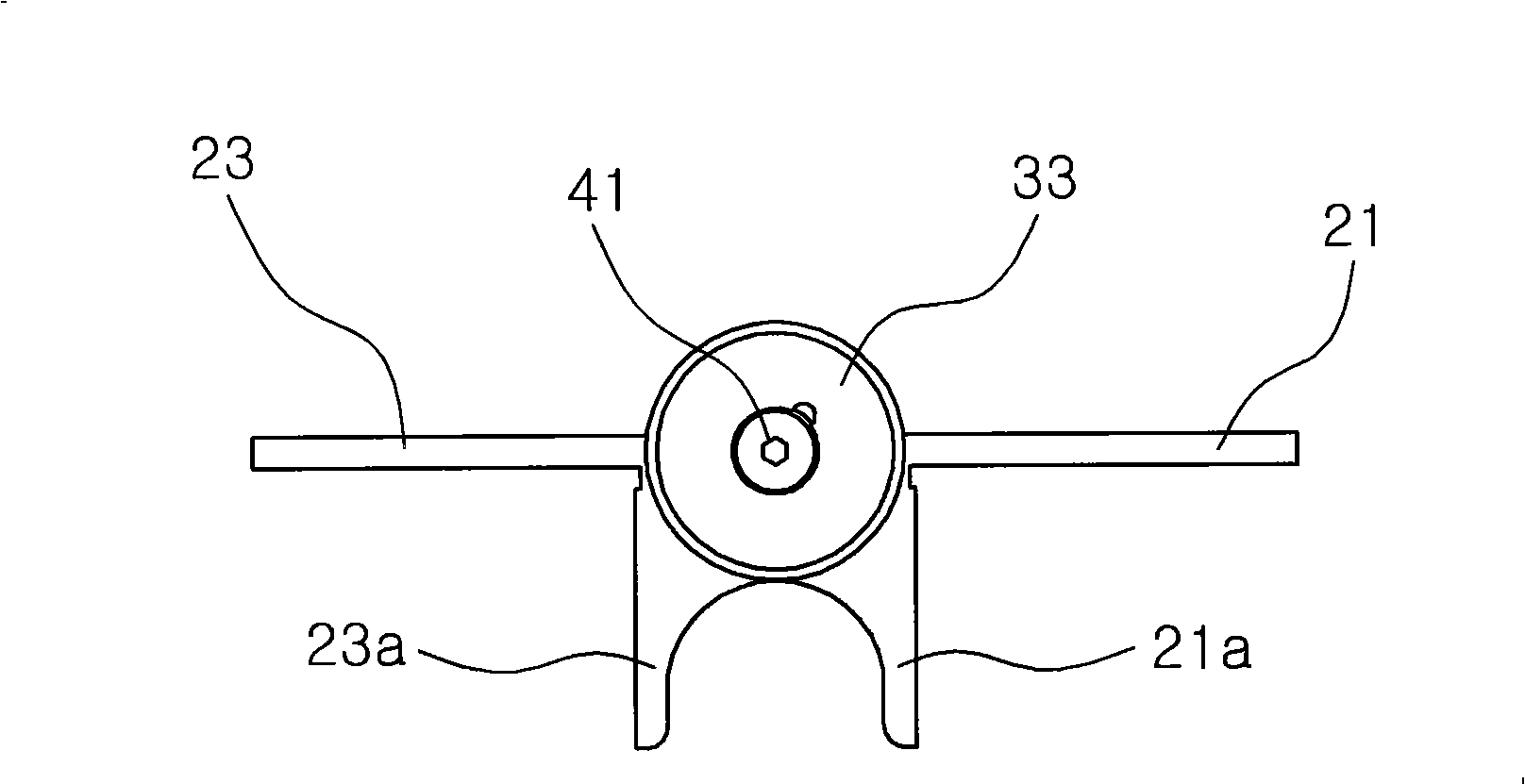

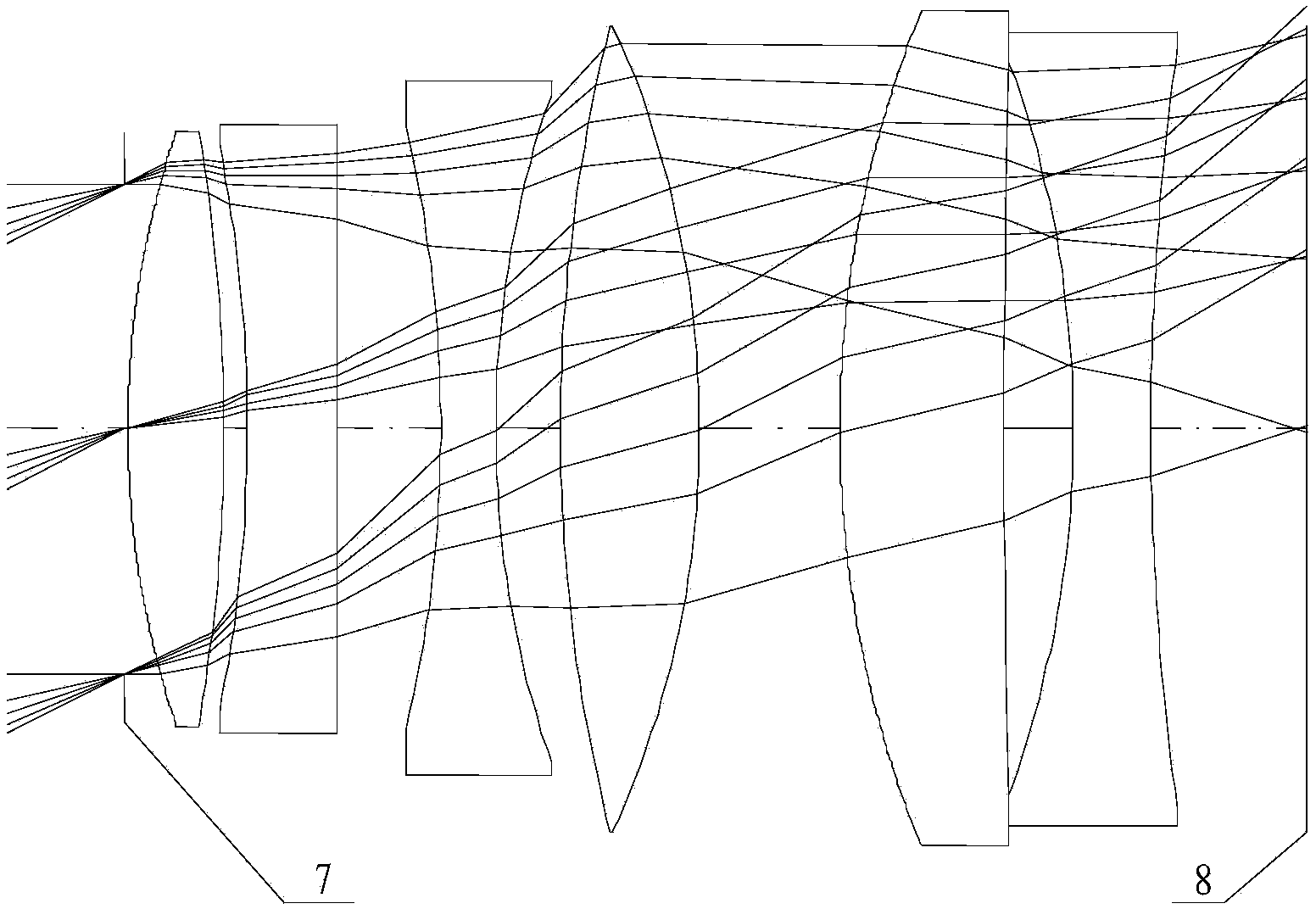

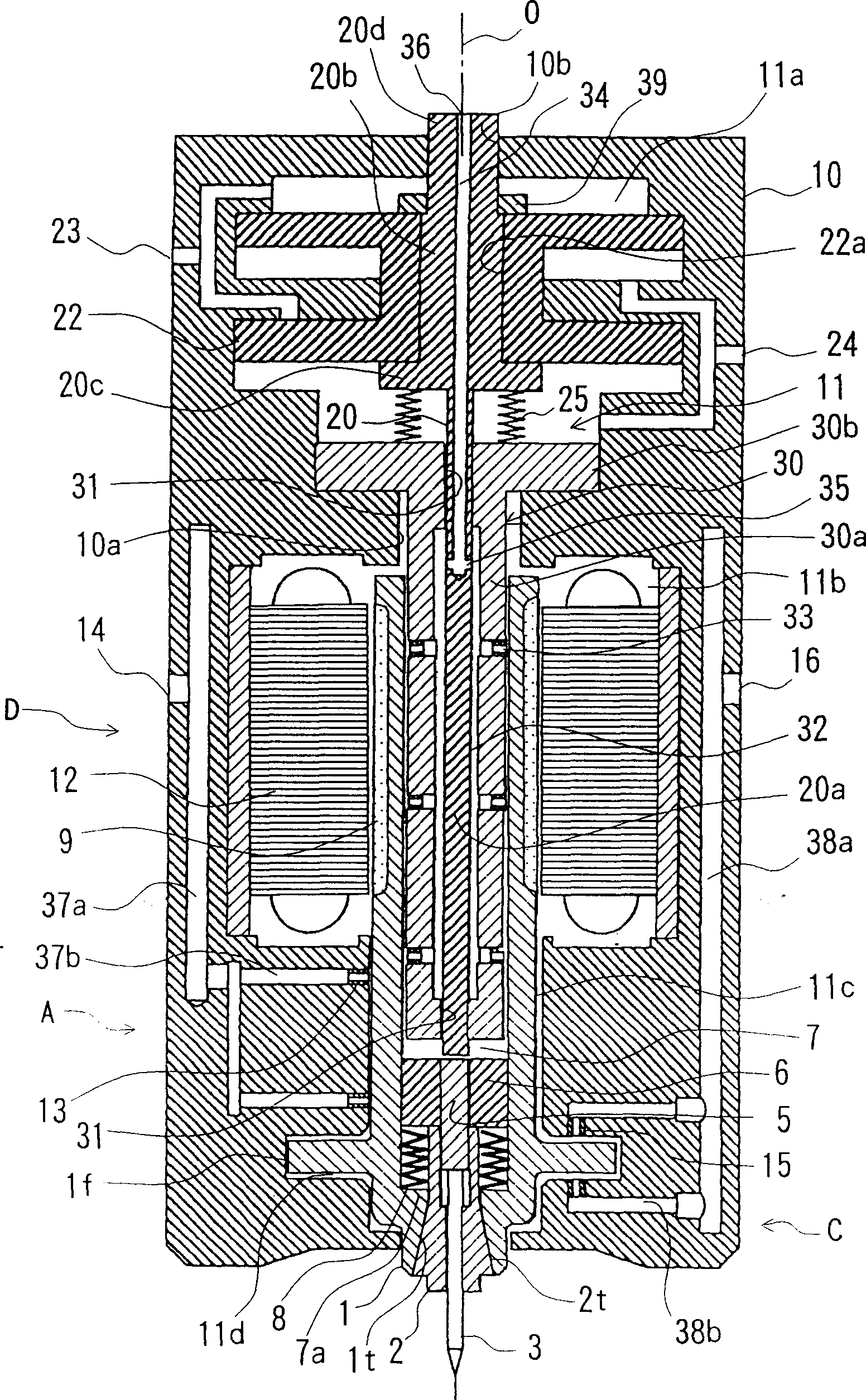

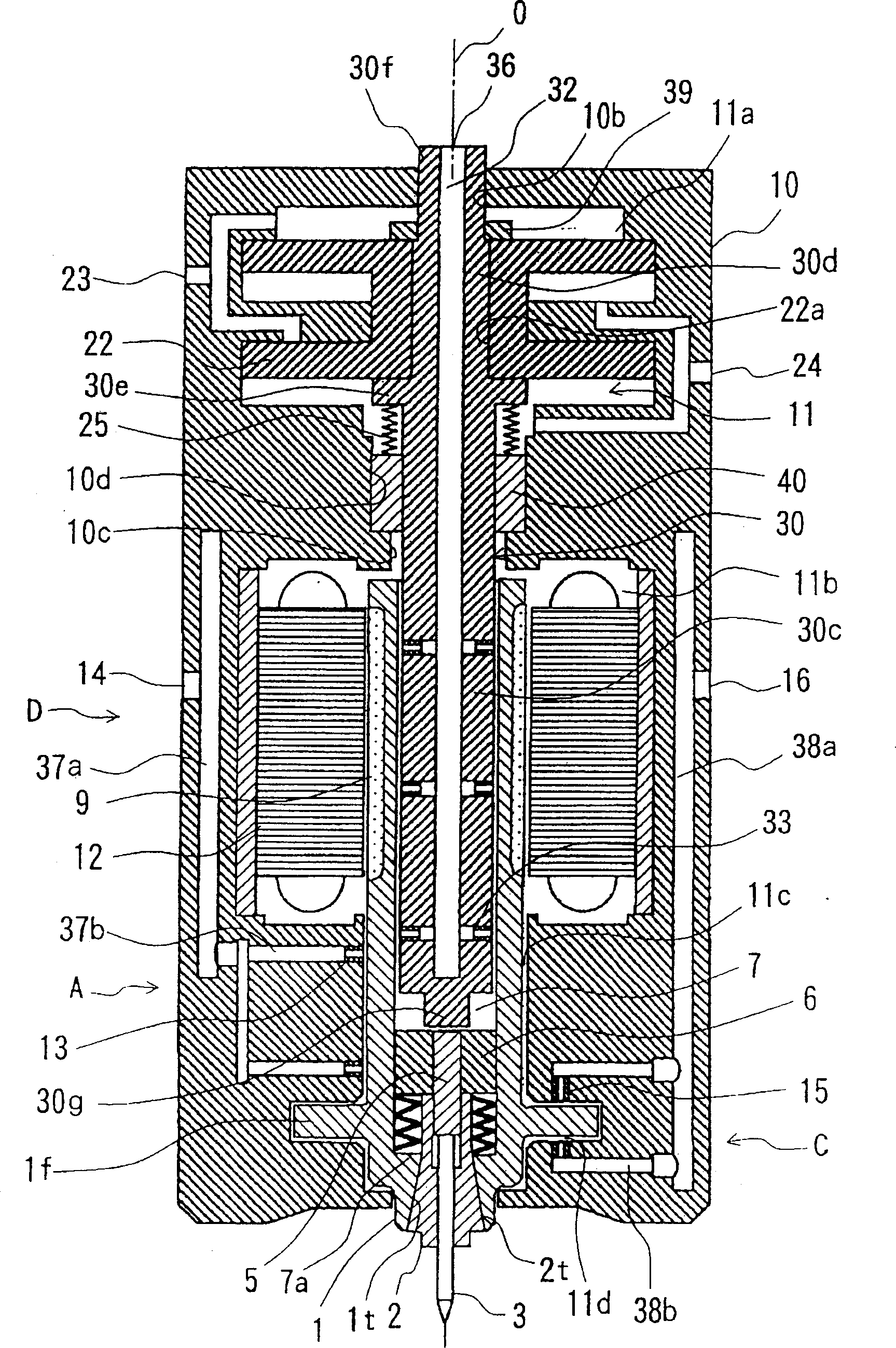

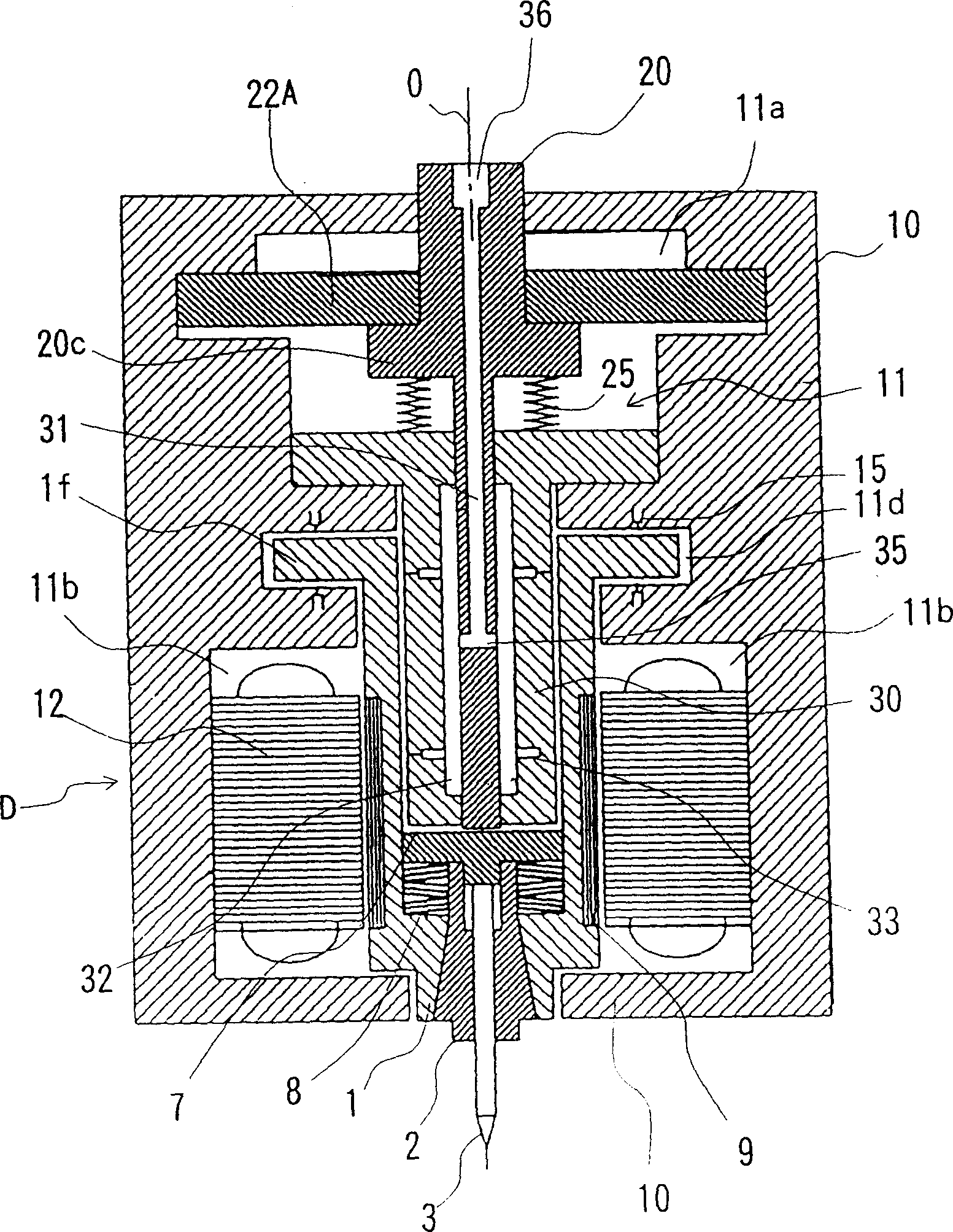

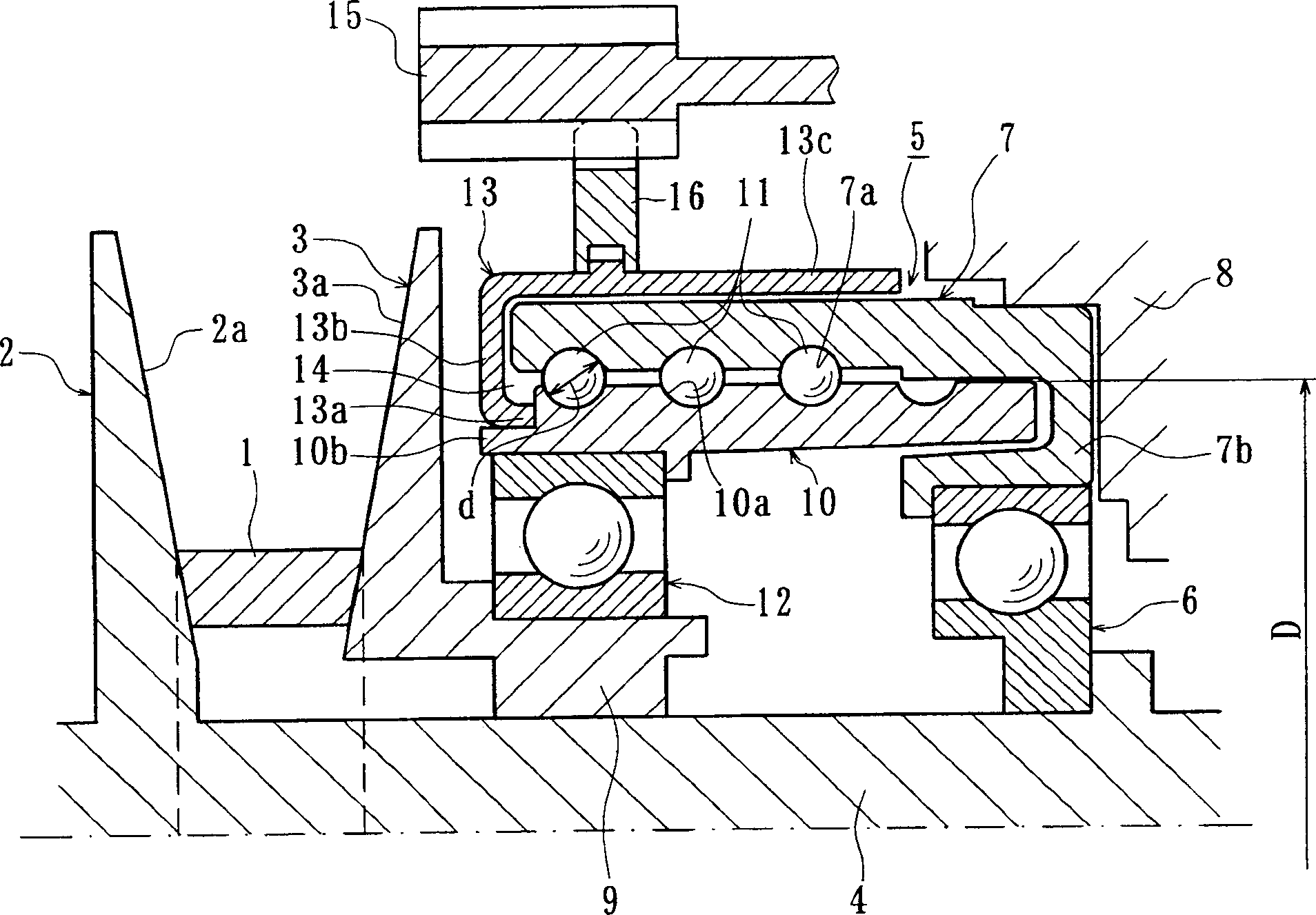

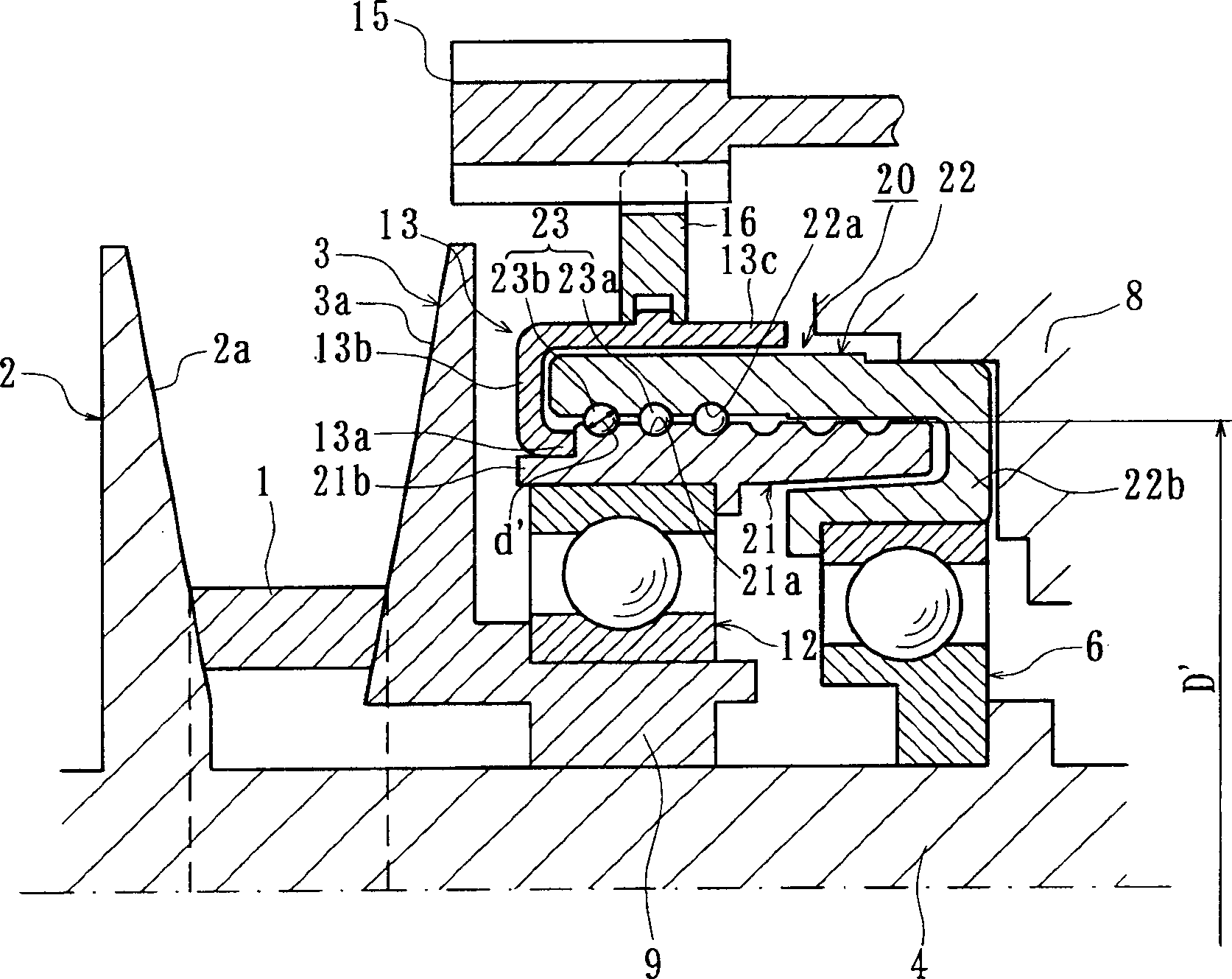

Hinge apparatus having automatic return function for use in building materials

ActiveCN101517184ARealization of automatic return functionClosing Force CompensationBuilding braking devicesPin hingesLinear motionReturn function

A hinge apparatus having an automatic return function for building materials is provided, in which a return spring is removed to thereby offer a closing force of each door with only a torsion spring. The hinge apparatus includes an upper body; a lower body; a shaft whose lower end portion is rotatably installed in the lower body; a piston whose outer circumference is slidably installed along the inner surface of the lower body, a rotational / linear motion converter which converts a rotational motion of the shaft into an axial linear motion of the piston according to rotation of the door; a damping unit which provides a damping function selectively where the piston ascends according to return of the door; a torsion spring which rotates the shaft in the direction returning the door at the closing time; and a clutch unit for stopping an increment of an elastic force due to reverse twisting of the spring where an opening angle reaches a clutch stop start angle, or for restoring the elastic force of the spring.

Owner:I ONE INNOTECH

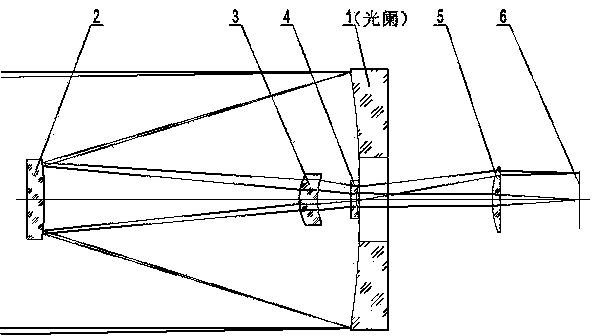

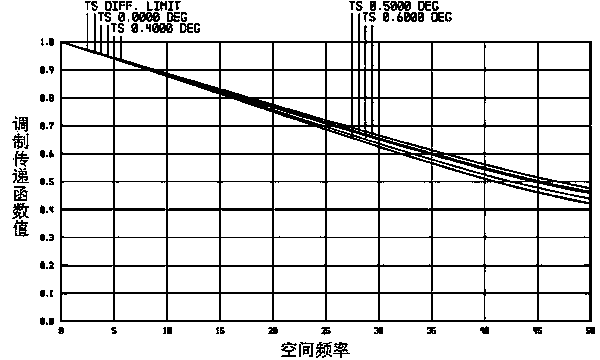

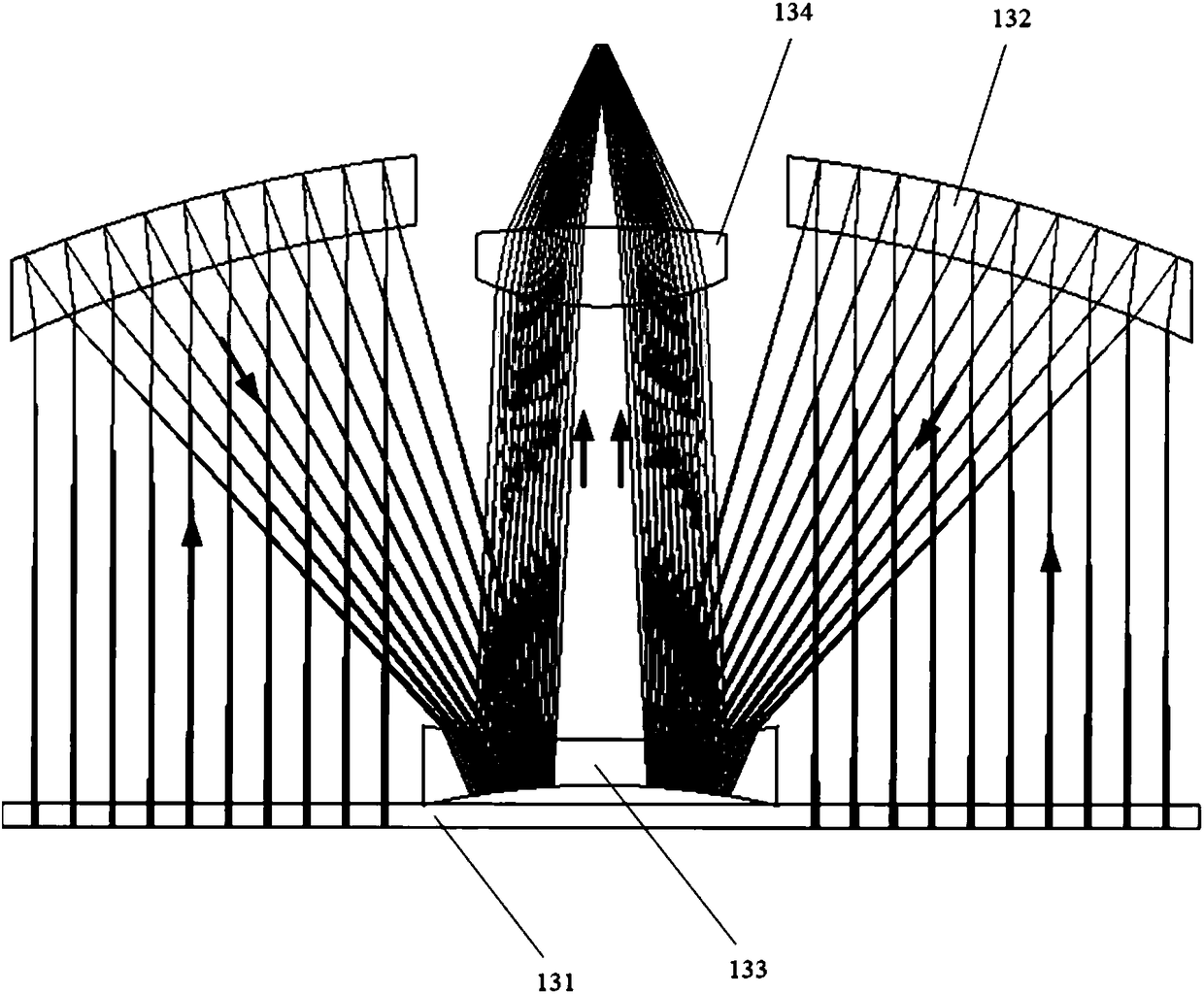

Reflex type telephoto objective lens

ActiveCN104317039ALong focal lengthShorten the overall lengthOptical elementsImaging qualityImage plane

The invention discloses a reflex type telephoto objective lens. According to the light ray passing sequence, an optical system of the reflex type telephoto objective lens comprises a front positive focal power mirror set and a rear negative focal power mirror set; the focal power of the positive focal power mirror set is 1 / 3-2 / 3 of the total focal power of the optical system, the positive focal power mirror set comprises a primary reflecting mirror and a secondary reflecting mirror, and a diaphragm is located on the primary reflecting mirror; the primary reflecting mirror is a concave aspherical mirror, and the secondary reflecting mirror is a high-order convex aspherical mirror; the negative focal power mirror set is composed of three lenses made of the same optical material, and the lenses are the positive meniscus lens bent towards an image plane, the biconcave negative lens and the plano-convex positive lens in sequence. The reflex type telephoto objective lens has the advantages of being long in focal length, large in aperture, small in blocking area, simple and compact in structure, wide in applicable waveband, small in chromatic aberration, good in imaging quality, capable of allowing image space to approximate a telecentric position, and easy to process, assemble and adjust.

Owner:SUZHOU UNIV

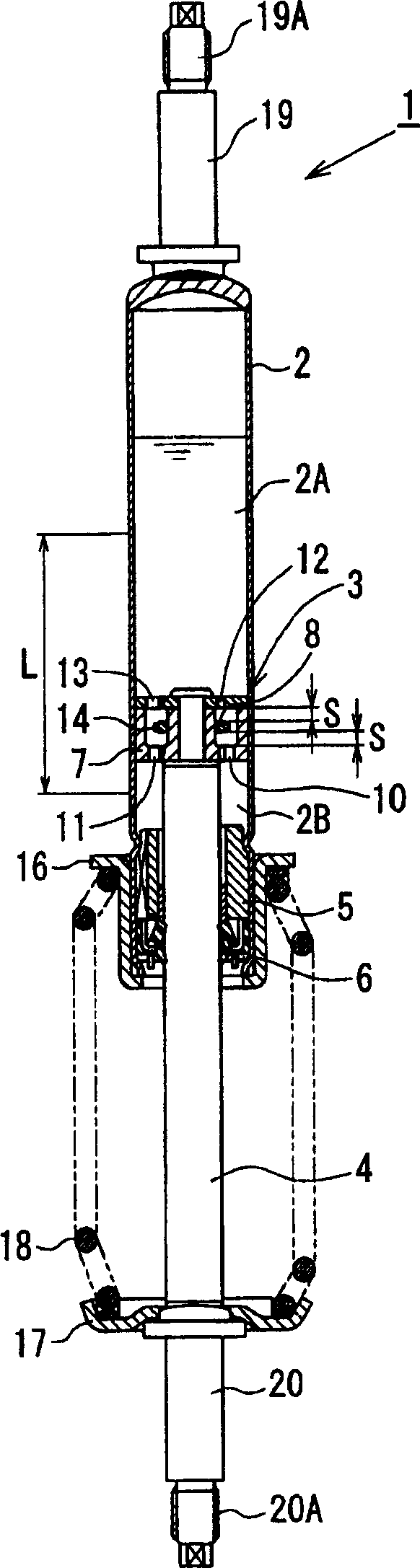

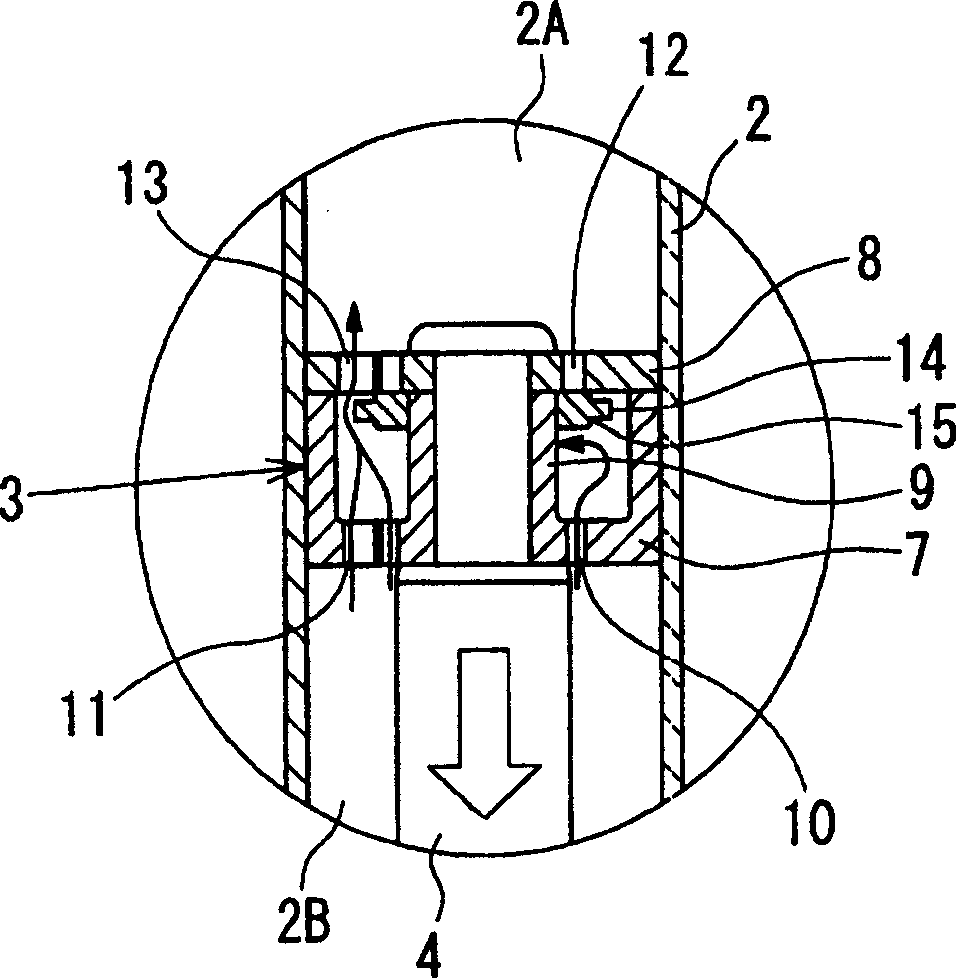

Hydraulic damper

InactiveCN1847508AReduce movementSmall damping forceOther washing machinesTextiles and paperSmall amplitudeMechanical engineering

A hydraulic damper that produces a small damping force for small-amplitude vibrations and a large damping force for large-amplitude vibrations in a hydraulic damper for washing machines. A piston (3) connected with a piston rod (4) is slidably embedded in a cylinder (2) in which oil and gas are mixed and sealed, and immersed in the oil. The extension side oil passage (10) and the shortening side hole (11) are arranged at the bottom of the piston body (7), and the shortening side oil passage (12) and the extension side hole (13) are arranged on the cover part (8). The body (14) is arranged axially movable inside the piston (3). When the piston rod is at a small amplitude, the moving distance of the valve body (14) is small, and the oil passages (10) and (12) on the extension side and the shortening side are opened, so a small damping force is generated. The moving distance of (14) becomes larger, and the valve body (14) closes the extension side and shortening side oil passages (10), (12), so a large attenuation force.

Owner:HITACHI LTD

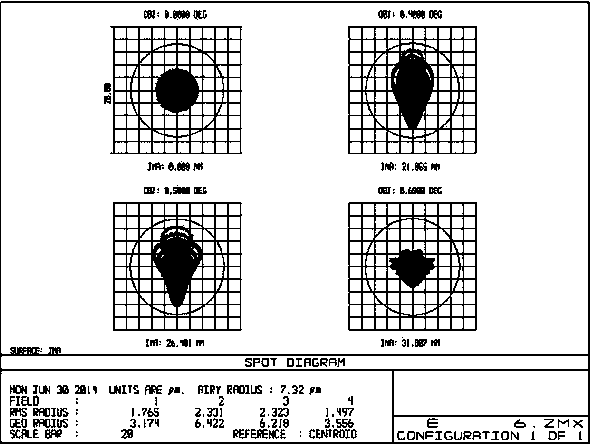

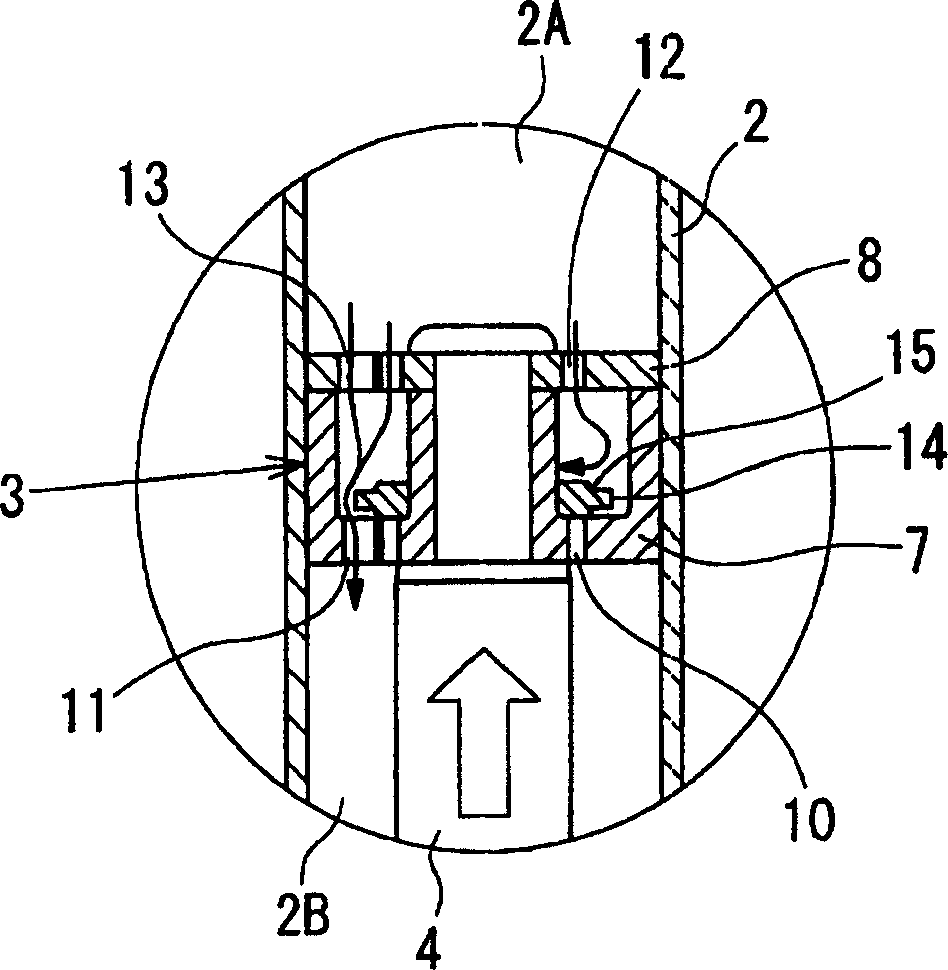

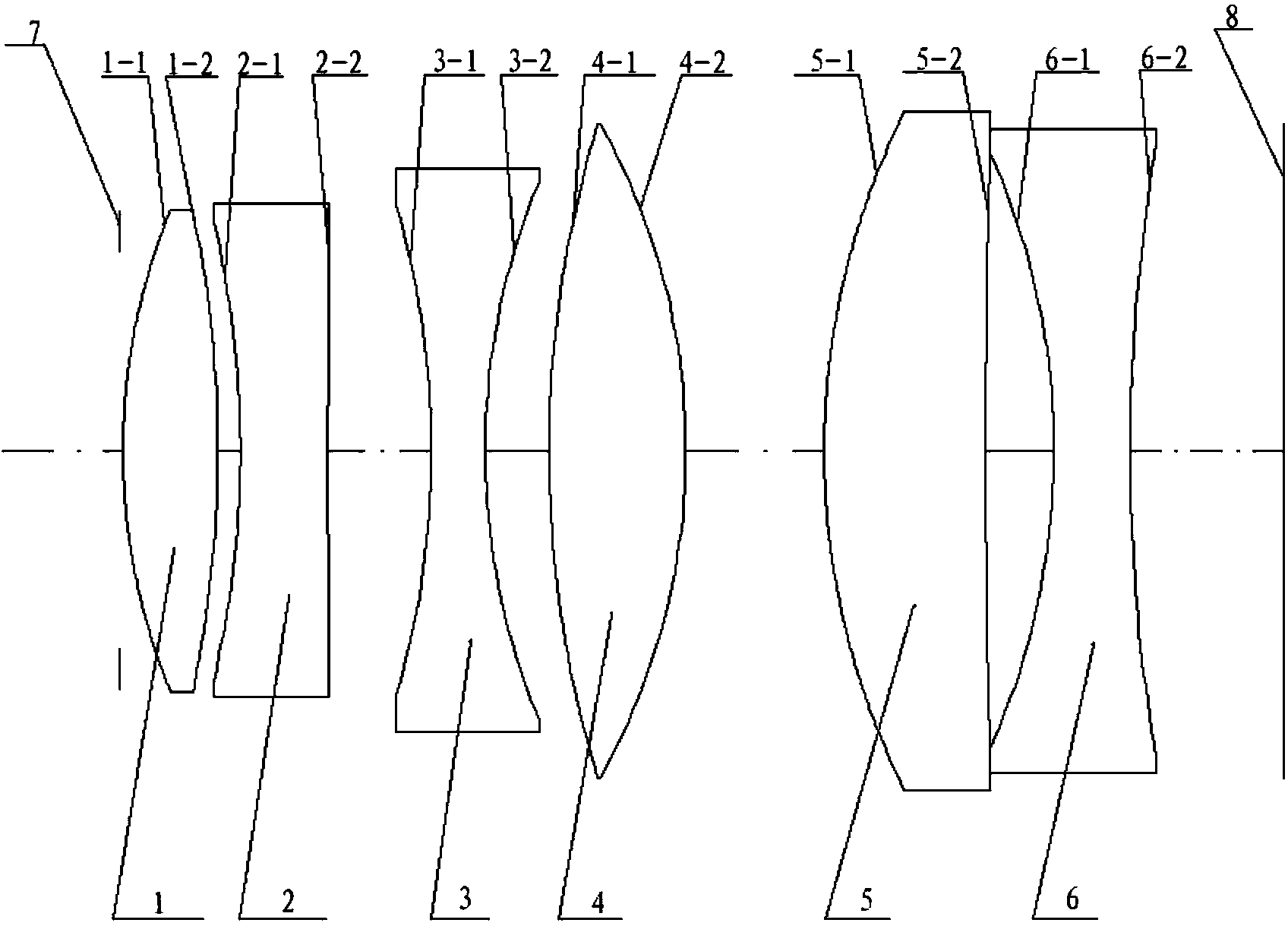

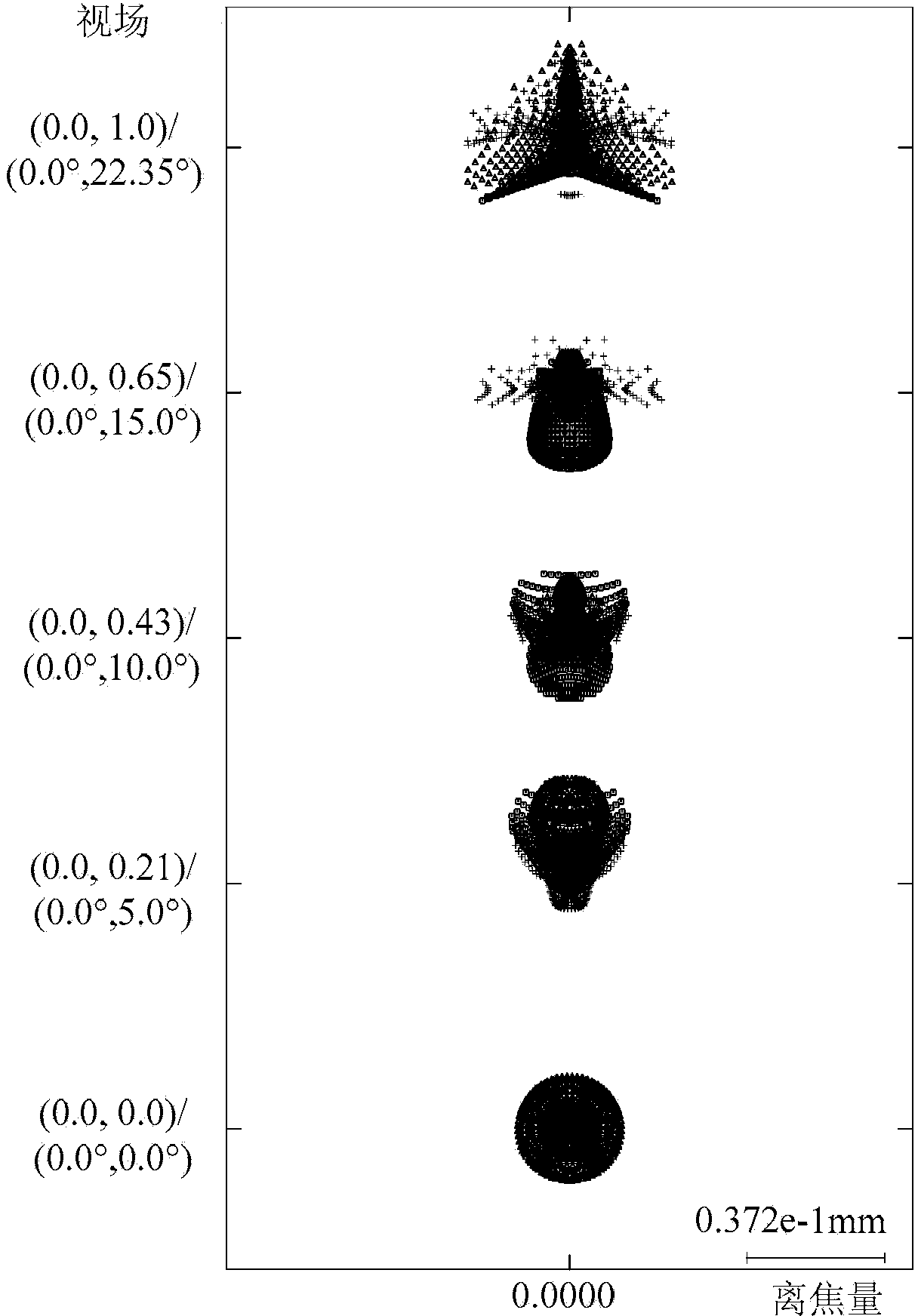

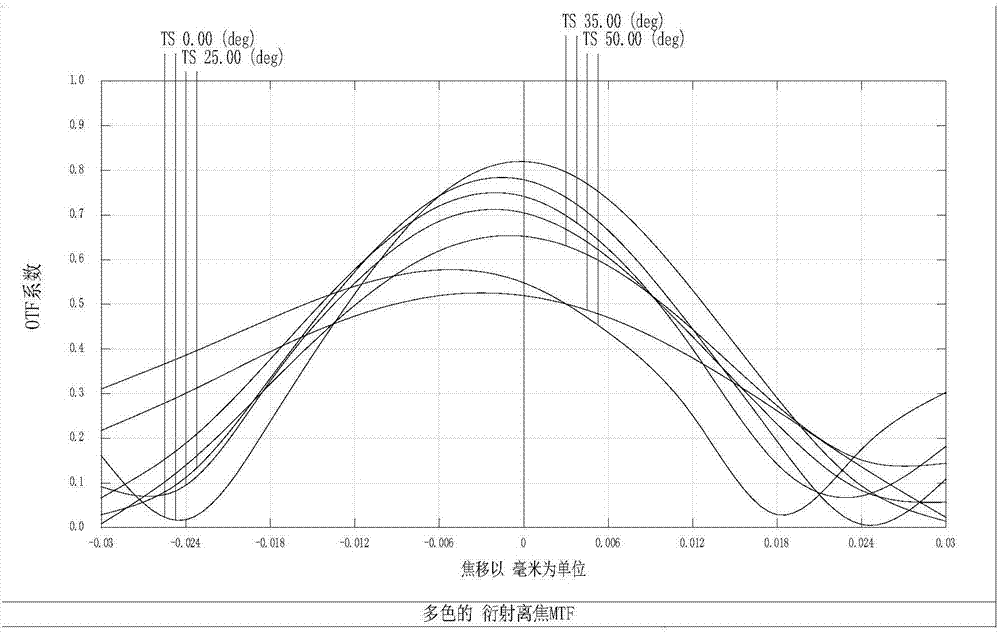

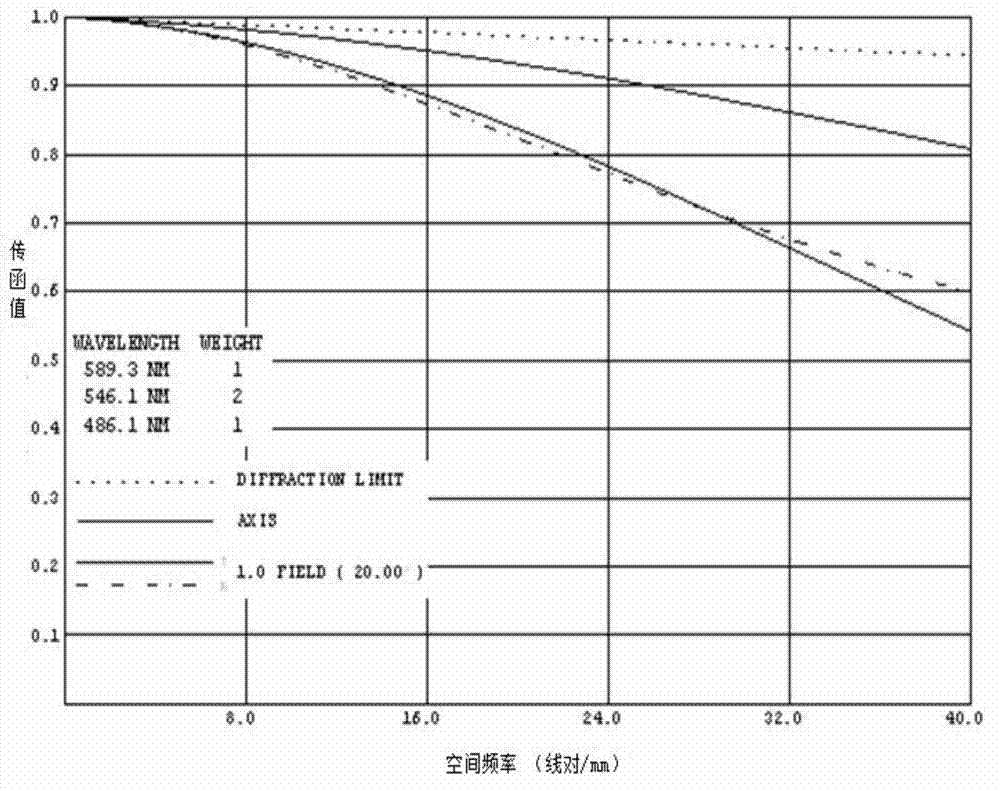

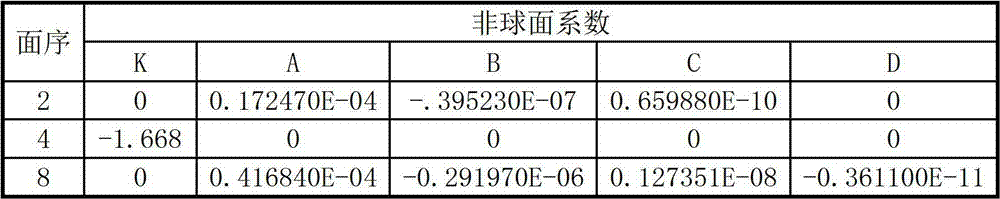

Large-viewing-field and high-precision star sensor optical system

The invention discloses a large-viewing-field and high-precision star sensor optical system, belongs to the field of optics, and aims to solve the problems of a conventional star sensor optical system. The system comprises a diaphragm, a lens group and an image plane, wherein light rays emitted by fixed stars in the viewing field go into the lens group through the diaphragm, and are imaged on the image plane after transmitted by the lens group; the lens group is a near image space telecentric optical system consisting of a first lens, a second lens, a third lens, a fourth lens, a fifth lens and a sixth lens; the first lens, the second lens, the third lens, the fourth lens, the fifth lens and the sixth lens are sequentially placed on the same optical axis in a direction from the diaphragm to the image plane; and the first lens, the fourth lens and the fifth lens are positive lenses, and the second lens, the third lens and the sixth lens are negative lenses.

Owner:HARBIN INST OF TECH

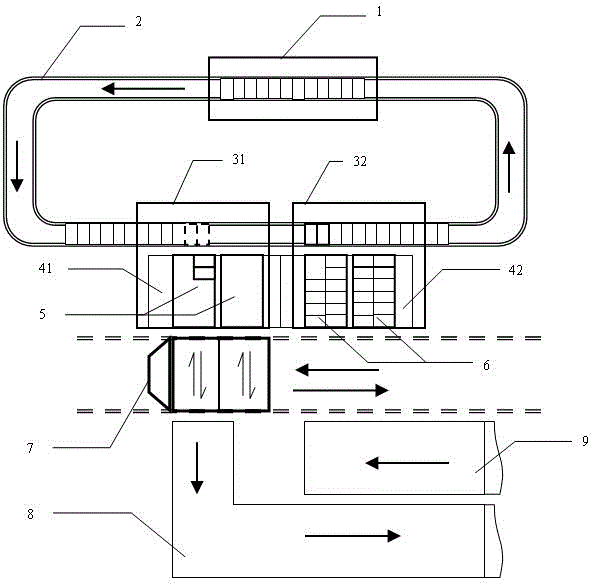

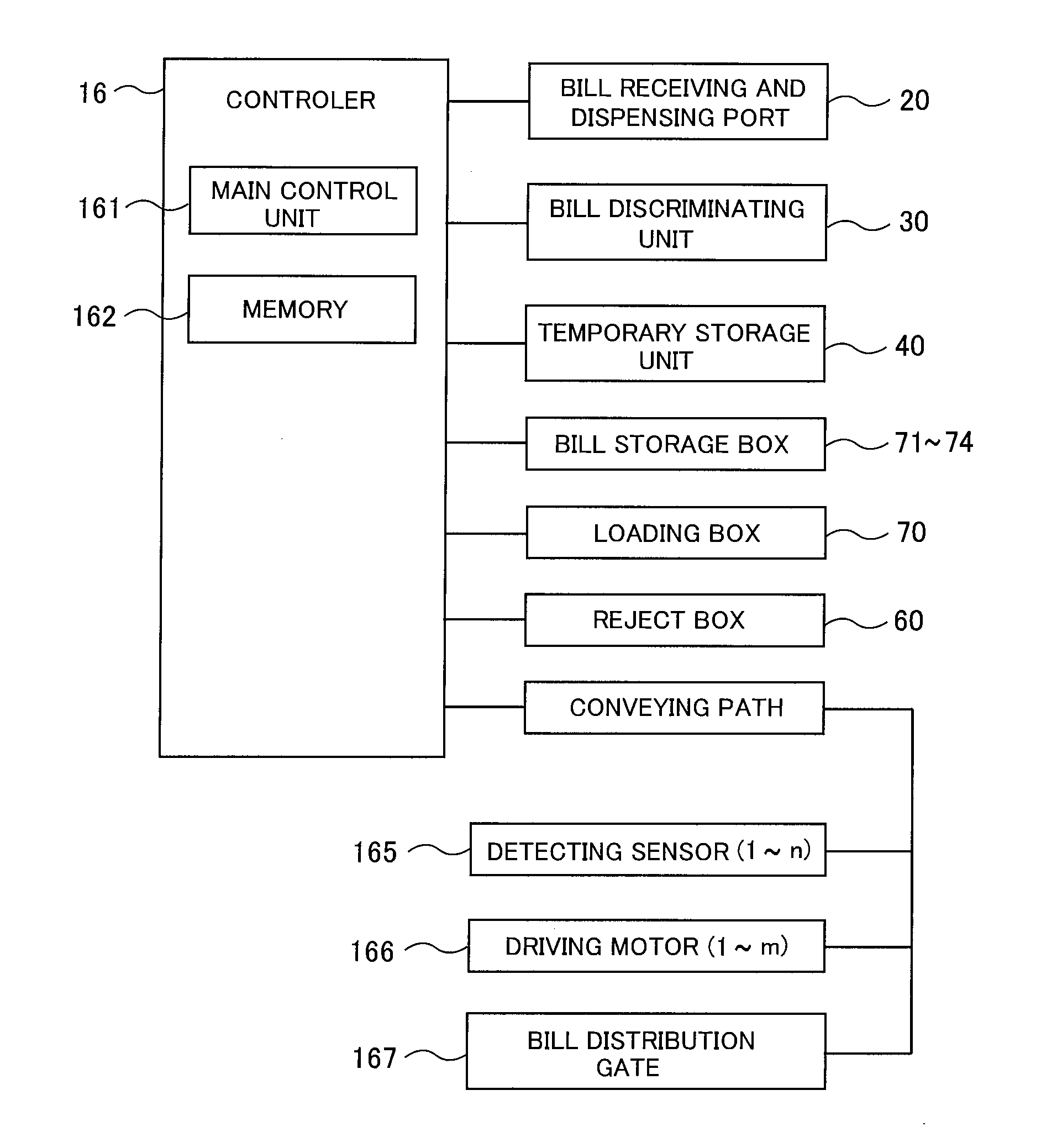

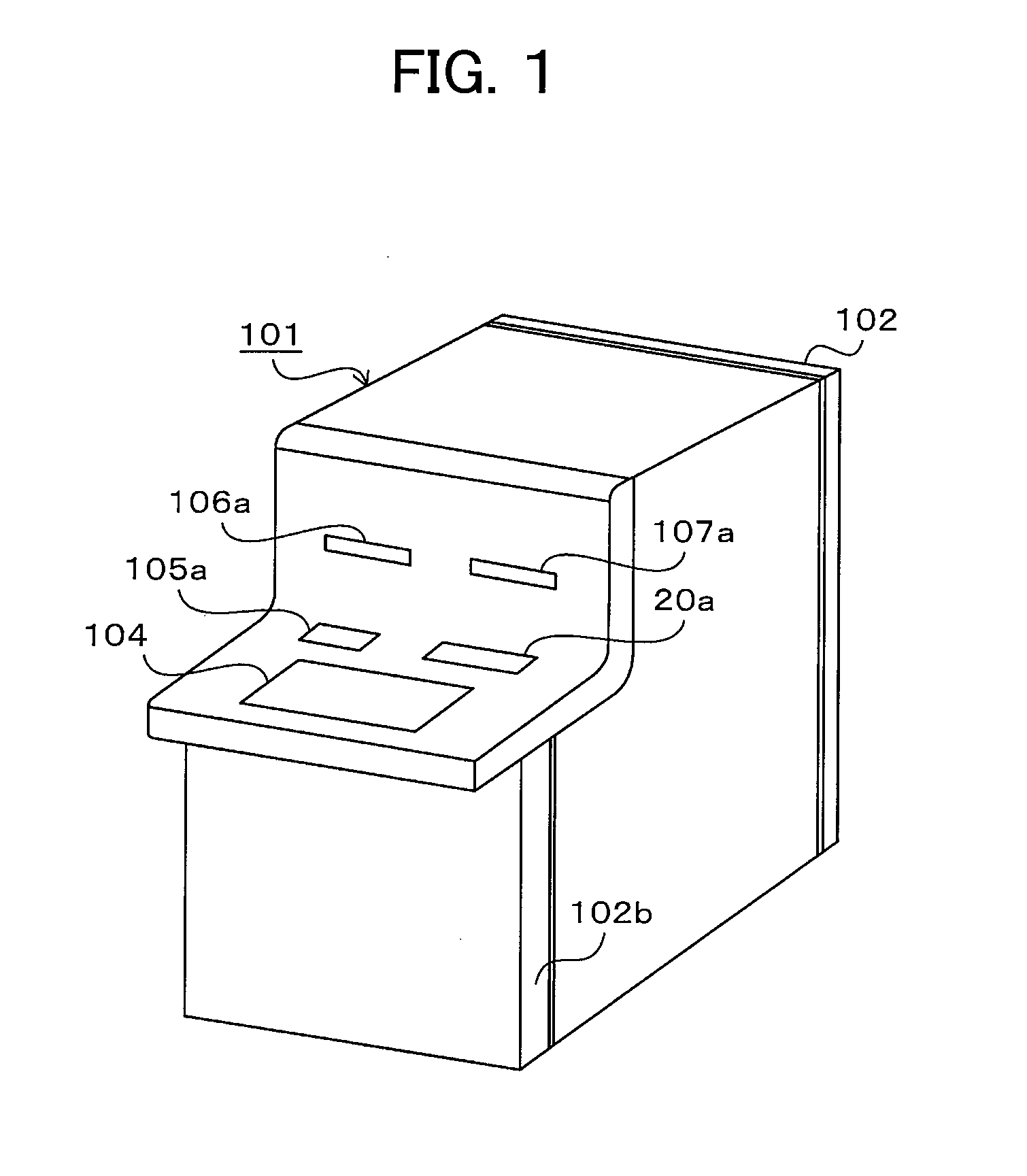

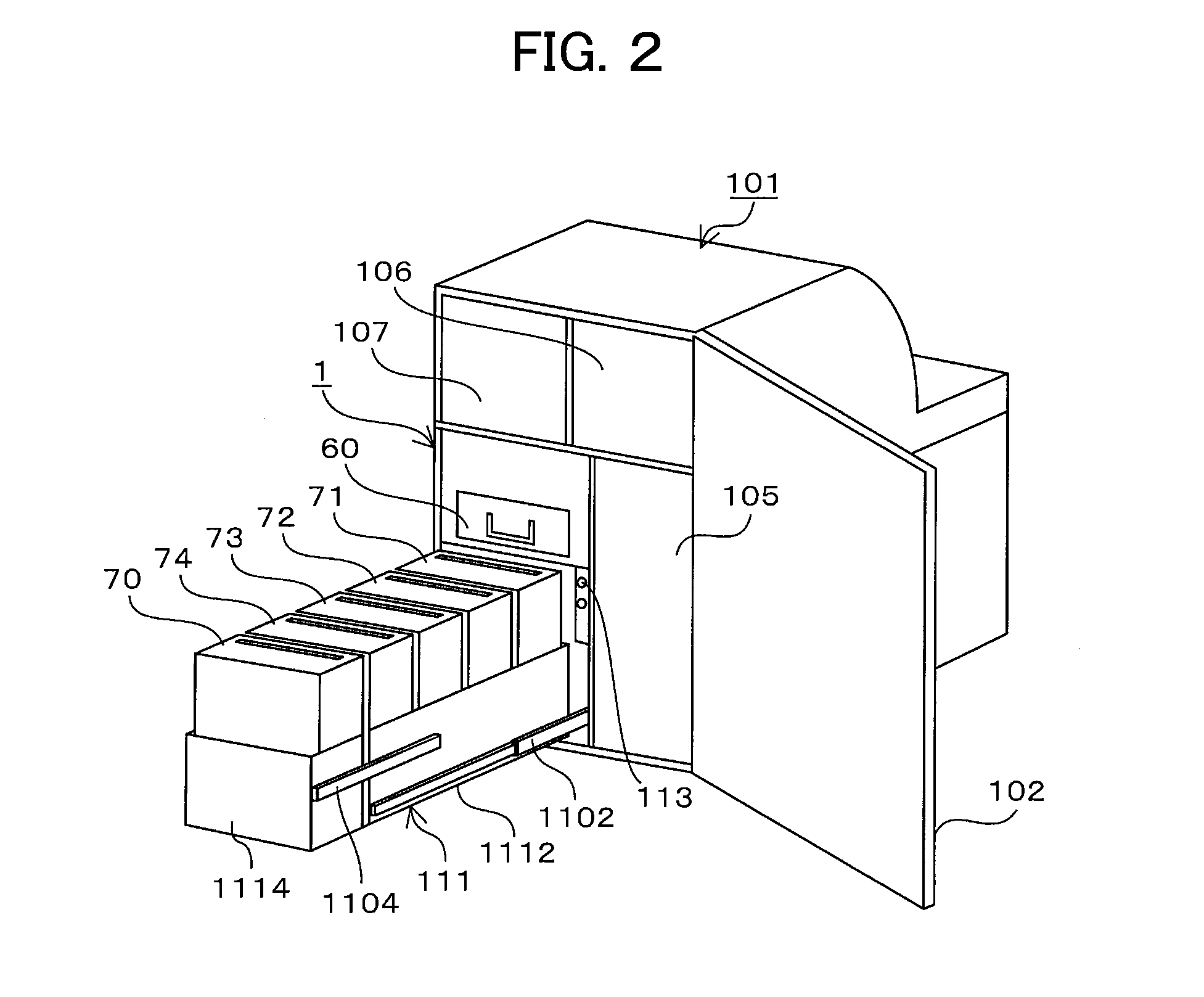

Bill handling apparatus

ActiveUS20110130870A1Shorten the overall lengthSimplify bill conveying mechanismDigital data processing detailsCoin/currency accepting devicesEngineeringMechanical engineering

A bill handling apparatus includes: a first loop-like conveying path that includes a bill discriminating unit, is connected to a bill receiving and dispensing port and a temporary storage unit, and connected to a plurality of loading boxes to convey bills in two directions; a second conveying path connected to the loading box to convey bills in two directions; a first gate that connects the first conveying path with the second conveying path and switches a conveying direction of the conveying path that conveys bills; and a controller that controls switching of the first gate and conveyance of the conveying path. The controller controls the bills conveyed to the first conveying path in one of the two directions to be conveyed to the loading box through the second conveying path via the first gate, and the bills conveyed from the loading box through the second conveying path to be conveyed to the first conveying path in one of the two directions via the first gate.

Owner:HITACHI CHANNEL SOLUTIONS CORP

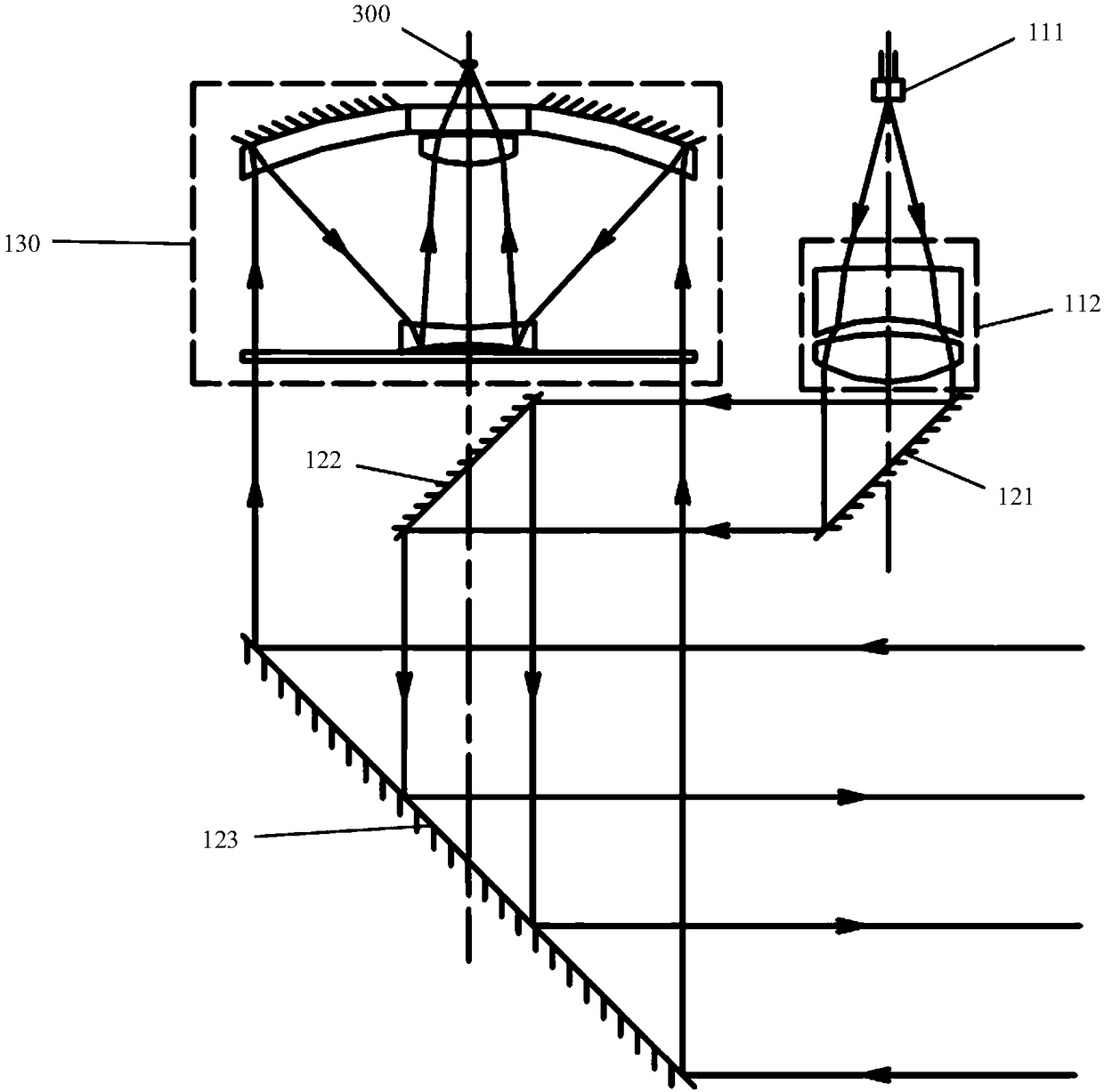

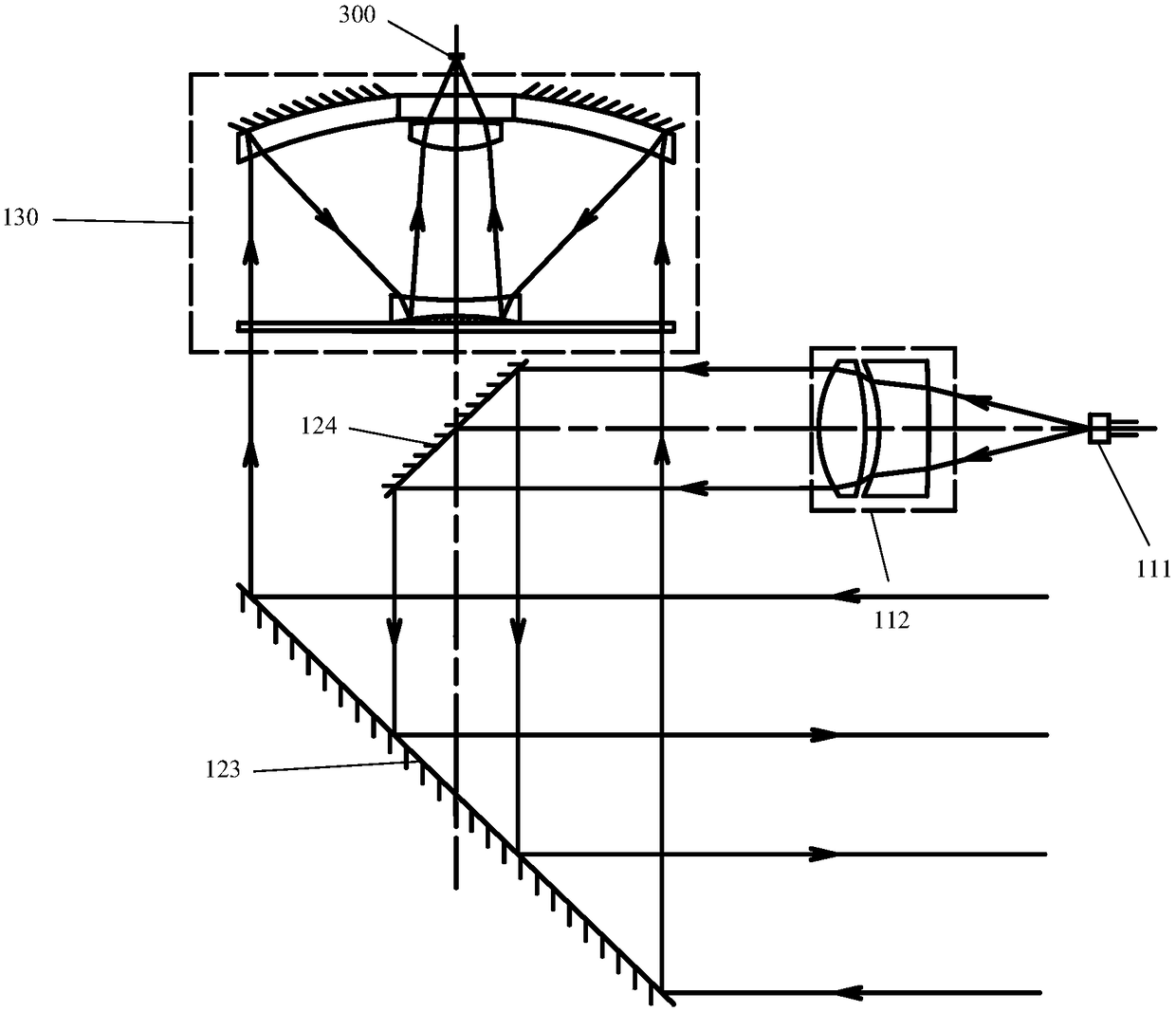

Laser radar optical system and laser radar

PendingCN108415002AShorten the overall lengthReduced Aperture BlockingWave based measurement systemsBlind zonePhotodetector

The invention provides a laser radar optical system and laser radar and relates to the technical field of laser measurement. The laser radar optical system comprises a transmitting system, a reflecting system and a receiving system; the transmitting system includes a laser source and a collimating lens unit which are coaxially arranged; the reflecting system reflects an optical axis of the transmitting system to be coaxial with that of the receiving system; a laser beam emitted by the laser source is collimated by the collimating lens unit into a parallel beam entering the reflecting system; the reflecting system reflects the parallel beam to the azimuthal axis of the laser radar for the purpose of scanning, and reflecting reflected light, returned by an object under measurement in the azimuthal axis, to the receiving system; the receiving system gathers the reflected light to a photodetector of the laser radar. Therefore, aperture covering due to the transmitting system at the receiving system center is decreased system total length and size are decreased, and measurement blind zones due to the use of traditional noncoaxial systems are avoided.

Owner:天津杰泰高科传感技术有限公司

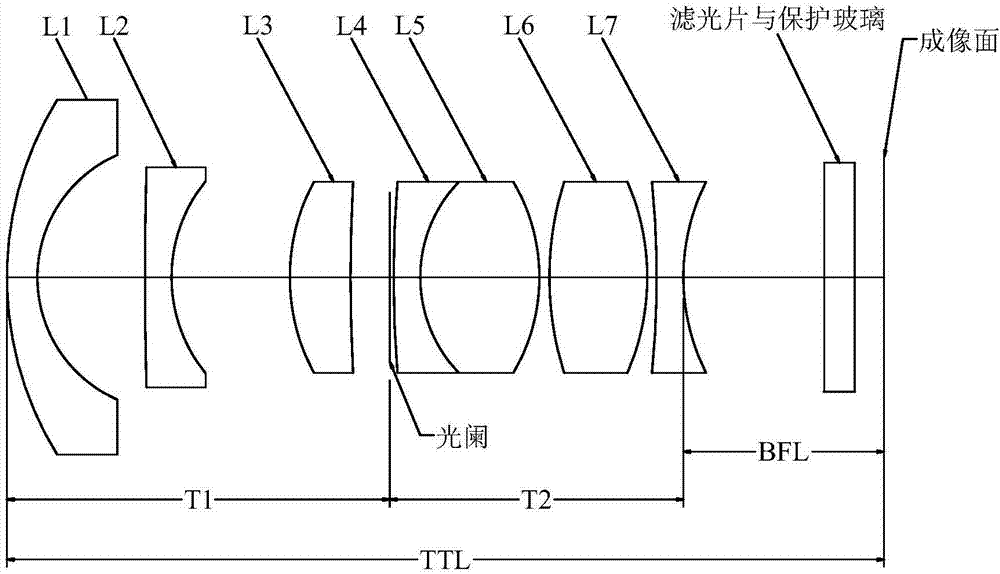

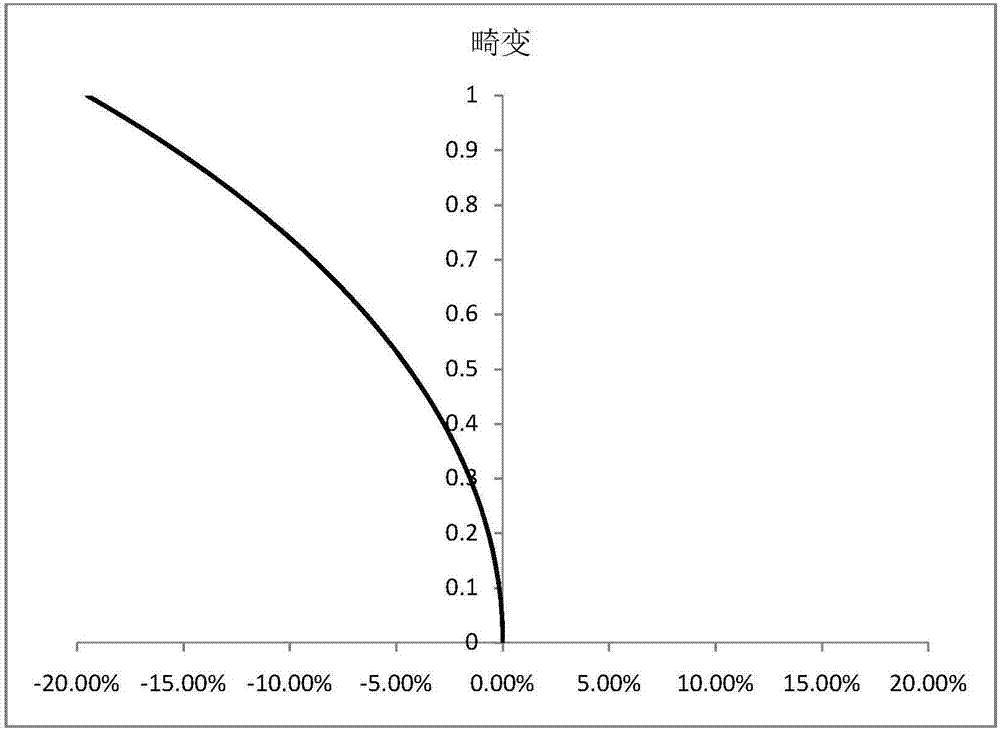

Low distortion wide-angle lens

PendingCN107577032AControl Relative Aperture SizeLower incident heightOptical elementsWide fieldLow distortion

The invention relates to a low distortion wide-angle lens, including a first lens, a second lens, a third lens, a aperture, a fourth lens, a fifth lens, a sixth lens and a seventh lens along the optical axis from the object side to the image side arranged in sequence. The first lens, the second lens, the fourth lens and the seventh lens are negative focal lenses. The third lens, the fifth lens andthe sixth lens are positive focal lenses. The fourth lens and the fifth lens form a glued lens group. The first lens and the second lens bend to the aperture. The low distortion wide-angle lens according to the invention has the advantages of wide field angle and low distortion.

Owner:舜宇光学(中山)有限公司

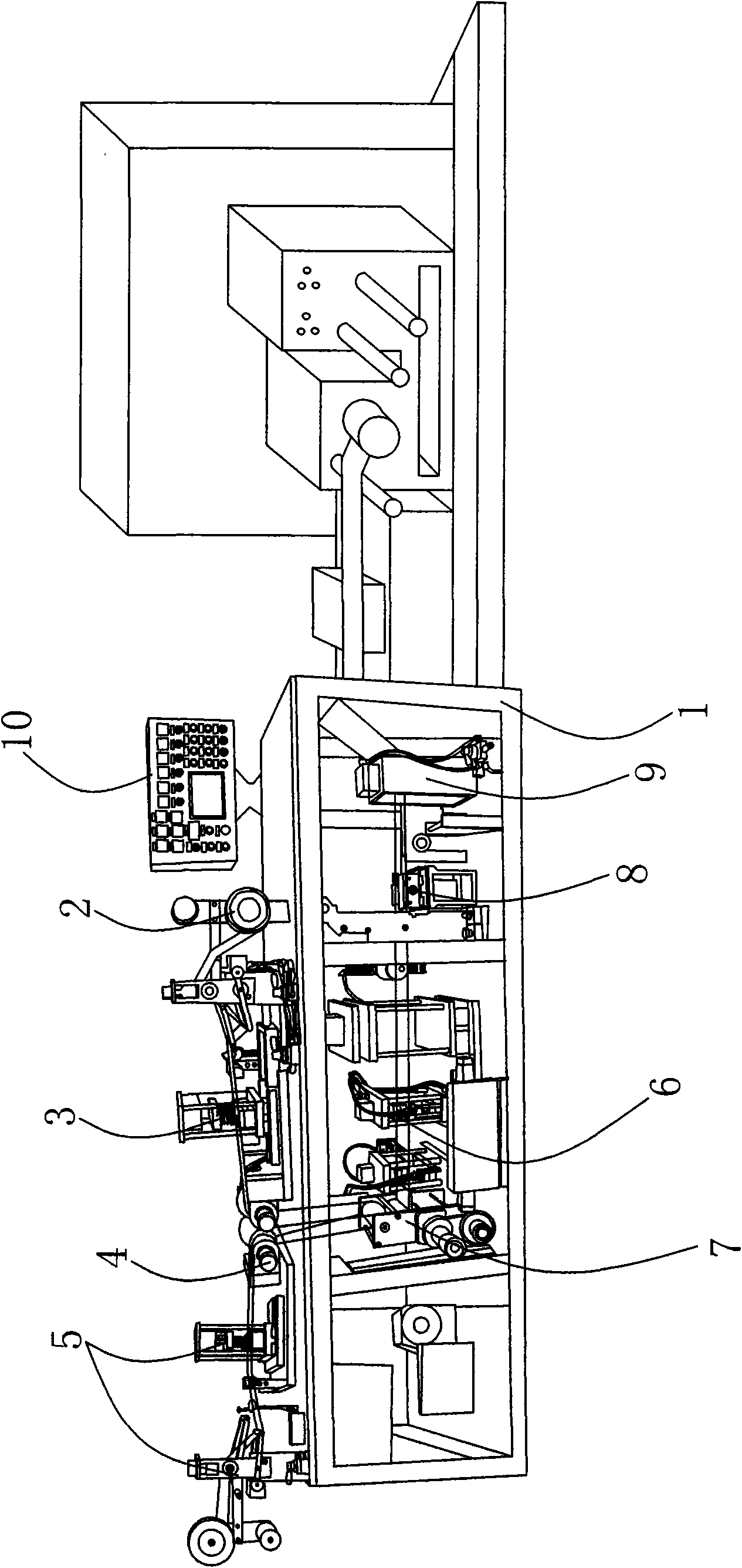

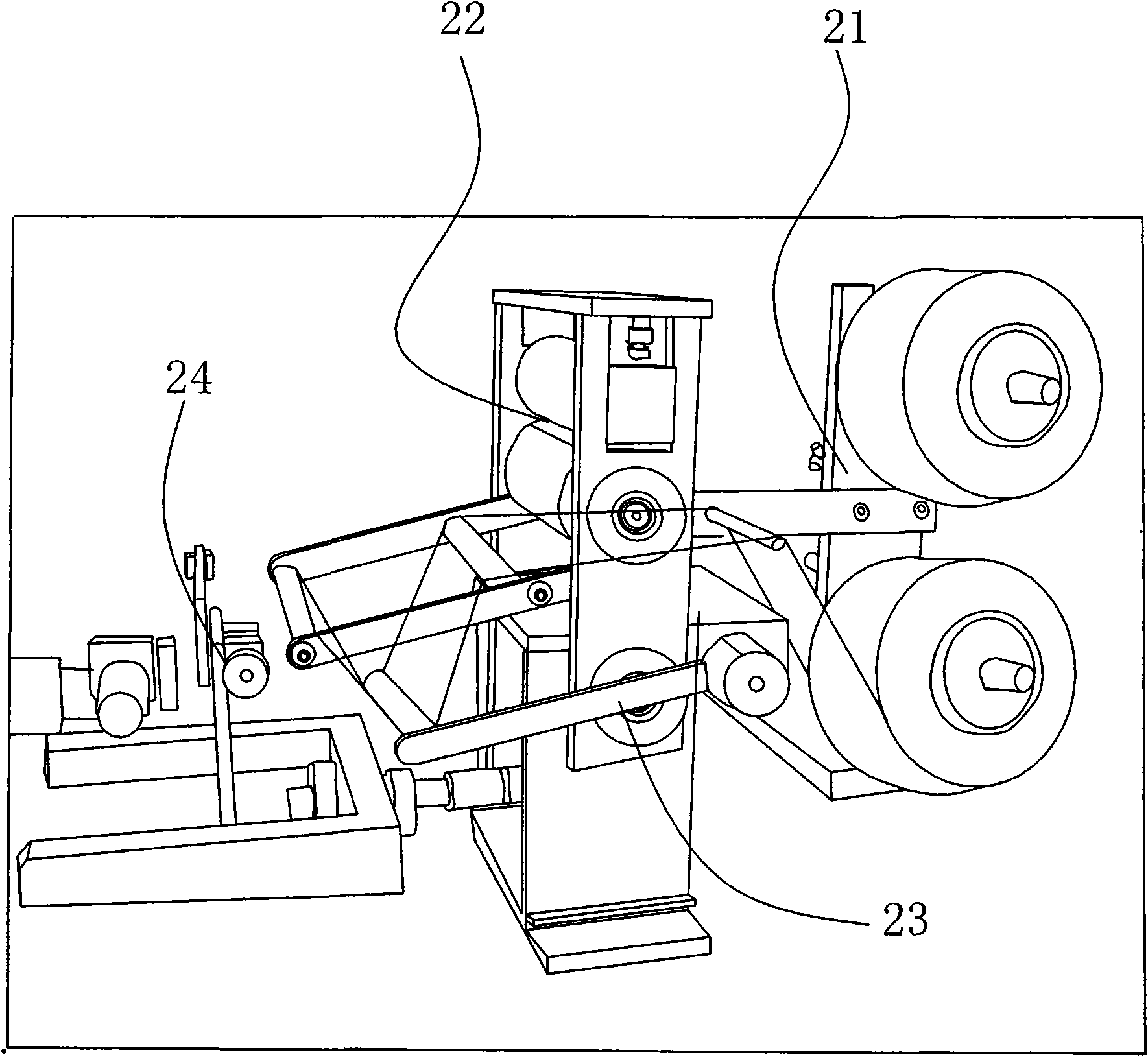

Molding machine

ActiveCN101572134AShorten the overall lengthSmall footprintInsulating conductors/cablesCopper wireMolding machine

The invention relates to a molding machine, comprising a machine frame, a glue film supply device, a glue film opening device, a primary molding body, a straight angle copper wire arraying device, a stiffening plate gluing device, a hot press molding device, a secondary molding device, a tape divider, a traction device, an electronic control panel structure and a wire collecting device. Due to the adoption of the structure for two-time molding respectively in upper part and the lower part, the total length of the machine is greatly shortened, the occupation area of the equipment is reduced, the back-and-forth motion range of operation is reduced, thus facilitating operation and loss reduction, improving working efficiency and achieving the aim of lowering production and manufacture cost; the stiffening plate gluing device employs the cutting mode which needs no replacement of blade and the delivery mode featuring integration of the cylinder and the frame, thus ensuring the whole gluing process is simple and easy and improving the stability and accuracy of gluing. The tape divider is added with a CCD automatic tracking system, thus ensuring the tape division accuracy is increased to 0.005; in addition, the glue film opening device and the primary molding body are provided, thus further improving the accuracy of the alignment of the opening during processing and the stability of the production process.

Owner:SHENZHEN WENXIN ELECTRONICS

Small light low-light-level night vision eyepiece optical system

ActiveCN103048771AGuaranteed performanceShorten the overall lengthMountingsMagnifying glassesNight visionEyepiece

The invention relates to a small light low-light-level night vision eyepiece optical system, and belongs to the technical field of design of optical systems. The eyepiece optical system comprises three groups of four coaxial optical lenses, an aperture and an image plane, wherein the aperture, a first lens, a second lens, a third lens, a fourth lens and the image plane are coaxially and sequentially arranged along the optical axis direction from the human eye observation side to the eyepiece image plane side. The first lens, the second lens and the fourth lens are positive lenses while the third lens is a negative lens. The second lens and the third lens are a double cemented lens group and the lens group is a negative lens. The image plane has bending characteristics. According to the compact eyepiece optical system consisting of the three groups of four coaxial optical lenses, the aperture and the image plane, after the constraint optimization of the radius of curvature of each lens, the mutual distance and material properties, the properties of the optical system are ensured, and simultaneously, the barrel length and the total length are shortened, and the weight is reduced.

Owner:LUOYANG INST OF ELECTRO OPTICAL EQUIP OF AVIC

Principal axis device

InactiveCN1485172ASimple structureRaise the natural frequencyShaftsLiquid cushion bearingsRotational axisEngineering

A bottomed hole opened to an end part on the opposite side to the holding side of a drill is formed around a rotation axis of the spindle. A center guide provided with a plurality of air supply holes of a journal gas bearing at the outer periphery is fitted to the bottomed hole and supported to a housing. Compressed air is blasted from the air supply holes to support the spindle radially from the center side. Since the spindle of such constitution can reduce mass, natural frequency is heightened to obtain structure causing no unstable phenomenon even if rotated at high speed.

Owner:HITACHI SEIKO LTD

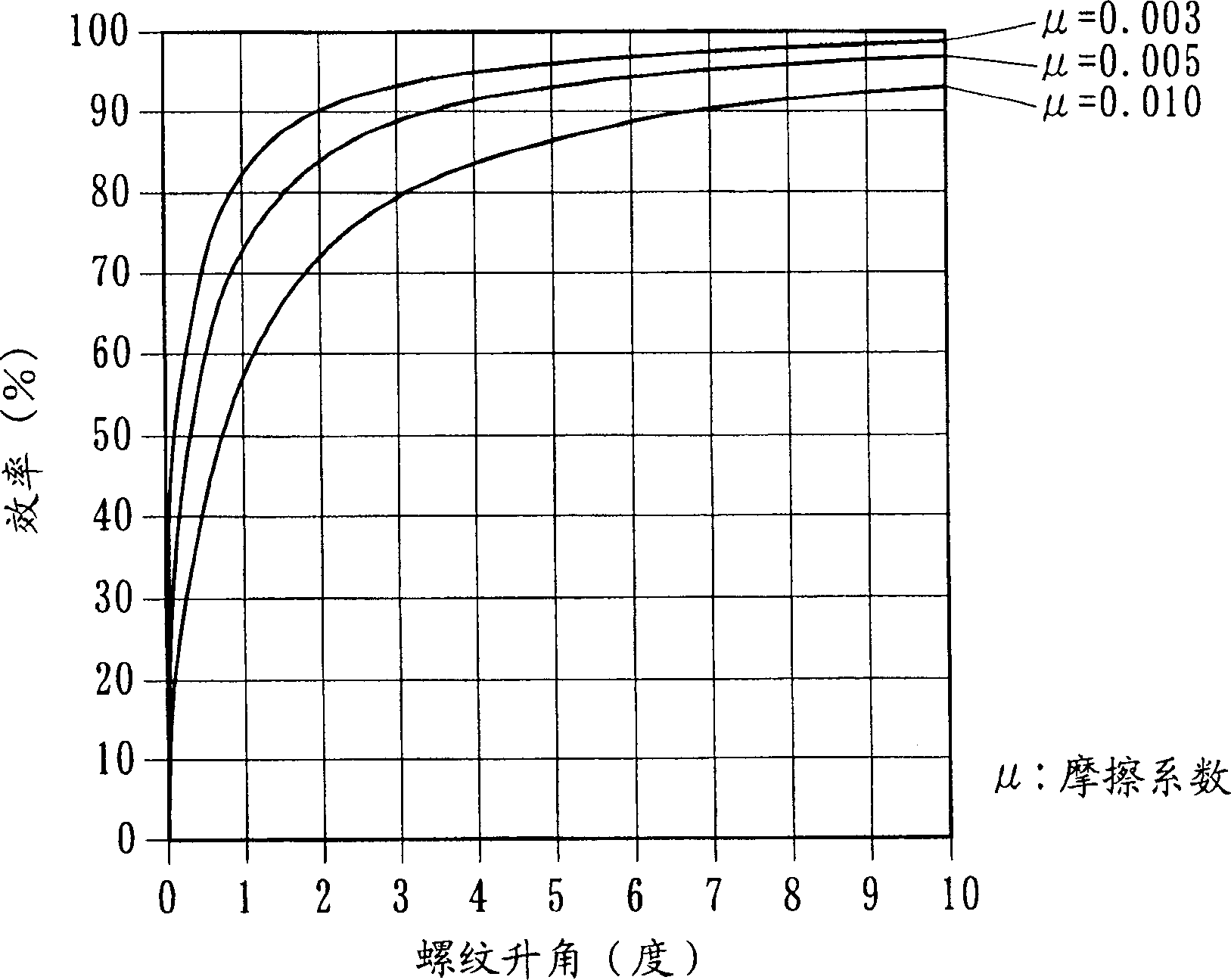

Ball screw and belt stepless variable speed devcie with same

InactiveCN1420293AShorten the overall lengthEliminate relative slidingGearing controlBearing componentsBall screwPulley

There are provided a ball screw enabling the reduction of weight and size of a CVT without reduction of the transmission efficiency as well as a CVT in which the ball screw is incorporated. A CVT of the present invention comprises an axially immovable pulley half 2 and axially movable pulley half 3 both mounted on a rotary shaft 4, and the axially movable pulley half 3 being moved by a ball screw 20 so as to infinitely vary the belt wrapping radius and thus the transmission speed, and is characterized in that a nut 22 forming one part of the ball screw 20 is immovably secured both in axial and rotational directions, a screw shaft 21 forming the other part of the ball screw 20 is movable both in axial and rotational directions and connected to the axially movable pulley half 3, and the axially movable pulley half 3 is axially moved by rotating the screw shaft 21.

Owner:NTN CORP

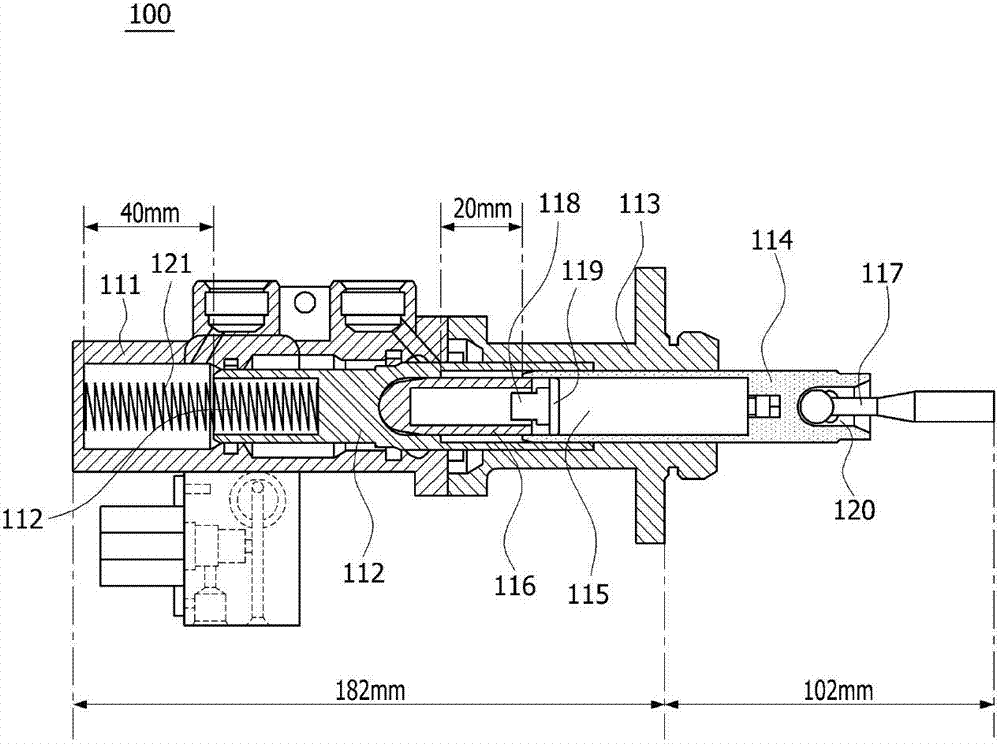

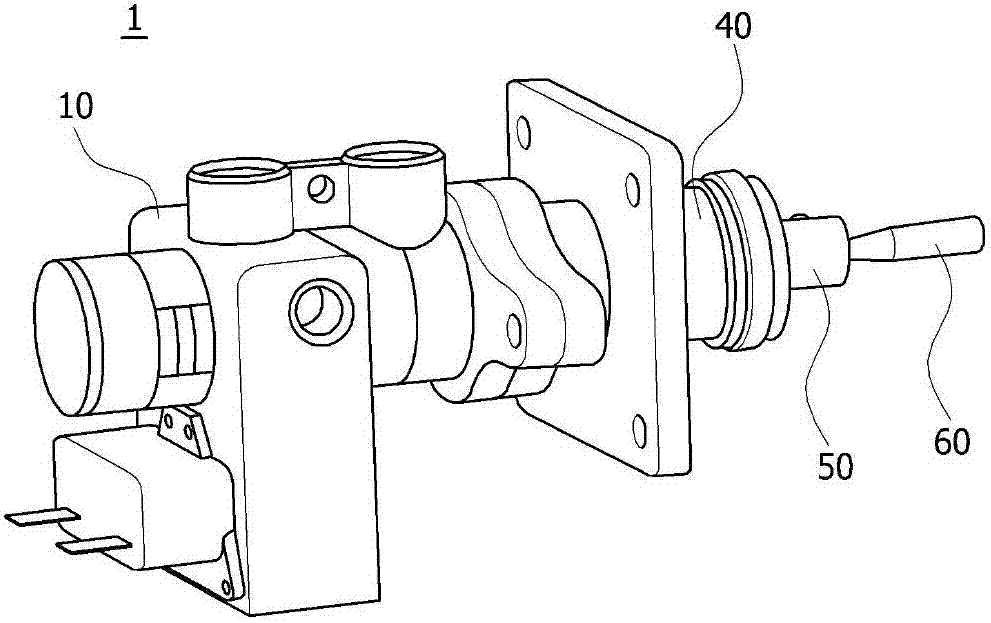

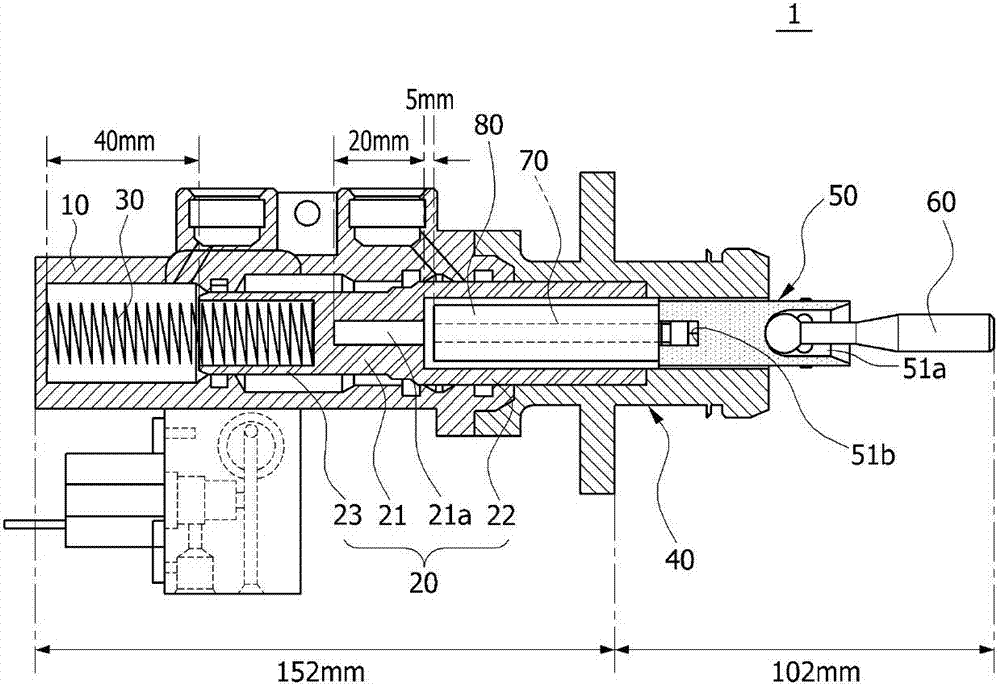

Electronic Hydraulic Brake Device

ActiveCN103481880AShorten the overall lengthReduce weightFluid braking transmissionEngineeringMechanical engineering

The invention relates to an electronic hydraulic brake device comprising a main shell storing fluid providing hydraulic pressure to wheels, a main piston part inserted in the main shell, an elastic part disposed in the main shell and supporting the main piston part elastically, a pedal force housing connected to one end of the main shell, a buffer cylinder part inserted in the pedal force housing, a piston rod part combined to the buffer cylinder part through pins and used for transmitting pressure of a pedal, a guide rod part in threaded connection with the buffer cylinder part, and a buffer part connected to the guide rod part and inserted in the main piston part.

Owner:HYUNDAI MOBIS CO LTD

Image taking optical system and image pickup apparatus equipped with same

InactiveCN102411190AShorten the overall lengthEasy to correctTelevision system detailsColor television detailsOptical axisConvex side

The invention provides an image taking optical system having a shortened length and commedably correcting aberration caused by reducton of final effective diameter of lens faces and an image pickup apparatus equipped with the same. The image taking optical system includes, in order from the object side, an aperture, a first lens having a biconvex shape and having a positive refractive power, a second lens having a concave surface facing the image side and having a negative refractive power, a third lens having a convex surface facing the image side and having a positive refractive power, and a fourth lens having a negative refractive power. The image taking optical system satisfies the conditional expression "0.6<d5 / (d5+d6)<0.8", where d5 is the air distance between the second lens and the third lens on the optical axis, and d6 is the thickness of the third lens.

Owner:OLYMPUS CORP

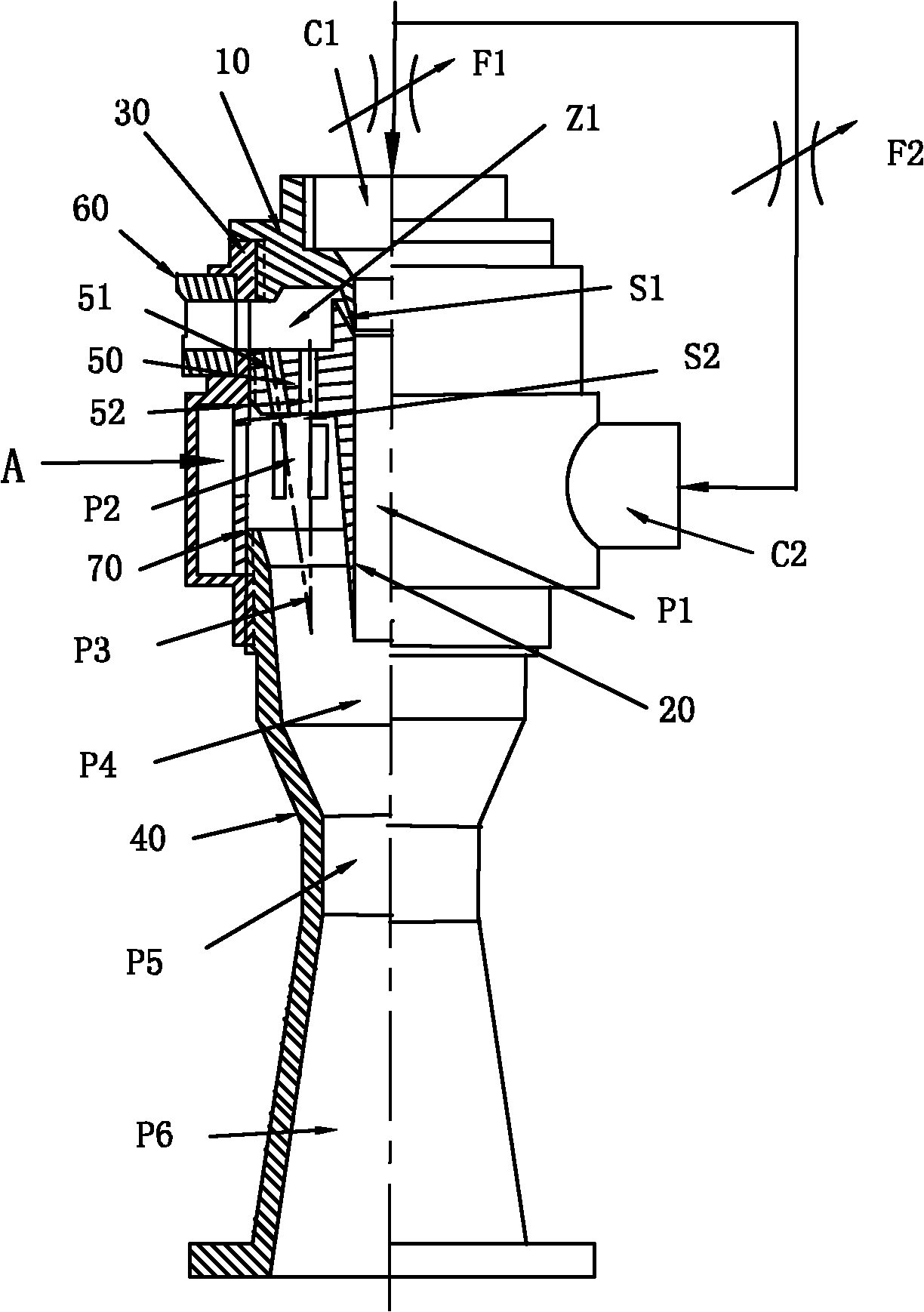

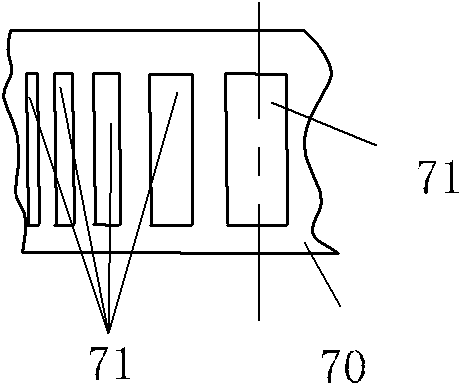

Dual ring ejector

InactiveCN102678634ASpeed up or enhance mixingSolve the problem of low ejection efficiencyJet pumpsMachines/enginesEngineeringInjector

The invention provides to a dual ring ejector, and relates to a fluid pump. An inner ring ejector apparatus is sequentially provided with a central time fluid inlet sleeve, an inner ring nozzle and a center mixing tube along an axle wire, a main stream annular cavity, an outer ring nozzle, an annular mixing room and an annular mixing tube are sequentially arranged on the periphery of the inner ring ejector apparatus along the axle wire by an outer ring ejector apparatus, a main stream inlet tube is communicated with an inner ring nozzle inlet and an outer ring nozzle inlet through the main stream annular cavity, the annular mixing room is communicated with an outer ring stream inlet tube and the annular mixing tube, an outer ring nozzle outlet is convex and protrudes into the annular mixing room and faces to the annular mixing tube, the two outlets of the mixing tubes are jointly communicated with a general mixing output tube, the same main stream is used by the inner ring ejector and the outer ring ejector for pumping time fluid, and after being mixed, the pumped time fluid enters the general mixing output tube for outputting. According to the dual ring ejector, the weight is light, the size in axial direction is small, the absorbing and ejecting rate is high, and the ejector performs well with mass flow and has various structure forms. The main stream can be used for injecting and mixing one or two time fluids, so as to realize output under uniform pressure.

Owner:韩铁夫

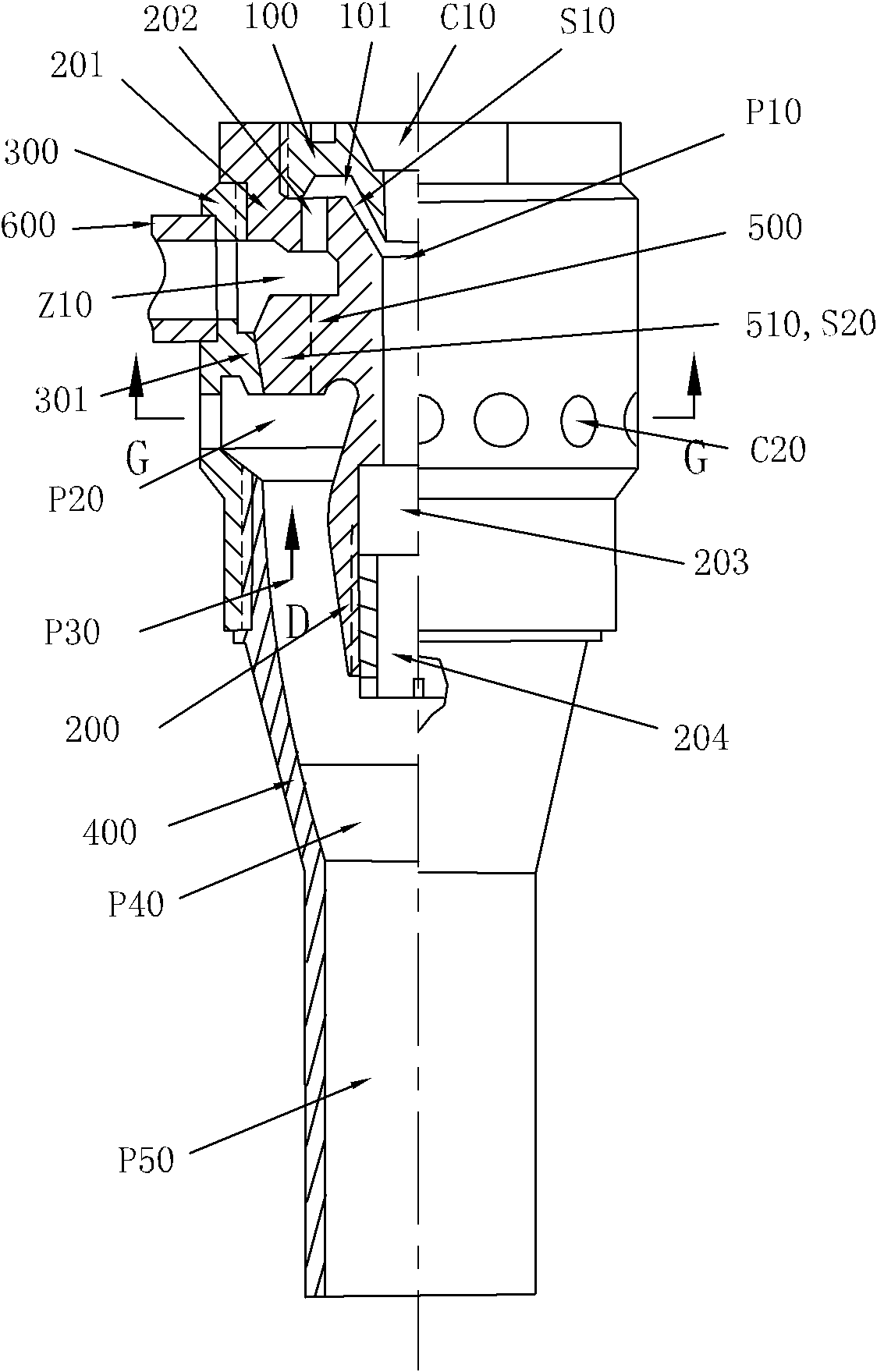

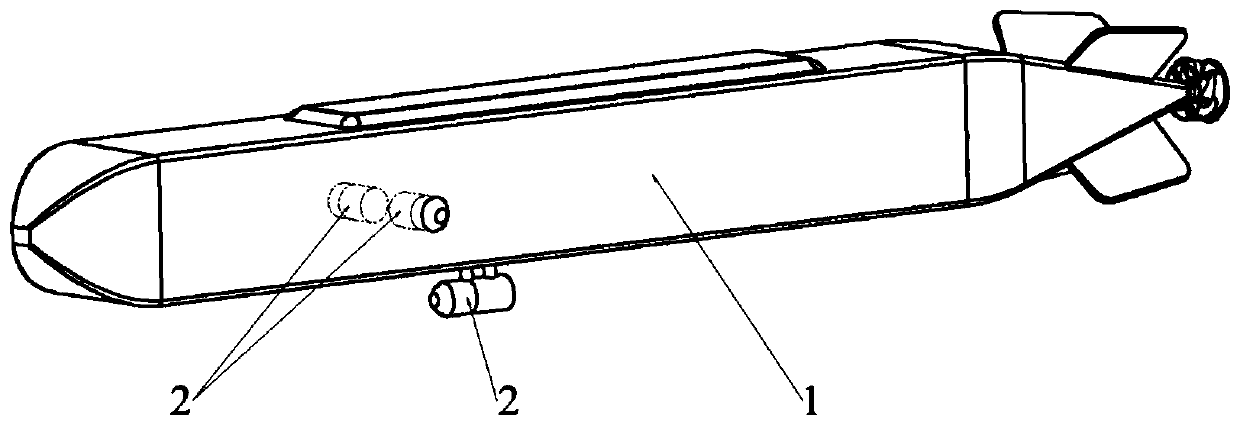

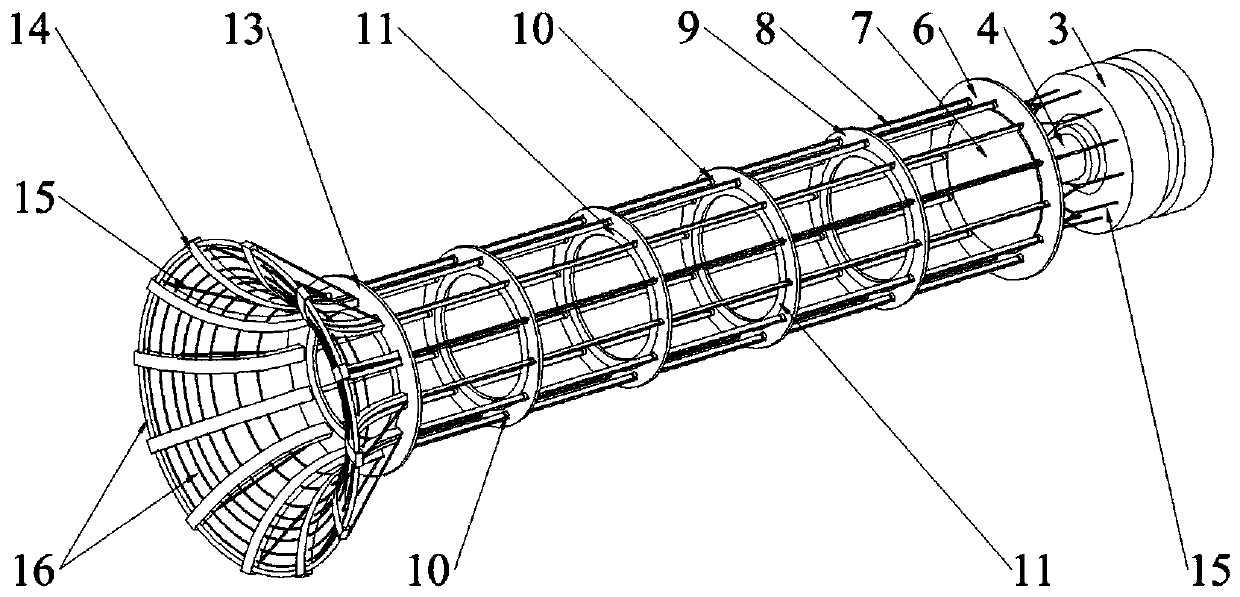

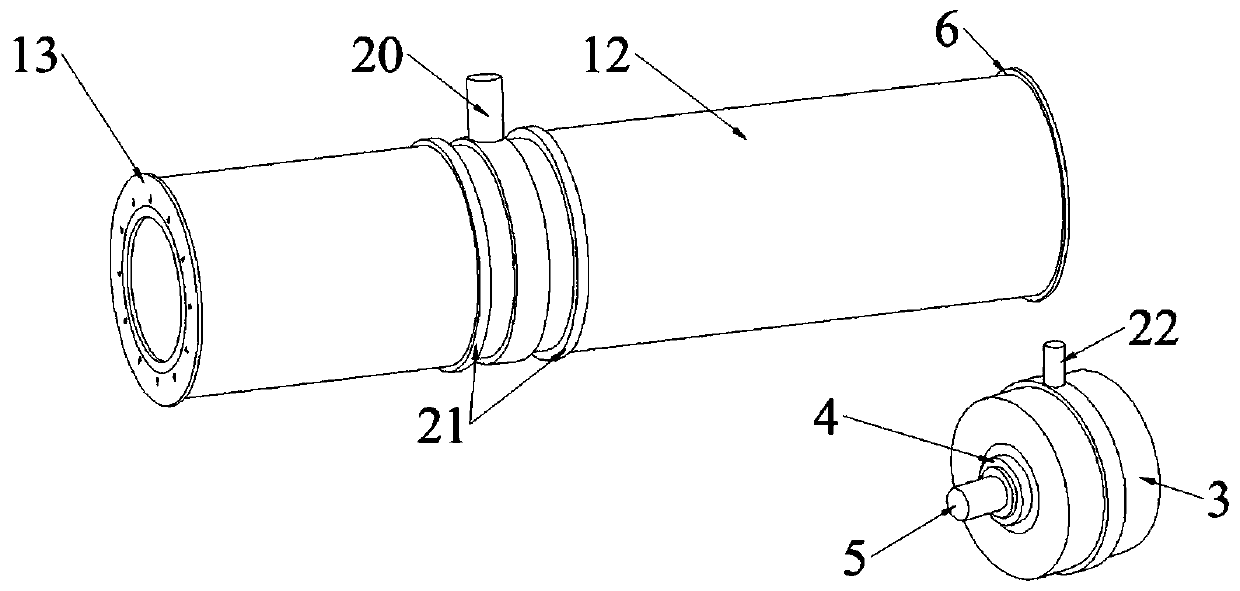

AUV (autonomous underwater vehicle) release and recovery device driven by hydraulic linkage device and applied to ultra-large type UUV (unmanned underwater vehicle)

ActiveCN110803269ACompact structureShorten the overall lengthUnderwater vesselsUnderwater equipmentElectric machineryEnvironmental geology

The invention provides an AUV (autonomous underwater vehicle) release and recovery device driven by a hydraulic linkage device and applied to an ultra-large type UUV (unmanned underwater vehicle), andbelongs to the technical field of underwater vehicles. The device comprises a motor box, a hydraulic device, a push rod, a recovery device and an external sleeve; the hydraulic device is mounted in the motor box, and a hydraulic rod of the hydraulic device extends out of the motor box; the recovery device is of a frame type cylindrical structure with one closed end, the closed end of the recoverydevice is coaxially and fixedly connected with the hydraulic rod of the hydraulic device through the push rod, and the other end is a recovery / release port; and the external sleeve coaxially sleevesthe periphery of the recovery device and is used for fixing the whole AUV release and recovery device to the ultra-large type UUV. All devices, including a driving device, required by AUV release andrecovery are integrated into a small tubular module, the structure is compact, and the device not only can be recovered into the large UUV, but also can be mounted outside an underwater platform to bean external load.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com