Patents

Literature

1087results about How to "Reduce machining accuracy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

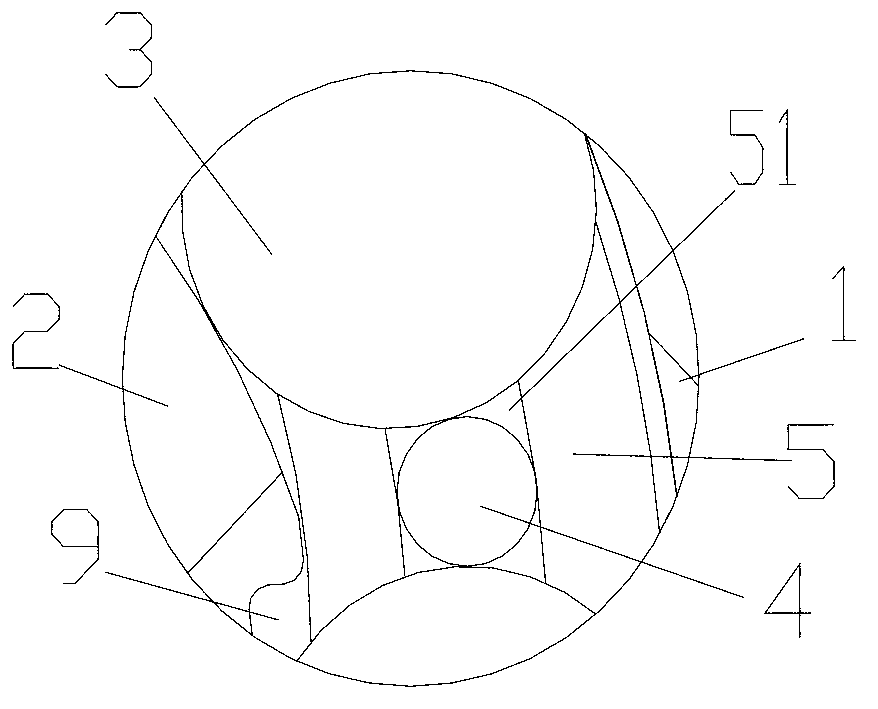

Automatic collecting and arranging machine for plastic soft bottle

ActiveCN101327851AImprove processing progressRealize the collectionProgramme-controlled manipulatorGripping headsAutomatic controlEngineering

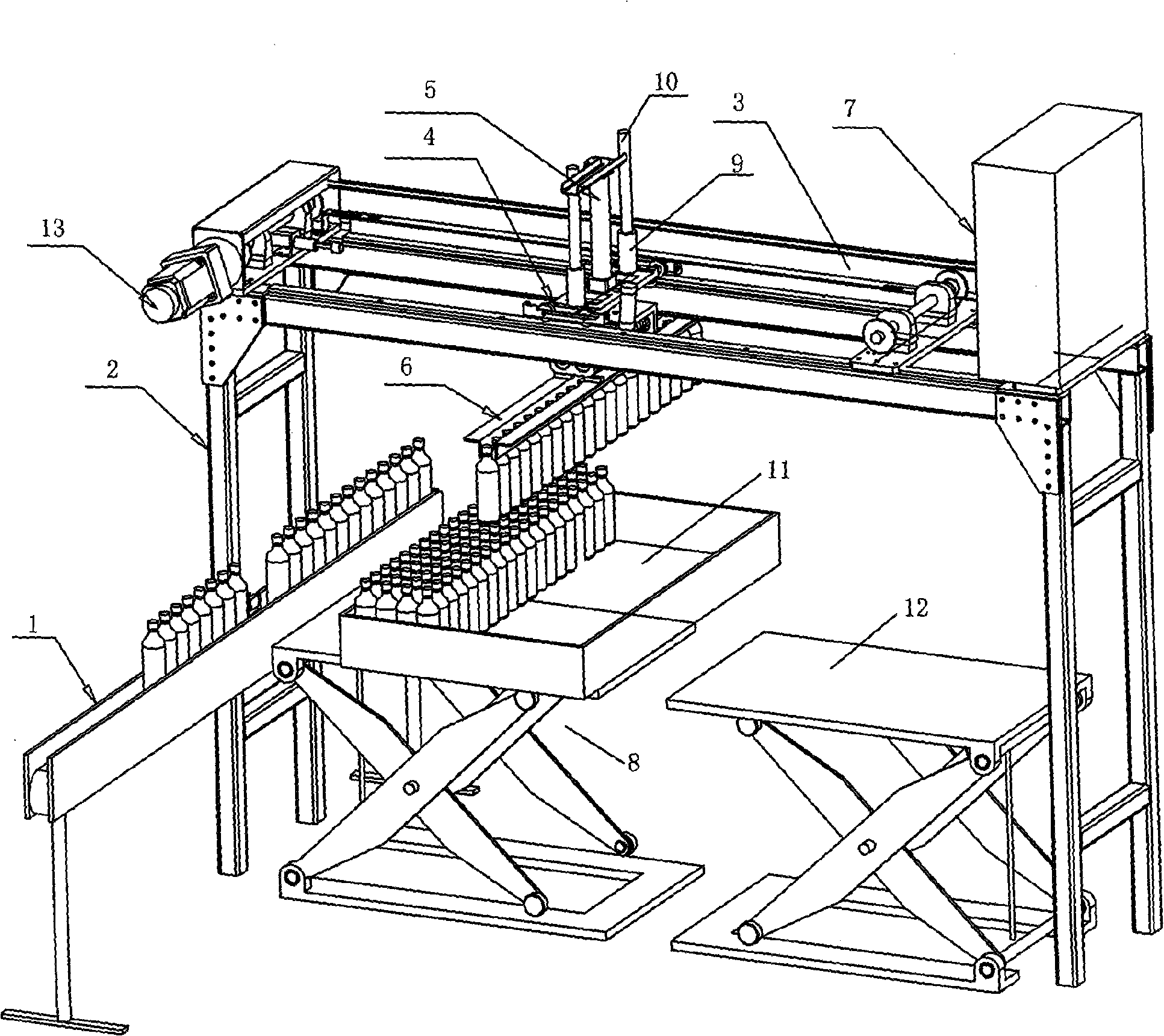

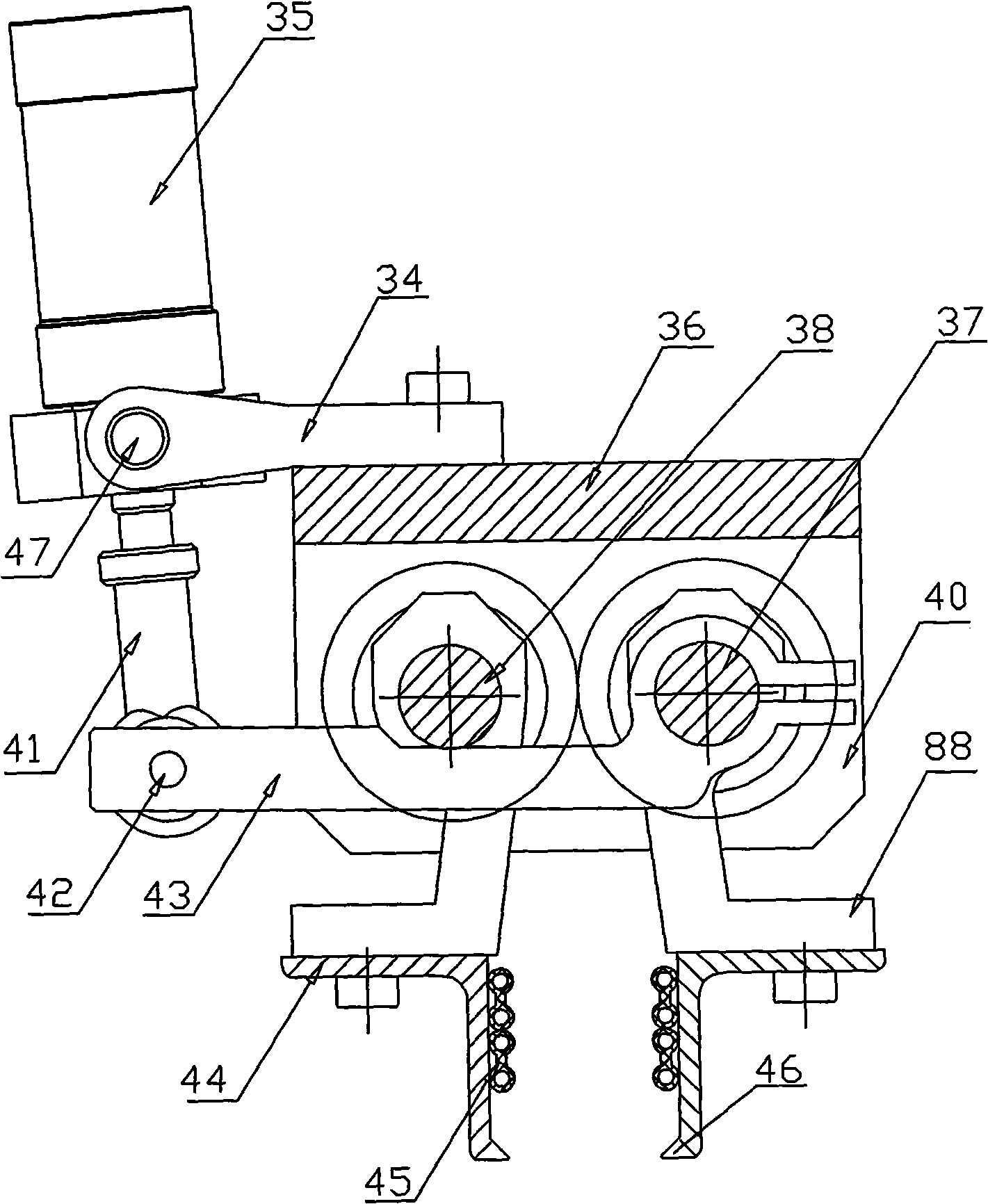

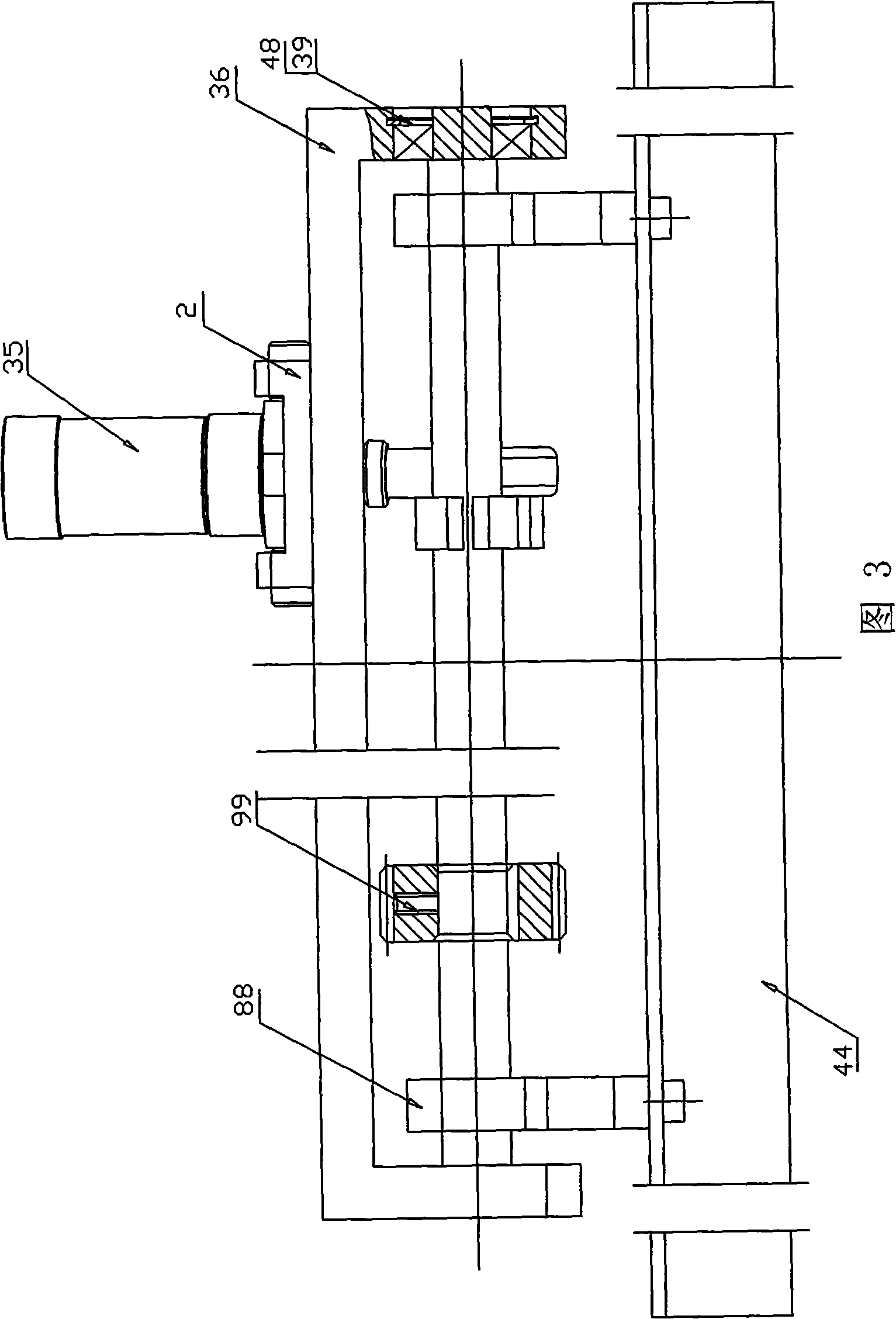

The invention discloses an automatic machine for collecting and sorting plastic soft bottles. The device comprises a conveyor for plastic bottles, soft bottles or soft bags, as well as a machine frame, wherein a traction device moving horizontally is arranged above the machine frame; a bottle clamping device connected via a lifting cylinder is arranged on a moving trolley of the traction device; the traction device, the lifting cylinder and the bottle clamping device are connected with an electric control device with electrical automatic control; a product collecting device is arranged below the machine frame beside the conveyor; and the electric control device controls the bottle clamping device to make vertical up-down lifting movement under the drive of the lifting cylinder and to make horizontal translating movement under the drive of the traction device, and controls the bottle clamping device to clamp a product input by the conveyor, to transfer the product to the product collecting device through the lifting cylinder and the traction device and then to unclamp the product. The machine can clamp, lift and translate plastic bottles, soft bottles or soft bags input by the conveyor to a preset distance, drop and put the bottles or bags into the product collecting device.

Owner:SICHUAN KELUN PHARMA CO LTD

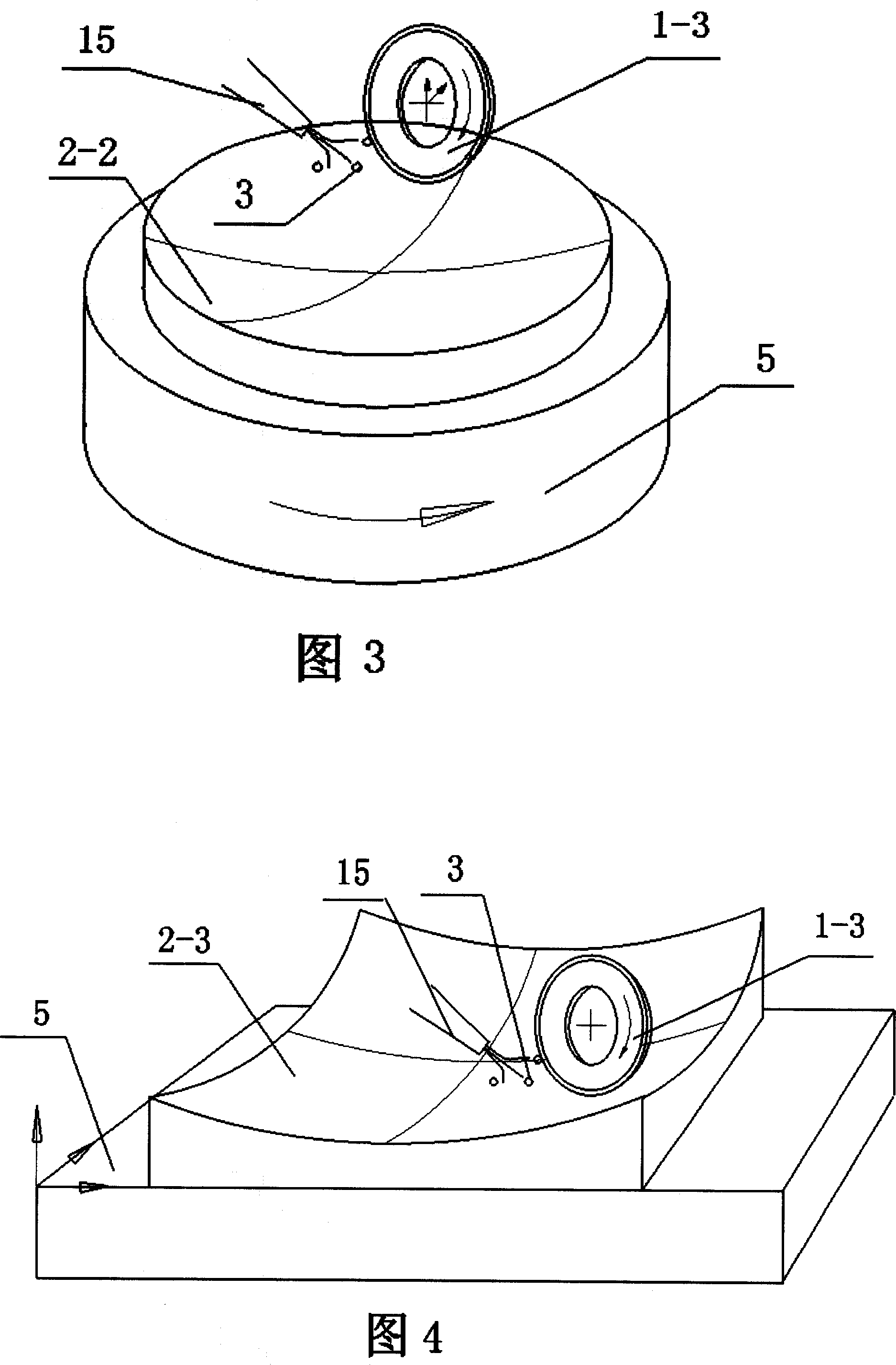

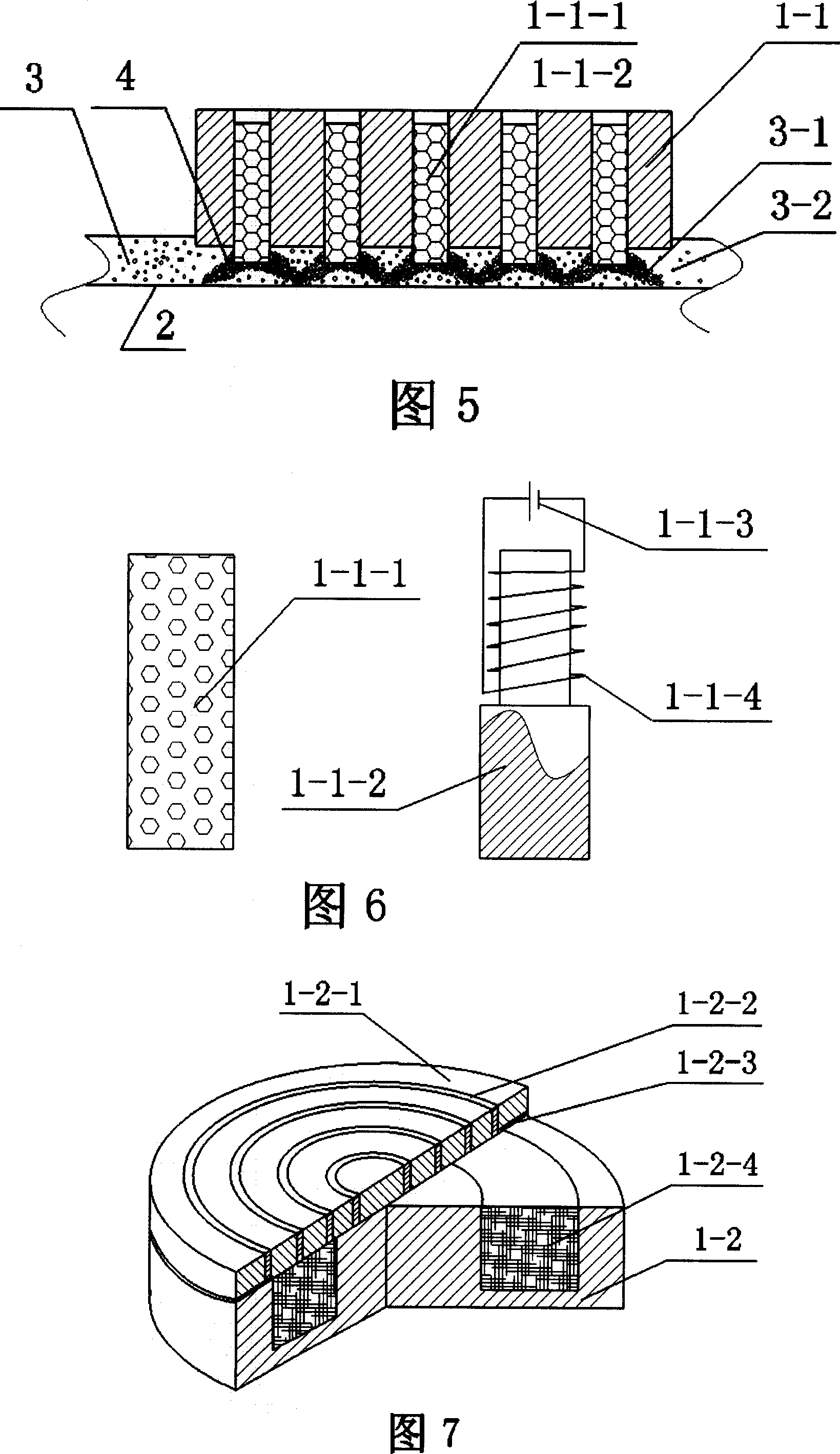

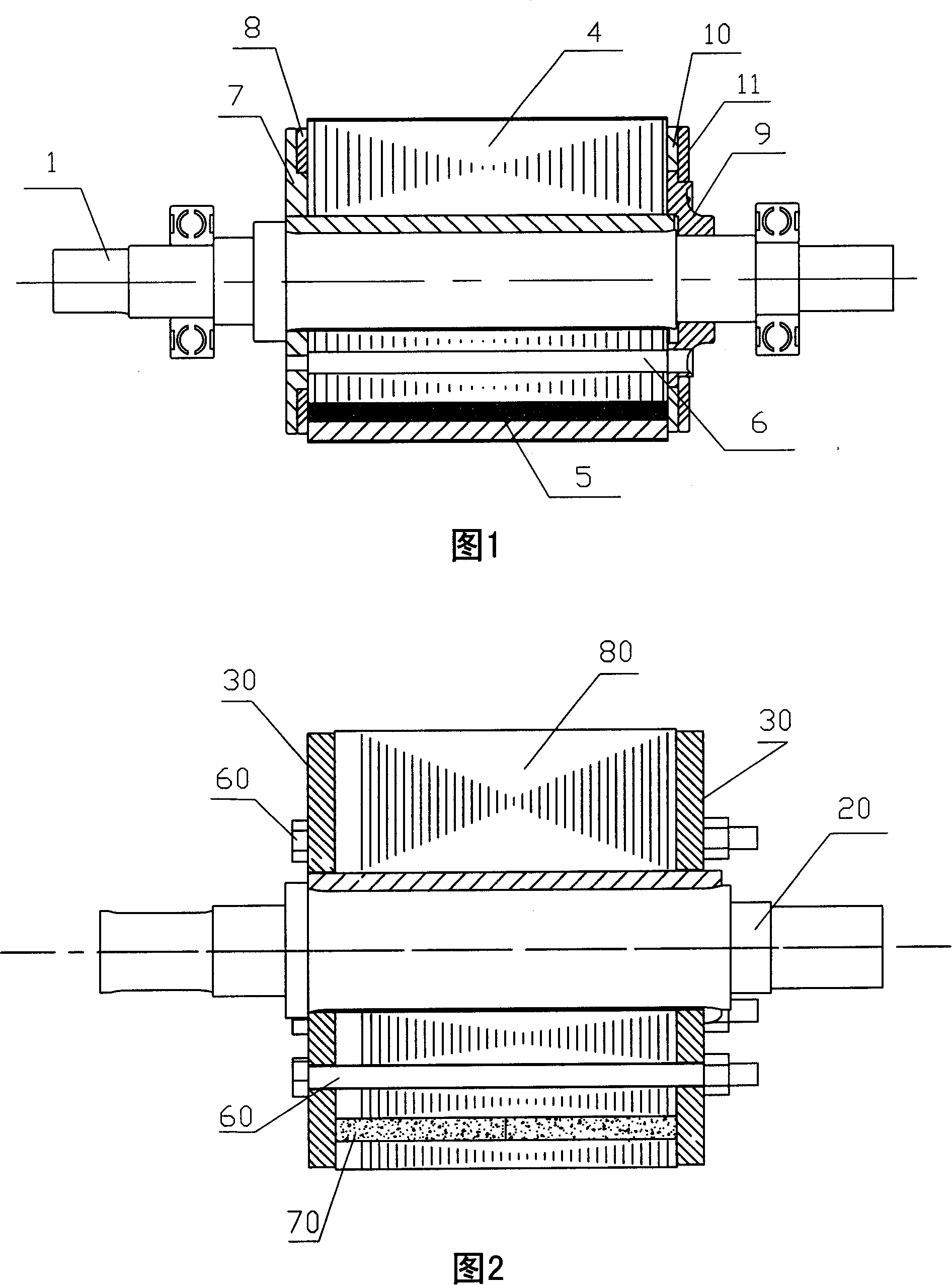

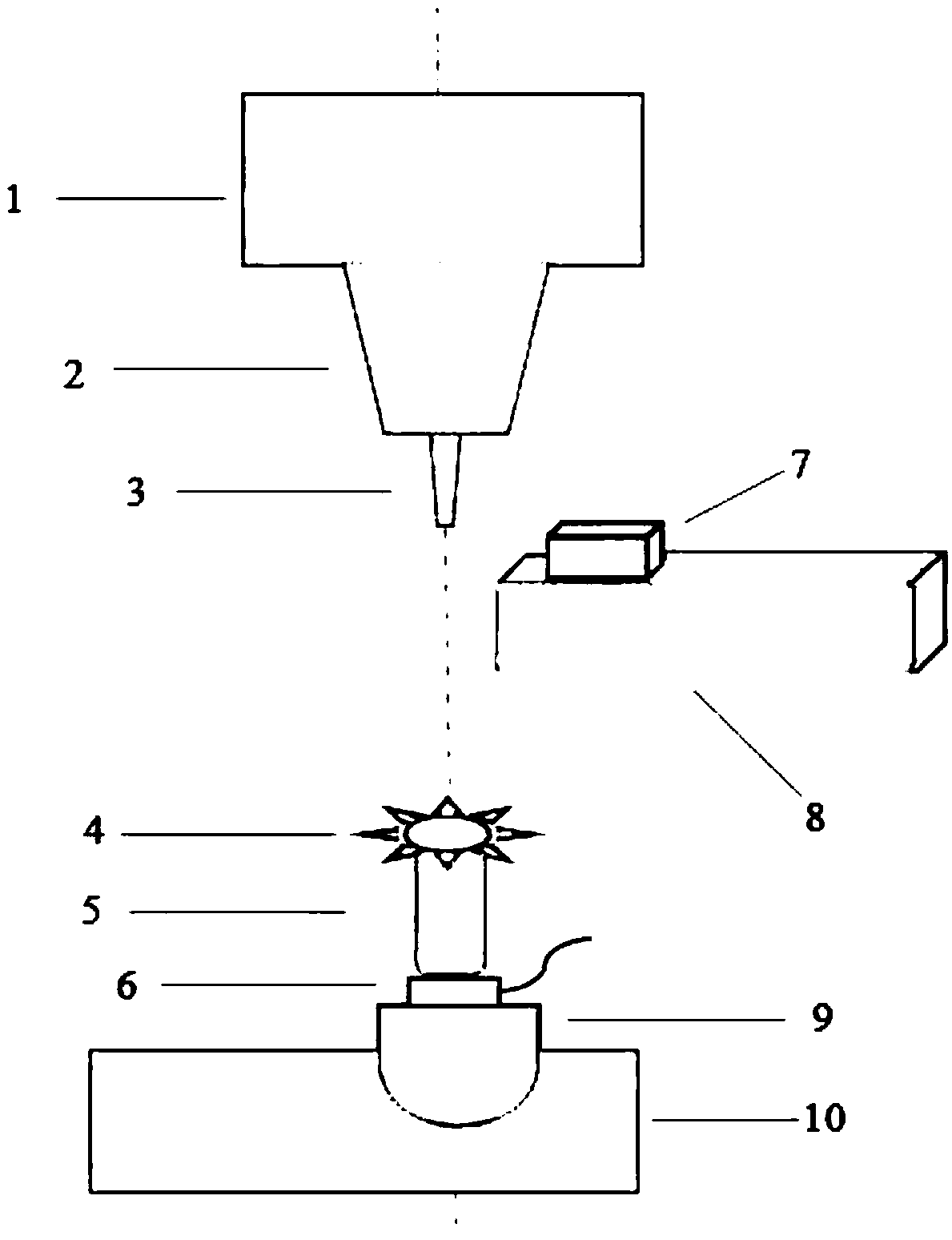

Grinding polishing method based on magnetic rheology effect and its polishing device

InactiveCN100999061AReduce removal rateReduce machining accuracyPolishing machinesPolishing compositions with abrasivesMagnetorheological fluidMaterials science

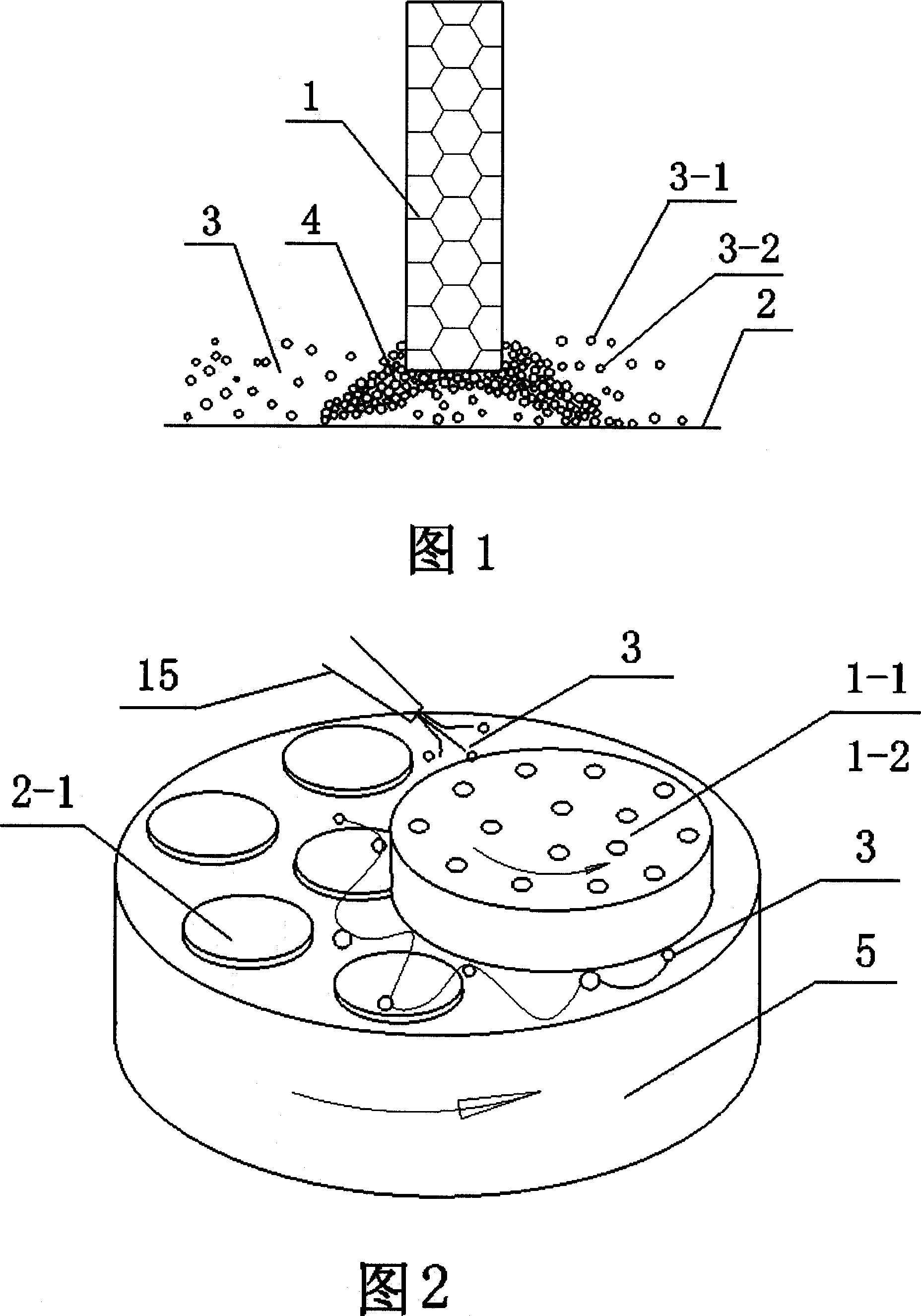

The present invention discloses a grinding-polishing method based on magnetorheological effect. Said method is characterized by that in the magnetorheological fluid a kind of free abrasive material is added, used as grinding-polishing liquor and injected into the between of magnetic body and workpiece surface, under the action of magnetic field the ferromagnetic particles in the magnetorheological fluid can be arranged by strings to cover the abrasive material pacticles and can be constrained in the end face of magnetic body to form magnetic grinding brush, said magnetic grinding brush can be used for grinding-polishing workpiece surface. Said invention also provides a grinding-polishing device for implementing said grinding-polishing method. Said device includes grinding tool mounted on main shaft connected with motor and working table for mounting workpiece.

Owner:GUANGDONG UNIV OF TECH

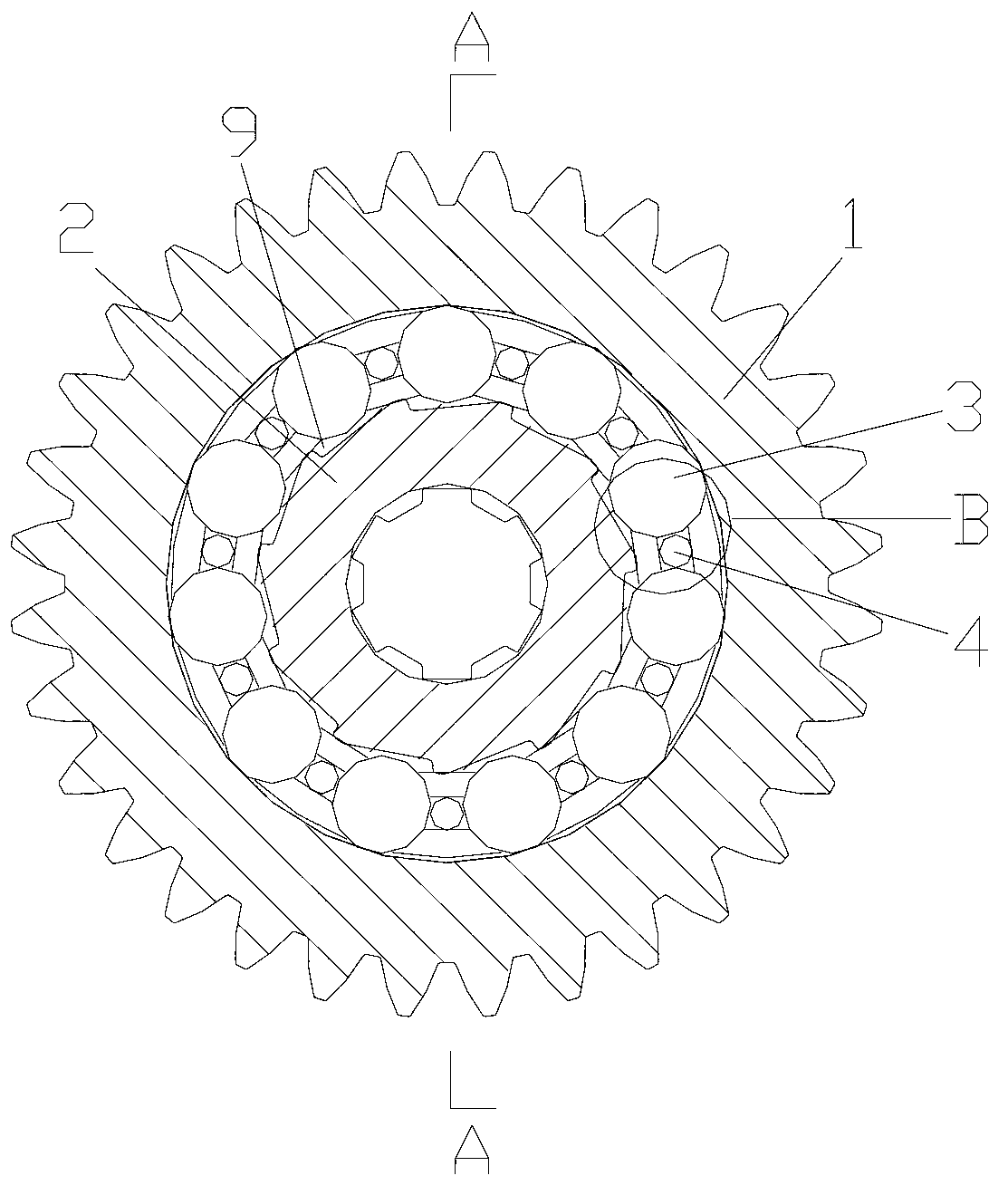

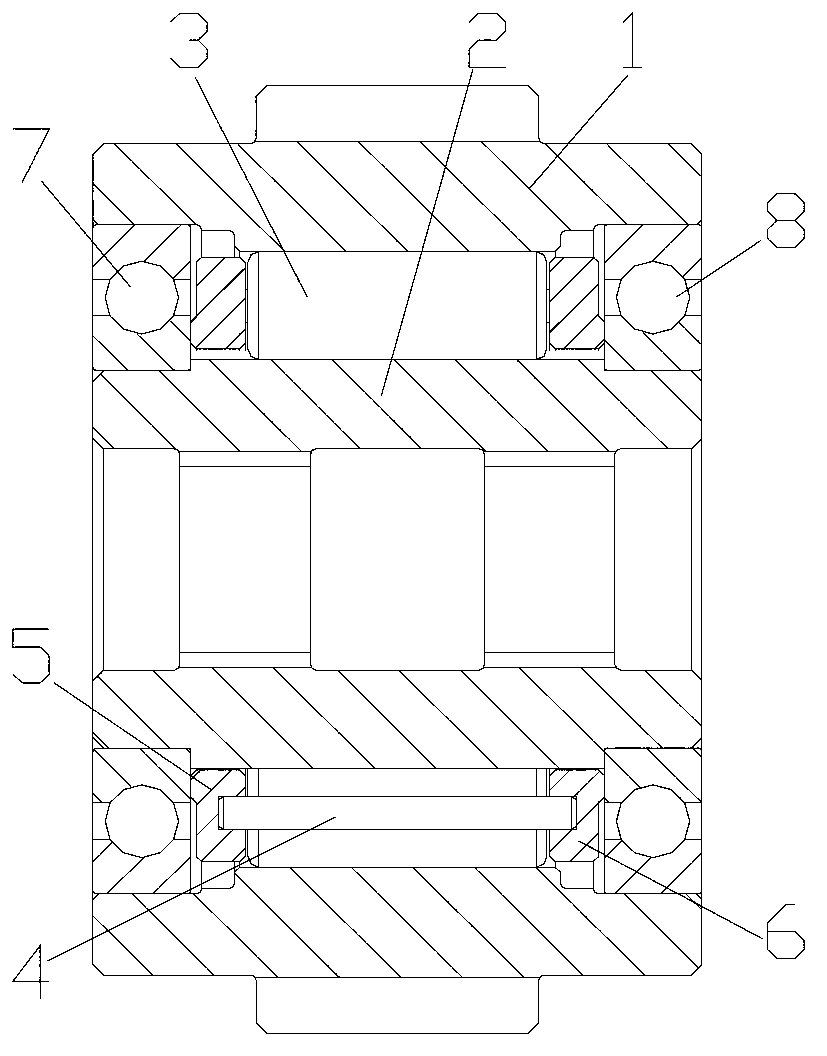

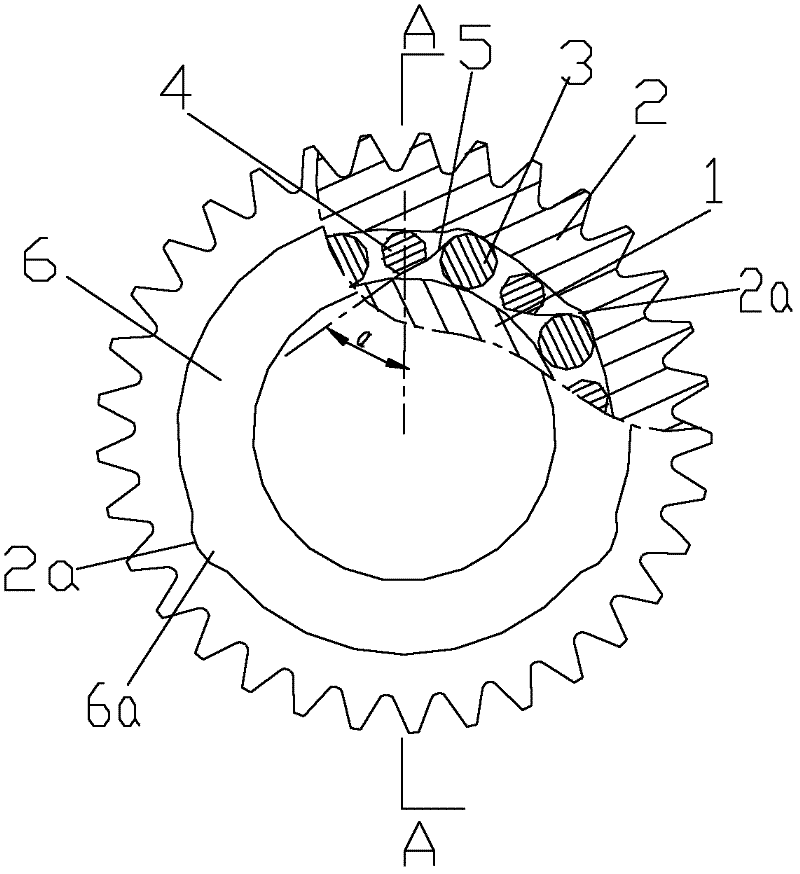

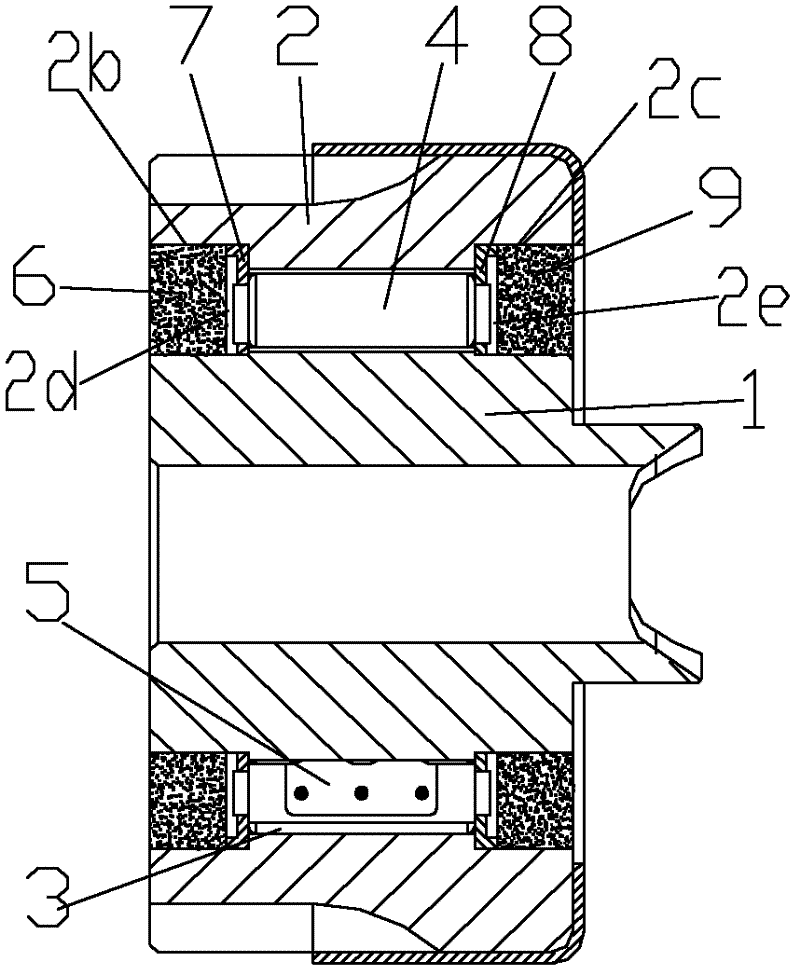

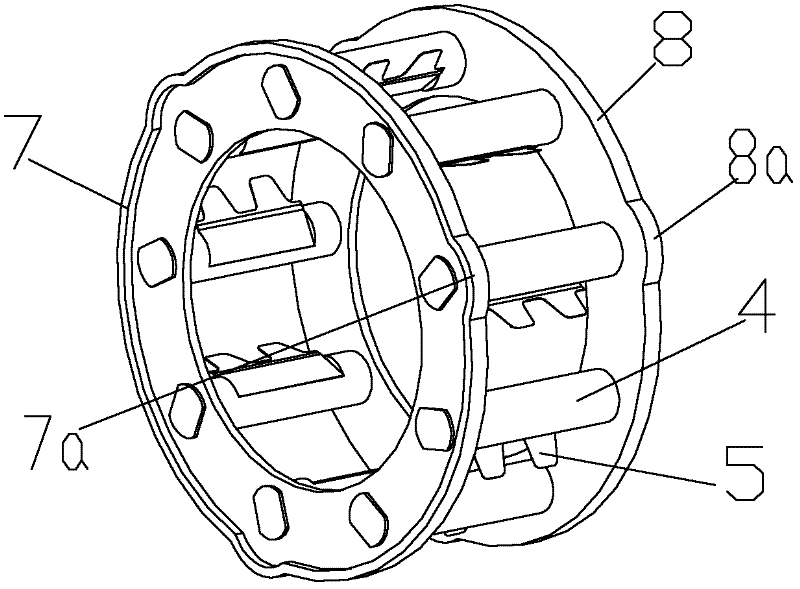

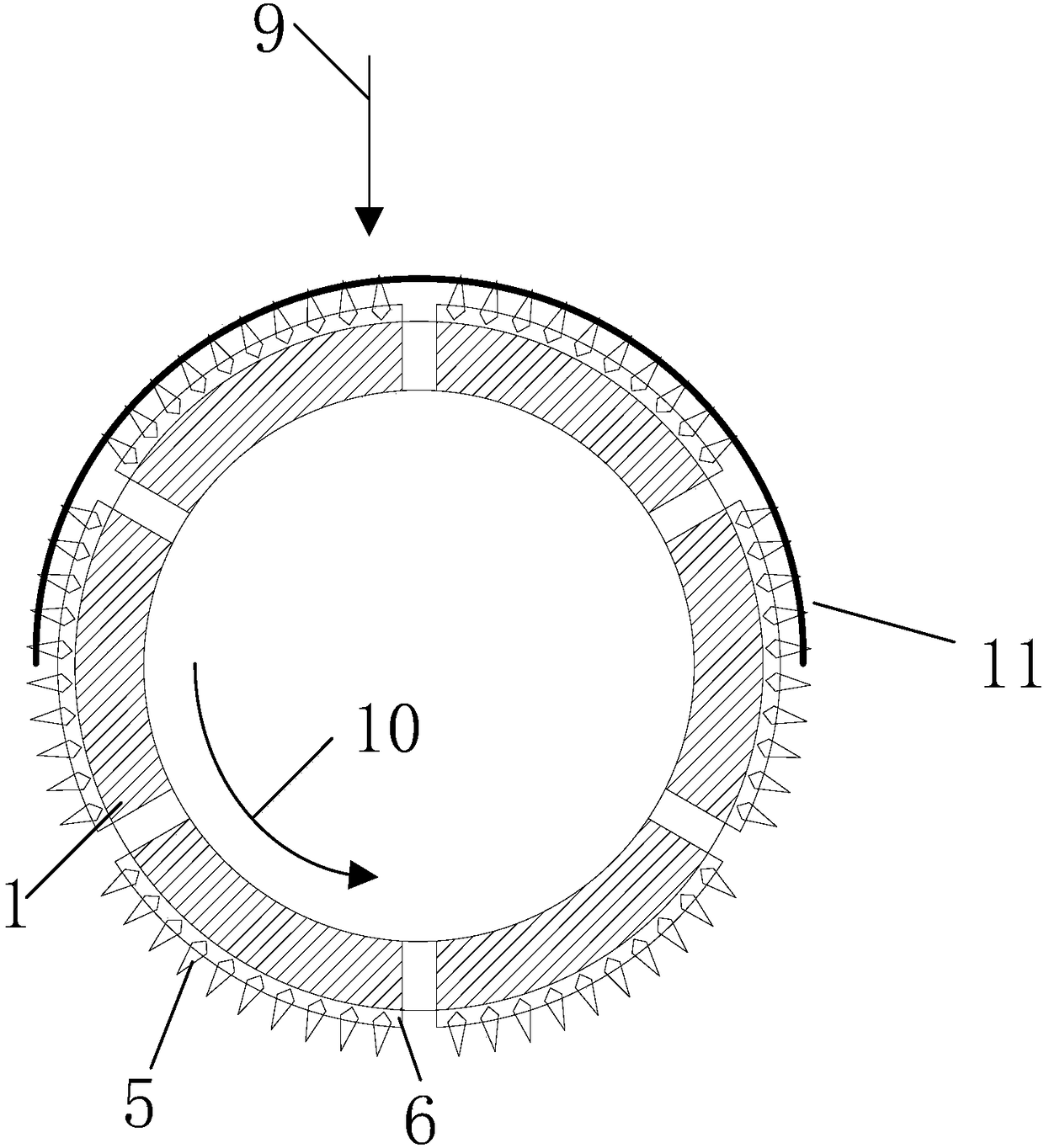

Floating auxiliary roller type overrun clutch

InactiveCN103307140AIncrease axial lengthIncrease the lengthFreewheel clutchesEngineeringMachining process

The invention discloses a floating auxiliary roller type overrun clutch which comprises an outer ring, an inner ring, rolling bodies and auxiliary rollers, wherein engagement spaces used for being engaged with or separated from the rolling bodies are formed between the outer ring and the inner ring; the auxiliary rollers are parallel to an axial line of the overrun clutch and are spaced from the rolling bodies; and the auxiliary rollers are arranged between the rolling bodies in such a way that the auxiliary rollers can move in a circumferential direction of the overrun clutch. According to the floating auxiliary roller type overrun clutch, the processing of a limiting seat is avoided, the processing process is simplified, the working efficiency is improved, and the processing cost is reduced; as the auxiliary roller structure is adopted, the axial length of the overrun clutch and the rolling bodies can be theoretically infinitely prolonged, the engagement length is prolonged, the bearing capacity of the overrun clutch is increased, the radial size of the overrun clutch under higher bearing capacity is reduced, and the service life of the overrun clutch is prolonged; and meanwhile, the probability of imbalance caused by application of a pretension force to point contact of each roller in the prior art is removed, thereby enabling each roller to keep parallel to the axial line of the inner ring.

Owner:SOUTHWEST UNIVERSITY

Piston-free Stirling engine system

InactiveCN101619687AReduce machining accuracyReduce assembly accuracyHot gas positive displacement engine plantsRoom temperatureEngineering

The invention discloses a piston-free Stirling engine system comprising a power driving device and a power transmission device, wherein the power driving device comprises an air cylinder and a thermoacoustic converter, and the thermoacoustic converter comprises a high-temperature end heat exchanger, a heat accumulator and a first room-temperature end heat exchanger; the power transmission device comprises an active piston and a first elastic piece far away from one end of the power driving device; the power driving device also comprises a heat buffer tube and an ejector which are sequentially arranged in the air cylinder, wherein the heat buffer tube is positioned on a position corresponding to the high-temperature end heat exchanger which is wrapped on the outer wall of the air cylinder and the heat accumulator; and the ejector is positioned on a position corresponding to the first room-temperature end heat exchanger which is wrapped on the outer wall of the air cylinder in the air cylinder. The invention replaces a part of the ejector, which is higher than a room-temperature end, with the heat buffer tube so that the ejector works in a room-temperature state, thereby enhancing the processing and assembling precision of the ejector and effectively prolonging the service life of the ejector.

Owner:LIHAN THERMOACOUSTIC TECH SHENZHEN

Coated cutting tool and method for producing the same

ActiveUS20080057280A1Improve fracture resistanceReduce machining accuracyPigmenting treatmentOther chemical processesX-rayWear resistance

Provided are a coated cutting tool having excellent wear resistance and excellent resistance to chipping as well as excellent fracture resistance such that the coated cutting tool is unlikely to cause backward movement of the tool edge position due to wear or chipping, and a method for producing the same.A coated cutting tool comprising a base material having a surface coated with a coating film, wherein the coating film comprises at least one layer comprised of a TiCN columnar crystal film, wherein the TiCN columnar crystal film has an average grain size of 0.05 to 0.5 μm, as measured in the direction parallel to the surface of the base material, and exhibits an X-ray diffraction pattern having a peak at a diffraction angle 2θ in the range of from 121.5 to 122.6° wherein the peak is ascribed to the (422) crystal facet of the TiCN columnar crystal as measured using CuKα radiation.

Owner:TUNGALOY CORP

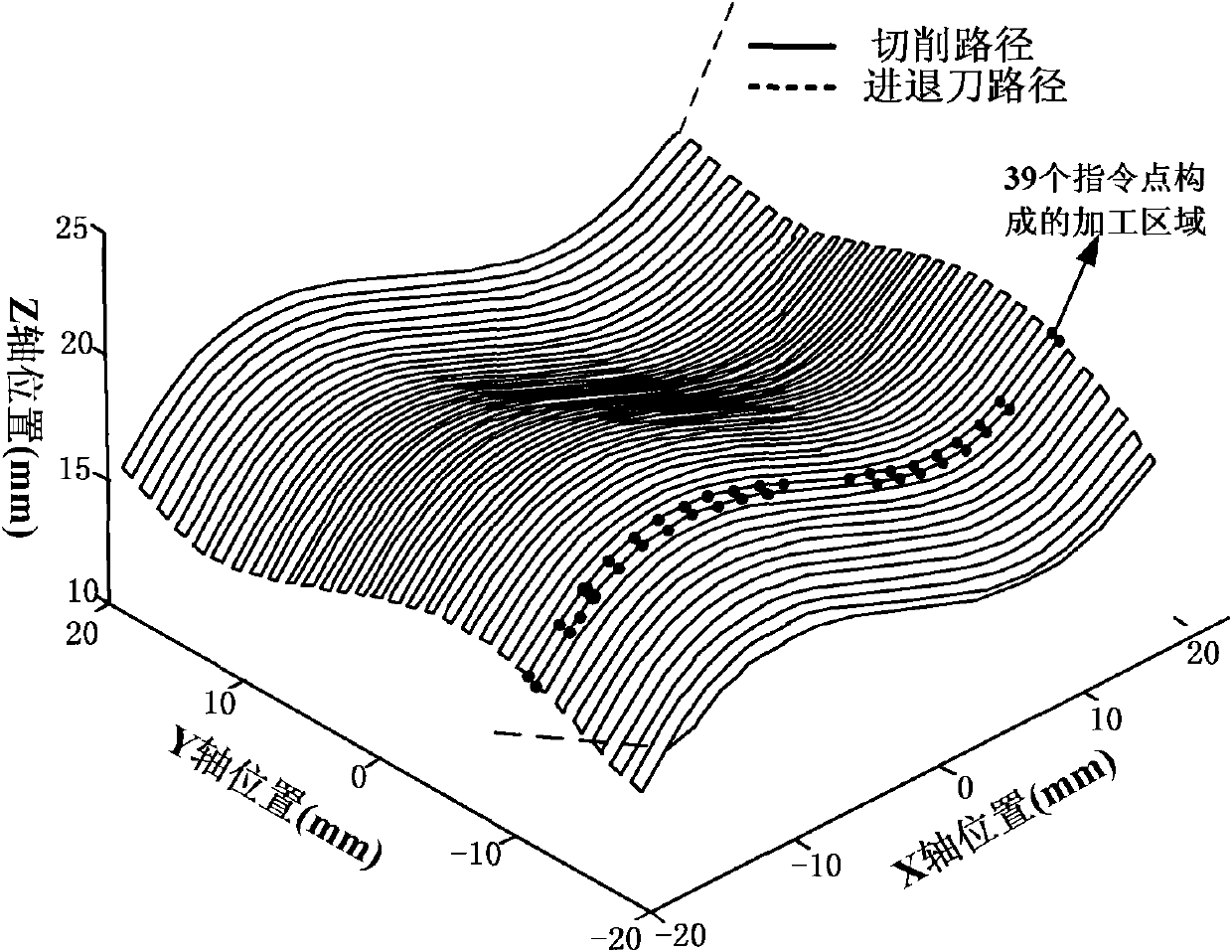

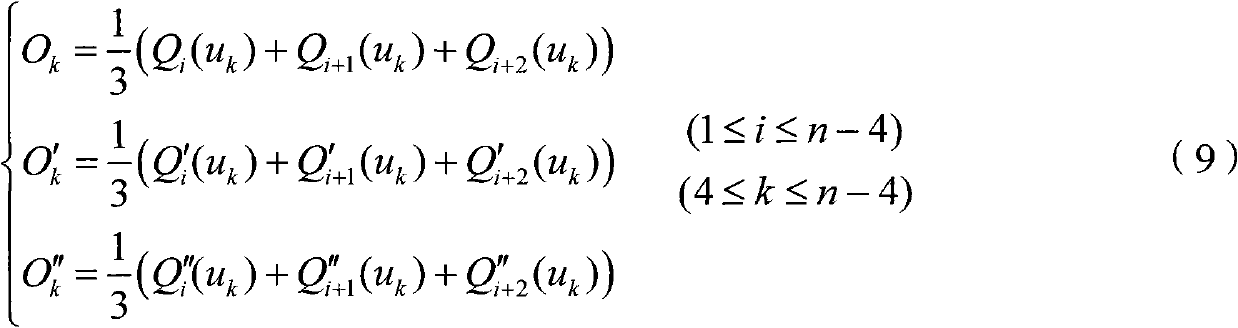

Command point shaping, compressing and interpolating method suitable for numerical control device

ActiveCN101907876AIncreased transfer speedImprove processing efficiencyNumerical controlProcessing accuracyLine segment

The invention relates to a command point shaping, compressing and interpolating method suitable for a numerical control device. The method comprises the following steps of: inserting an arc which has a distance with the middle point of a tolerance set by the numerical control device and is tangential with segments of adjacent command points to the middle point of every three adjacent command points when a numerical control processing procedure judges that any three adjacent command points on a processed curve surface meet a continuous processing condition, wherein the tangential points are used as interpolation points; trimming the interpolation points to reduce calculation errors and rounding errors in the process of reckoning the interpolation points; selecting a characteristic interpolation point through judging the bending directions of processing paths of all the interpolation points; fitting by using a continuous polynomial spline curve with a second derivative to generate a smooth curve; approximately calculating the interpolation points of a current interpolation period and sending the positions of the interpolation points to a servo system of the numerical control device; and driving a servo motor to move. The invention furthest improves the processing efficiency and reduces the influences of the calculation errors and the rounding errors on the processing precision and the processed surface smoothness.

Owner:SHENYANG GOLDING NC & INTELLIGENCE TECH CO LTD

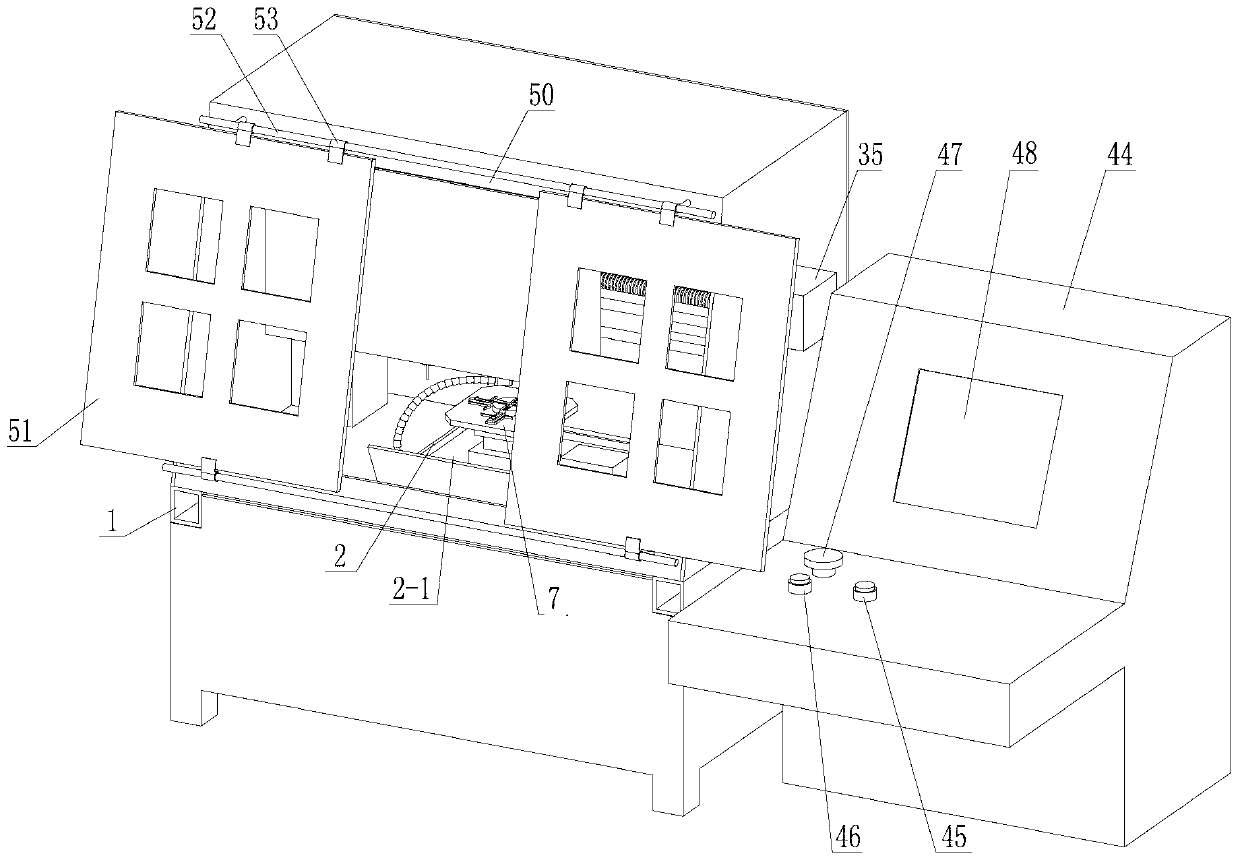

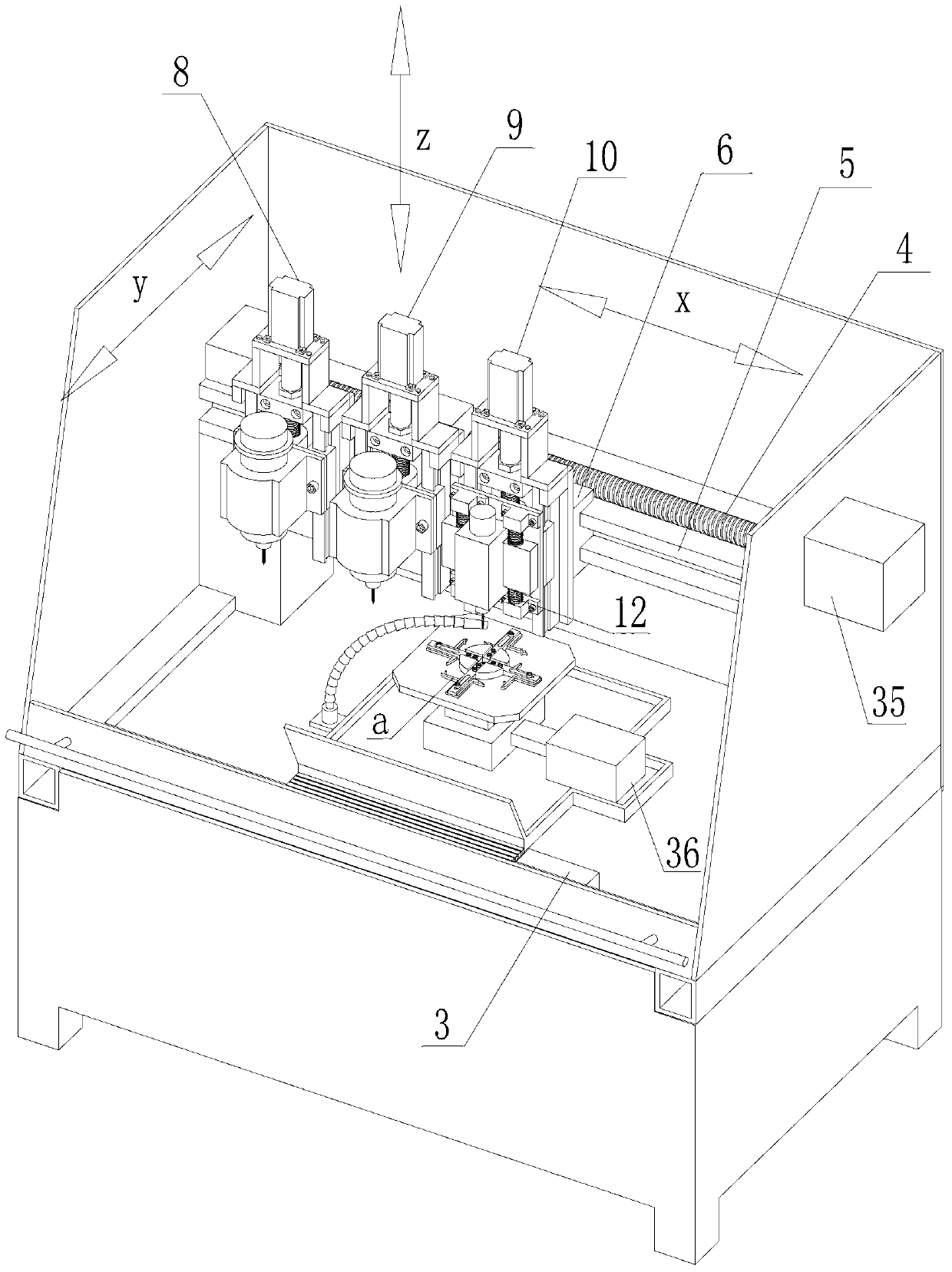

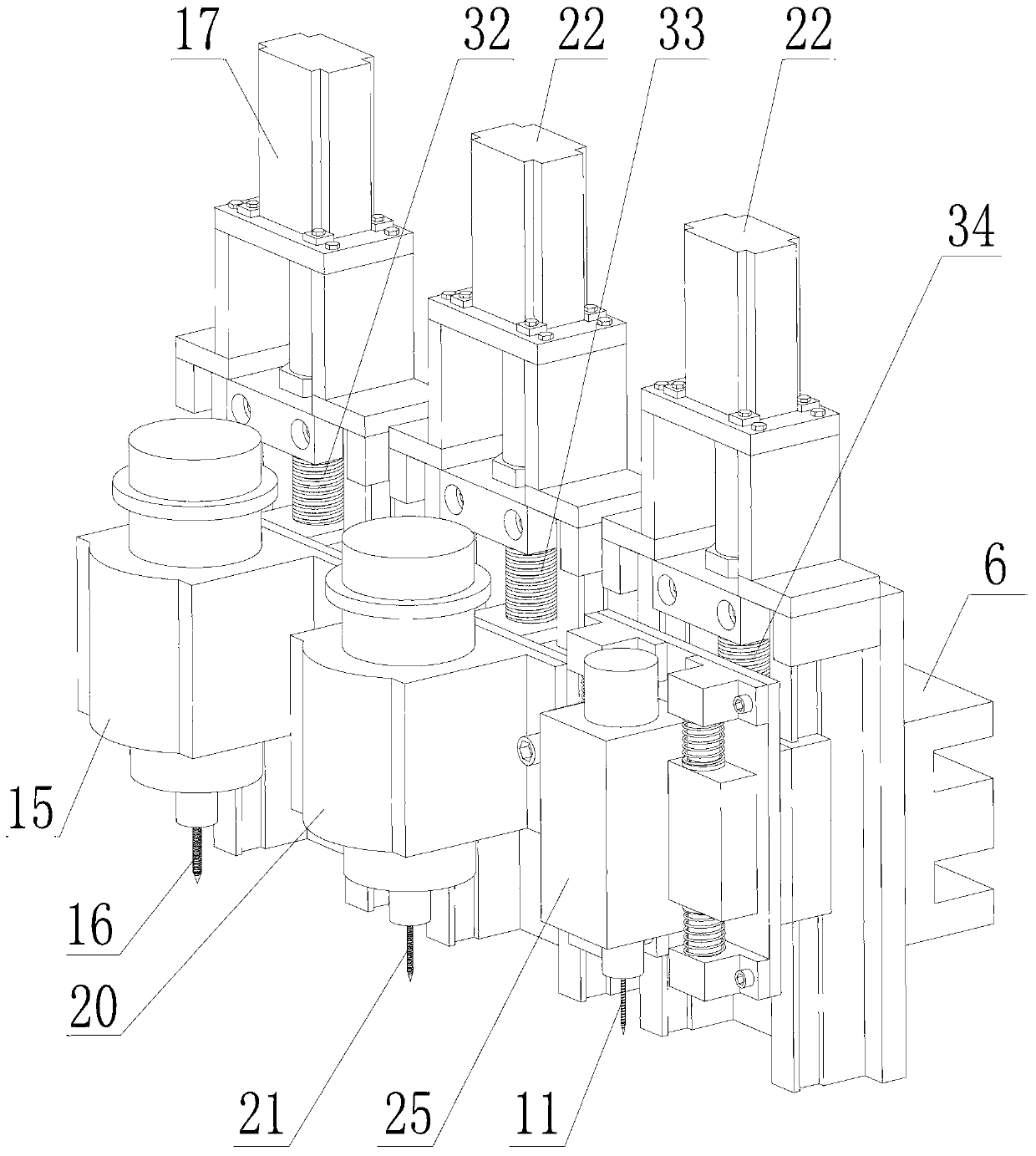

Multi-functional all-in-one automatic drilling and tapping machine tool

InactiveCN103341653AGuaranteed service lifeGuaranteed YieldThread cutting machinesBoring/drilling componentsEngineeringHardness

A multi-functional all-in-one automatic drilling and tapping machine tool comprises assemblies, mutually assembled in a reasonable mode, such as a machine frame, a working table, a concave table, an X-axis servo motor, a Y-axis servo motor, a driving lead screw, a transverse guide rail, a main sliding seat, a multi-workpiece-holder mechanism, a pre-drilling mechanism, a drilling mechanism, a tapping mechanism, a screw tap and a buffer mechanism. Through the reasonable arrangement, automatic micro hole pre-drilling machining, automatic micro hole drilling machining and automatic micro hole tapping machining are achieved through the multi-functional all-in-one automatic drilling and tapping machine tool, and a plurality of problems that at present, the ratio of finished products is low when high-hardness workpiece micro holes are drilled and tapped, the machining cost is too high, the labor intensity of workers is high and automatic machining is difficult to achieve are effectively solved. The multi-functional all-in-one automatic drilling and tapping machine tool is simplified in structure, can achieve all-in-one automatic machining for the high-hardness workpiece micro holes, is high in machining accuracy, low in cost and convenient to maintain, and deserves popularization.

Owner:LISHUI NANGUANG MEASURING & CUTTING

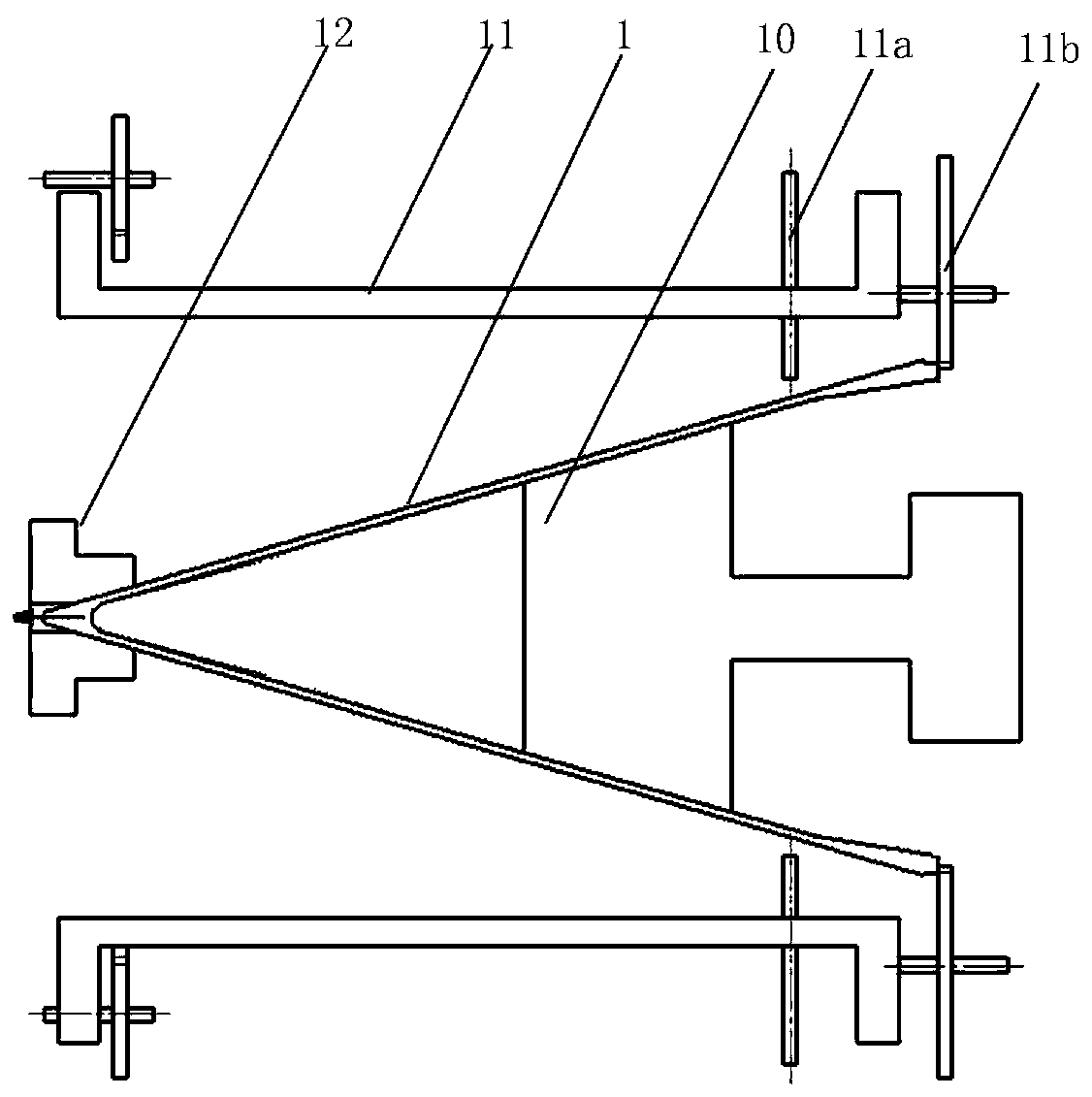

Millimeter wave rectangular-circular transition integrated corrugated horn antenna and processing method

InactiveCN101662072AAvoid discontinuitiesSmall VSWRWaveguide hornsWaveguide type devicesHorn antennaStanding wave ratio

The invention discloses a millimeter wave rectangular-circular transition integrated corrugated horn antenna and a processing method and adopts integrated disposable electroforming for processing. A shell is internally provided with an inner cavity communicating from top to bottom in the shell, and the inner cavity consists of a corrugated inner wall radiation section, a circular waveguide extension section, a rectangular-circular transition waveguide section and a rectangular waveguide extension section from top to bottom, and one end of the port of the rectangular waveguide extension sectionin the shell is assembled with a connection part through sleeve joint. The corrugated horn antenna is electroformed by an inner core with the structure the same as that of the inner cavity, the integrated structure is adopted instead of various independent parts, the discontinuity of inner section change and deteriorated smoothness of a transition part caused by the processing dimension difference of all components, assembly and positioning error and other reasons are avoided, voltage standing wave ratio is reduced and antenna performance is improved, and compared with the traditional discrete part scheme, the scheme also reduces the requirement on processing accuracy properly. In the invention, the antenna performance, production technology complexity and time cost are all improved.

Owner:BEIHANG UNIV

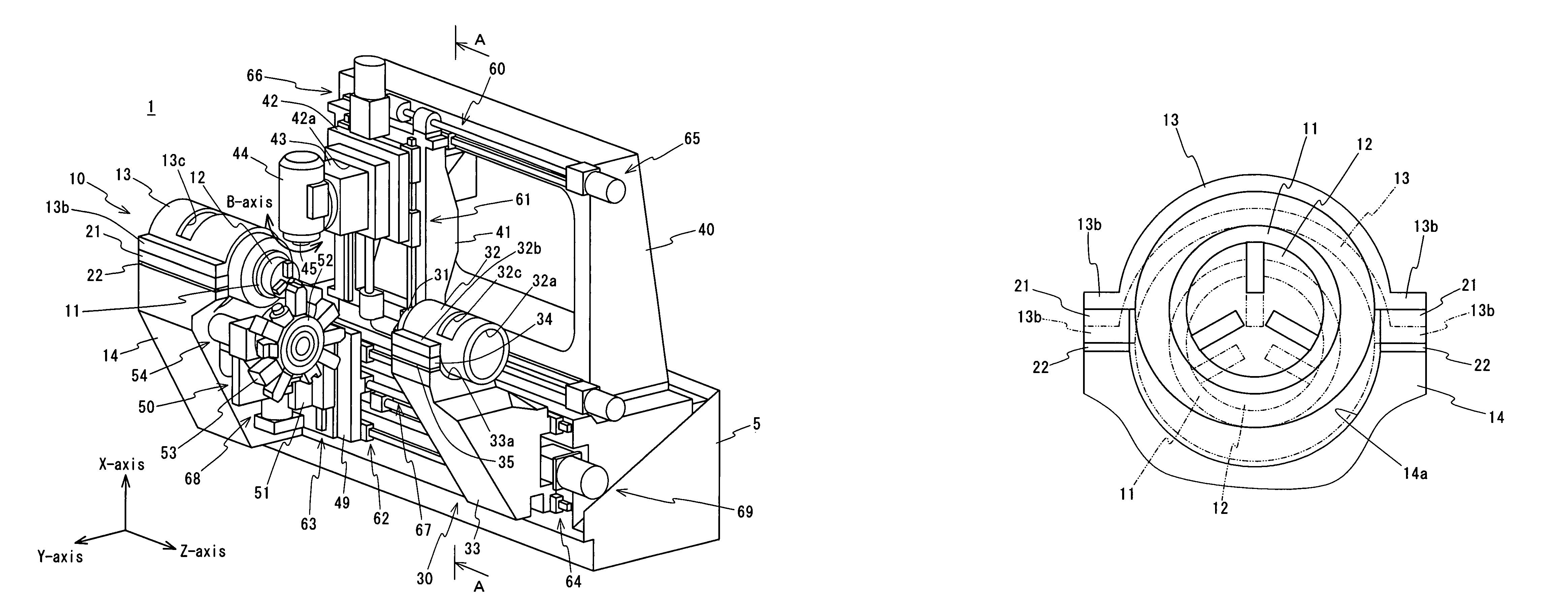

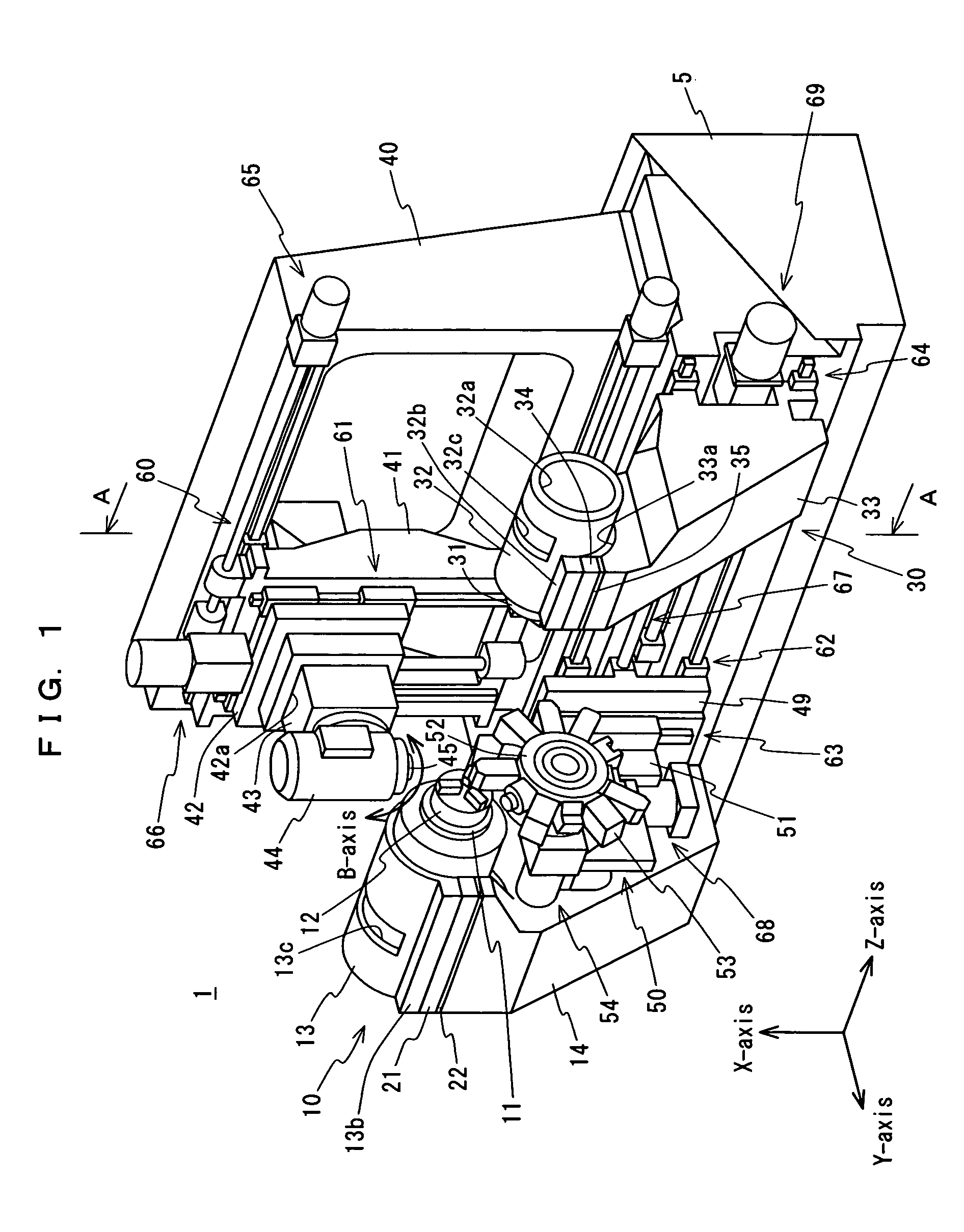

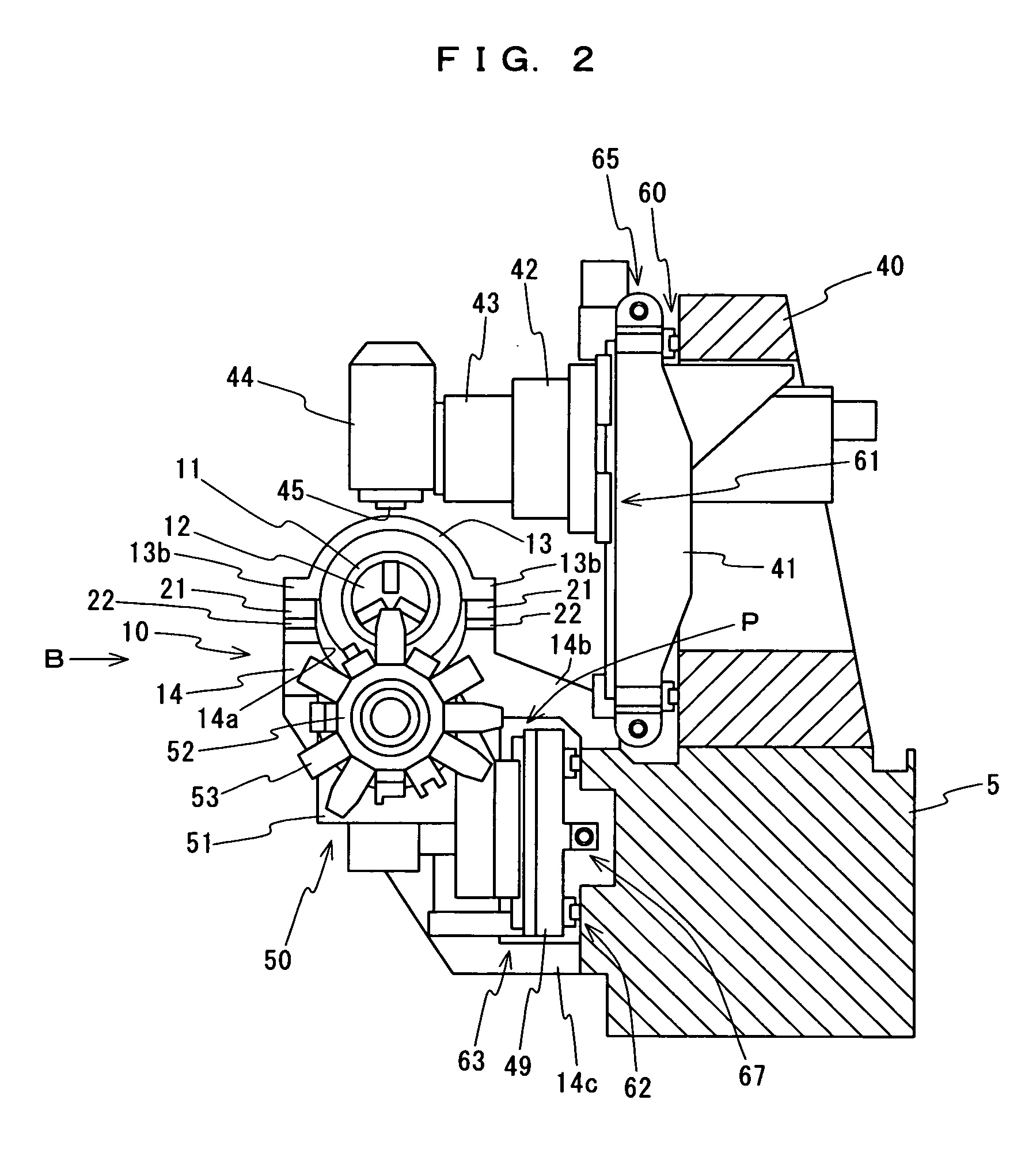

Lathe

InactiveUS7039992B2Improve accuracyHigh precision machiningAutomatic/semiautomatic turning machinesAuxillary equipmentEngineeringMechanical engineering

A lathe 1 comprises a bed 5, a headstock 10 having a housing 13 and a support base 14, a main spindle 11, a first tool rest 44, and a second tool rest 50. The support base 14 is formed so as to have a concave portion 14a on the upper portion thereof and so that the upper portion protrudes toward the second tool rest 50. The tool rest body 51 of the second tool rest 50 is configured so as to be movable into and out of a space formed downward from the upper portion of the support base 14. The housing 13 has a holding hole 13a for rotatably holding the main spindle 11, and installation portions 13b. The installation portions 13b are supported on the support base 14 in a state wherein a predetermined clearance is provided between the housing 13 and the concave portion 14a.

Owner:DMG MORI CO LTD

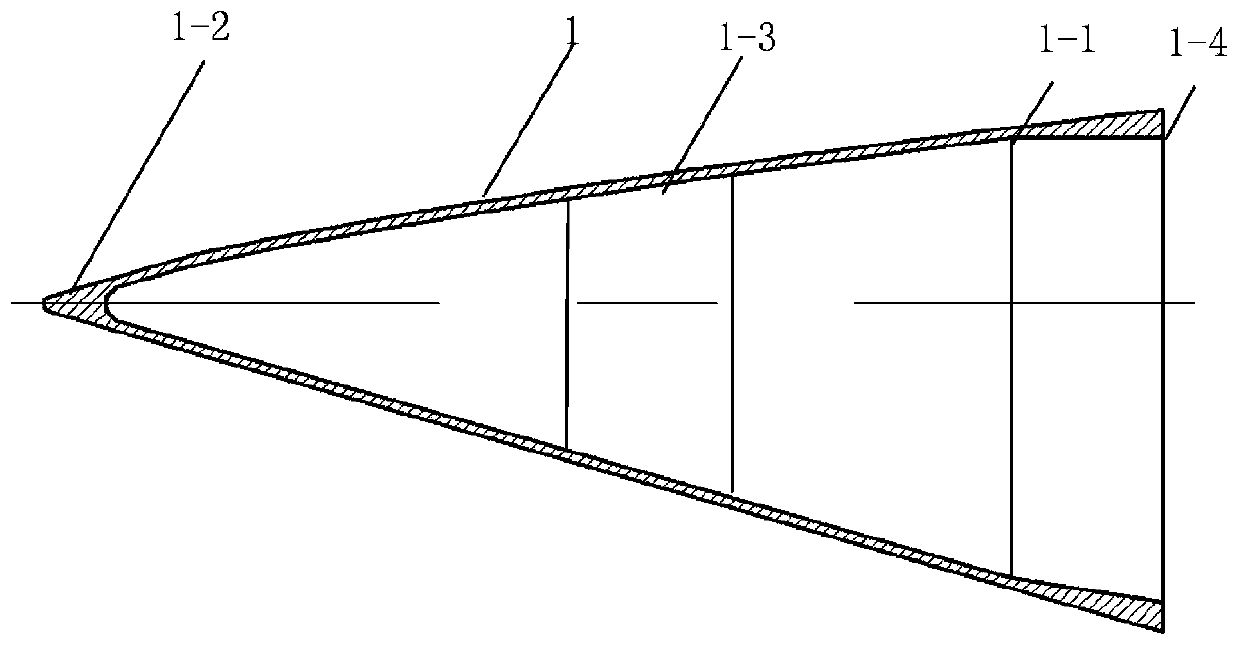

Machining process of middle-long thin-wall blades

ActiveCN103008741AReduce cumulative errorReduce processing stress deformationMilling equipment detailsEngineeringMachining process

The invention discloses a machining process of middle-long thin-wall blades, which belongs to the technical field of machining of blades. The machining process is implemented by a detailed process of integrated rough machining and integrated fine machining, wherein the integrated rough machining comprise the specific steps of rough machining of each surface of a blade tip, each surface of a blade root and a molded surface of a steam passage; and the integrated fine machining comprises the specific steps: semifinishing of each surface of the blade tip and each surface of the blade root, fine machining of each surface of the blade tip, each surface of the blade root and each residue, semifinishing of the steam passage and fine machining of the steam passage. According to the machining process of the middle-long thin-wall blades, the operation is simple and convenient, the use is convenient and fast, the cost is low, the machining efficiency is high, and the operation is easy and labor-saving; and the deformation of the middle-long thin-wall blades is controlled within 0 to 0.8mm, the normal machining of a subsequent mold correction process is facilitated, and the machining of each blade is finished once.

Owner:SICHUAN MIANZHU XINKUN MACHINERY MAKING

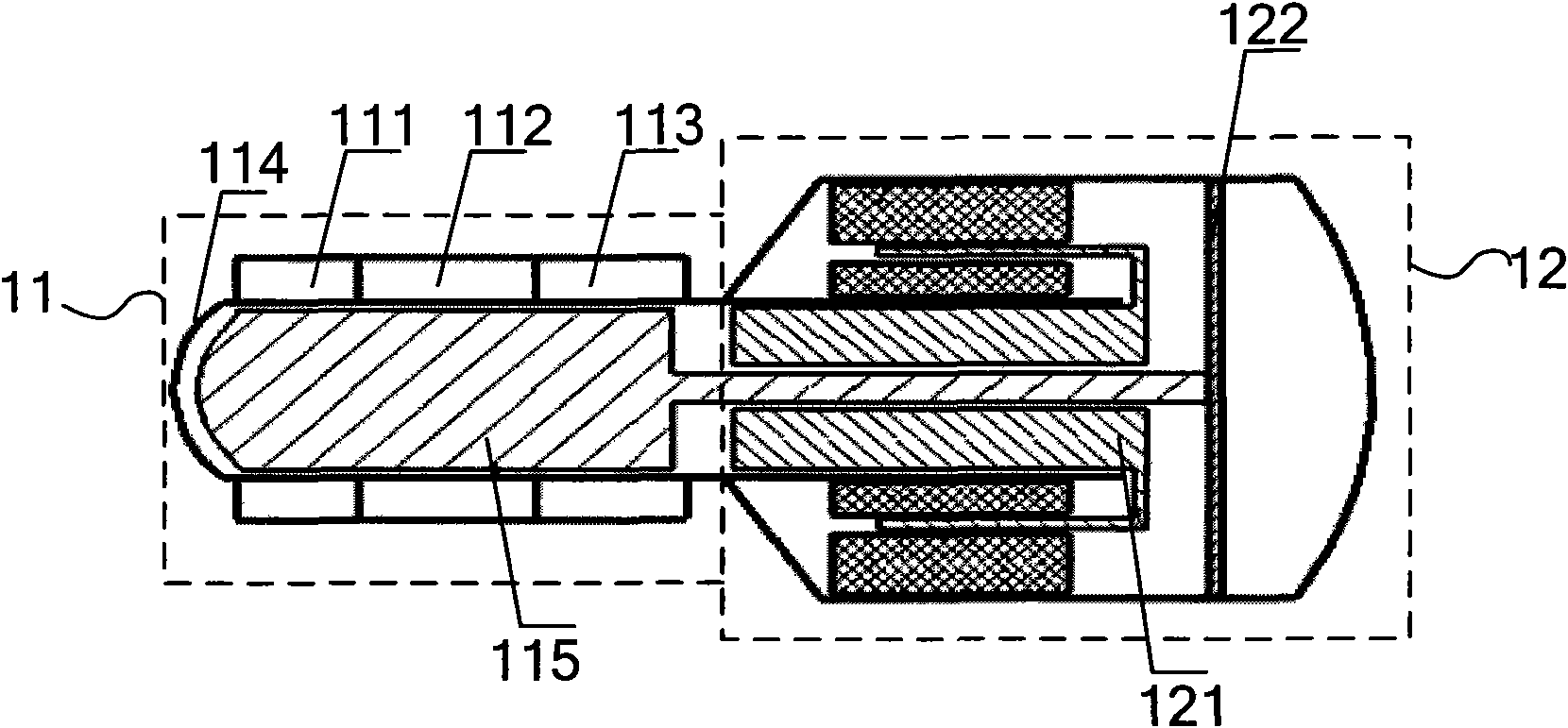

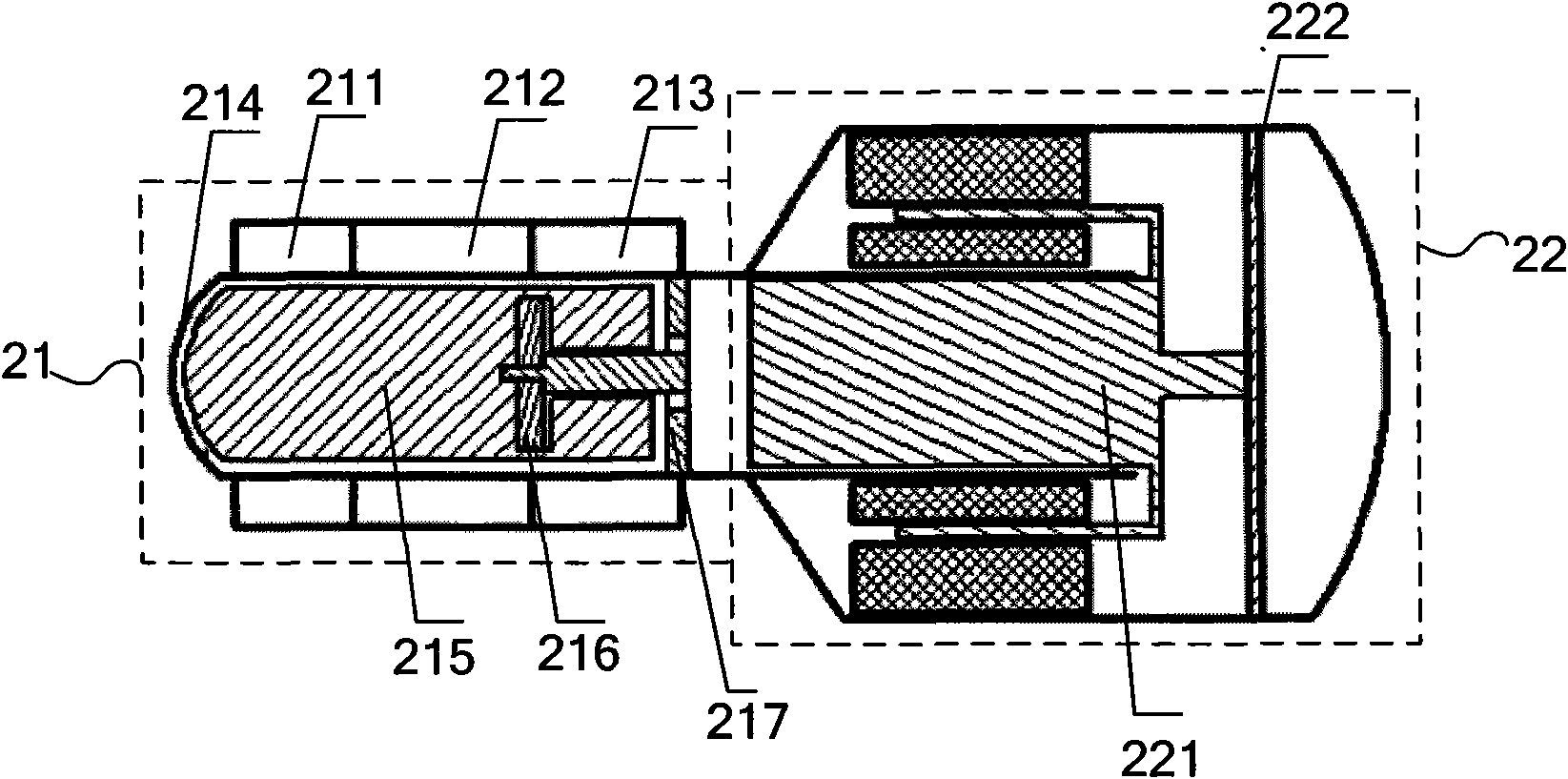

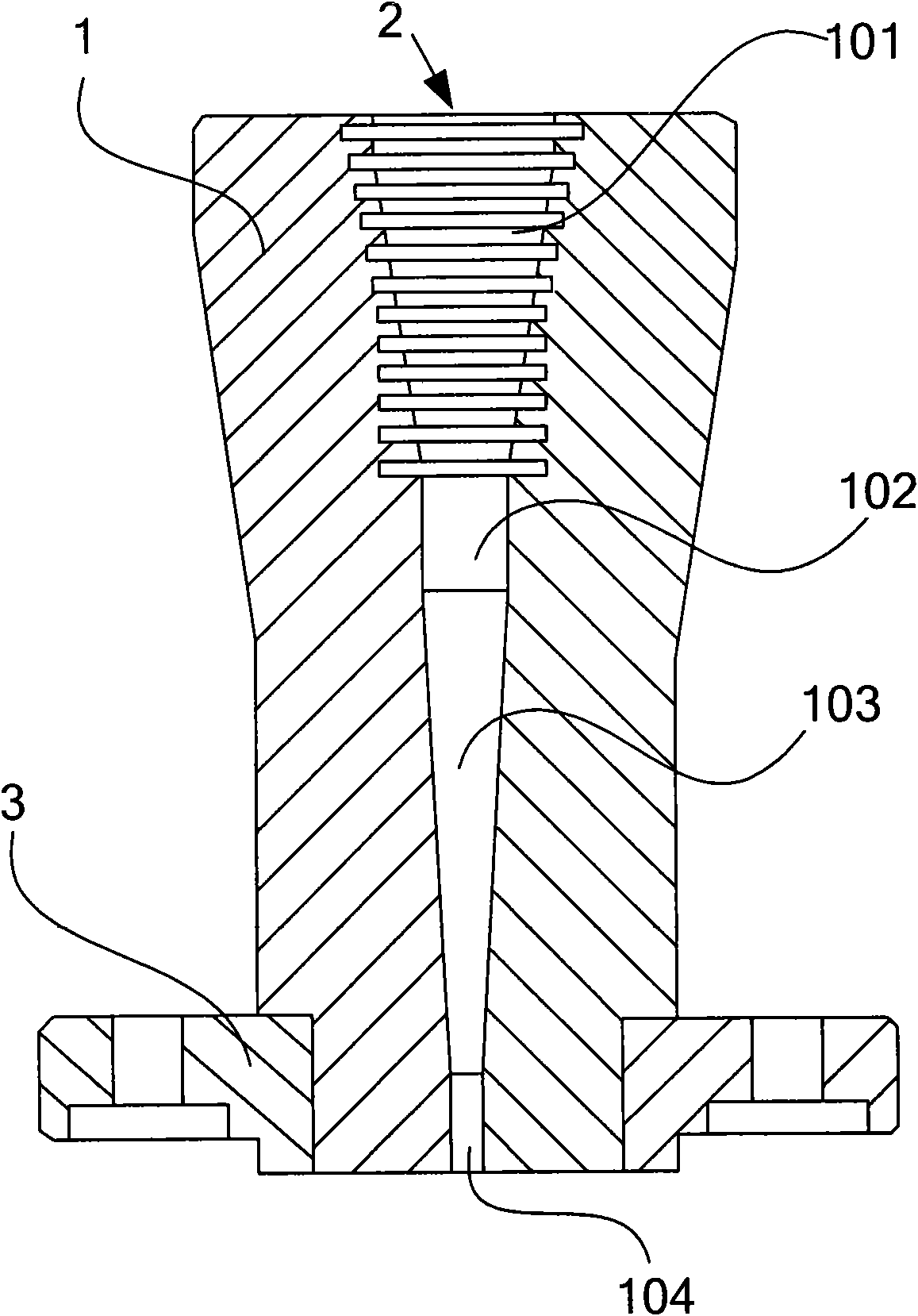

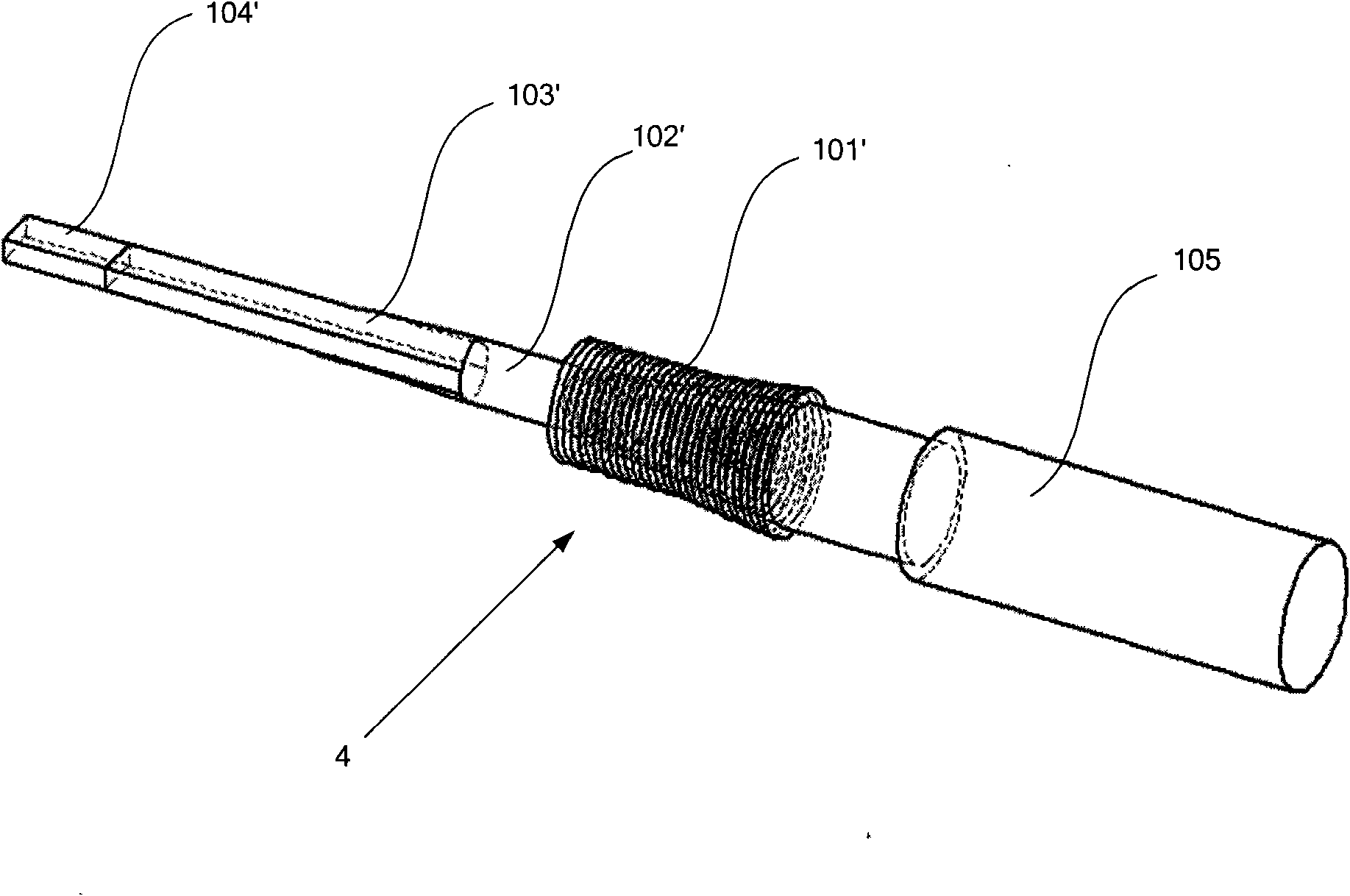

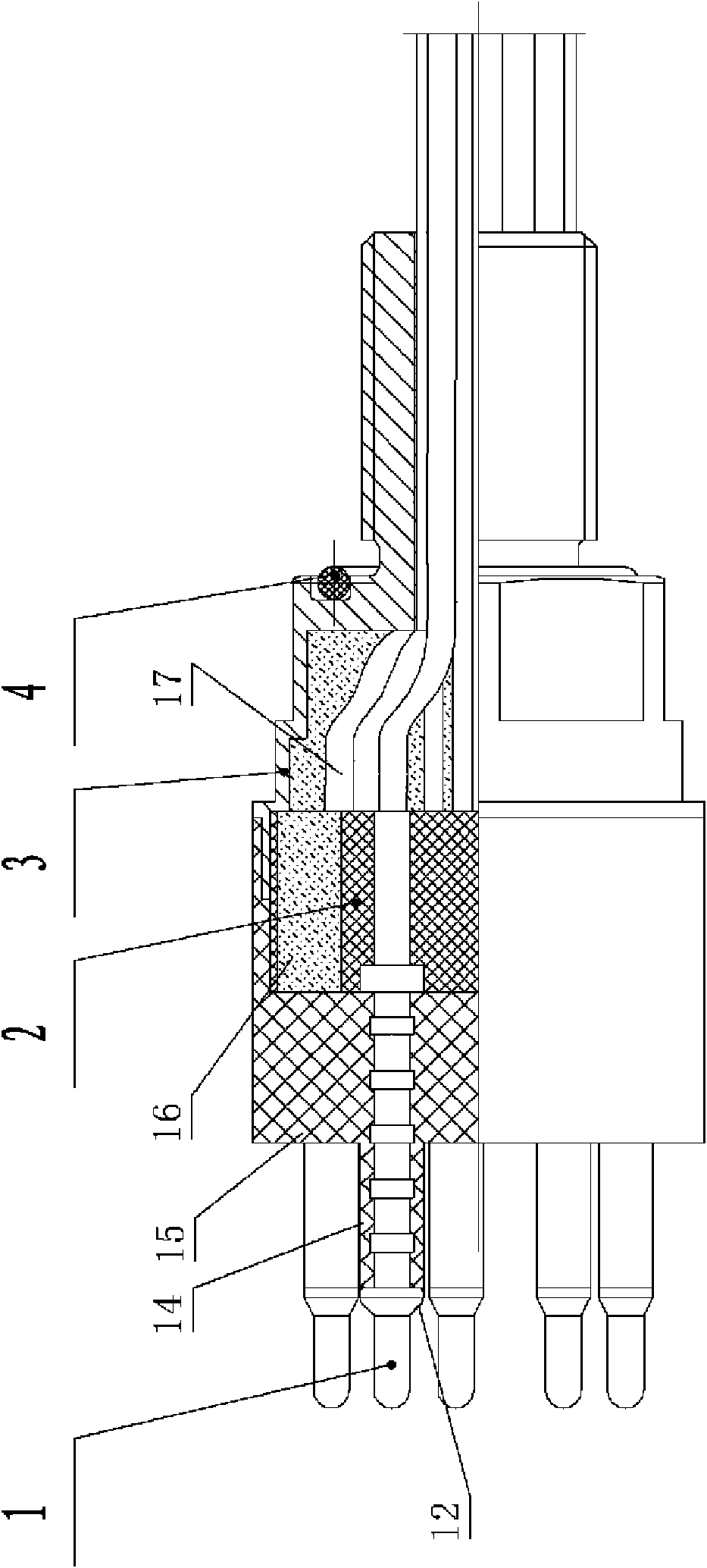

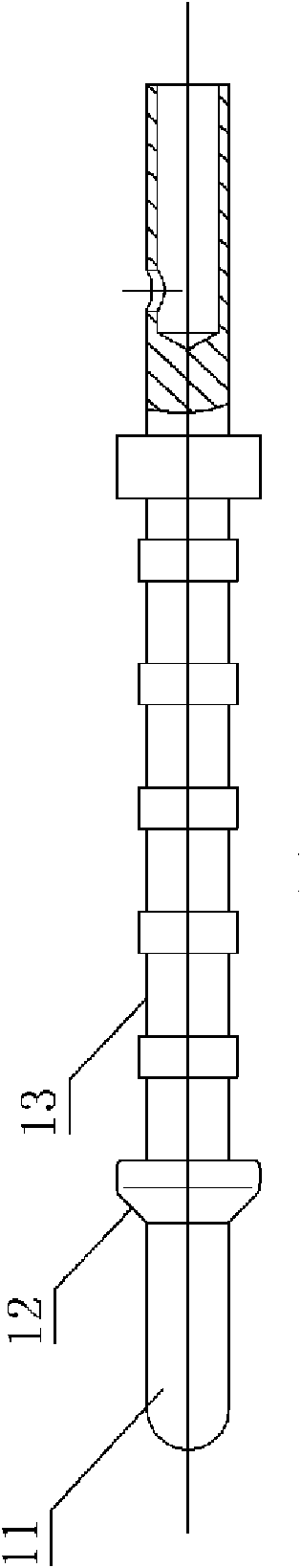

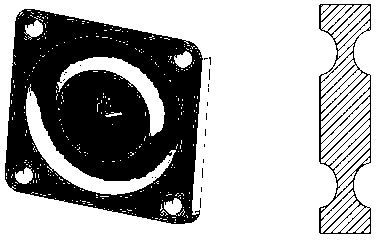

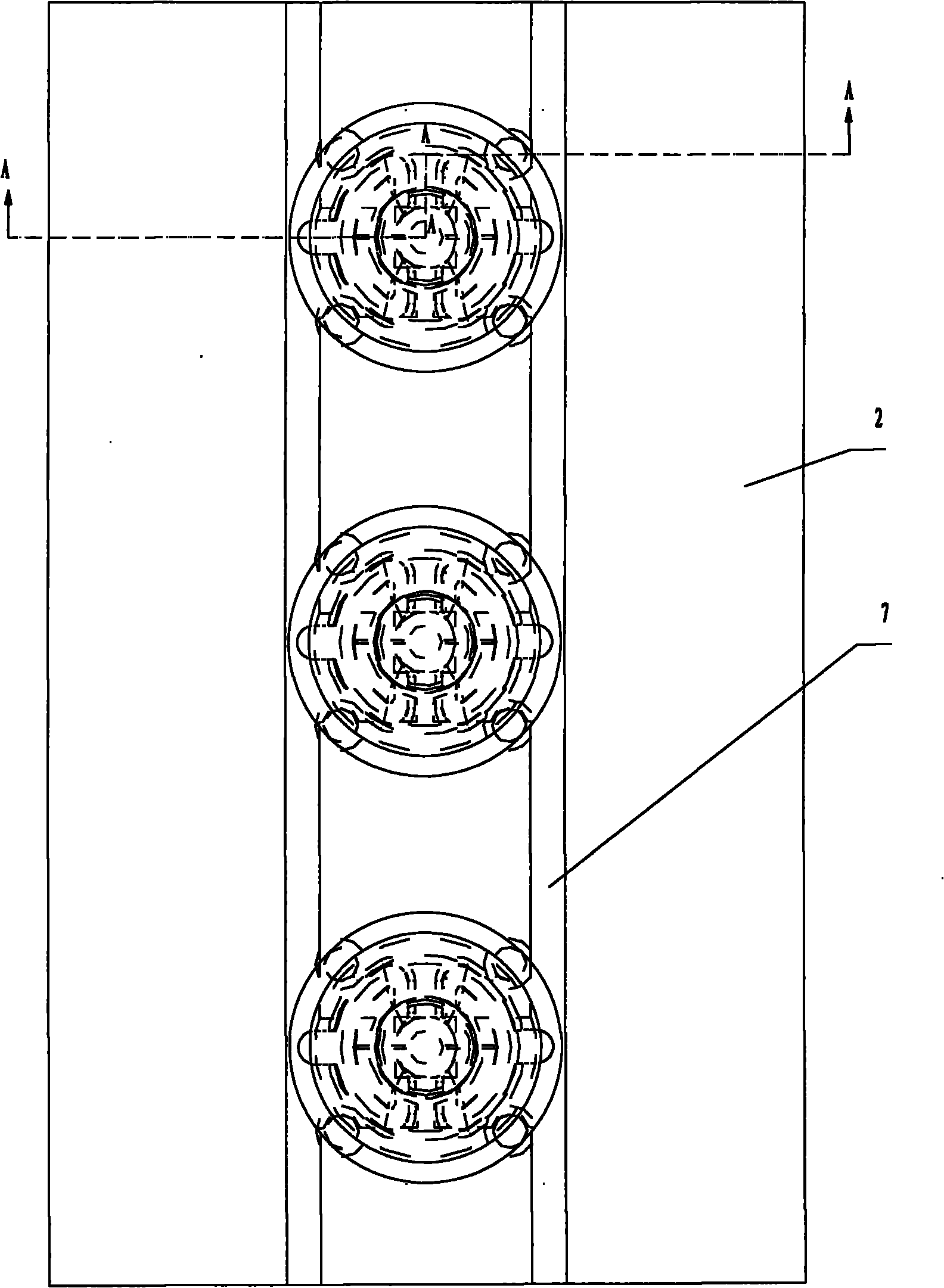

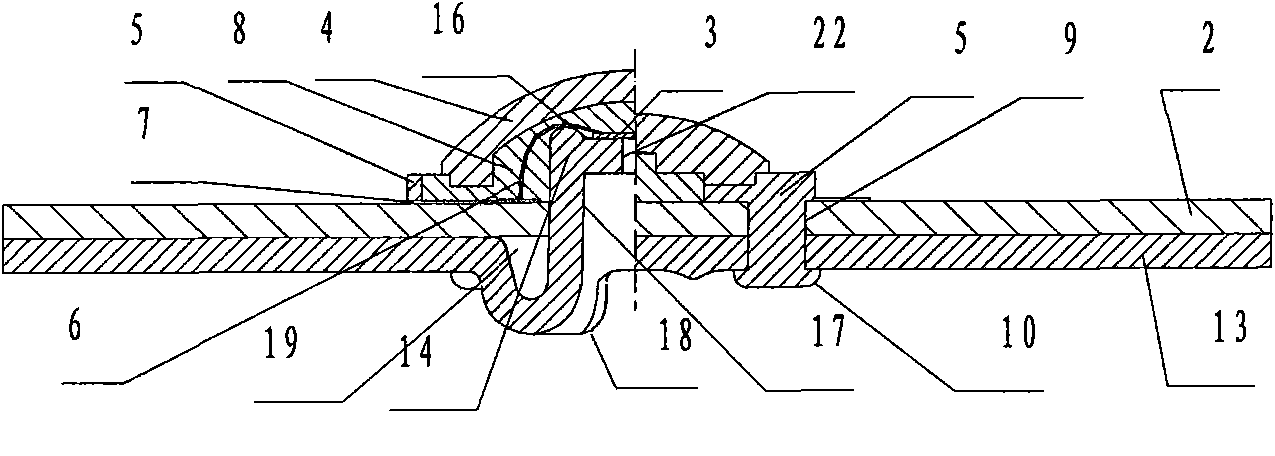

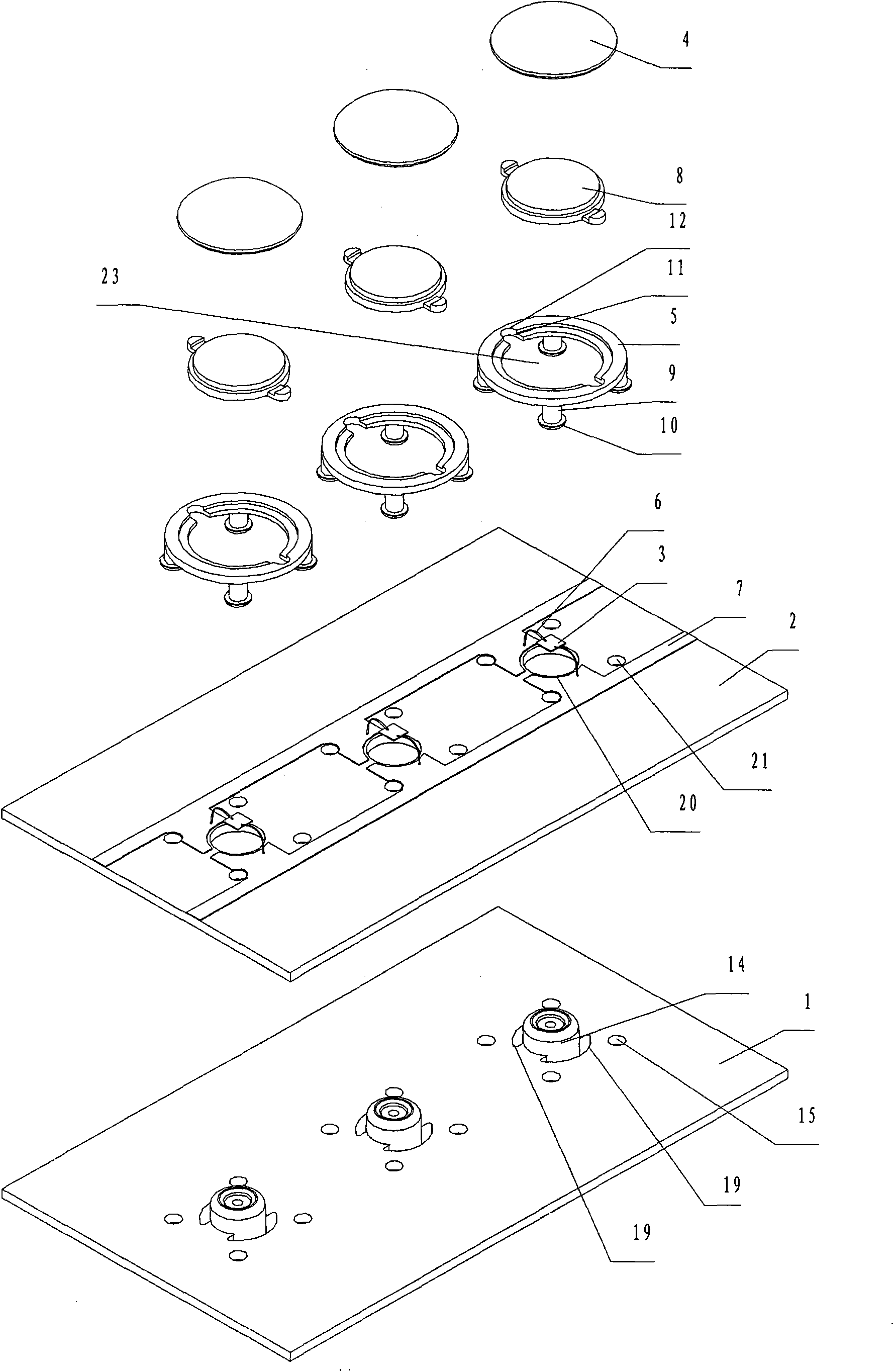

Direct-plug water-sealed connector component, plug thereof and socket thereof

InactiveCN101615748AImprove sealingReduce radial profile sizeCoupling device detailsTwo-part coupling devicesVulcanizationElectrical and Electronics engineering

The invention relates to a direct-plug water-sealed connector component, a plug thereof and a socket thereof. The connector component comprises a plug shell and a plug insulator which are connected together; a group of pin contact pieces are axially arranged on the plug insulator; a plug vulcanized body covers the front end and surrounding wall of the plug insulator through vulcanization; the rear end of the plug vulcanized body extends to seal and cover the front end of the plug shell; the pin contact pieces are fixed into a whole through the vulcanization by the plug vulcanized body; the parts, exposed from the plug vulcanized body, of the pin contact pieces form pin plug-in connection sections; the parts, close to the plug vulcanized body, of the pin plug-in connection sections are covered by a corresponding vulcanized protrusion extended from the front end of the vulcanized body to form vulcanized plug-in connection sections; the parts, on the front end of the vulcanized plug-in connection sections, of the pin plug-in connection sections are bare pug-in connection sections; the diameter of the bare pug-in connection sections is smaller than that of the vulcanized plug-in connection sections; and a plug-in connection guide part is arranged at the surface joint part of the bare pug-in connection sections and the vulcanized plug-in connection sections. The connector component can be plugged directly in water.

Owner:CHINA AVIATION OPTICAL-ELECTRICAL TECH CO LTD

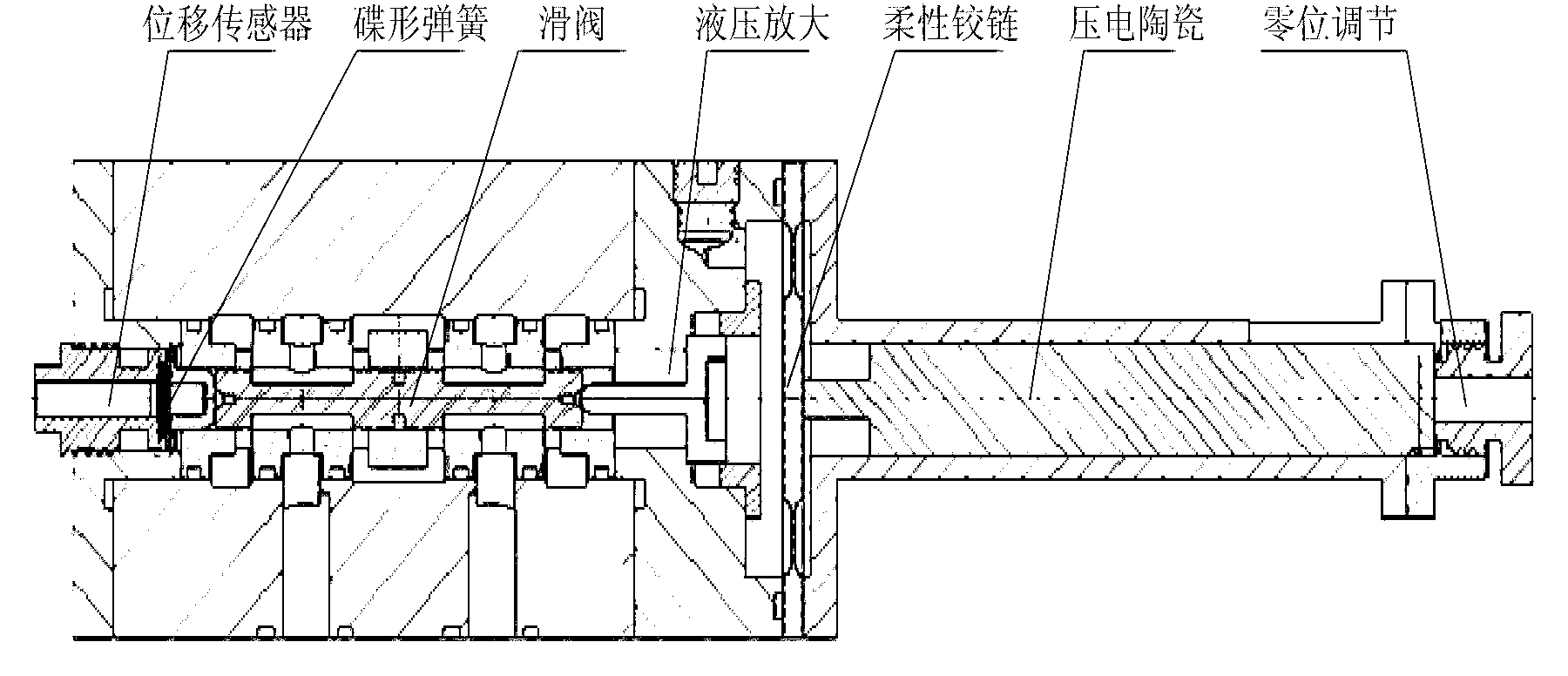

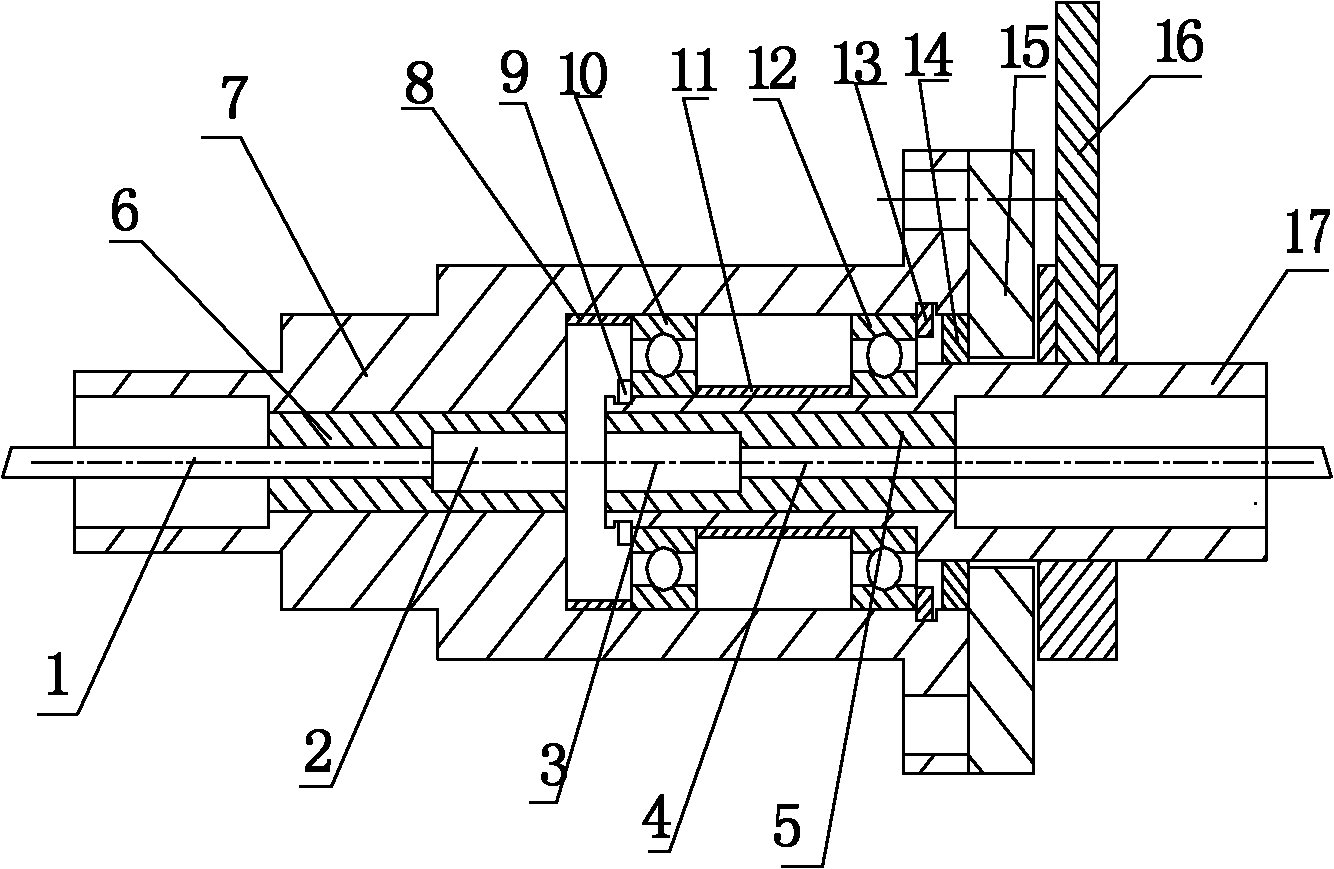

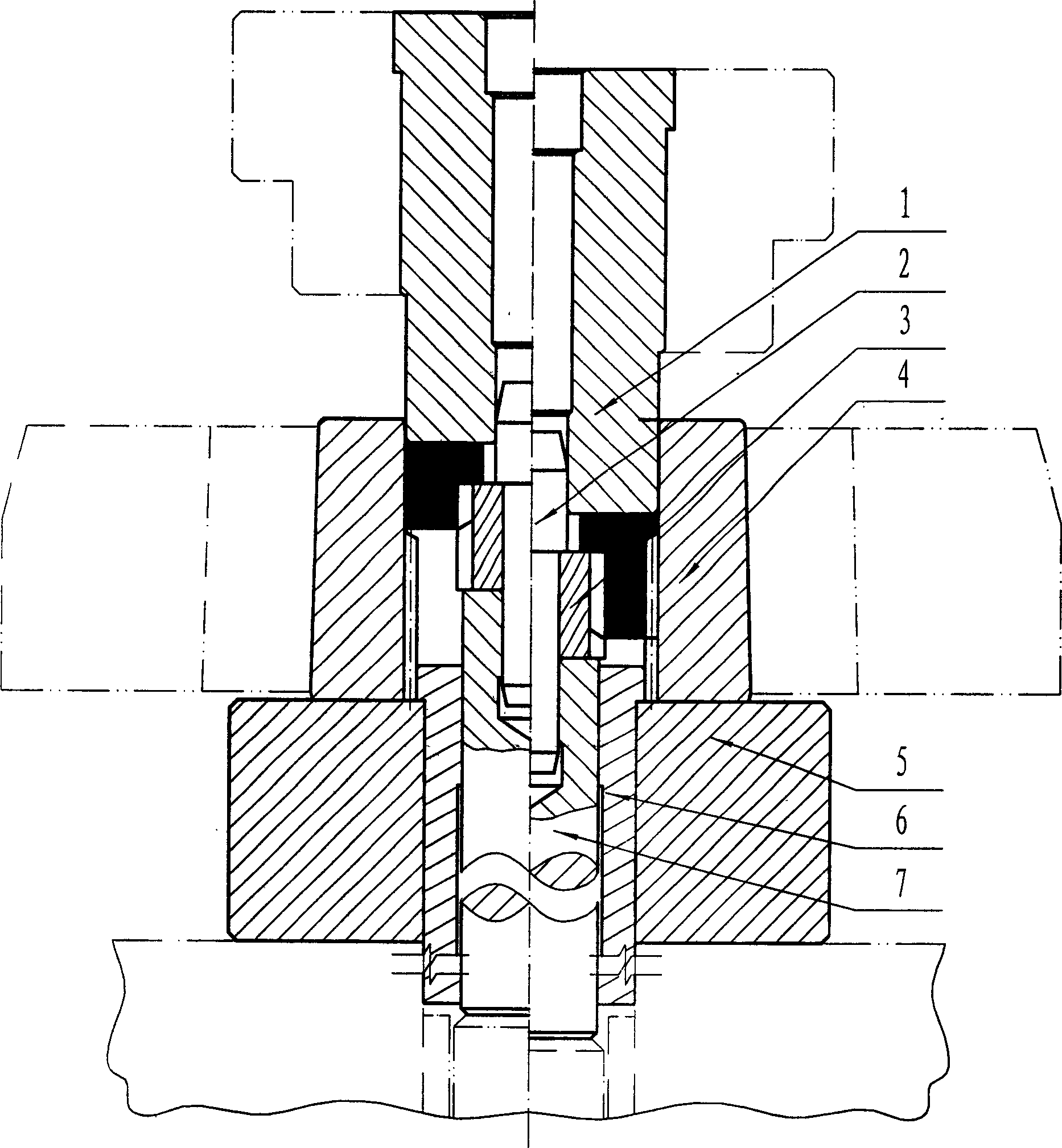

Piezoelectric ceramic direct-driving servo valve based on hydraulic micro-displacement amplification structure

InactiveCN103016434ASimple structureReduce machining accuracyServomotor componentsPistonElectrohydraulic servo valve

Owner:BEIHANG UNIV

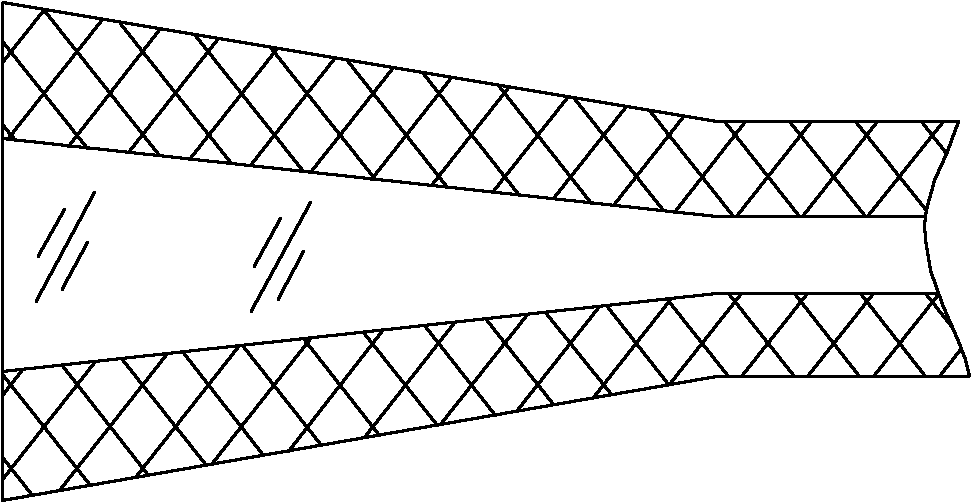

Circulating System for a Linear Guideway

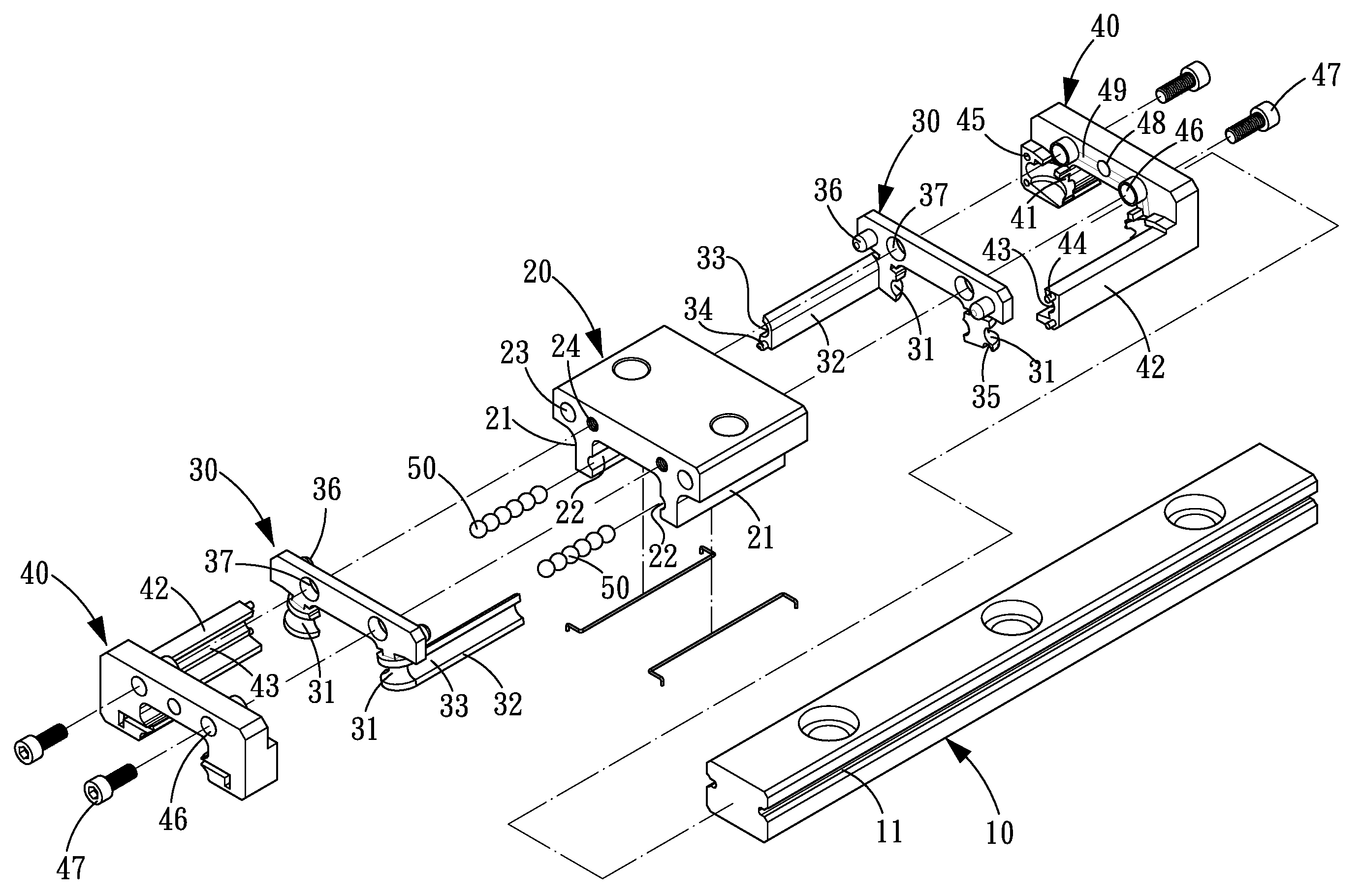

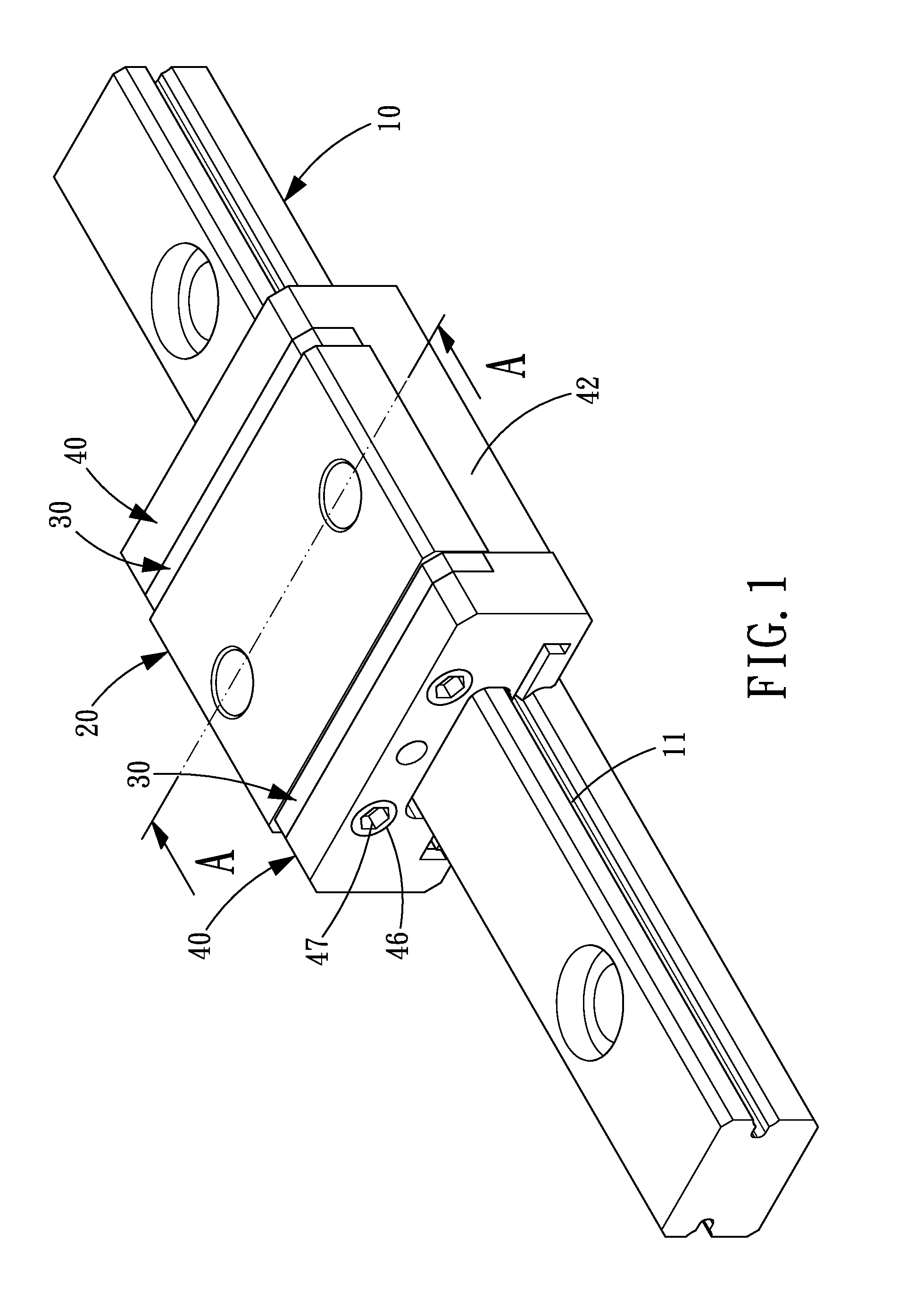

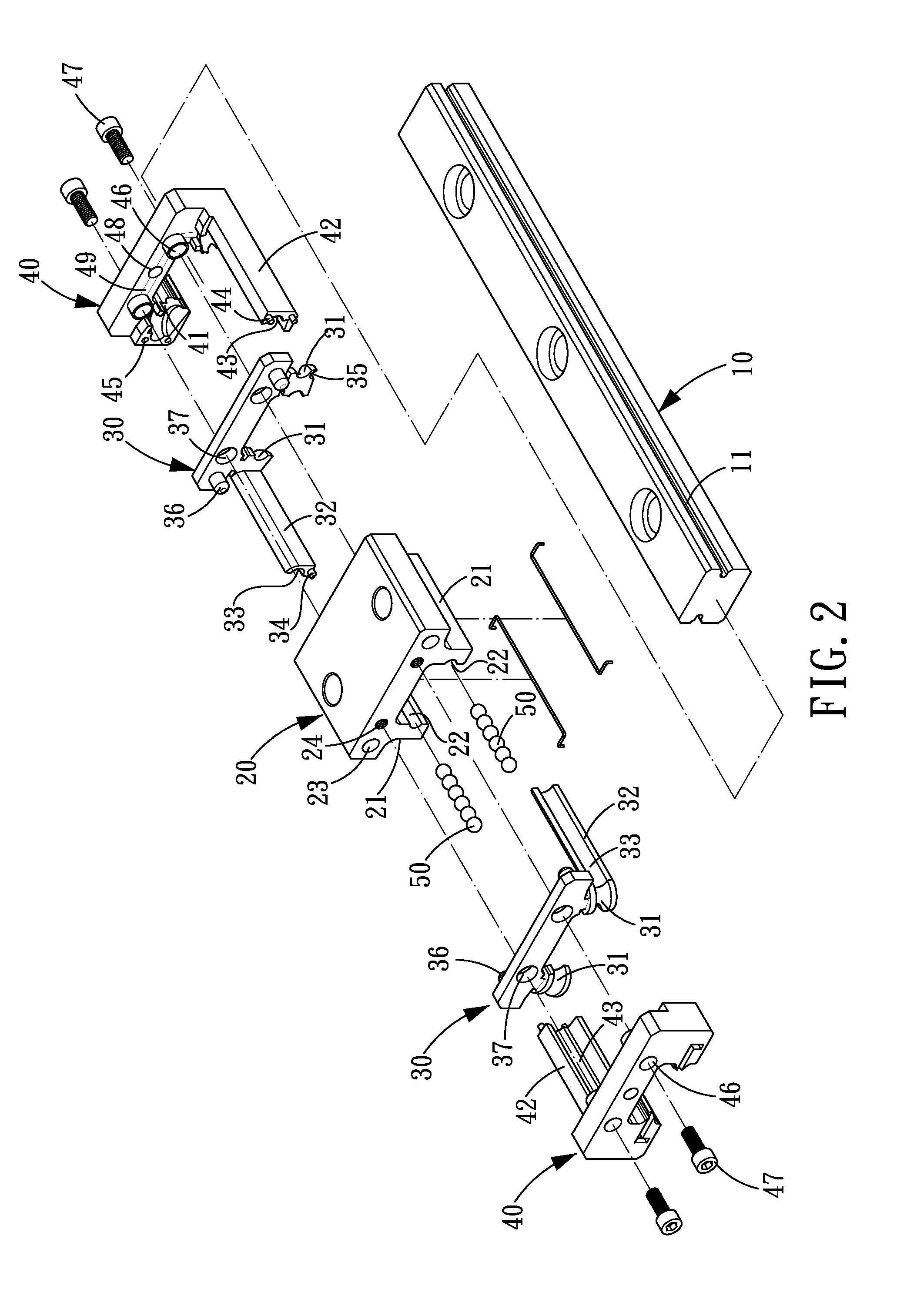

ActiveUS20110033141A1Reduce the cost of the whole machineFacilitate quick mass productionLinear bearingsPlastic injection moldingPlastic materials

A circulating system for a linear guideway comprises a slide block, a slide rail, two cover plates, two end caps and plural rolling elements. The slide block is disposed on the slide rail. The two cover plates and the two end caps are disposed at two opposite ends of the slide block, respectively. Between the two cover plates and the two end caps are disposed inner return and outer return blocks, respectively, and the inner return and the outer return blocks each are defined with half rolling paths to form complete rolling paths. Both ends of a complete rolling path and both ends of a complete loaded path are connected to both ends of two complete return paths to complete circulation paths. The inner and outer return blocks are made by common plastic injection molding, and the formed rolling paths are made of plastic material.

Owner:HIWIN TECH

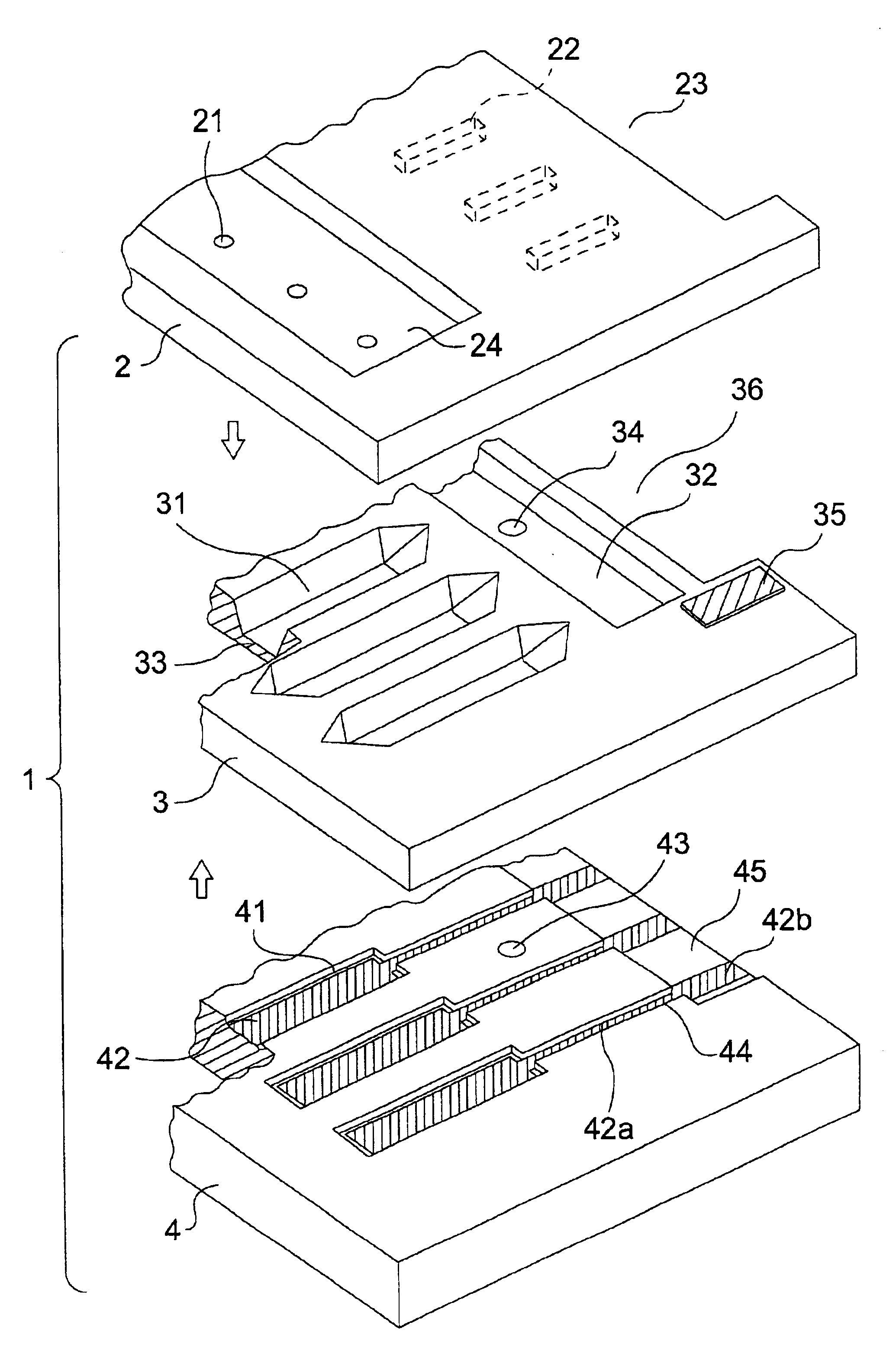

LED (Light Emitting Diode) integrated structure, manufacturing method, lamp, display screen, backlight device, projecting device and injection mould of forming plastic part

InactiveCN101963295AReduce distanceRealize high-definition image displayPlanar light sourcesPoint-like light sourceLuminous fluxLight-emitting diode

The invention relates to an LED (Light Emitting Diode) integrated structure comprising a radiating base plate, an LED chip, a lens, a plastic piece of a positioning lens or a forming lens, a conducting wire and a layout circuit conducting layer, wherein two or more than two chip fixing lug bosses which are integrally formed with the radiating base plate are arranged on the radiating base plate, a first through hole of the positioning lens or the forming lens is arranged on the plastic piece of the positioning lens or the forming lens, the chip fixing lug bosses are arranged in the first through hole, the layout circuit conducting layer is extended between the inside wall of the first through hole and the outside walls of the chip fixing lug bosses, one end of the conducting wire is electrically connected with the LED chip, and the other end of the conducting wire is electrically connected with the layout circuit conducting layer which is extended between the inside wall of the first through hole and the outside walls of the chip fixing lug bosses. The LED integrated structure has the advantages of low thermal resistance of an intermediate link, good heat radiating performance, accurate position relation of the lens and the chip, high luminous flux, simple structure, simple assembly, good radiating effect and good optical effect.

Owner:杨东佐

Permanent-magnetic electric machine rotor magnet steel fixing structure

ActiveCN101083411AImprove mass to powerSimple designMagnetic circuit rotating partsRotor magnetsDynamic balance

The invention discloses a permanent motor rotor alnico fixing structure, mainly comprising: rotating shaft, rotor iron core, two alnico pressure plates and magnet, where the two alnico pressure plates are separately arranged on two end surfaces of the rotor iron core and fixed, the rotating shaft runs through the middles of the alnico pressure plates and the rotor iron core and is fixed, and especially, the alnico pressure plate is formed with several screw holes for regulating dynamic balance, where the axes of these screw holes are distributed on a circle coaxial with the rotating shaft. And it has simple structure and is convenient to dynamic balancing.

Owner:BYD CO LTD

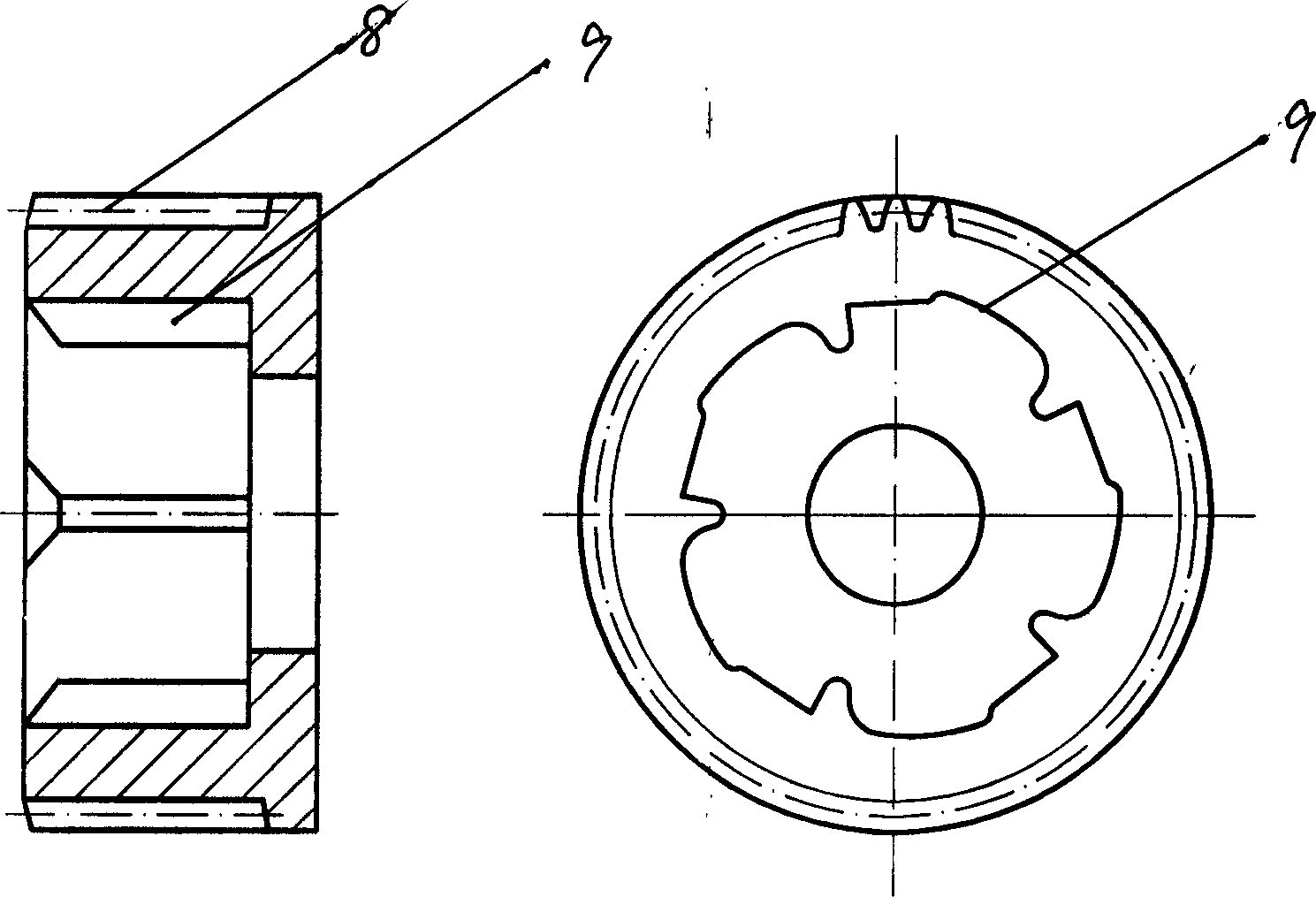

Heavy Duty Overrunning Clutch

The invention discloses a heavy-duty overrunning clutch, which comprises an outer ring, an inner ring, a plurality of rollers and a retaining frame. The retaining frame comprises a support ring I, a support ring II and a plurality of support columns corresponding to the rollers. Spring plates are fixedly arranged on the support columns along the axial direction and are used for applying pre-tightening force on the rollers along the engagement direction of an engagement slot. The direct processing of a limit seat on the outer ring can be avoided, the working efficiency can be increased, the processing cost can be reduced, the service life can be prolonged, and the transmission effect can be guaranteed. Moreover, relevant components can be replaced easily after being damaged, the outer ringneeds not to be rejected as a whole, and the cost of maintenance and use can be reduced. The axial length of the overrunning clutch and the rollers can be increased theoretically indefinitely, the engagement length can be increased, and thus the bearing capacity of the overrunning clutch can be improved. Meanwhile, the pre-tightening force can be applied at multiple points of the rollers according to needs, and the limiting balance for the rollers can be guaranteed while the axial length is ensured, so that the rollers cannot deviate from the axial line of the inner ring. Therefore, the stable operation of the overrunning clutch can be ensured, and mechanical failure can be avoided.

Owner:SOUTHWEST UNIVERSITY

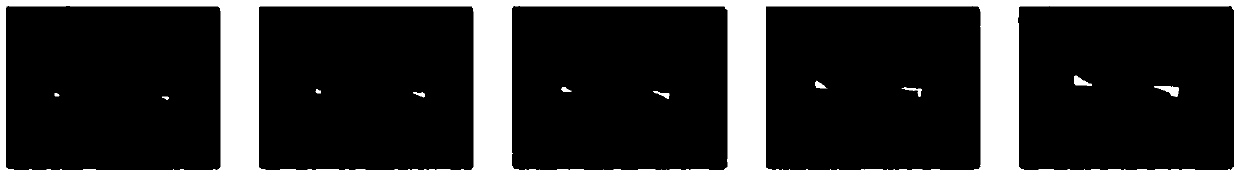

Automatic monitoring method for high-speed milling cutter abrasion

ActiveCN107717631AReflect wear limitAchieve Life PredictionMeasurement/indication equipmentsNumerical controlMean square

The invention discloses an automatic monitoring method for high-speed milling cutter abrasion, and belongs to the field of precision manufacturing. The method comprises the steps that an imaging device directly faces the end of a cutter to collect images repeatedly within the machining intervals set by a numerical control program, wherein the cutter is a milling cutter of a numerical control milling machine; gray-level mean square error counting is carried out on the middle area ( including the area where the cutter is located) of each acquired image, the image with the maximum mean square error is selected as a focused target image, and a white area formed by abrasion exists in the target image; and the abrasion parameter characteristics of the white area are extracted, wherein the abrasion parameters comprise a length, a width and an area, and the abrasion parameter characteristics are used as representation forms of cutter abrasion. According to the automatic monitoring method for the high-speed milling cutter abrasion, the abrasion amount of a micro-milling cutter can be monitored, and the service life of the cutter can be predicted; and damage to a to-be-machined semi-finishedworkpiece or reduction of machining precision caused by the over-damaged cutter can be avoided.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

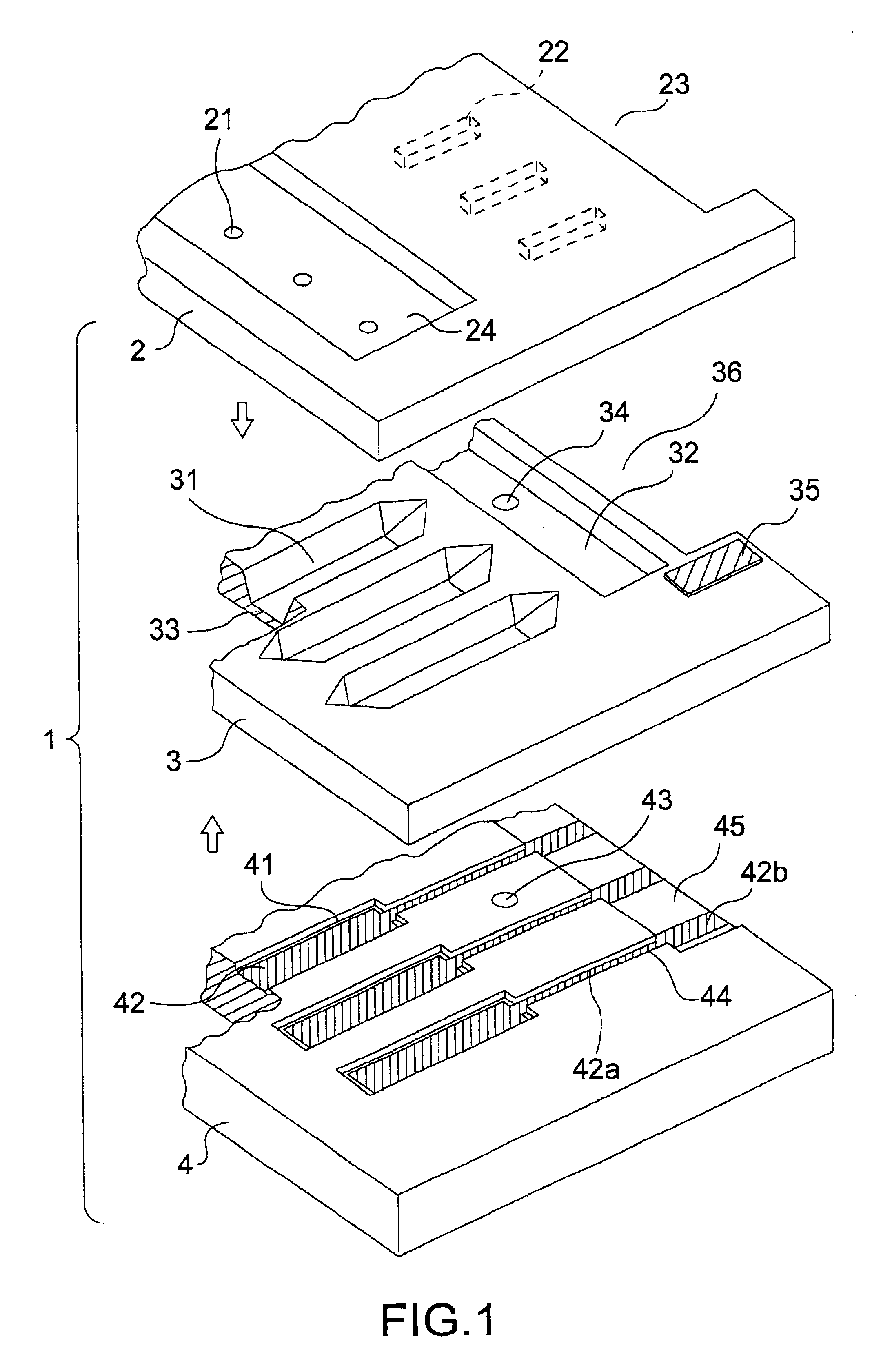

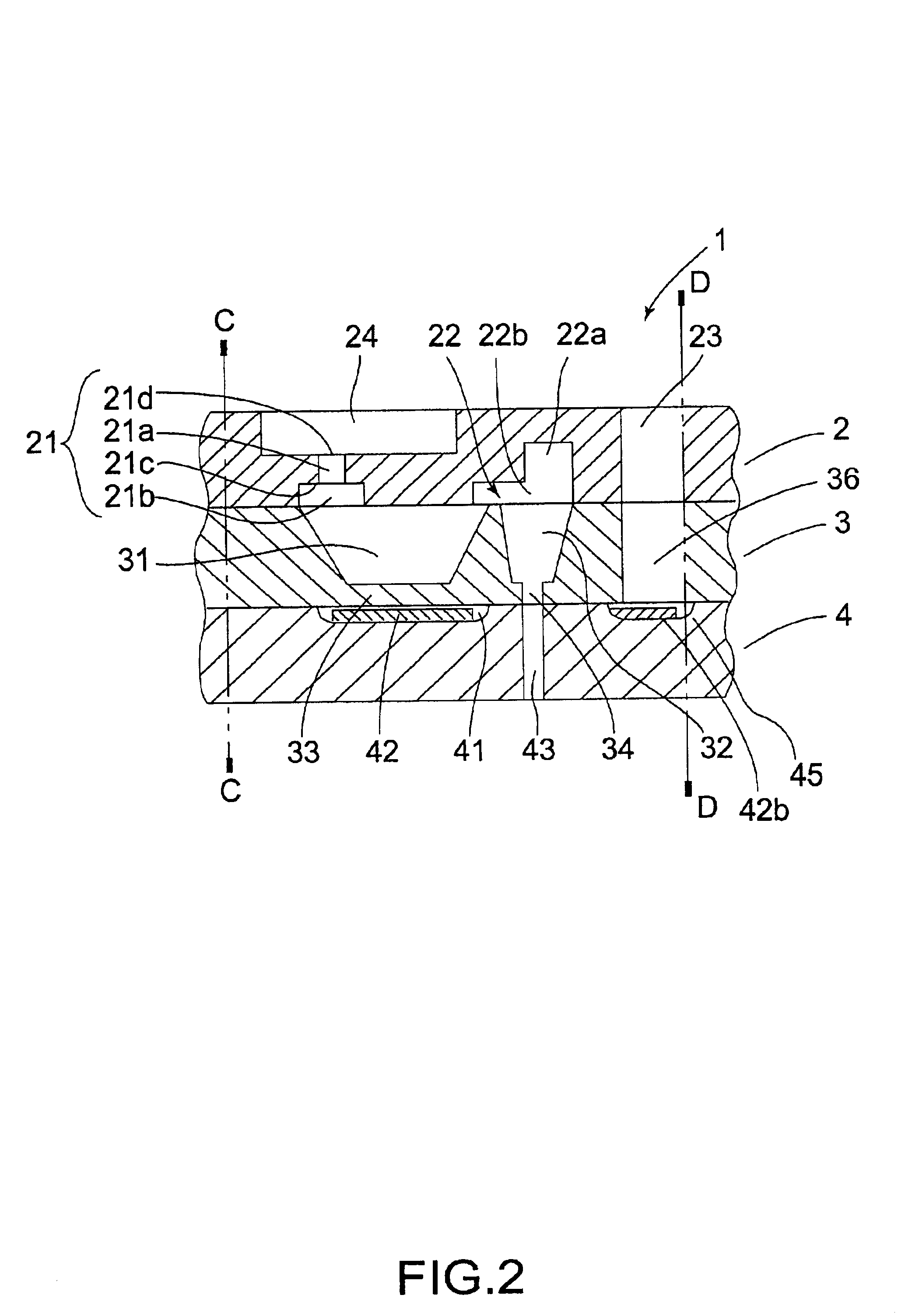

Ejection device and inkjet head with silicon nozzle plate

InactiveUS6863375B2Without lowering processing accuracyReduction of etching speed can be preventedRecording apparatusRecord information storageControl signalEngineering

A silicon nozzle plate includes nozzles each with a first nozzle portion having a circular cross-section and a second nozzle portion having a circular cross-section wherein the circular cross-section of the first nozzle portion is smaller than the circular cross-section of the second nozzle portion. In one embodiment the nozzle plate is utilized in an inkjet head and includes a recess having a flat bottom surface that commonly communicates with a plurality of first nozzle portions and a through hole that exposes terminal portions that supply control signals to pressure generators.

Owner:SEIKO EPSON CORP

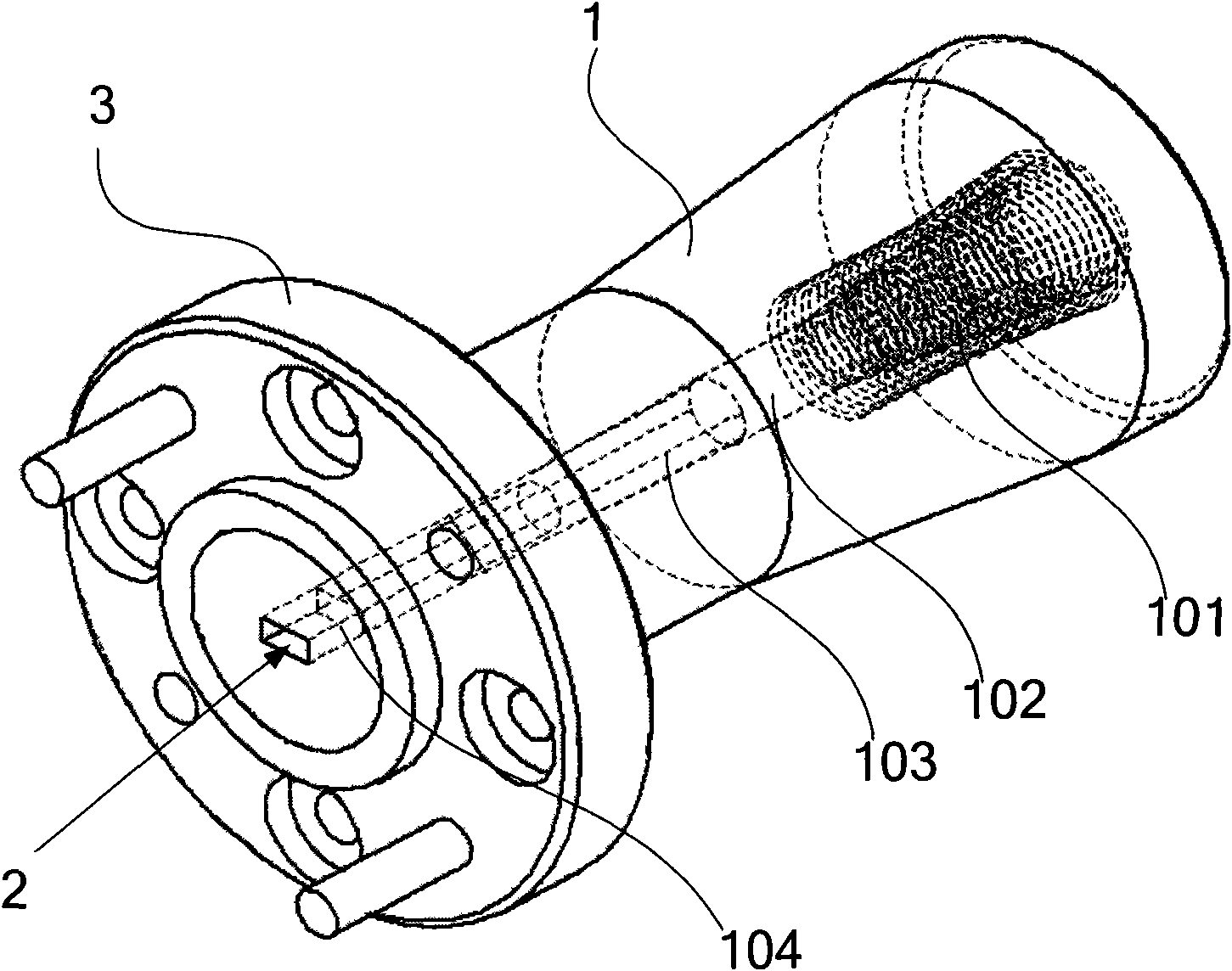

Optical fiber rotary connector

InactiveCN101986176ARealize signal transmissionReduce transmission lossCoupling light guidesPerformance indexEngineering

The invention relates to an optical fiber rotary connector, which comprises a stator head, a rotor head, a stator shell for fixing the stator head, a rotor sleeve for fixing the rotor head and a rotary connection device. The stator shell is sleeved outside the rotor sleeve; the rotary connection device is arranged between the stator shell and the rotor sleeve; a stator optical fiber is a hot-expanded core optical fiber or conical optical fiber with an end part core diameter of 20-40 mu m; and the rotor optical fiber has the same structure as the stator optical fiber. The optical fiber rotary connector provided by the invention solves the problems that the conventional optical fiber rotary connector has complicated structure, is difficult to install, cannot realize signal transmission of a single-mode optical fiber, and can realize the performance indexes of low cost, simple installation, high coupling efficiency, stable performance and long service life.

Owner:FEMTO TECH XIAN

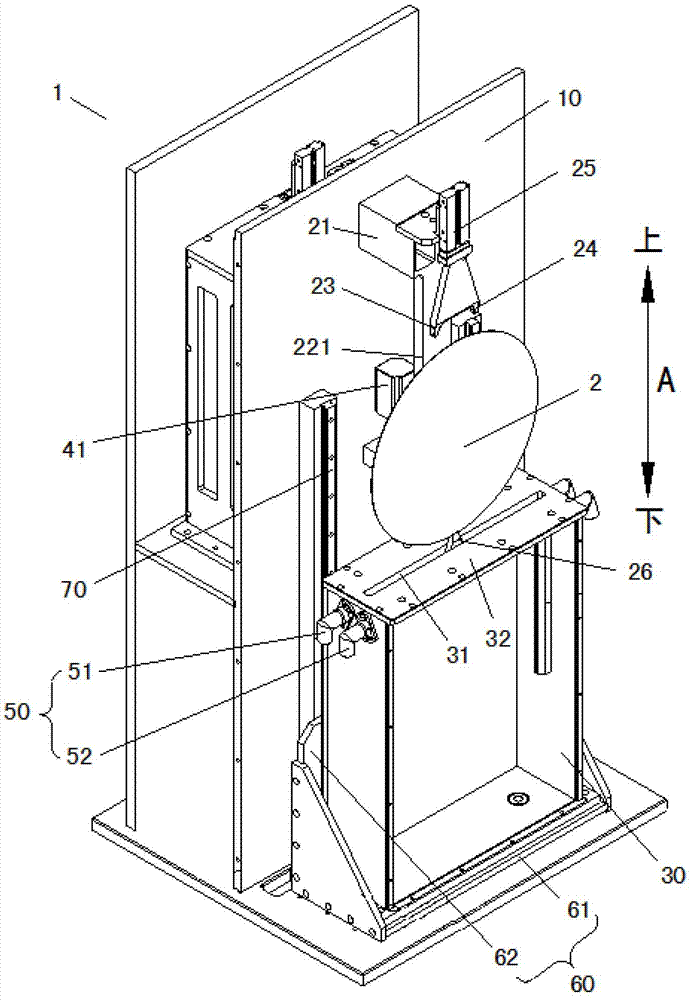

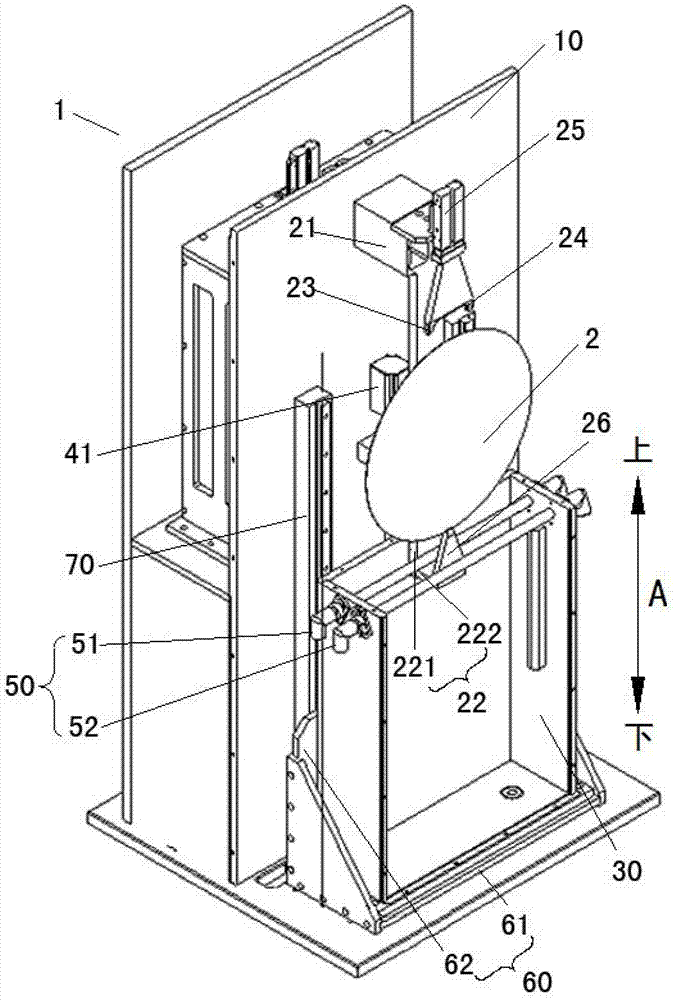

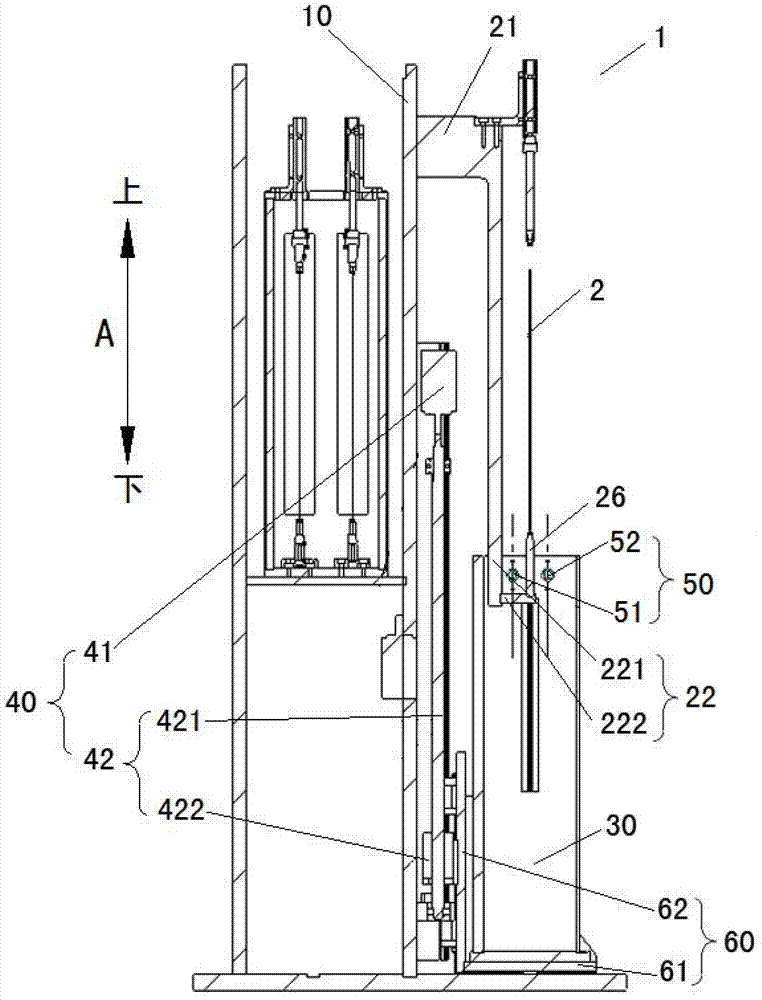

Wafer drying device

ActiveCN102768972AReduce machining accuracyReduce difficultyDrying gas arrangementsSemiconductor/solid-state device manufacturingRabbetIsopropyl alcohol

The invention discloses a wafer drying device. The wafer drying device comprises a body, a wafer clamping mechanism, a water tank, a water tank driving piece and an isopropyl alcohol (IPA) drying system, wherein the wafer clamping mechanism is arranged on the body and used for supporting a wafer which is directed along a vertical direction; the water tank is arranged on the body moveably up and down, and a rabbet which penetrates the top wall of the water tank along the vertical direction and where the wafer passes through is arranged in the top wall; the water tank driving piece is arranged on the body and connected with the water tank for driving the water tank to move up and down; and the IPA drying system is arranged on the water tank and used for drying the wafer. According to the embodiment of the invention, the wafer drying device has the advantages of small manufacturing difficulty, low manufacturing cost, high reliability and the like, and repositioning precision requirements on a mechanical arm which carries the wafer are greatly reduced.

Owner:TSINGHUA UNIV

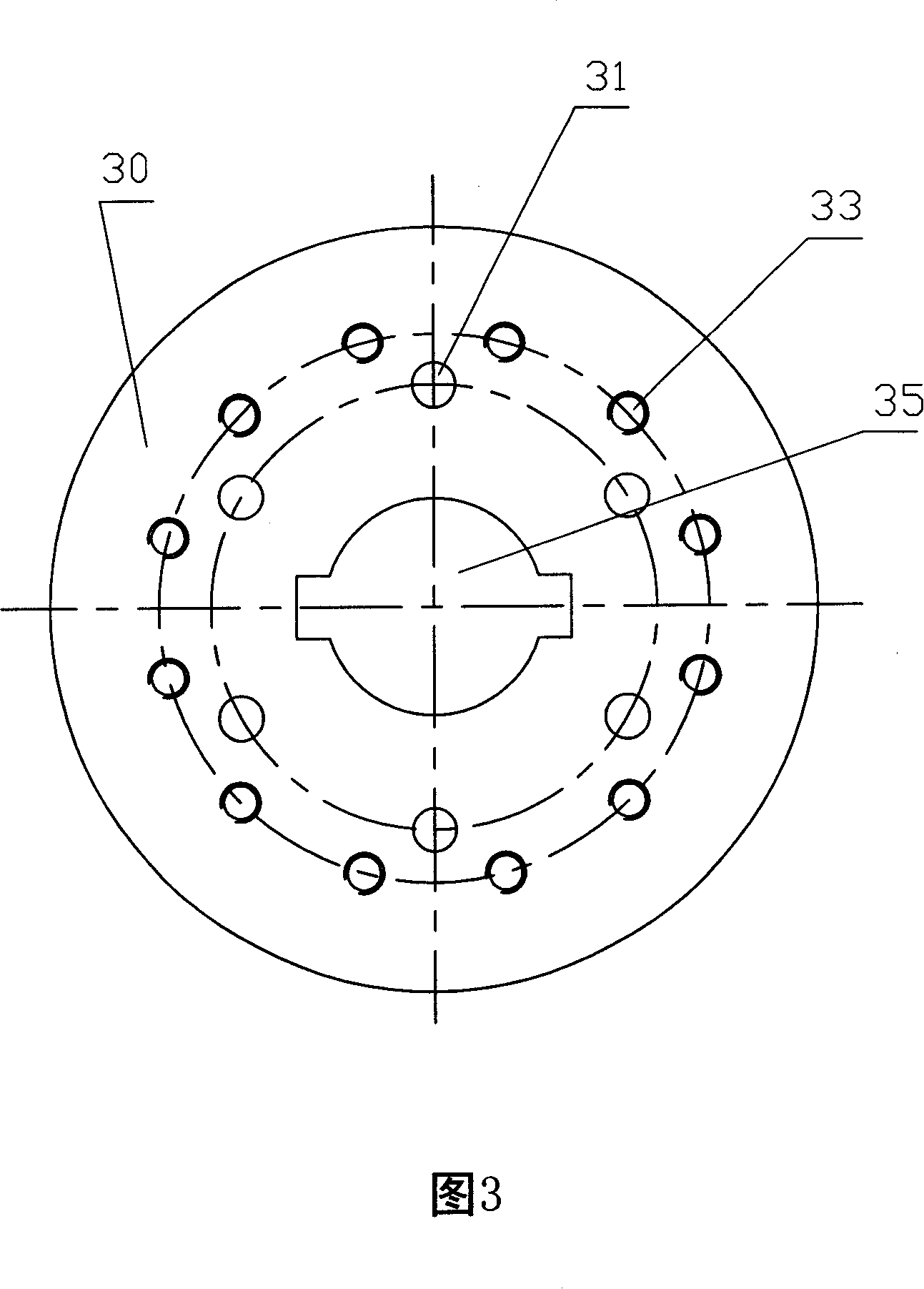

Ring gear or flange processing method

InactiveCN101508073ASave resourcesImprove ergonomicsPortable liftingOther manufacturing equipments/toolsProduct processingQuenching

The invention discloses a method for processing a gear ring or a flange. The method is characterized in that: putting square steel bars or flat steel bars in grooves of three wheels, extruding the steel bars into a circular spiral shape, and forming circular arc square steel after manual or mechanical cutting; putting the circular arc square steel into a cold bending rolling machine for circular extrusion to make two ends of the circular arc square steel overlap; lifting the two overlapping ends to be aligned by a steel stick; welding the two ends together by a butt welder; polishing expelled weld, burr and the like of welded junction by a polisher after flattening treatment of a hydraulic press to form the shape of the gear ring capable of deep processing; and on the basis of the shape of the gear ring or the flange, sequentially performing turning, hobbing, chamfer processing, high-frequency quenching and tempering to form a finished product, namely the gear ring. The method can effectively control the product processing precision, has the advantages of resource conservation, non-pollution, high work efficiency, quick forming and low production cost, and improves the production efficiency.

Owner:任海滔

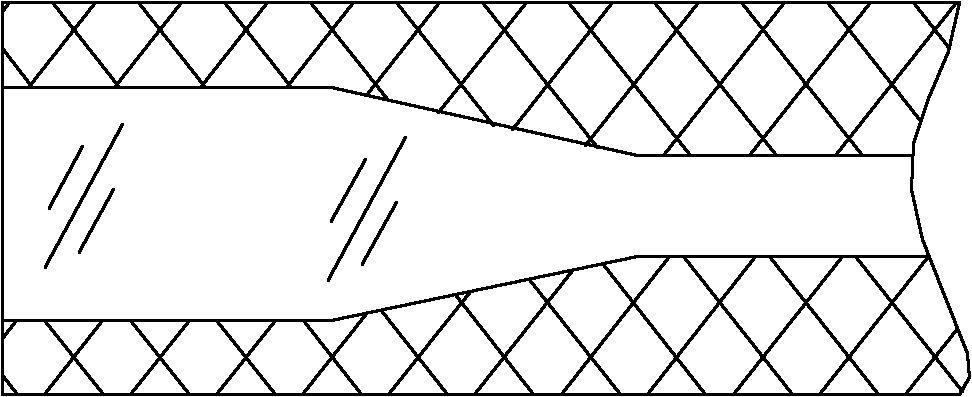

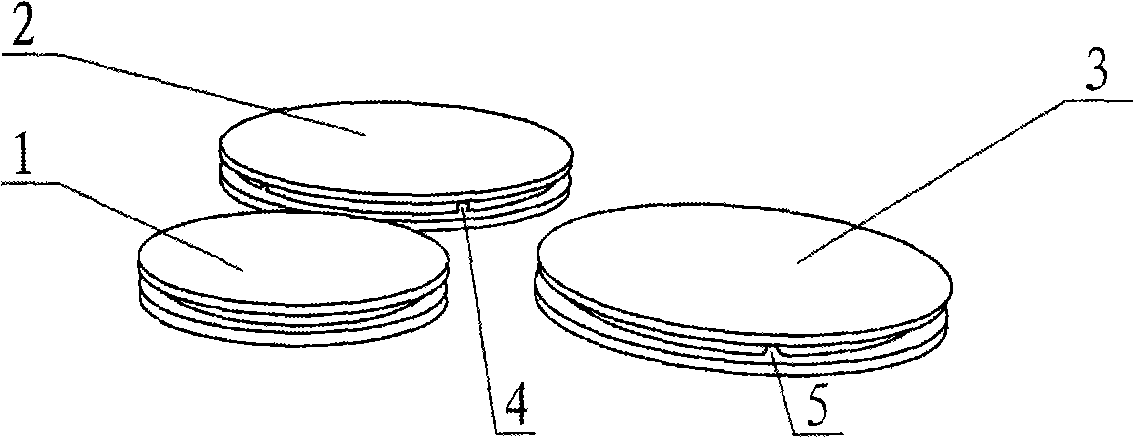

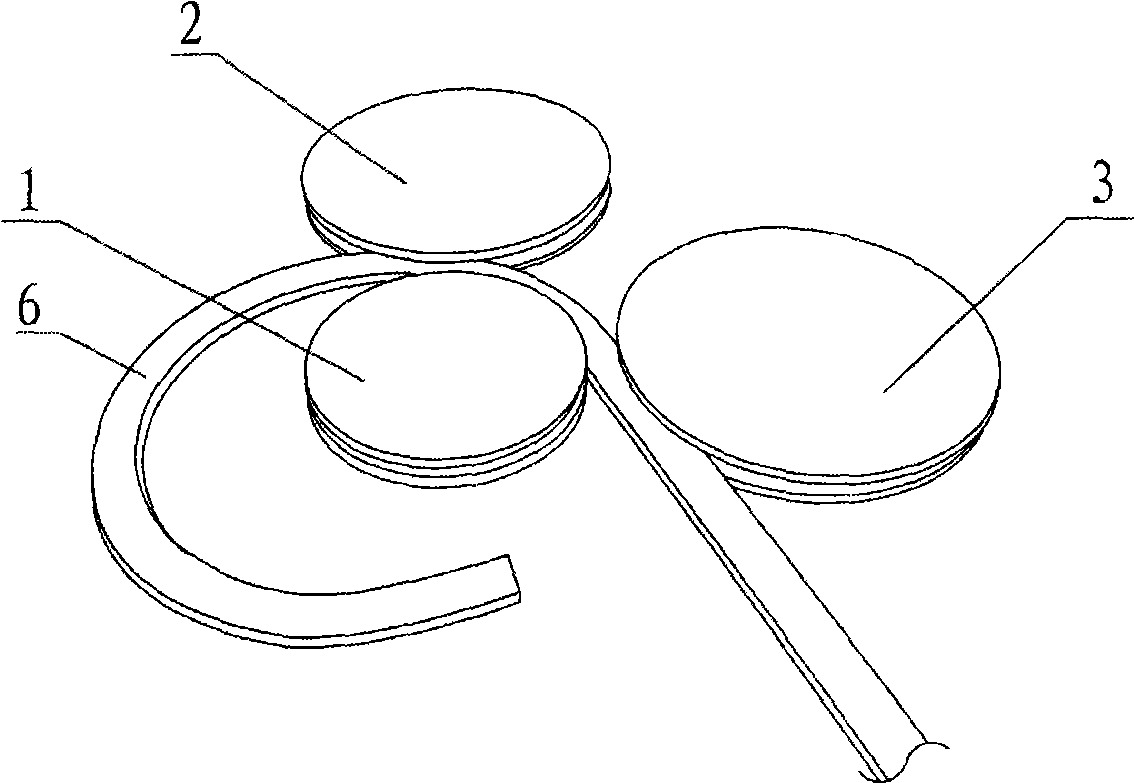

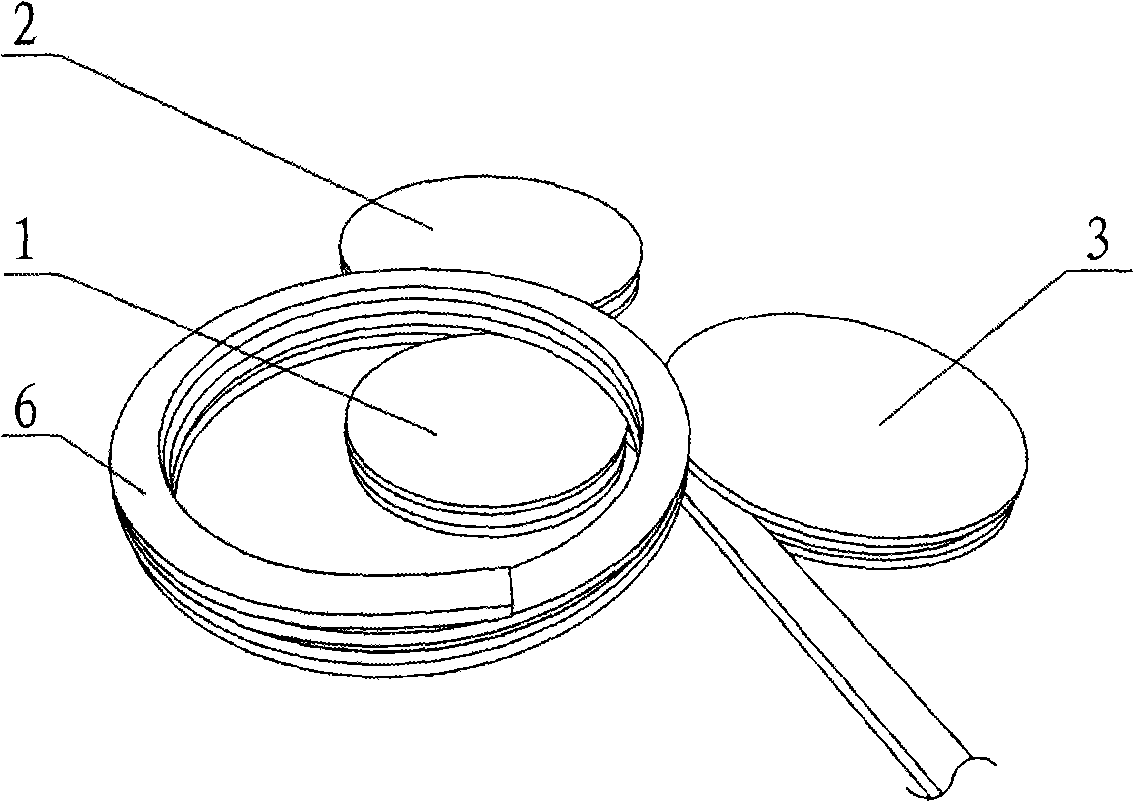

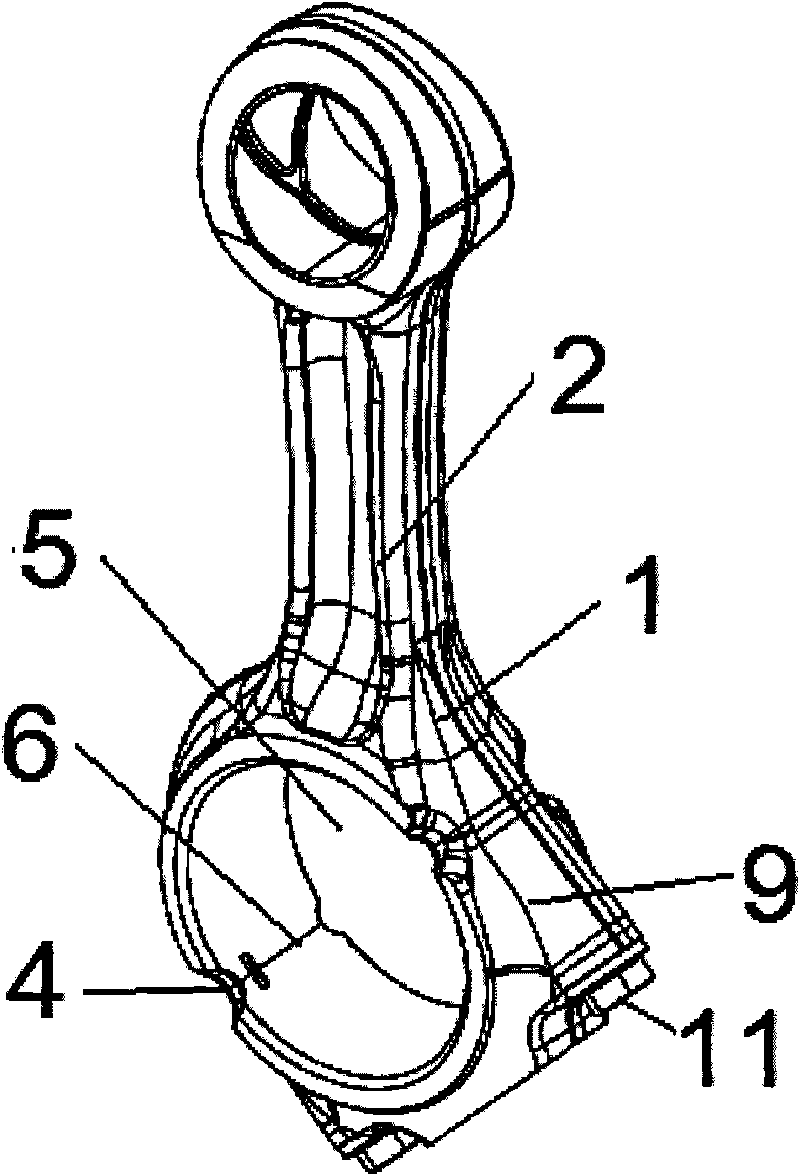

Processing method of engine connecting rod

The invention provides a processing method of a connecting rod, applied in the field of an engine connecting rod. The processing method comprises the following steps: a) processing a bolt connecting hole (3) on a broken cross-section (10) of a connecting rod blank (1); b) arranging a preprocessing stress groove (4) on the edge of the connecting rod blank (1), and arranging a precrack groove (6) at the inner side of a connecting rod large-head hole (5); c) applying a cracking stress F (7) vertical to the predetermined broken section to the connecting rod large-head hole (5) on cracking processing equipment of the connecting rod; d) meshing a broken connecting rod body (2) and a connecting rod cover (9), penetrating with a bolt (11) and screwing tightly; and e) changing the finish-boring carried out in the connecting rod large-head hole (5) into a processing method of honing technique. The processing method greatly reduces the quantity of procedures, and improves the production efficiency; in addition, after the connecting rod body is separated from the rod cover, the separating surfaces of the rod and the cover can be meshed completely, and extra bolt positioning holes do not need to be added.

Owner:CHERY AUTOMOBILE CO LTD

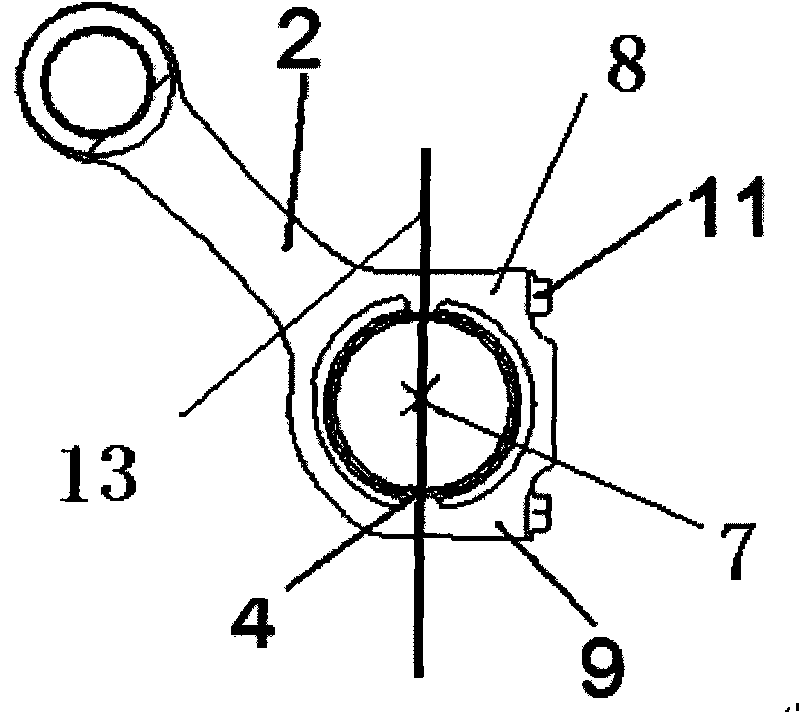

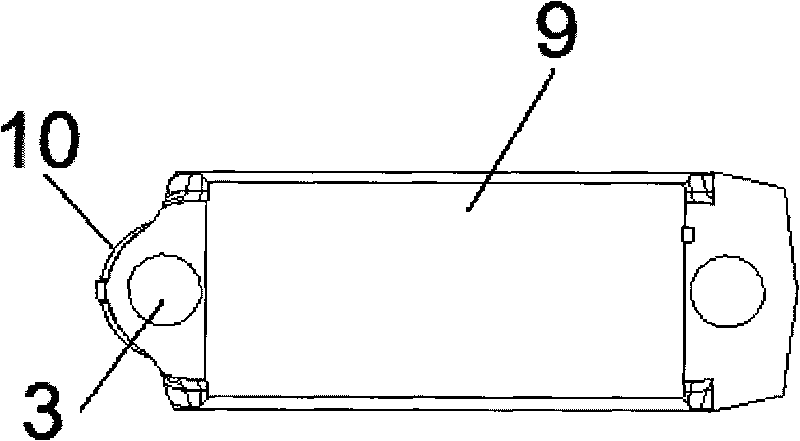

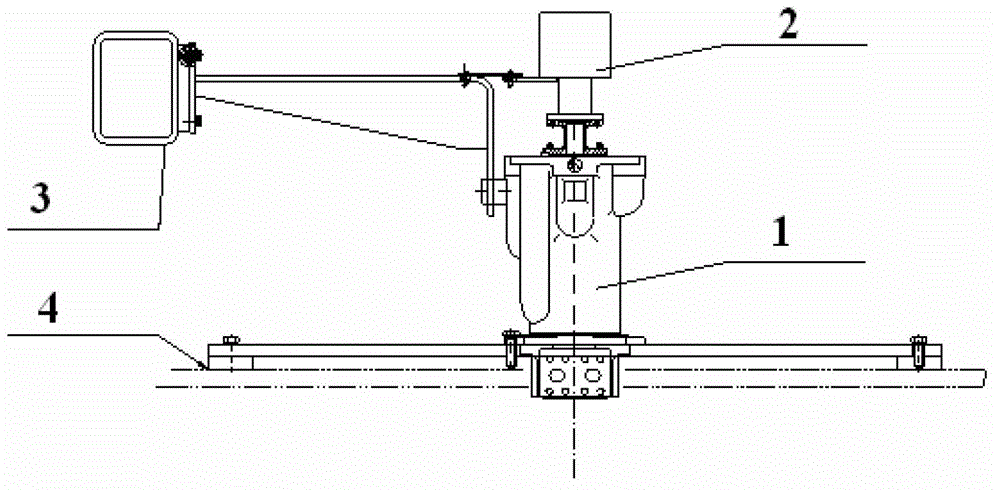

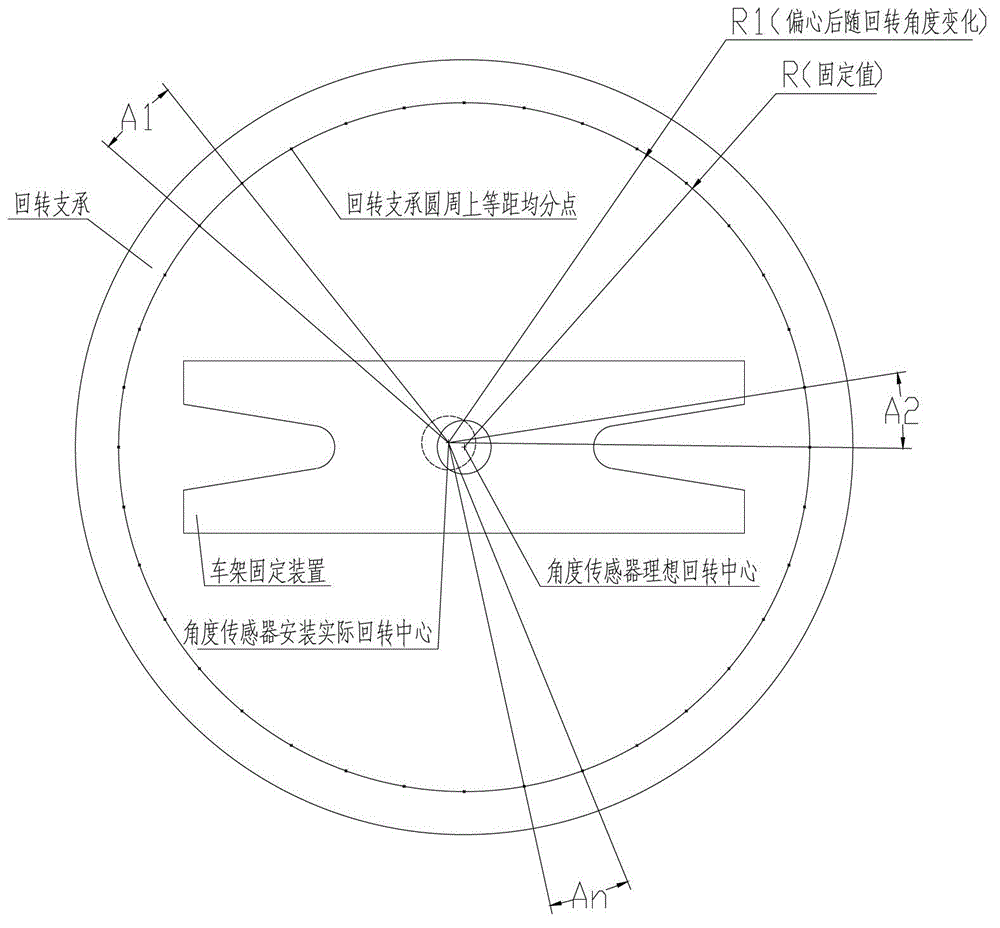

Equipment, system and method for determining revolving angle and engineering machine

InactiveCN102944209AImprove accuracyReduce machining accuracyMeasurement devicesLoad-engaging elementsEngineeringReducer

The invention discloses equipment, a system and a method for determining the revolving angle of a revolving device and an engineering machine. The revolving device is driven by a revolving motor through a speed reducer. The equipment comprises a receiving device for receiving the rotating angle of the revolving motor or a revolving angle transmission detection gear connected with the revolving device or the speed reducer, and a control device for calculating the relative revolving angle of the revolving device according to the rotating angle and the transmission ratio between the revolving motor and the revolving device or the transmission ratio between the revolving angle transmission detection gear and the revolving device, and determining the current absolute revolving angle of the revolving device according to the relative revolving angle and a stored previous absolute revolving angle. Through the technical scheme, the installation requirement of the revolving angle sensor and the concentric condition of the revolving device can be not required to be satisfied, so that eccentric measuring errors do not exist, the accuracy of a measuring result is high, and high reliability is realized.

Owner:ZOOMLION HEAVY IND CO LTD

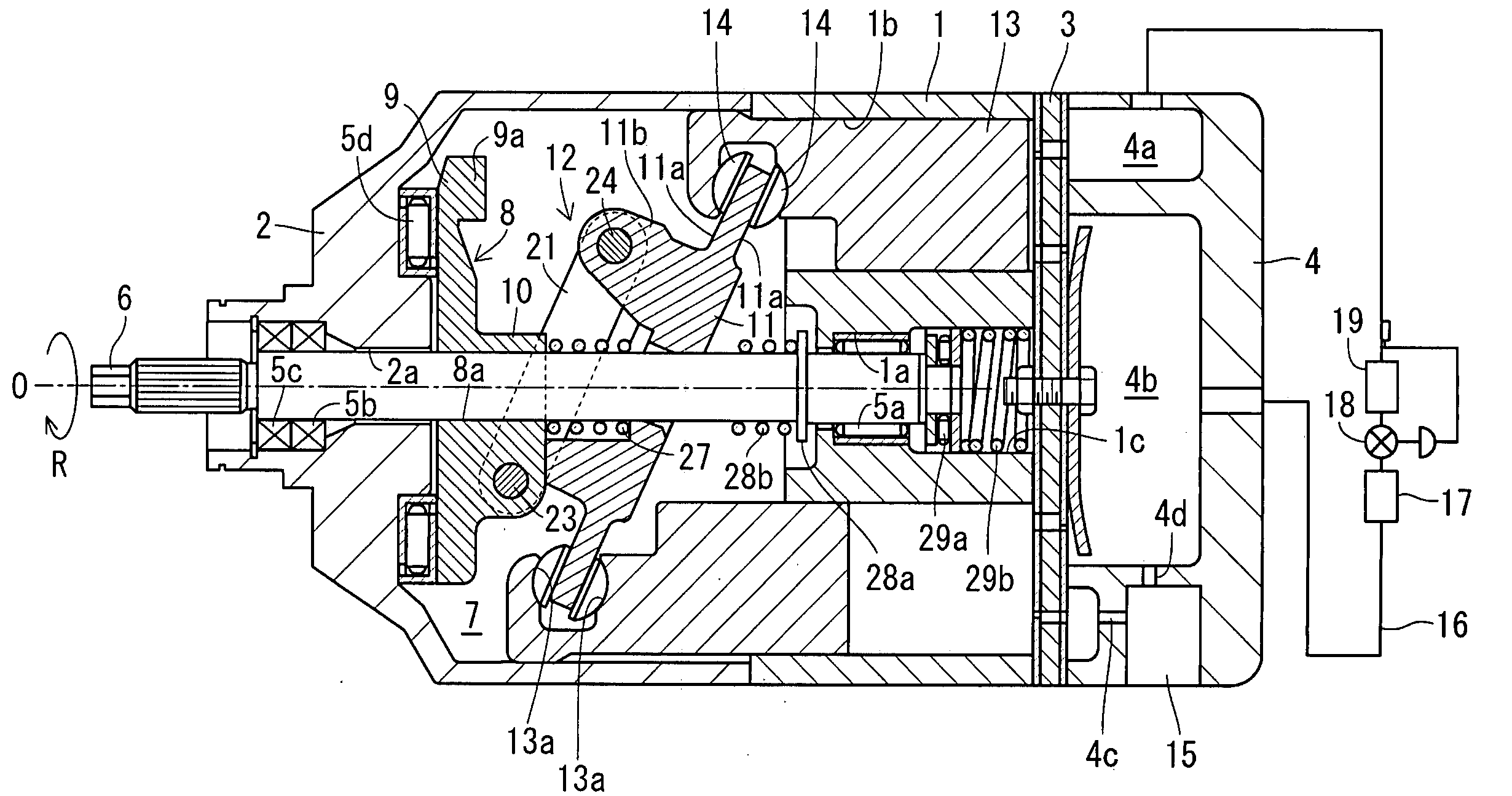

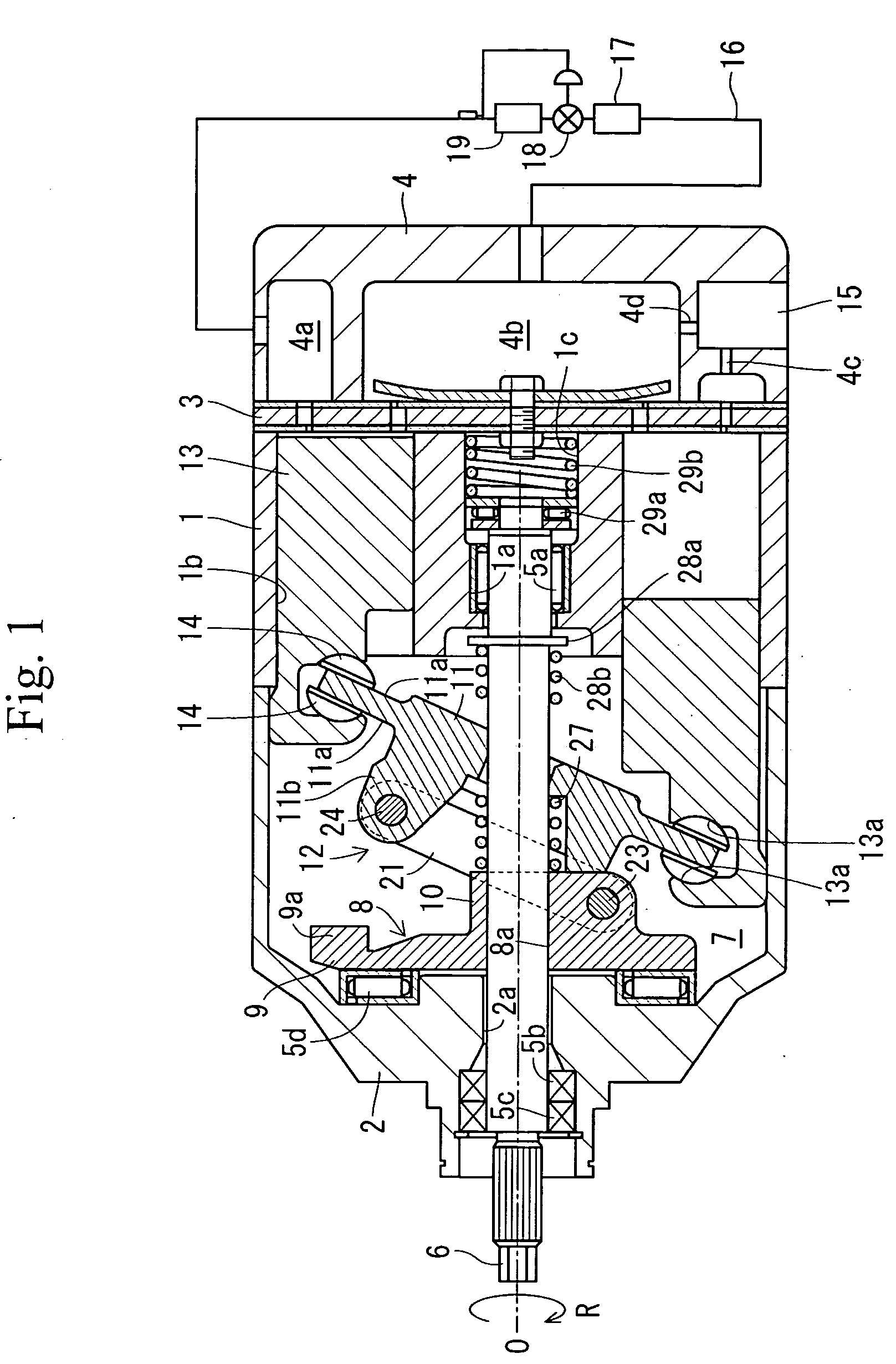

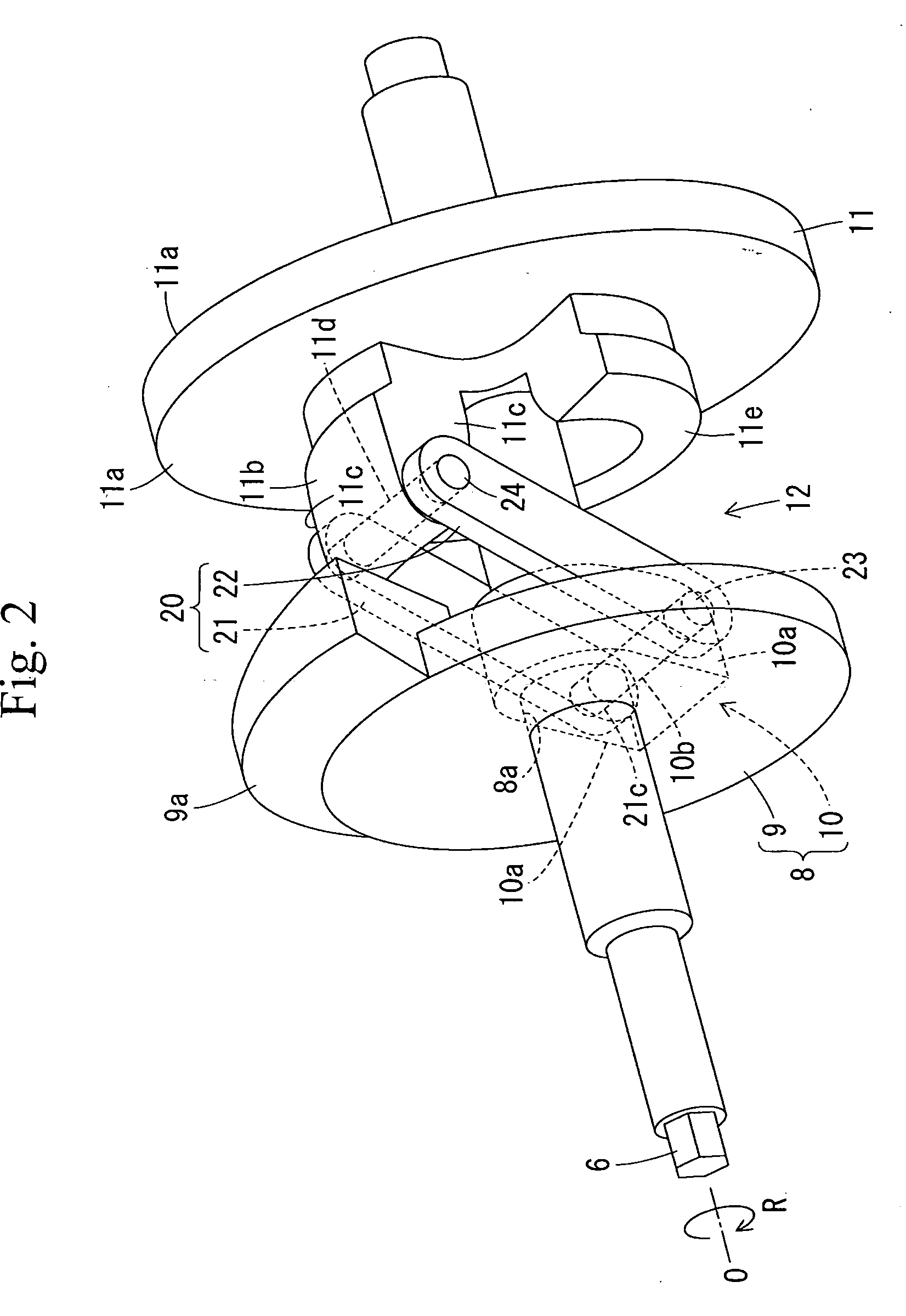

Capacity-variable type swash plate compressor

InactiveUS20090107327A1Preferable operability of a link mechanismReduce manufacturing costFluid-pressure actuatorsEngine componentsEngineeringSwash

A capacity-variable type swash plate compressor in which the preferable operability of a link mechanism and reduction of manufacturing cost are realized is provided. According to the compressor in the present invention, a link mechanism includes one swash plate arm and intermediate arms. The intermediate arms include first and second intermediate arms. The first and second intermediate arms are joined while being rotatably supported by a lug member and the swash plate arm via a lug-side pin which constitutes a lug-side axis and a swash-plate-side pin which constitutes a swash-plate-side axis and clamping the lug member and the swash plate arm via the lug-side pin and the swash-plate-side pin so as to allow a sliding movement.

Owner:TOYOTA IND CORP

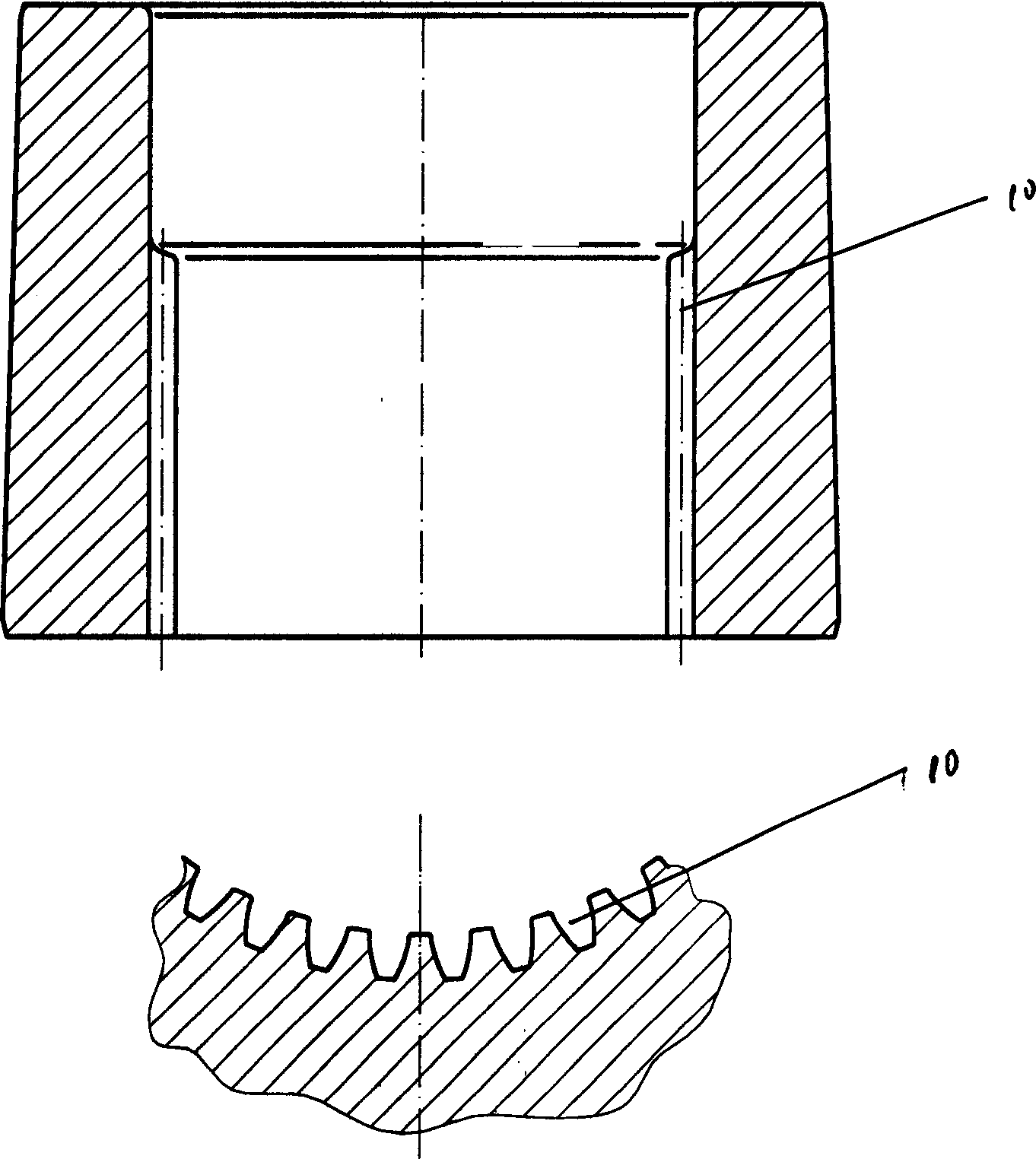

Maching process and mold for annulus of external gear reduced one-way device

InactiveCN1772431AImprove ergonomicsFast formingExtrusion diesOther manufacturing equipments/toolsProduct processingMachine press

The present invention discloses machining process and special mold for annulus of external gear reduced one-way device. The making process includes cold extruding the blank inside a cold mold in a pressing machine, re-extruding inside the secondary mold to form outer surface gear, further machining and heat treatment to complete the machining. The mold includes male mold, outer teeth extruding mold, female mold block, mandrel and mandrel guiding sleeve. The making process has effectively controlled product machining precision, high efficiency and low cost.

Owner:陈萌

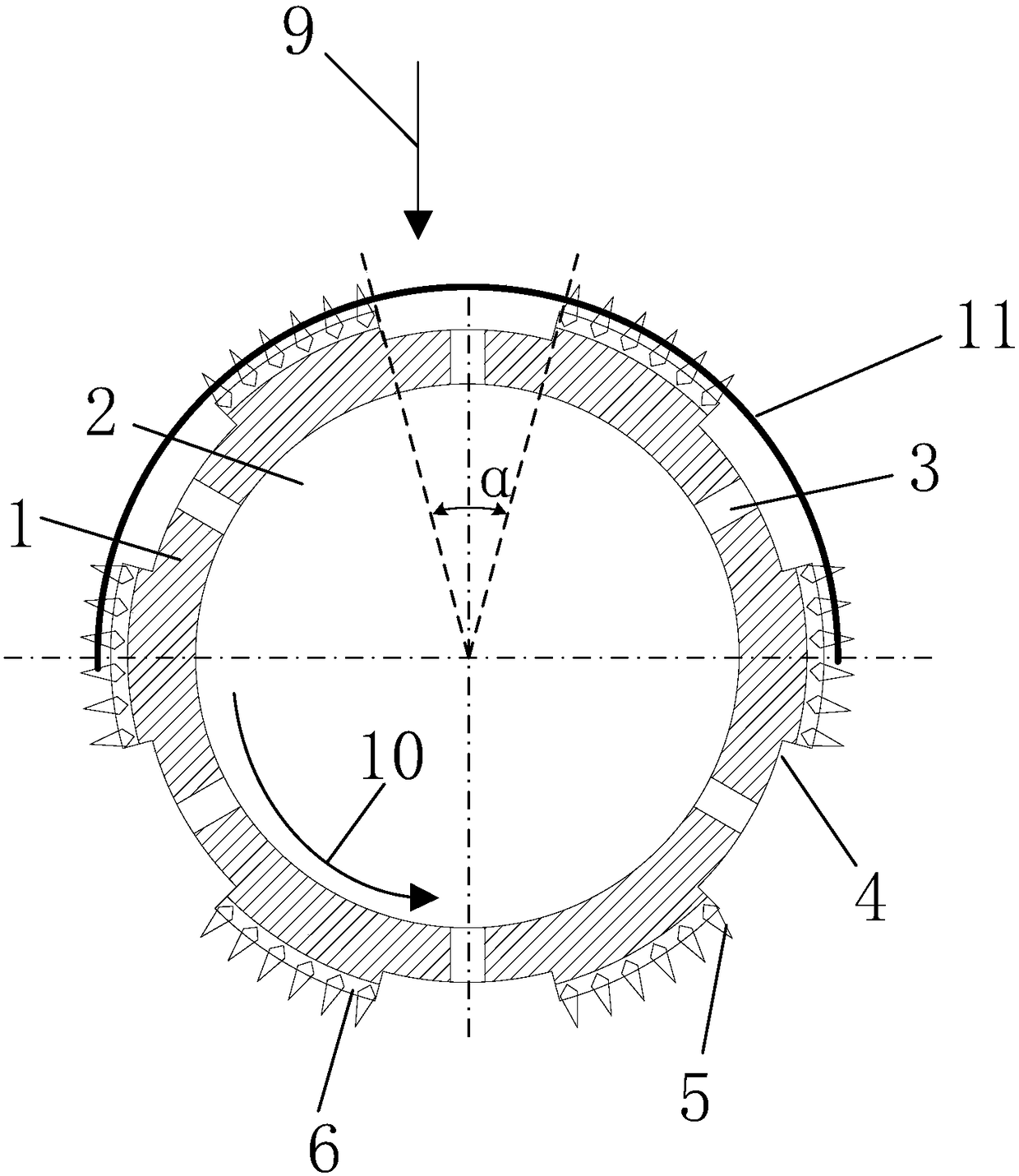

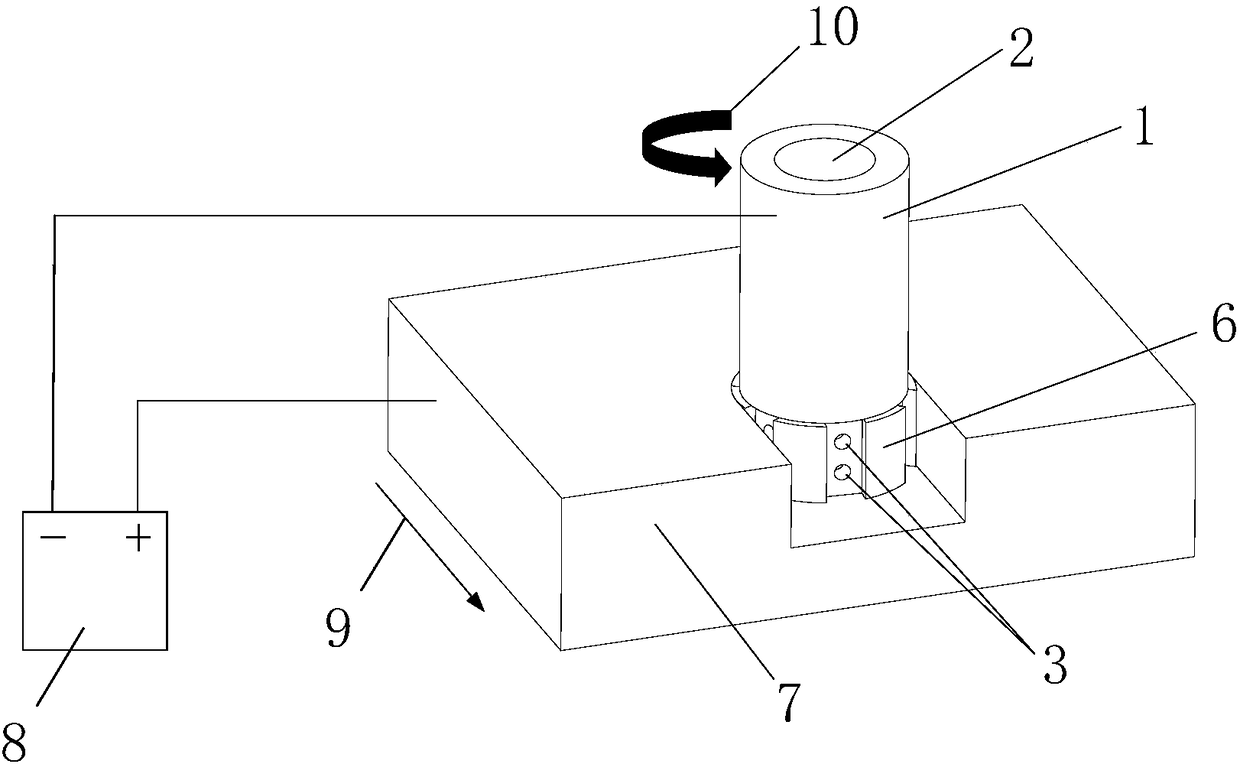

Electrolytic milling-grinding machining tool cathode with efficiency and precision and electrolytic milling-grinding method

The invention relates to an electrolytic milling-grinding machining tool cathode with efficiency and precision and an electrolytic milling-grinding method, and belongs to the field of electrolytic milling-grinding composite machining. According to the electrolytic milling-grinding machining tool cathode and the electrolytic milling-grinding method, a plurality of arc-shaped grooves at equal intervals are formed in the lower end of the side wall of the tool cathode, the side walls of the grooves are insulated, and diamond abrasive particles are inlaid in the wall surfaces of the portions, except for the grooves, of the side wall of a cathode base body through a resin binder, so that electrochemical anodic dissolution only exists in the surfaces of the portions, opposite to the grooves, of aworkpiece, at the moment, the depths of the grooves become a part of a machining gap, accordingly the contact depth between the diamond abrasive particles in the portions, except for the grooves, ofthe side wall of the cathode base body and the machining surface of the workpiece is increased, then the grinding effect of the diamond abrasive particles on the workpiece in the electrolytic milling-grinding process is enhanced, and the precision and the surface quality of the electrolytic milling-grinding machining can be improved; and moreover, compared with the electrolytic milling-grinding finish machining under the low current density in the past, the tool cathode can adopt higher current density, and the machining efficiency can be improved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

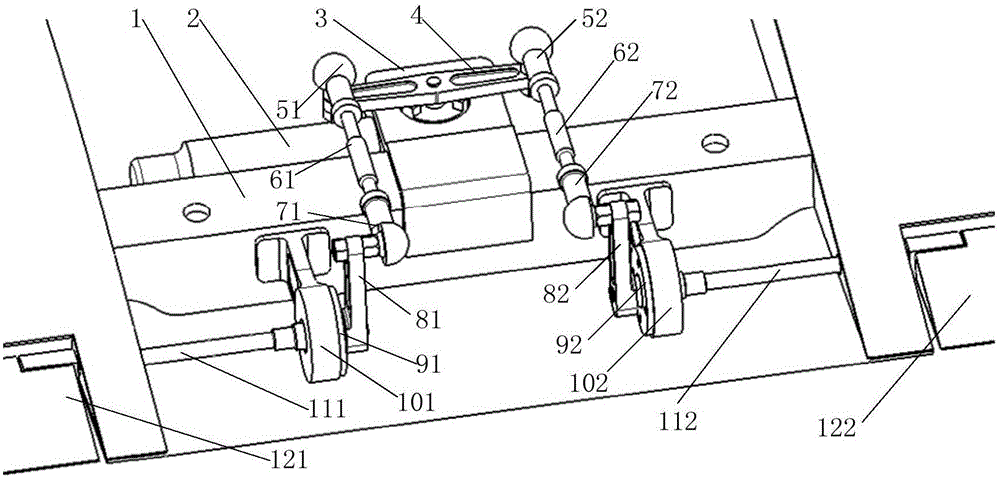

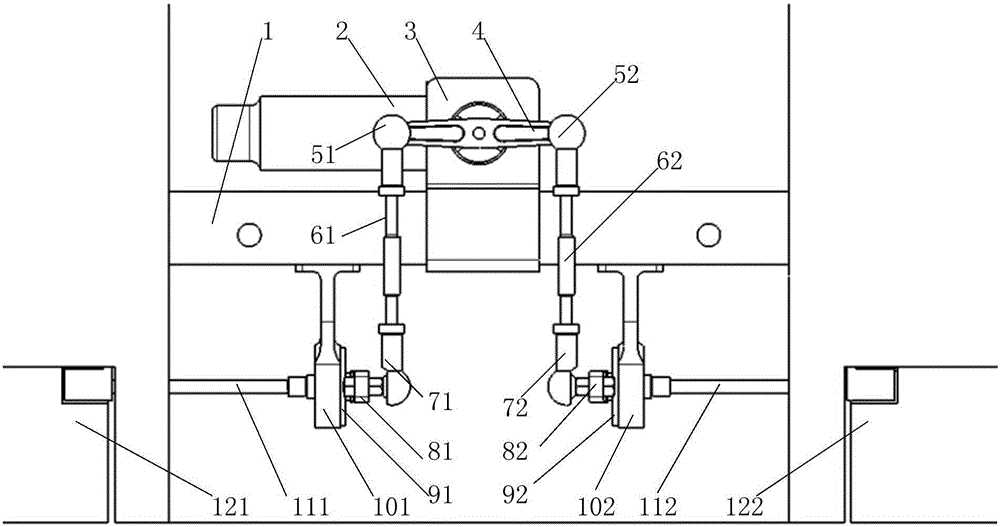

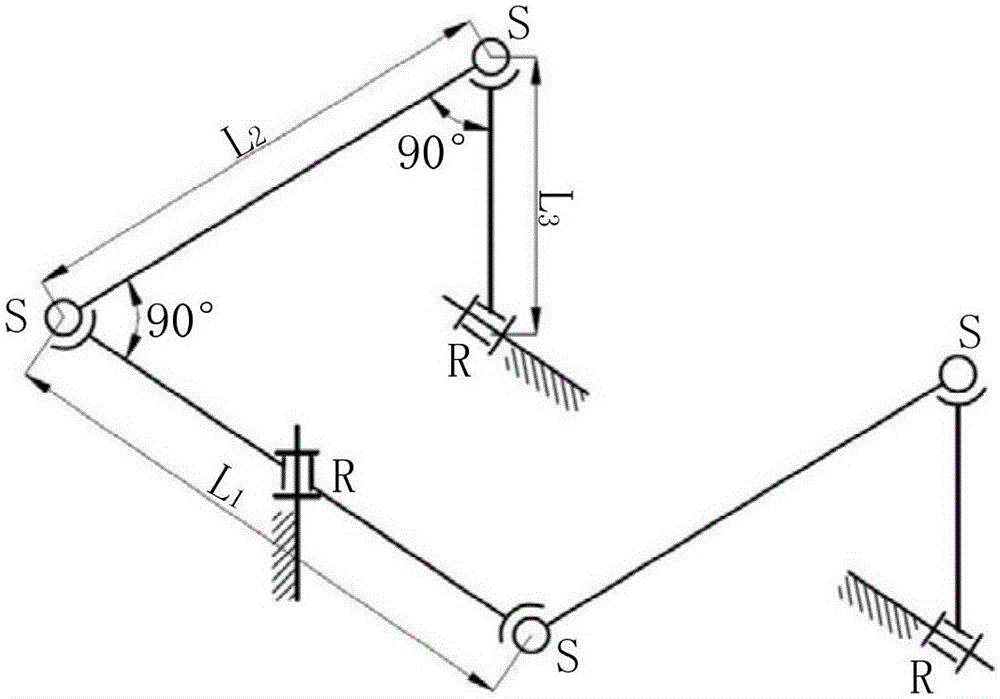

Control surface differential drive mechanism suitable for unmanned aerial vehicle

ActiveCN105151278ARealize differential rotationReduce control difficultyWithout power ampliicationWith power amplificationEngineeringUnmanned air vehicle

The invention relates to a control surface differential drive mechanism suitable for an unmanned aerial vehicle. The control surface differential drive mechanism comprises a common module, a left aileron drive mechanism module and a right aileron drive mechanism module. A dual-output steering engine connecting rod (2) is driven by an electric steering engine (2) to rotate, and a left aileron rudder shaft (111) and a right aileron rudder shaft (112) are driven to rotate oppositely through movement of a left connecting rod (61), a right connecting rod (62), a left rudder shaft connecting rod (81) and a right rudder shaft connecting rod (82), so that a left aileron (121) and a right aileron (122) deflect oppositely. Differential drive of the left aileron and the right aileron is achieved through a dual RSSR space four-connecting-rod combined mechanism, movement synchronization of the left aileron and the right aileron is achieved, constant-speed transmission of the left aileron and the right aileron is achieved, meanwhile, the requirements for machining precision and tools are lowered, and manufacturing cost is reduced.

Owner:CHINA ACAD OF LAUNCH VEHICLE TECH

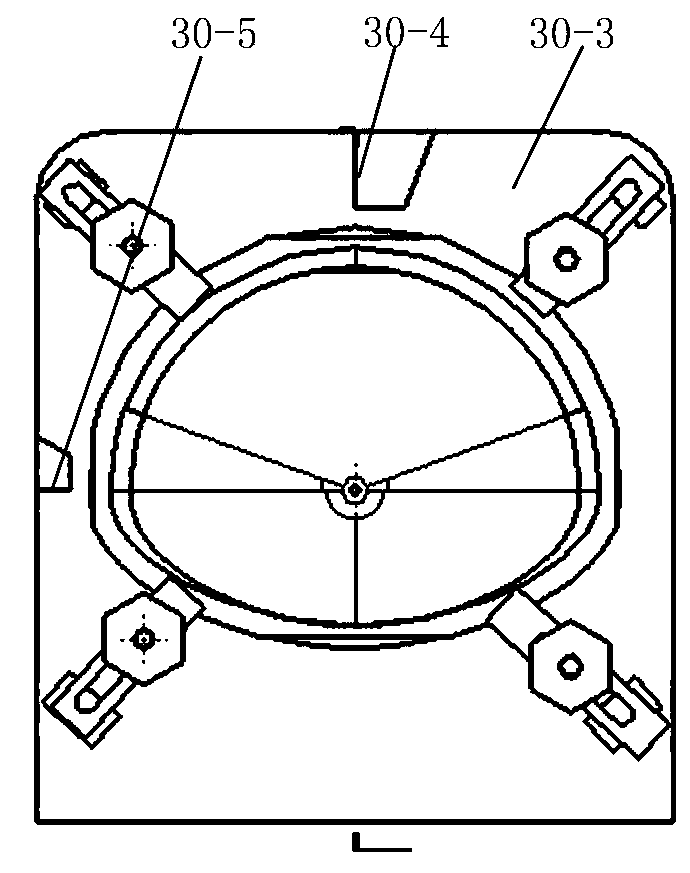

Special-shaped ceramic antenna cover machining device and method

ActiveCN109702605AUnified processing standardsControl machining accuracyRadiating element housingsWorking accessoriesMechanical engineeringEngineering

The invention provides a special-shaped ceramic antenna cover machining device and method. The device comprises a head cone supporting ring, an inner molded surface aligning ring, end face pressing plates and a plurality of outer supporting mechanisms. Each outer supporting mechanism comprises an outer support and an adjusting screw rod, and the inner molded surface aligning ring comprises an insertion end and a fixed end. According to the device and method, the machining reference of an antenna cover is determined through a primary alignment tool, it is guaranteed that the position of a clamping space of the antenna cover in all working procedures is free of deviation, the machining reference is unified, and the machining precision is effectively controlled.

Owner:AEROSPACE INST OF ADVANCED MATERIALS & PROCESSING TECH

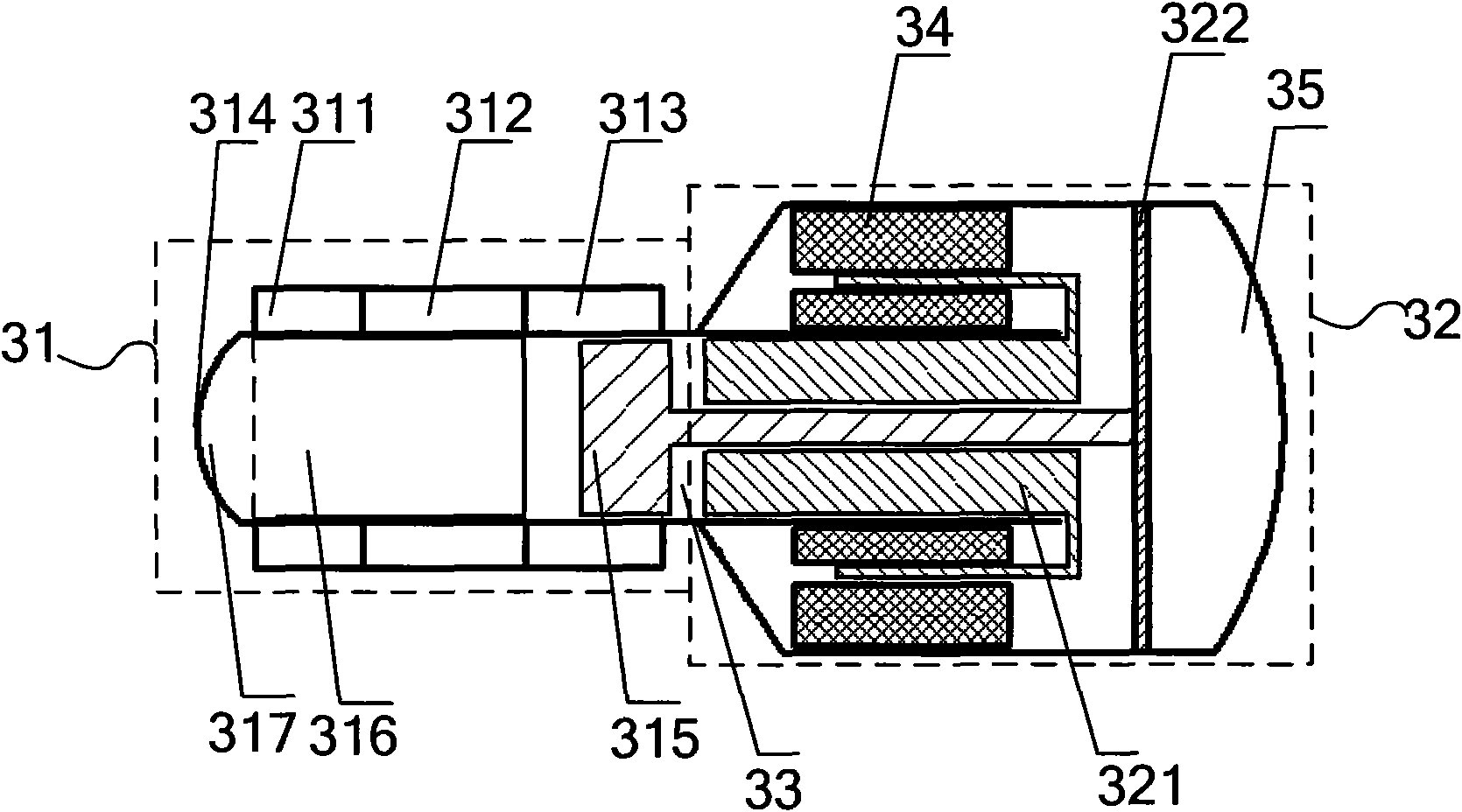

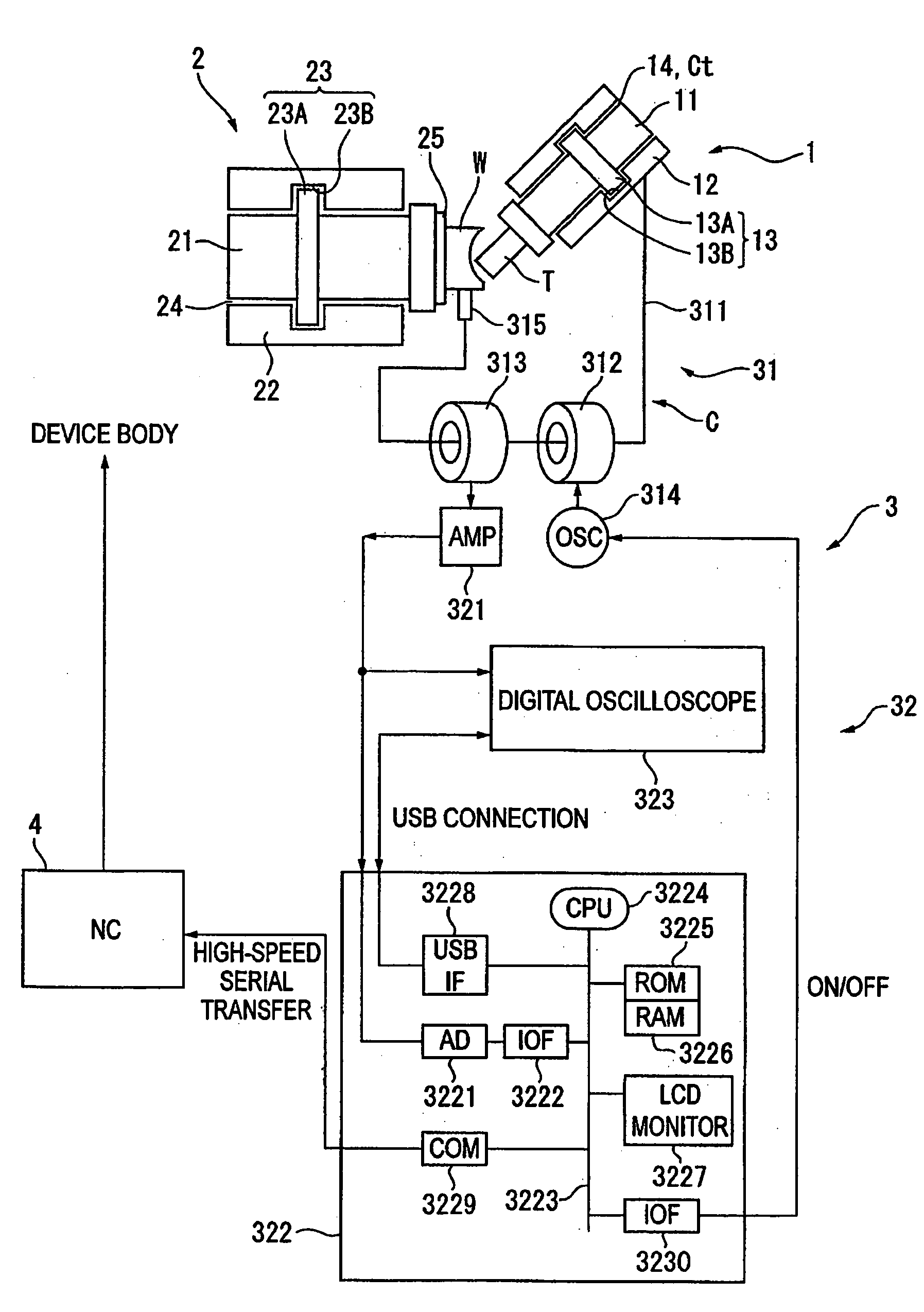

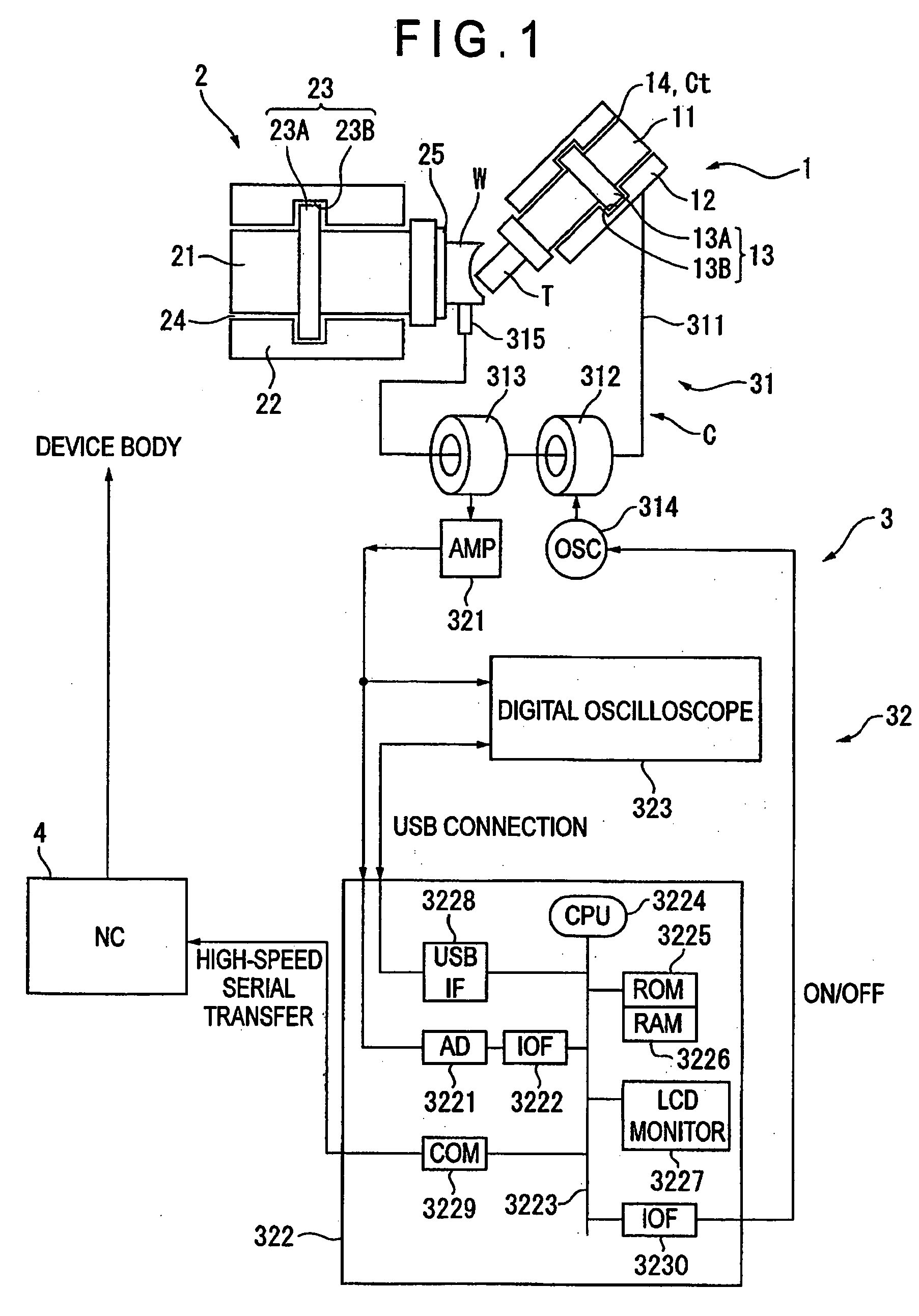

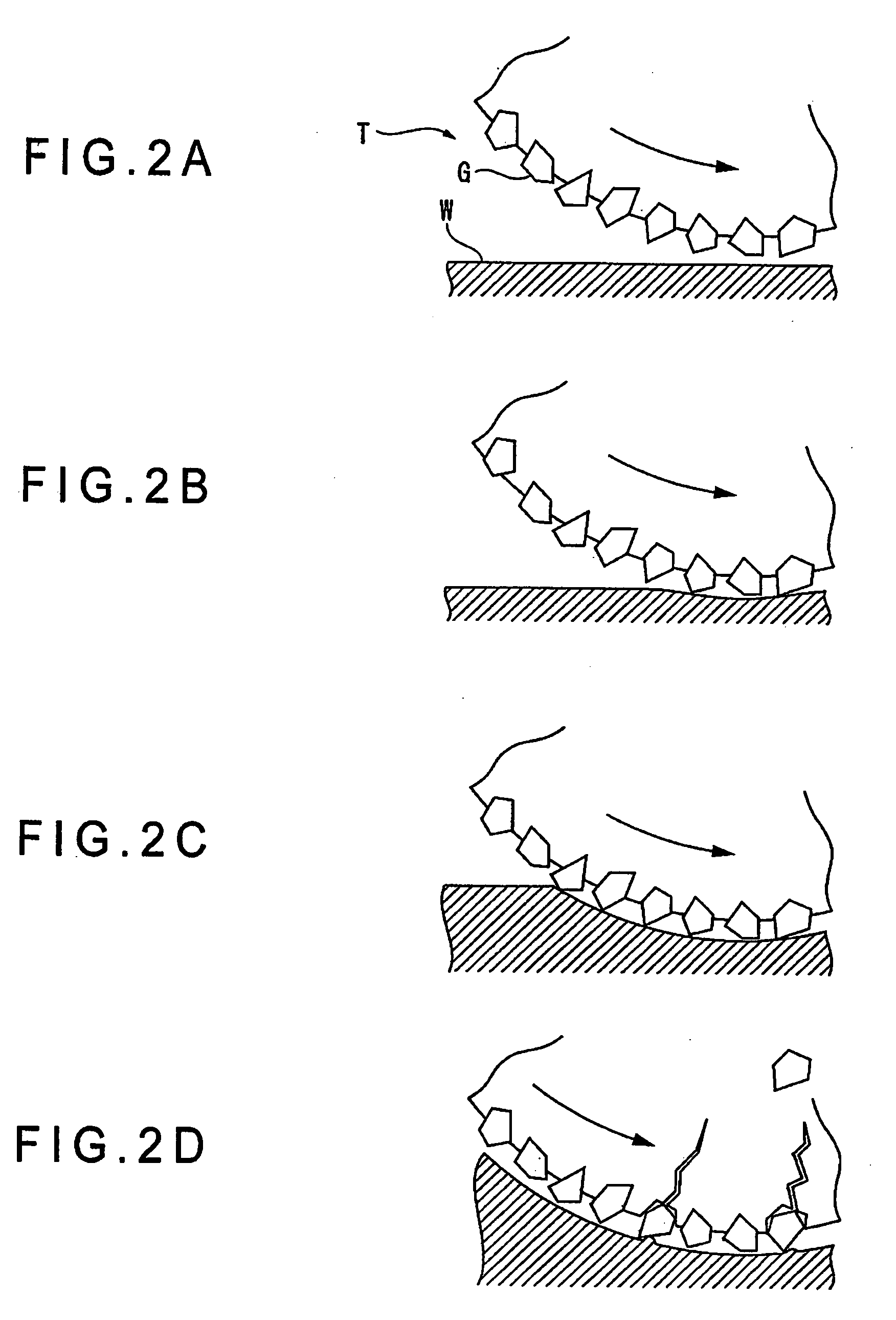

Machining device

InactiveUS20060019578A1Avoid damagePreventing in machining accuracyAutomatic control devicesThread cutting machinesElectrical conductorAlternating current

According to a machining device for machining a conductive workpiece (W) by a conductive (T), when the tool (T) contacts the workpiece (W) in machining, there is formed a closed-circuit (C) connecting the tool (T), the workpiece (W), a brush (315), a conductor (311), a main spindle housing (12), a main spindle (11) and again the tool (T in that order. Alternating-current is inducted to the closed-circuit (C) by a high-frequency generator (314) and an exciting coil (312). As a contact state between the tool (T) and the workpiece (W), impedance of the closed-circuit (C) is changed and then the alternating-current is changed, so that induction current is generated at a detector coil (313), thus monitoring and controlling the contact state by way of the induction current. Since a light contact state can constantly be maintained in machining according to a monitoring condition including a light / heavy contact-determining threshold, cutting resistance will not increase, thereby preventing damage on the tool (T) and deterioration in machining accuracy.

Owner:GIRO GH +1

CBN (Cubic Boron Nitride) grinding wheel

ActiveCN106625297AReduce grinding temperatureReduce power lossAbrasion apparatusGrinding devicesProcessing accuracyThermal conductivity

The invention relates to the field of superhard materials, and concretely relates to a CBN (Cubic Boron Nitride) grinding wheel. The invention provides the CBN grinding wheel, which has favorable shock resistance and shape retention, and can bear a larger load during a high-speed grinding process. The CBN grinding wheel comprises a steel core and an abrasive ring. The steel core and the abrasive ring are combined through a binding agent. The CBN grinding wheel is characterized in that the abrasive ring is prepared from the following raw materials in percentage by mass: 30 to 70 percent of CBN abrasive, 20 to 60 percent of metal binding agent, and 2 to 10 percent of auxiliary adhesion agent. The CBN grinding wheel provided by the invention has favorable heat conductivity and is beneficial for reducing the grinding temperature, so that the power loss is reduced, and the grinding speed is improved; the auxiliary adhesion agent in a formula is beneficial for forming pores, and the characteristic of high holding force of the metal binding agent is combined, so that a chip space can be effectively enlarged, and abrasives are more sufficiently utilized; and the grinding wheel has the characteristics of high grinding efficiency, low grinding temperature, low power loss, good processing accuracy, long service life and the like.

Owner:磐维科技(青岛)有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com