Large-viewing-field and high-precision star sensor optical system

A technology of star sensor and optical system, which is applied in the optical field to achieve the effect of increasing the relative aperture, small absorption and shortening the total length of the system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

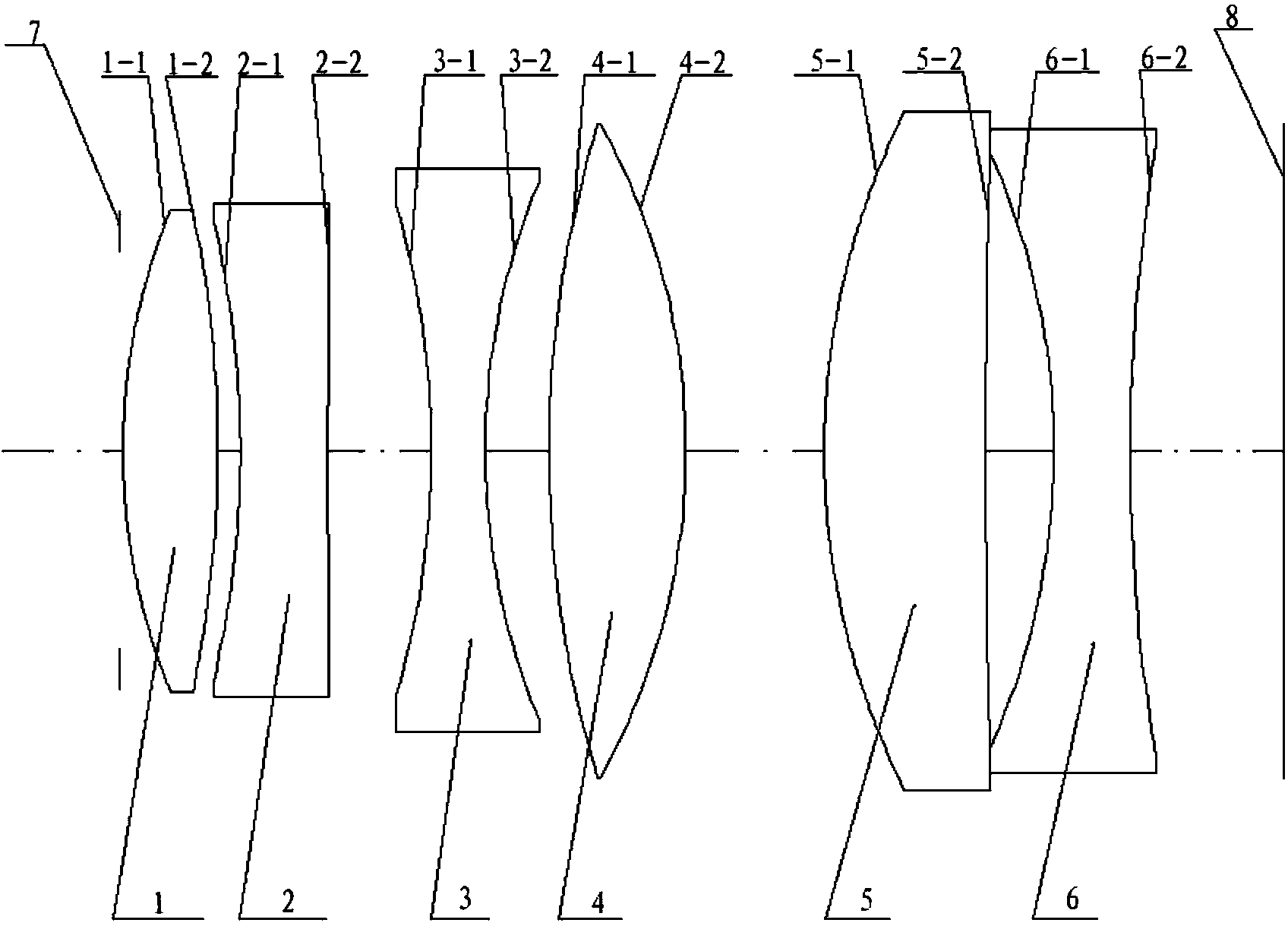

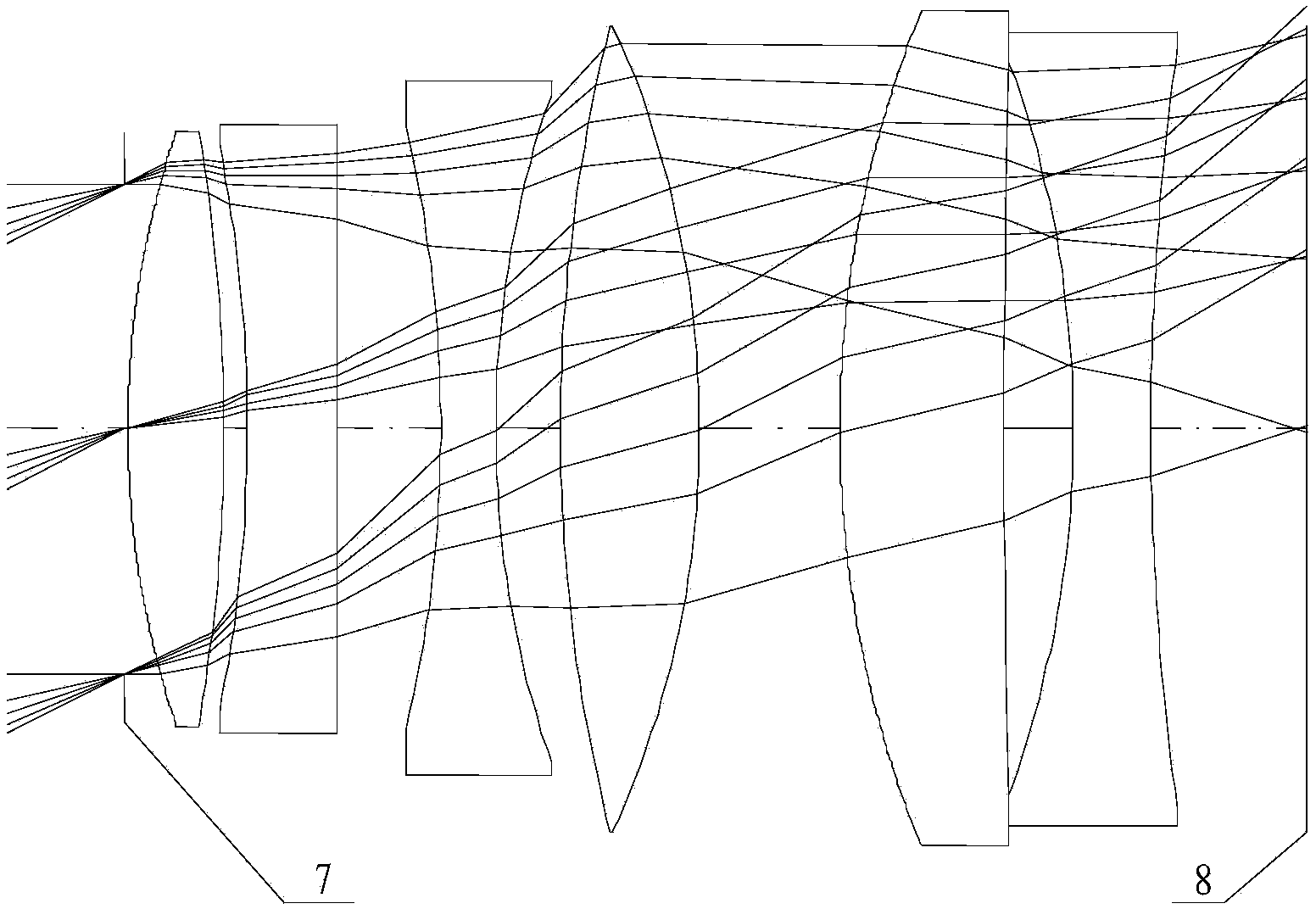

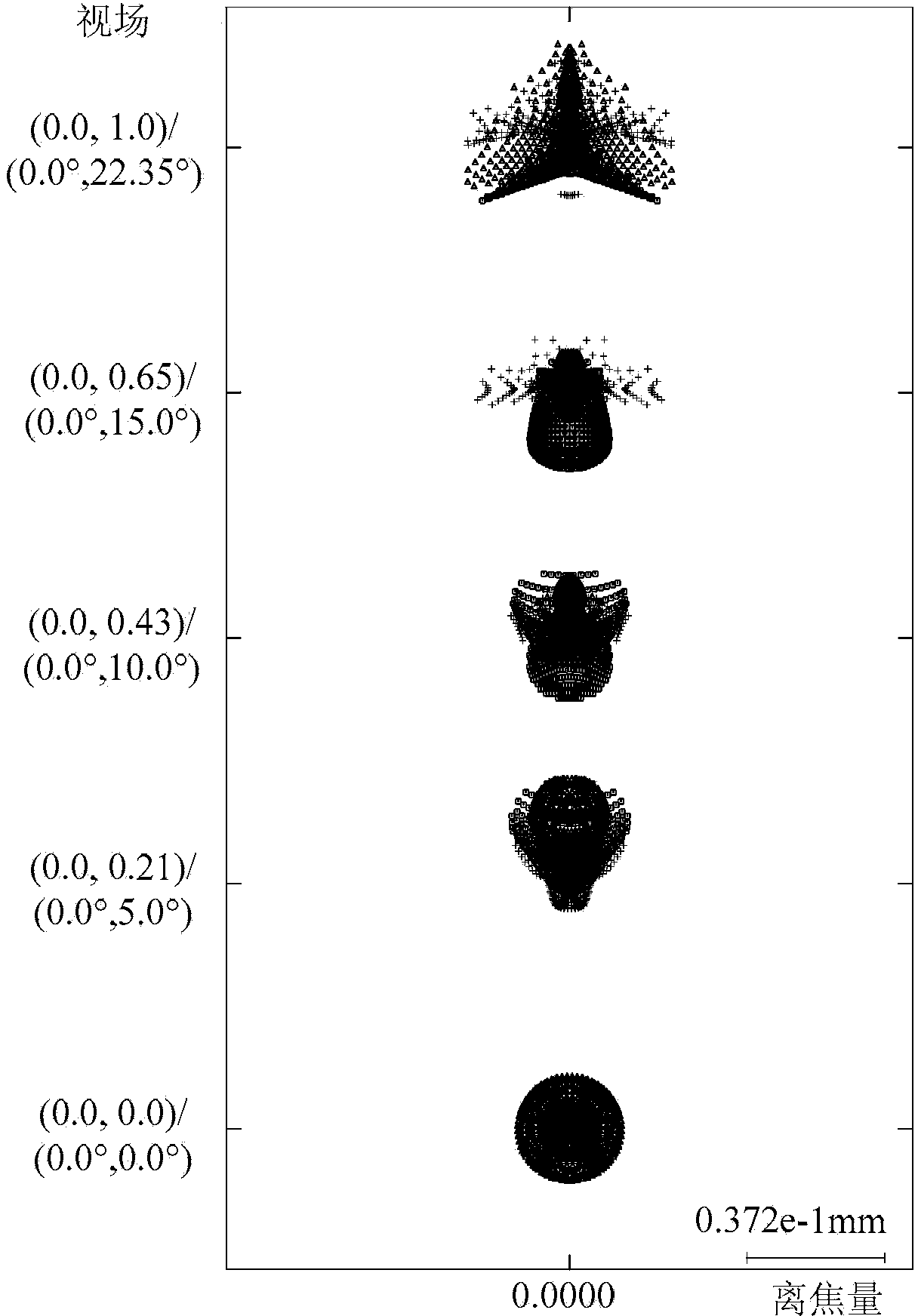

[0024] Specific implementation mode one: the following combination Figure 1 to Figure 7 Describe this embodiment mode, a kind of high-precision star sensor optical system of large field of view described in this embodiment mode, it comprises diaphragm 7, lens group and image plane 8, the light that the star sends in the field of view enters through diaphragm 7 to The lens group, after being transmitted by the lens group, forms an image on the image plane 8;

[0025] The lens group is a near image telecentric optical system composed of the first lens 1, the second lens 2, the third lens 3, the fourth lens 4, the fifth lens 5 and the sixth lens 6;

[0026] The first lens 1, the second lens 2, the third lens 3, the fourth lens 4, the fifth lens 5 and the sixth lens 6 are sequentially placed on the same optical axis according to the direction from the diaphragm 7 to the image plane 8;

[0027] The first lens 1, the fourth lens 4 and the fifth lens 5 are positive lenses, and the ...

specific Embodiment approach 2

[0034] Specific embodiment two: this embodiment is described further to embodiment one, the mirror surface of each eyeglass in the set lens group facing the diaphragm 7 is the first mirror surface, and the mirror surface facing the image plane 8 is the second mirror surface, then the mirror surface of the lens group Each mirror surface is the first mirror surface 1-1 of the first lens 1, the second mirror surface 1-2 of the first lens 1, the first mirror surface 2-1 of the second lens 2, and the second mirror surface 2-2 of the second lens 2 , the first mirror surface 3-1 of the third lens 3, the second mirror surface 3-2 of the third lens 3, the first mirror surface 4-1 of the fourth lens 4, the second mirror surface 4-2 of the fourth lens 4, the second mirror surface 4-2 of the fourth lens 4 The first mirror surface 5-1 of the fifth mirror 5, the second mirror surface 5-2 of the fifth mirror 5, the first mirror surface 6-1 of the sixth mirror 6 and the second mirror surface 6...

specific Embodiment approach 3

[0036] Specific embodiment three: this embodiment will further explain embodiment two, the positional relationship of each lens in the lens group, and the radius of curvature of each lens are selected according to the following table:

[0037]

[0038] The distance between the second mirror surface 6-2 of the sixth lens 6 and the next mirror surface along the central axis in the above table refers to the distance between the second mirror surface 6-2 of the sixth lens 6 and the image plane 8 along the central axis in the table.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com