Optical fiber rotary connector

A rotary connector and rotary connection technology, applied in the direction of coupling of optical waveguides, can solve the problems of inability to realize single-mode fiber signal transmission, difficult installation, complex structure, etc., and achieve simple structure, reduced machining accuracy, and high coupling efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

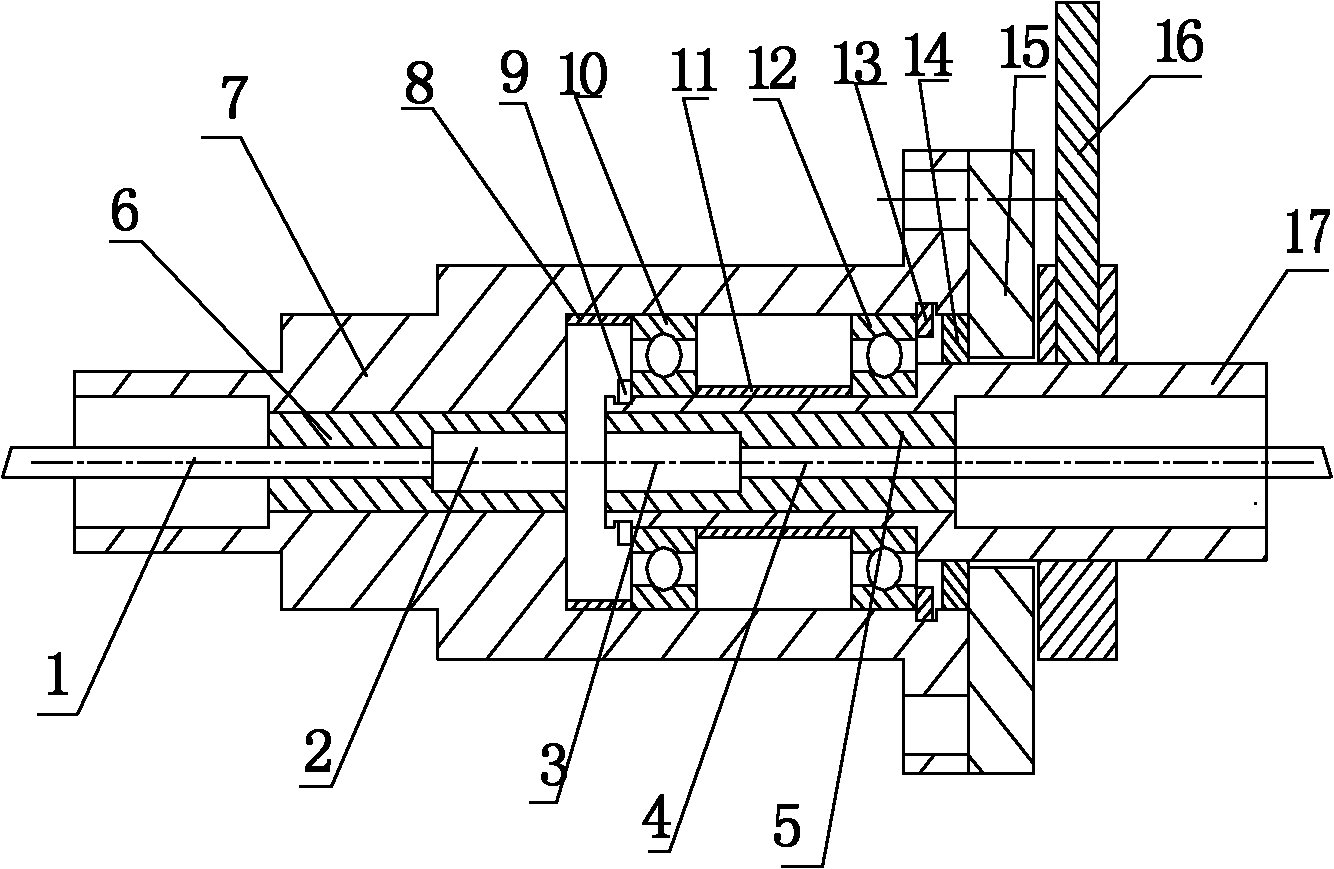

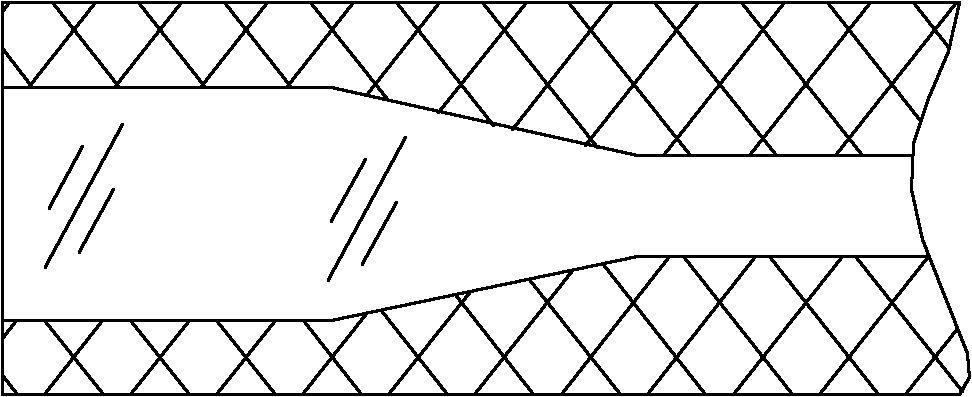

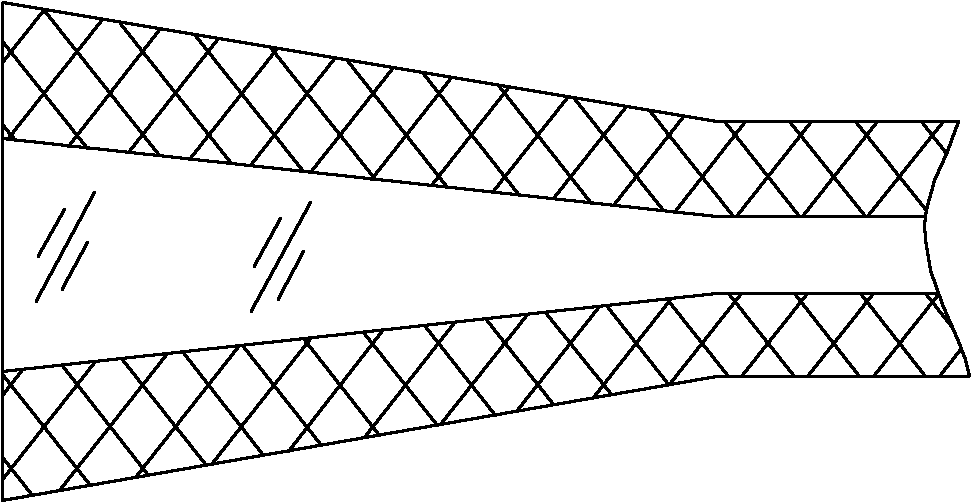

[0030] The invention provides an optical fiber rotary connector. The optical fiber rotary connector includes a stator head, a rotor head, a bearing, a rotor sleeve, an end cover, a spring seal, a rotor lever, an elastic retaining ring, and a spacer. The stator head includes a stator collimator and a stator fiber embedded in one end of the stator collimator. The other end of the rotor collimator is embedded with a rotor lens. The rotor head includes a rotor collimator and a stator lens embedded in one end of the rotor collimator. The rotor The other end of the collimator is embedded with a rotor lens, the stator lens is connected with the stator optical fiber, and the rotor lens is connected with the rotor optical fiber. The rotor fiber and the stator fiber can be tapered fiber (taper fiber) or thermally expanded core fiber (TEC fiber). The rotor lens and the stator lens can adopt self-focusing lens, C lens (C lens), aspheric lens. Various optical fibers can be combined with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com