Patents

Literature

196results about How to "Improve processing progress" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

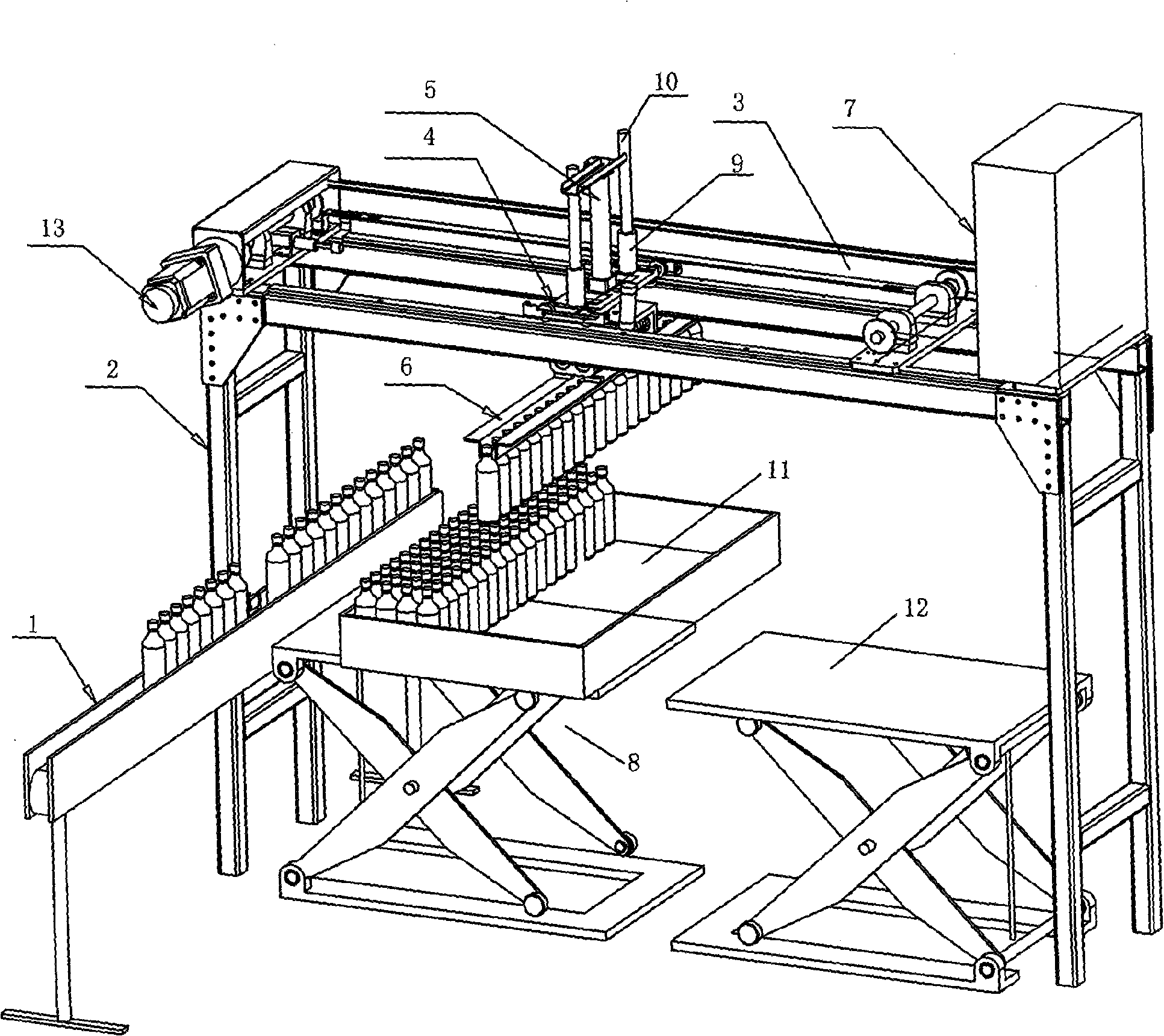

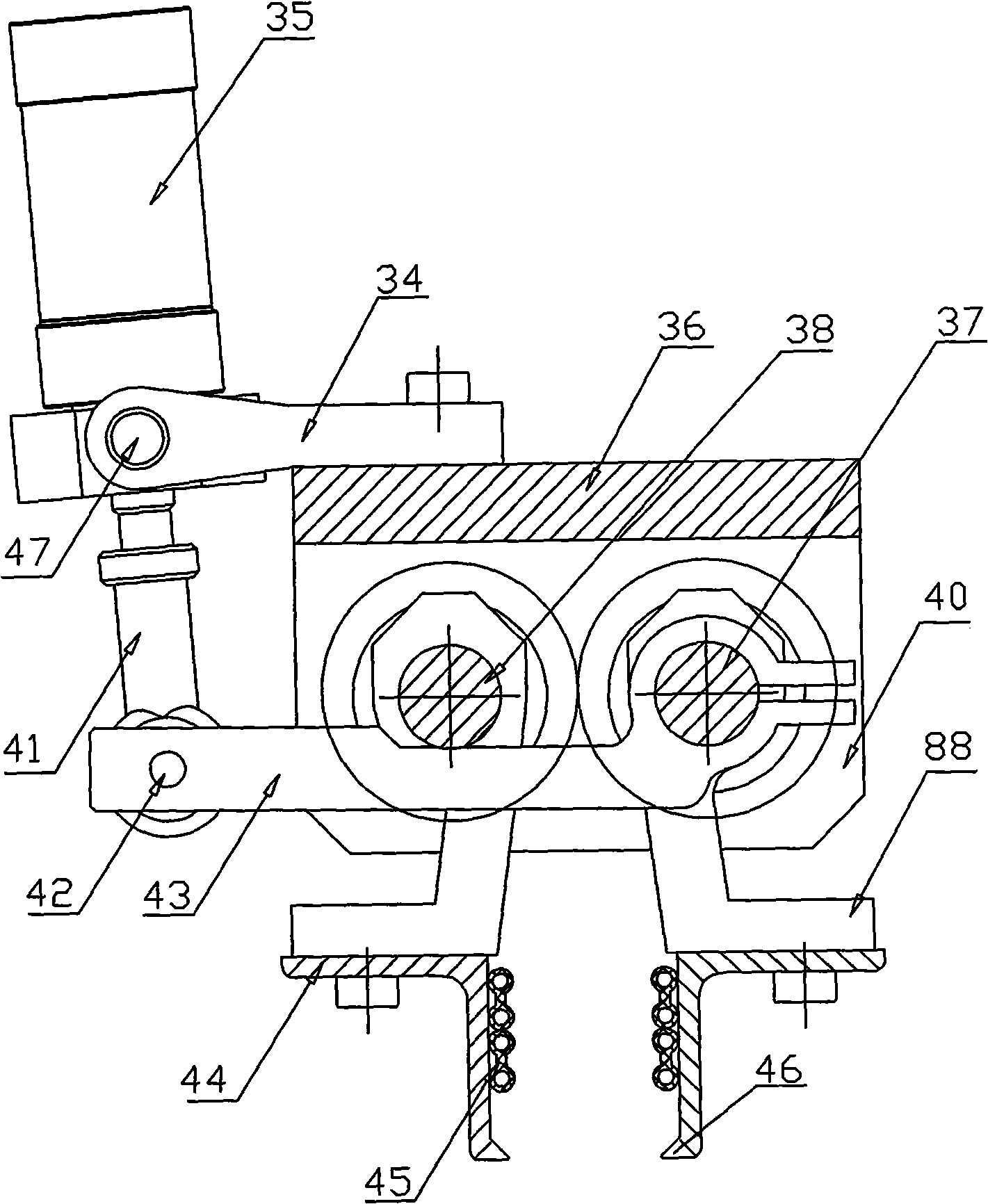

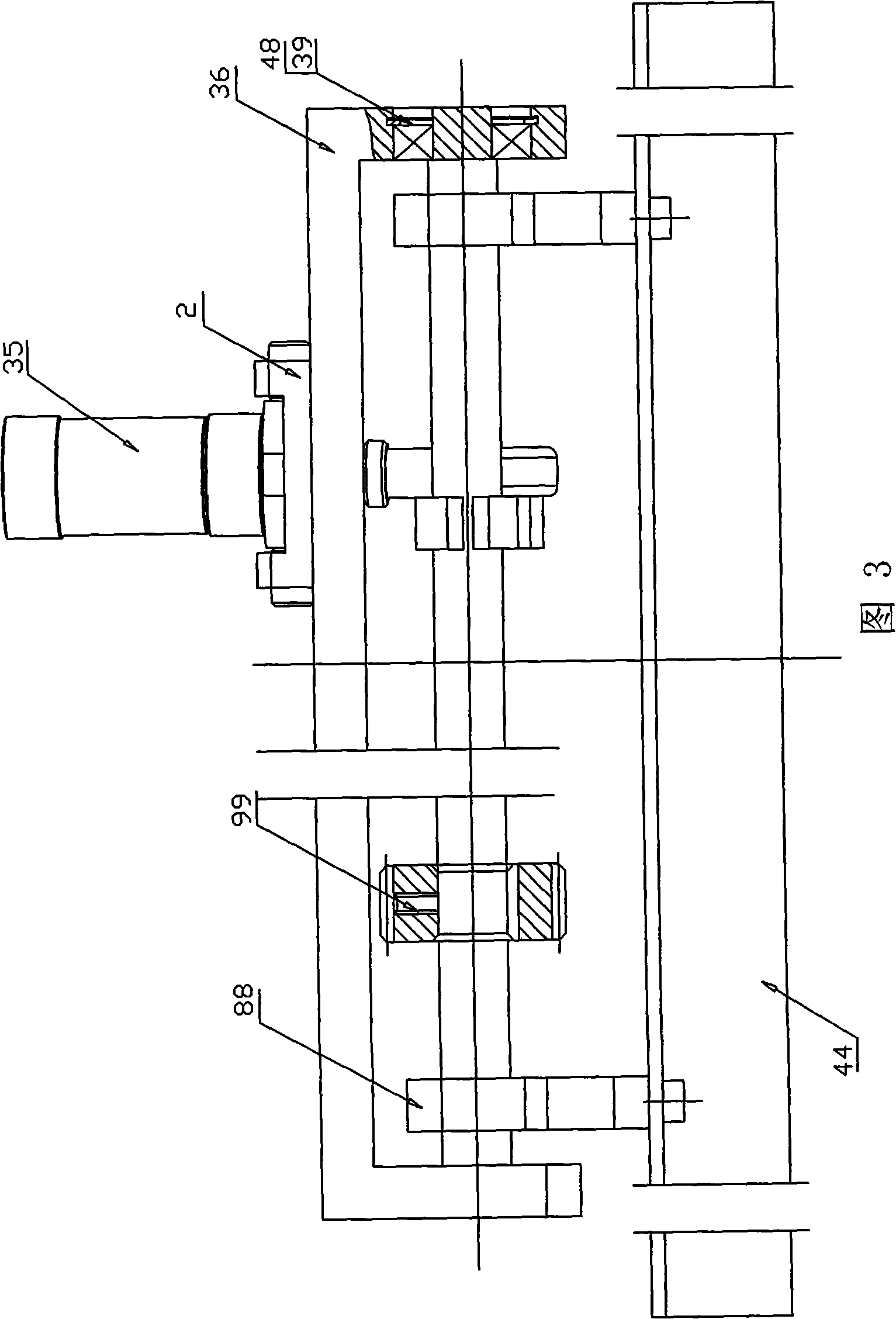

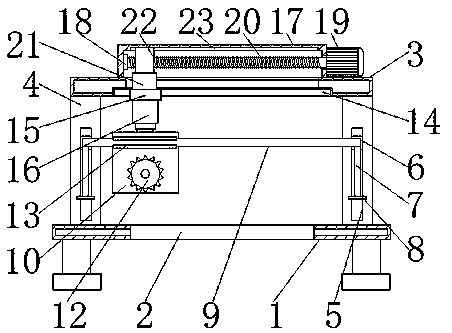

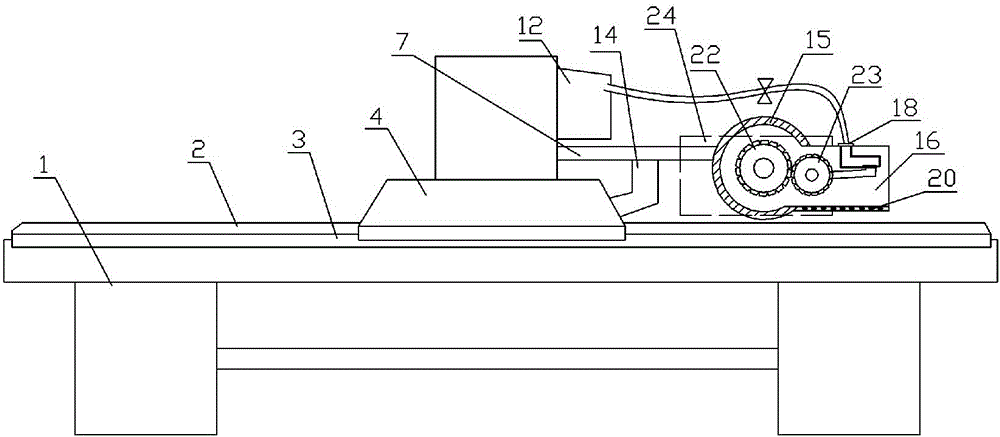

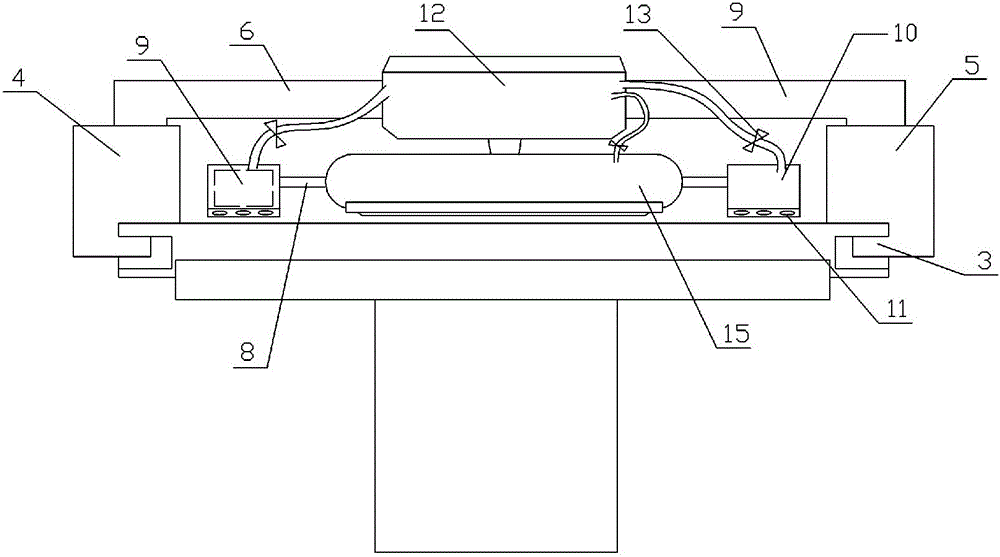

Automatic collecting and arranging machine for plastic soft bottle

ActiveCN101327851AImprove processing progressRealize the collectionProgramme-controlled manipulatorGripping headsAutomatic controlEngineering

The invention discloses an automatic machine for collecting and sorting plastic soft bottles. The device comprises a conveyor for plastic bottles, soft bottles or soft bags, as well as a machine frame, wherein a traction device moving horizontally is arranged above the machine frame; a bottle clamping device connected via a lifting cylinder is arranged on a moving trolley of the traction device; the traction device, the lifting cylinder and the bottle clamping device are connected with an electric control device with electrical automatic control; a product collecting device is arranged below the machine frame beside the conveyor; and the electric control device controls the bottle clamping device to make vertical up-down lifting movement under the drive of the lifting cylinder and to make horizontal translating movement under the drive of the traction device, and controls the bottle clamping device to clamp a product input by the conveyor, to transfer the product to the product collecting device through the lifting cylinder and the traction device and then to unclamp the product. The machine can clamp, lift and translate plastic bottles, soft bottles or soft bags input by the conveyor to a preset distance, drop and put the bottles or bags into the product collecting device.

Owner:SICHUAN KELUN PHARMA CO LTD

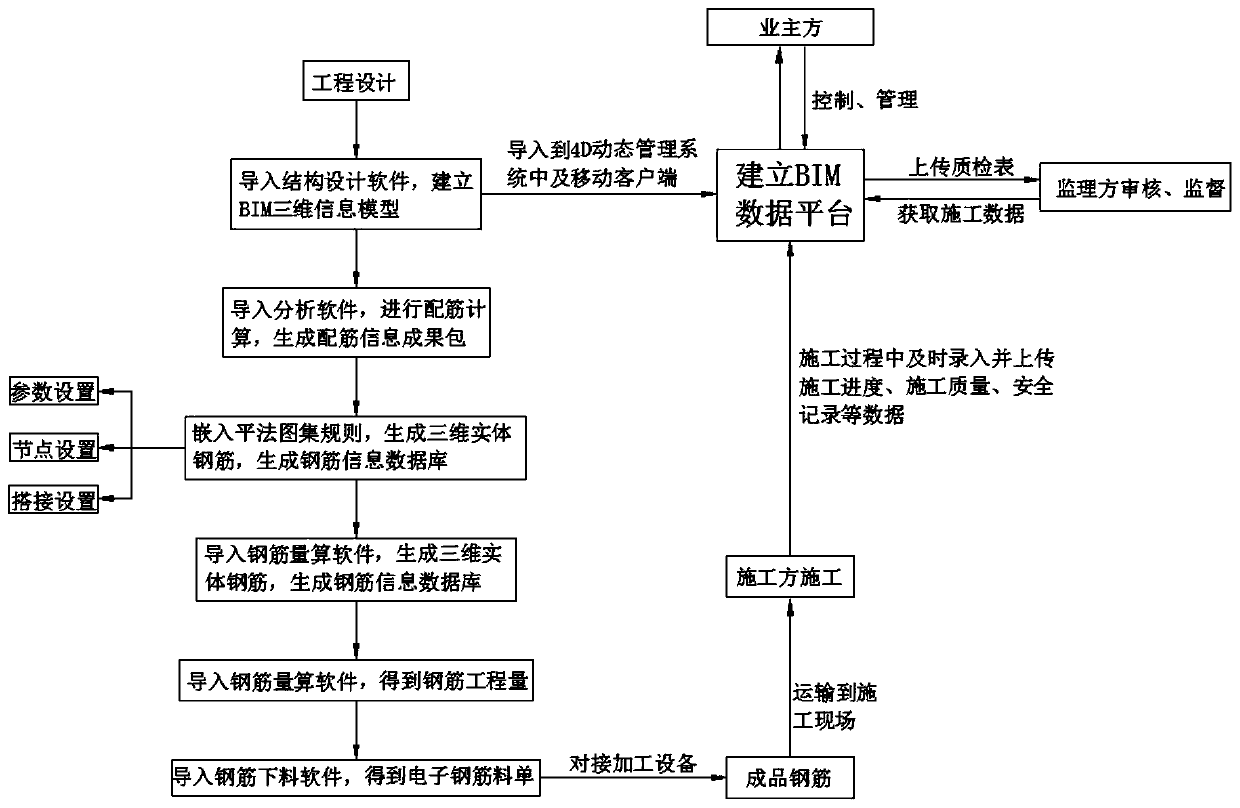

Steel bar information full life cycle management method based on BIM technology

ActiveCN109785436AEasy to manageSave human effortOffice automation3D modellingFull life cycleDesign software

The invention discloses a steel bar information full life cycle management method based on a BIM technology, and belongs to the field of BIM technology application, and the method comprises the following steps: 1, importing structure design software on a BIM platform, and building a BIM three-dimensional information model; And step 2, importing analysis software on the BIM platform to form a component flat reinforcement information achievement package. BIM database platform establishment, the steel bar information can become a database file capable of being inherited and traced; Proprietor, the design party, the construction party and the supervision party are taken as application participants of the BIM system; The comprehensive project management system is operated through the Web browser and the mobile client, the construction transparency is improved, the proprietor unit, the supervision unit, the construction unit and the like can timely and accurately know the quality, safety andprogress of a construction site, it is ensured that a project is smoothly carried out, and information is provided for full-life-cycle information management of steel bars.

Owner:广东星层建筑科技股份有限公司

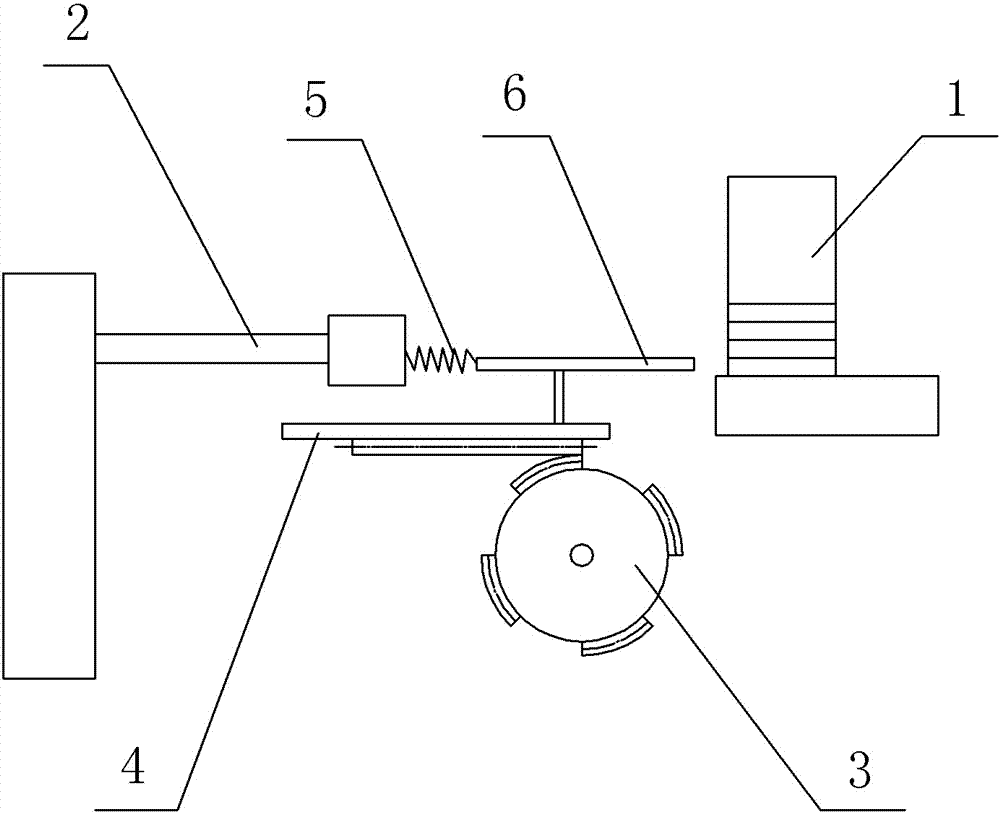

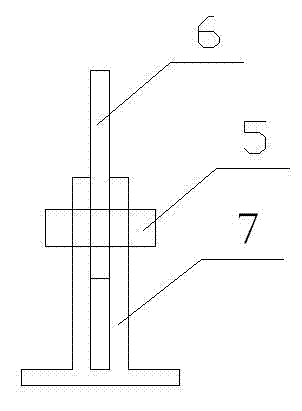

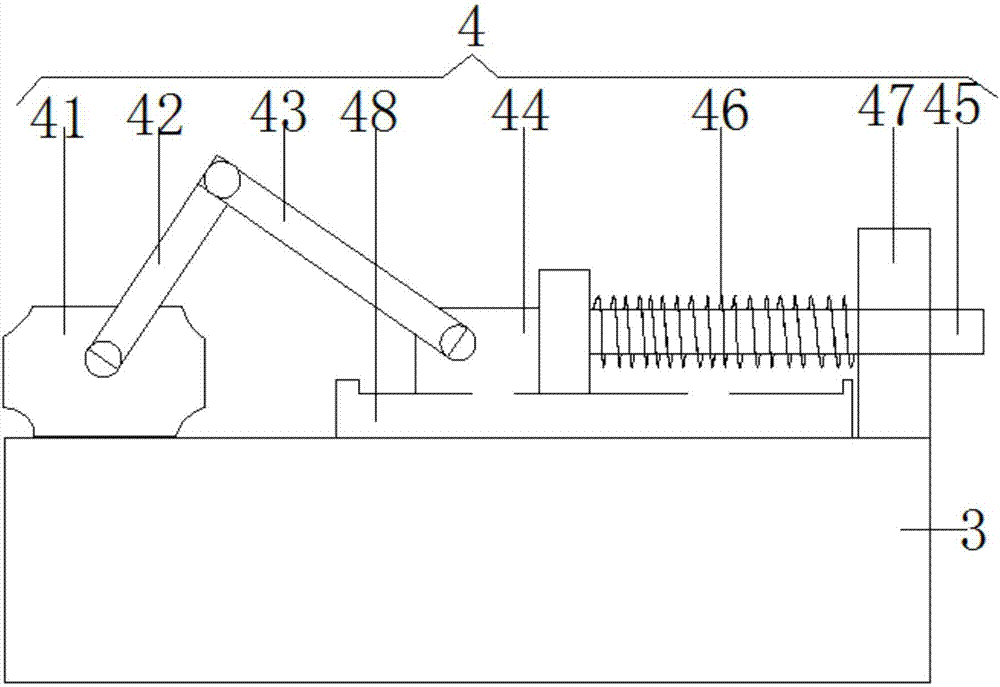

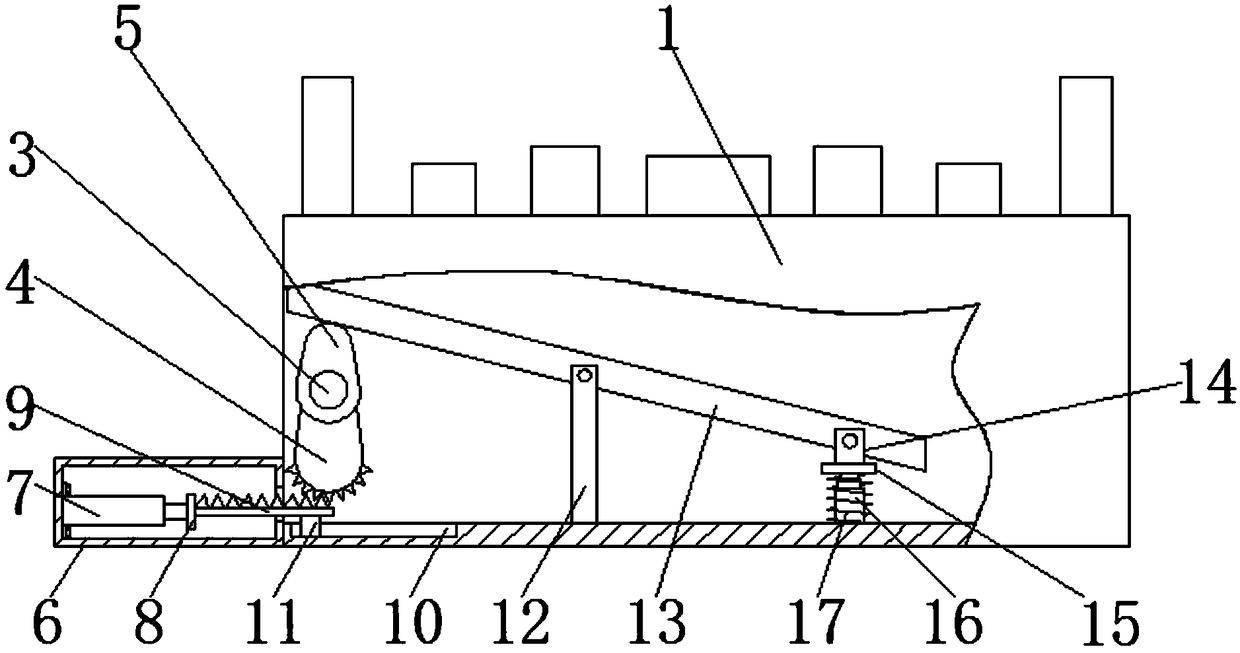

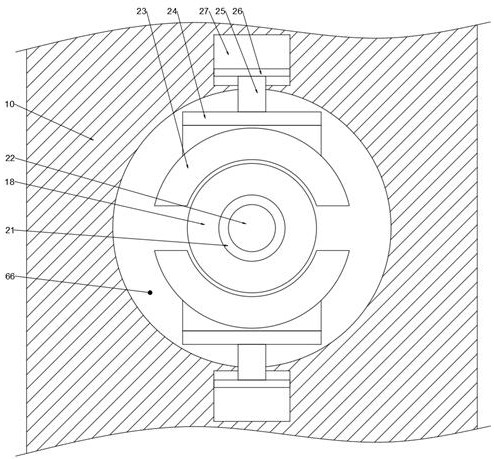

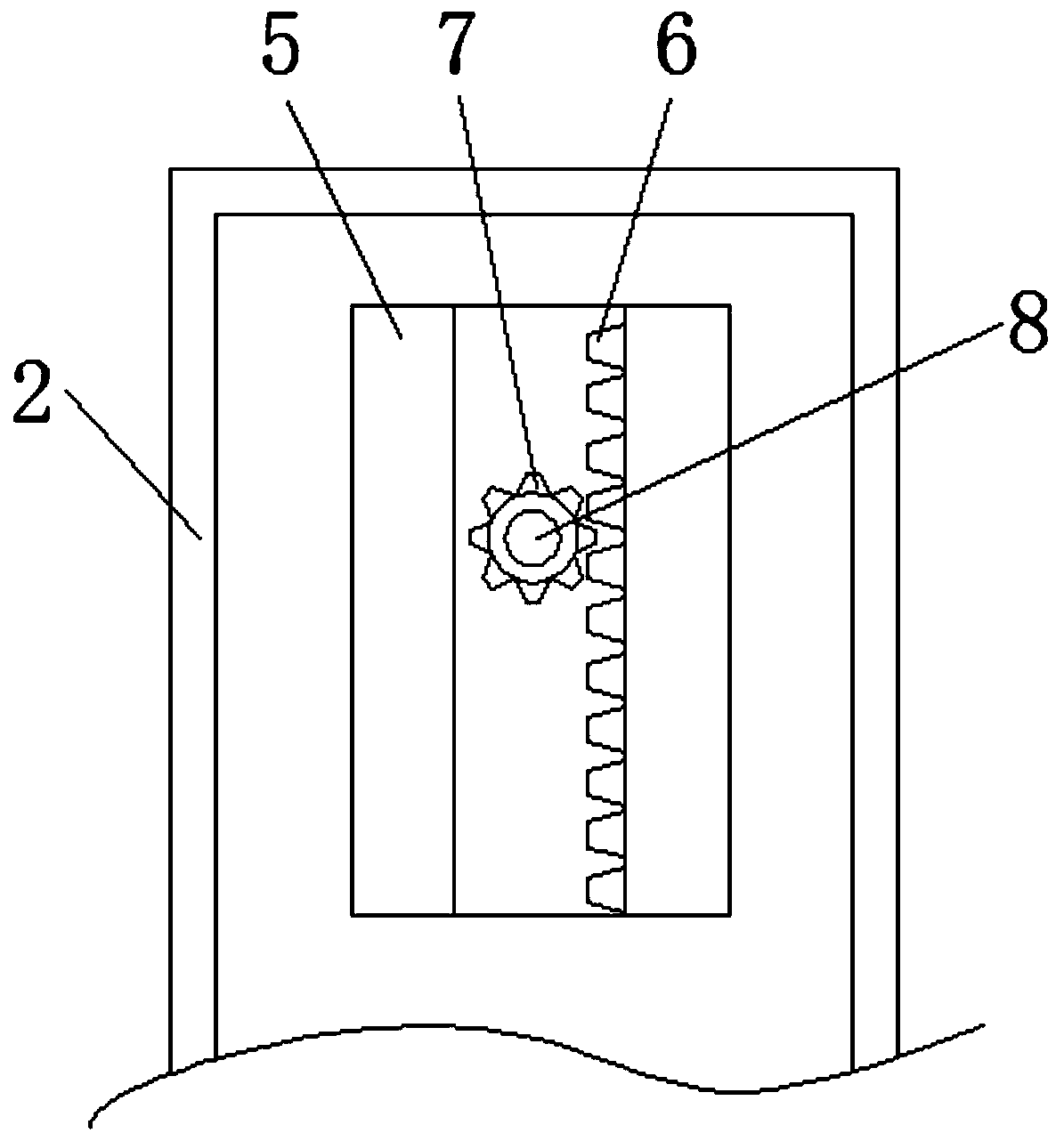

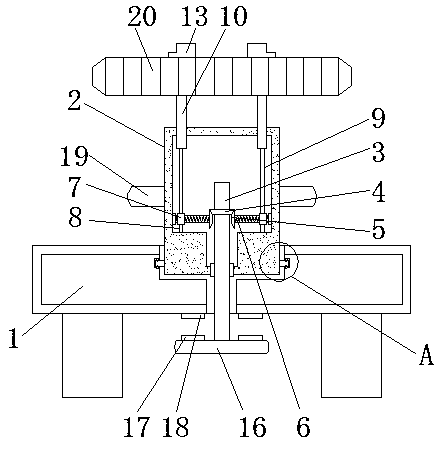

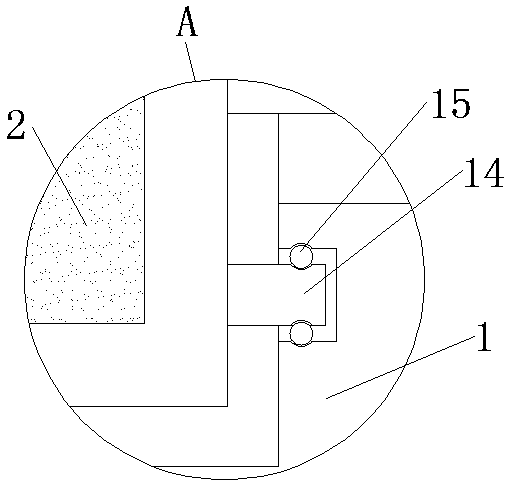

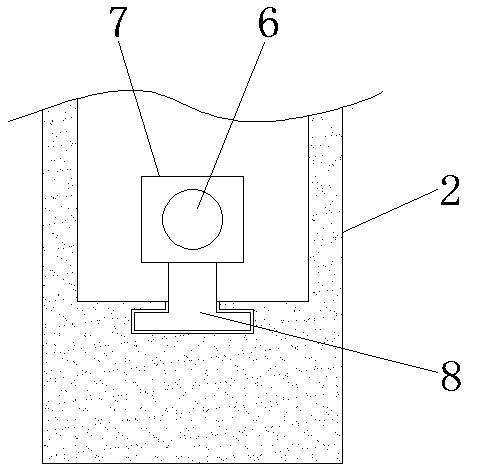

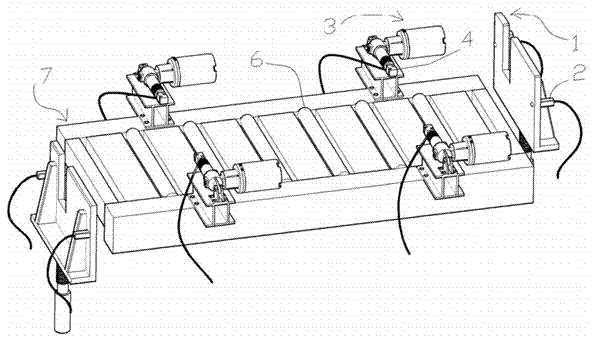

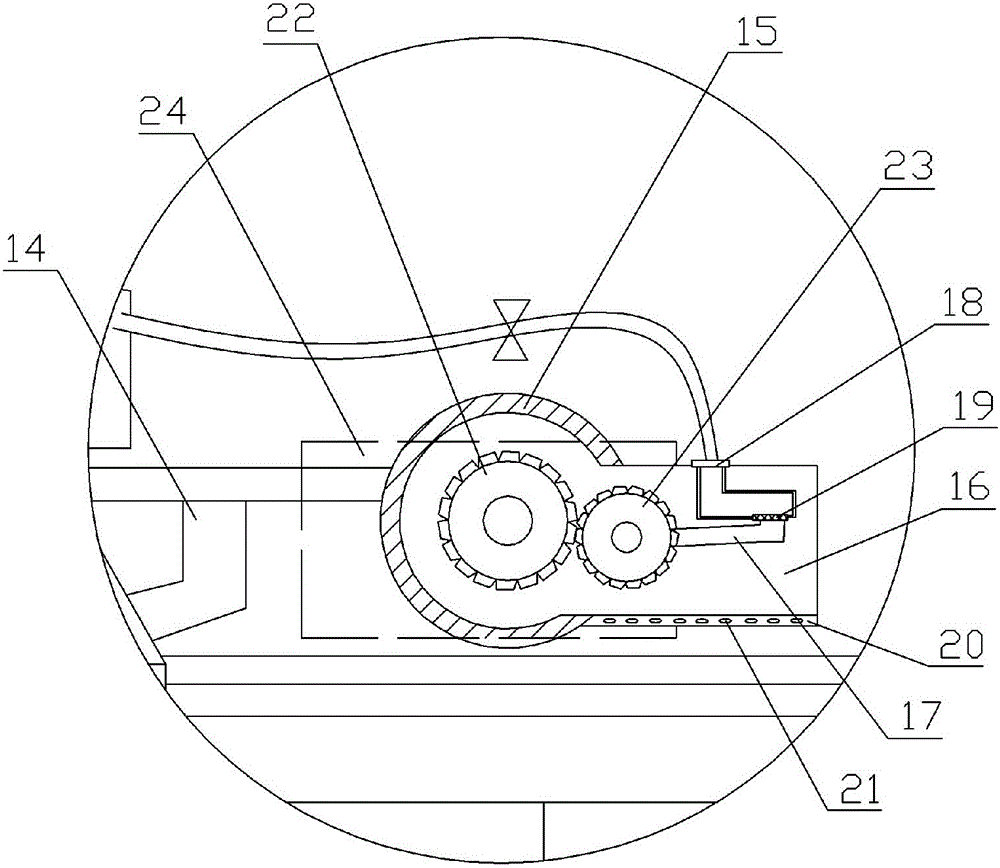

Feeding device

InactiveCN103754632AImprove work efficiencyImprove processing progressConveyor partsEngineeringMechanical engineering

The invention discloses a feeding device. The feeding device comprises a push rod, a base, a tooth missing gear as a force application device, and a drive rod with a rack, wherein a plurality of tooth missing sections are arranged on the tooth missing gear, the tooth missing gear is driven by a motor and engaged with the rack on the drive rod, the drive rod is connected with the push rod, and the push rod is connected to the base through a return spring. The feeding device is capable of realizing multiple reciprocating actions by virtue of the plurality of tooth missing sections as the gear rotates by one circle, and therefore, the working efficiency of the feeding device is improved and the processing progress is accelerated.

Owner:CHONGQING MING SHIELD ELECTROMAGNETIC VALVE

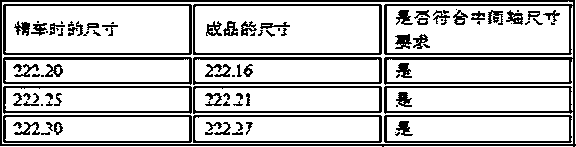

Middle shaft machining technology

InactiveCN103624503AGuaranteed size fluctuationsReduce processVehicle componentsMachining processMachining time

The invention discloses a middle shaft machining technology. The middle shaft machining technology comprises the steps of blanking, forging, isothermal normalizing, finish turning, tooth manufacturing, spline rubbing, hole drilling, heat treatment, straightening, external grinding, cleaning, finished product detecting, and packaging and storing, wherein the length of blanks is turned into 222.2-222.3mm in the step of finish turning. According to the technology, the length of the blanks is turned into 222.2-222.3mm before heat treatment, working allowance of secondary finish turning is not reserved, a workpiece is made to reach the requirements of the size and beats of a middle shaft only through one time of finish turning before the heat treatment, and secondary finish turning is not needed, so that the machining processes of the middle shaft are reduced, middle shaft machining time is shortened, the middle shaft machining progress is quickened, and production efficiency is improved.

Owner:CHONGQING YUQING MACHINERY MFR

Steel plate crankle processing technology and special apparatus thereof as well as crankle component processing technology

The invention belongs to the field of steel-structure component processing, and in particular relates to steel plate crankle processing. According to the steel plate crankle processing technology, a plate is arranged in a single-side fixed dual-hinge-shaft bending apparatus; a hydraulic apparatus performs single-point pushing; a fixture rotates around a rotary hinge shaft; the pushing is quick atfirst and then slow later and performed gradually by stages; the bending process is corrected by flame in combination with machinery, wherein the flame temperature is 100 DEG C lower than the normal correction temperature; and after the forming, the component is continuously pressurized and laid for 2-3 days. The steel component processing technology provided by the invention is different from the common steel structure processing technology that the coordinate points are controlled according to the elevation section for blanking, and the hydraulic apparatus cooperates with a special apparatus and the steel plate after blanking is subjected to single-point bend forming, thereby guaranteeing the forming quality of the crankled component and realizing high processing speed.

Owner:DALIAN BRANCH OF CHINA CONSTR EIGHTH ENG DIV CORP

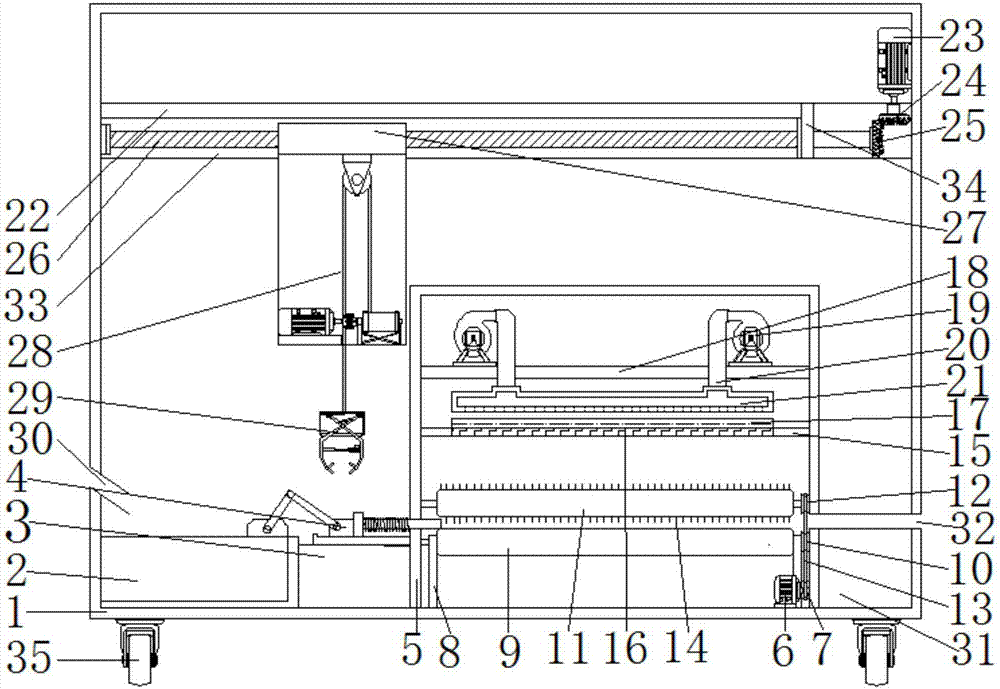

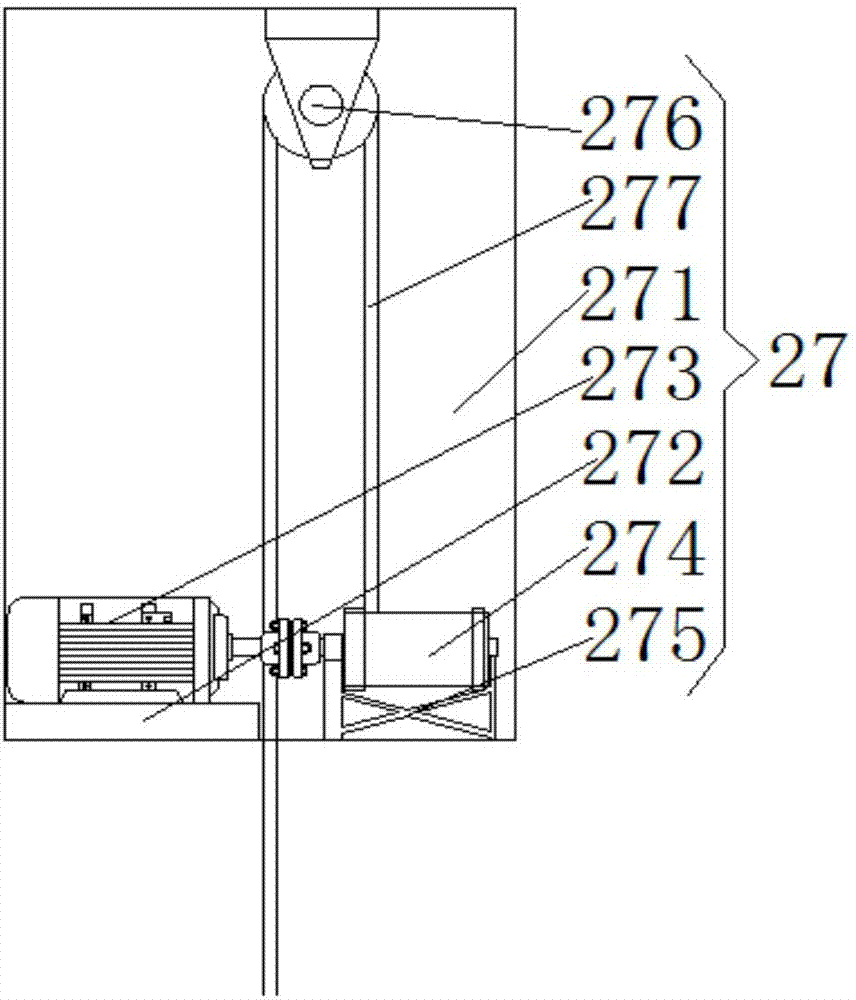

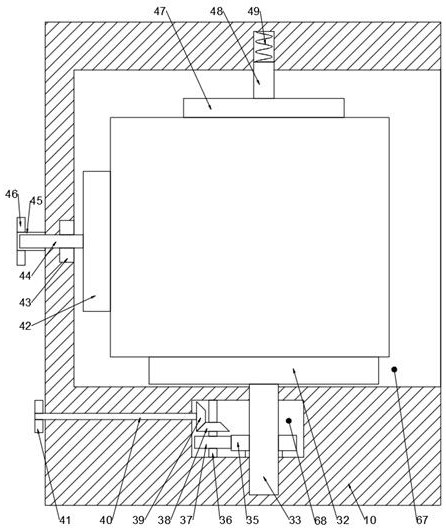

Automatic drying device for bamboo toy processing

InactiveCN107388792AImprove processing progressIncrease productivityDrying gas arrangementsDrying machines with progressive movementsCouplingProduction chain

The invention relates to the technical field of bamboo processing and provides an automatic drying device for bamboo toy processing. The automatic drying device for bamboo toy processing comprises an outer box. A discharging device is fixedly connected to the top of a support platform. A heating device is fixedly connected to the top of a first support plate. An air outlet of an air blower communicates with an air supply opening through a pipeline. An output shaft of a second motor is rotationally connected with a first circular cone bevel gear through a coupling. The inner surface of a second circular cone bevel gear is fixedly connected with a roller lead screw through a flat key. A threaded sliding block is connected to the outer surface of the roller lead screw in a threaded manner. A lifting device is fixedly connected to the bottom of the threaded sliding block. A clamping device is fixedly connected to the bottom of the lifting device. By the adoption of the automatic drying device, automatic feeding can be achieved, the automatic drying device is connected with other processing equipment, the processing and production chain is complete, the processing speed is increased, the production efficiency is improved, workpeices are dried quickly, the time is saved, the cost is lowered, the automatic discharging is achieved, the automatic operation is adopted in the whole process, no manual operation is needed, and the personal safety is protected.

Owner:安吉县怡成竹木工艺品厂

Automobile stamping die with vibrating material-sliding function

InactiveCN108326182AWith vibration and sliding functionSolve the problem of not having the function of vibrating and sliding materialStripping-off devicesSlide plateEngineering

The invention discloses an automobile stamping die with a vibrating material-sliding function. The automobile stamping die comprises a stamping die body. The front side and the rear side of the left side of an inner cavity of the stamping die body are both fixedly connected with bearings, a cylinder is connected between the two bearings in a sleeved mode, the center of the surface of the cylinderis sleeved with a tooth disc, and the positions, located on the front side and the rear side of the tooth disc, of the surface of the cylinder are sleeved with cams correspondingly. The bearings, thecylinder, the tooth disc, the cams, a shell, an electric telescopic rod, a connecting plate, a push rod, a sliding groove, a sliding block, supporting rods, sliding plates, movable blocks, fixed plates, telescopic rods and springs are arranged and mutually matched, so that the problem that an existing stamping die does not have the vibrating material-sliding function is solved; when the stamping die body is used, the condition that blockage occurs during discharging of waste materials can be avoided through the vibrating sliding plate, accordingly, a large amount of the time of a user is saved, the progress of automobile part machining is accelerated, and therefore using by the user is facilitated.

Owner:郑州东青信息科技有限公司

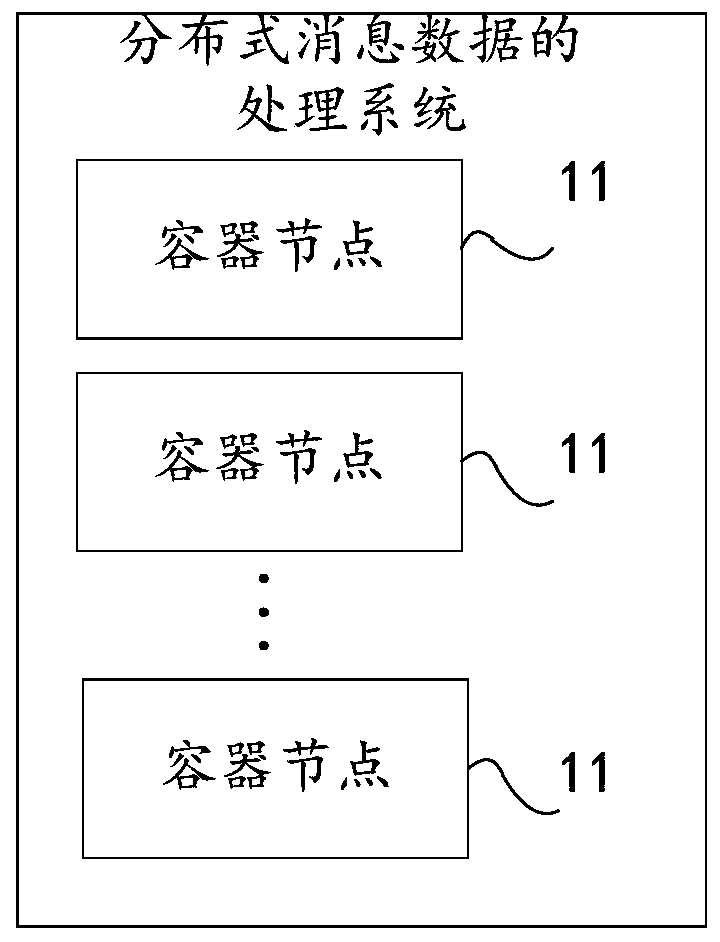

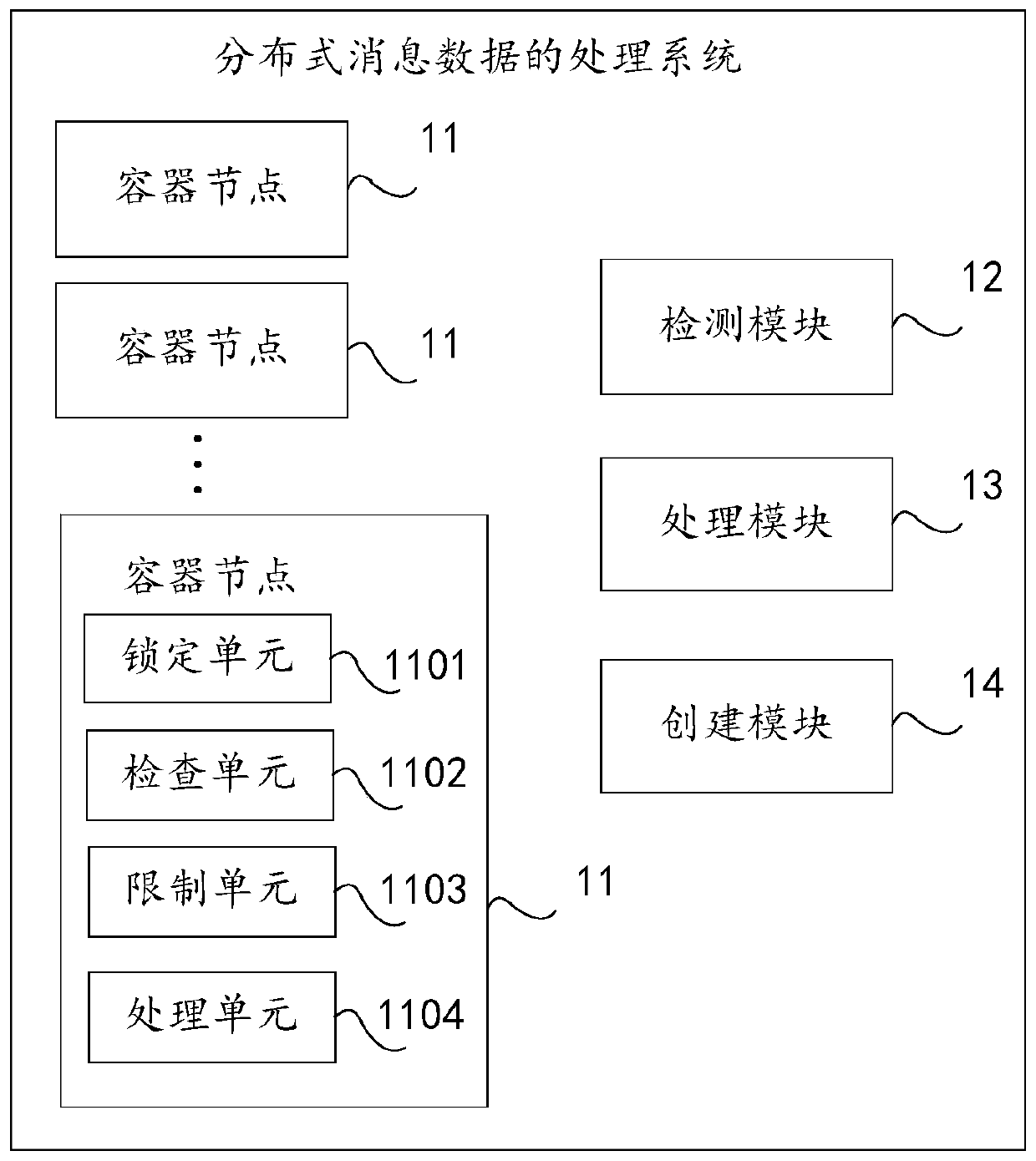

Distributed message sending processing system and processing method thereof

ActiveCN111245900AImprove processing progressImprove sending efficiencyInterprogram communicationTransmissionThe InternetHigh availability

The invention discloses a distributed message sending processing system and a processing method thereof, and relates to the technical field of the Internet. The system comprises at least one containernode used for carrying out distributed sending processing on message data to be sent and processed, wherein each container node can start at least one thread to obtain the message data for distributed sending processing. The number of container nodes in the processing system and the number of threads correspondingly started by a single container node can be dynamically adjusted according to the message amount of message data to be sent and processed. The method can greatly improve the processing progress of a large amount of to-be-sent message data, improves the sending efficiency of the message data, and achieves the timely information interaction with a user. The purpose of integrating message sending is achieved, and high availability, high performance and data consistency of a messagesending system are guaranteed. The method is suitable for distributed processing of the message data.

Owner:北京水滴科技集团有限公司

Processing method of Mao bamboo rotary slice

A technology for spin-cutting bamboo to obtain bamboo fly includes such steps as installing cutter blade, cutting short, shaping, peeling, making conic clamper, fixing and spin-cutting. Its advantages are high utilization rate of bamboo, low cost and high productivity.

Owner:胡正仁

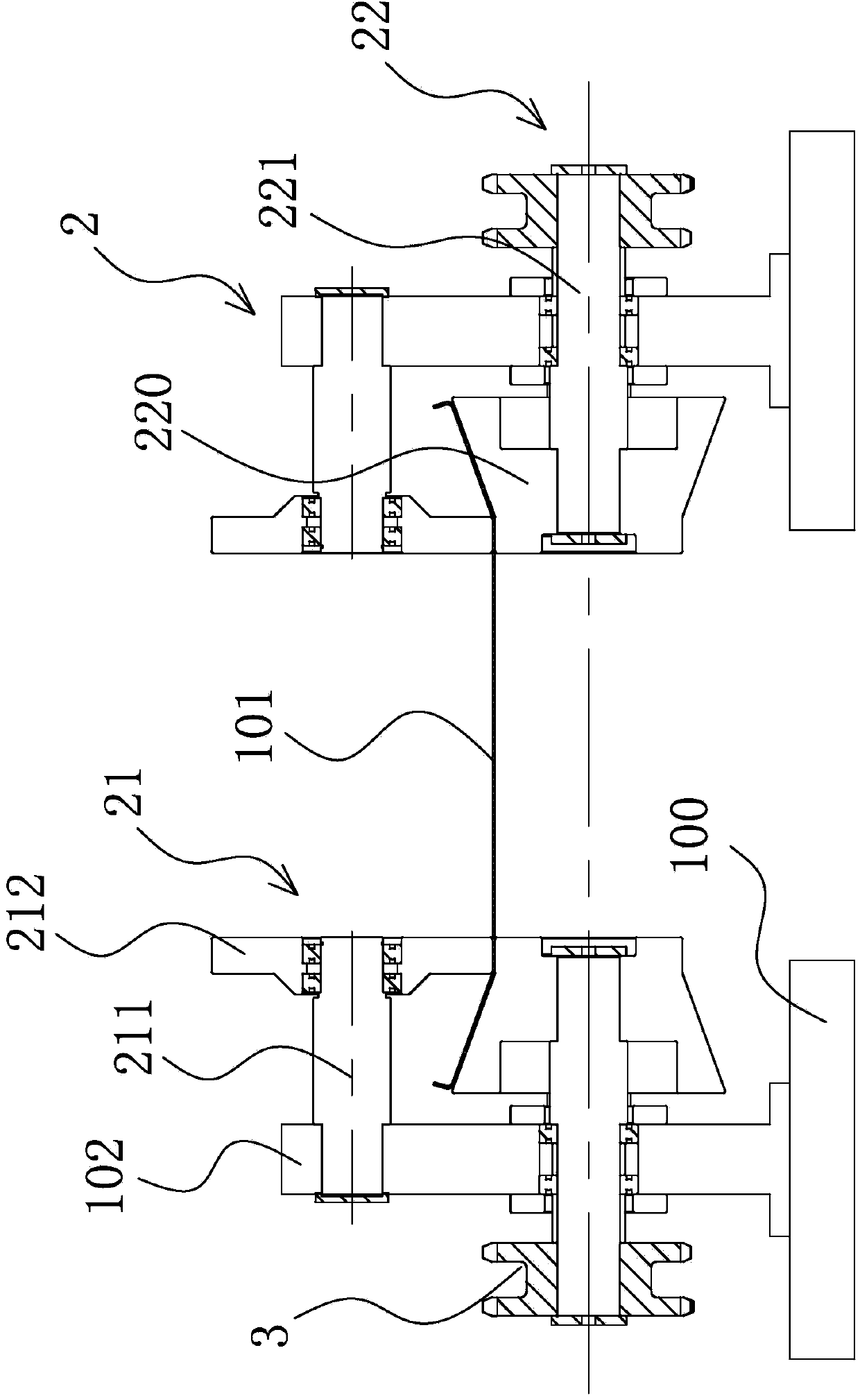

Double-station clamp for engine support bracket

InactiveCN108705341AShorten clamping positioning timeReachable detachable installationPositioning apparatusMetal-working holdersEngineeringFlat panel

The invention discloses a double-station clamp for an engine support bracket. The double-station clamp comprises base support legs, wherein a limiting clamp groove is formed in each of a left supportrotating shaft and a right support rotating shaft; a clamping plate is arranged on the side, close to the interior, of each of the left support rotating shaft and the right support rotating shaft; a limiting clamp block is fixedly connected to the side, close to the outside, of each clamping plate; side hold-down mechanisms are fixedly connected to the top of an operation panel and located on twosides of the back side of a front limiting block; and a top end hold-down mechanism is fixedly connected to the position, close to the middle of the back side, of the top of the operation panel. The double-station clamp relates to the technical field of clamps; the clamp and the whole engine support bracket are detachably mounted; the clamping positioning time of the engine support bracket is shortened during processing; the processing and production efficiency is improved; double-station clamping and fixing of the engine support bracket are realized; the processing progress is improved; the distance between double stations is guaranteed; and the stations are prevented from influencing each other during processing.

Owner:安徽永泰汽车零部件有限公司

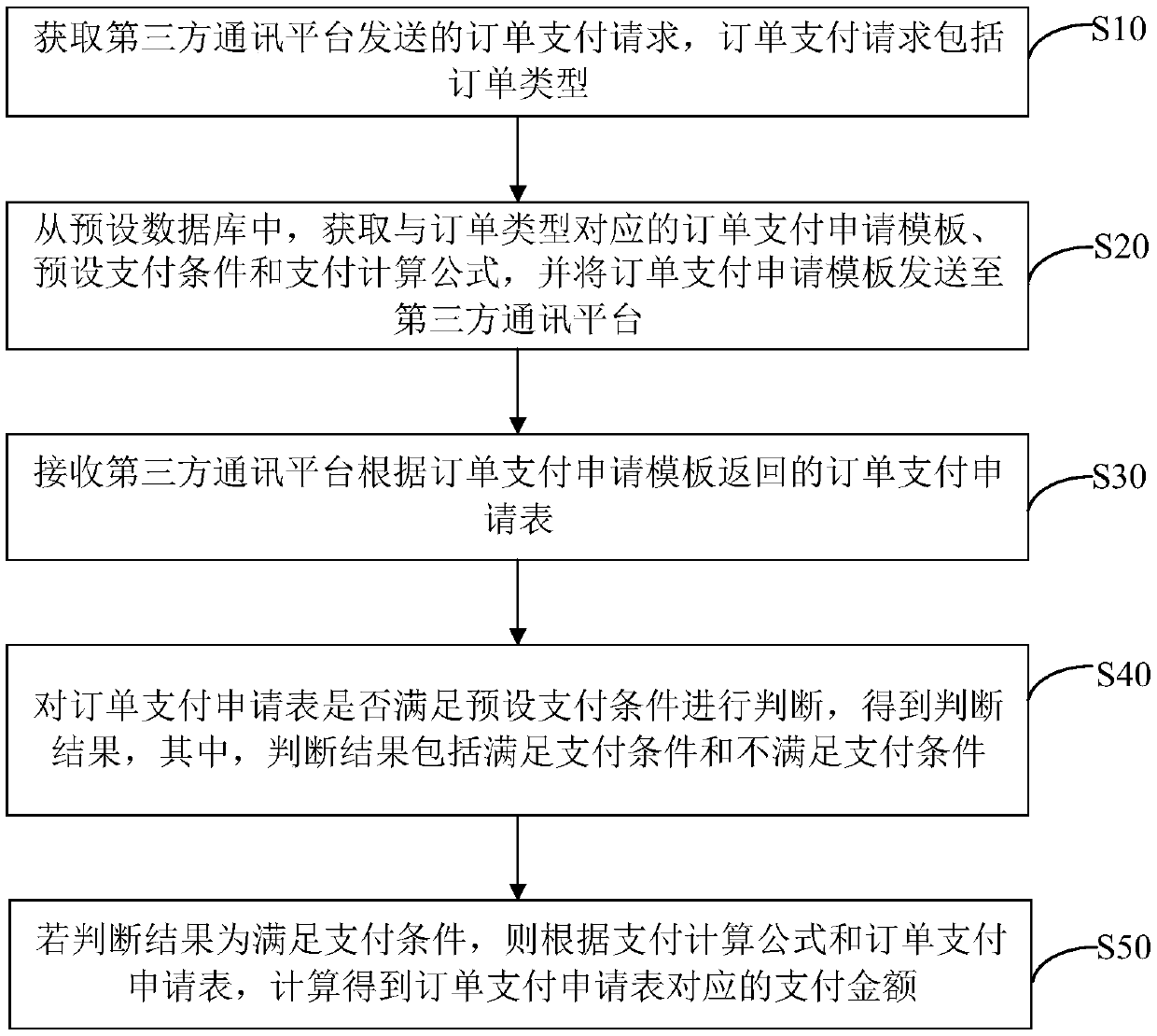

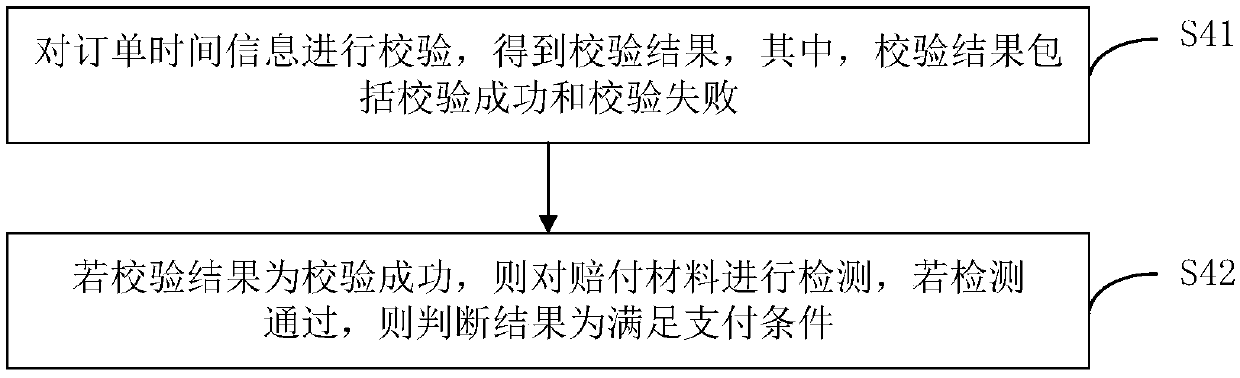

Order processing method and device, computer device and storage medium

PendingCN109544090AImprove processing efficiencyImprove processing progressFinanceOffice automationPaymentThird party

The invention discloses an order processing method and device, a terminal equipment and a storage medium. The method comprises the following steps: obtaining an order payment request sent by a third party communication platform, wherein the order payment request comprises an order type; obtaining an order payment application template corresponding to an order type, presetting a payment condition and a payment calculation formula from a preset database, and sending the order payment application template to a third party communication platform; receiving an order payment application form returned by the third-party communication platform according to the order payment application template; Whether the order payment application form meets the preset payment conditions is judged, and the judgement result is obtained; If it is judged that the payment condition is satisfied, the payment amount corresponding to the order payment application form is calculated according to the payment calculation formula and the order payment application form. The order processing method intelligently examines the order and intelligently pays the order through a third-party communication platform, which improves the order processing efficiency.

Owner:PING AN TECH (SHENZHEN) CO LTD

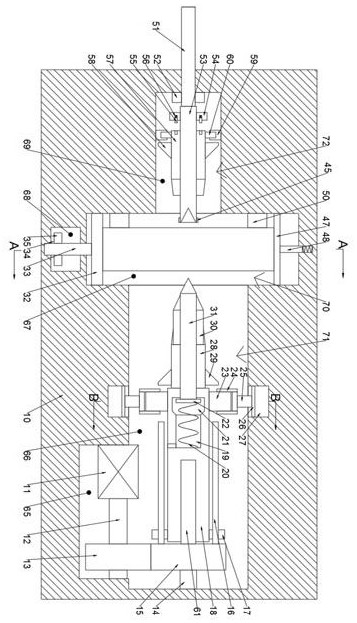

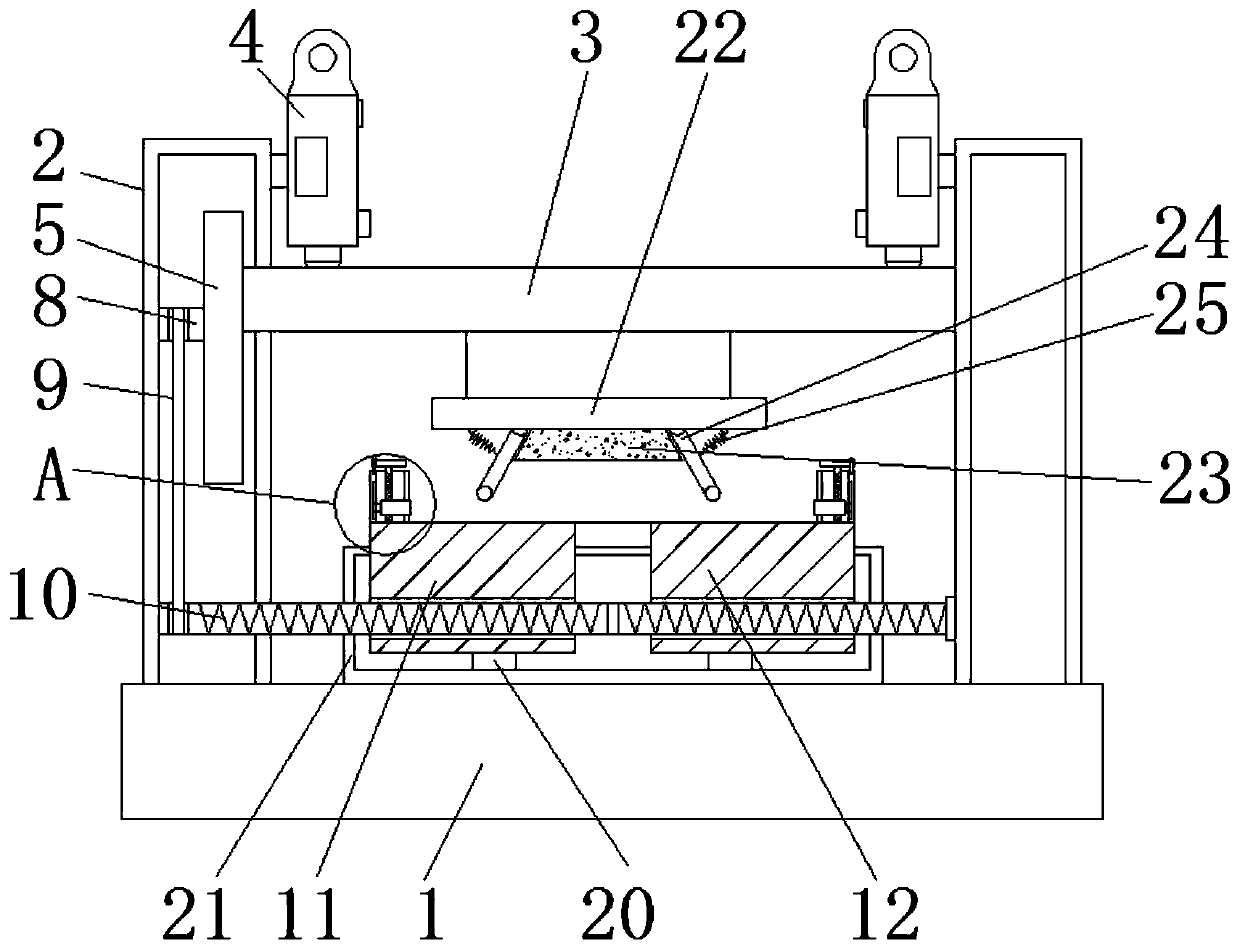

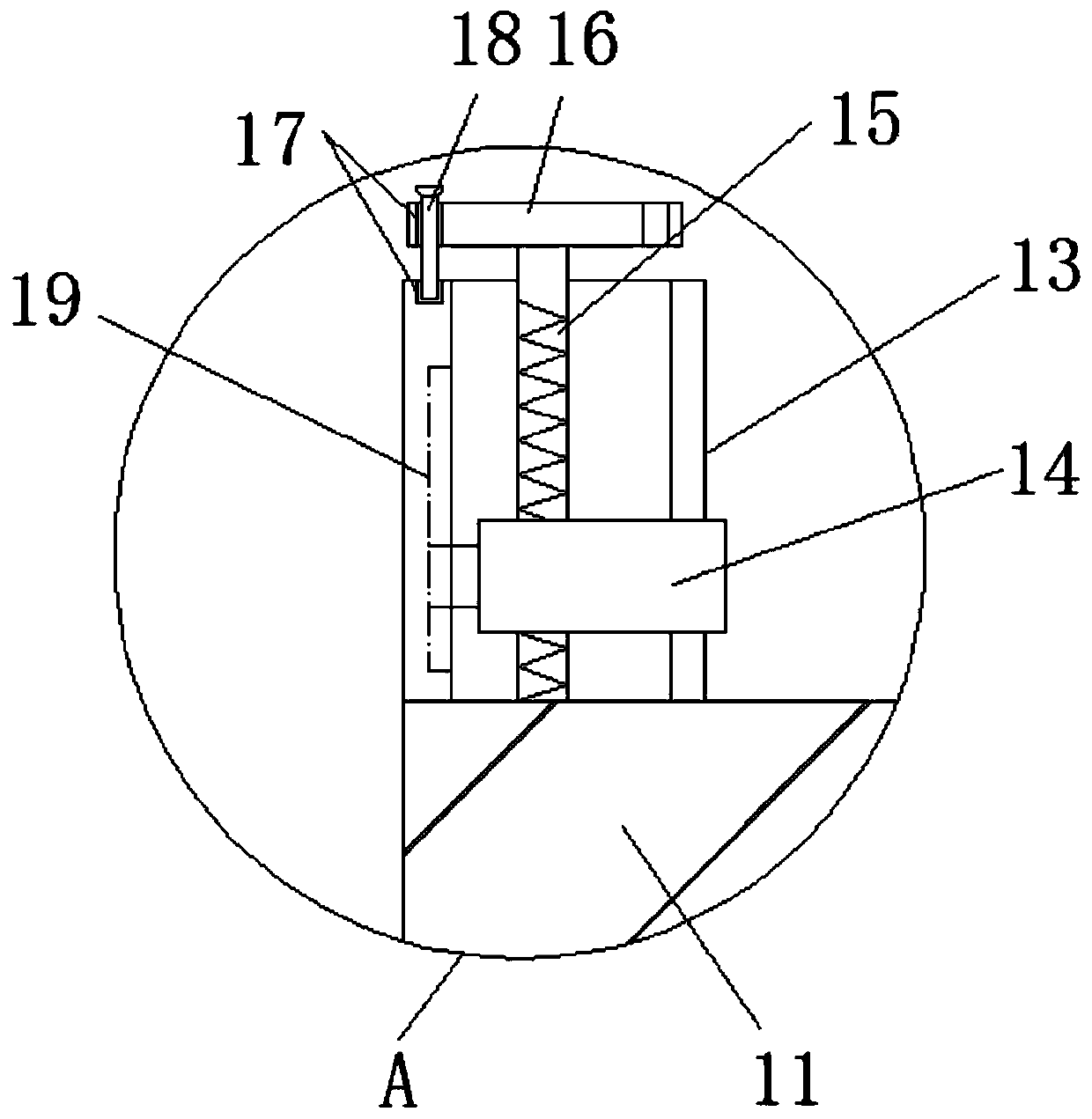

Automatic drilling and grinding equipment for plates

InactiveCN112139823AStable processingHigh precisionOther manufacturing equipments/toolsElectric machineryEngineering

The invention discloses automatic drilling and grinding equipment for plates. The automatic drilling and grinding equipment for the plates comprises a machine body, wherein a fixing cavity is formed in the machine body; a drilling cavity is formed in the right side of the fixing cavity; a power cavity is formed in the lower side of the drilling cavity; a rapid grinding cavity is formed in the leftside of the fixing cavity; a clamping cavity is formed in the lower side of the fixing cavity; a drilling device for drilling and chamfering the plates is arranged in the drilling cavity; the drilling device comprises a main motor fixedly installed on the left side wall of the power cavity; the main motor is in power connection with a motor shaft; a clamping device for clamping and fixing the plates is arranged in the fixing cavity; and a grinding device for grinding the walls of inner holes is arranged in the grinding cavity. The equipment can quickly complete the hole machining of plate parts without the need for carrying out rough machining and fine finishing for the holes, only the plates need to be fixed, and hole machining and chamfering machining are completed at a time, so that time and labor are saved, the machining efficiency is high, and the overall machining progress is accelerated.

Owner:福州鼓楼禾尚舒科技有限公司

Stretching and leveling device for production of spinning cloth

InactiveCN110644176AEasy to operateGuaranteed stabilityTenters/driers accessoriesHydraulic cylinderSpinning

The invention discloses a stretching and leveling device for production of spinning cloth. The stretching and leveling device for production of spinning cloth comprises a base, a hydraulic cylinder, avertical plate and a bottom plate, wherein vertical columns are arranged on the left side and the right side of the upper portion of the base; a cross beam is arranged on the inner sides of the vertical columns; a hydraulic cylinder is mounted above the cross beam; a vertical plate is fixed at the left end of the cross beam; a rack is arranged in the vertical plate; the rear side of the rack is in engaged connection with a connecting gear; the gear is fixed at the right end of a rotating shaft; the lower portion of the rotating shaft is connected with a first lead screw through a transmissionbelt; compression rollers are separately arranged on the left side and the right side of an ironing plate; the outer side of each compression roller is connected with the bottom plate through an elastic spring. According to the stretching and leveling device for production of the spinning cloth, a clamping plate is arranged in a fixing plate, the clamping plate is in threaded connection with a second lead screw, thus, the second lead screw can rotate to adjust the height of the clamping plate to carry out compression operation on the spinning cloth with different thicknesses, and the stability of processing of the spinning cloth in the later period is guaranteed.

Owner:陈学祥

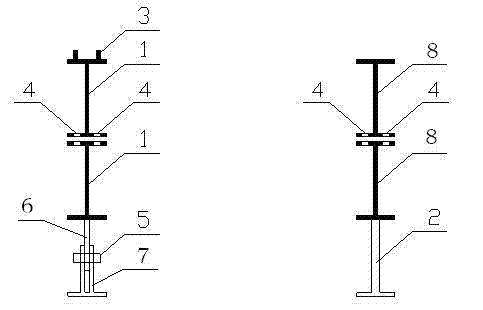

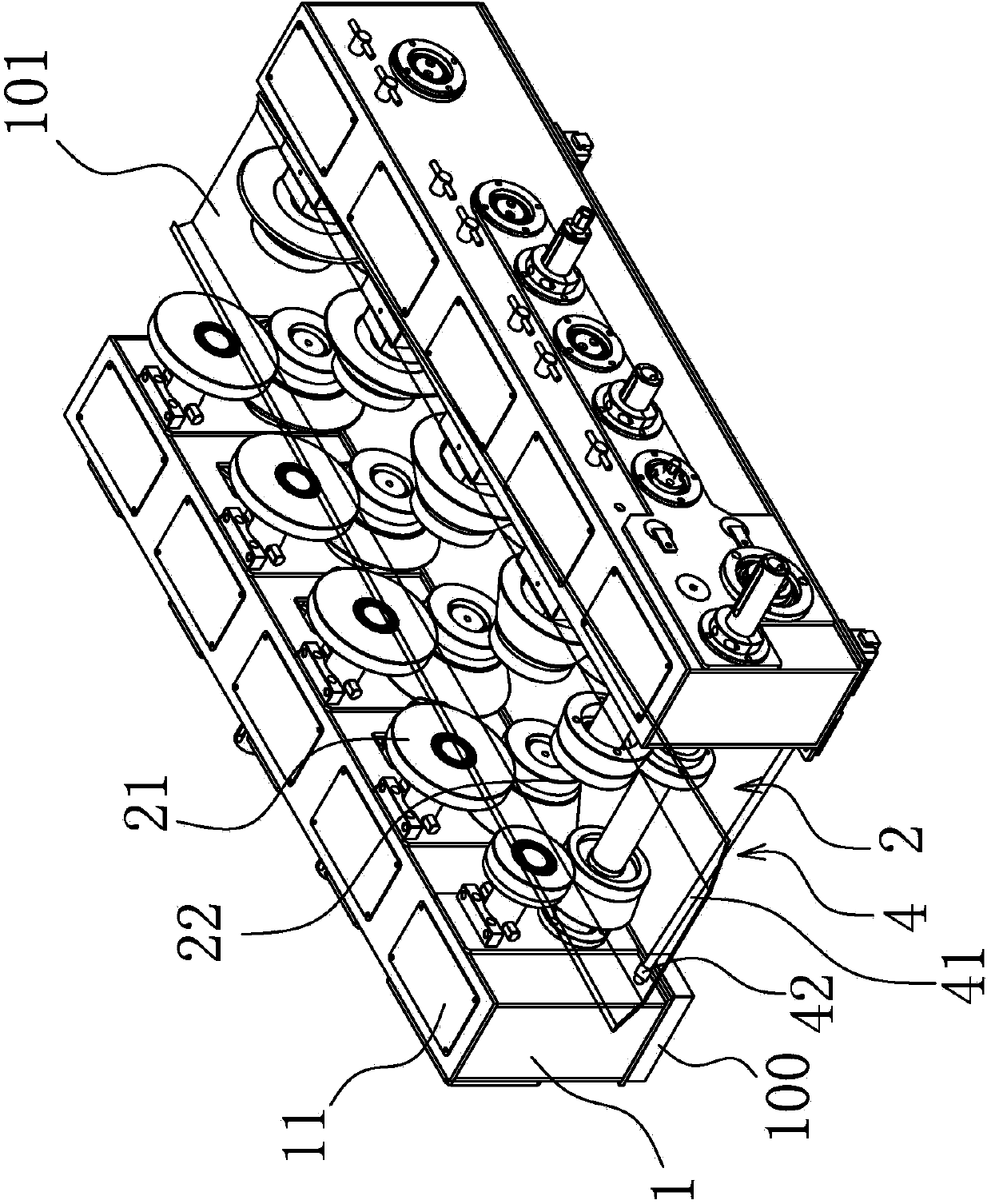

Novel purline molding device

InactiveCN104028593AImprove rigidityEliminate reaction forceMetal working apparatusProcessing accuracyEnergy consumption

The invention provides a novel purline molding device, belongs to the technical field of mechanical equipment, and solves the technical problems that the machining in the prior art is time-consuming and labor-consuming, and the precision cannot be ensured. The novel purline molding device comprises a machine seat, wherein two transmission box bodies are oppositely arranged on the machine seat; the distance between the two transmission box bodies is adjustable on the machine seat; a plurality of positioning holes are formed in the side walls of the transmission box bodies; roller molding mechanisms are detachably mounted on the transmission box bodies through the positioning holes; each roller molding mechanism comprise an upper roller component and a lower roller component; each lower roller component is connected with a drive mechanism; each drive mechanism is arranged in the corresponding transmission box body. The novel purline molding device has the advantages of high machining precision, low machining cost, low energy consumption, high safety and the like.

Owner:HANGZHOU YIBO MACHINERY

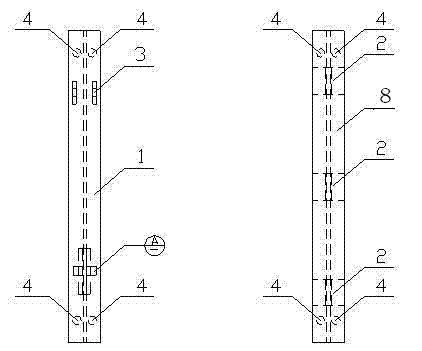

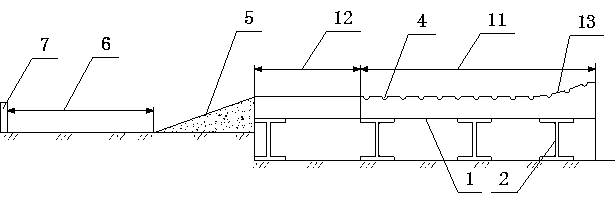

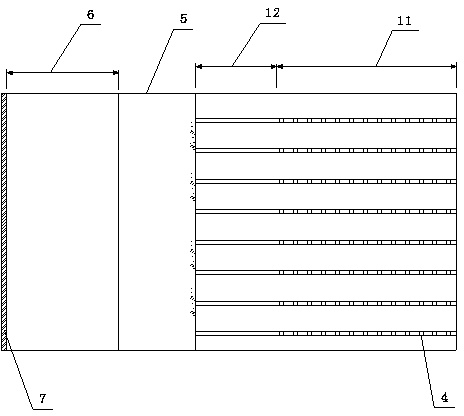

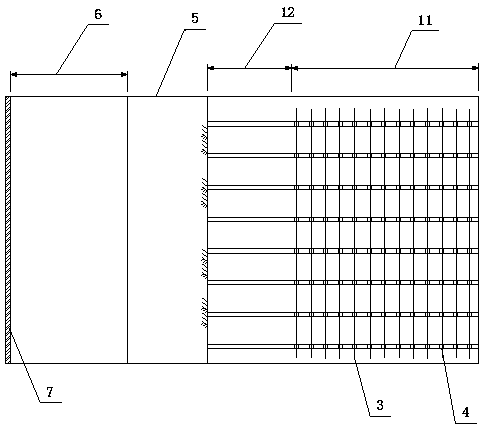

Serration-type steel reinforcement cage machining jig frame and construction method thereof

ActiveCN103586374AImprove processing qualityImprove processing progressMeshed-ring wire networkRebarMachining

The invention discloses a serration-type steel reinforcement cage machining jig frame, and belongs to the field of steel reinforcement cage machining. The jig frame is divided into a main rib welding and forming area and a spiral rib bonding area, wherein the tail portion of the main rib welding and forming area is an arc section, and the upper surface of the main rib welding and forming area is provided with a plurality of notches matched with intervals and diameters of main ribs at equal intervals. The construction method sequentially includes the following steps that the main ribs needing to be welded are placed in the notches of the main rib welding and forming area of each jig frame one by one, firstly, the main ribs on the arc section of each jig frame are welded and roll towards the spiral rib bonding area of the corresponding jig frame after welding, the main ribs sequentially roll, are sequentially welded and ultimately roll to the spiral rib bonding area, and spiral stirrups are bound. According to the jig frame and a construction method of the jig frame, all the main ribs of a machined steel reinforcement cage are evenly distributed, machining quality of the steel reinforcement cage is higher, function requirements can be met on the condition that the machining progress of the steel reinforcement cage is accelerated, construction operators and equipment investment are reduced, and machining cost of the steel reinforcement cage is reduced.

Owner:CCCC SHEC FOURTH ENG +1

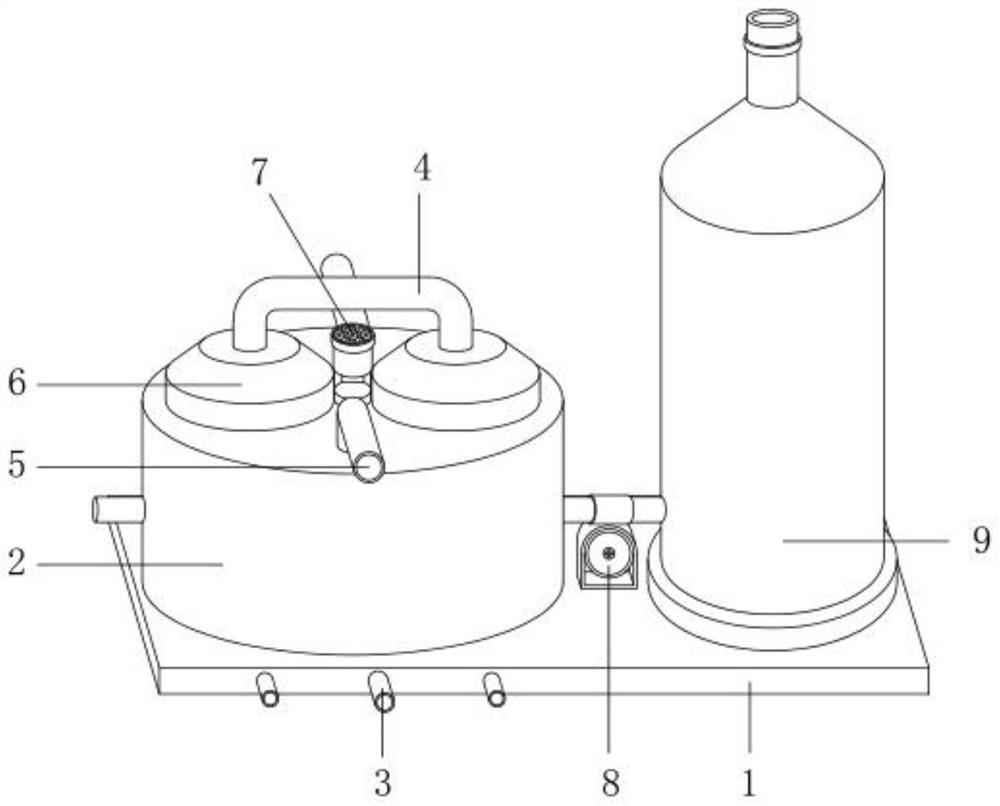

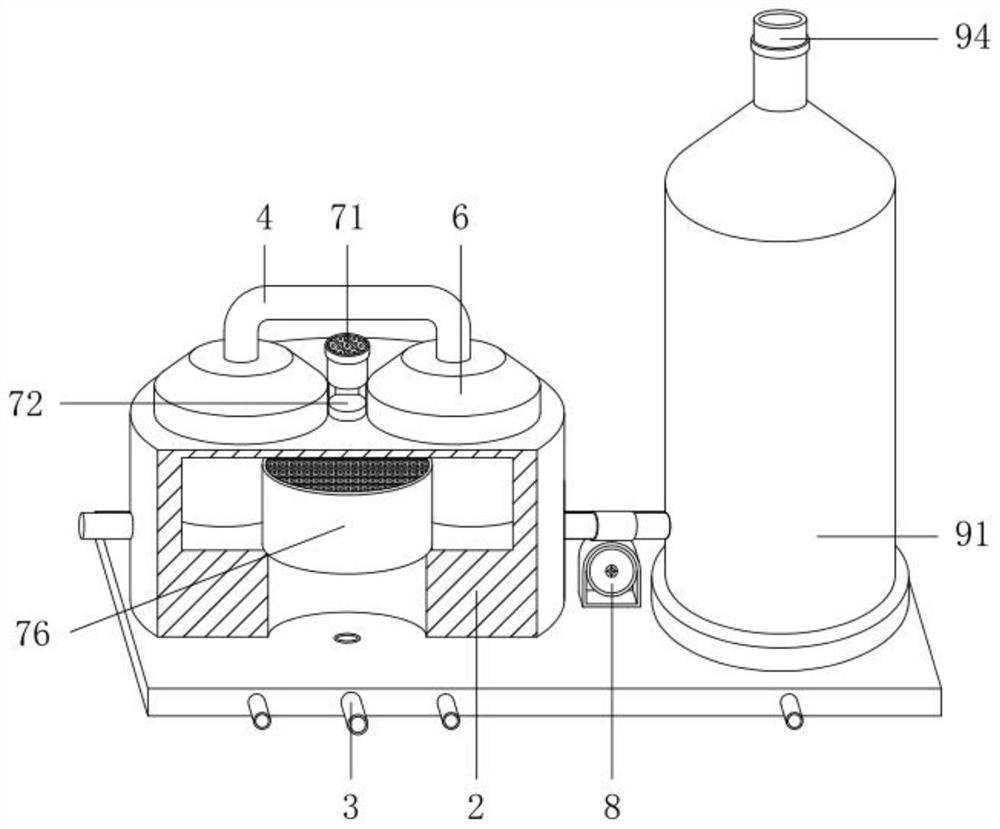

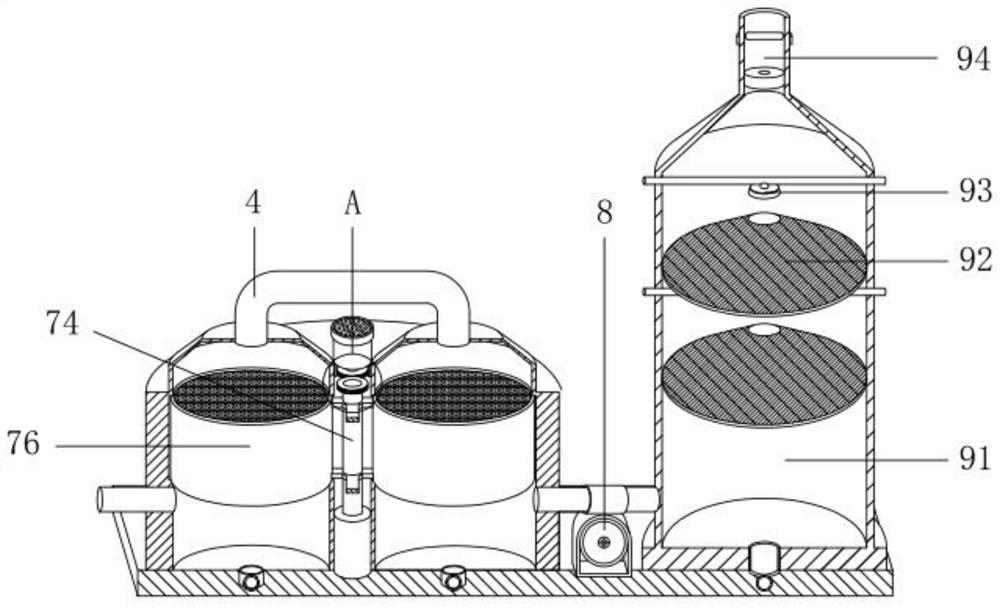

Industrial waste gas treatment and purification device

InactiveCN112246070AAvoid the problem of time-consuming and labor-intensive replacement workAvoid time-consuming and labor-intensiveGas treatmentDispersed particle separationExhaust fumesProcess engineering

The invention discloses an industrial waste gas treatment and purification device, which comprises: a base, wherein two liquid discharging pipes are arranged at the left end of the front side of the base; a desorption tank connected with the left side of the upper surface of the base in a sealed mode; the liquid discharging pipes; a gas inlet pipe communicated with the inner cavity of the desorption tank and arranged on the left side of the desorption tank, wherein the two liquid discharging pipes are respectively communicated with the inner cavities of two adsorption tanks; the two adsorptiontanks respectively arranged on the left side and the right side of the inner cavity of a purification tank; and a guide pipe, wherein the left end and the right end of the outer wall of the guide pipe are respectively connected with the top ends of the two adsorption tanks in a sealing manner. According to the industrial waste gas treatment and purification device, the problem that time and laborare consumed when the adsorption box is replaced is solved, waste gas can be continuously treated while the desorption box conducts desorption work, and the waste gas treatment progress is accelerated; and the waste gas is treated through an adsorption method and a spraying method, so that the waste gas is purified more thoroughly, the effect is better, resources can be recycled, resource waste is avoided, and environmental protection is facilitated.

Owner:廖俊辉

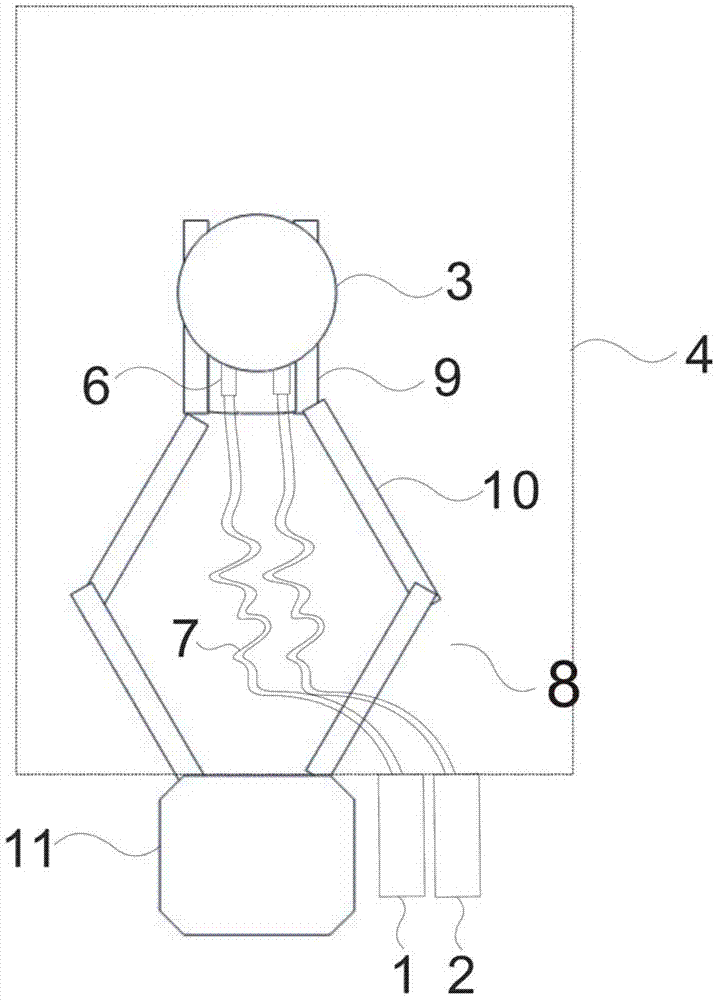

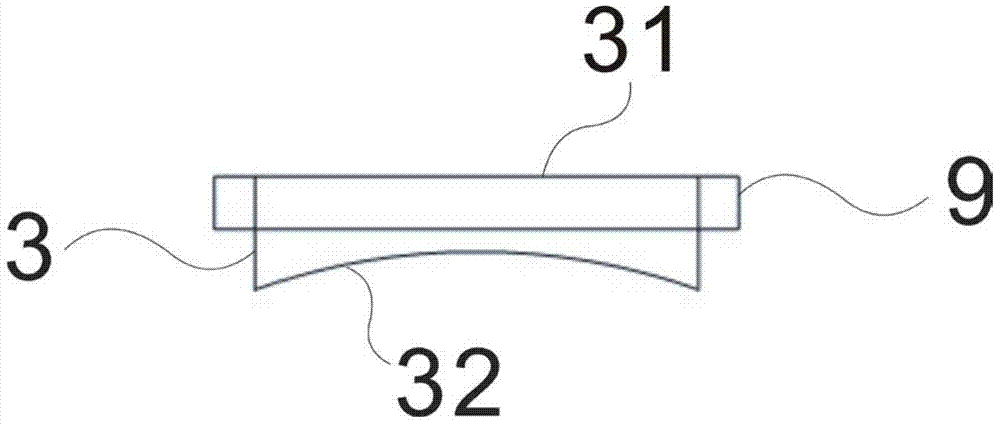

Wafer reaction chamber cleaning device

InactiveCN103681247AReduce scrap rateSimple structureHollow article cleaningSemiconductor/solid-state device manufacturingNitrogenEngineering

The invention discloses a wafer reaction chamber cleaning device. The wafer reaction chamber cleaning device comprises arranging a vacuum pump and a nitrogen tank outside a reaction chamber and is composed of a cleaning facial disc and a mechanical hand, wherein the cleaning facial disc is arranged inside the reaction chamber and used for cleaning the reaction chamber and the lower facial disc of the cleaning facial disc is provided with a plurality of holes; the mechanical hand comprises a clamping unit, mechanical arms and a frame, the clamping unit is arranged at the ends of the mechanical arms and used for clamping the cleaning facial disc, the mechanical arms are movably mounted on the frame, and the clamping unit and the upper facial disc of the cleaning facial disc are connected through fixing units. The wafer reaction chamber cleaning device is simple in structure and convenient to use, can clean the reaction chamber by transmitting the cleaning facial disc through the mechanism arms without damaging the vacuum environment of the reaction chamber and further remove dirt inside the reaction chamber without opening and resetting the reaction chamber, thereby improving the technical progress during production application, saving the resetting time and reducing the rejection rate of wafers and the economic loss.

Owner:SHANGHAI INTEGRATED CIRCUIT RES & DEV CENT

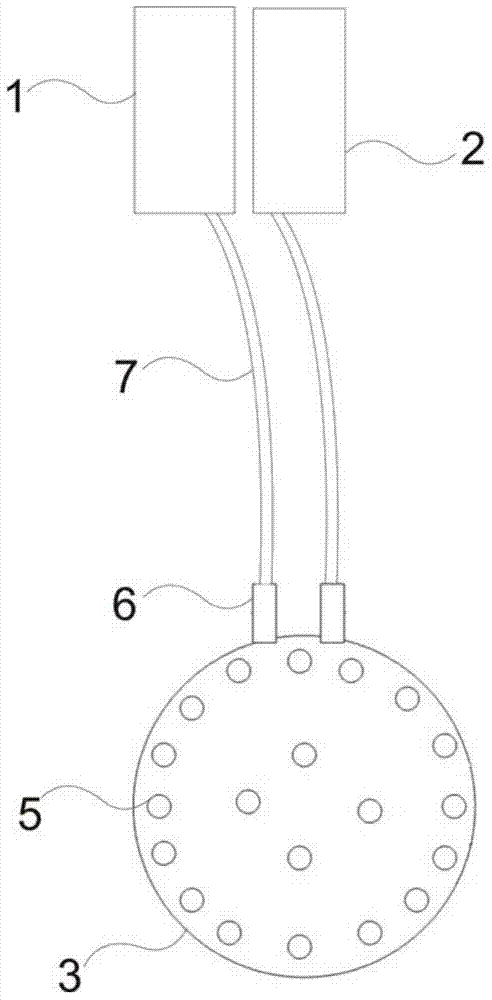

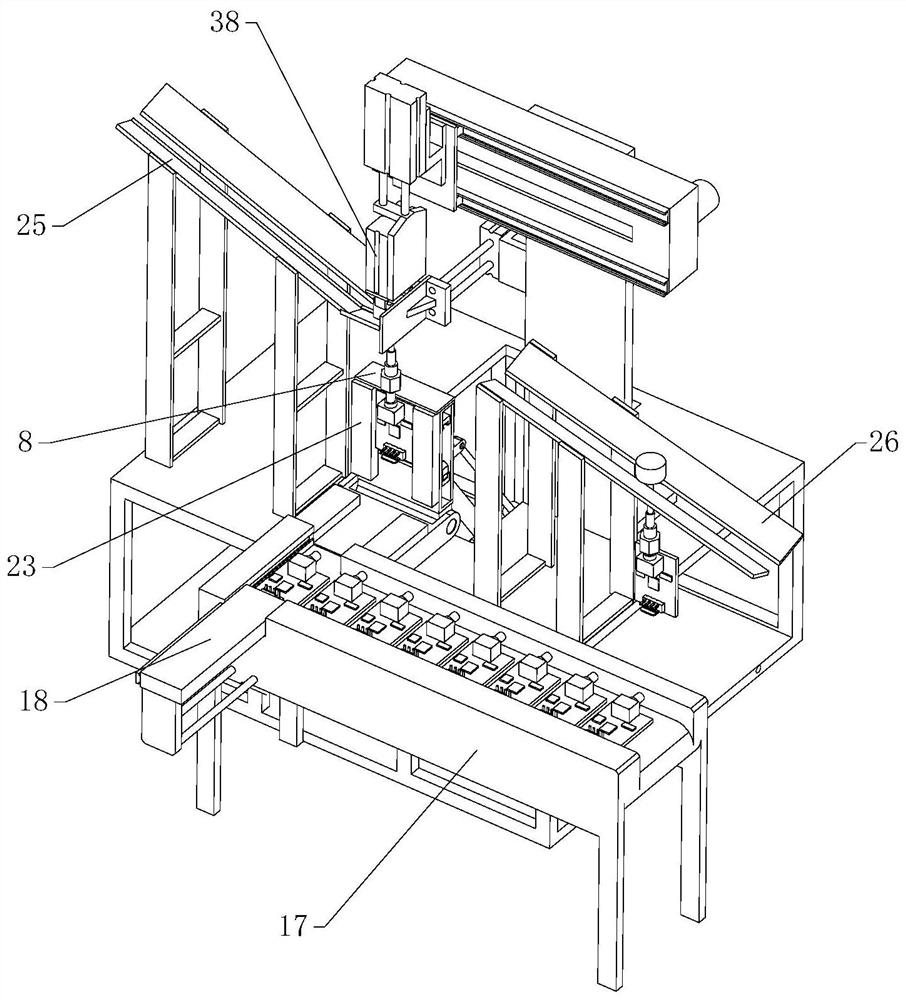

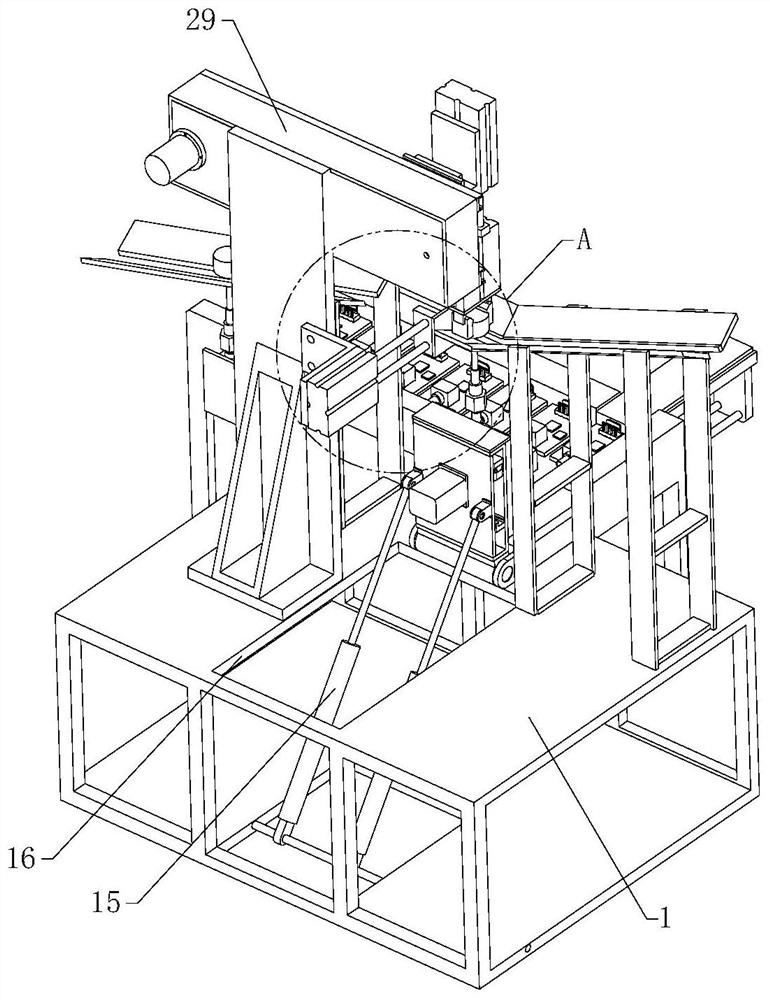

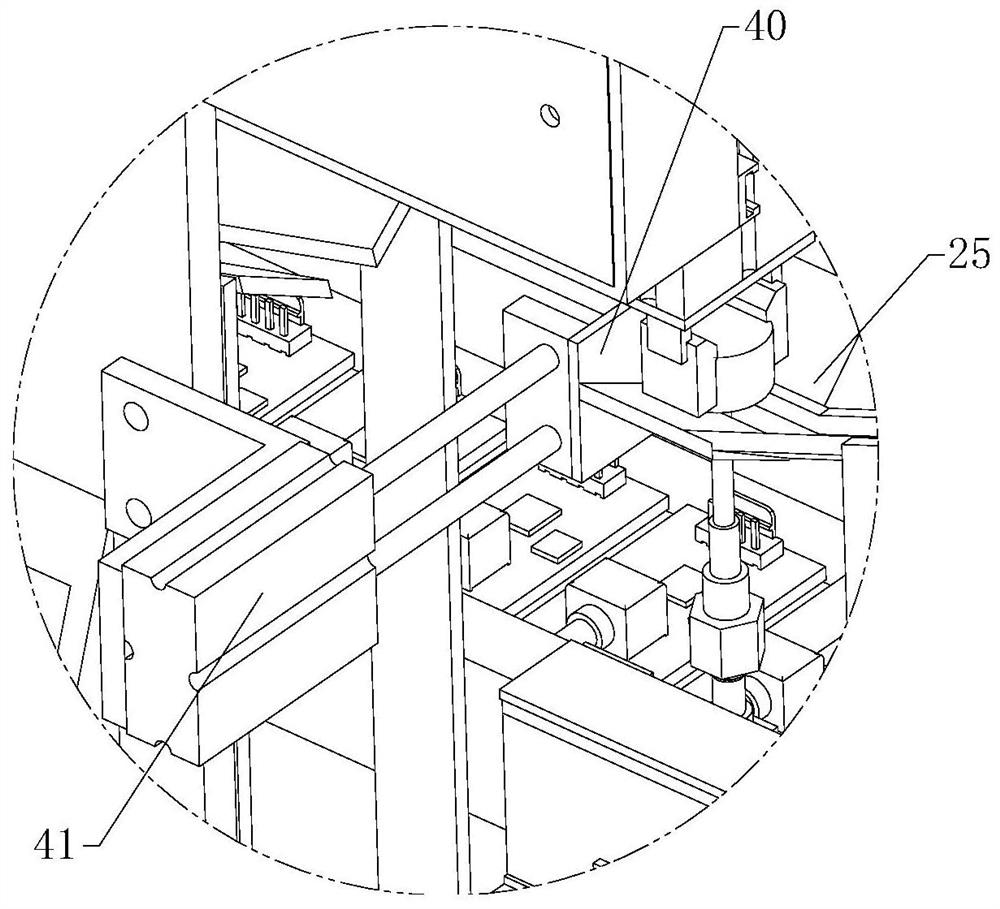

Automatic abutting equipment for main control board of SMA mini antenna

ActiveCN112707128APrecise dockingIncrease productivityConveyor partsEngineeringMechanical engineering

The invention relates to the technical field of SMA antenna processing, in particular to automatic abutting equipment for a main control board of an SMA mini antenna. The equipment comprises a machining table, a conveying mechanism which is erected on one side of the machining table; a positioning turnover mechanism which is arranged on the machining table; and an antenna positioning and conveying mechanism which is arranged on the machining table for conveying, positioning and unloading an antenna. The equipment is characterized in that the positioning turnover mechanism comprises a material guide sliding table arranged on the machining table, wherein one end of a material guide sliding way is in butt joint with the conveying end of the conveying mechanism; a hollow overturning plate which is arranged at the end, far away from the conveying mechanism, of the material guiding sliding table in an overturning mode, and one end of the overturning plate is hinged to the end, far away from the conveying mechanism, of the material guiding sliding table; and two positioning plates which are symmetrical and can be arranged on the upper surface of the overturning plate in the opposite direction or in the reverse direction. The equipment can conduct abutting assembly on a main control panel of the SMA mini antenna automatically, so that the production efficiency is improved, and the machining progress is accelerated.

Owner:成都美数科技有限公司

Cutting device for glass machining

InactiveCN109049355AImprove processing progressSpeed upWorking accessoriesStone-like material working toolsEngineeringThreaded rod

The invention discloses a cutting device for glass machining. The cutting device for glass machining includes a working table, wherein an inner cavity of the working table is provided with a cutting groove, a supporting plate is arranged on the top of the working table, supporting rods are symmetrically welded between the supporting plate and the working table, the front faces of the supporting rods are welded with sliding rails, the inner walls of the sliding rails are slidably connected with first sliding blocks. According to the cutting device for glass machining, through mutual cooperationof the working table, the cutting groove, the supporting plate, the supporting rods, the sliding rails, the first sliding blocks, connecting rods, fixing plates, a sliding rod, a motor housing, a motor, a tooth disk, guiding rails, a first sliding groove, a second sliding block, an electric telescopic rod, a housing, a bearing, a positive and negative motor, a threaded rod, a fixing block, a screw block and a second sliding groove, the problem of low efficiency of manual cutting is solved, the cutting device does not need manual cutting when in use, the efficiency of cutting is accelerated, the schedule of glass machining is accelerated, and the situation that glass is damaged and cannot be used due to deviation in glass cutting is avoided.

Owner:王亮

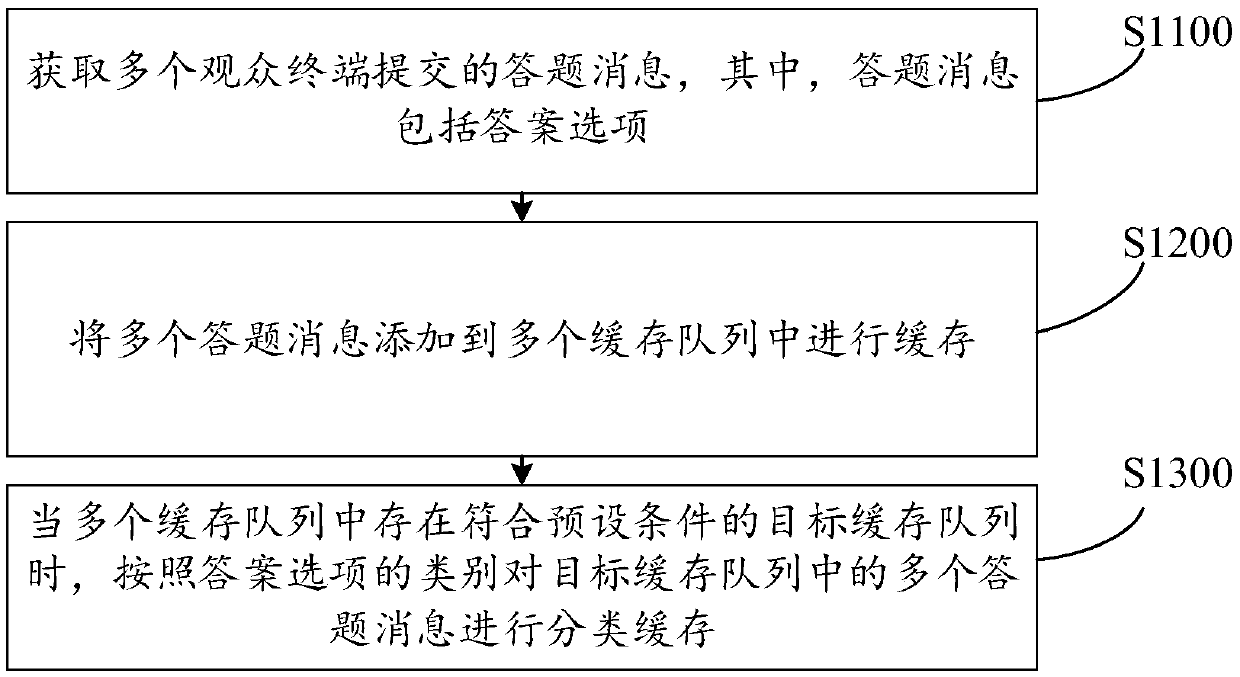

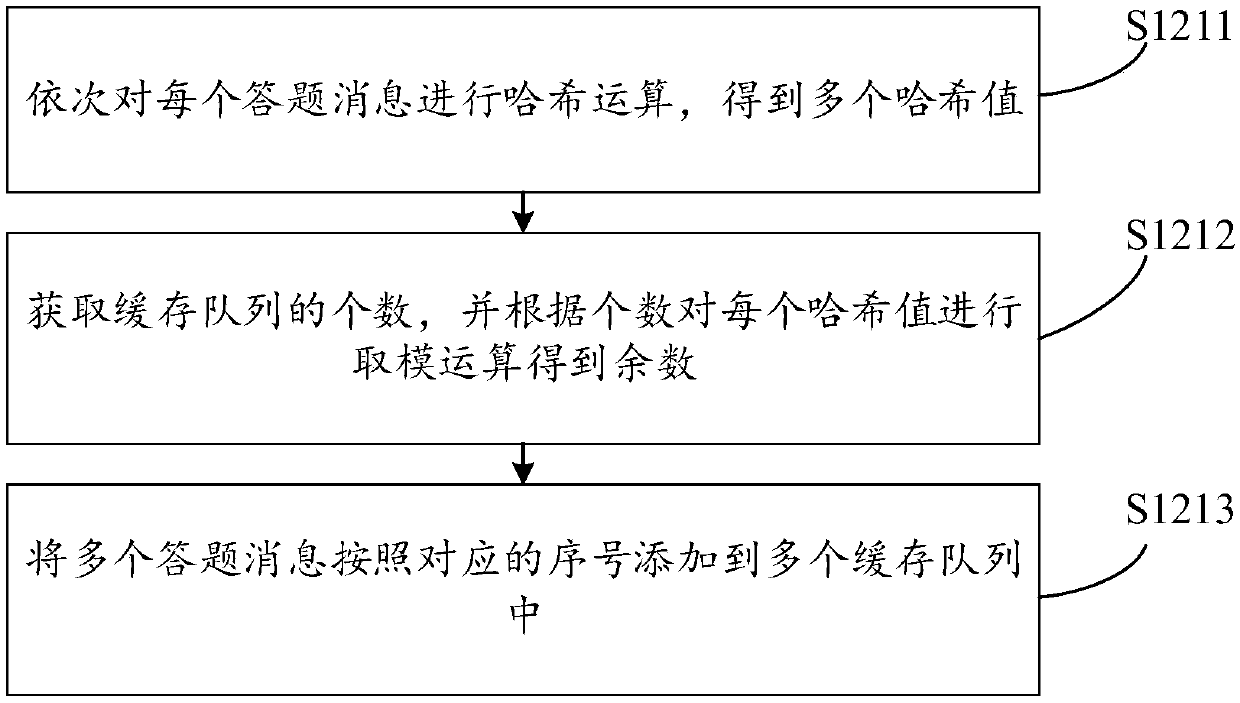

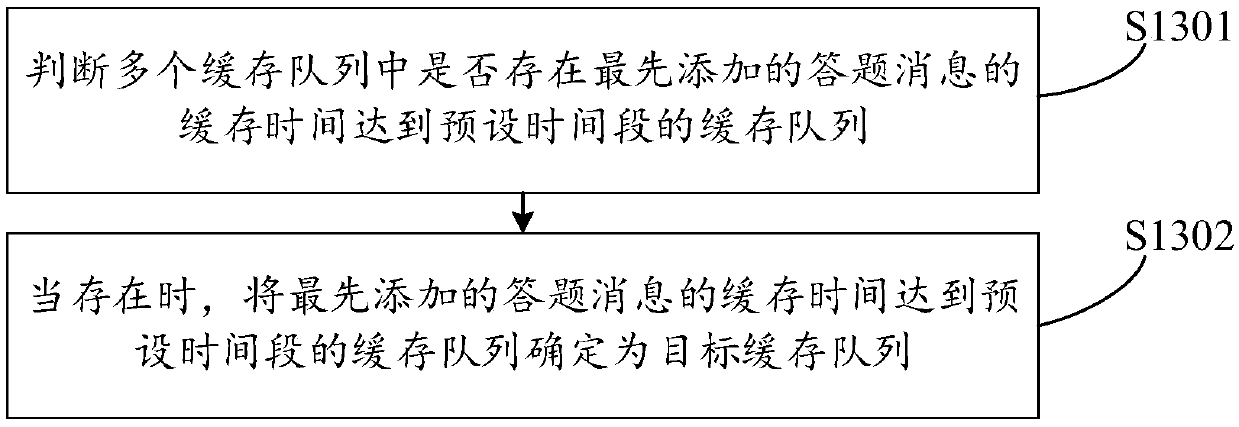

Live broadcast answer processing method and device, computer readable storage medium and terminal

ActiveCN109684102ARelieve dealing with stressImprove concurrent processing performanceInterprogram communicationText database indexingBroadcastingDistributed computing

The embodiment of the invention discloses a live broadcast answer processing method and device, a computer readable storage medium and a terminal, and the method comprises the steps: obtaining answermessages submitted by a plurality of audience terminals, the answer messages comprising answer options; Adding the answer messages into a plurality of cache queues for caching; And when a target cachequeue meeting a preset condition exists in the plurality of cache queues, carrying out classified caching on the plurality of answer messages in the target cache queue according to the category of the answer option. According to the method, the answer message can be subjected to delay processing, the processing pressure of the server is relieved, the concurrent processing capacity of the server can be improved, the processing progress is improved, and the processing time is shortened. In addition, according to the method, when the number of audiences in the answering direct broadcasting roomis large, it is only needed to set a plurality of cache queues according to audience processing in the answering direct broadcasting room, and expansion is facilitated.

Owner:BIGO TECH PTE LTD

Adjustable clamping mechanism for gear chamfering processing and clamping method thereof

PendingCN110640236AImprove practicalityImprove processing progressGear-cutting machinesGear teethGear wheelEngineering

The invention discloses an adjustable clamping mechanism for gear chamfering processing and a clamping method thereof. The adjustable clamping mechanism for the gear chamfering processing comprises abottom seat, a vertical plate, a clamp block and a gear body, wherein a vertical pillar is arranged above the bottom seat, a rotary rod is arranged in the vertical pillar, a first bevel gear is fixedon the outer wall of the rotary rod, a second bevel gear is connected onto the outer wall of the first bevel gear in a meshing mode, a lead screw runs through the interior of the second bevel gear, the top of a first clamping block is connected with a second clamping block through an elastic force spring, a dial block is arranged on the outer wall of the middle of the vertical pillar, and the gearbody is arranged on the outer sides of the first clamping block and the second clamping block. According to the adjustable clamping mechanism for the gear chamfering processing, the elastic force spring is arranged between the first clamping block and the second clamping block, and the first clamping block and the second clamping block are both in an L shape, and then can clamp and fix gears different in thickness, improve practicability of the clamping mechanism, and quicken processing progress of the gear chamfering.

Owner:盐城永安科技有限公司

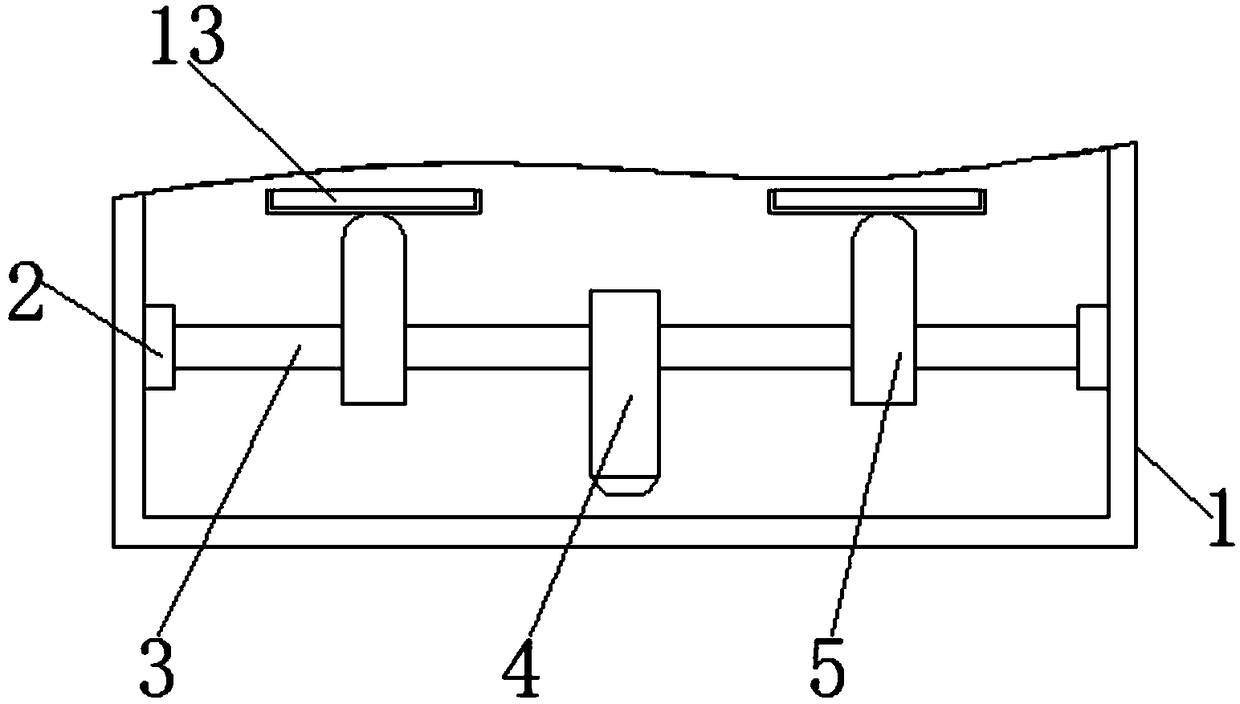

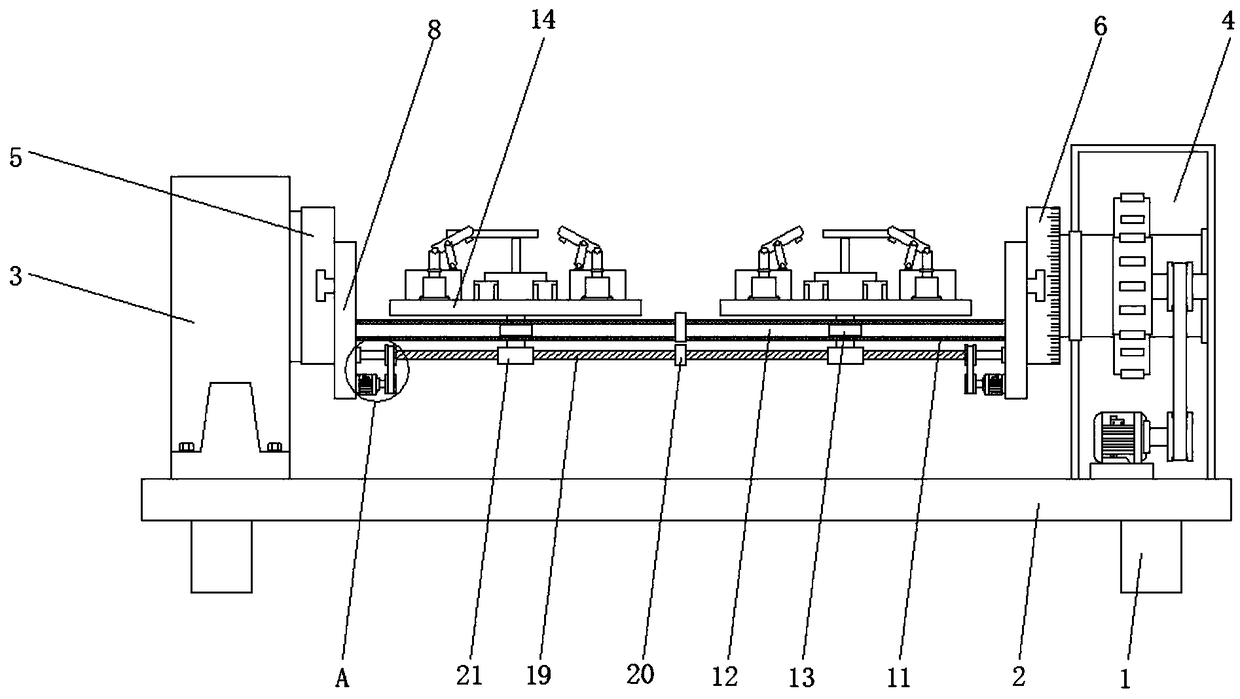

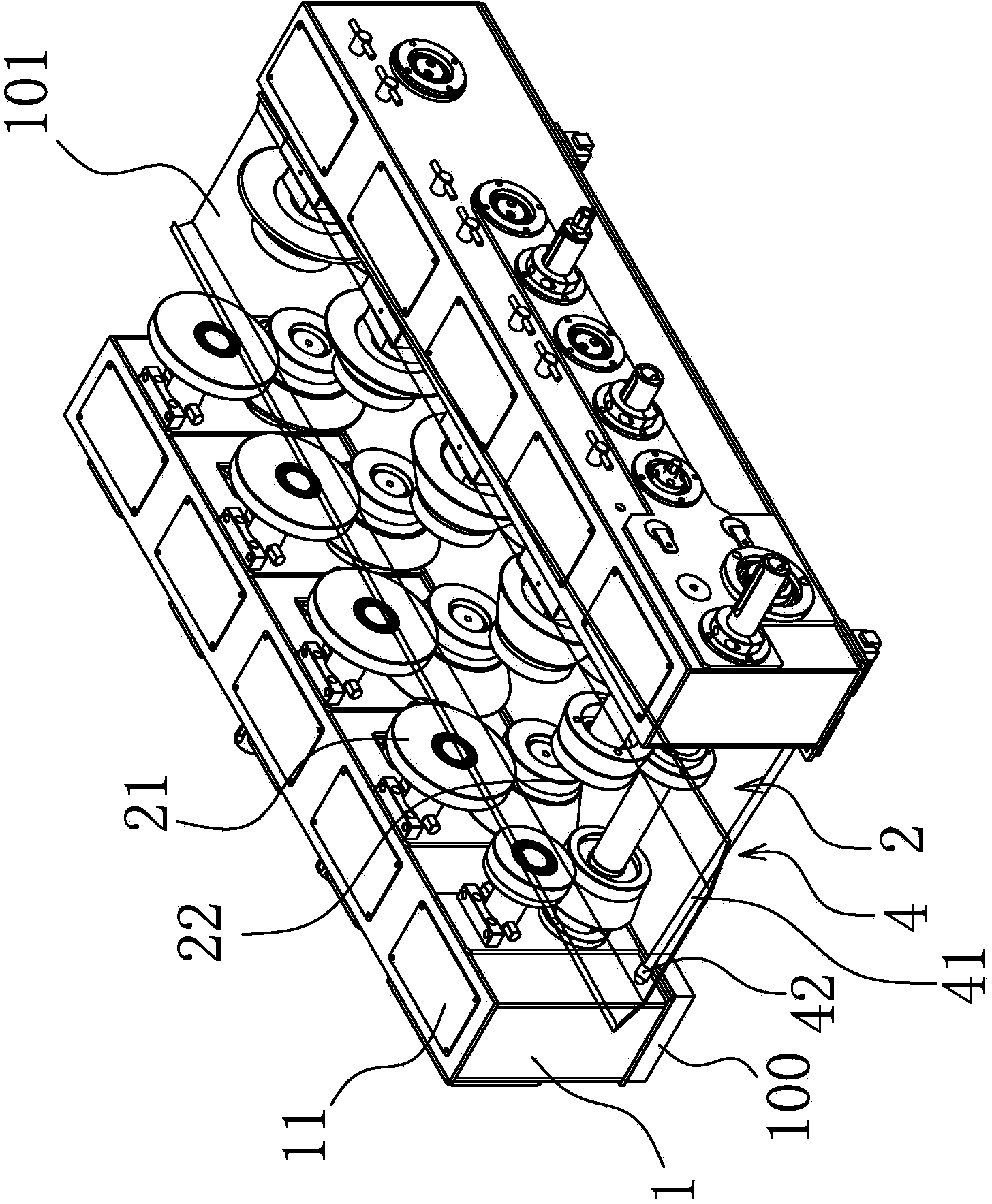

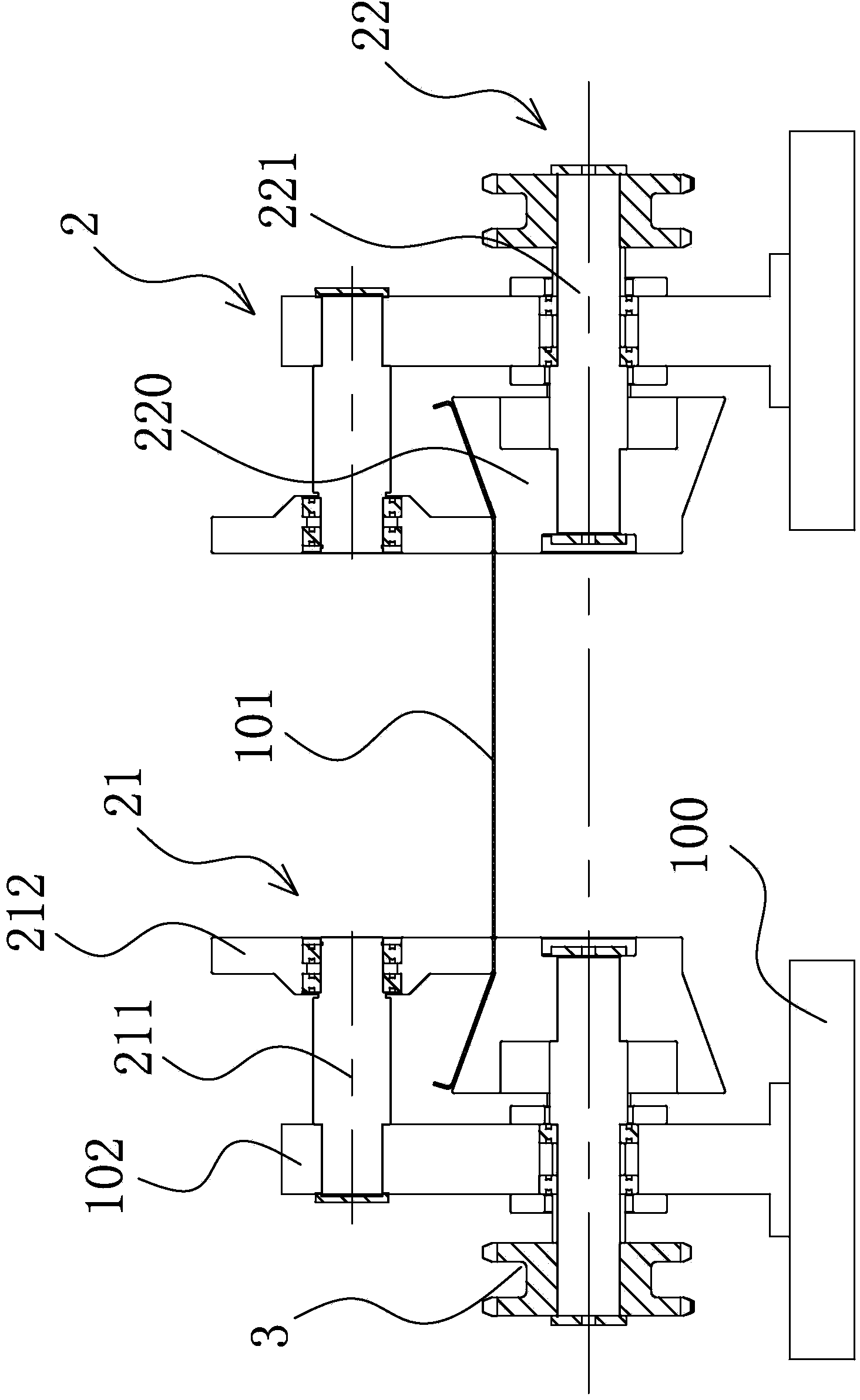

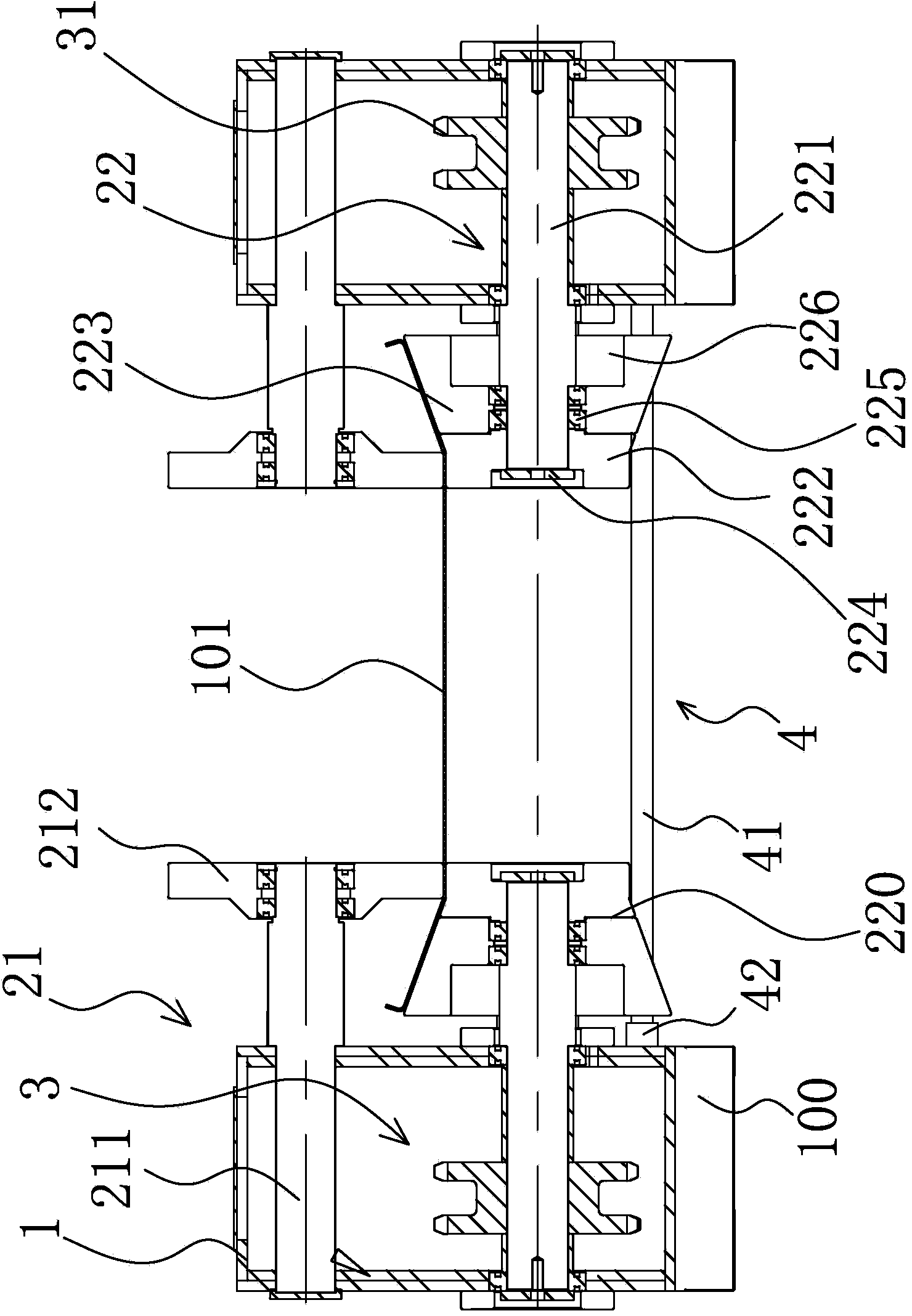

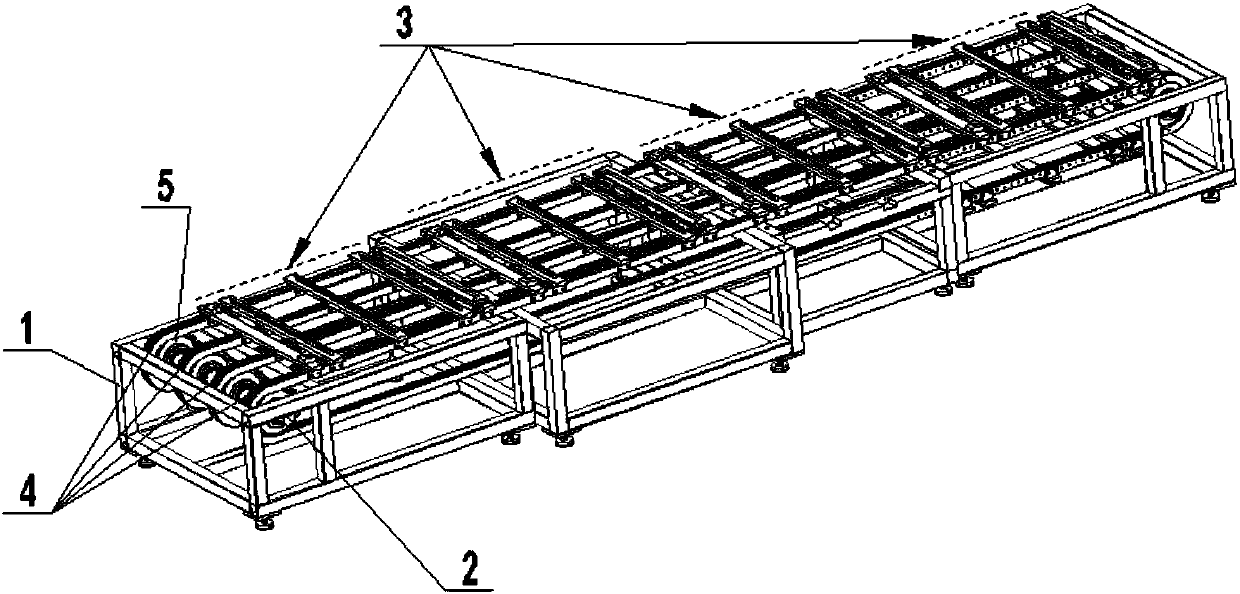

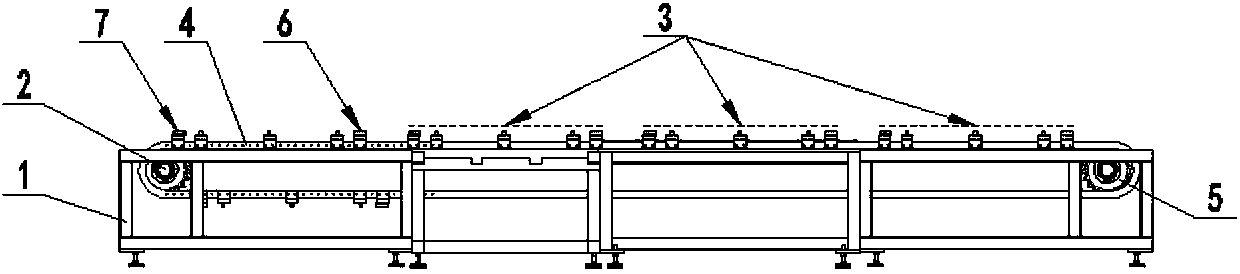

Conveying equipment for automated production line for steel grid plates

The invention provides conveying equipment for an automated production line for steel grid plates. The conveying equipment comprises a rack, transmission shafts, multiple clamp mechanisms and multipletransmission belts. The two ends of the transmission shafts are mounted at the two sides of the rack through bearing seats correspondingly. Each transmission shaft is provided with multiple transmission wheels, wherein the number of the transmission wheels on one transmission shaft is the same as that of the transmission wheels on another transmission shaft. Each transmission belt is connected with the transmission wheels at the corresponding positions of all the transmission shafts an engaged manner. Each clamp mechanism comprises a limiting device A, a limiting device B and two or more clamp bearing plates. Each clamp bearing plate is mounted on the corresponding transmission belt. Each limiting device A and the corresponding limiting device B are mounted on the corresponding clamp bearing plates correspondingly. By means of the conveying equipment, all the clamp mechanisms used in all procedures for producing the steel grid plates are unified into the fixed form and mounted on an annular conveying belt of a conveying mechanism, so that the clamp mechanisms enable the manufacturing procedure positions to be changed with operation of the conveying belt; the automation level of steel grid plate production is raised; and product precision, quality and conformance are improved.

Owner:张文安

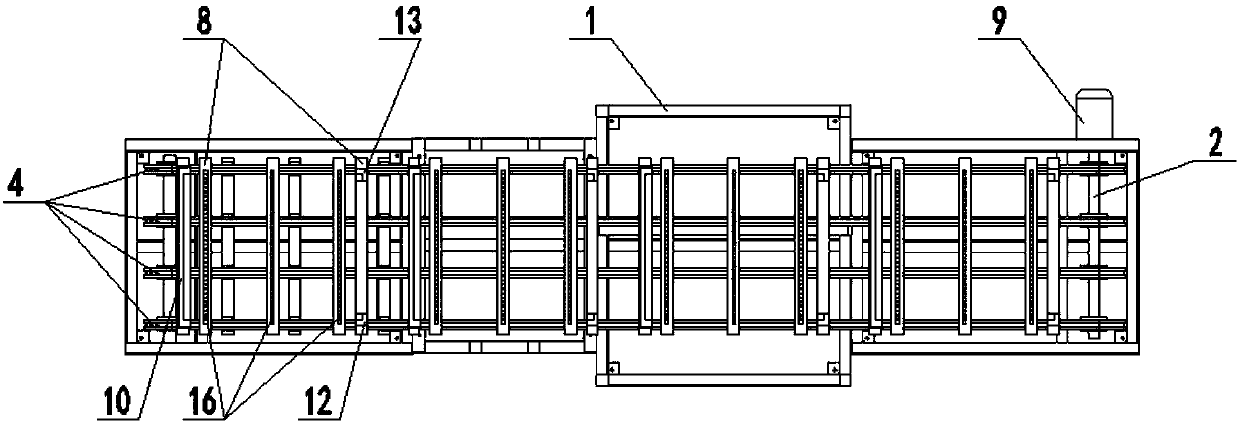

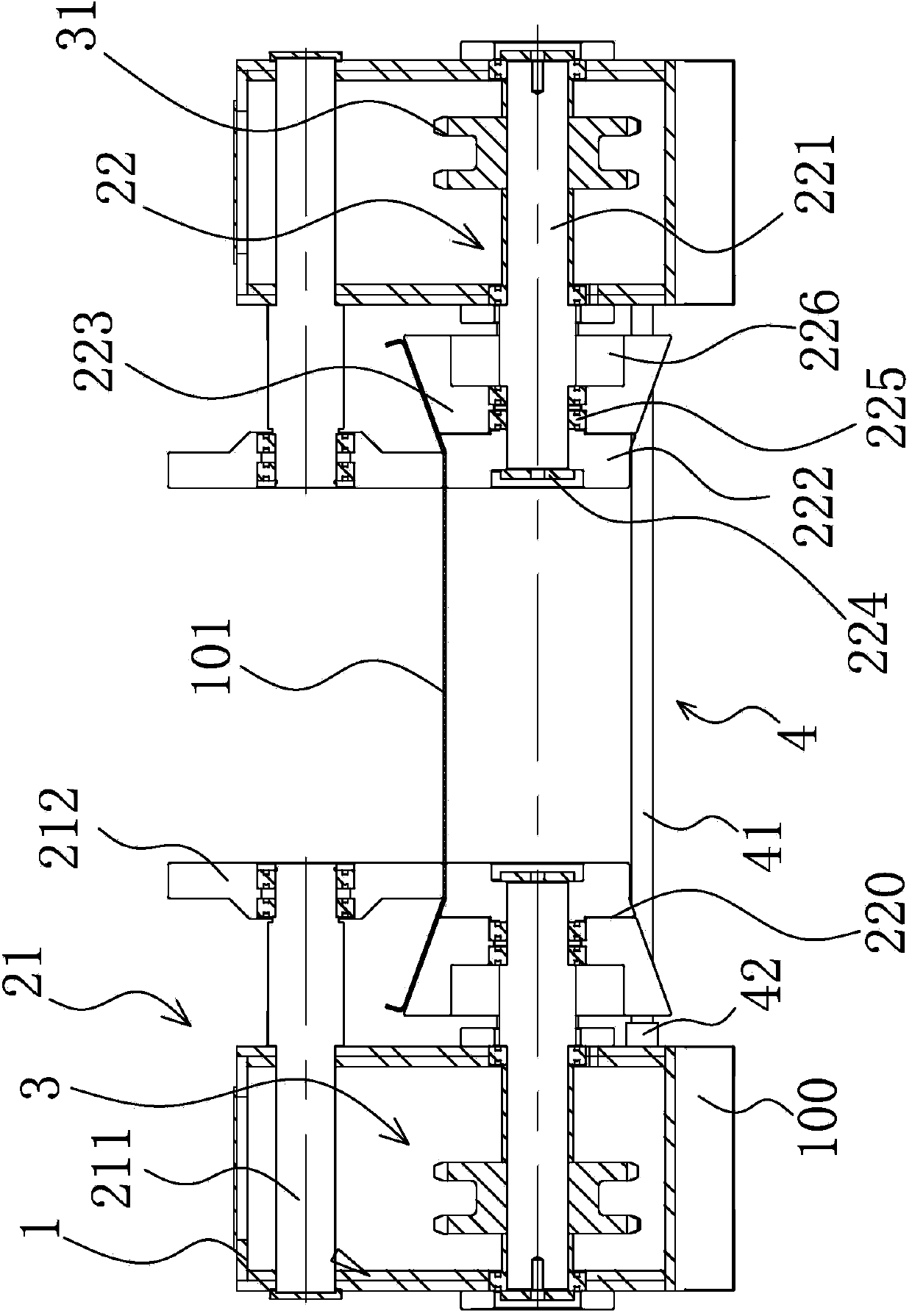

C/Z purlin exchange production line

The invention provides a C / Z purlin exchange production line, and belongs to the technical field of mechanical equipment. The C / Z purlin exchange production line solves the technical problems that time and labor are wasted in machining, precision cannot be ensured and the like in the prior art. The C / Z purlin exchange production line comprises an emptying device, a feeding leveling device, a roll forming device and a receiving device which are sequentially connected, the roll forming device comprises a base, two transmission cases are oppositely arranged on the base, the distance between the two transmission cases on the base can be adjusted, the side walls of the transmission cases are provided with a plurality of positioning holes, a roller forming mechanism is detachably mounted on the transmission cases through the positioning holes and comprises an upper roller component and a lower roller component, and a gear reversing mechanism is further arranged on the roll forming device. The C / Z purlin exchange production line has the advantages of high machining precision, low machining cost, low energy consumption, high safety and the like.

Owner:HANGZHOU YIBO MACHINERY

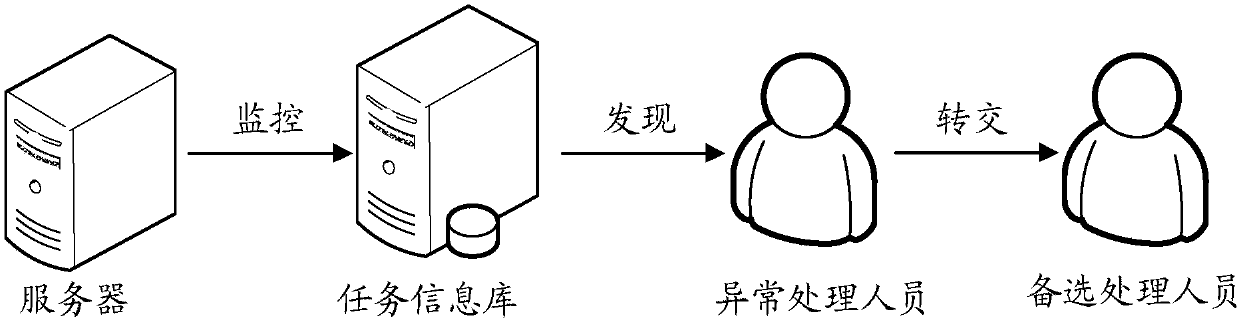

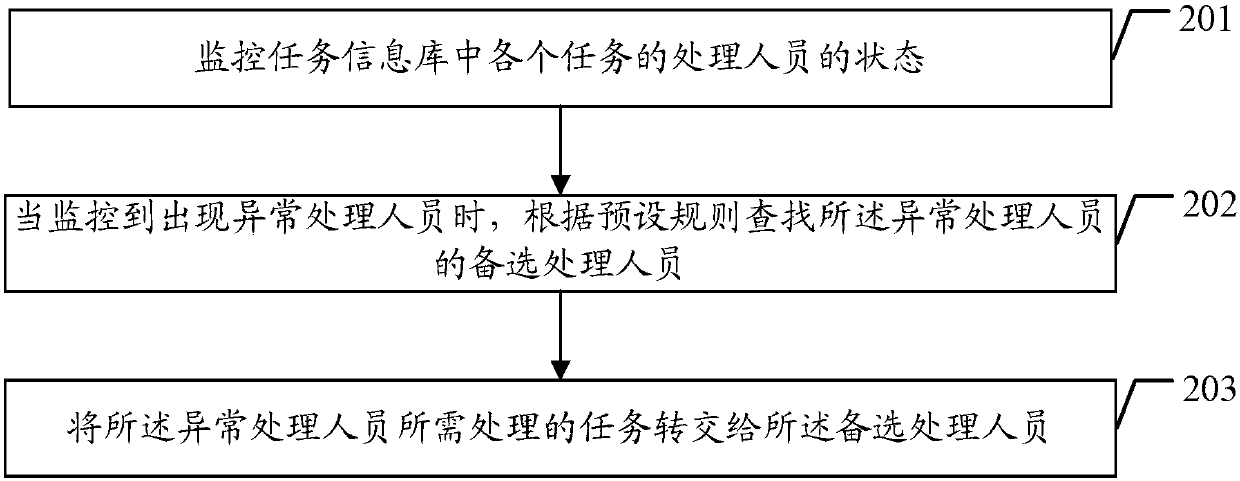

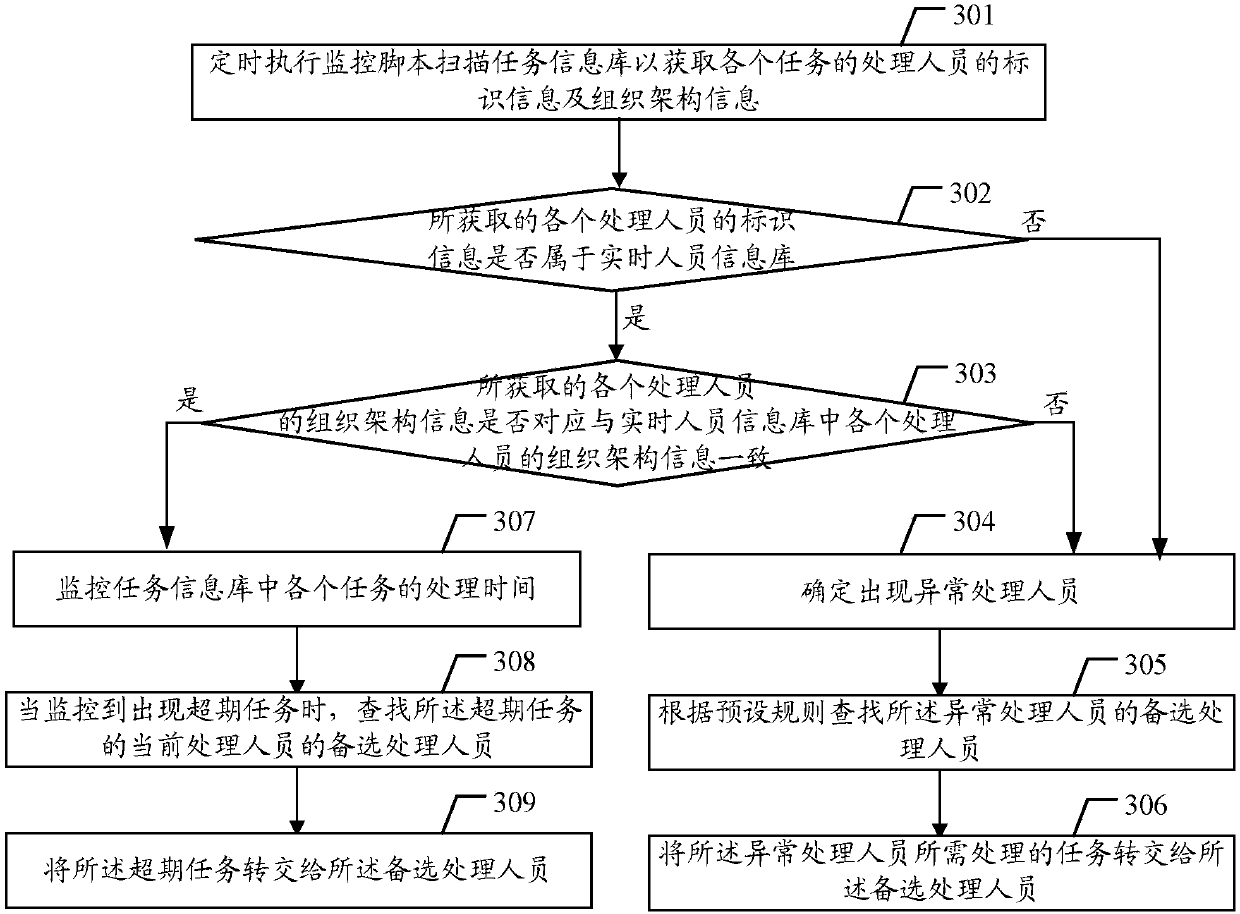

Task management method and device

ActiveCN107742174AImprove processing progressImprove processing efficiencyResourcesInformation repositoryTask management

Embodiments of the invention disclose a task management method and device. The task management method comprises the following steps of: monitoring a state of a processing staff of each task in a taskinformation library; when an abnormal processing staff is monitored, searching an alternative processing staff of the abnormal processing staff according to a preset rule; and handing over a task to be processed by the abnormal processing staff to the alternative processing staff. According to the method and device, task delay or pending caused by staff abnormity can be avoided, the task processing speed can be improved and the task processing efficiency can be improved.

Owner:TENCENT TECH (SHENZHEN) CO LTD

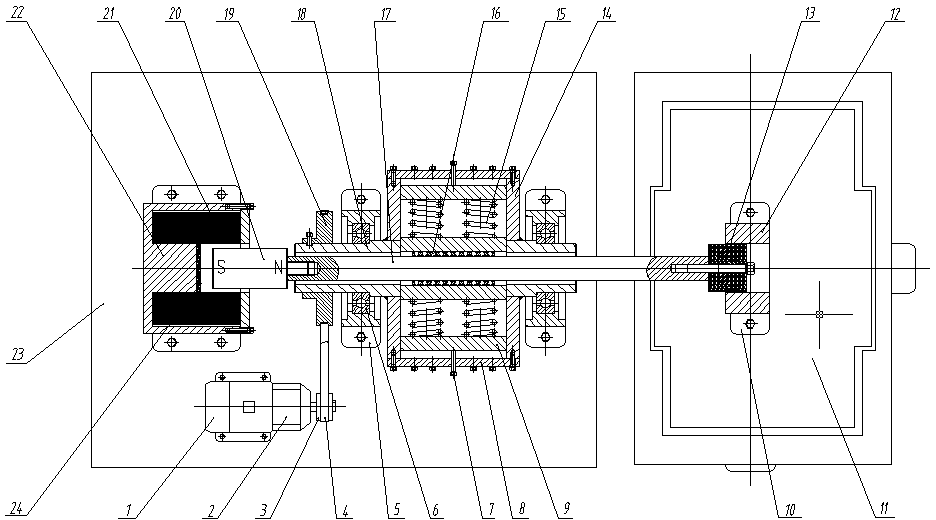

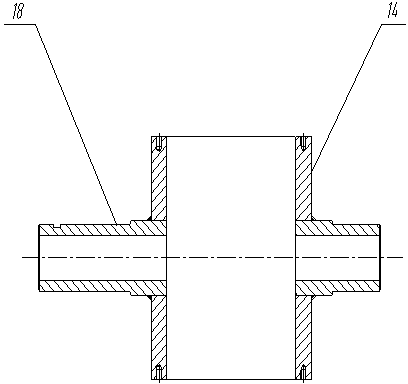

Universal grinding device

InactiveCN103317434AGuaranteed grinding depthImprove processing progressLapping machinesLapping toolsMagnet coilProcessing accuracy

The invention relates to a universal grinding device. Along with increase of machining requirements, the requirement on the machining precision of certain inner holes cannot be effectively met by commonly used electrolytic polishing and magnetic grinding. A grinding head is arranged at one end of a grinding shaft of the universal grinding device, and a magnetic block is arranged at the other end of the grinding shaft and is inserted into an electromagnetic coil assembly; a shell is arranged on the outside of the grinding shaft, a grinder body and grinding shaft sleeves at two ends of the grinder body are welded together to form the shell, and the grinding shaft sleeves are connected with a power transmission mechanism; ejector blocks are arranged on the opposite inner walls of the grinder body, a linear bearing is mounted on a part, which is arranged in the grinder body, of the grinding shaft, regulating spring assemblies are arranged among the linear bearing and the ejector blocks, and regulating screws are mounted among the ejector blocks and the grinder body. The universal grinding device has the advantages that the grinding shaft sleeves and the grinder body are in rotating states, so that the grinding depth of the grinding head can be guaranteed, holes of workpieces can be machined in a 360-degree range, the machining progress is greatly improved, and the roughness of the surface of each ground inner hole can reach Ra0.05.

Owner:XIAN TECHNOLOGICAL UNIV

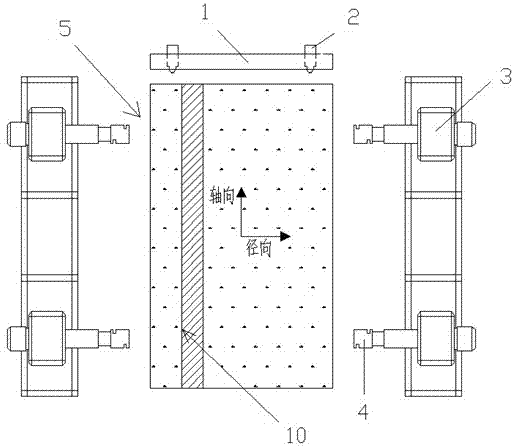

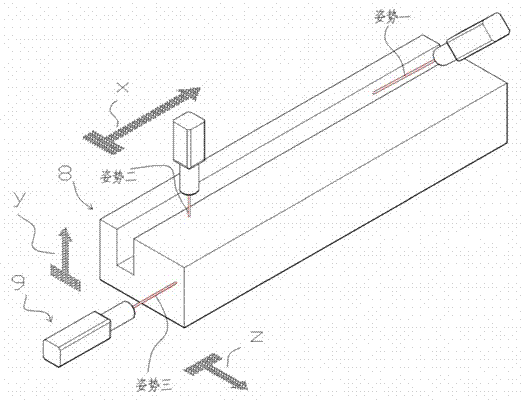

Automatic accurate positioning method for large workpiece

InactiveCN102830718AEasy to measureHigh precisionControl using feedbackCost (economic)Radial position

The invention discloses an automatic accurate positioning method for a large workpiece. The automatic accurate positioning method is applicable to a large workpiece to be machined which has the following characteristics: the workpiece is rectangular and possibly has deviations on the contour dimensions of length, width and height, a positioning reference vertical surface is arranged on the top of the workpiece, and the workpiece needs to be moved and positioned in the horizontal plane. The automatic accurate positioning method comprises the following steps: (1), the workpiece is horizontally conveyed to a reference position in the axial direction by a roller way; (2), the radial position of the workpiece is subjected to preliminary positioning through a servo electric push rod; (3), the position deviation is measured, aiming at the positioning reference vertical surface; and (4), the servo electric push rod finishes accurate positioning according to the preliminary positioning parameters and the measured position deviation. The automatic accurate positioning requirement on the large workpiece in the machining process can be accurately and rapidly realized through the construction technique provided by the invention, the machining speed is effectively accelerated, the machining quality is ensured, the project safety is guaranteed, and the economic cost is reduced.

Owner:CENT SOUTH UNIV

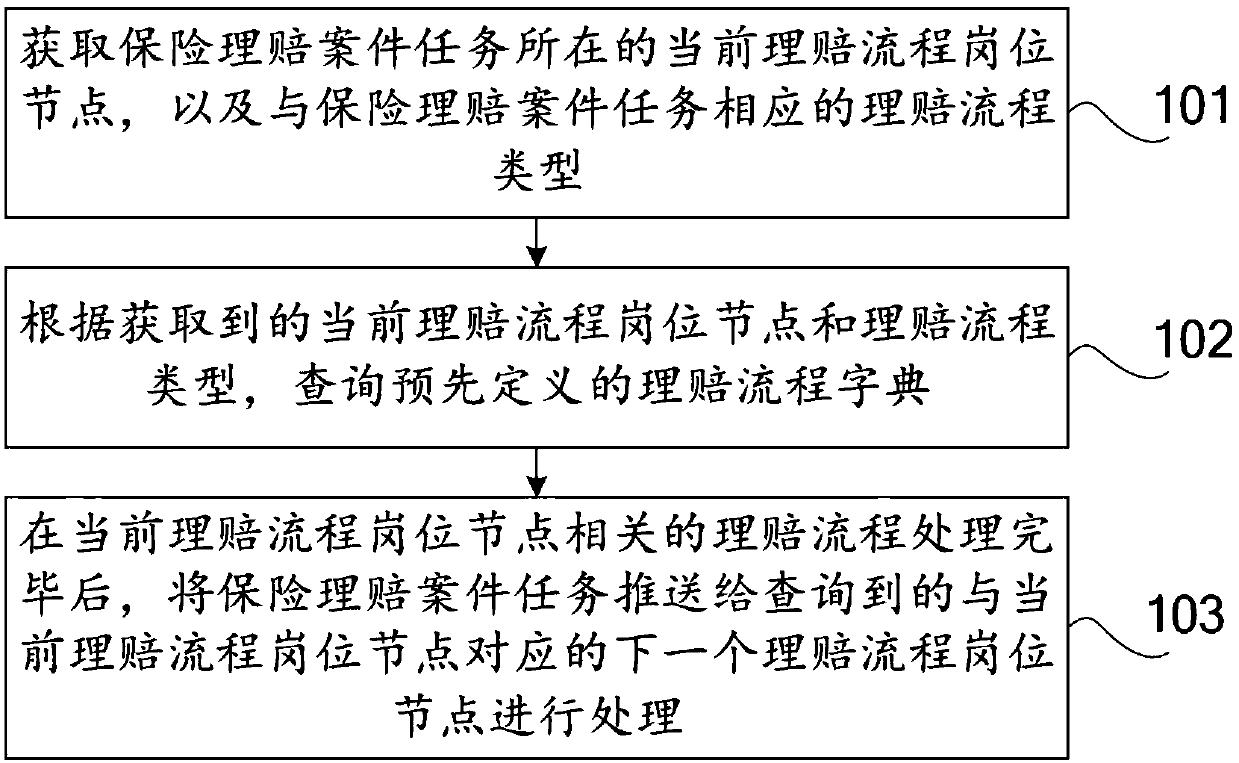

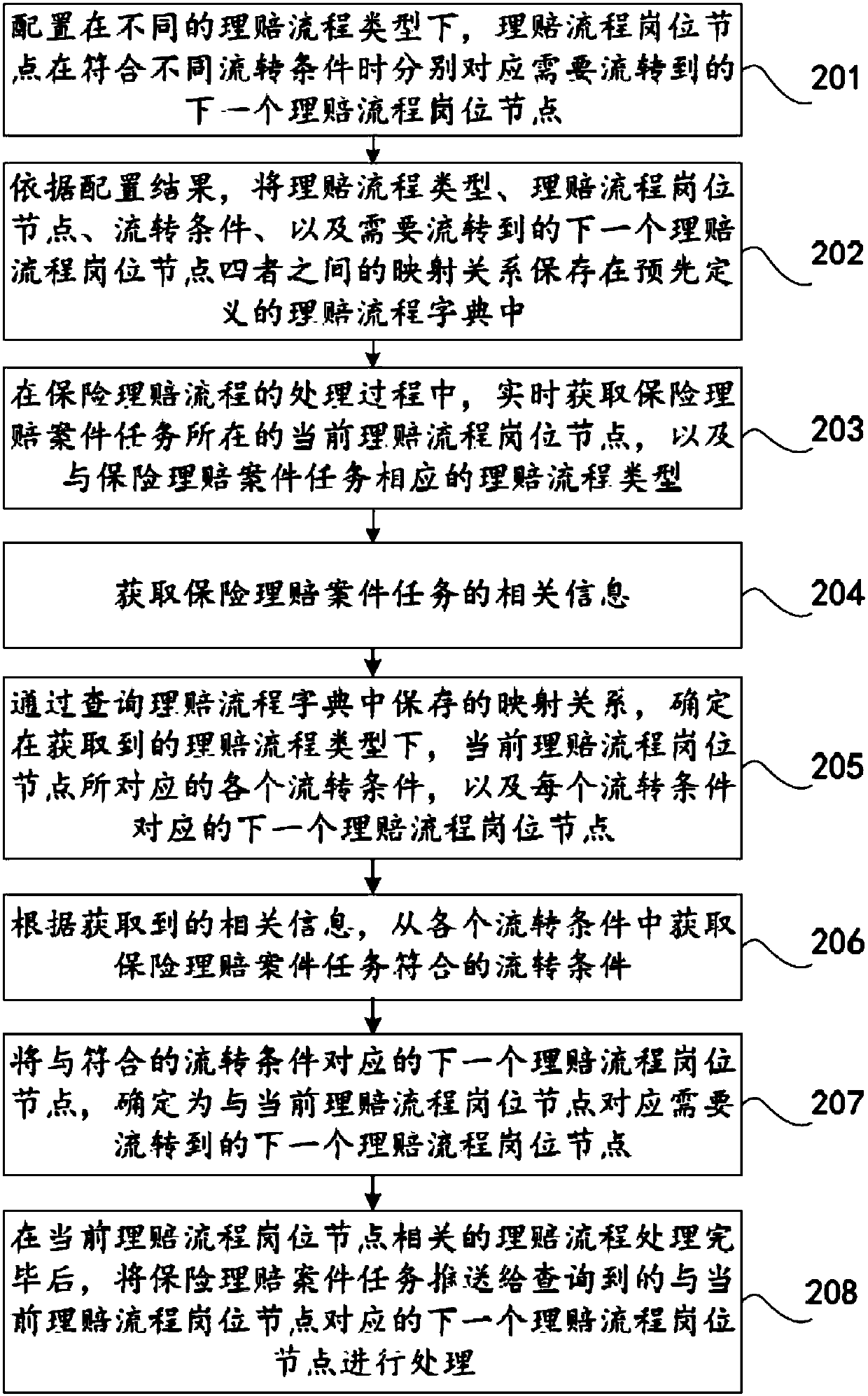

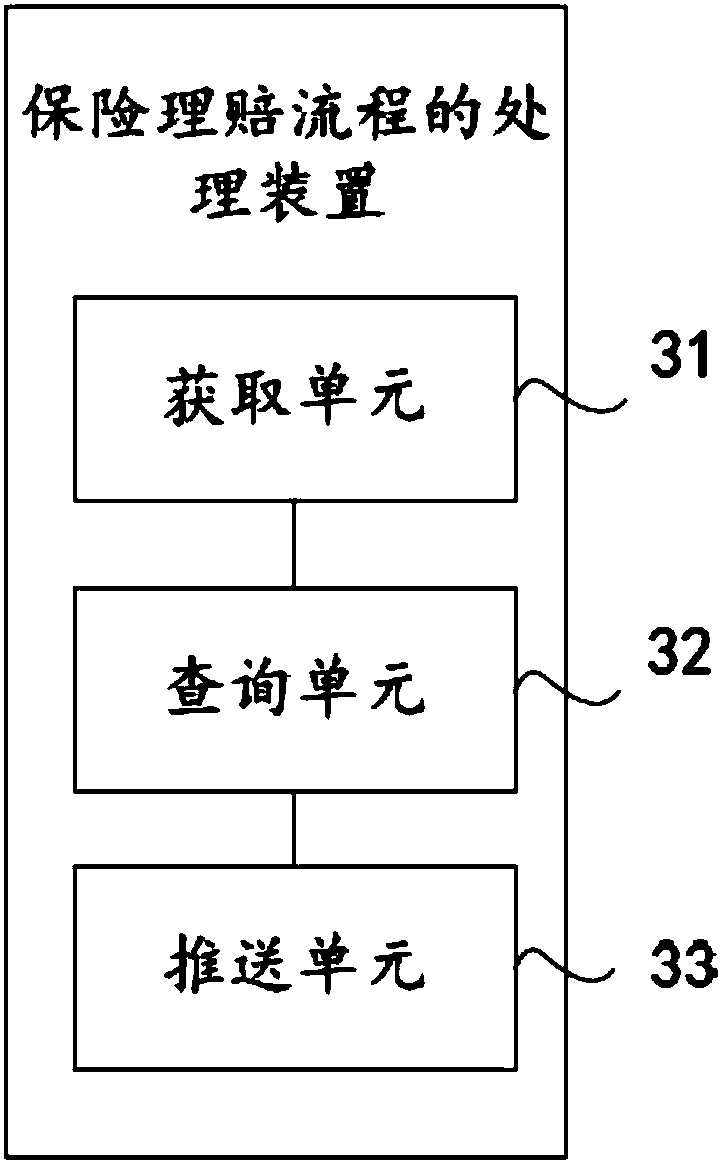

Method and device for processing insurance claim process

InactiveCN107909488ASave push timeImprove processing progressFinanceOffice automationComputer scienceProcess type

The invention discloses a method and a device for processing an insurance claim process, and relates to the technical field of insurance claim for improving the efficiency and the accuracy of the insurance claim. The method comprises the following steps of obtaining a current claim process station node where an insurance claim case task is located, and a claim process type corresponding to the insurance claim case task; inquiring a pre-defined claim process dictionary according to the current claim process station node and the claim process type, wherein the claim process dictionary includes next claim process station nodes which are respectively corresponding to the claim process station nodes and need to be transferred under different claim process types; and after the claim process related to the current claim settlement process station node is processed, pushing the insurance claim case task to the queried next claim process station node corresponding to the current claim settlement process station node for processing. The method and the device are suitable for processing the insurance claim process.

Owner:PING AN TECH (SHENZHEN) CO LTD

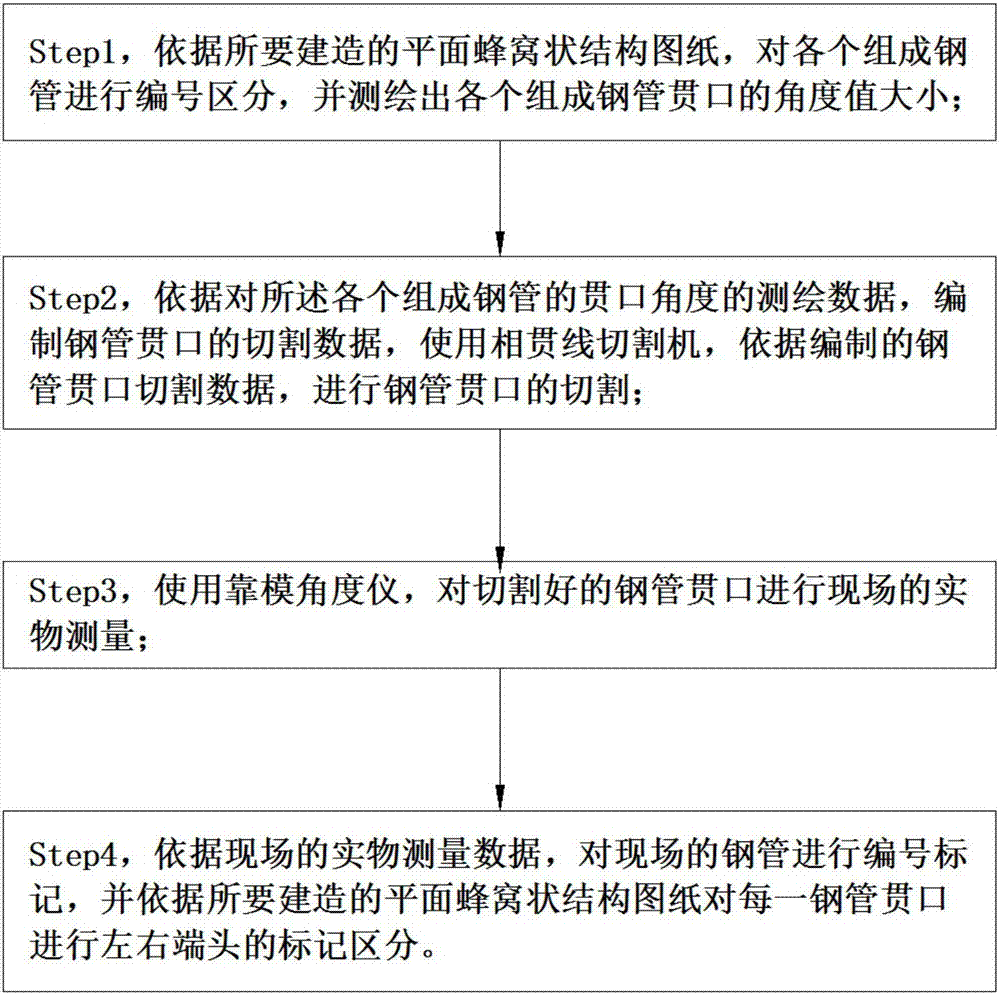

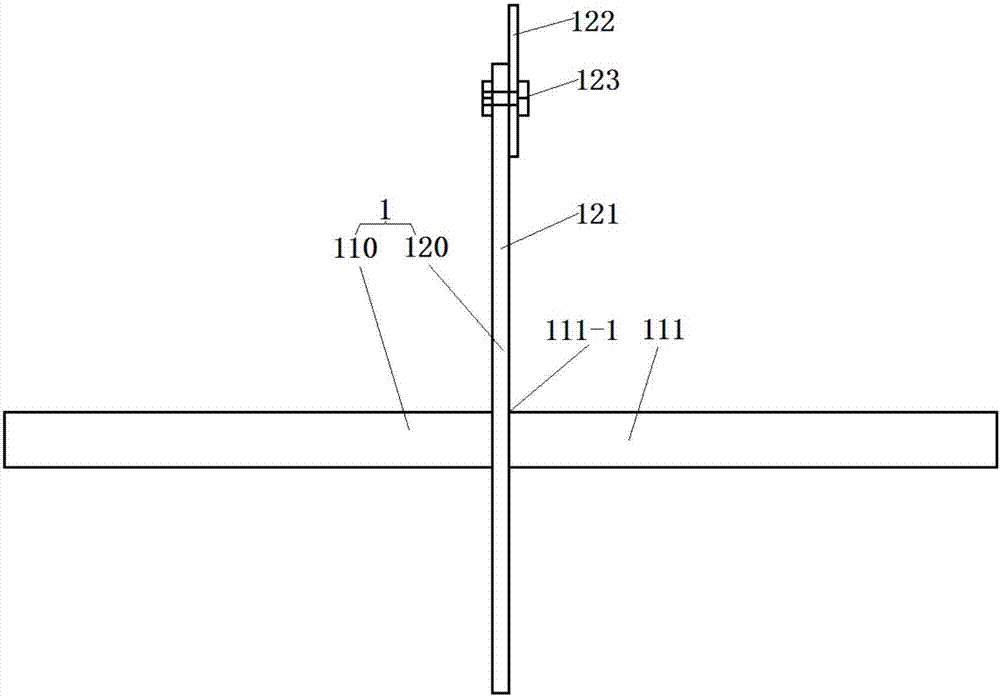

Planar honeycomb tube truss construction method applied to profiling angle instrument

ActiveCN107130805AImprove assembly efficiencyFlexible processingBuilding material handlingSurveyorHoneycomb structure

The invention discloses a planar honeycomb tube truss construction method applied to a profiling angle instrument. The method comprises the following steps of Step1, numbering various steel tubes for distinguishing according to a to-be-constructed planar honeycomb structure drawing, and surveying and mapping angle values of various through openings of forming the steel tubes; Step2, compiling cutting data of the through openings of the steel tubes for surveyed and mapped data of the angles of the through openings of forming the steel tubes, and cutting the through openings of the steel tubes by using an intersecting line cutting machine according to the compiled cutting data of the through openings of the steel tubes; Step3, carrying out on-site actual measurement on the cut through openings of the steel tubes by using the profiling angle instrument; and Step4, numbering and marking the steel tubes of the scene according to the actual measurement data of the scene, and numbering left and right ends of each through opening of the steel tube for distinguishing according to the to-be-constructed planar honeycomb structure drawing.

Owner:SHENZHEN JINXIN GREEN CONSTR LTD BY SHARE LTD

Screw tap machining method

A screw tap machining method is characterized in that coarse steel material is acidized and polished to remove surface dirt so as to obtain a blank, aging treatment is performed on the blank, thermal treatment is then performed on the blank, low-temperature preheating temperature is 245-300 DEG C, tempering temperature is 124-345 DEG C, tempering time is 30-40 minutes, machining a screw tap on a lathe, burr and quenching treatments are performed on a tapping part, quenching temperature is 500 DEG C, sand conditioning is performed on a screw tap part, carburization is then performed, the taken-out screw tap is soaked in mixed solution of polyurethane and sodium benzoate, the concentration of the polyurethane is 45-60%, and the concentration of the sodium benzoate is 4-5%. By the method which is simple and few in steps, the screw tap with the durable screw tap part can be manufactured, use of the screw tap is facilitated, and machining progress is increased.

Owner:吴加庆

Pushing wheel type gluing system and using method

ActiveCN106076733AEvenly distributedEasy to useLiquid surface applicatorsCoatingsGear wheelEngineering

The invention discloses a pushing wheel type gluing system and a using method. The pushing wheel type gluing system comprises a machine base and a workbench arranged on the machine base, wherein guide rail slide slots are formed at the front side and the rear side in the length direction of the workbench; a first slide block and a second slide block are separately arranged in the guide rail slide slots at the front side and the rear side in a sliding fit mode; a beam is connected between the first slide block and the second slide block; a grinding roller is hinged on a supporting framework; a glue accommodating cavity is arranged at the side end of the grinding roller; a sealing plug capable of sealing a feeding hole is fixedly connected on a rotary shaft; a lower glue plate is arranged on the bottom of the glue accommodating cavity; a plurality of drip holes which are horizontally arranged are formed in the lower glue plate; the feeding hole communicates with a loading box through a glue tube; the end part of the grinding roller is fixedly connected to a first gear; and a second gear engaged with the first gear is mounted on the end part of the rotary shaft. The using method comprises three steps of discharging, motor starting and feeding hole automatic opening. The pushing wheel type gluing system aims to solve the problem that processing progress and efficiency are affected by material stacking collapse due to the fact that a current gluing section bar is flatted by a heavy object.

Owner:重庆新锐科技服务有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com