Automatic collecting and arranging machine for plastic soft bottle

An automatic collection and sorting machine technology, applied in the direction of automatic packaging control, packaging bottles, manipulators, etc., can solve the problems of difficult processing, high labor costs, high precision, etc., and achieve perfect processing progress, reduce production costs, and high operating speed Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

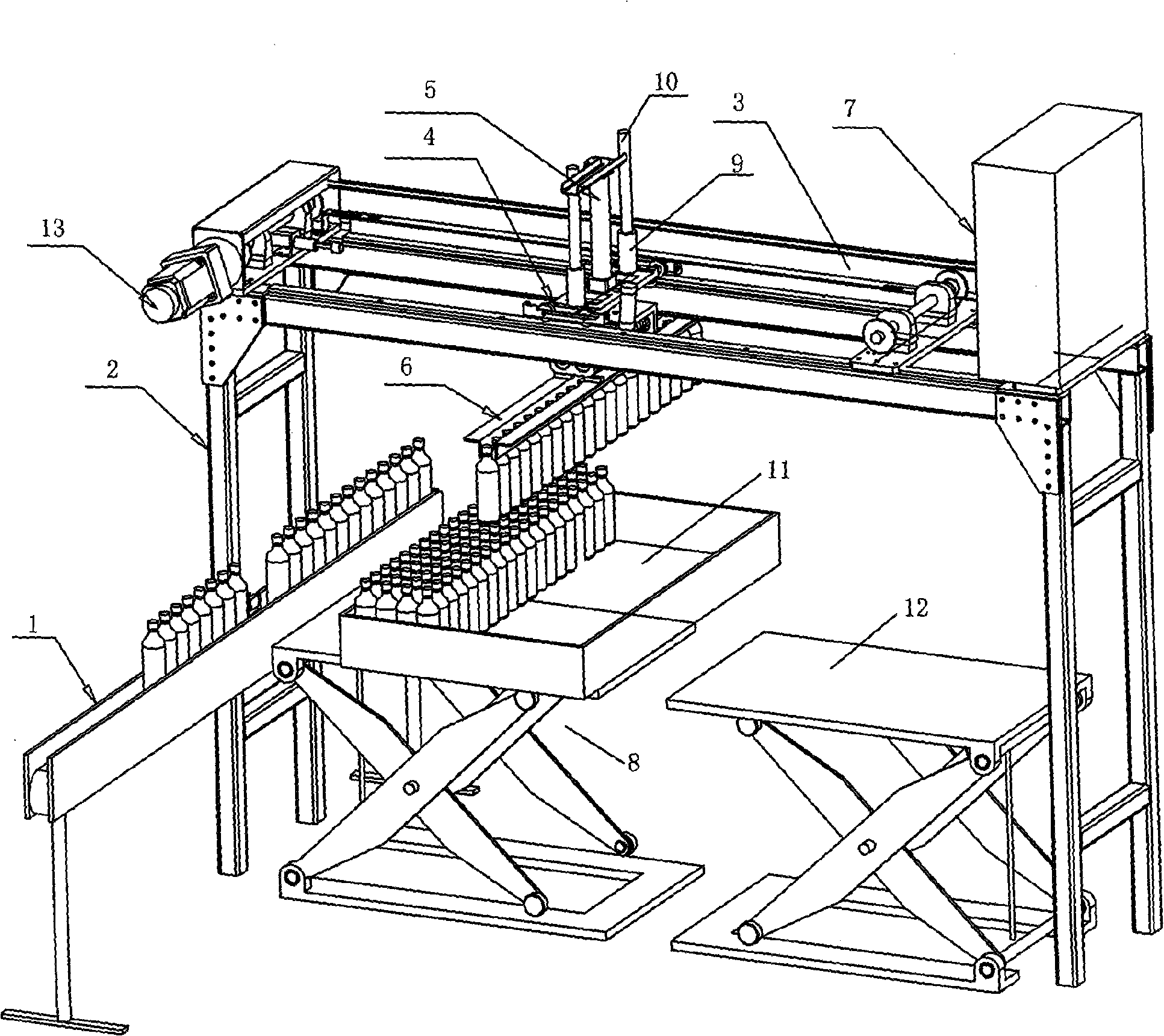

[0031] Refer to attached figure 1 , the invention discloses a plastic soft bottle automatic collecting and sorting machine, which includes a conveyor 1 for filling plastic bottles, soft bottles or soft bags, a frame 2, and a horizontally moving traction device 3 is arranged above the frame 2. The mobile trolley 4 of the traction device 3 is provided with a bottle clamping device 6 connected through the lifting cylinder 5, and the electric control device 7 with electric automation control is connected on the traction device 3, the lifting cylinder 5 and the bottle clamping device 6. A product collection device 8 is provided below the frame 2 next to the conveyor 1. The electronic control device 7 controls the bottle clamping device 6 to move vertically up and down under the drive of the lifting cylinder 5, and controls the bottle clamping device 6 to move up and down in a vertical direction. Driven by the traction device 3, it moves horizontally, and controls the clamping devic...

Embodiment 2

[0033] On the basis of Embodiment 1, a guide device is provided on the mobile trolley 4 of the frame 2, and the guide device includes a guide sleeve 9 fixed on the mobile trolley 4 and a guide shaft 10 cooperating with the guide sleeve 9. The guide shaft 10 is loosely matched with the guide sleeve 9, and runs through the mobile trolley 4 and is fixedly connected with the bottle clamping device 6. There are two guiding devices, which are symmetrically arranged on both sides of the lifting cylinder 5. The center line of the guiding device is parallel to the center line of the lifting cylinder 5, and through the compensation of the floating joint, the lifting caused by the parallel error can be overcome. Movement hindrance. The product collecting device 8 includes a product collecting tray 11 and a hydraulic lifting platform 12 , and the product collecting tray 11 is installed on the hydraulic lifting platform 12 .

Embodiment 3

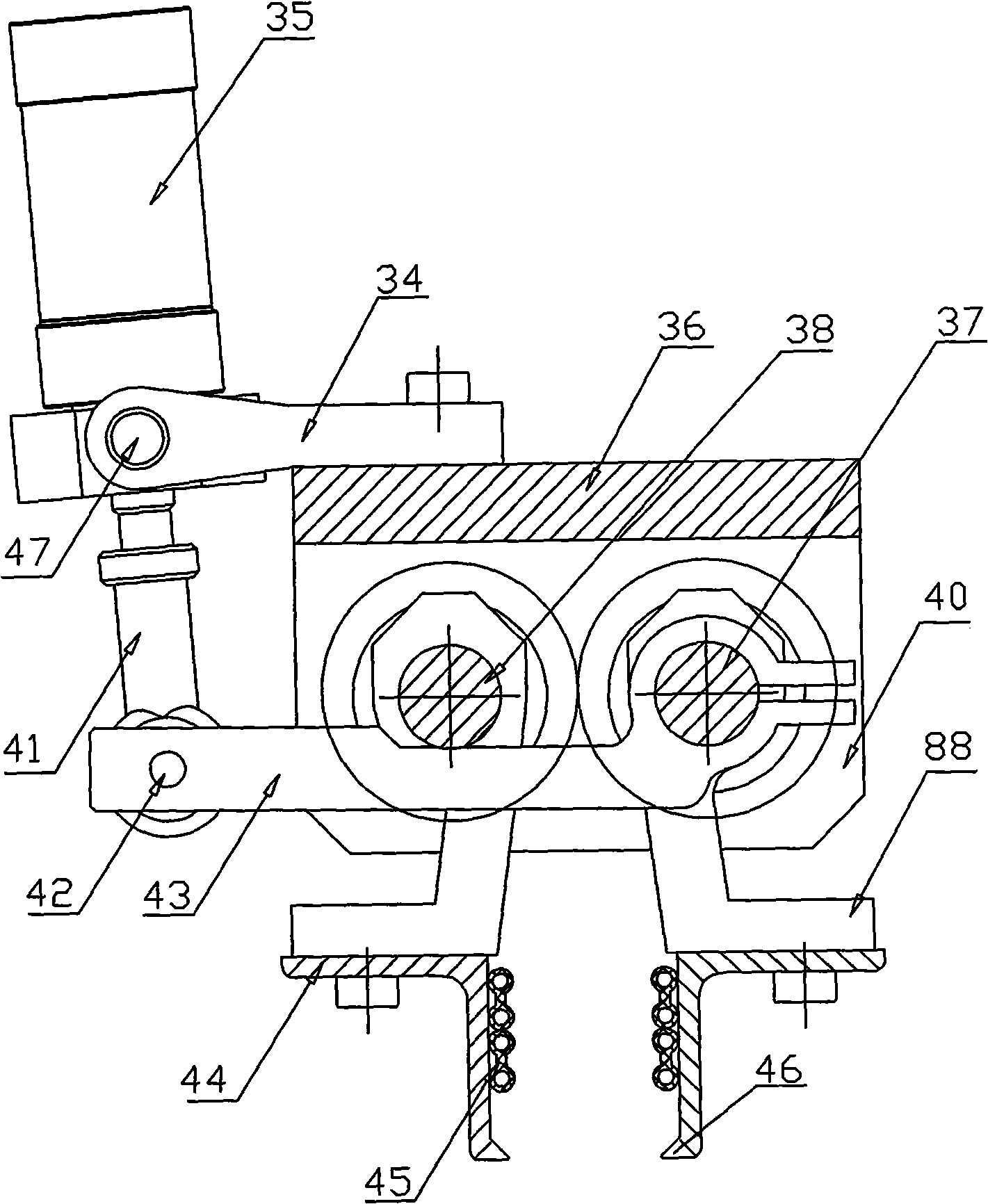

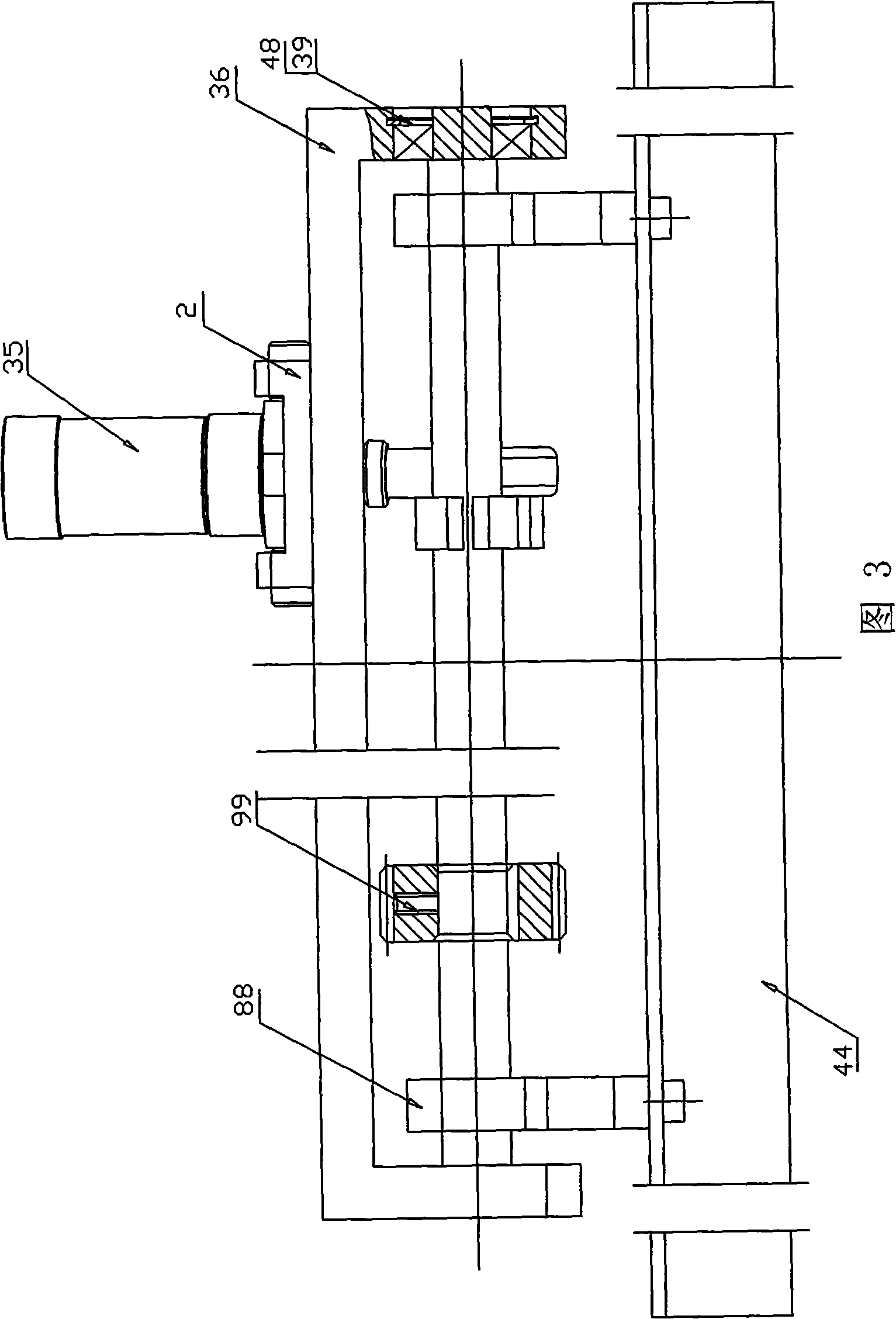

[0035] With reference to accompanying drawings 4 and 5 of the description, on the basis of embodiment 1 or / and 2, the traction device 3 includes a servo motor 13, and the drive shaft 14 driven by the servo motor 13 is arranged at two ends of the drive shaft 14. A driving sprocket 15 and a traction chain 16 meshed with the driving sprocket 15, two traction chains 16 are respectively connected with the two ends of the mobile trolley 4 through the connector 17, and the opposite end of the driving shaft 14 is provided with a driven shaft 18. The traction chain 16 is meshed with the driven sprocket 19, and the connecting piece 17 is fixed to the moving trolley 4 through the traction fixing frame 20. Between the traction fixing frame 20 and the four corners near the moving trolley 4, Translation bearing 21, described translation bearing 21 is fixed on the translation support shaft 22, and translation support shaft 22 and mobile trolley 4 ends are fixed through self-contained screw th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com