Novel purline molding device

A forming device and a new type of technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of unguaranteed accuracy, time-consuming and laborious processing, etc., and achieve the effect of saving processing costs, improving safety, and fast measurement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

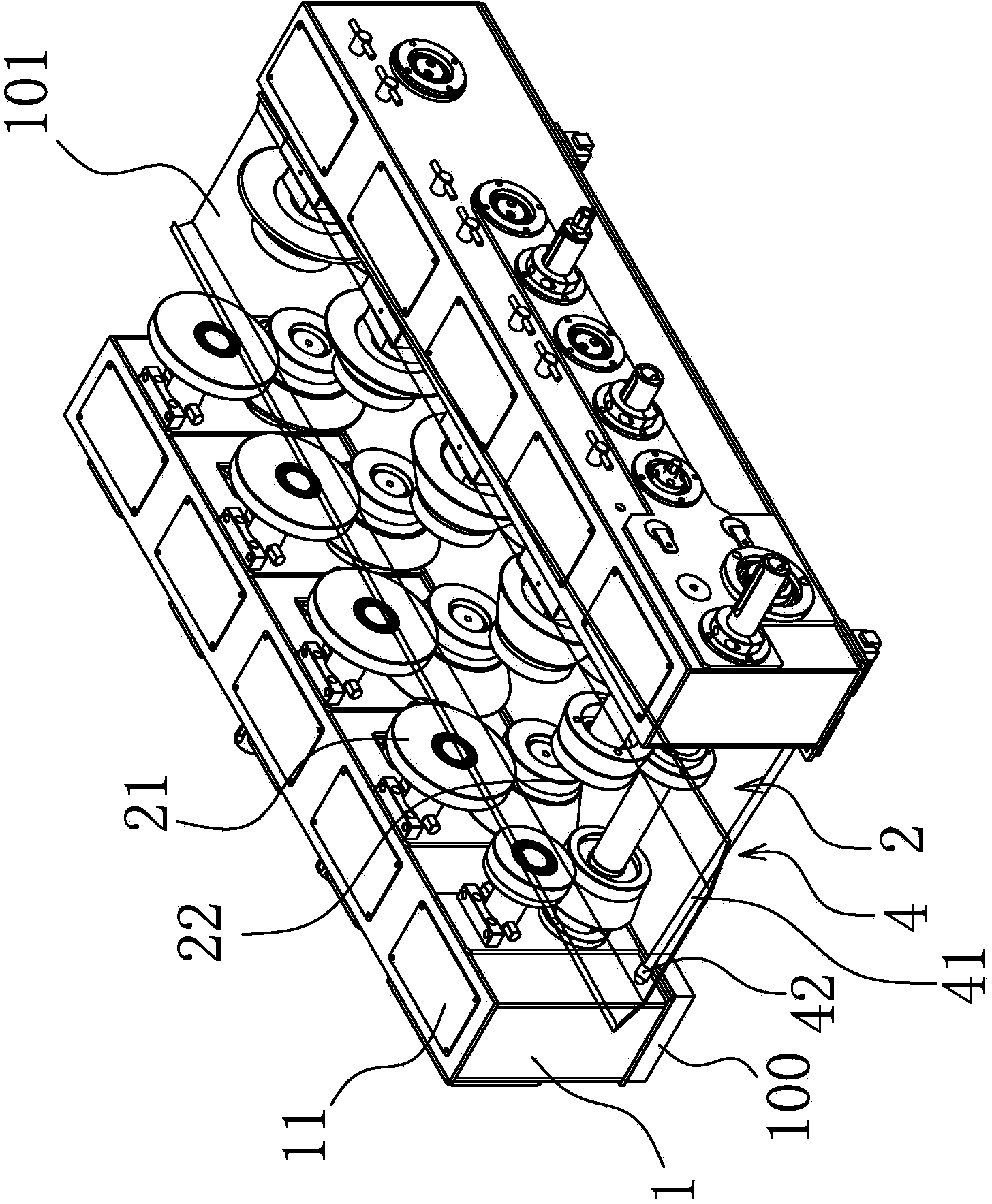

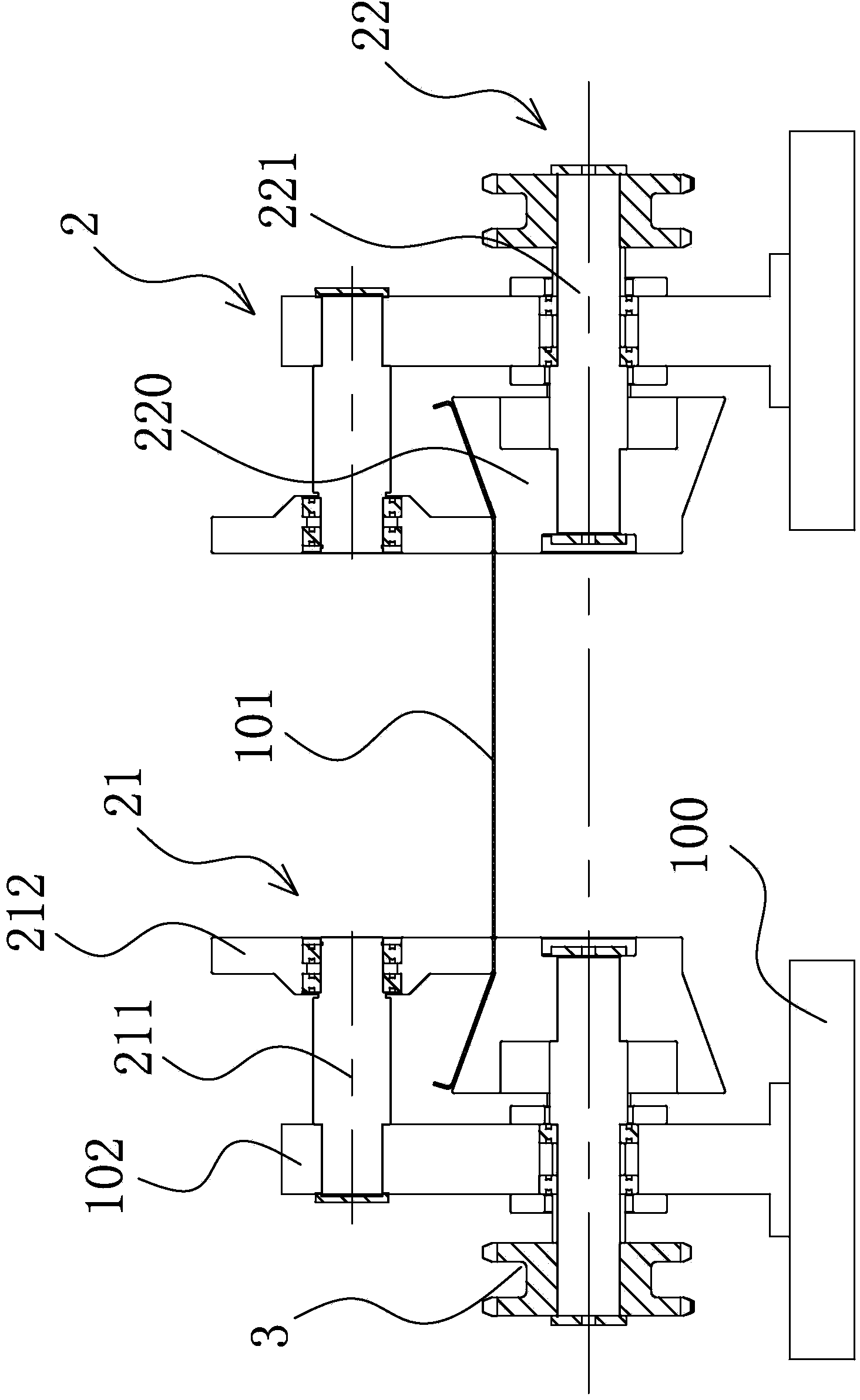

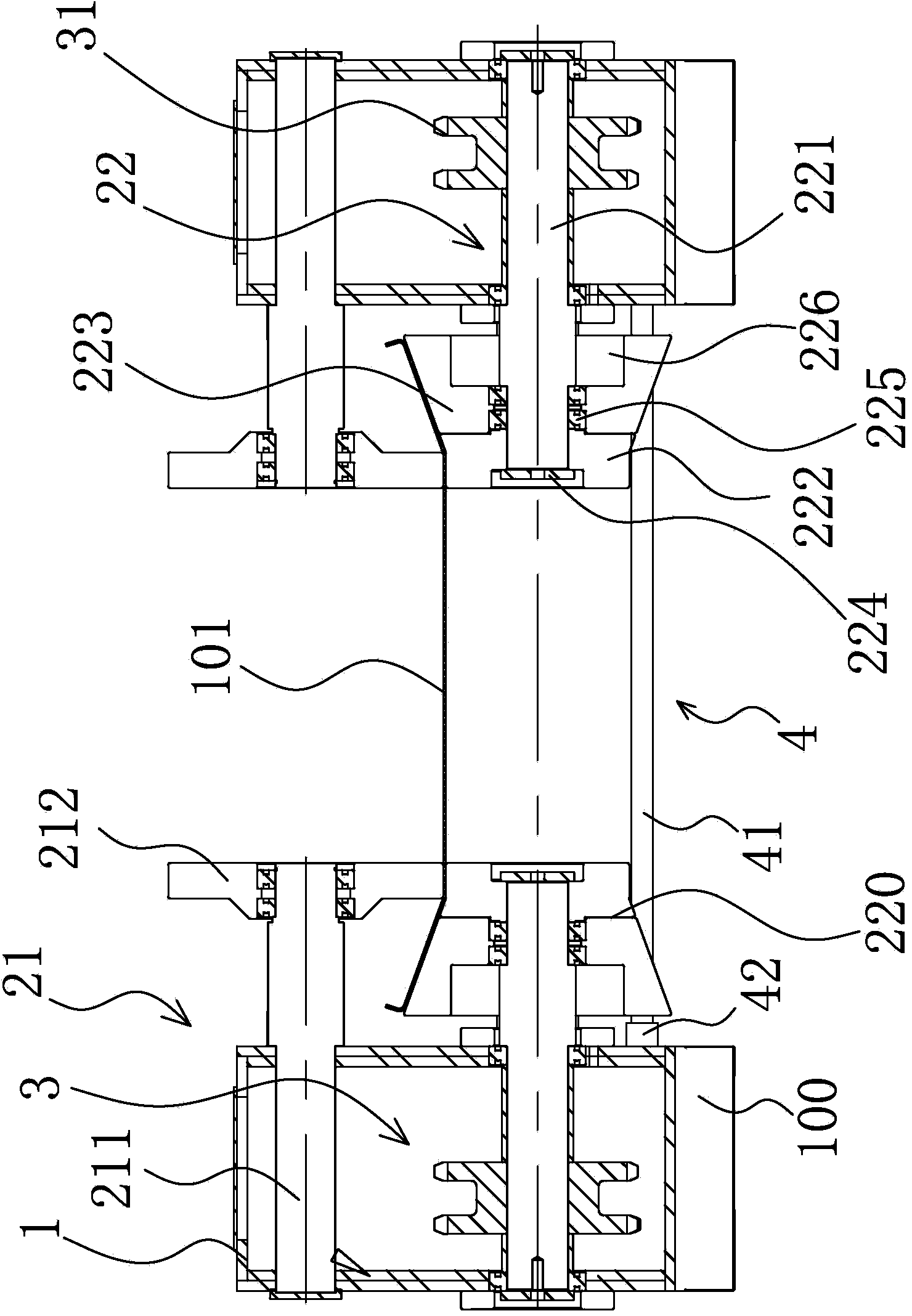

[0023] Such as figure 1 , image 3 As shown, the present invention provides a new purlin forming device, including a machine base 100, two transmission boxes 1 are oppositely arranged on the machine base 100, and the distance between the two transmission boxes 1 is on the machine base 100 Adjustable, easy to replace and produce purlins of different specifications. The transmission box 1 is a hollow structure surrounded by plates, and its shape can be varied. In this embodiment, the transmission box 1 is in the shape of a cuboid. The side wall of the body 1 is provided with several positioning holes (not shown in the figure), and the roller forming mechanism 2 is detachably installed on the transmission case 1 through the positioning holes, and the roller forming mechanism 2 includes an upper roller assembly 21 and the lower roller assembly 22, the lower roller assembly 22 is connected to the drive mechanism 3 and the drive mechanism 3 is arranged in the transmission case 1, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com