Buried type hinge apparatus having automatic return function

An automatic return and embedded technology, applied to hinges with pins, switches with braking devices, lighting and heating equipment, etc., can solve the problems of loose clamping screws and loss of automatic return function of hinge equipment, etc., to achieve Cost reduction, reliable automatic return function, and the effect of increasing the overall length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

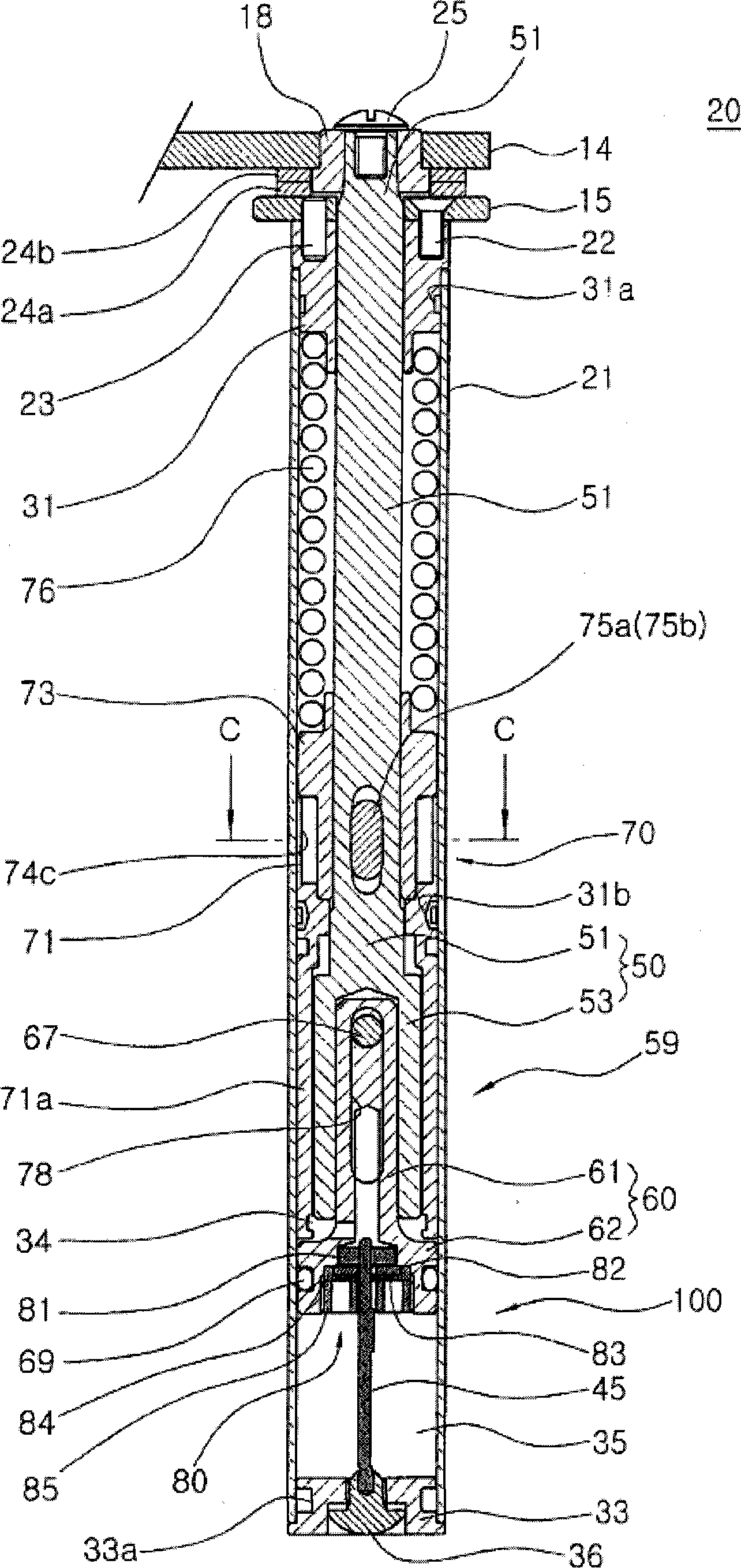

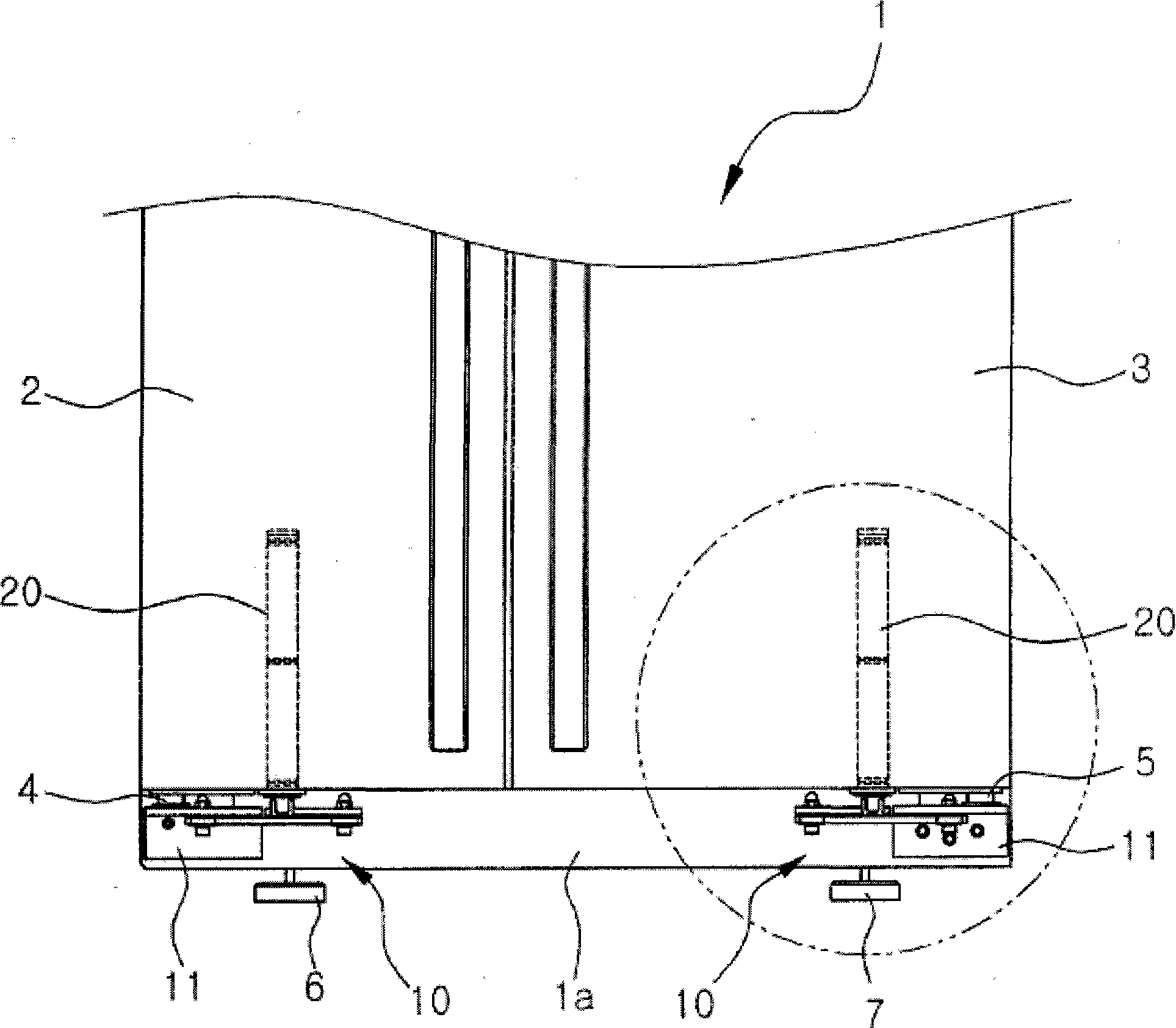

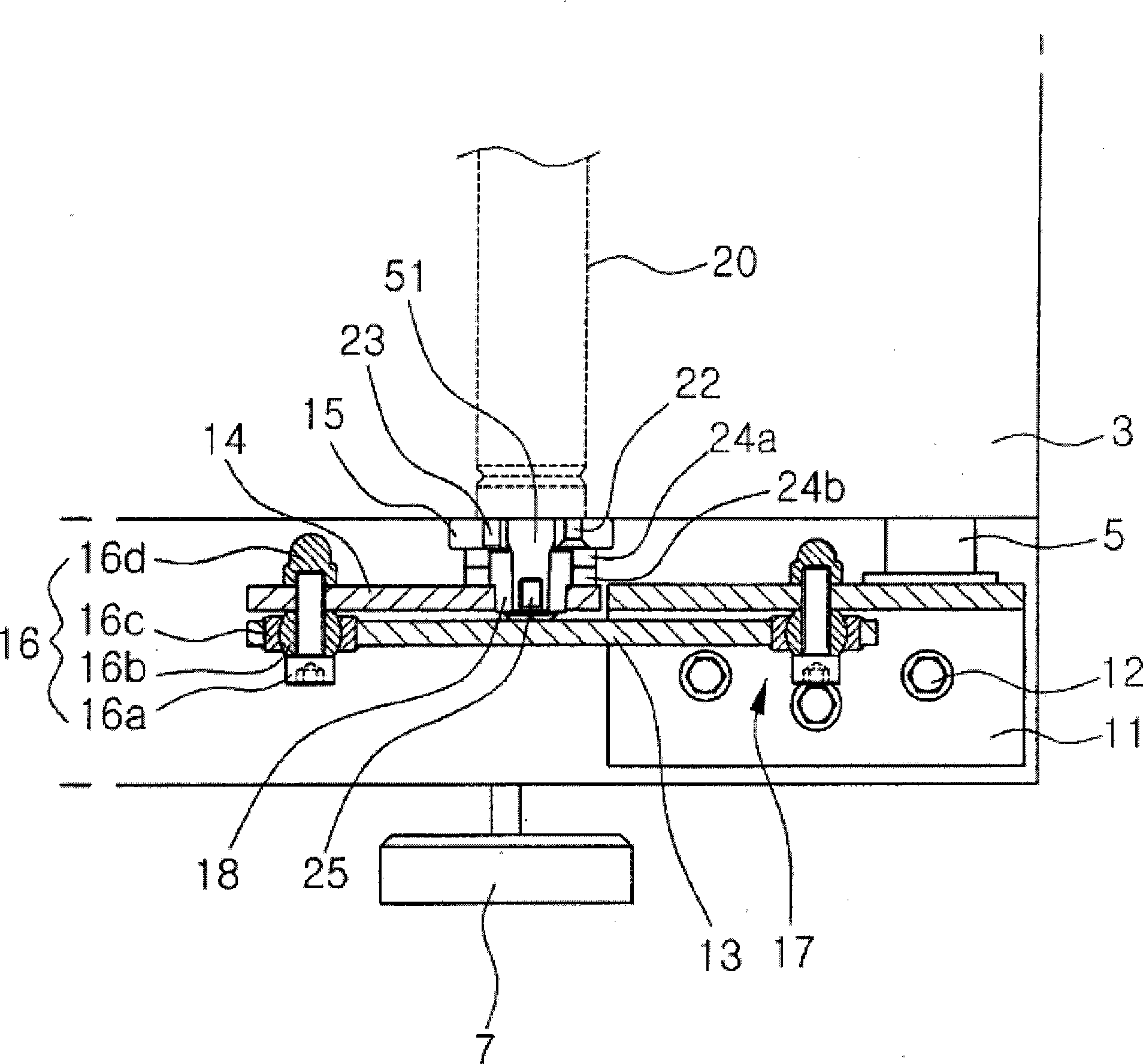

[0084] An embedded hinge device with an automatic return function according to a preferred embodiment of the present invention will be described below with reference to the accompanying drawings. In all the following embodiments, similar reference numerals represent similar elements.

[0085]figure 1 is a cross-sectional view showing a hinge device with an automatic return function used in a refrigerator door according to a first embodiment of the present invention, the hinge device being implemented using a rotation / linear motion conversion unit. Figure 2A It is a front view showing the state that the hinge device with automatic return function, which is used in the refrigerator door according to the first embodiment of the present invention and realized by using the rotation / linear motion conversion unit, is installed in the refrigerator using the link unit. Figure 2B yes means Figure 2A An enlarged cross-sectional view of the linkage unit. Figure 2C yes Figure 2A An...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com