Drily hung vitrolite wall surface decoration system and construction method thereof

A technology of wall decoration and construction method, which is applied to the wall decoration system of dry-hanging porcelain panels and its construction field, which can solve the problems of large differences in thermal expansion and contraction, crack deformation, etc., and achieve material reduction, cost saving, and uniform color natural effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

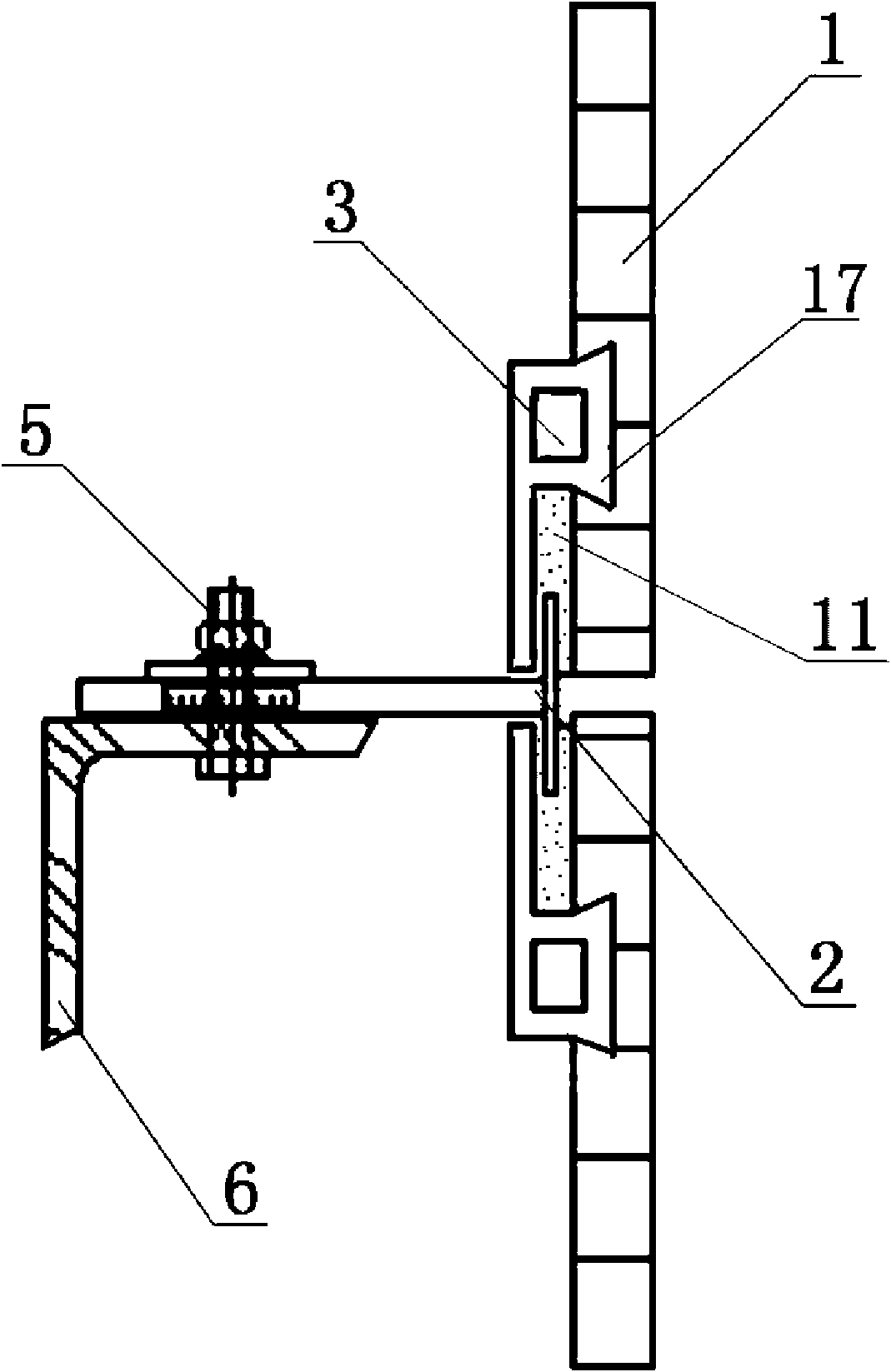

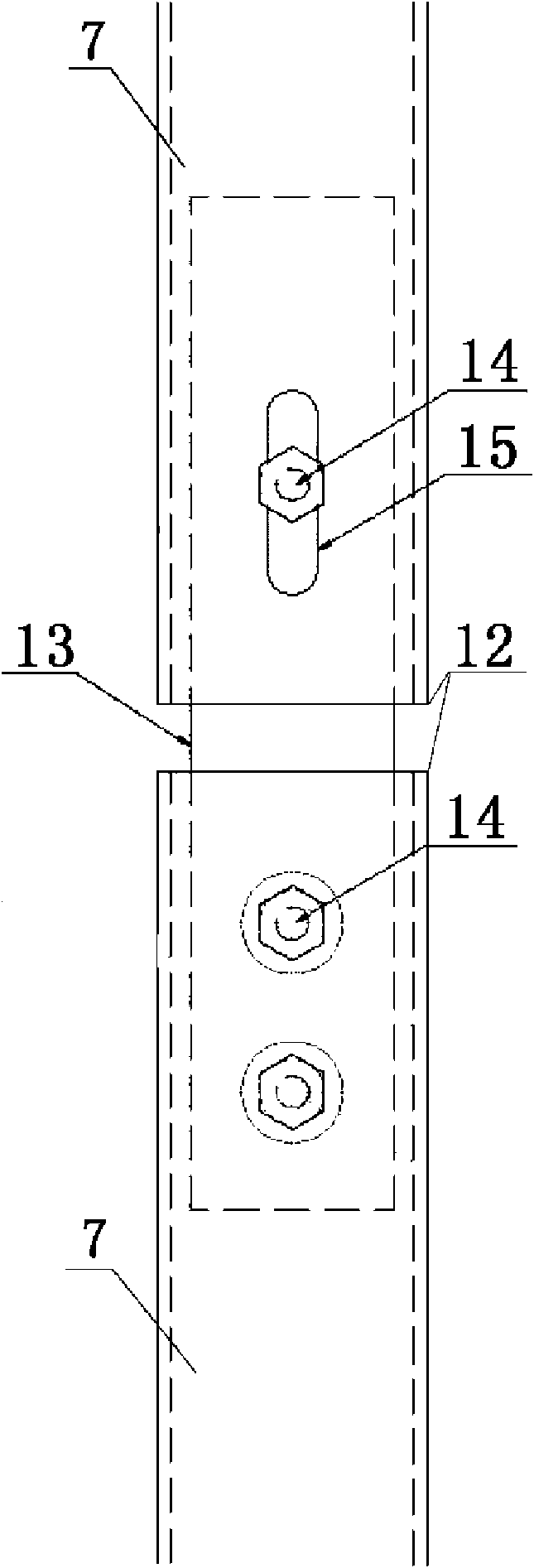

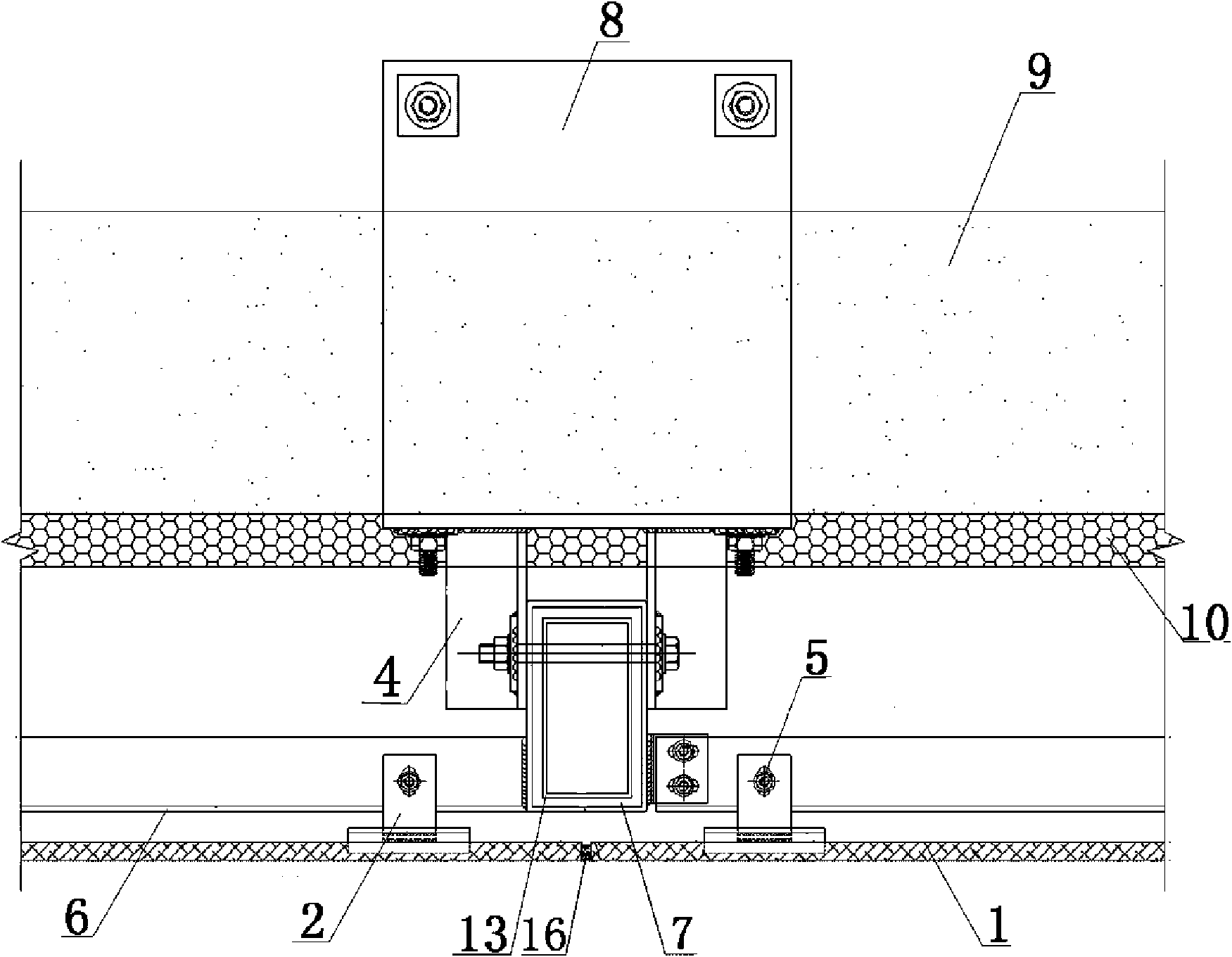

[0035] Examples see figure 1 , image 3 As shown, a dry-hanging porcelain plate wall decoration system includes a porcelain plate 1 connected to the main building wall 9, and is characterized in that: the main building wall 9 is connected to the embedded part 8, and the embedded part 8 is connected to the vertical keel 7 through the connecting piece 4 on each floor. The connecting piece on each floor can be angle steel or square steel. The vertical keel 7 is vertically connected to the horizontal keel 6. The bottom angle of the groove 17 is between 45-60 degrees. The dovetail groove is embedded with the anchor piece 3, and the anchor piece 3 has a pair of anchor heads matching the dovetail groove of the porcelain plate. The anchor head is inserted into the dovetail groove on the back of the porcelain plate. A cavity for penetrating and anchoring the head of the T-shaped pendant is formed between the plate and the back of the porcelain plate. The head of the T-shaped pendant ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com