Steel plate crankle processing technology and special apparatus thereof as well as crankle component processing technology

A technology of processing technology and special equipment, which is applied in the field of steel plate bending and torsion processing, can solve the problems of narrow internal space, difficult welding, and large processing errors of steel plate parts, and achieves simple structure, fast processing speed, and guaranteed forming quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

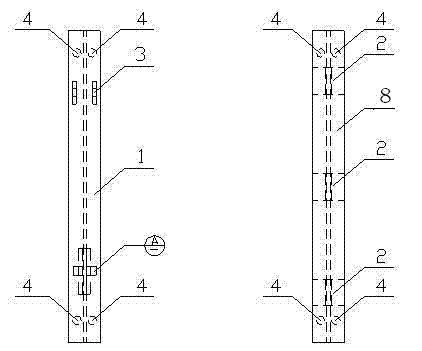

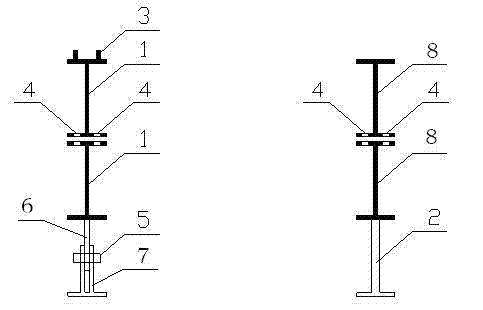

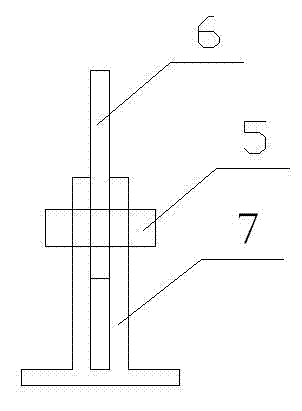

[0026] like Figure 1-3 The special equipment for steel plate bending and torsion shown is divided into a fixed side fixture 1 and a rotating side fixture 8. Both the fixed side fixture 1 and the rotating side fixture 8 are composed of an upper plate and a lower plate, and the upper plate and the lower plate are made of 20# I-beam I-beam, the bottom of the upper plate and the top of the lower plate have bolt holes 4, through which the bolt holes are connected by M18 bolts, the lower plate of the fixed side clamp is fixed on the supporting base 2, and one end of the lower plate of the rotating side clamp is fixed on the shaft hole. On the connecting plate 6, the connecting plate 6 is installed on the twisted support 7 through the rotating shaft core 5 with a diameter of 48mm, and the other end is a suspended pressure end, and the pressure end of the rotating side clamp has a baffle 3, that is, the steel plate is bent and twisted. Special unilateral fixed twisted shaft bending e...

Embodiment 2

[0028] Steel plate bending and torsion processing technology, the plate is placed in the single-sided fixed twisted shaft bending equipment, and the hydraulic equipment is used to press down at a single point, and the fixture rotates around the rotating shaft. During the process, the flame is combined with mechanical correction, and the flame temperature is 100°C lower than the normal correction temperature; after forming, continue to pressurize and let it stand for 2 to 3 days. After the deformation has no rebound tendency, slowly release the pressure and check the spatial position of the steel plate after forming , The positional relationship of the coordinate points of the steel plate to ensure that it meets the requirements of the detailed design drawings.

Embodiment 3

[0030] The processing technology of bending and torsion components is carried out in four steps: steel plate bending and torsion → pre-assembly → reassembly → welding and flaw detection. The specific process is as follows: Figure 4 Shown:

[0031] The first step is to bend and twist the steel plate: use special equipment to place the upper flange plate, the lower flange plate, the web on both sides and the longitudinal stiffener on the special equipment to make the space bent and twisted steel plate. First, place the plate on one side and fix it Twisted shaft bending equipment adopts hydraulic equipment to press down at a single point, and the fixture rotates around the rotating shaft. When pressing down, it is urgent and then slow, step by step, and carried out in stages; the bending process is corrected with flames and machinery, and the flame temperature is corrected higher than normal The temperature is 100°C lower; after forming, continue to pressurize and let it stand f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com