Hinge apparatus having automatic return function for use in building materials

一种自动返回、铰链装置的技术,应用在有销的铰链、建筑、建筑物构造等方向,能够解决上凸轮轴总长长等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

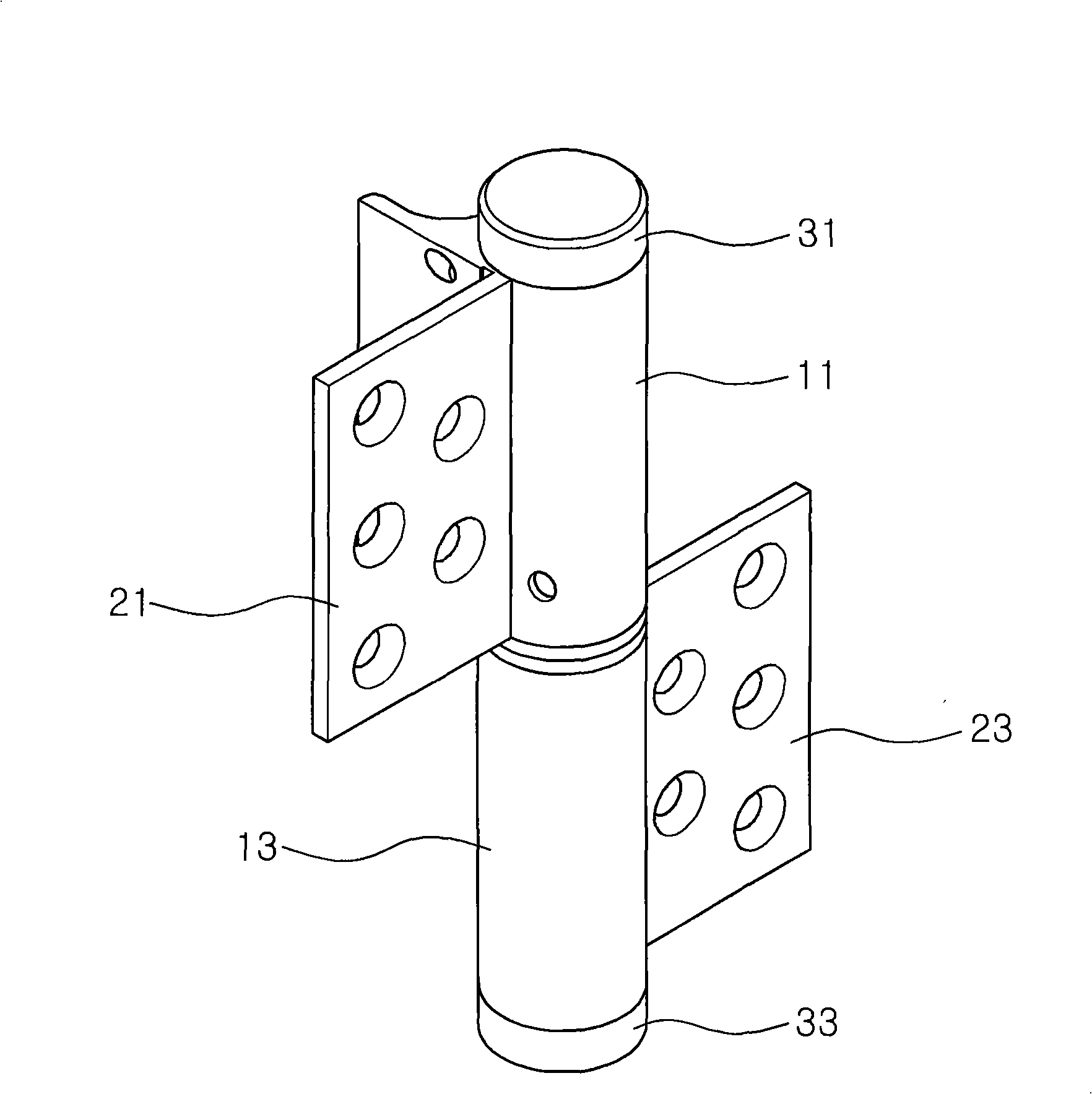

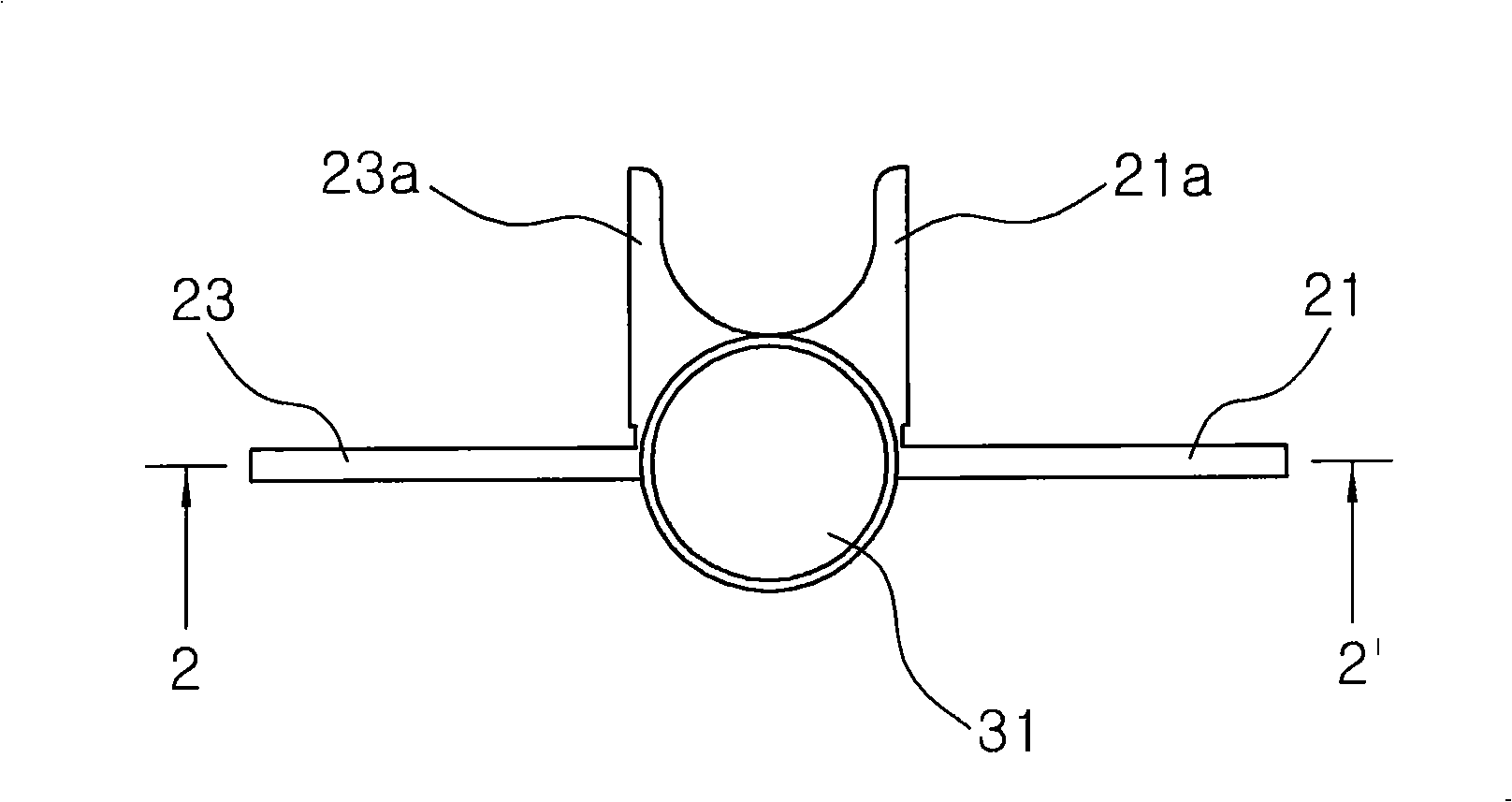

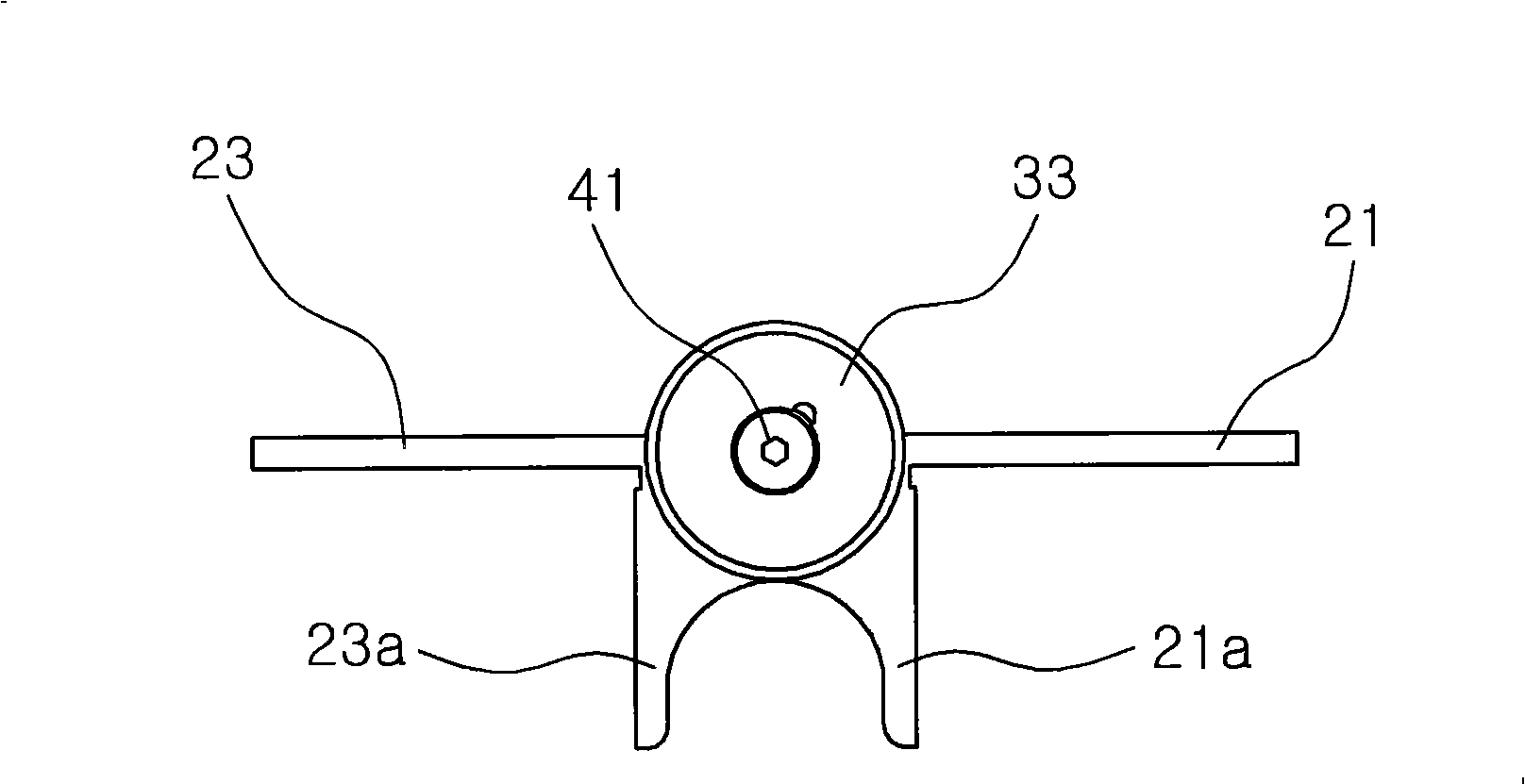

[0122] First, if Figures 1A to 4 The shown hinge device with automatic return function is accomplished by using a rotary / linear motion converter, which according to the first embodiment of the invention shown in FIG. The motion is converted to axial linear motion of the piston.

[0123] The hinge device with automatic return function according to the present invention includes an upper part 11 and a lower part 13, which are placed along the lengthwise direction in substantially the same axial direction. The upper part 11 is integrally formed and extended at one side of the first hinge 21 fixed to the door 1 , and the lower part 13 is integrally formed and extended at the other side of the second hinge 23 fixed to the door frame 3 . A plurality of through holes 22 into which fastening screws 22a are inserted are formed in the first and second hinges 21 and 23, respectively. The hinge device according to the above-mentioned embodiments of the present invention has described a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com