Automatic accurate positioning method for large workpiece

A technology for precise positioning and large workpieces, applied in the direction of using feedback control, etc., can solve the problems of difficult to achieve automatic precise positioning requirements, difficult to ensure positioning accuracy, difficult to operate, etc., to achieve convenient measurement, easy promotion and application, and ensure processing quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the technical means, creative features, work flow, and use methods of the present invention achieve the purpose and effect easily understood, the present invention will be further described below in conjunction with specific embodiments.

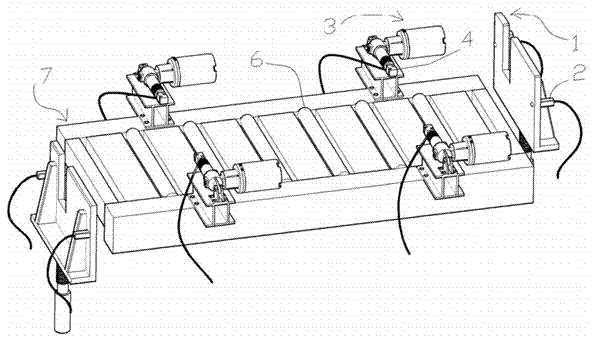

[0024] figure 1 Shown is a schematic structural diagram of a platform device of a specific example of the present invention. As shown in the figure, the platform 7 includes: a roller table 6, which is used to transmit the workpiece 5 placed on the platform; a limit switch 2 is installed in the baffle plate 1, and the workpiece touches the limit switch to obtain the axial position positioning of the workpiece Signal: The four push rod systems include the servo motor 3 and the push rods connected together. The push rod system is driven by the servo motor, and the radial position of the workpiece on the platform is moved forward by driving the push rod. There is a pressure sensor 4 in front of the push rod, which can ob...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com