Patents

Literature

58results about How to "Low friction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

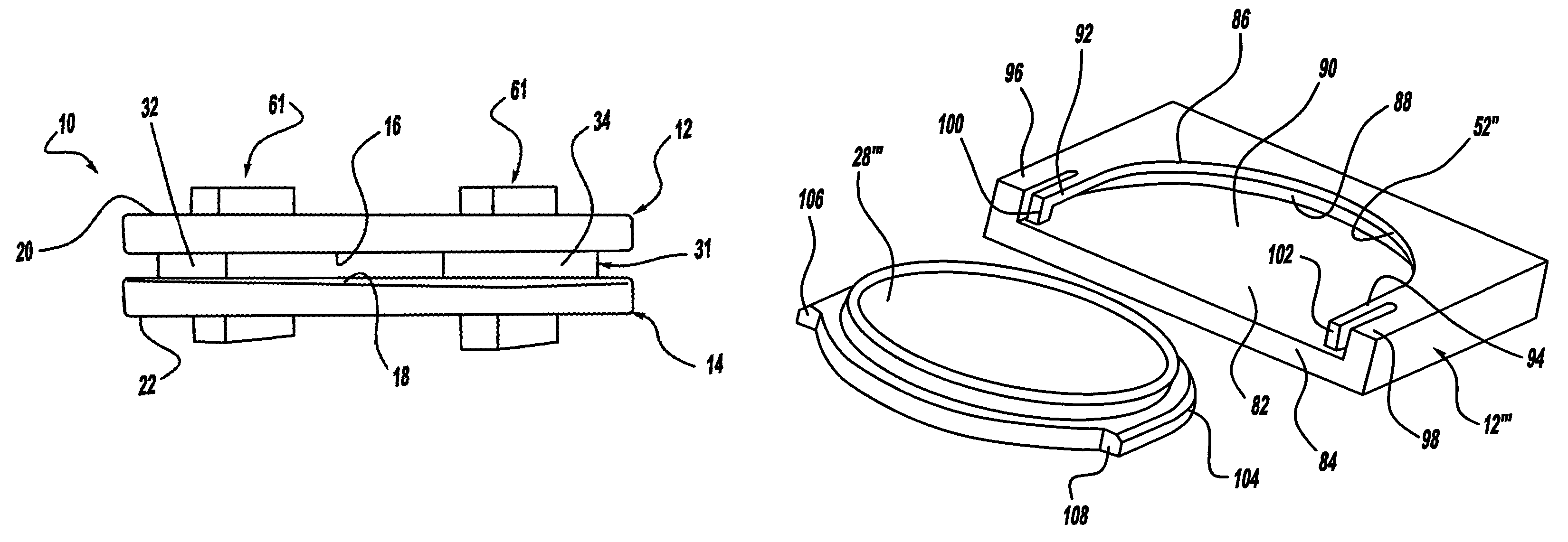

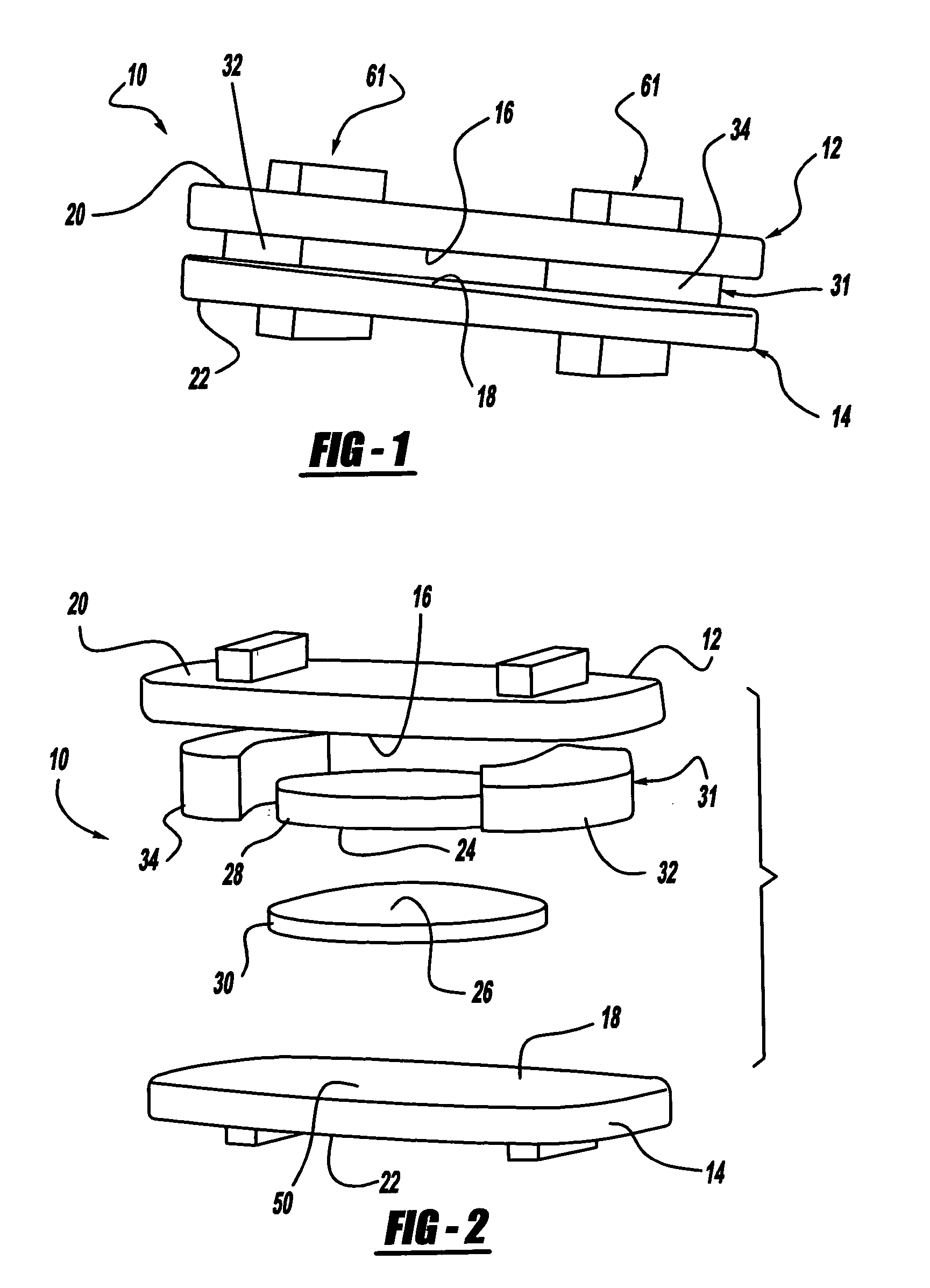

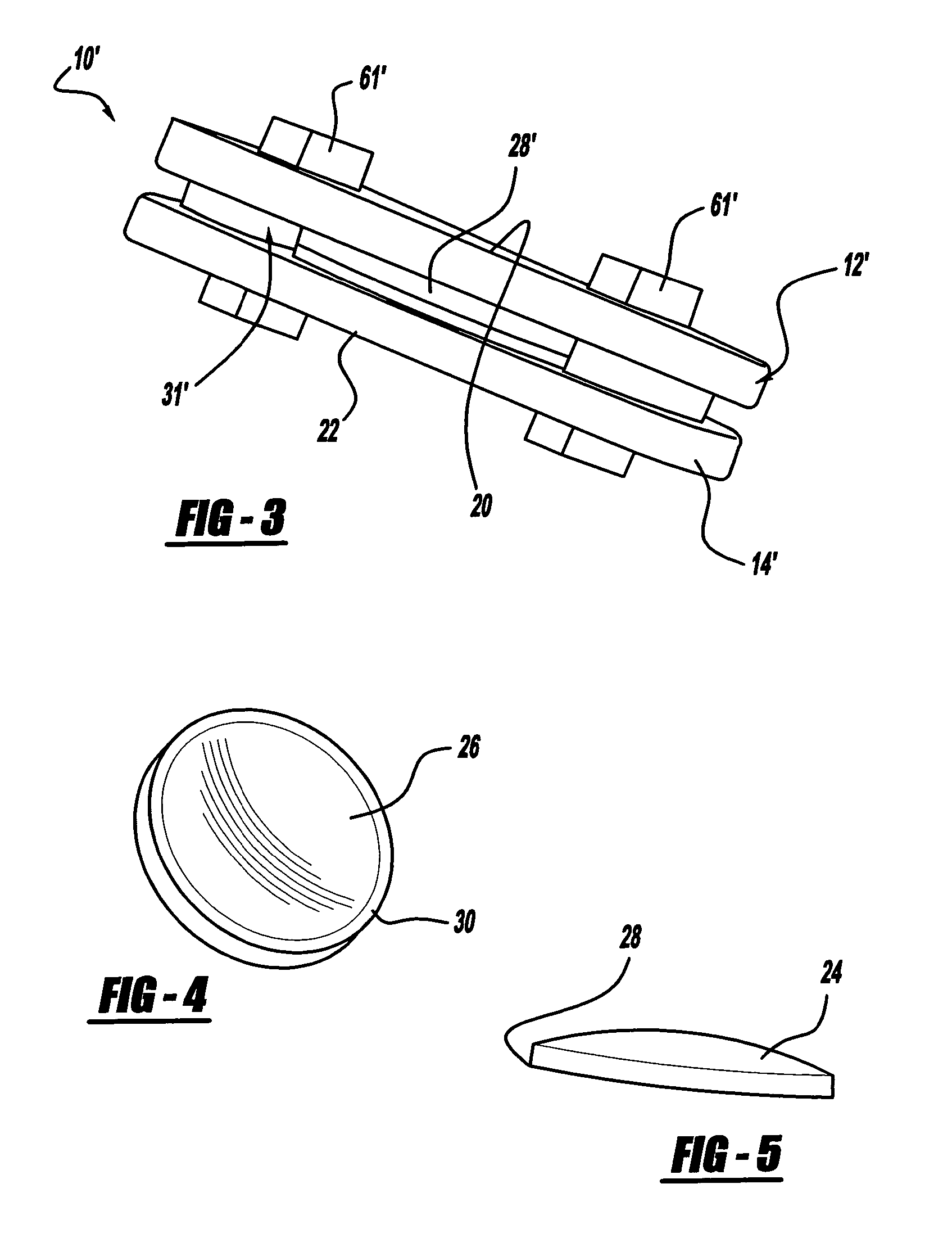

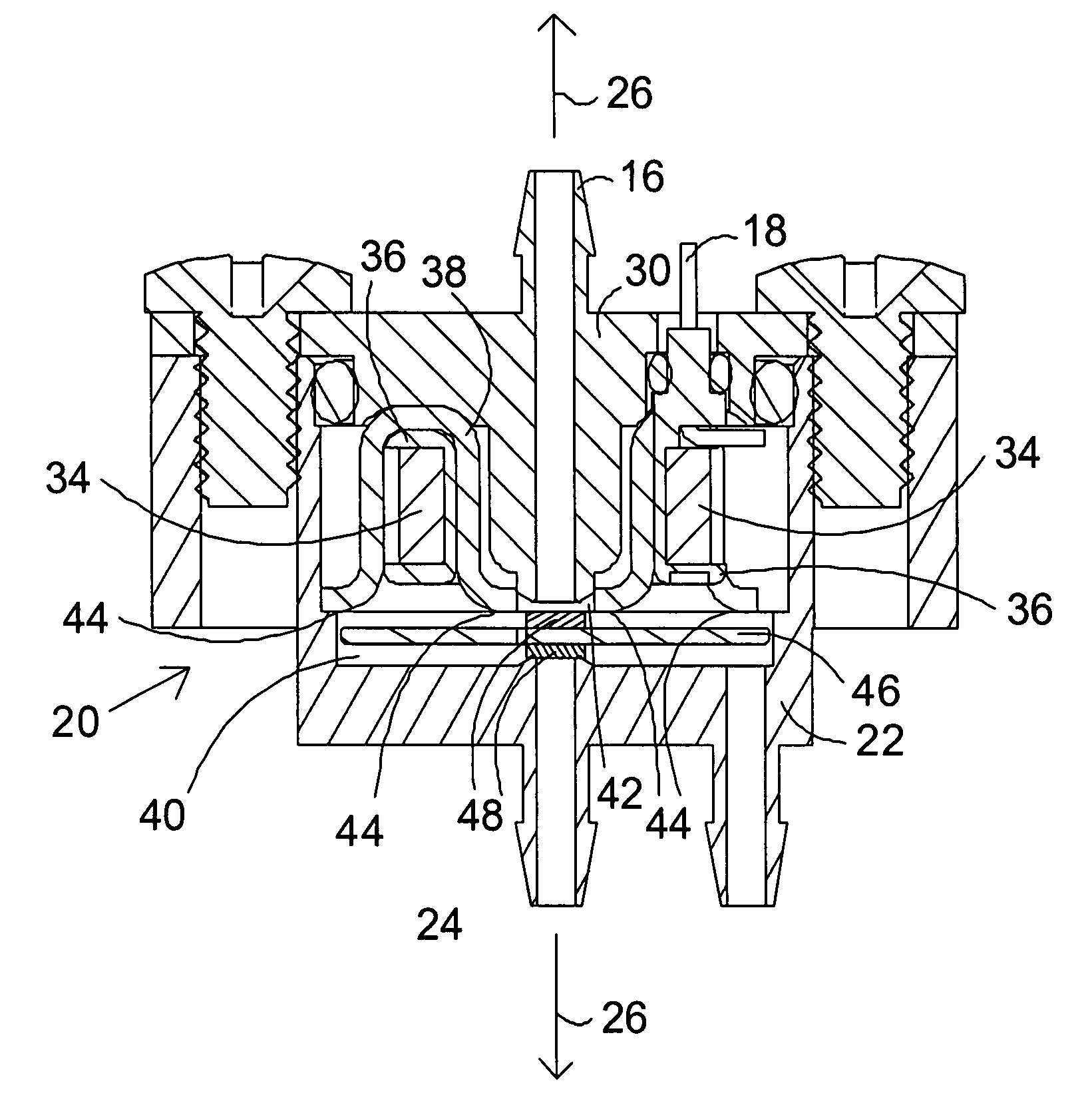

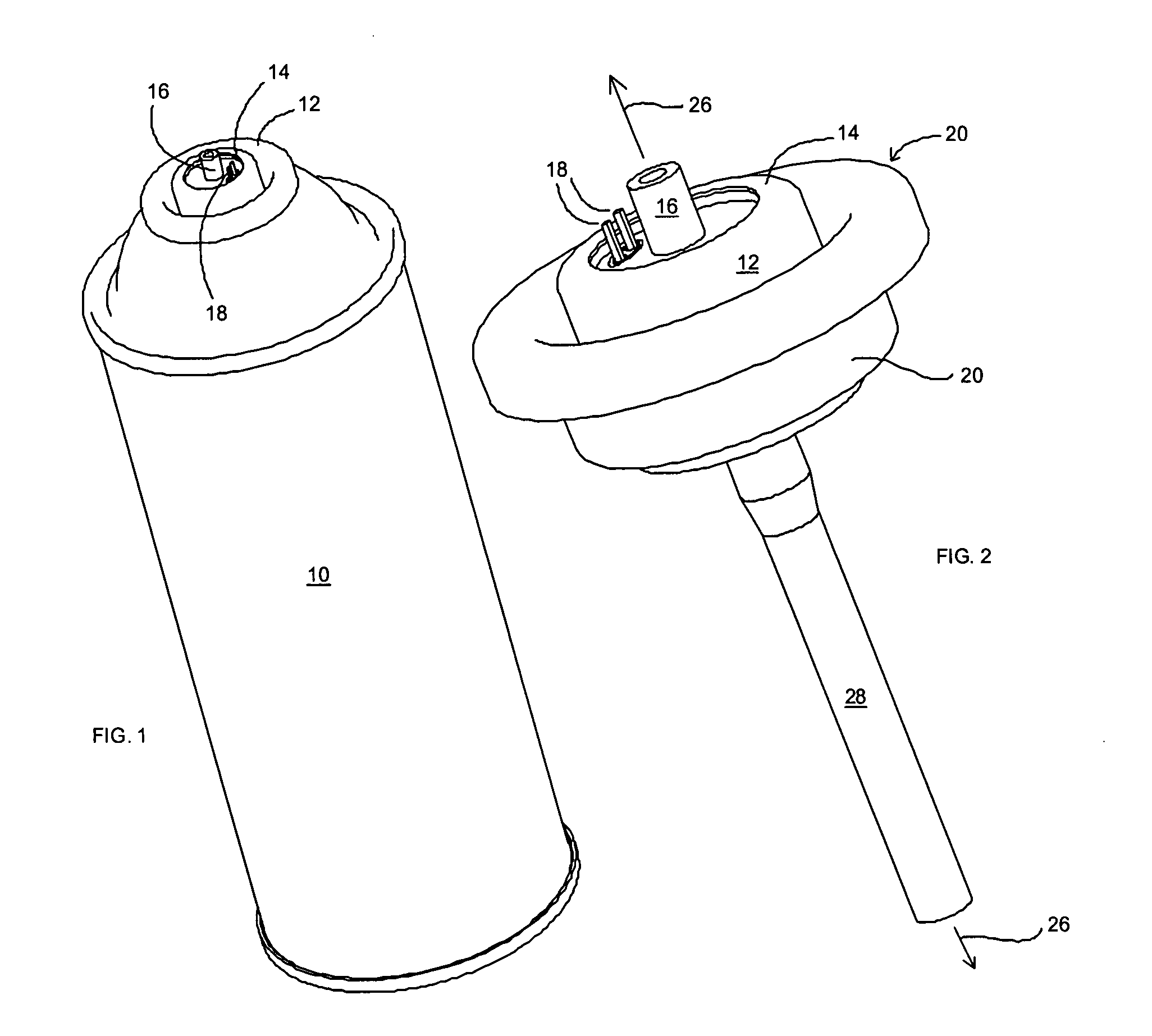

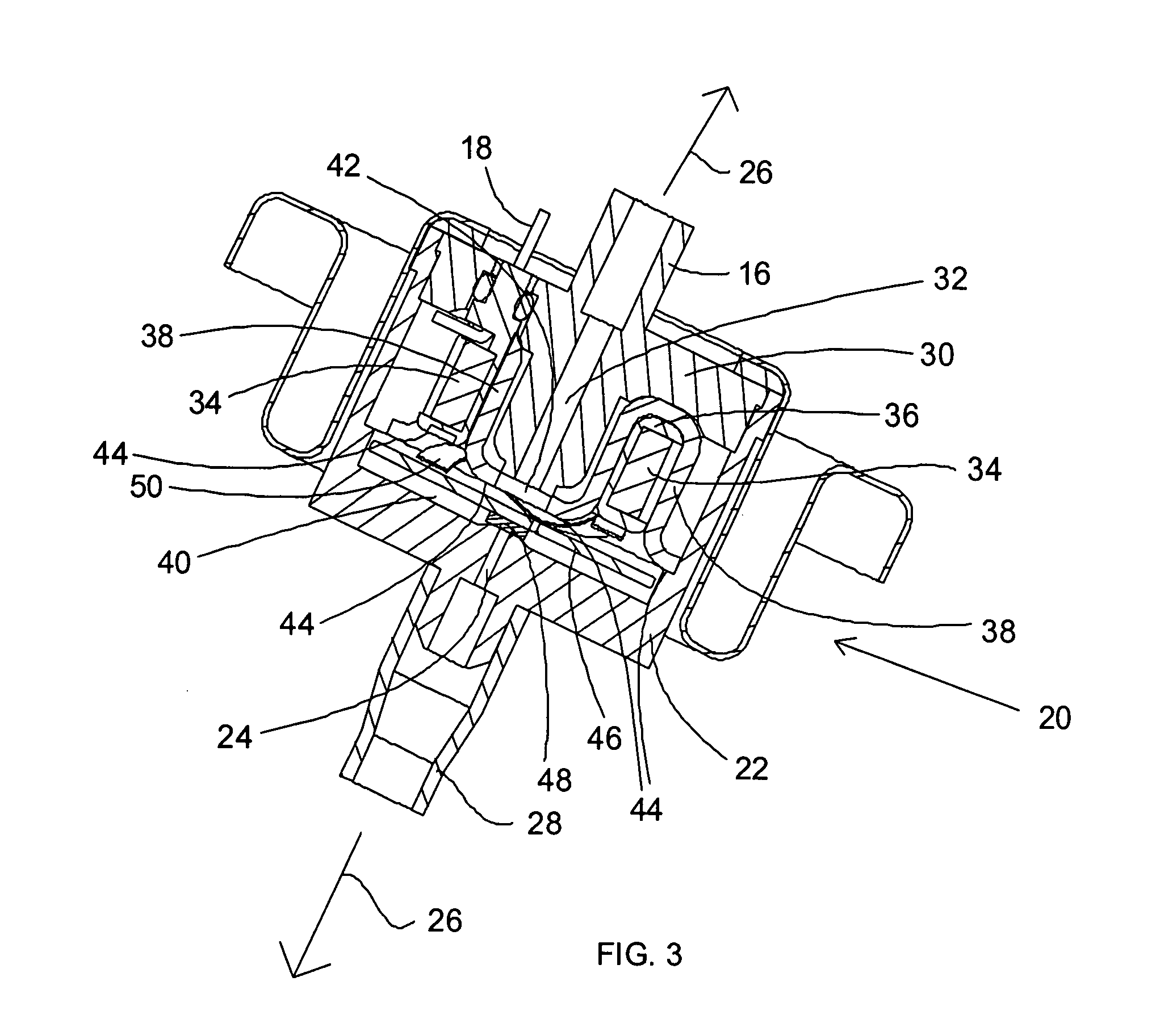

Artificial intervertebral disc

An artificial intervertebral disc includes housing members including spaced inner surfaces facing each other and oppositely facing outer surfaces for engaging spaced apart vertebral surfaces. Bearing surfaces extend from each of the inner surfaces for engaging each other while allowing for low friction and compression resistant movement of the housing members relative to each other while under compression. Load sharing pads are disposed between the inner surfaces and about at least a portion of the bearing surfaces for sharing absorption compressive loads with the bearing surfaces while limiting the relative movement of the housing members.

Owner:AESCULAP IMPLANT SYST

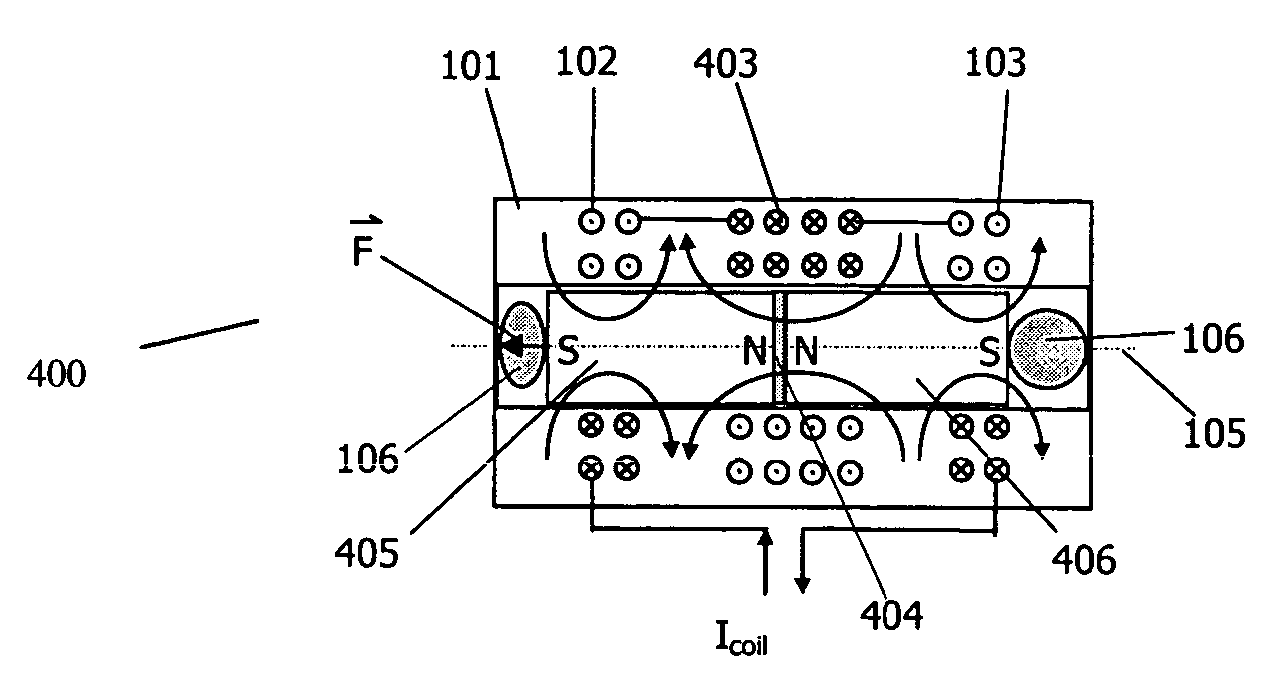

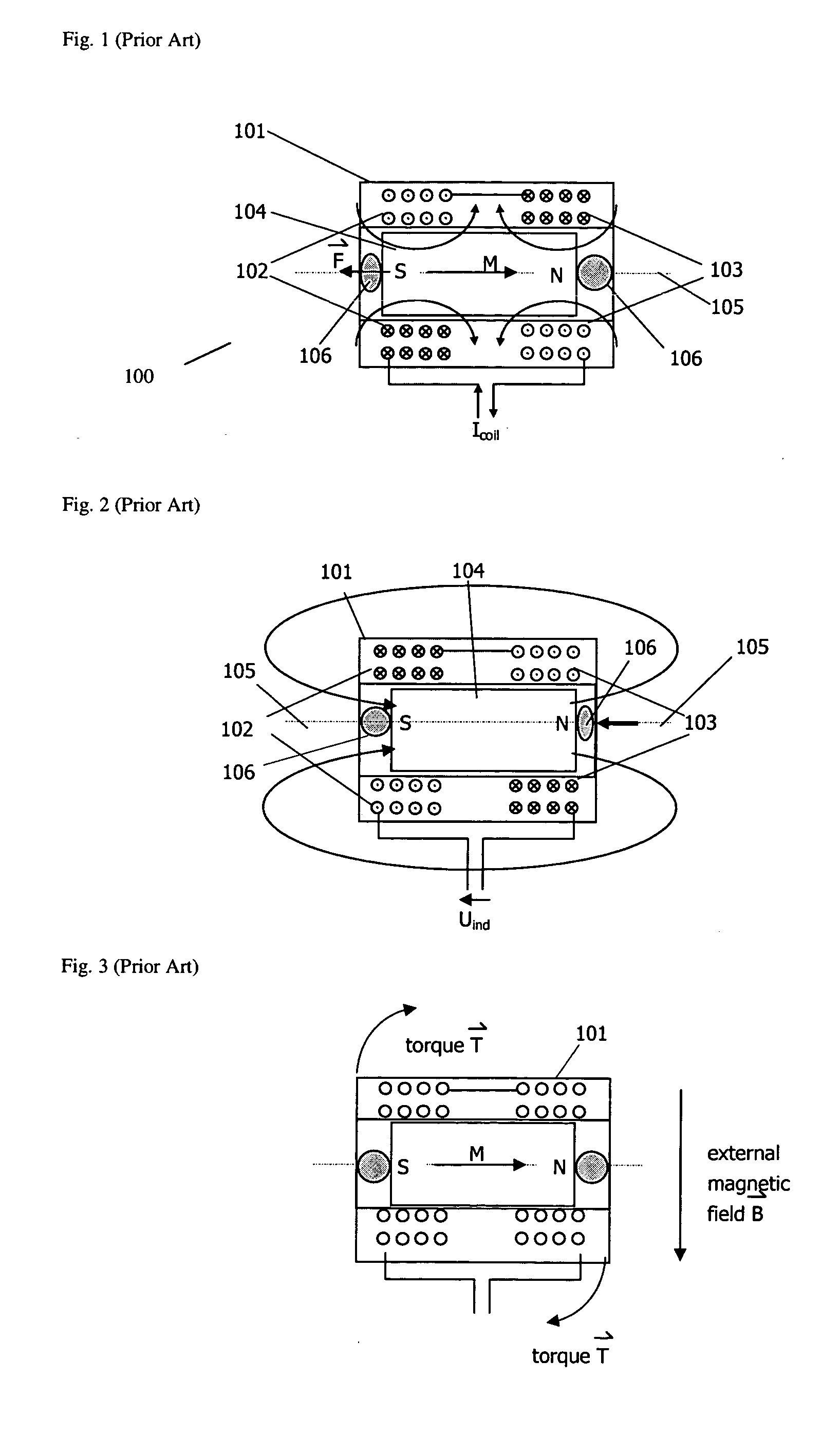

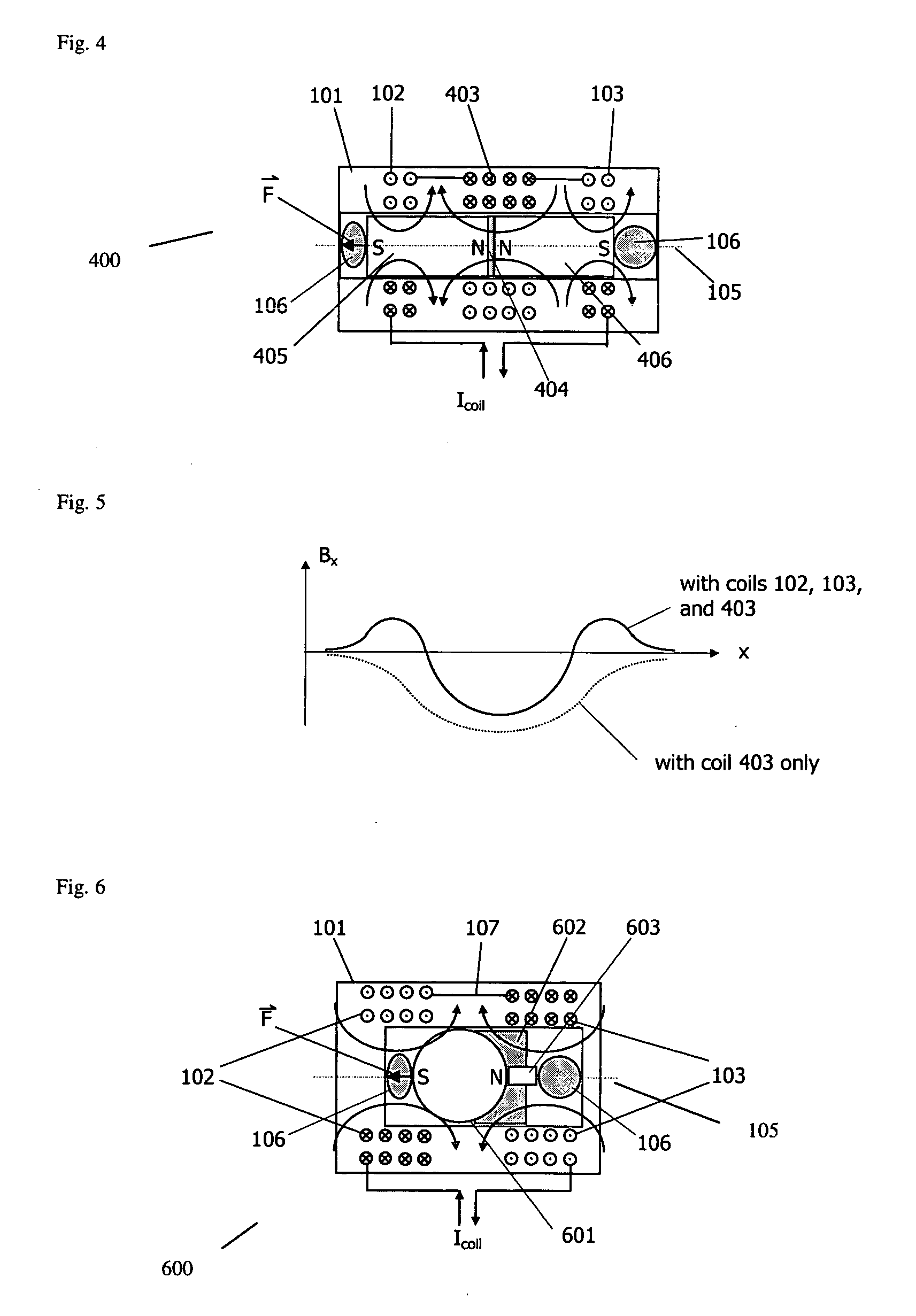

System and method for reducing effect of magnetic fields on a magnetic transducer

ActiveUS20050001703A1Low frictionReduce frictionVibration measurement in solidsMagnetic movement switchesMagnetMagnetic transducers

An electromagnetic driver transducer free of torque in the presence of an external magnetic field, of any direction and orientation (such as in a Magnetic Resonance Imaging environment). The transducer includes a housing. At least one coil is associated with the housing. A plurality of magnets within the housing are aligned along an axis in an anti-parallel orientation. The magnets are free to move along an axis, wherein vibration of the magnets causes vibration of the housing. The transducer may be, for example, fixed to an ossicle.

Owner:MED EL ELEKTROMEDIZINISCHE GERAETE GMBH

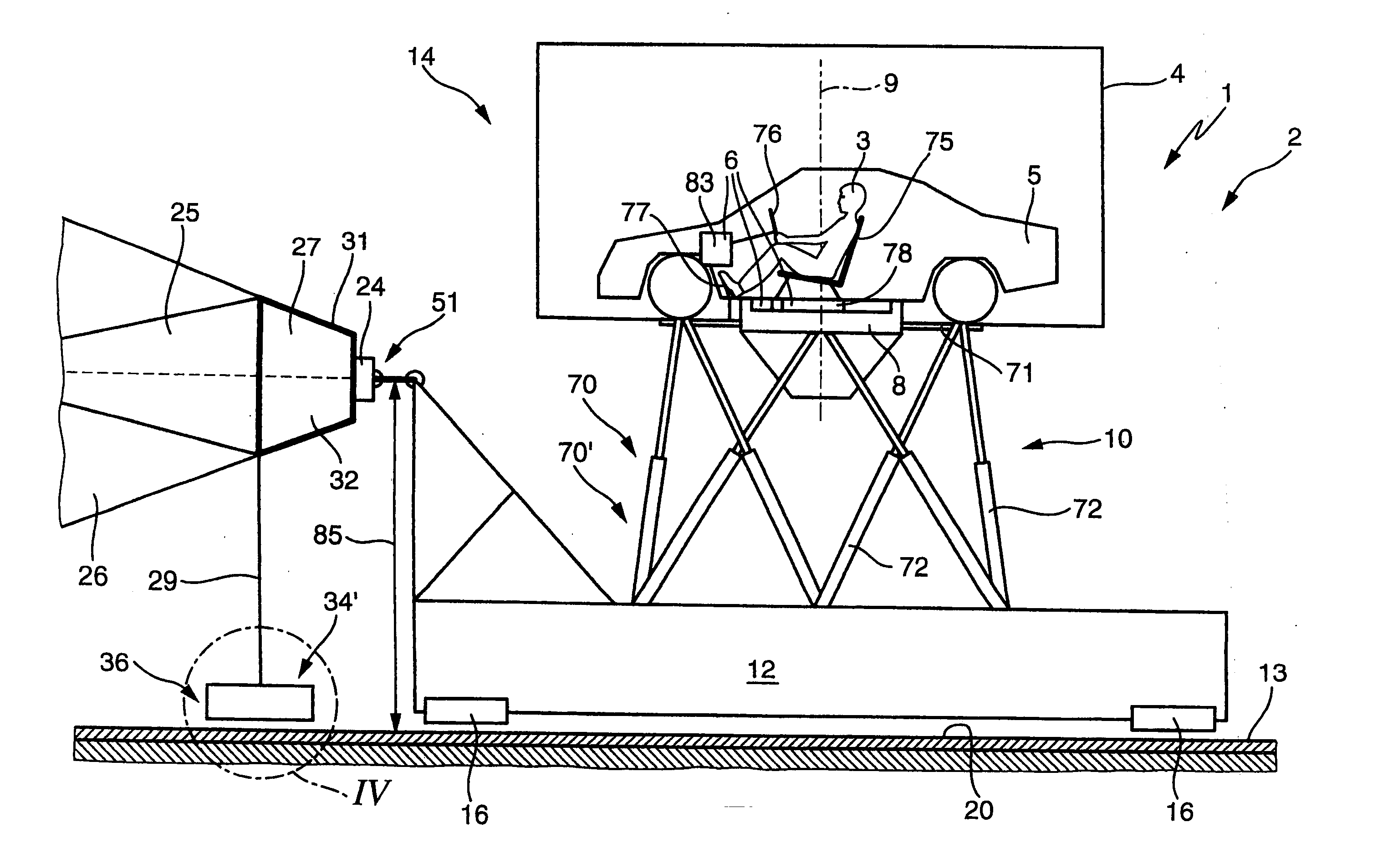

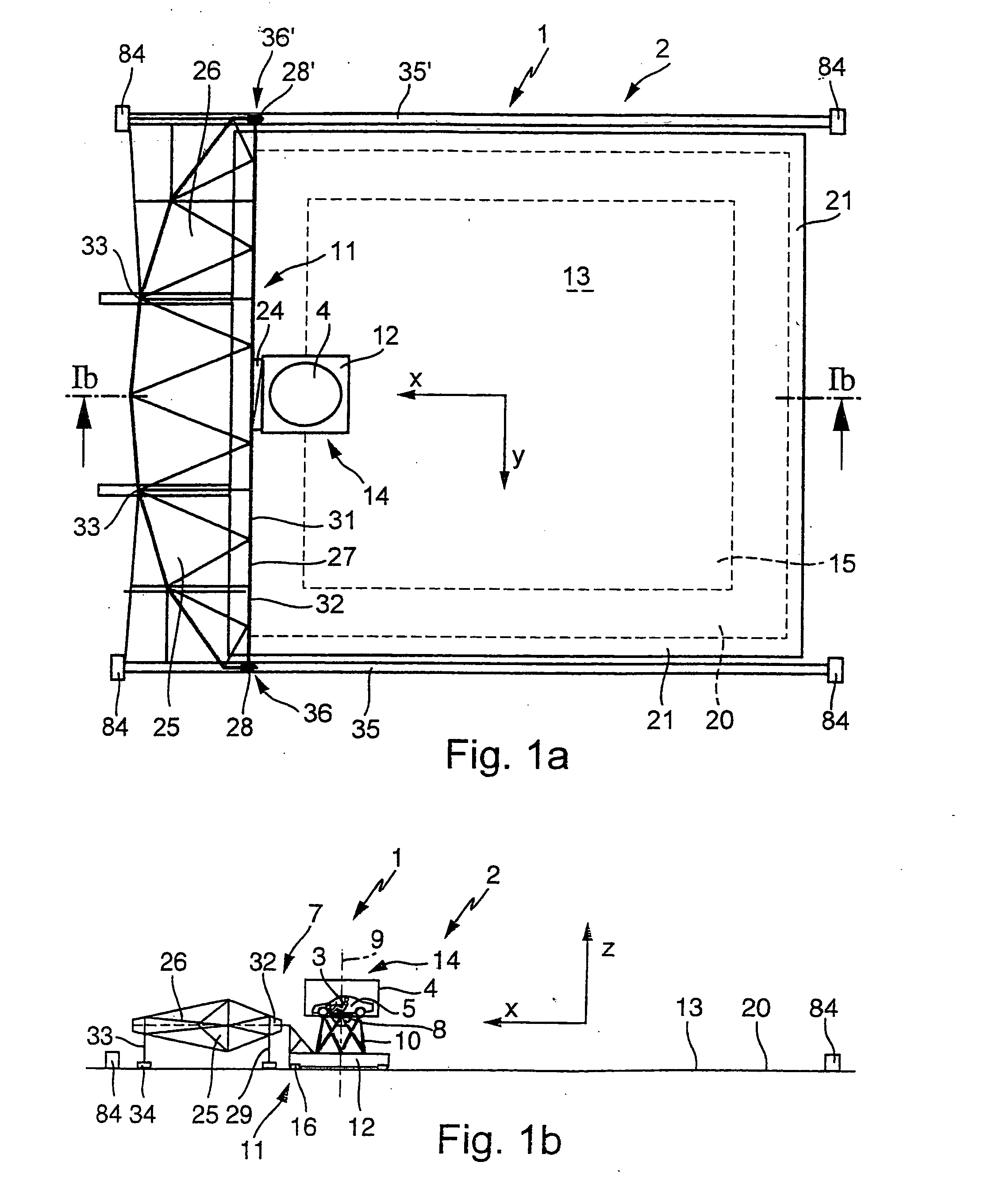

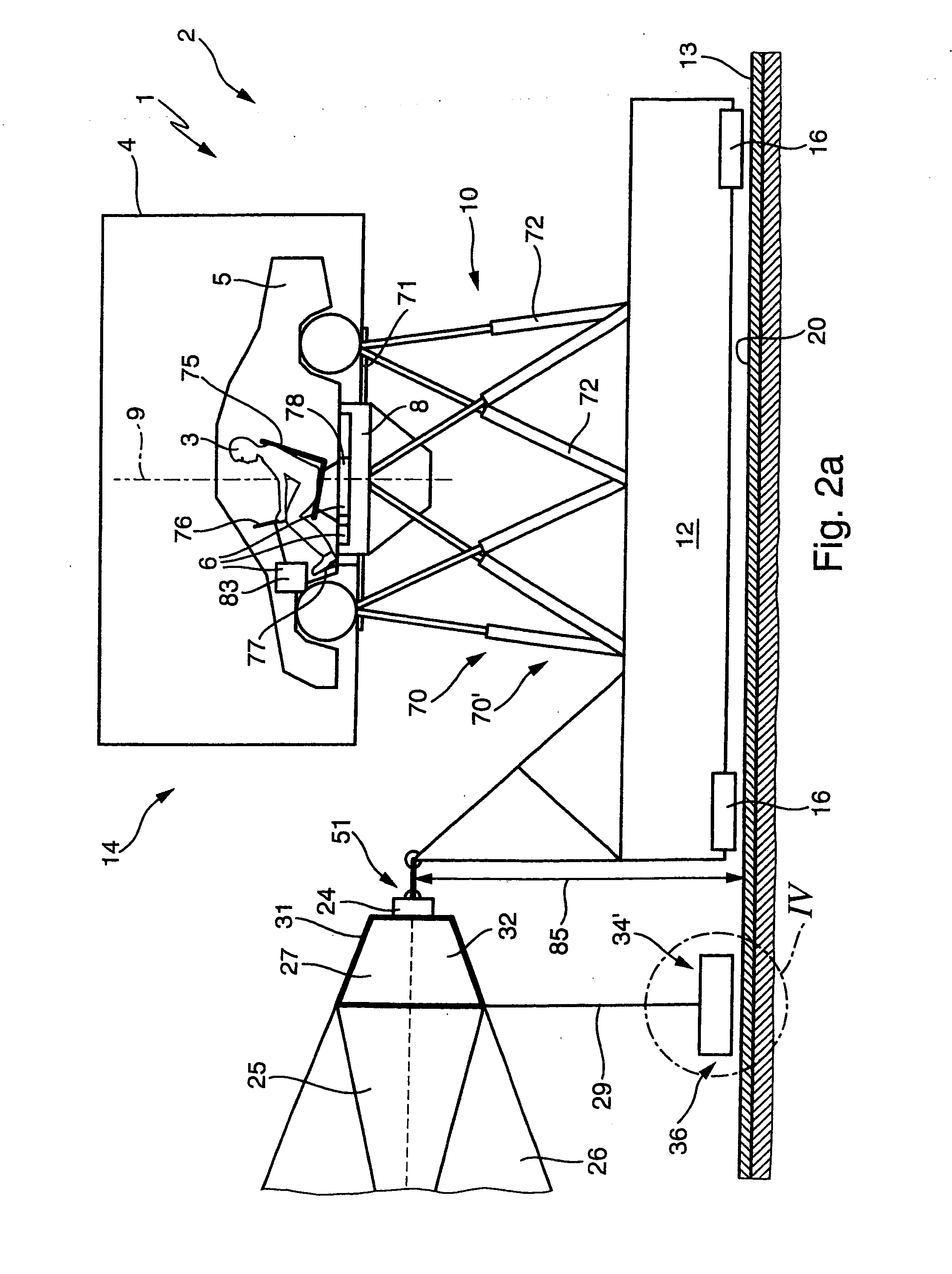

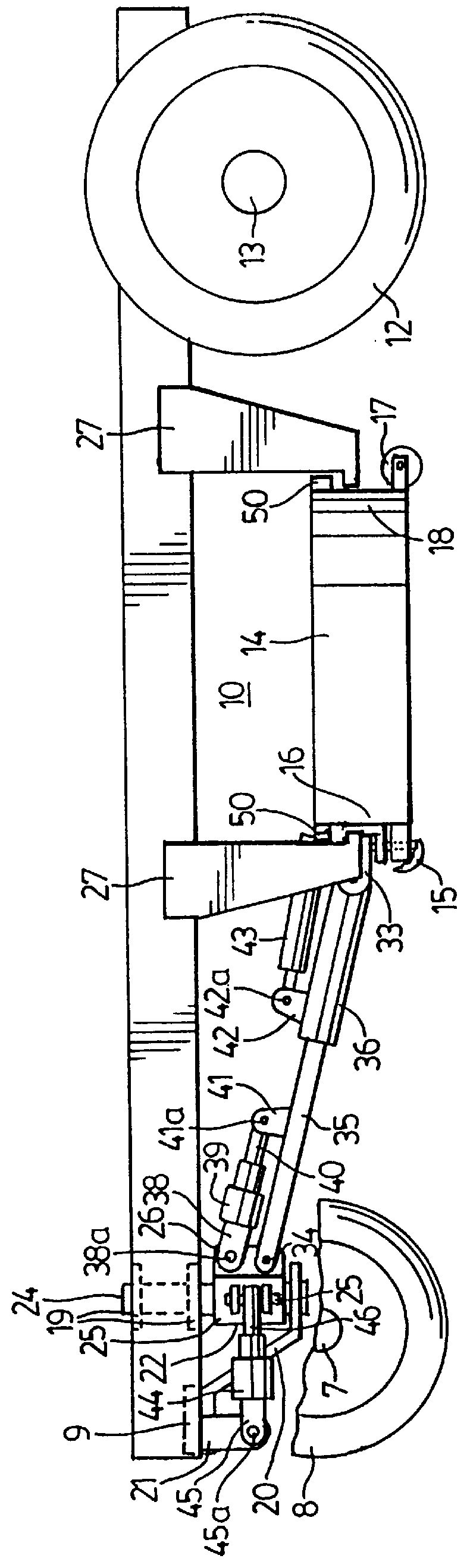

Driving simulator

InactiveUS20050042578A1Prevent riskLow frictionVehicle testingCosmonautic condition simulationsManipulatorDriving simulator

Owner:DAIMLER AG

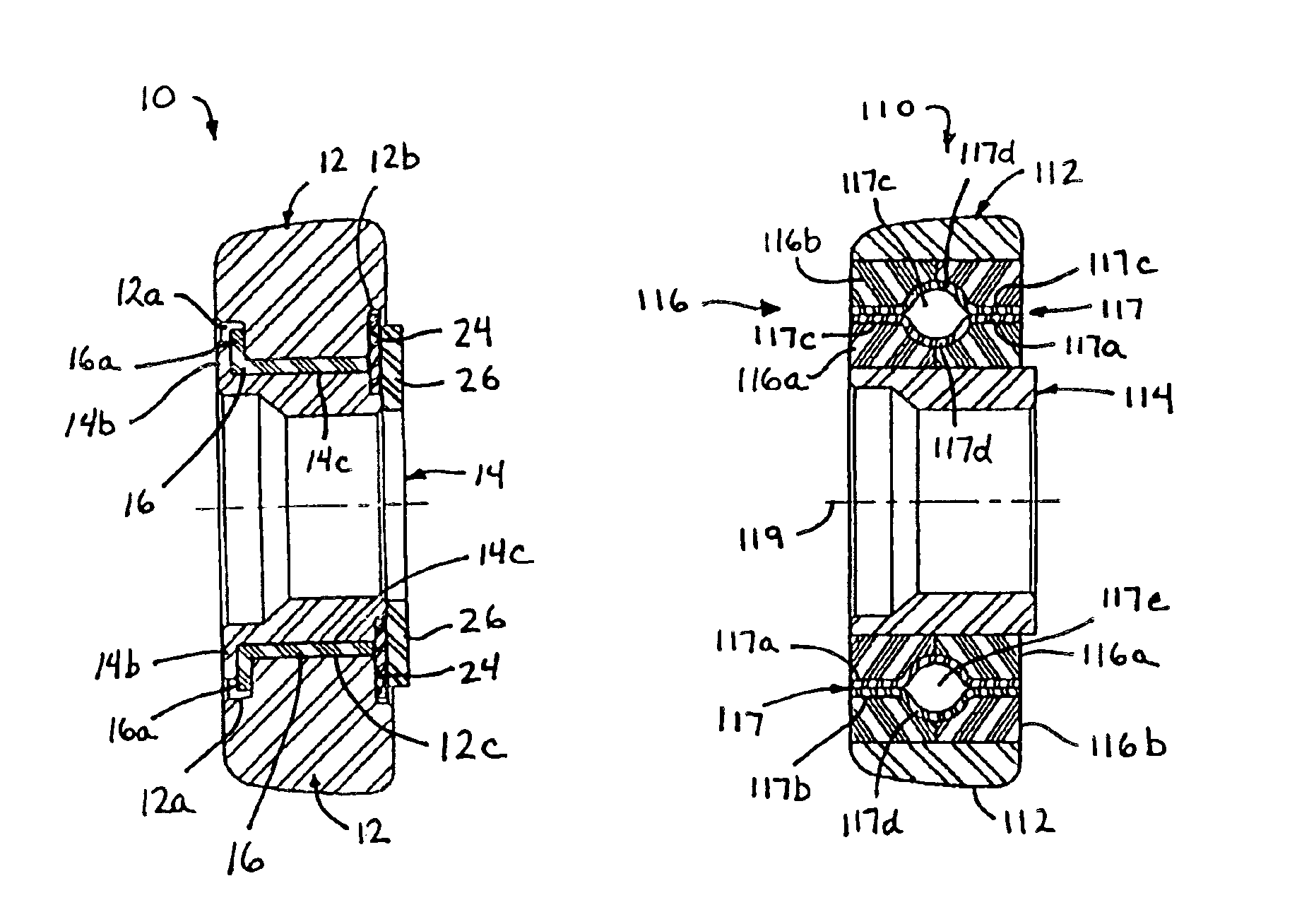

Journal bearing for trolley wheel

ActiveUS6880469B2Low frictionContaminate useRail-engaging wheelsAgricultural machinesEngineeringRadial projection

A trolley wheel assembly includes a wheel portion rotatably positioned around a hub portion and at least one sliding member positioned between the wheel portion and the hub portion. The sliding member defines a mating surface for mating with a generally correspondingly formed mating surface of the wheel portion and / or the hub portion. The mating surface of the sliding member defines a radial projection at least substantially circumferentially around the sliding member. The radial projection may slidably mate with the generally correspondingly formed mating surface of the wheel portion and / or the hub portion to facilitate rotation of the wheel portion about the hub portion. The wheel assembly may include one or more inserts that define the correspondingly formed mating surface and that are positioned between the sliding member and the wheel or hub portion to facilitate manufacturing and assembly of the wheel assembly.

Owner:FROST TECH

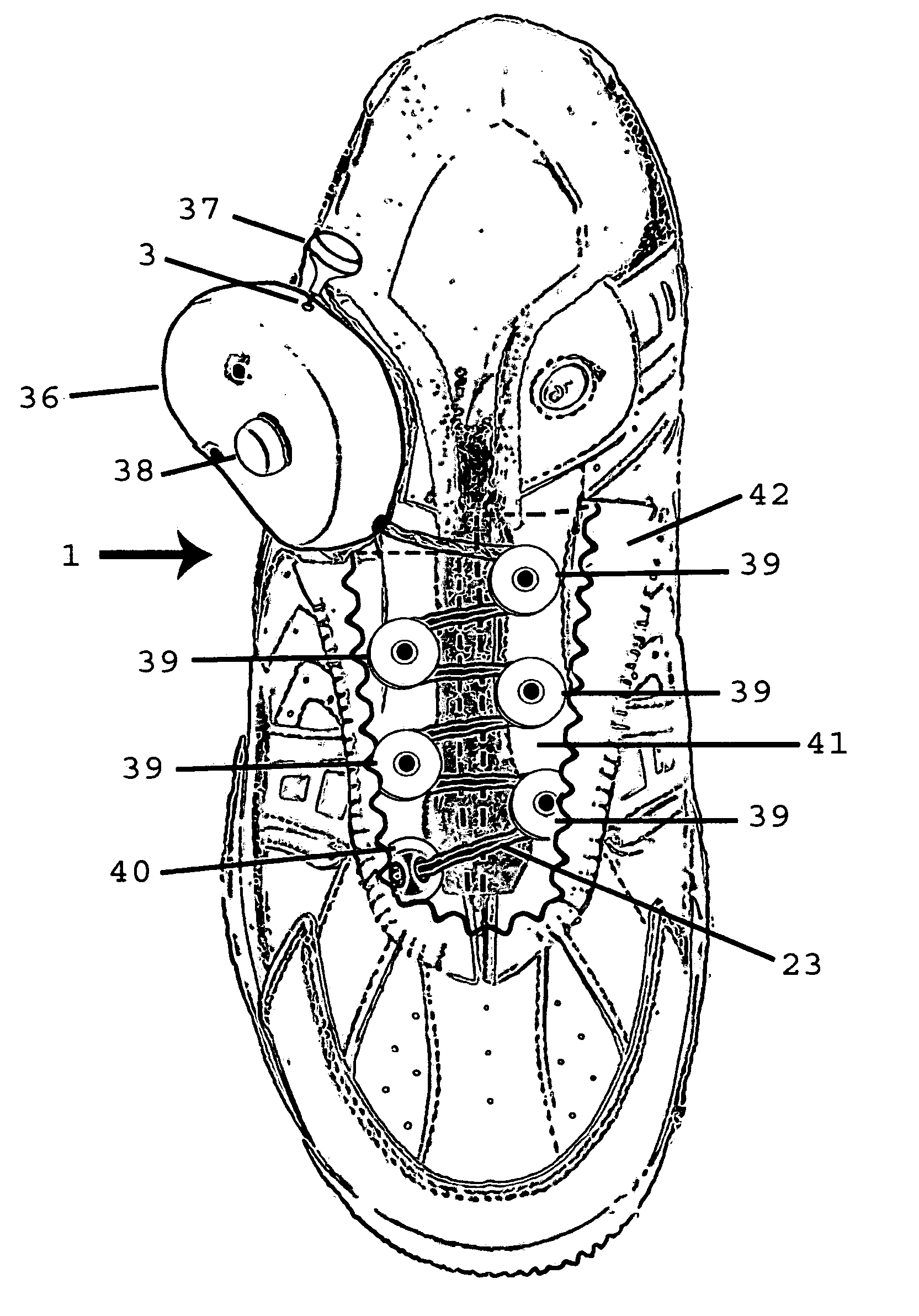

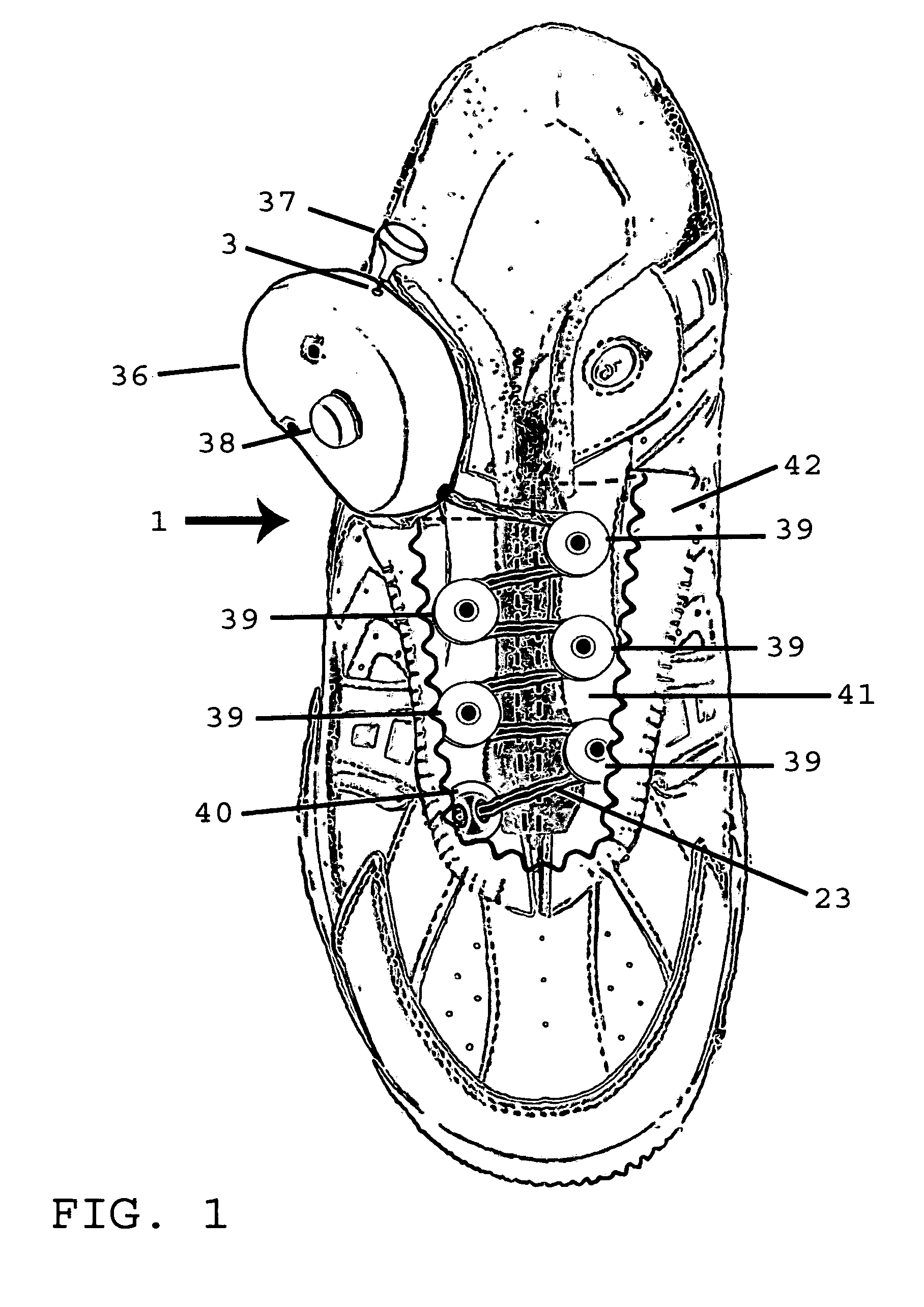

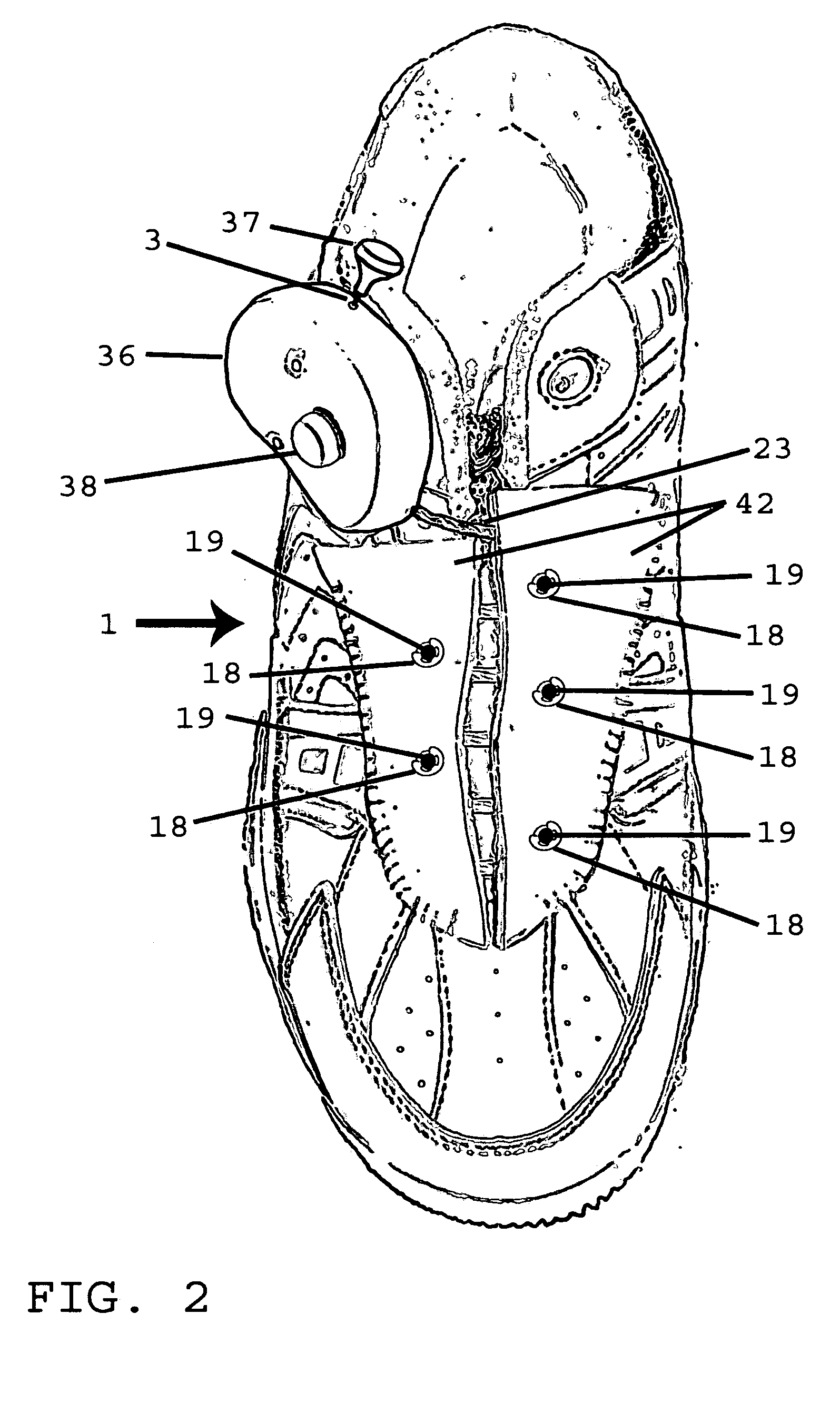

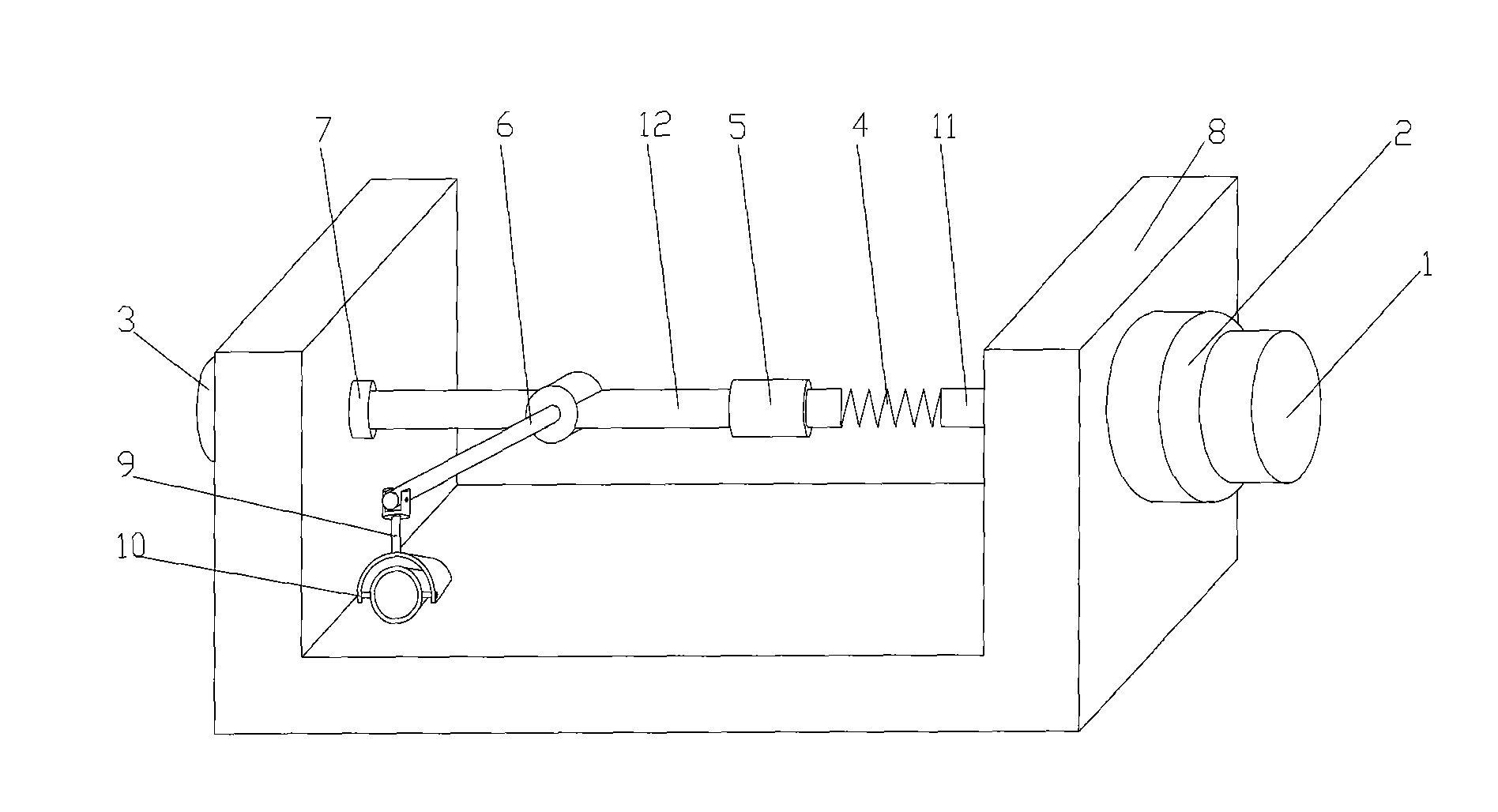

Pull-cord and pulley lacing system

A convenient lacing system including a drawing mechanism, pulleys or some other form of low friction lace paths, an attachment point, and a lace. The lace terminates at the attachment point, and follows a path around the outside hemispheres of the pulleys (or through the lace paths), criss-crossing between the two rows of pulleys without the lace overlapping. The pulleys are aligned generally in two rows on either side of an area to be drawn together. A drawing mechanism is attached at the non-terminating end of the path of the lace, and through use of a pull-cord draws in the lace and tightens the item to which the system is attached by drawing the pulleys (lace paths) closer together. The use of pulleys allows the system to distribute tension evenly along the path of the lace, and aids in the convenience of tightening.

Owner:YOUNG TREVOR ALAN

Cold pad-batch dyeing process for pure cotton fabric

InactiveCN102535201ALower average tensionLow frictionTextile storage in superimposed formTextile storage in wounded formRoom temperaturePlastic film

The invention discloses a cold pad-batch dyeing process for pure cotton fabric. The process flow comprises the steps of: padding and rolling a mixed liquor of a dye and an alkaline agent, coiling and plastic film coating, rotating stacking, primary water washing, soaping, secondary water washing and drying. In the padding and rolling process, an active dye at a concentration of 10g / l is adopted, 10-15 g / l of water glass is adopted as the alkaline agent, a concentration of urea is 3 to 5g / l and a concentration of sodium sulfate is 10g / l. The rotating stacking process is performed for 16h at a room temperature of 10-15 DEG C. By the adoption of the process of the invention, energy can be saved, consumption can be reduced, the fixation ratio of the dye is increased, the grade of the product is improved, and the process cost is low. Besides, the conditions of the cold pad-batch dyeing process are moderate, the fabric is subjected to low tension and small friction, and the apparent effects and hand-feel of the fabric are improved to a great extent.

Owner:CHANGSHU KAIDA PRINTING & DYEING

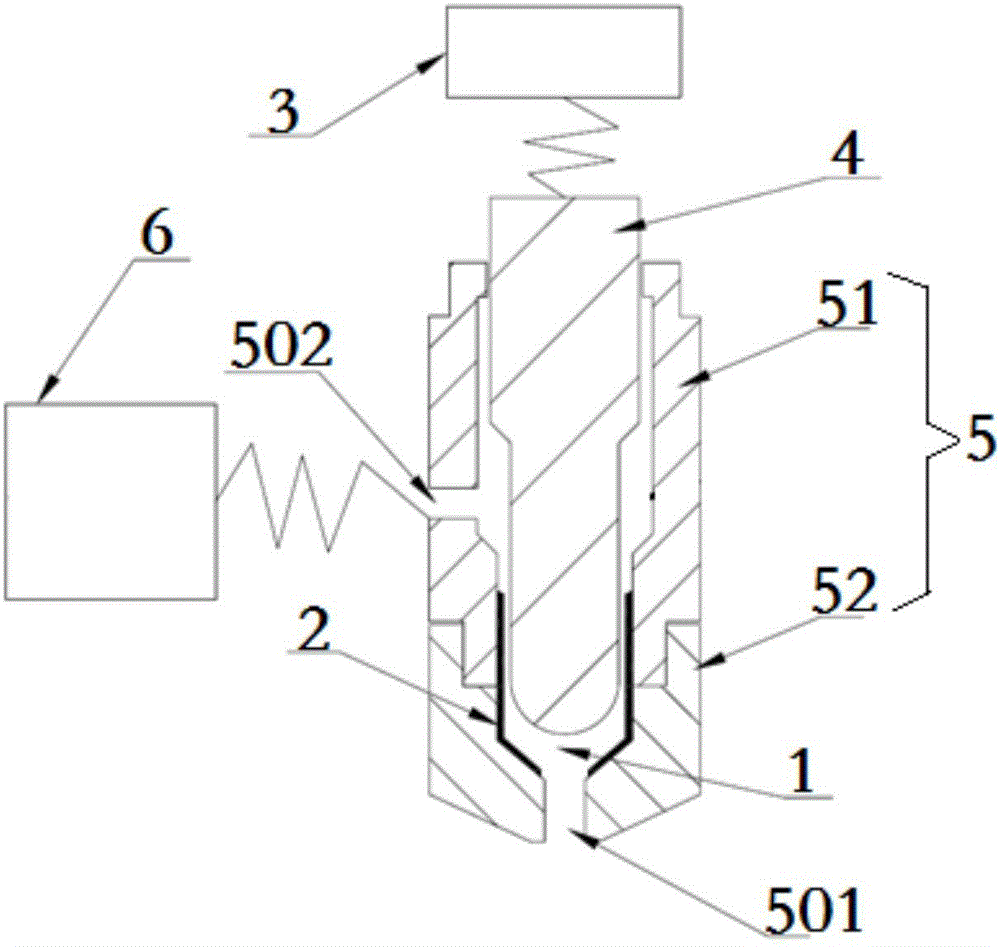

Auxiliary rehabilitation exercise device for realizing finger rehabilitation exercise

InactiveCN101637428AHas a shock-absorbing effectStableChiropractic devicesMagnetorheological fluidTransducer

The invention discloses an auxiliary rehabilitation exercise device for realizing finger rehabilitation exercise. The device comprises a bracket and a finger support arranged on the bracket. One end of the bracket is provided with a first shaft, and one end of the first shaft is connected with a motor; the other end of the bracket is provided with a second shaft, one end of the second shaft is connected with a magnetorheological fluid damper, and the other end of the second shaft is connected with the other end of the first shaft by a spring; the finger support is fixed on the second shaft, the second shaft is also provided with an angular transducer for measuring angular displacement of the second shaft and a force transducer for measuring torque of the second shaft. Compared with the prior art, the device combines active and passive finger rehabilitation exercises, is especially suitable for the rehabilitation exercise of single wounded finger. Meanwhile, the device has simple and compact structure and low machining precision requirement.

Owner:SOUTHEAST UNIV

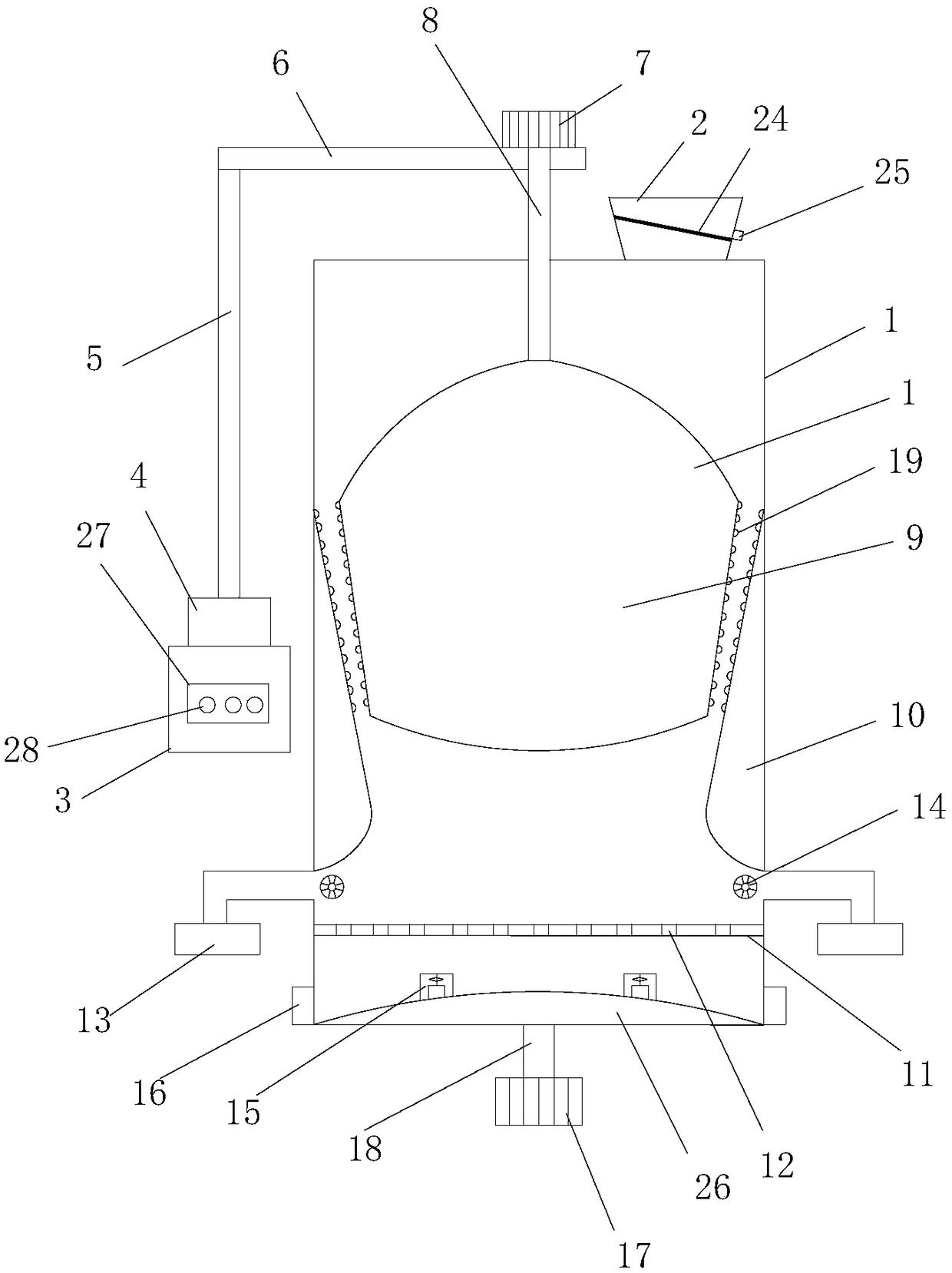

Multifunctional efficient rice husking machine

InactiveCN108160146ALow frictionLess corrosiveGrain huskingGrain polishingHydraulic cylinderPulp and paper industry

The invention discloses a multifunctional efficient rice husking machine and relates to the field of cereal processing equipment. The multifunctional efficient rice husking machine comprises a rice husking machine body, a feeding hopper, a control box and a hydraulic cylinder, wherein the hydraulic cylinder is arranged above the control box, the top of the hydraulic cylinder is connected to a telescopic rod, the upper end of the telescopic rod is connected to a platform plate, a first motor is arranged on the platform plate, a first rotating shaft is arranged below the first motor, the upper end of the first rotating shaft penetrates through the platform plate and is connected to the output end of the first motor, the lower end of the first rotating shaft extends into the rice husking machine, a grinding cone is arranged in the rice husking machine, a grinding disc matched with the grinding cone is arranged on the inner wall of the rice husking machine, and discharge ports are formed in the side walls of the left and right sides of the bottom of the rice husking machine. The rice husking machine disclosed by the invention is high in grinding efficiency and good in grinding effect,and the degree of purity of ground white rice meets the using demand. The multifunctional efficient rice husking machine has a function of adjusting the grinding strength, and is simple to operate andhigh in working reliability.

Owner:马斌祥

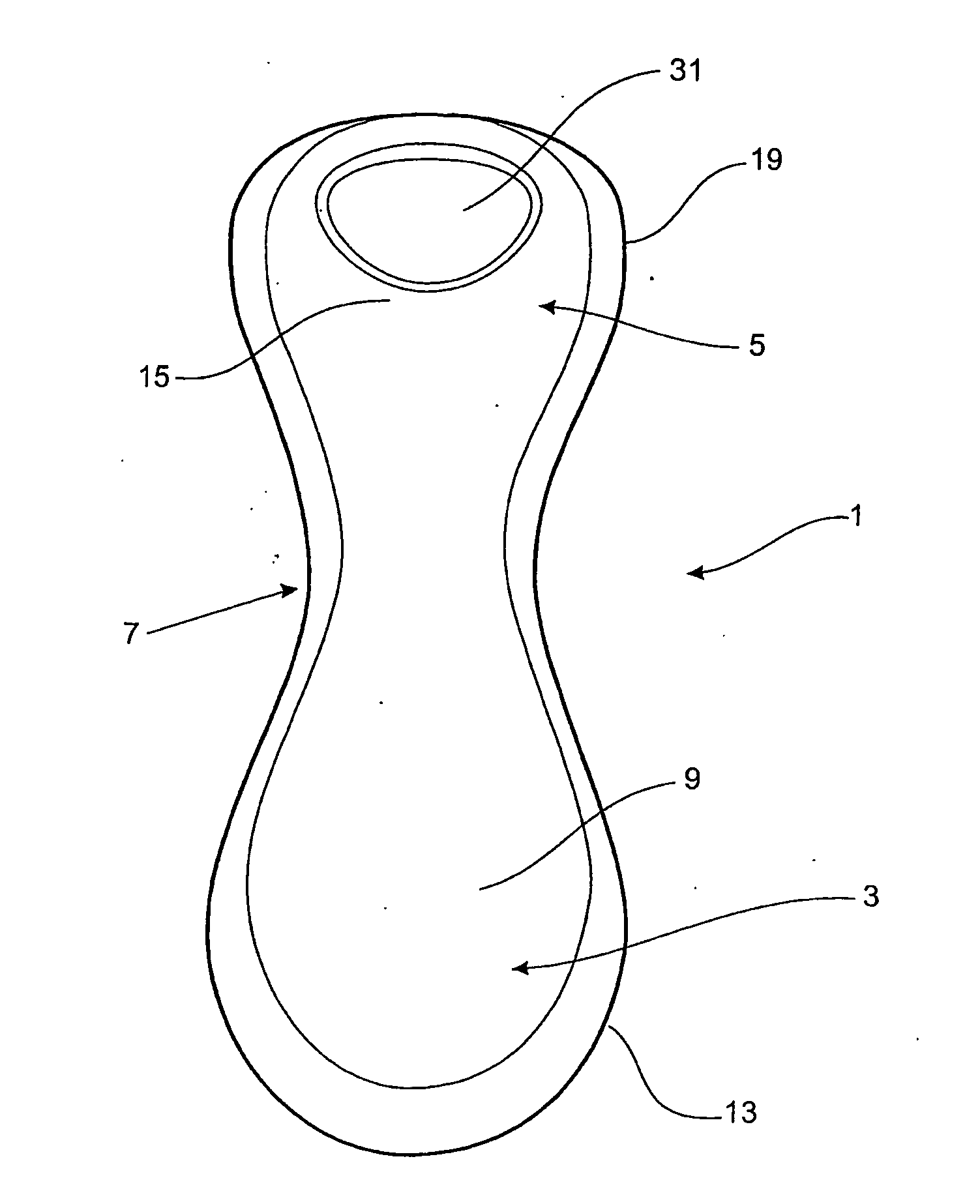

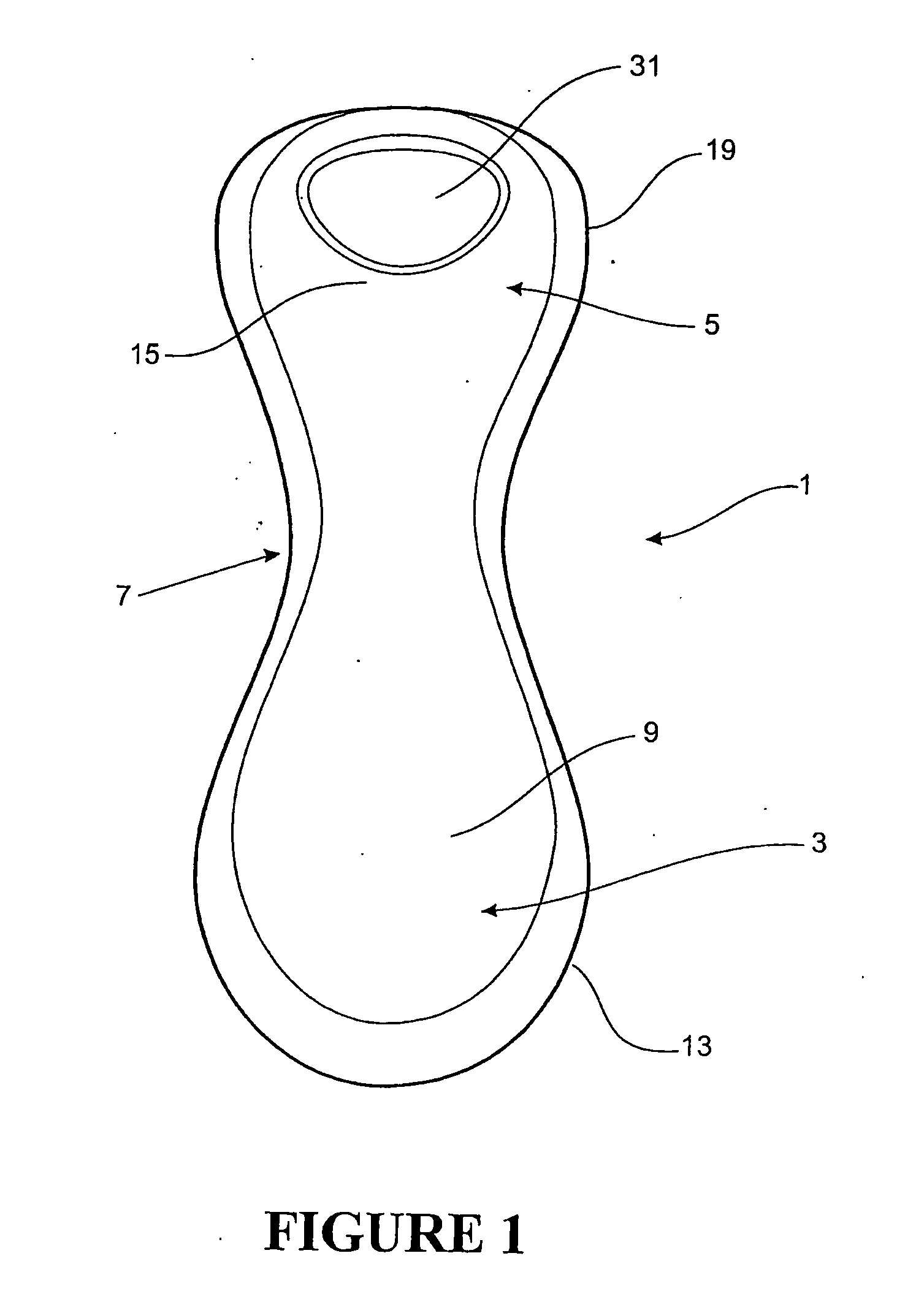

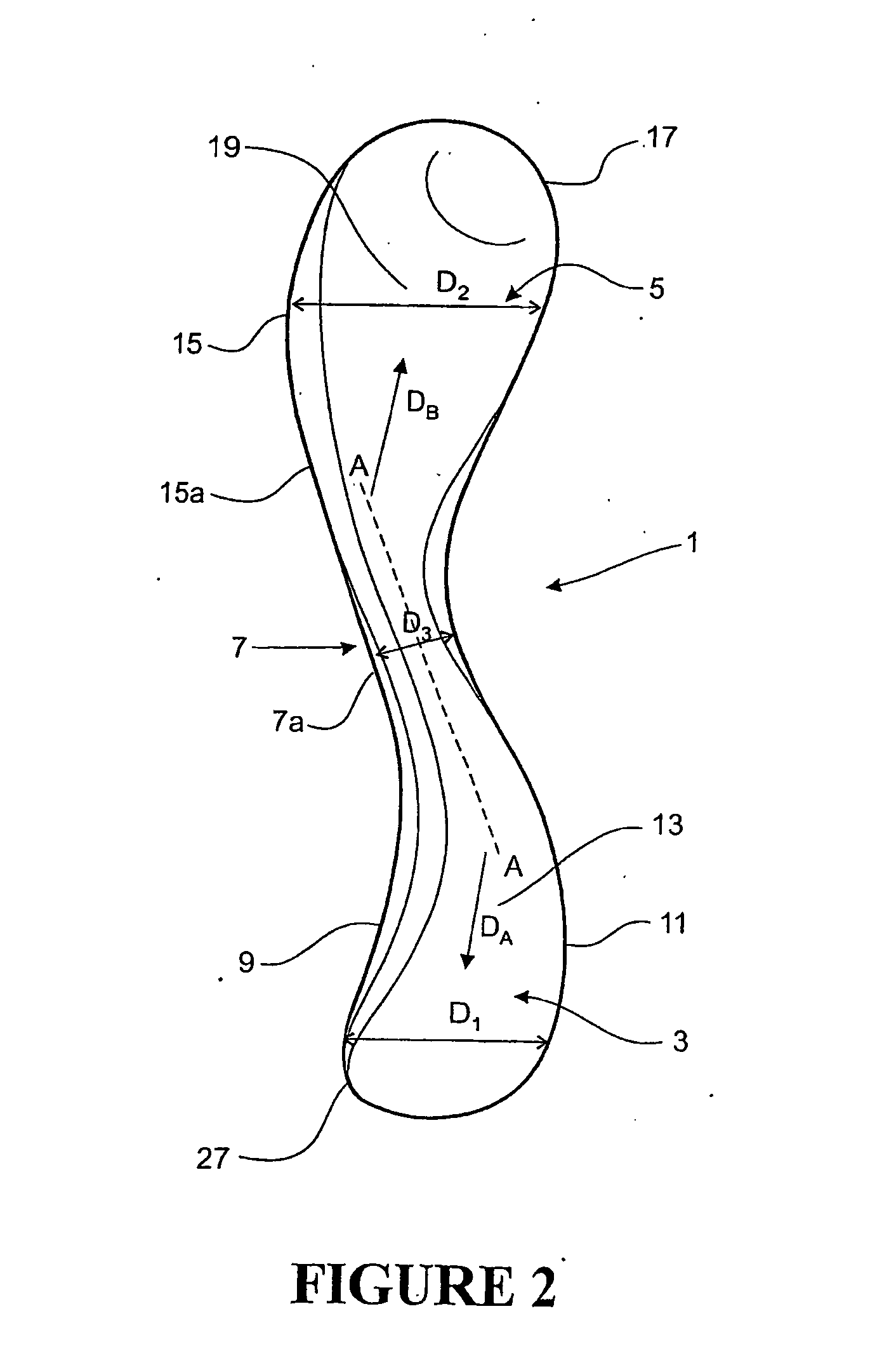

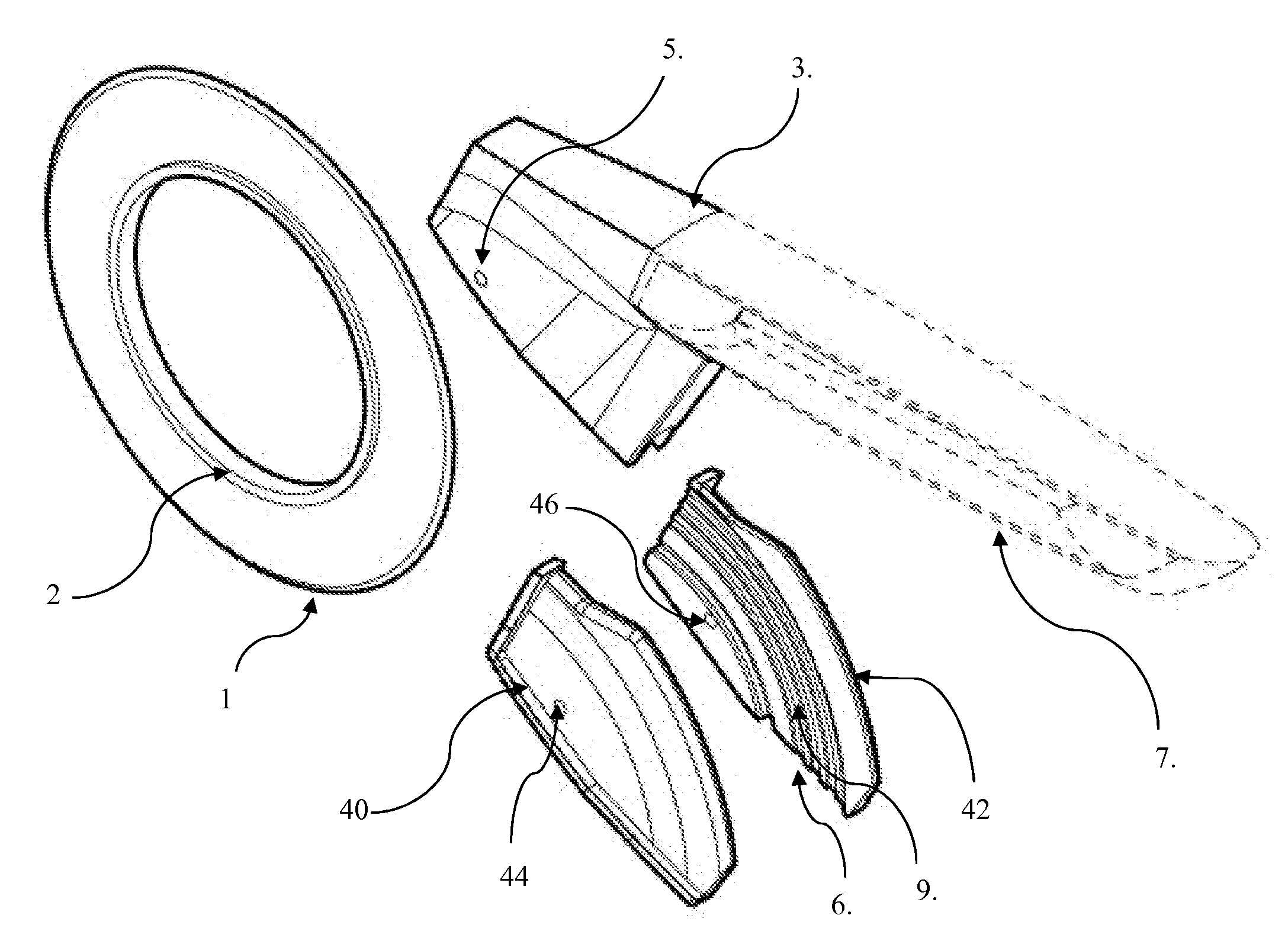

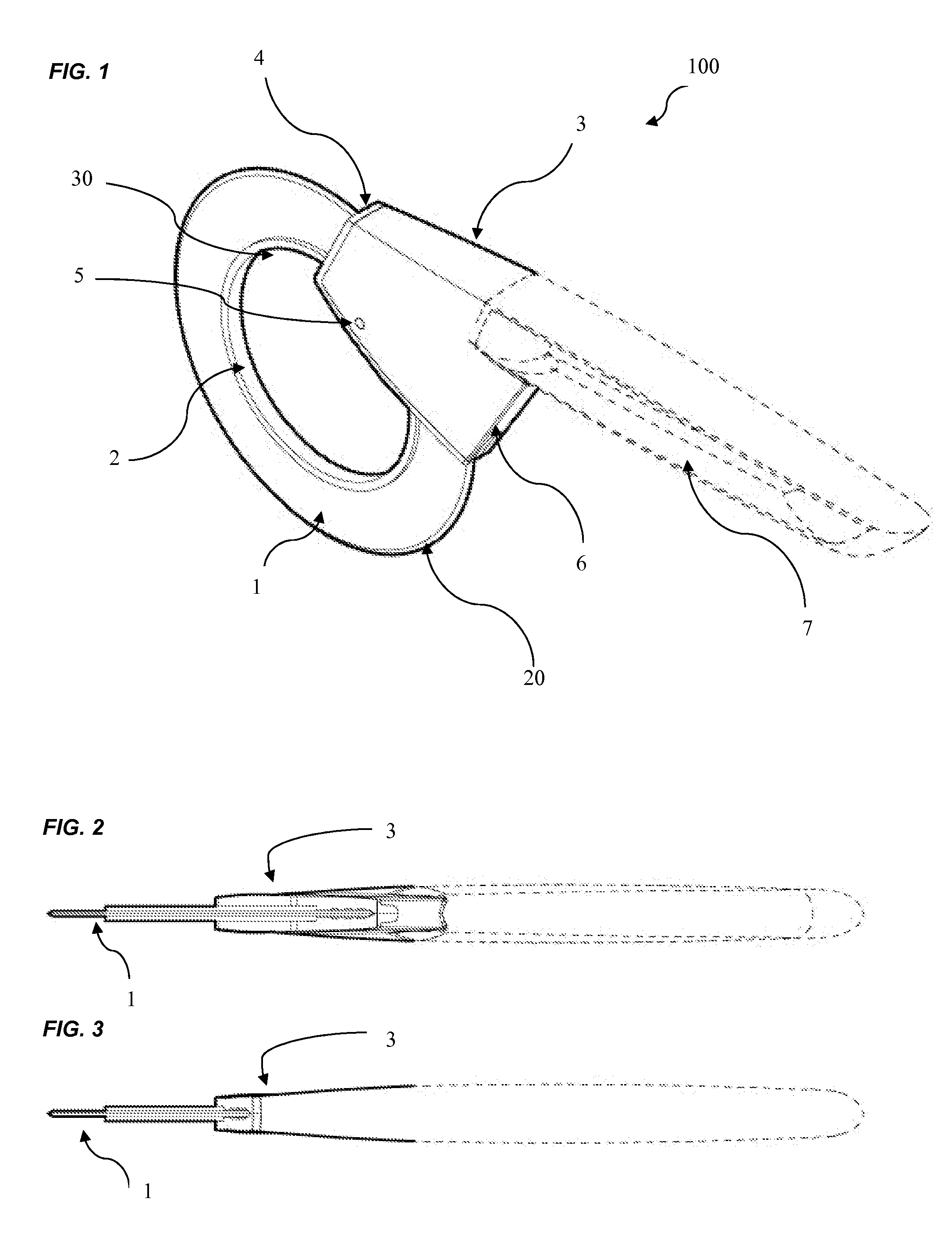

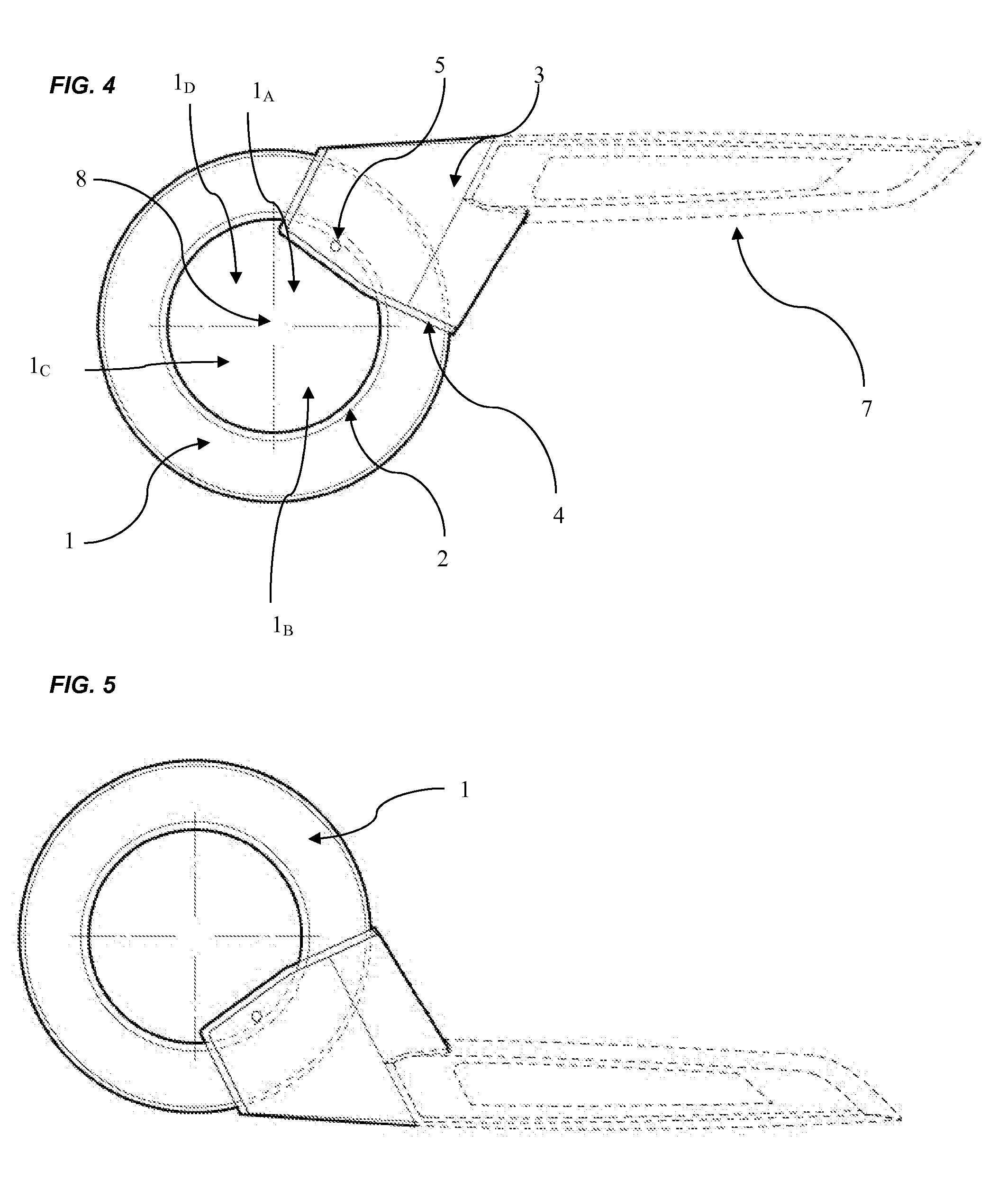

Device for exercising or supporting the pelvic floor muscles

InactiveUS20130005543A1Low frictionImproving insertion and removalMuscle exercising devicesFemale humansVagina

A device (101) for supporting or exercising the pelvic floor muscles in a female human. The device has a unitary elongate body having a first enlarged end (103), a second enlarged end (105), and a relatively narrow interconnecting region (107) that interconnects the first enlarged end and the second enlarged end. The first enlarged end (103) generally extends in a first direction from the interconnecting region (107) and from one end of the interconnecting region. The second enlarged end (105) generally extends in a second generally opposite direction from the interconnecting region (107) and from the other end of the interconnecting region. The first enlarged end (103), the second enlarged end (105), and the narrow interconnecting region (107) are substantially fully insertable into the vagina to provide resistance to contraction of the pelvic floor muscles.

Owner:ORELLE LTD

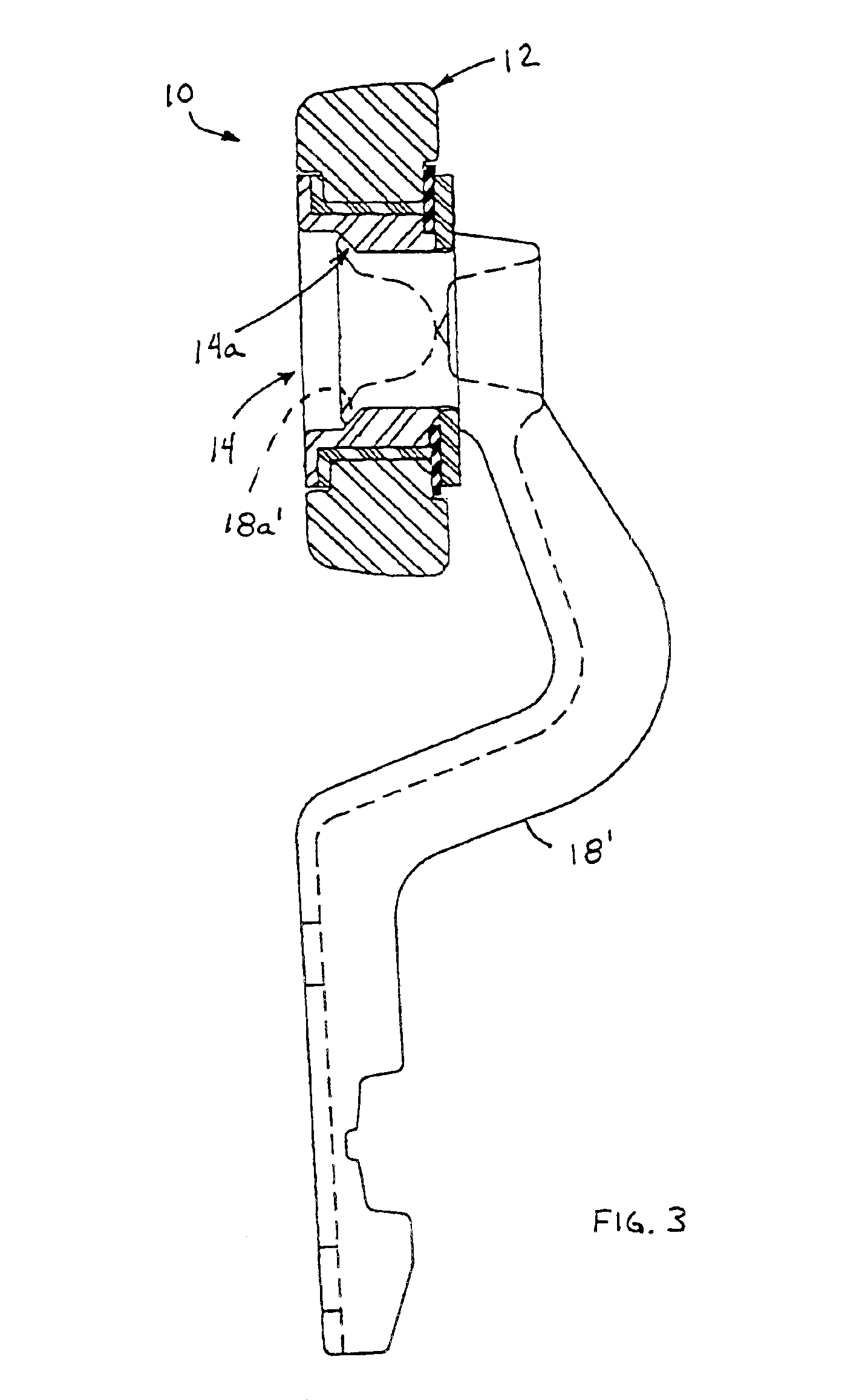

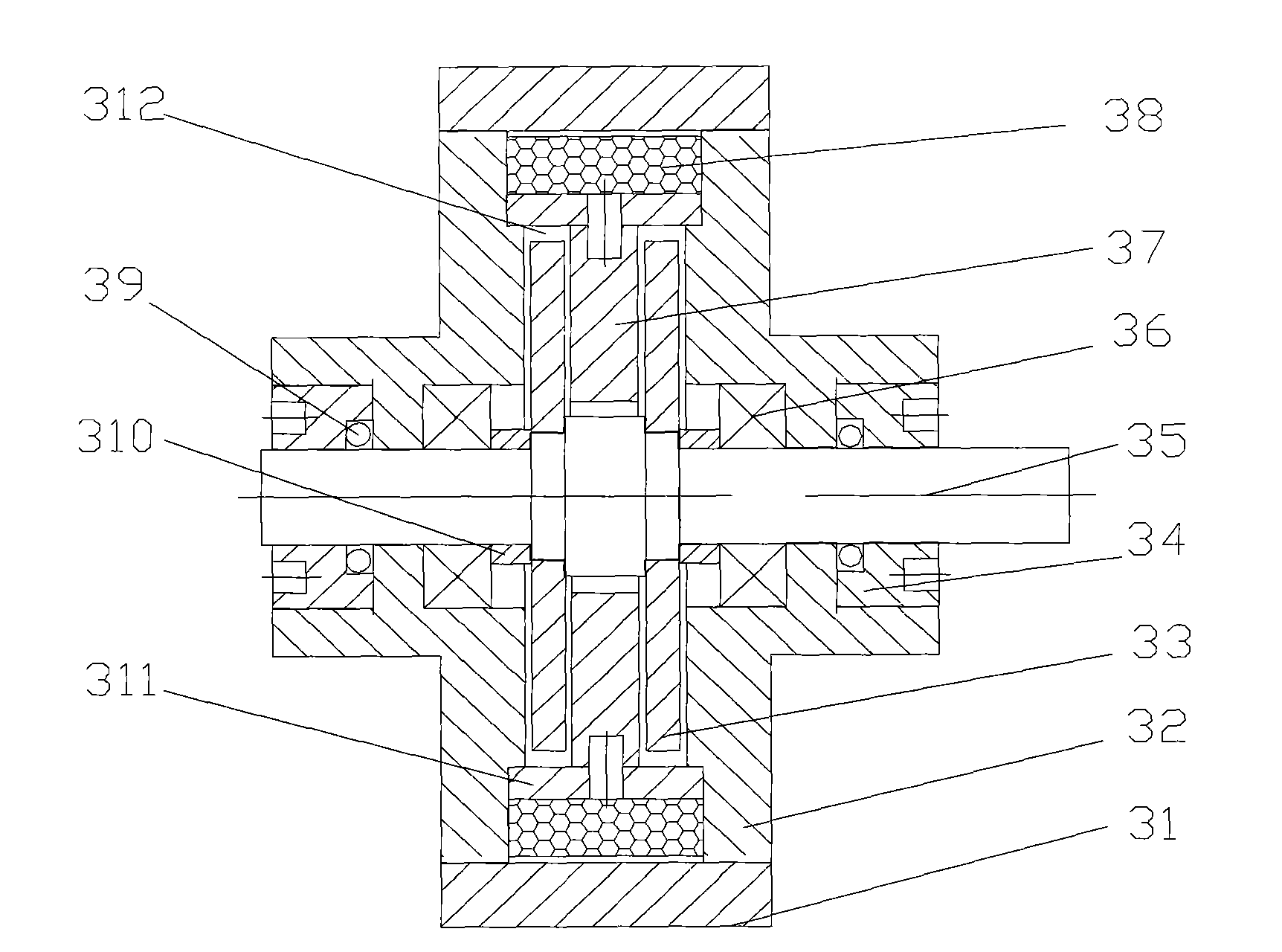

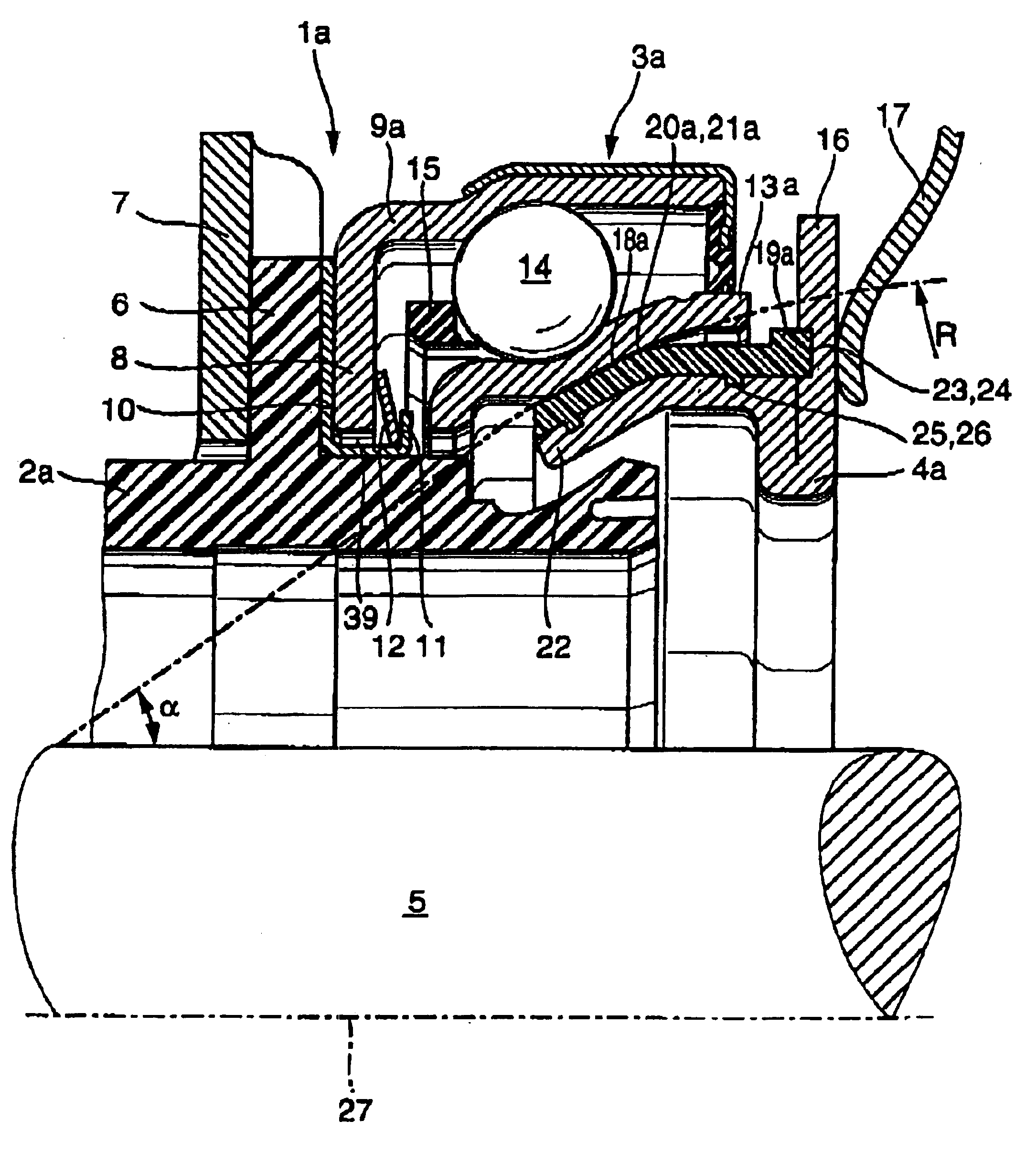

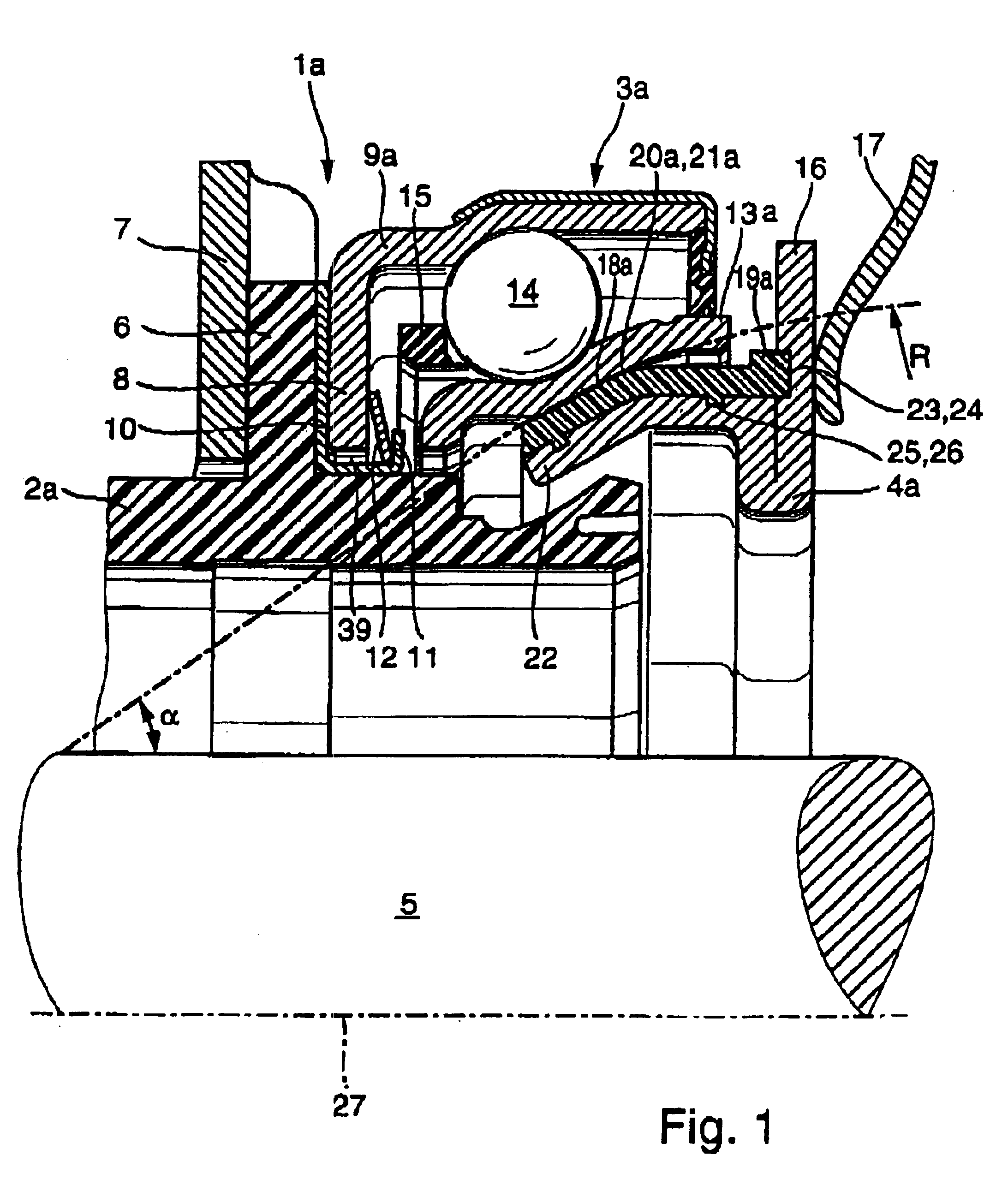

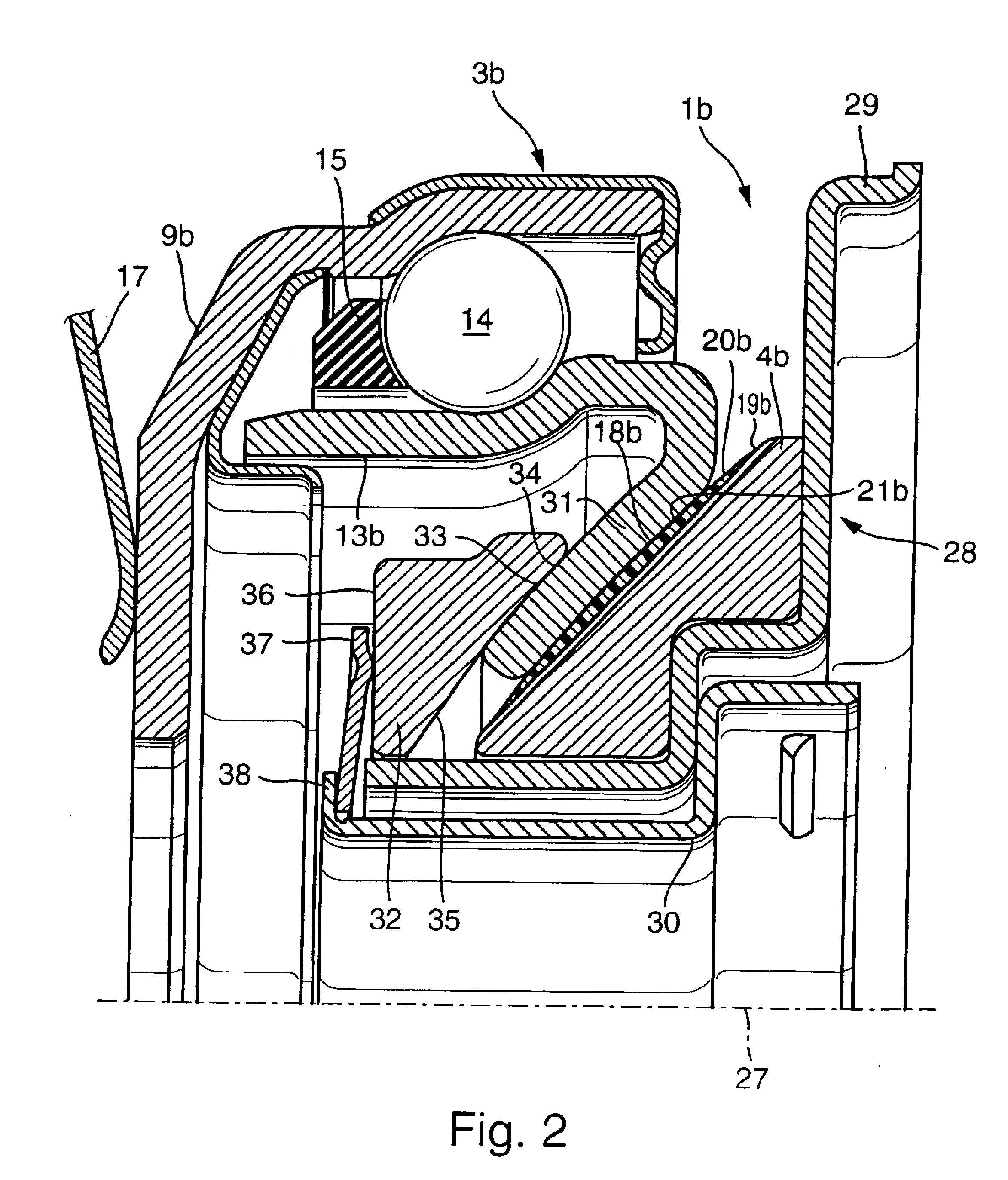

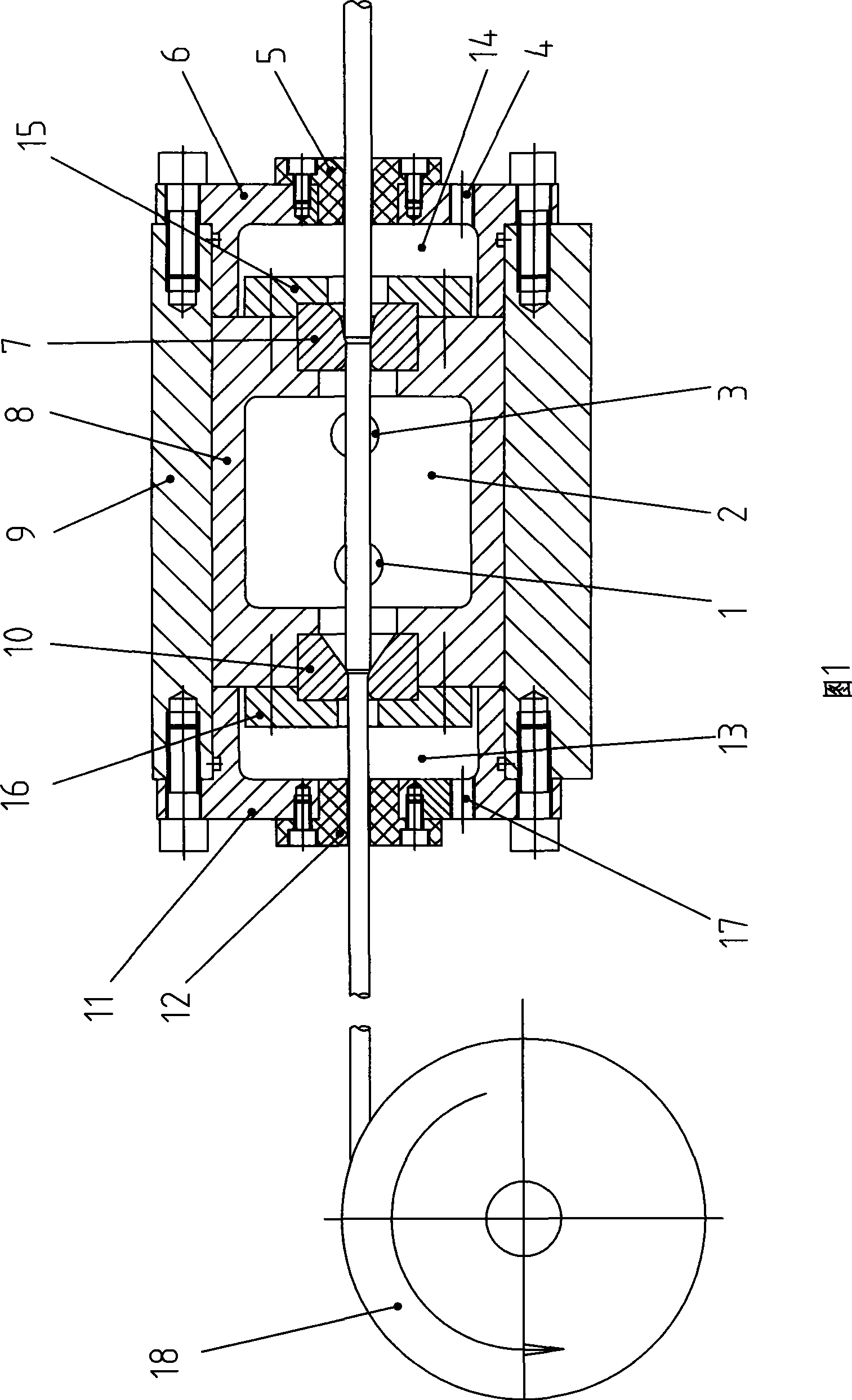

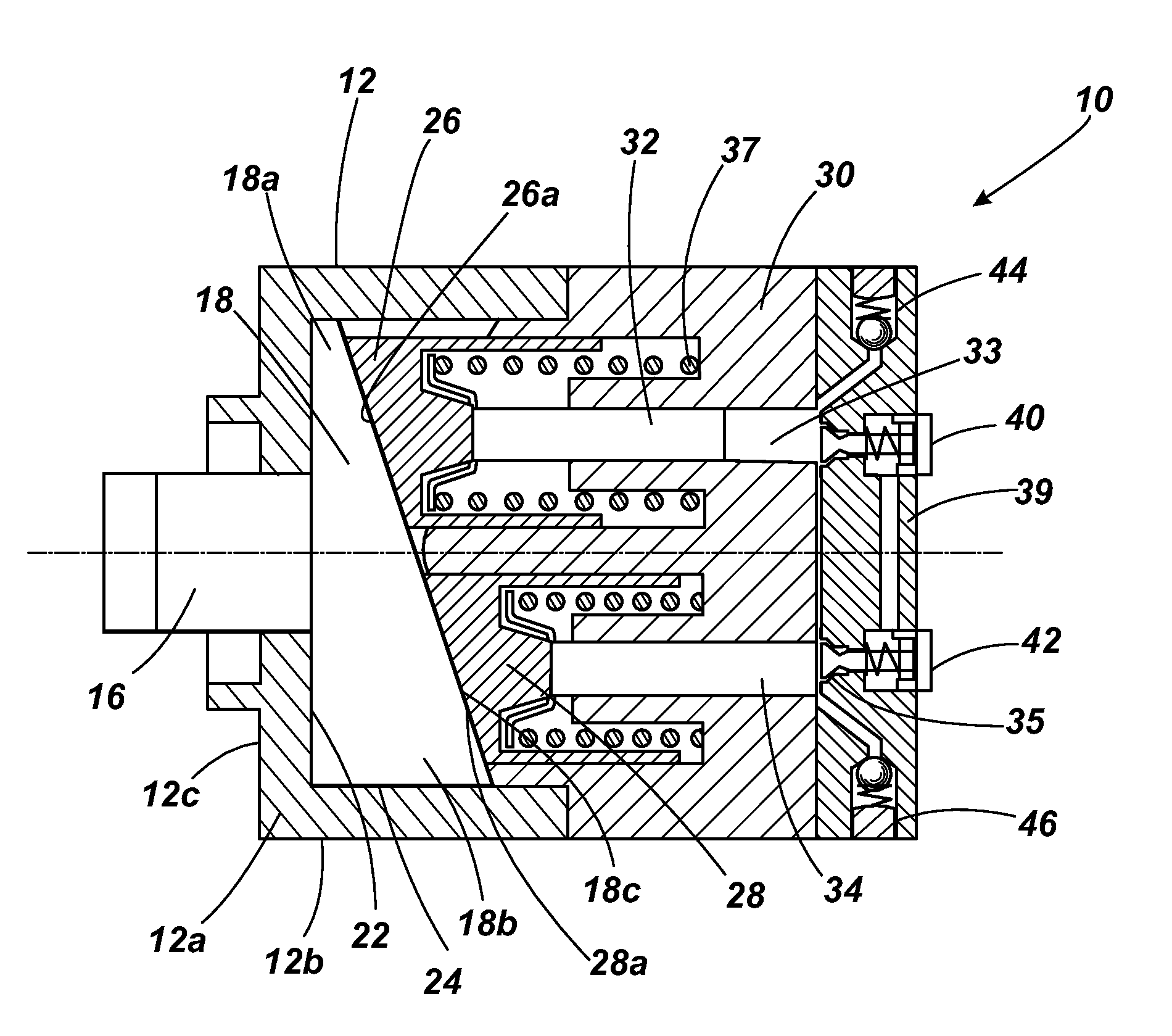

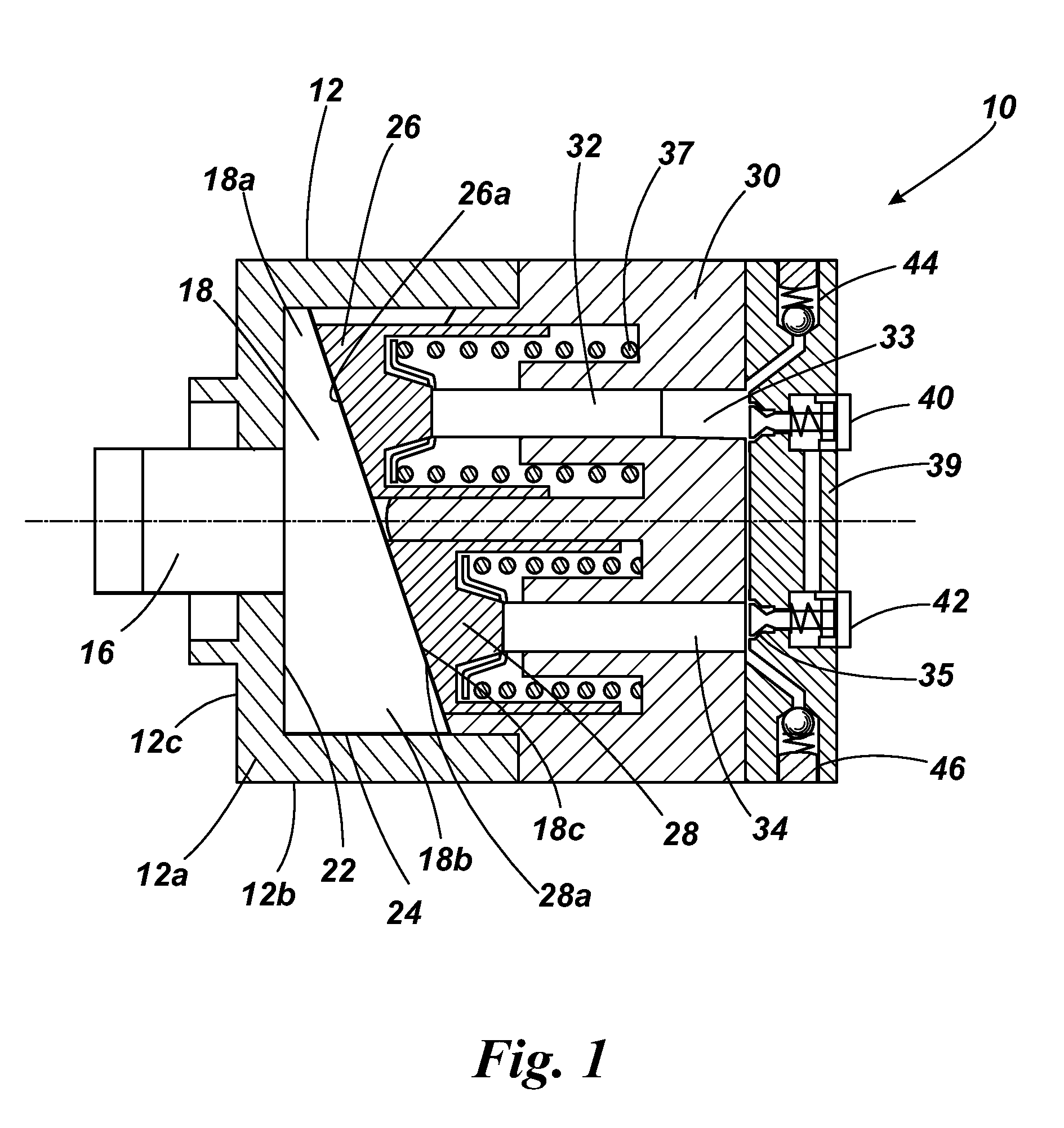

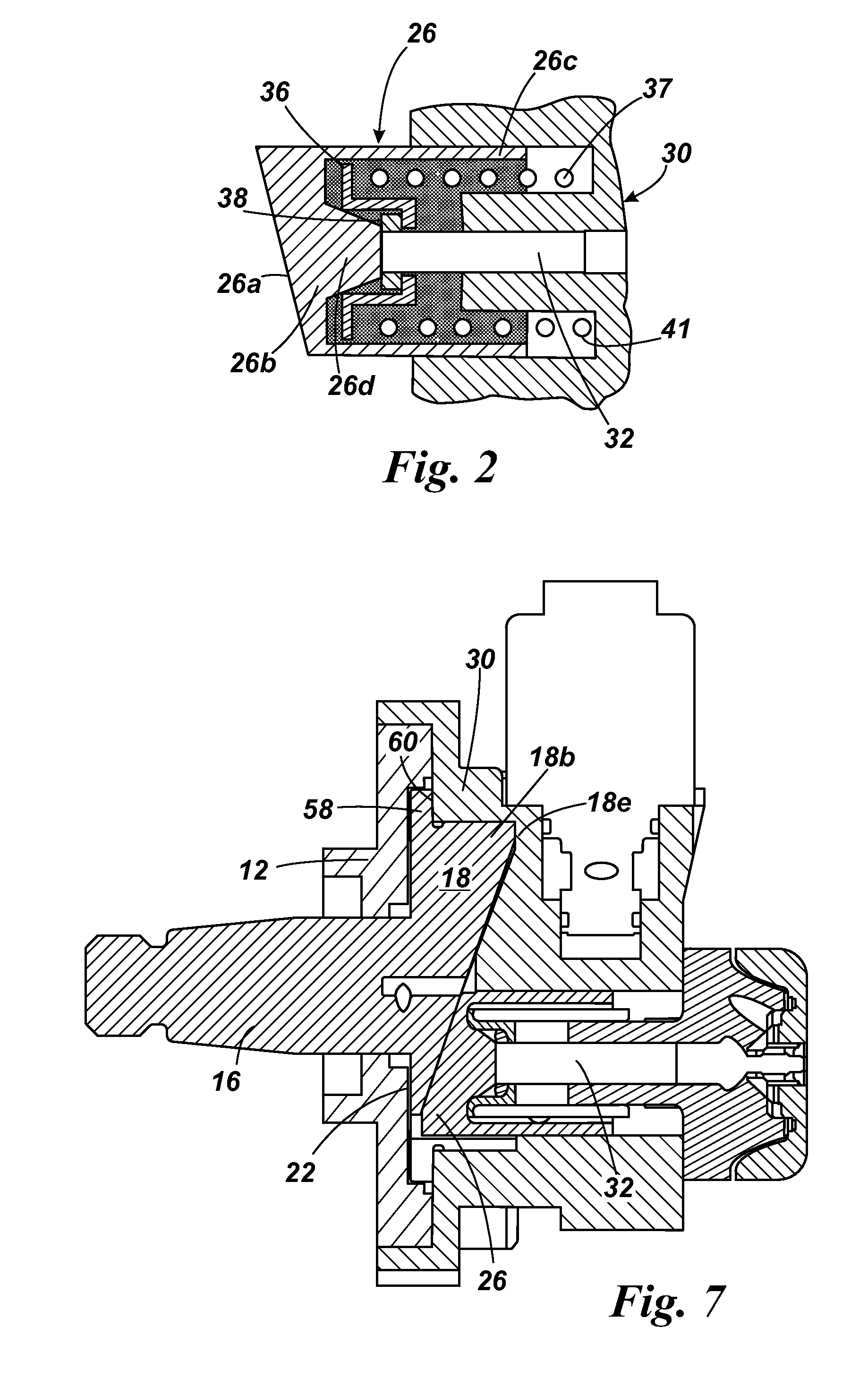

Self-adjusting clutch release bearing

InactiveUS6843354B2Improve crack resistanceLow frictionRolling contact bearingsBearing componentsClutchInternal combustion engine

A self-adjusting release bearing in the form of a tapered rolling bearing for a separating clutch disposed between an internal combustion engine and a gearbox of a motor vehicle, includes a non-rotating first bearing ring, a revolving second bearing ring, and a plurality of rolling elements guided between the first and second bearing rings. Supported upon a calotte-shaped section of one of the first and second bearing rings in a contact zone is an adjustment ring having a complementary calotte-shaped section to thereby allow pivoting of the release bearing, whereby a sliding element made of thermoplastic material is disposed in the contact zone.

Owner:SCHAEFFLER TECH AG & CO KG

Compact solenoid valve

InactiveUS20080277501A1Low frictionHigh forceOperating means/releasing devices for valvesLiquid spraying apparatusMagnetic fluxEngineering

A valve is provided having a solenoid coil in an integrally formed magnetic material having a cross-sectional configuration resembling a bundt pan. Such a structure can be stamp-formed and creates an enlarged surface area available for the magnetic flux to the armature at the bottom of the bundt cross-section. However, since the ends of the stamped structure are not relevant to the magnetic circuit, they can be left unfinished. A thin, flat plate armature and an axial flow valve assembly allows for low friction, low mass movement of the valve seal. Placement of the armature and solenoid across a small air gap provides a high force, very fast response time with minimal electrical power consumption.

Owner:EVERETT WILLIAM F +1

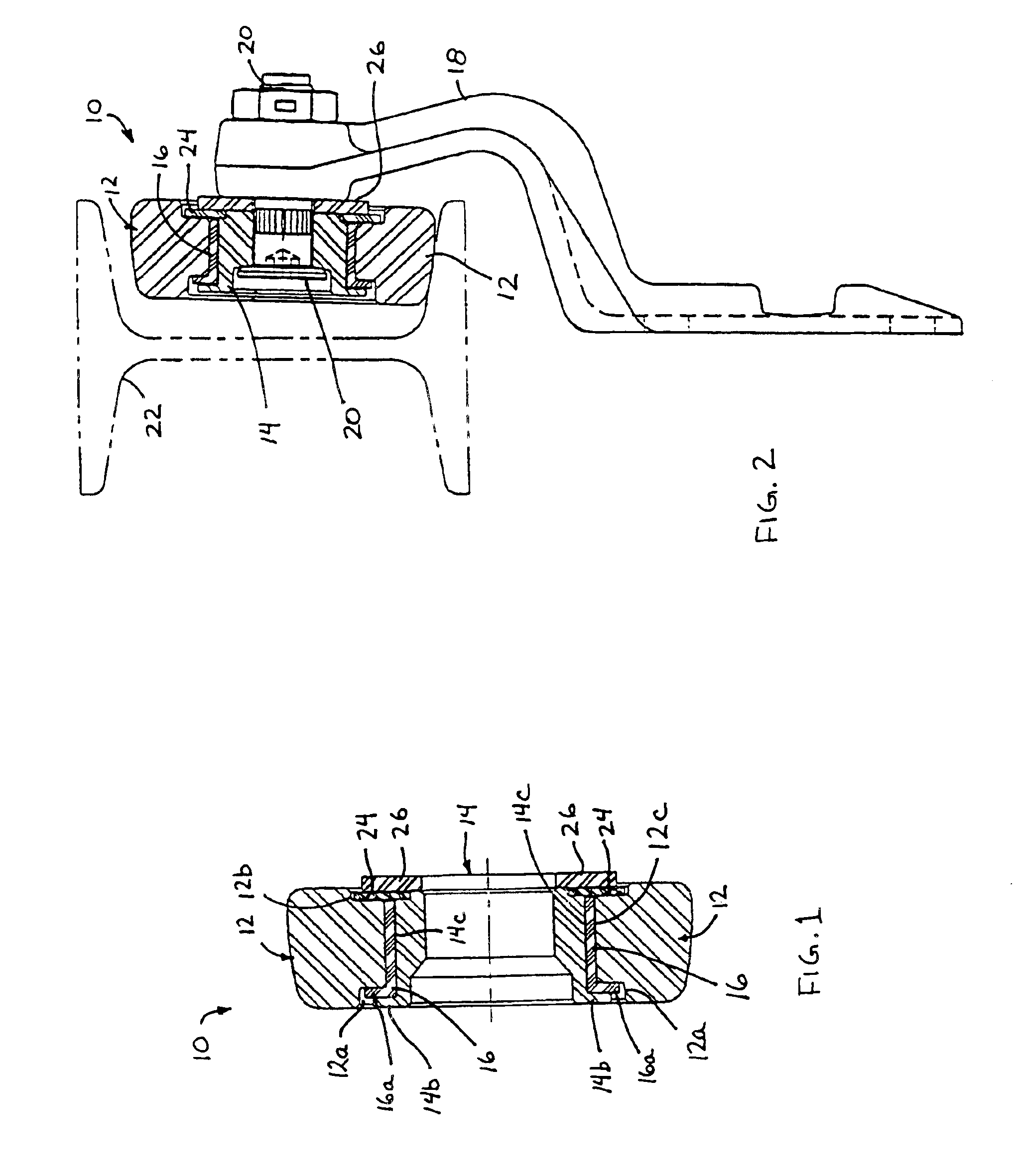

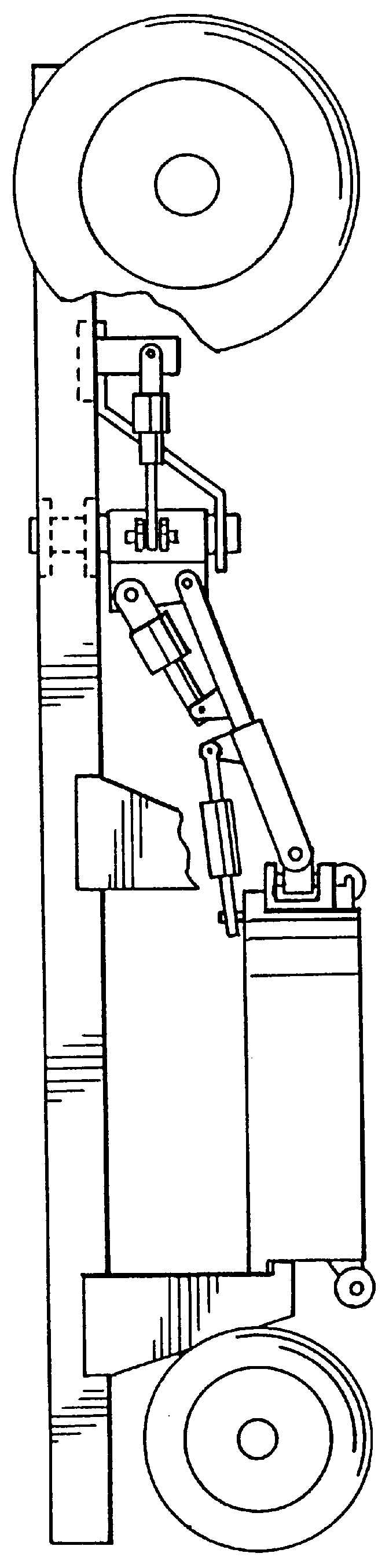

Ground-engaging shoe assembly for a power mower

A ground-engaging shoe assembly is provided for a power mower in which a mower blade is rotated in an upright shaft. The ground-engaging shoe includes a hub support assembly which is secured to the mower housing of the power mower. A ground-engaging shoe assembly is secured to a bearing housing which is located at the lower end of a hollow rotatable shaft, the ground-engaging shoe assembly including a bearing within which the hollow shaft rotates, whereby the ground-engaging shoe assembly is stationary. The bearing housing is adapted selectively to accept different ground-engaging shoes. An adjusting bolt extends through the hollow shaft and is secured at its lower end to the bearing housing An upper tower housing is adapted to transfer loading weight through the adjusting bolt to the bearings. The adjusting bolt is vertically-adjustably-secured at its upper end with respect to the upper tower housing by means of a locking-type nut. Thus, the cutting height of the mower blade is adjusted by loosening the locking-type nut, and by turning the adjusting bolt, e.g., by means of a slot at its upper end, thereby safely and easily adjusting the height of the mower blade by raising or lowering the ground-engaging shoe.

Owner:GUMMERSON ELWYN

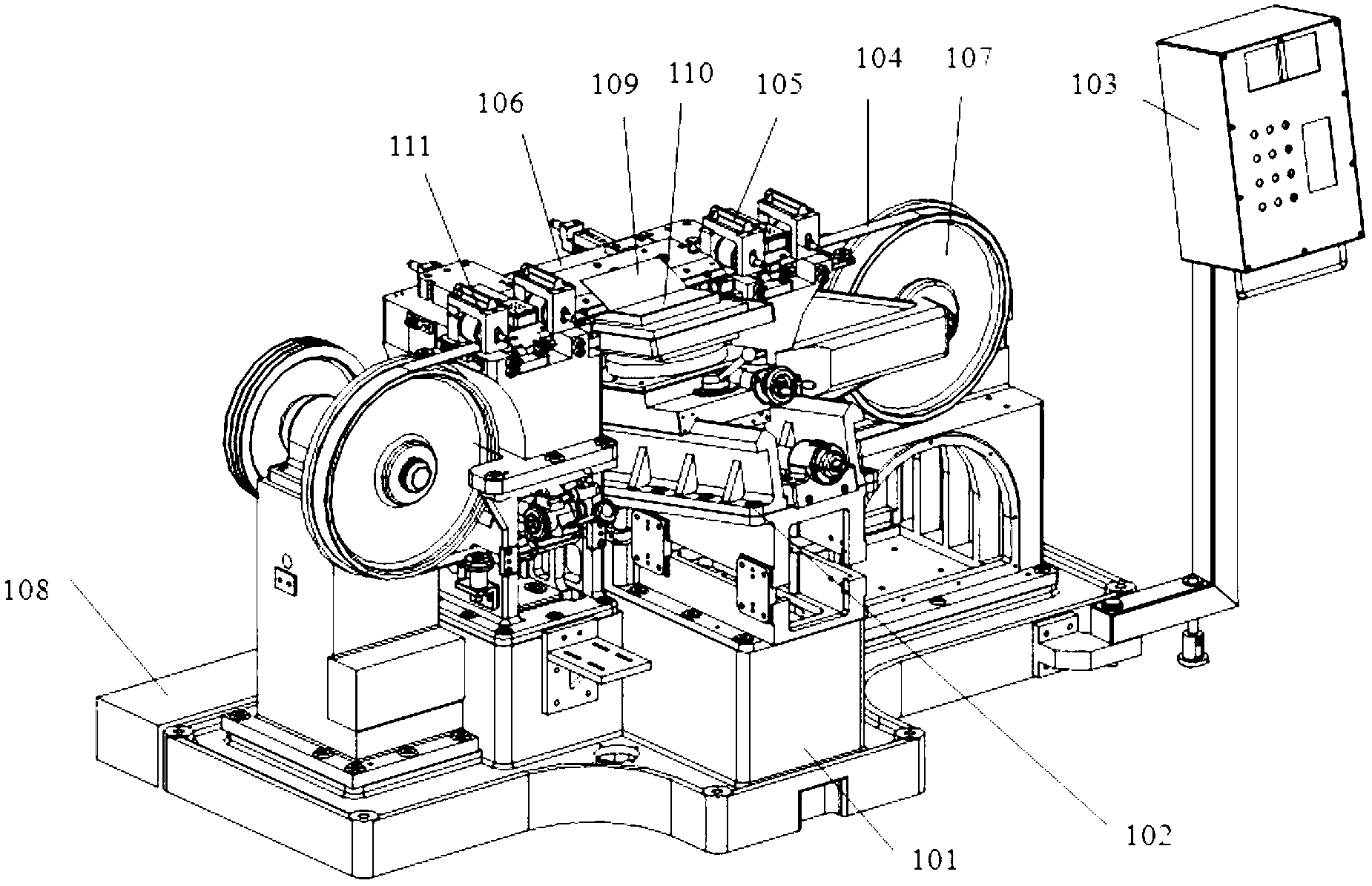

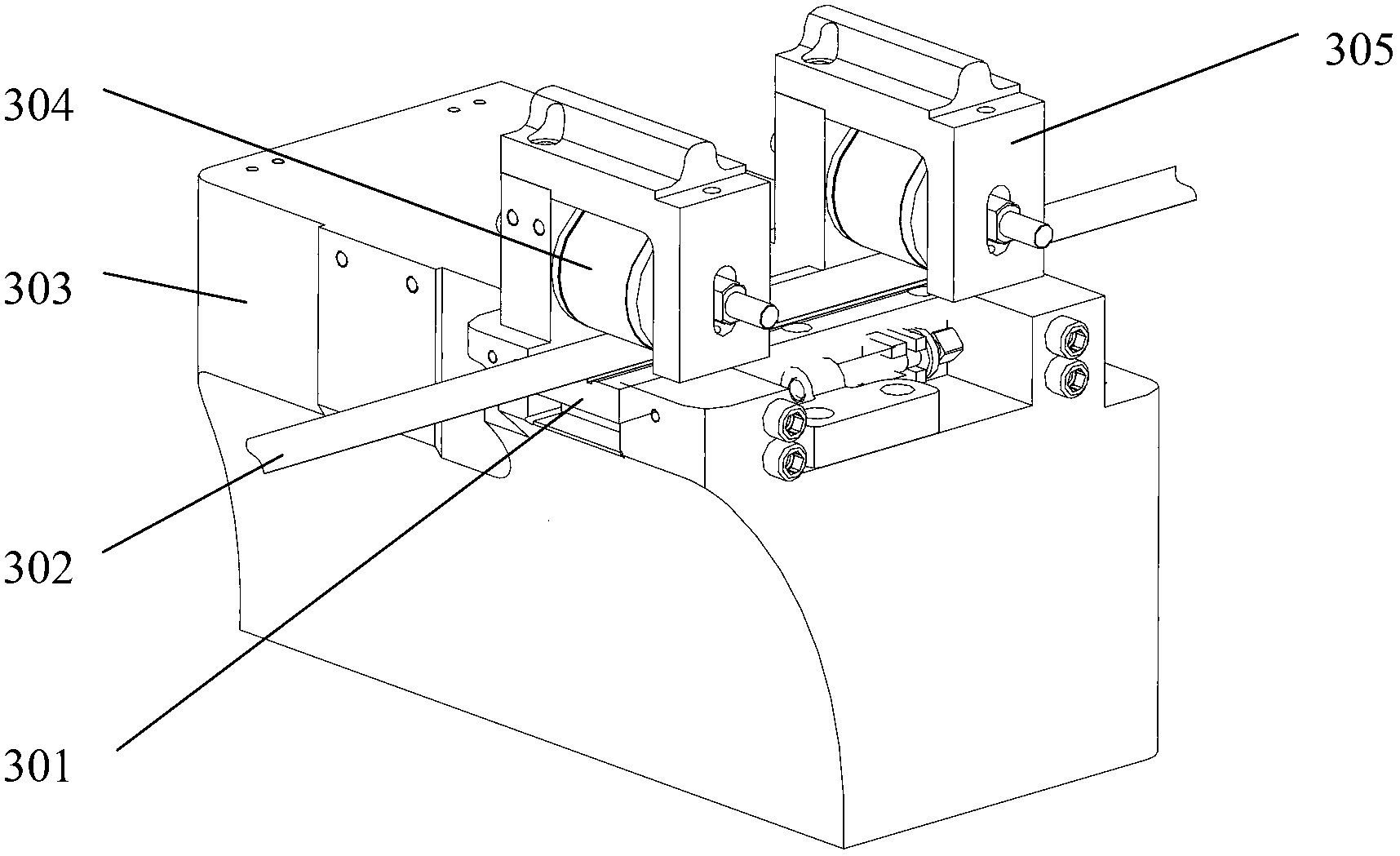

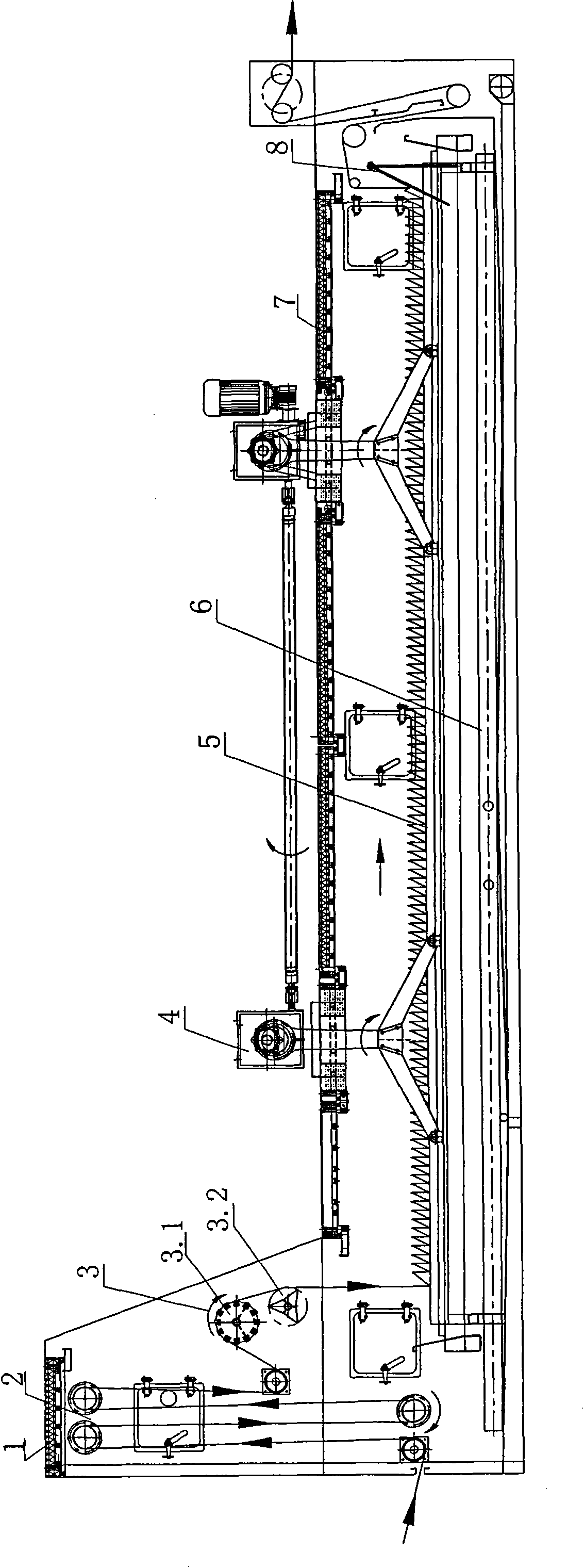

Slicing machine and method for processing flexible non-metal slice with high-precision thickness and wide format

ActiveCN103223678AAvoid high pressureLow frictionMetal working apparatusArticle feedersEngineeringMetal

The invention discloses a slicing machine and a method for processing a flexible non-metal slice with a high-precision thickness and a wide format. The slicing machine comprises a lathe bed, a band knife, a press knife guiding device and a block knife guiding device. The processing method comprises the steps as follows: adjusting the feeding angle of a processed object to be larger than the angle of an inclined surface of the front end of a bedplate and the angle of a cutting edge of the band knife to be smaller than the feeding angle simultaneously; and operating with the band knife, and enabling the feeding direction of a sliced and processed object to be downward relative to the band knife and the processed and separated slice to move backwards after the slice passes through the block knife guiding device. The slicing device is provided with a plurality of vibration damping devices, so that larger vibration cannot be generated in the running process of the band knife; and according to the processing method,the processing function is achieved by the sharp cutting edge, and the flexible non-metal slice with the high-precision thickness and the wide format can be rapidly and efficiently processed.

Owner:INST OF CHEM MATERIAL CHINA ACADEMY OF ENG PHYSICS

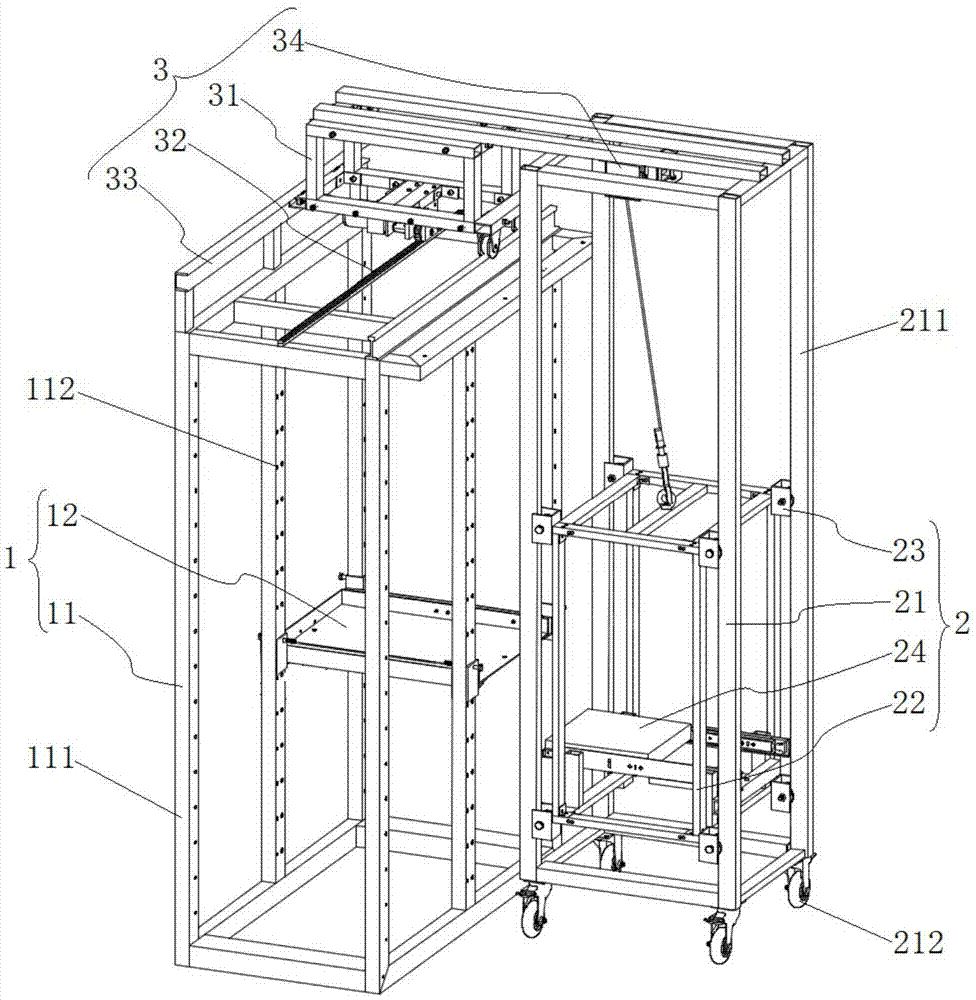

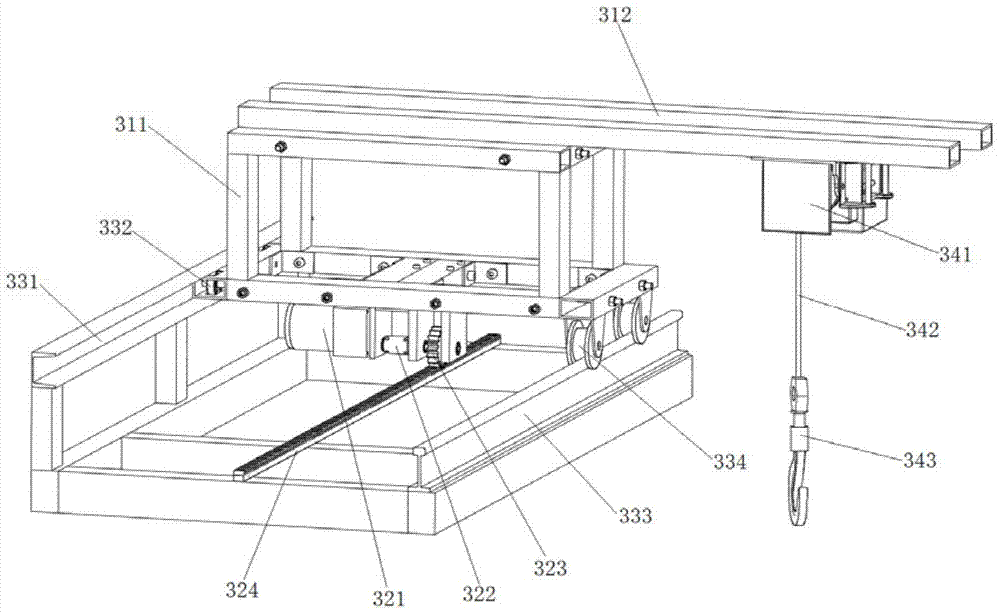

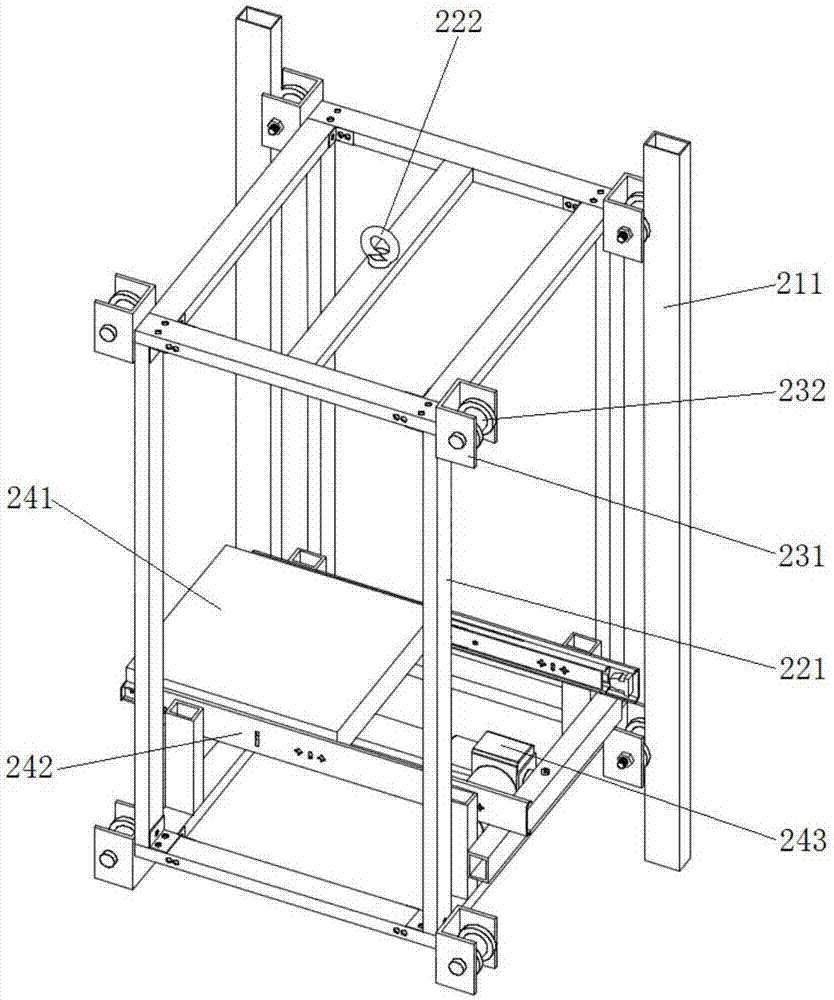

High level rack with intelligent and automatic loading and unloading functions

ActiveCN105438704AImprove loading and unloading efficiencySimple structureStorage devicesEngineeringMechanical engineering

Owner:美玛特电子科技(常州)有限公司

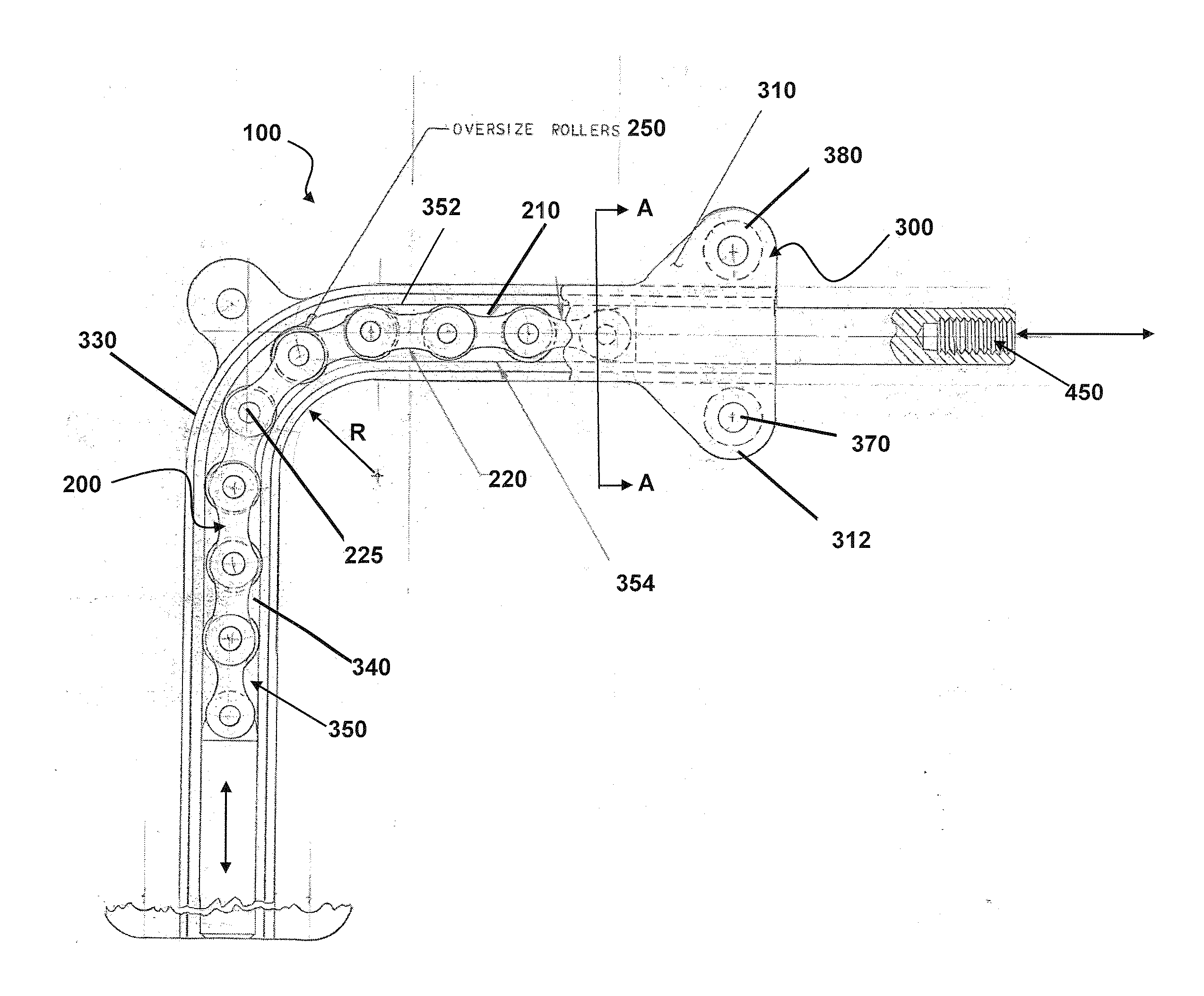

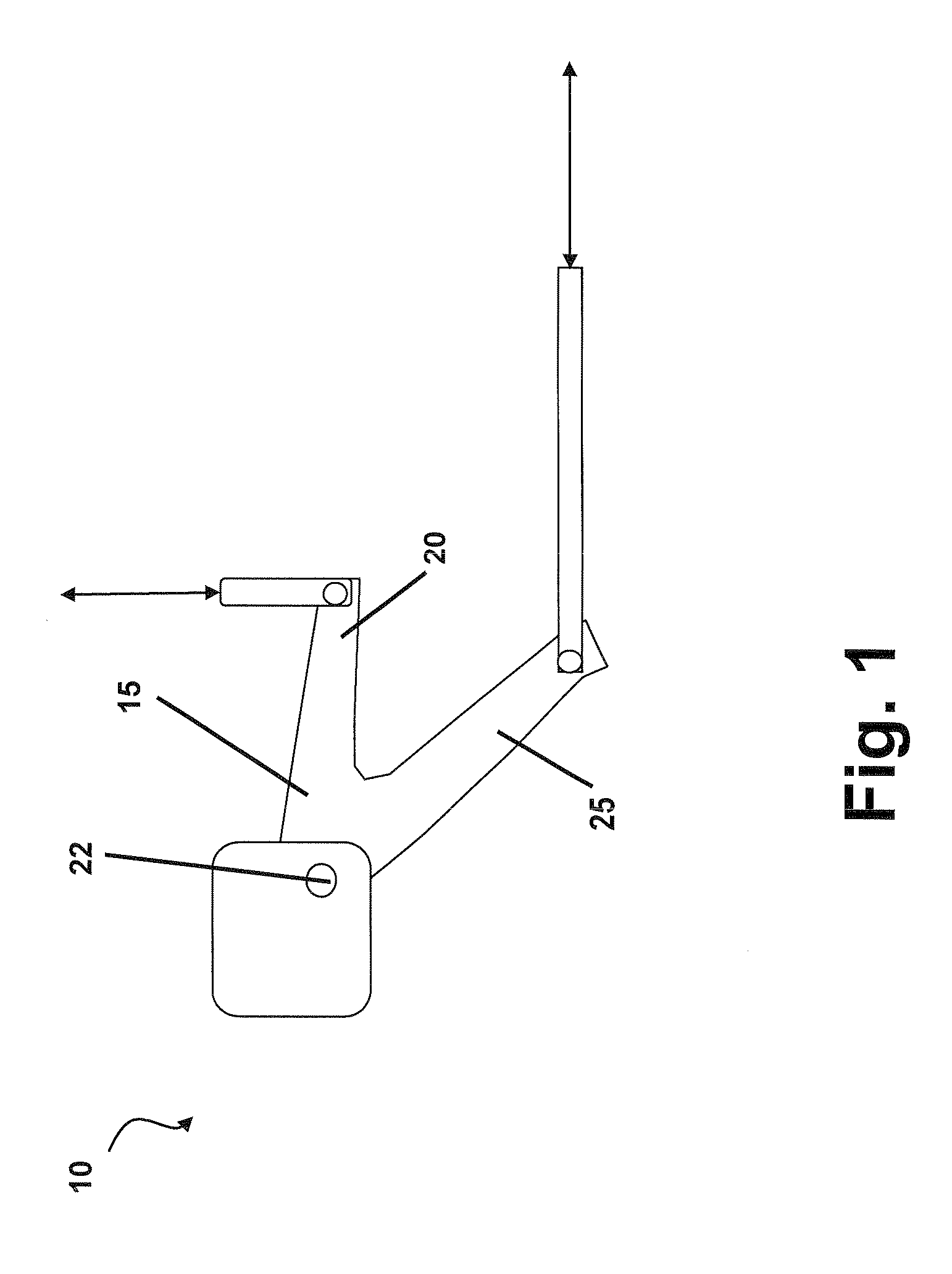

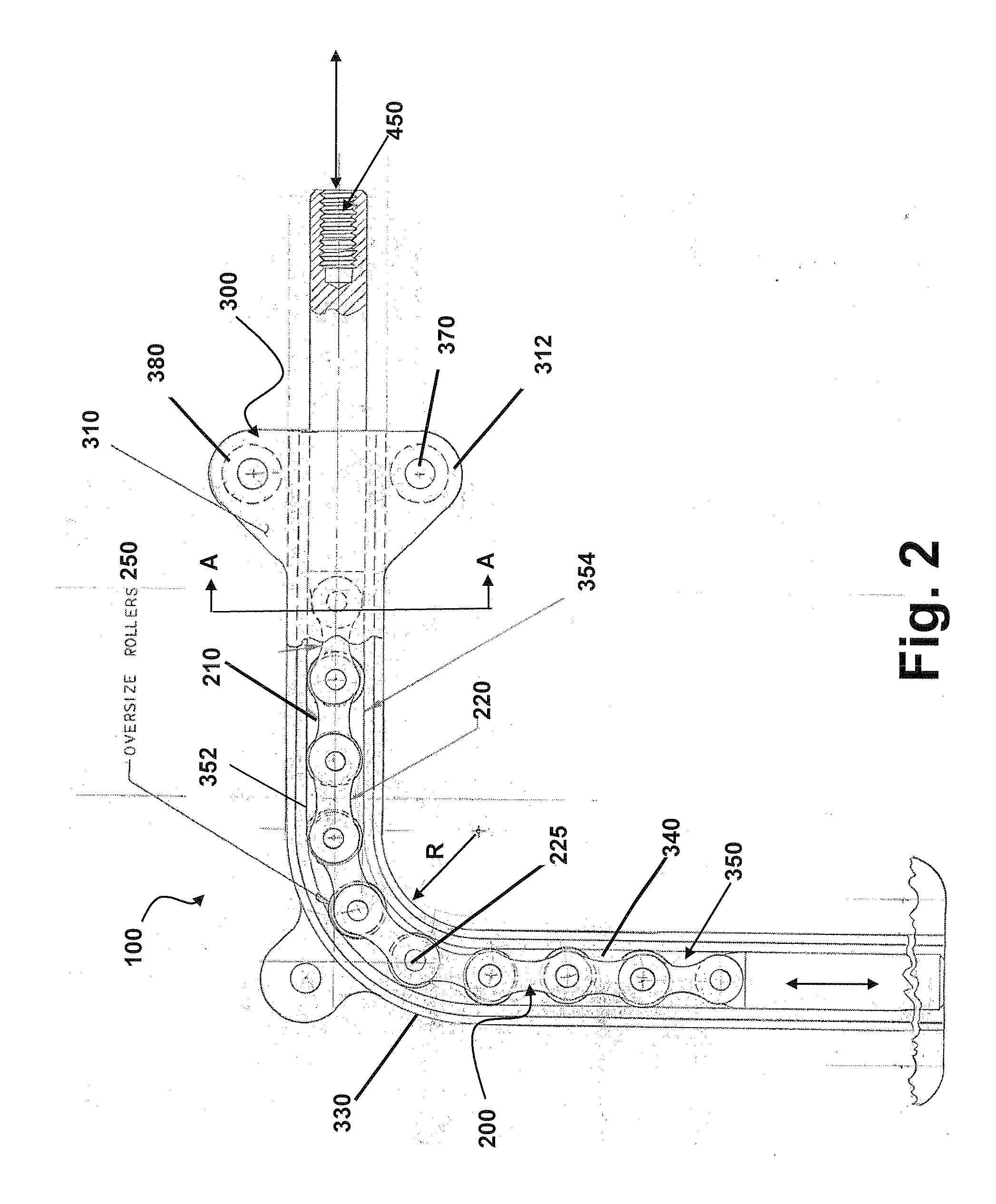

Force transfer assembly

InactiveUS20110308338A1Low frictionLow hysteresisFriction gearingsMultiple dimensionMechanical engineering

A force transfer assembly that can transfer force at various angles and through relatively small bend radii includes a roller chain constrained in a raceway channel. The configuration provides multi-dimensional support so that a roller chain assembly, typically constrained to tensile loading, may also be used for compressive loading. A method for transmitting force along a non-linear path includes configuring a raceway channel having an upper raceway surface and a lower raceway surface, securing a chain assembly into the raceway channel between the upper raceway surface and the lower raceway surface with at least one lateral securing mechanism, and applying a tensile or compressive force to one end of the chain assembly in order to have the chain assembly transfer the tensile or compressive force to the other end of the chain assembly.

Owner:SCHLUCKEBIER FLOYD A

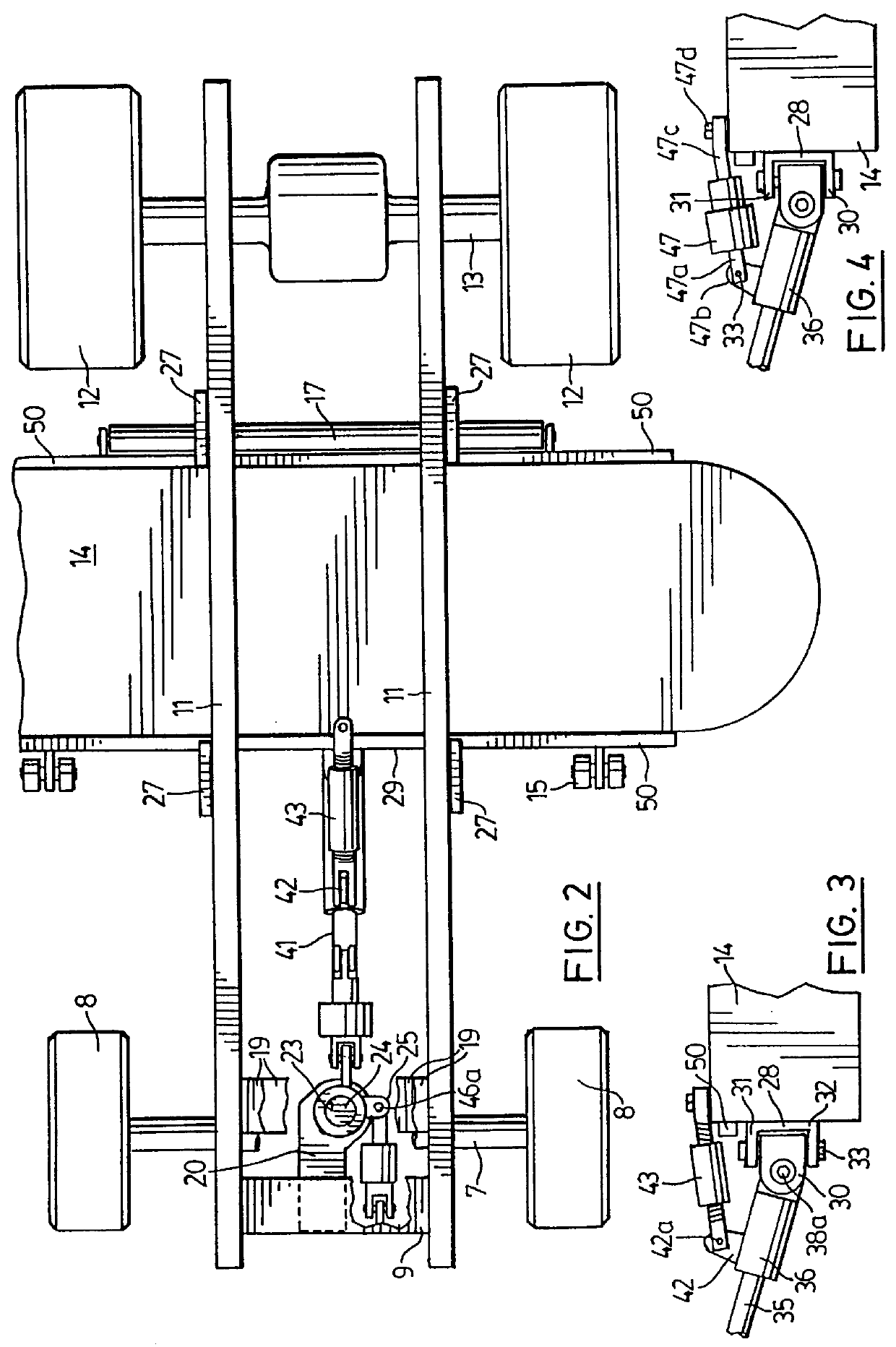

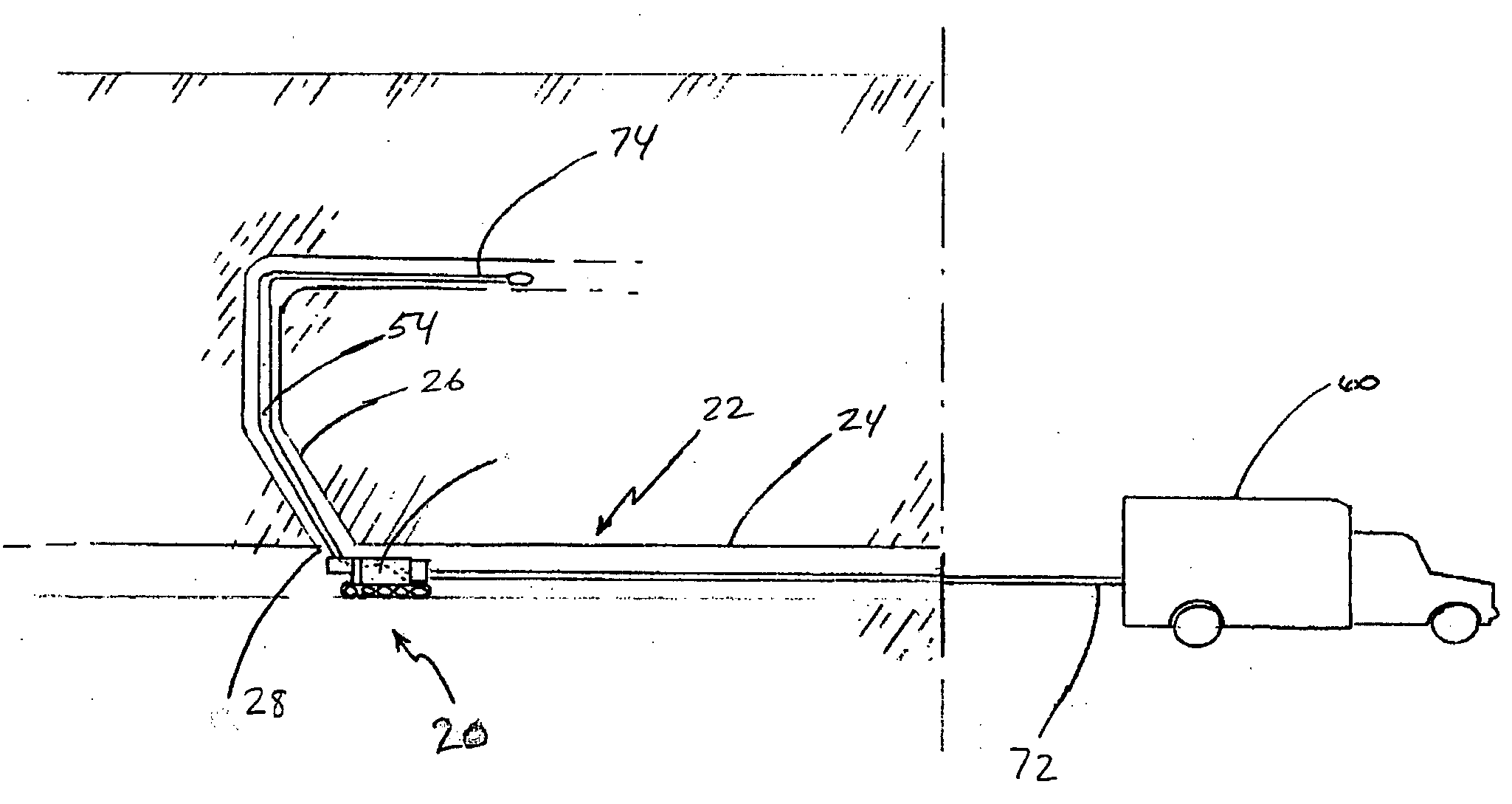

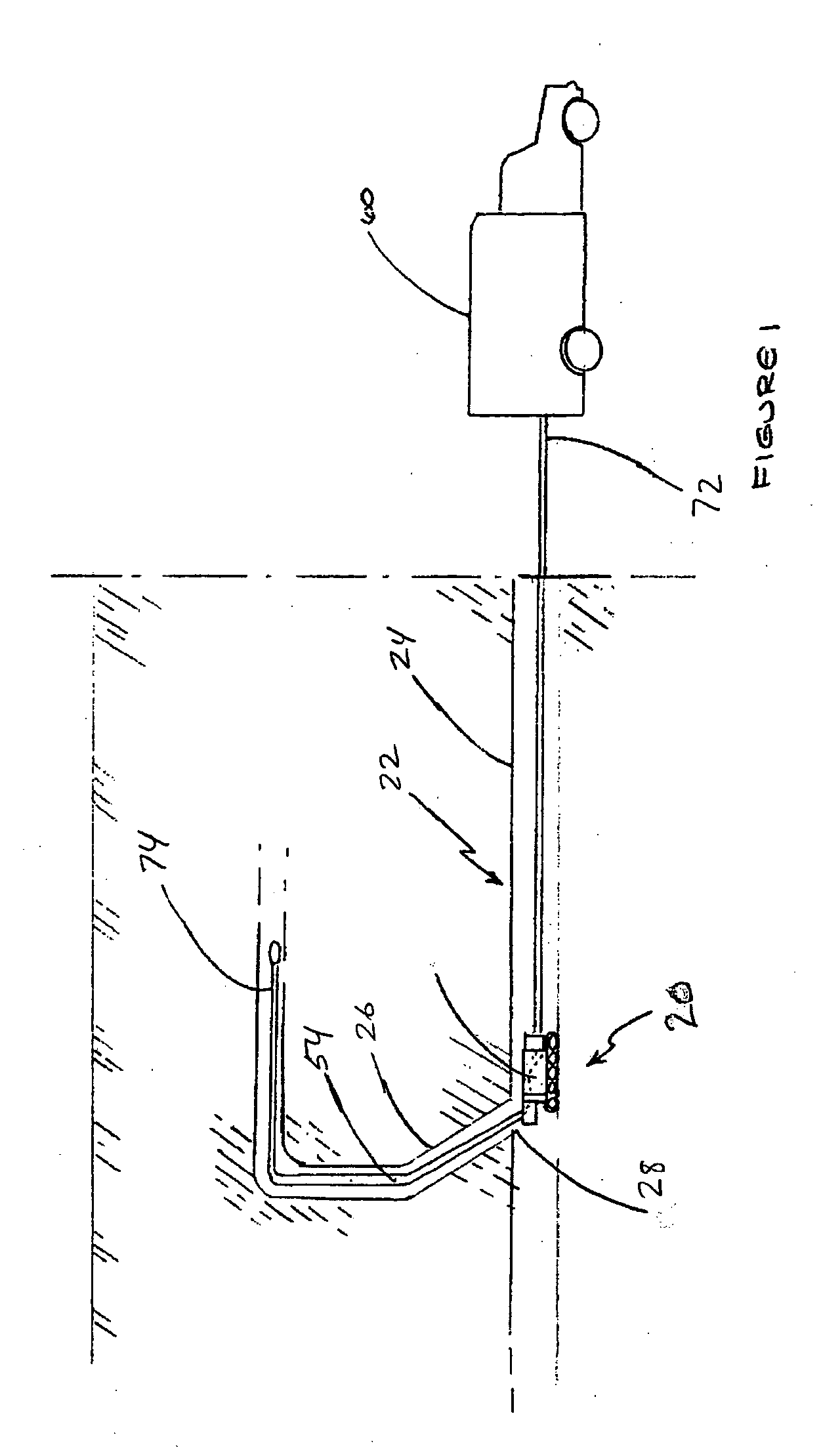

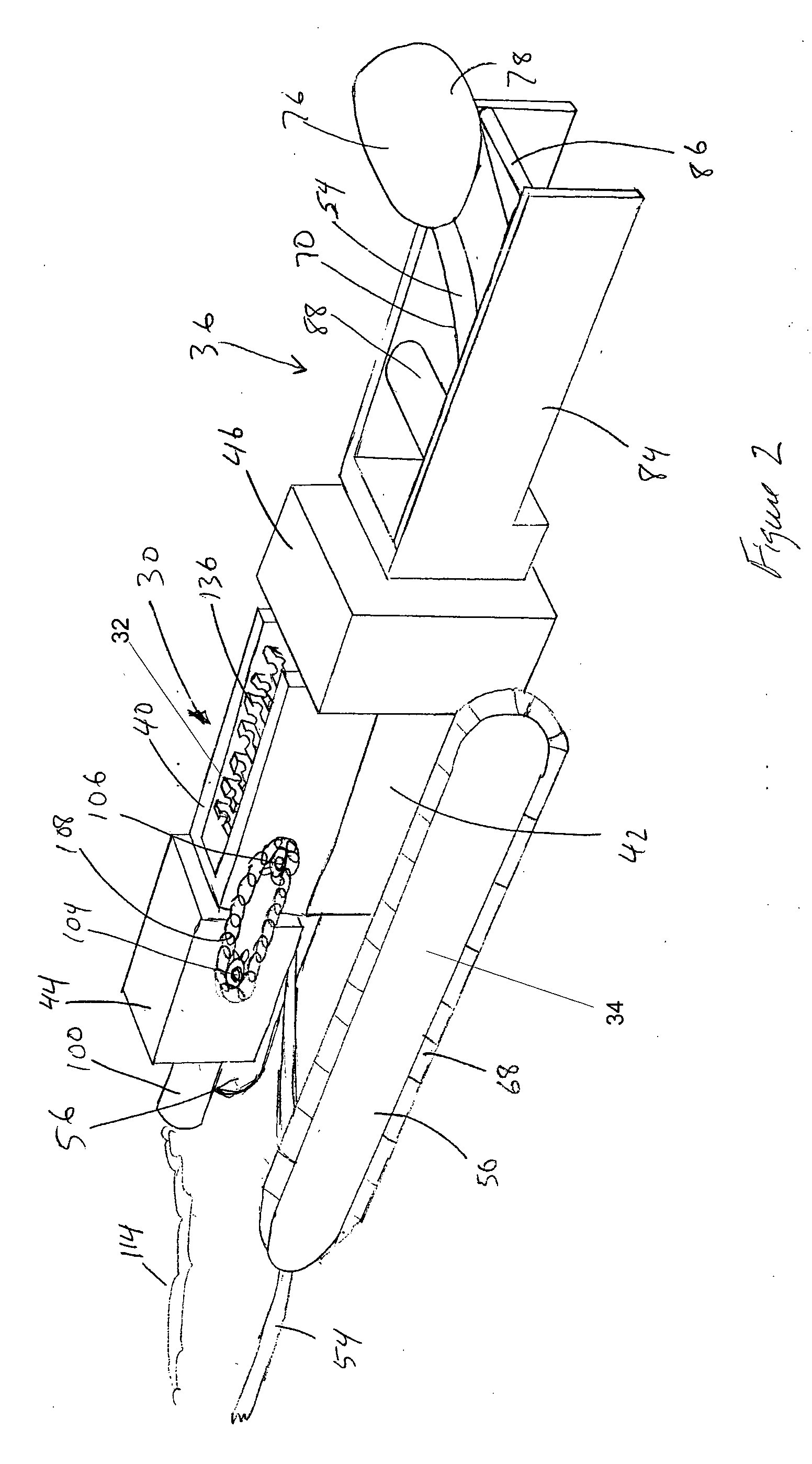

Apparatus for inspecting a lateral conduit

InactiveUS20050034544A1Low frictionLong wearing pressure surfaceMaterial analysis by optical meansStructural/machines measurementMechanical engineering

An apparatus for inspecting a lateral conduit from a main conduit including a frame, an upper push rod drive assembly and a lower push rod drive assembly. The upper push rod drive assembly includes an upper track having a plurality of upper attachments mounted thereto for engaging the push rod. The lower push rod drive assembly includes a lower track having a plurality of lower attachments mounted thereto for engaging the push rod. The push rod is held between the upper and lower attachments and in a preferred embodiment, some of the upper attachments, some of the lower attachments and the push rod move with a linearly synchronized motion.

Owner:HATHORN CORP

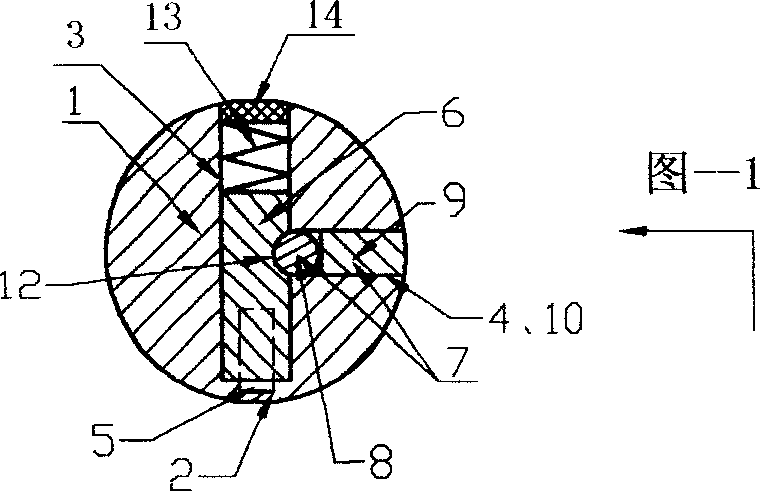

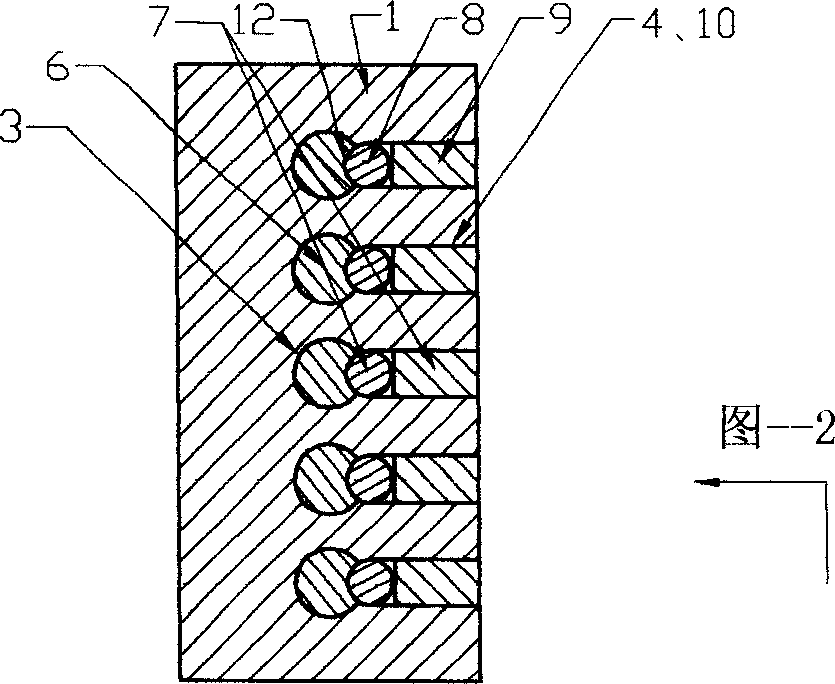

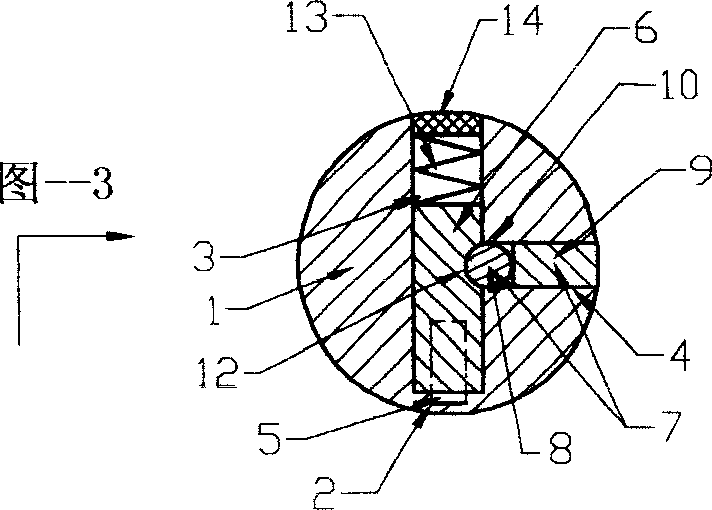

Structure for lock cylinder

The structure of a lock element comprises a lock element (1), a key hole (2), a marble hole (3), a side marble hole (4), an angle key (5), an angle marble (6) and a side marble (7), featuring in the side marble (7) being separated into the small marble(8) and a lock bolt (9). It solves the high precision requirement, processing difficulty and unsmooth plugging for the angle marble, with reduced cost and improved quality.

Owner:谢煜光

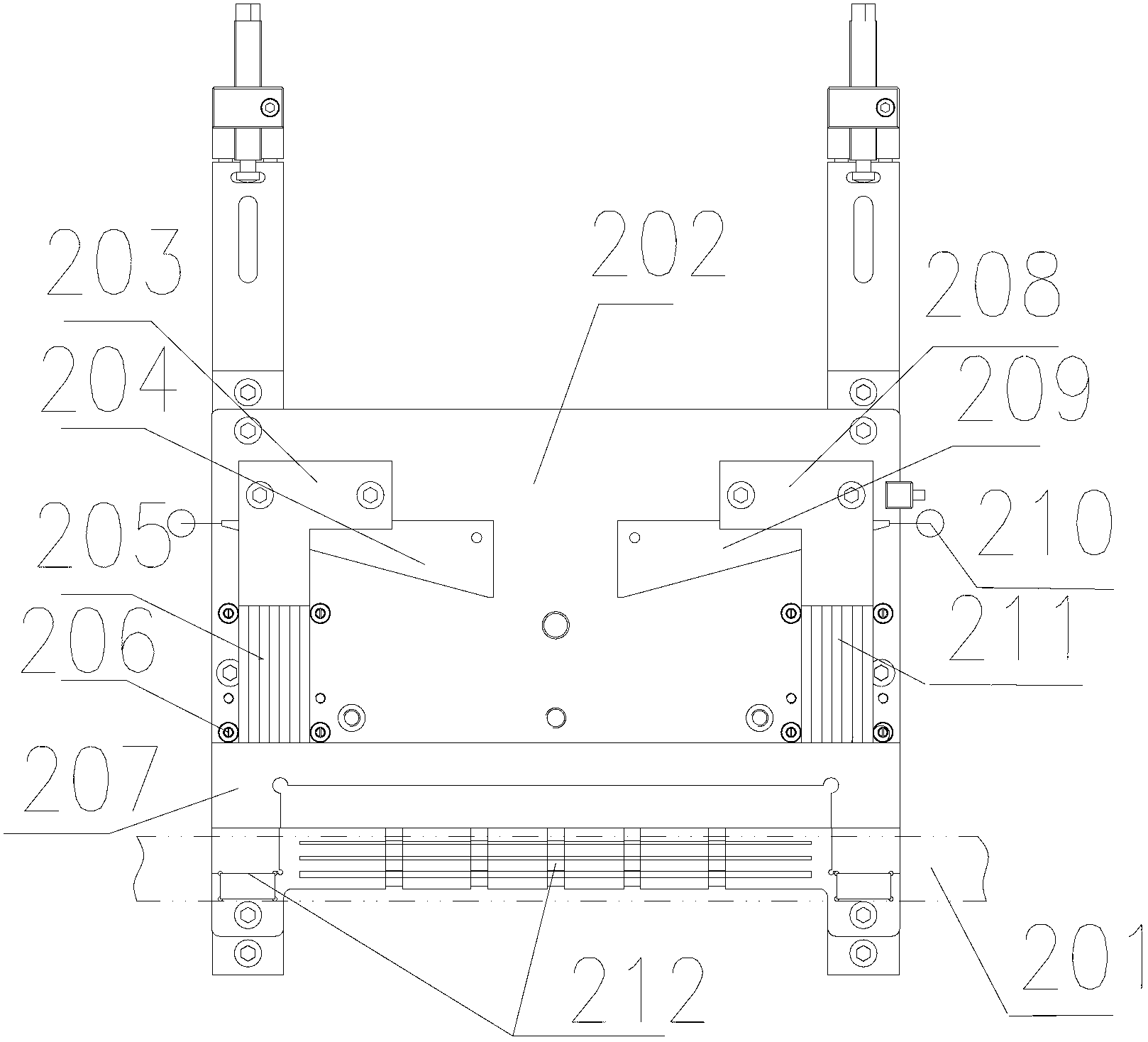

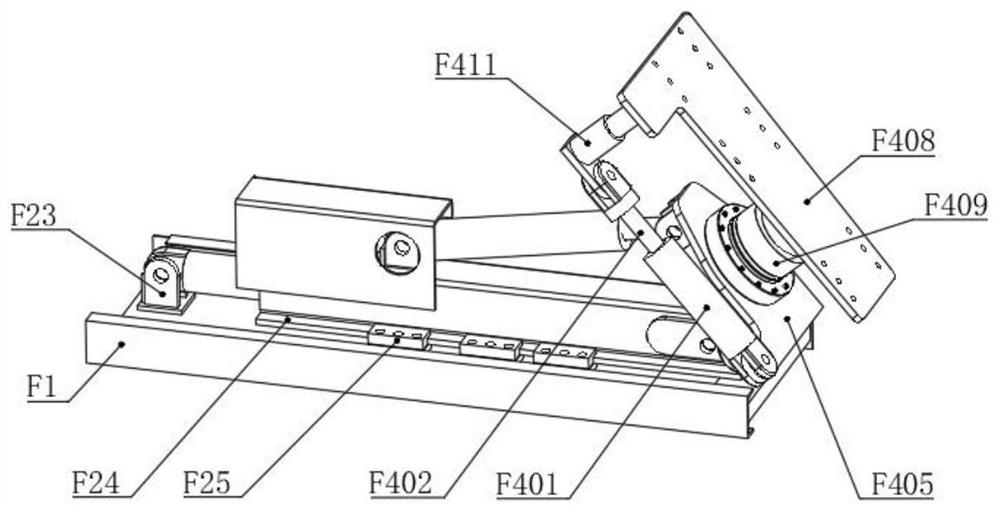

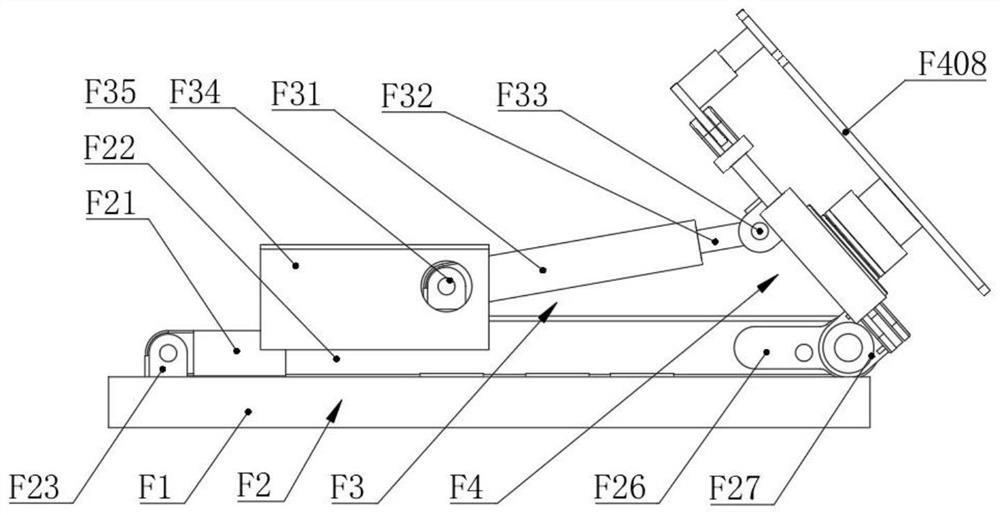

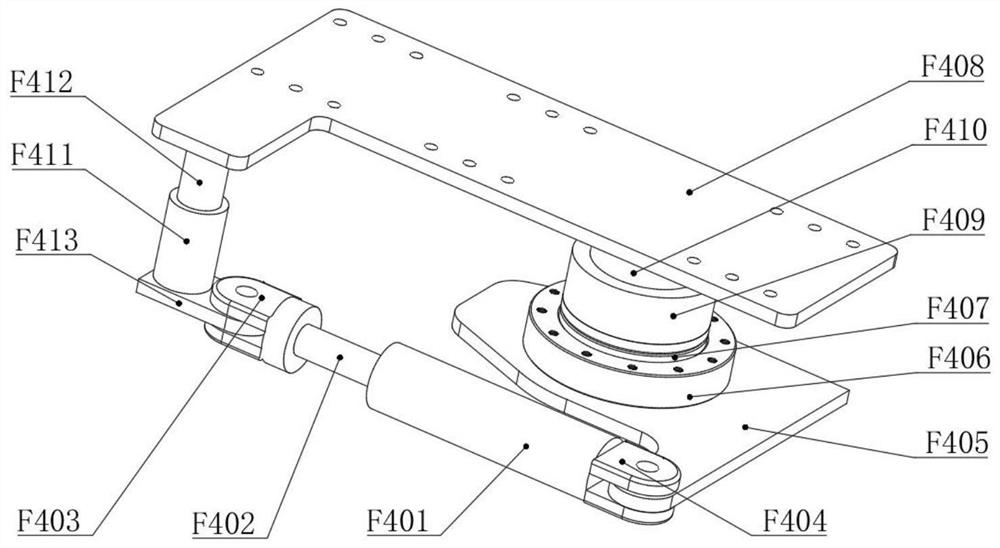

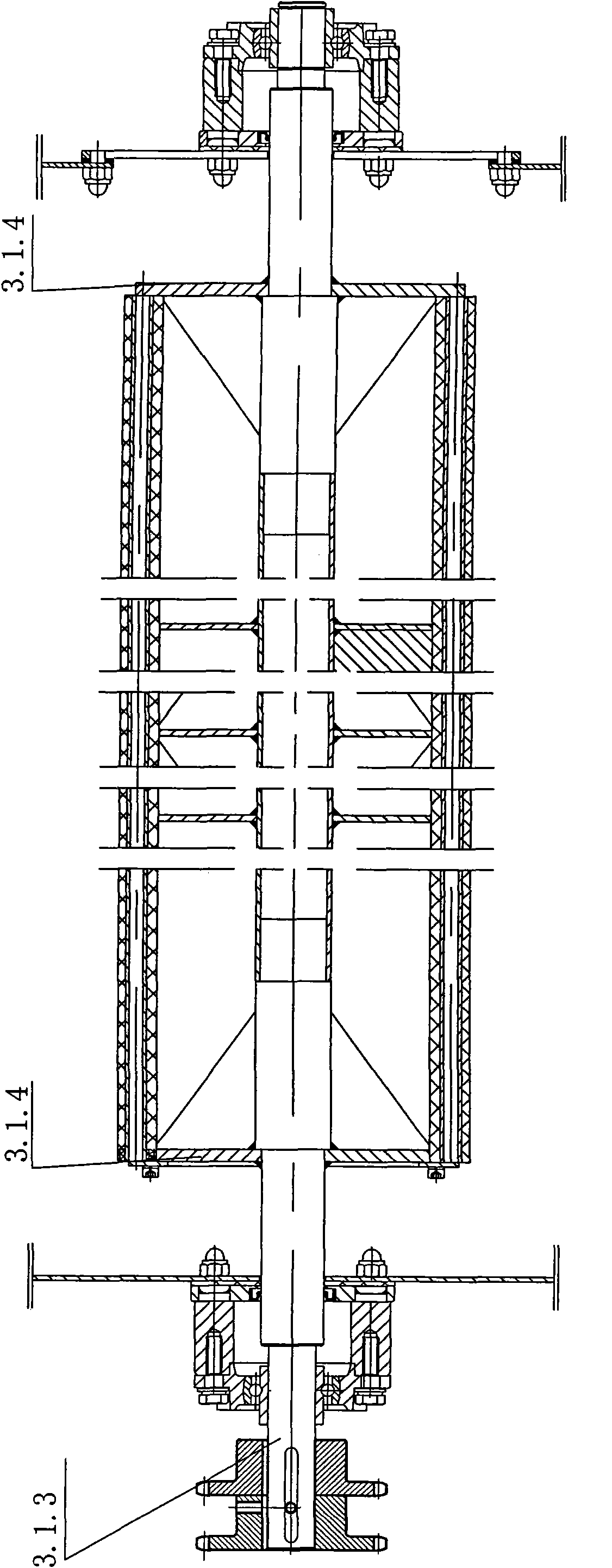

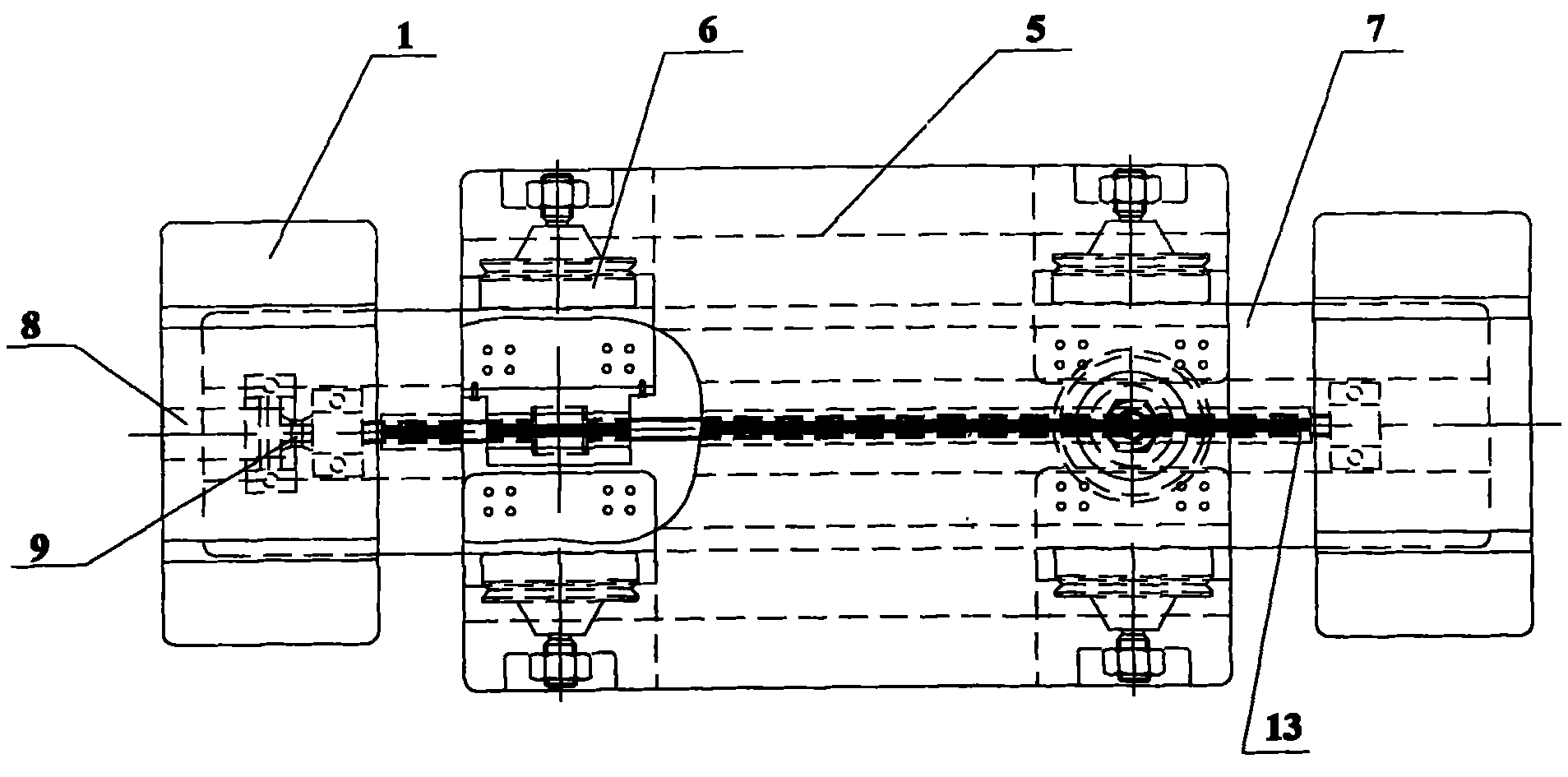

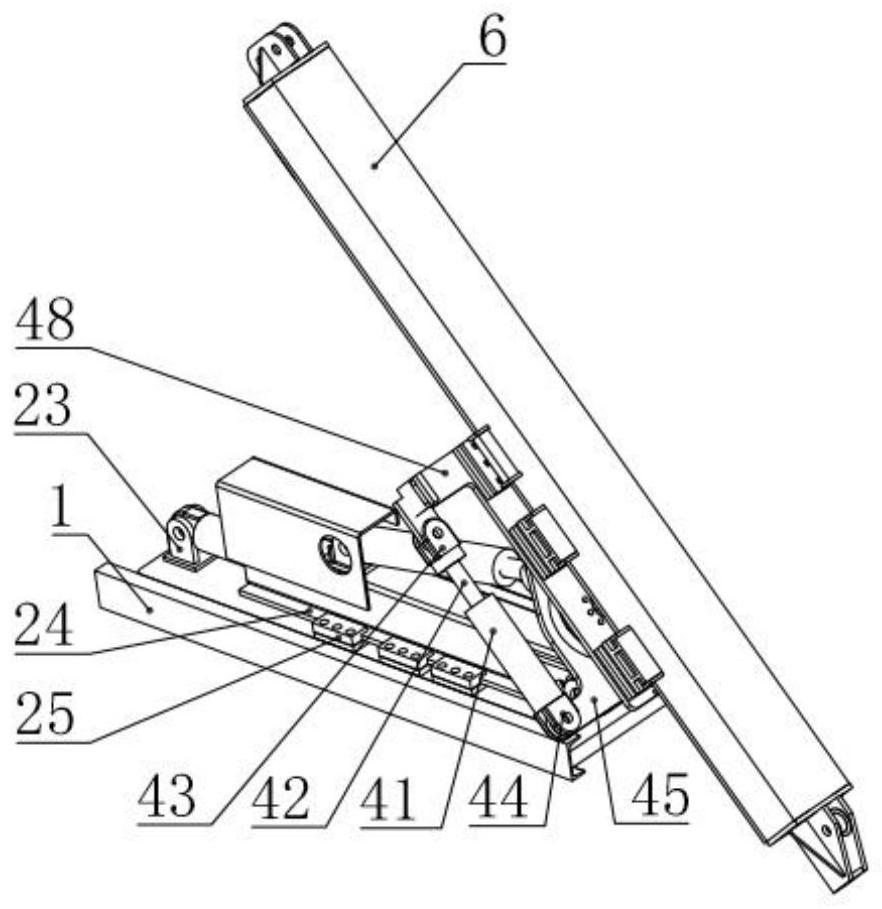

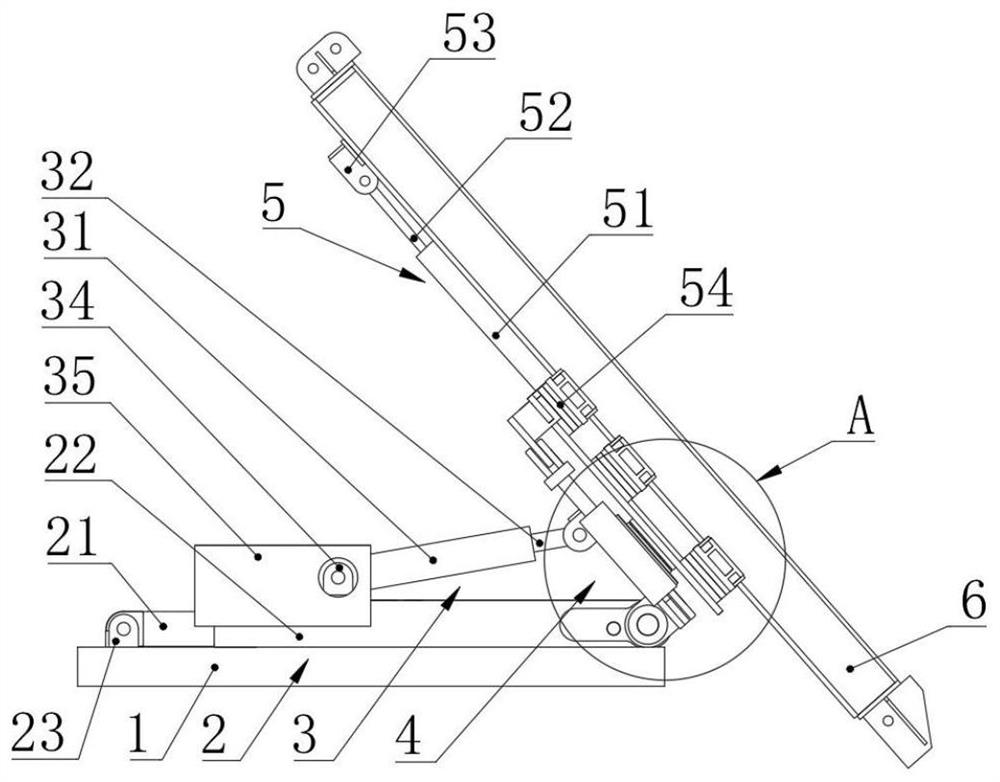

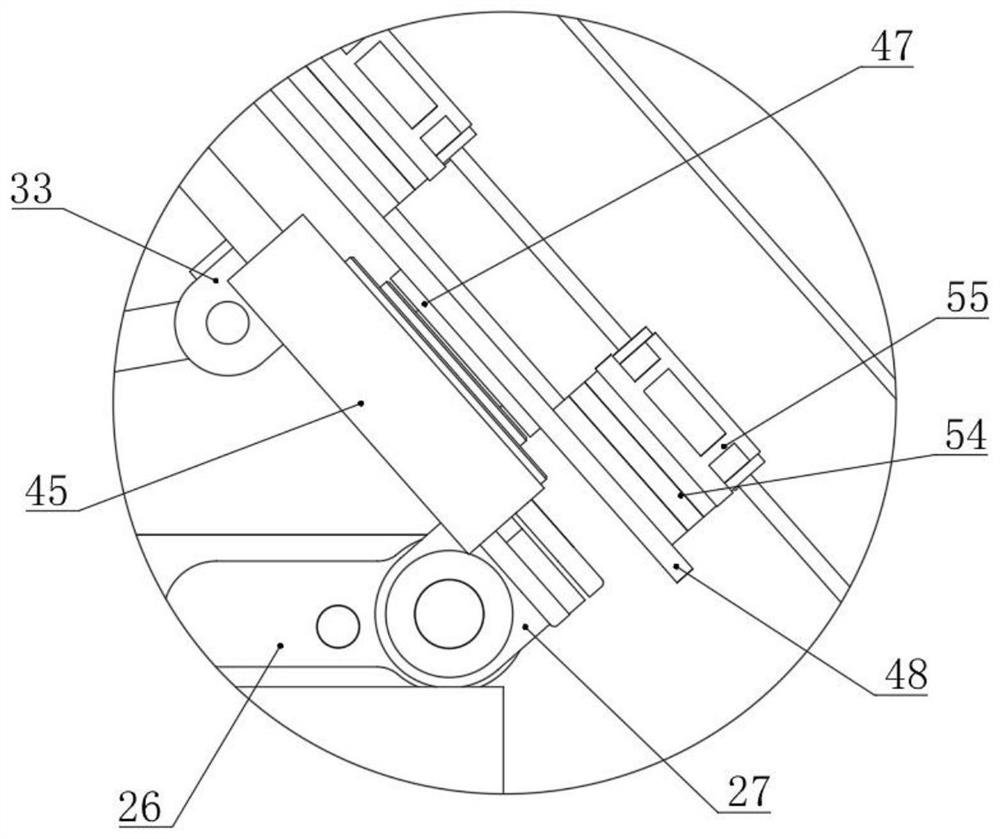

Drilling machine with deflection mechanism and using method thereof

InactiveCN111927314ACompact structureSimple structureDerricks/mastsDirectional drillingControl engineeringMachine

The invention belongs to the technical field of drilling machines, and particularly relates to a drilling machine with a deflection mechanism and a using method thereof. The drilling machine comprisestwo sliding block devices, a double-row chain guide rail device, a lifting arm device, a guide sleeve device, a power head device and a deflection device; the guide sleeve device and the power head device are each slidably connected with the lifting arm device through one sliding block device; and the guide sleeve device is detachably connected with the power head device, and when the two slidingblock devices slide, the guide sleeve device and the power head device move synchronously. The using method of the drilling machine comprises the following steps of 1, adjusting the deflection device; 2, adjusting the position of a drill arm; 3, carrying out power output of the two sliding block devices; 4, carrying out power transmission of the two sliding block devices; 5, carrying out power output of the power head device; and 6, drilling the guide sleeve device. The drilling machine is convenient to operate, stable and reliable, long in service life, capable of adapting to most construction sites, and high in adaptability of working sites.

Owner:李文美

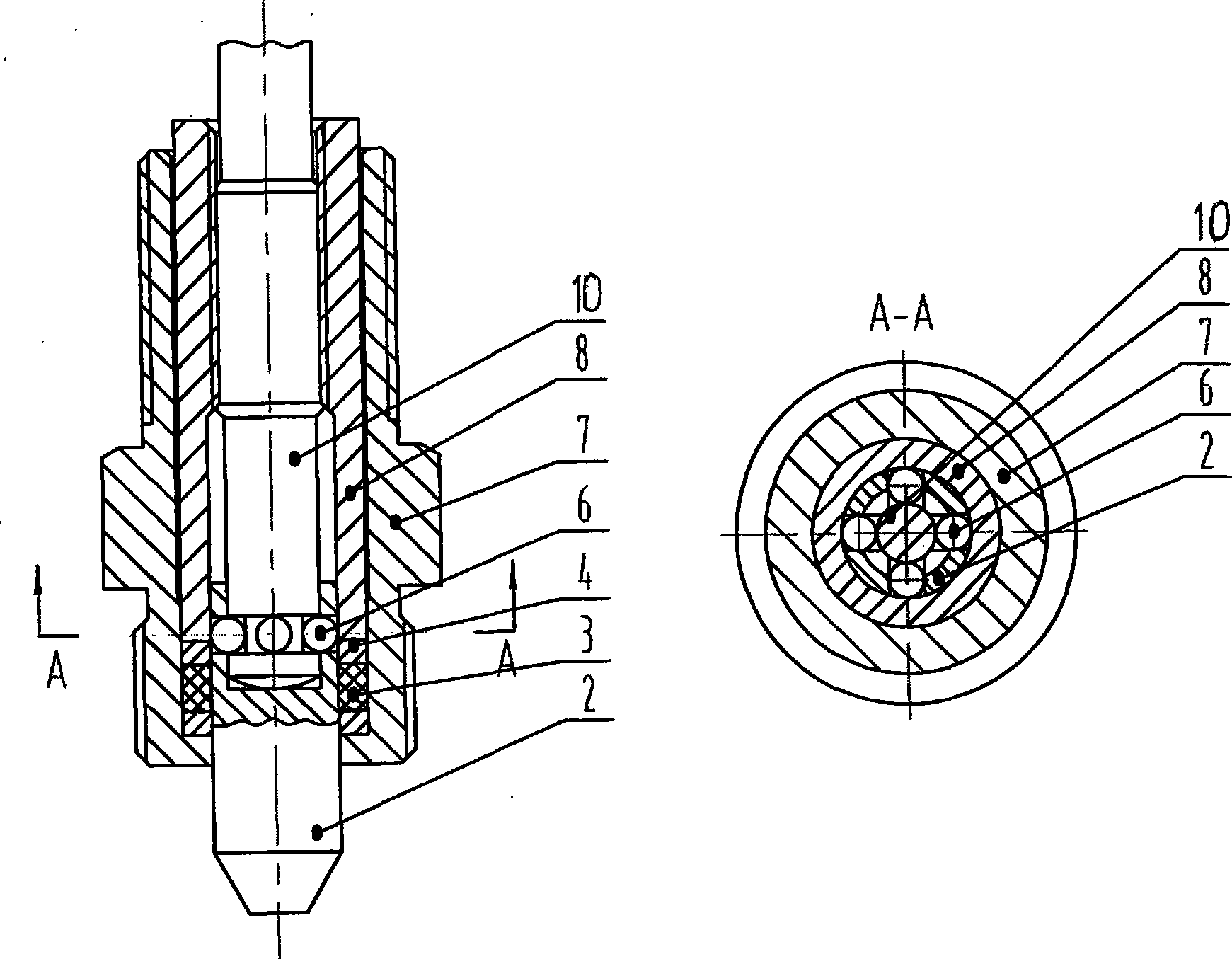

Pressure die-drawing device for producing bimetallic wire

The invention discloses a double metal wire production device, particularly a pressure die drawing device used for producing double metal wires. The device comprises a die holder (9) and a drawing die (10) connected with the die holder (9). The device is characterized in that the wire feeding side of the drawing die (10) is provided with an oil pressure cavity (2) communicated with a hydraulic power device, and the wire feeding position of the oil pressure cavity (2) is provided with a sealing device. The device has the advantages that the lubricating material has large adhesive force on the wire blank surface; the drawing die has small friction with the wire surface; the drawing die and wire blank can be cooled and has balanced temperature at any time during drawing; and the device can achieve good metallurgical bonding, good wire surface quality with surface stress evenly distributed and more superfine radial dimension.

Owner:王玉凯 +3

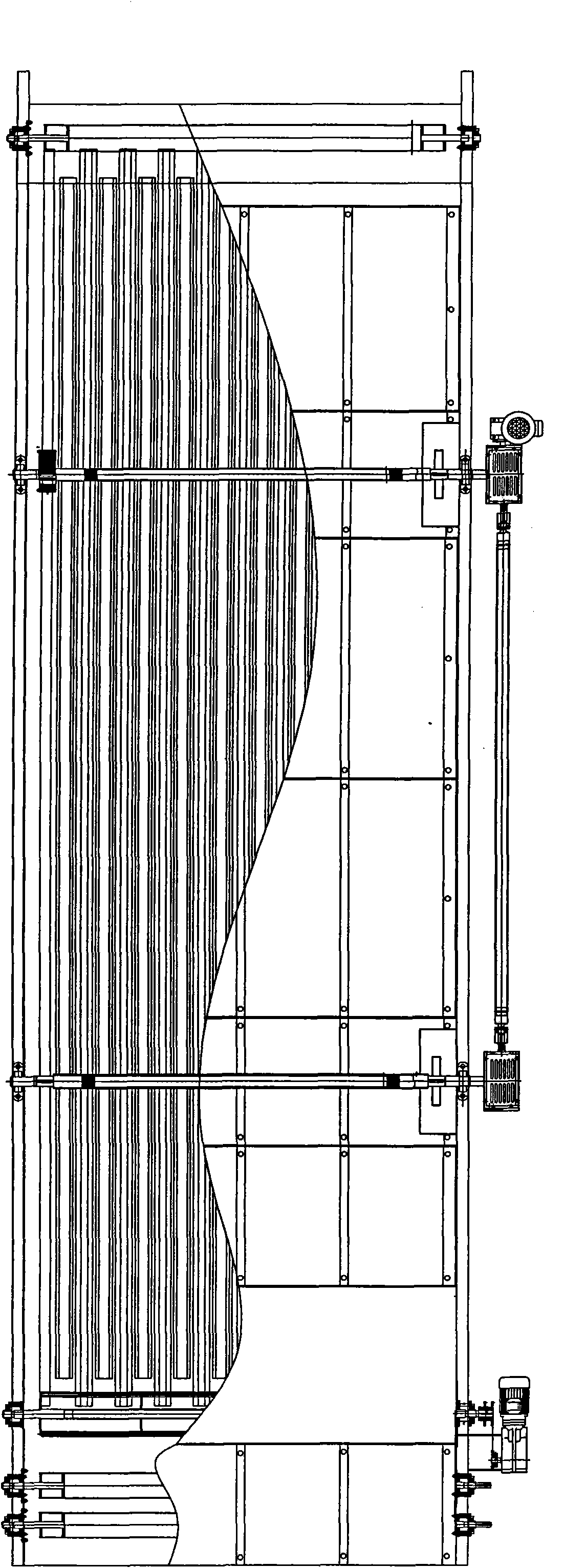

Progressive slow piling steaming box

ActiveCN101892568AReduce stacking timeWon't scratchTextile treatment machine arrangementsTextile treatment carriersPolyesterDrive shaft

The invention relates to a progressive slow piling steaming box which is suitable for the steaming and the rinsing or the dying after the cold pad-batch pretreatment and the piling and the steaming before the printing of pure cotton and cotton-polyester blended fabrics. The steaming box comprises a box body (1), a progressive slow piling device (4) and a cloth supporting basket (5), wherein the progressive slow piling device (4) and the cloth supporting basket (5) are arranged in the box body (1); the progressive slow piling device (4) comprises a gear box motor (4.15), three transmission shafts (4.14), four rocker arm mechanisms and a cloth moving basket (4.16); a plurality of cloth supporting strips I (4.16.1) and a plurality of cloth supporting strips II (5.1) are convexly arranged on the cloth moving basket (4.16) and the cloth supporting basket (5) and distributed along the length direction of the box body; and the cloth supporting strips I (4.16.1) on the cloth moving basket (4.16) and the cloth supporting strips II (5.1) on the cloth supporting basket (5) are mutually spaced. The steaming box can ensure that the surfaces of fabrics cannot be scratched to have grinding defects and can not be scalded and has uniform and thorough steaming effect.

Owner:江阴福汇纺织有限公司

Rotary cutting tool

InactiveUS20150266193A1Low frictionReduce frictionMetal working apparatusKnife bladesFood preparation

The disclosed subject matter relates to a cutting tool apparatus that may be used in food preparation and food service. The cutting tool may include a blade used for cutting. The blade may rotate about an axis. A housing may be coupled to the blade to support the blade. The blade may include channels that mate with housing channels. A handle may be coupled with the housing.

Owner:BELL GRANT

Fluid pump assembly

A fluid pump assembly comprising a driven cam and a reciprocating member reciprocal within a bore provided in a pump housing as the cam is driven, in use, to cause pressurisation of fluid within a pump chamber. The pump assembly further comprises an interface between the cam and the reciprocating member, for example in the form of bevelled surfaces of the cam and the reciprocating member, which serve to drive the reciprocating member (i) to translate in a first, axial direction within the bore and (ii) to rotate within the bore in a second, rotational direction. An optional feature of the fluid pump assembly is that the pump housing defines a bearing for the cam which is provided with a recess to define a region of weakness to allow the bearing to deflect, in use, thereby to provide an increased lubrication volume between the cam and the bearing. The reciprocating member may take the form of a tappet which cooperates with a pumping plunger to pressurise fluid within the pump chamber.

Owner:DELPHI TECH HLDG S A R L

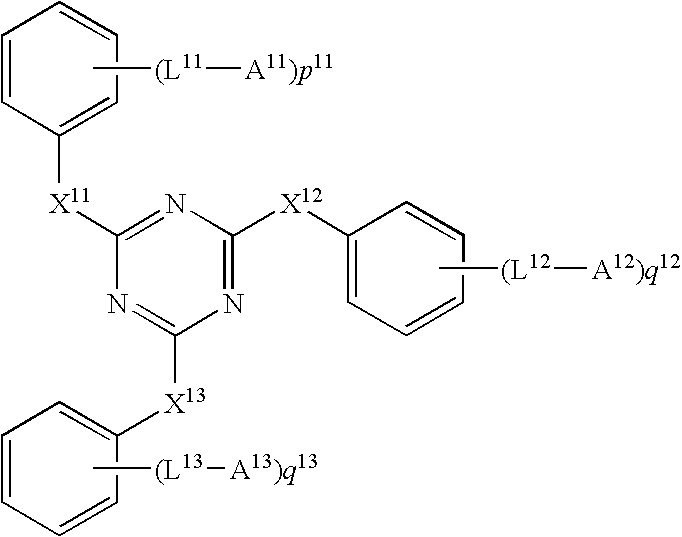

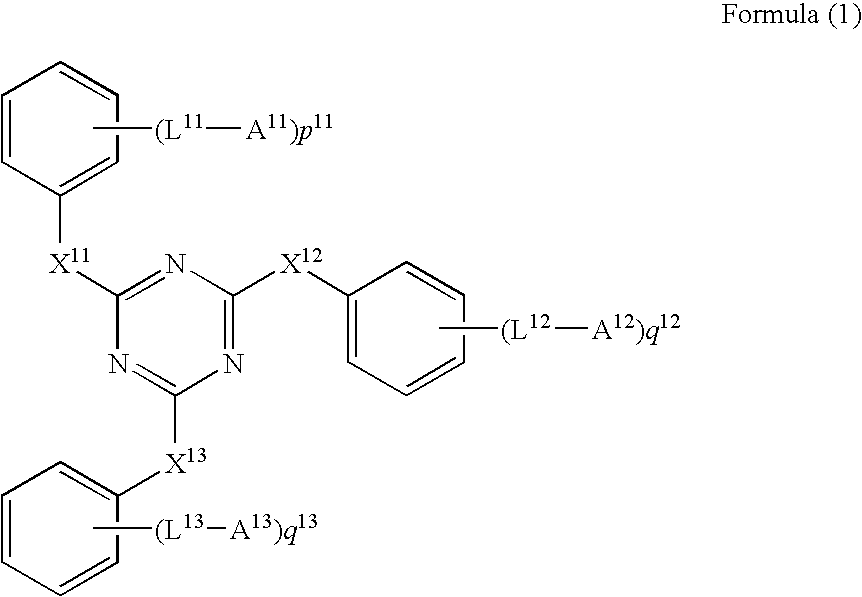

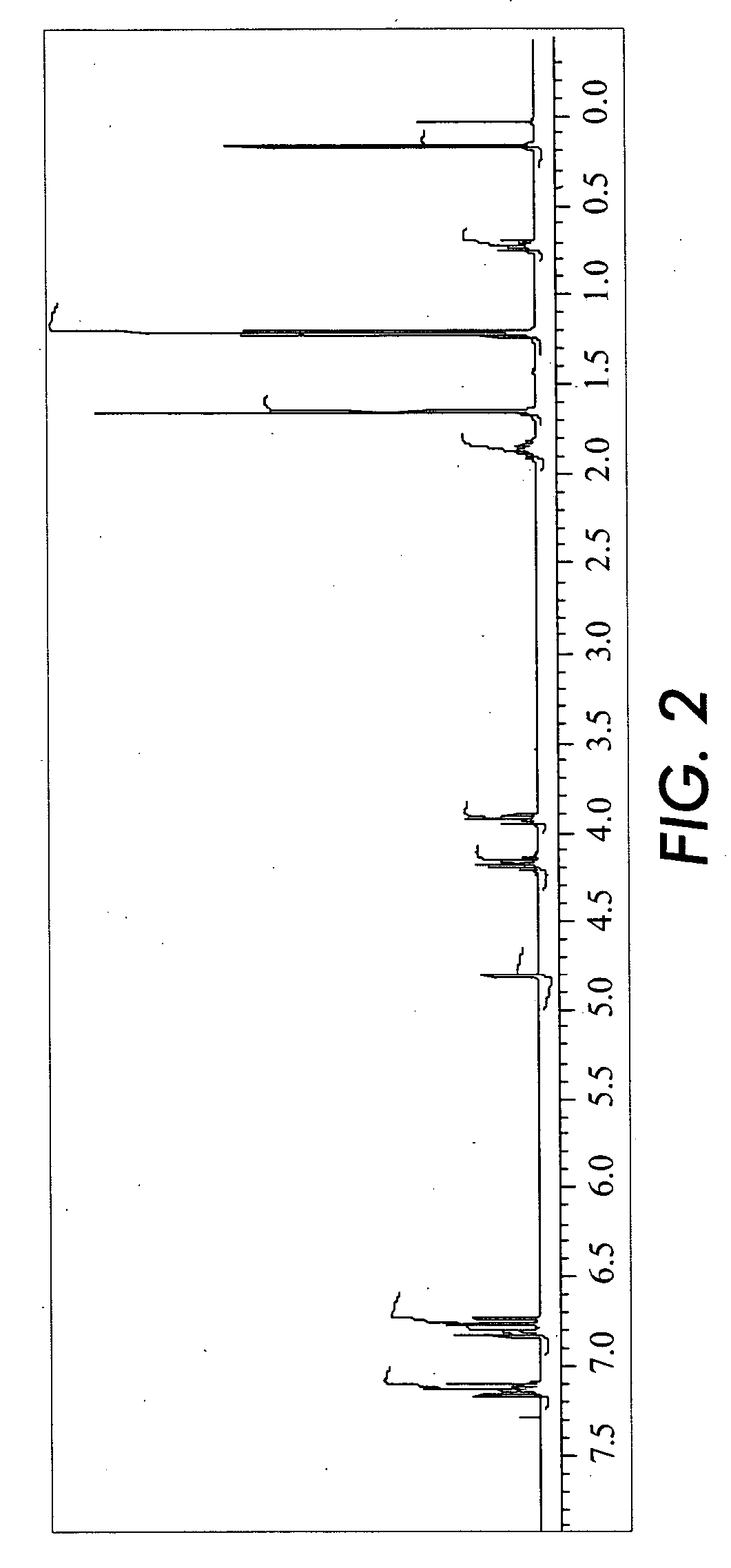

Lubricant composition and triazine ring-containing compound

InactiveUS20060068997A1Low frictionHigh practicalityOrganic chemistryAdditivesCarbonyl groupOxygen atom

A lubricant composition comprising a compound represented by the following formula that can maintain a low friction and a high abrasion resistance on the sliding surface over an extended period of time: wherein X11 to X13 each represent a single bond, an NR1 group, an oxygen atom, a sulfur atom, a carbonyl group, a sulfonyl group or a divalent linking group comprising these groups in combination; L11 to L13 each represent a single bond, an NR1 group, an alkylene group, an oxygen atom, a sulfur atom, a carbonyl group, a sulfonyl group or a divalent linking group comprising these groups in combination; R1 is a hydrogen atom or an alkyl group; A11 to A13 each represent an aromatic group or heterocyclic group; and p11 to p13 each independently represent an integer of from 1 to 5.

Owner:FUJIFILM CORP

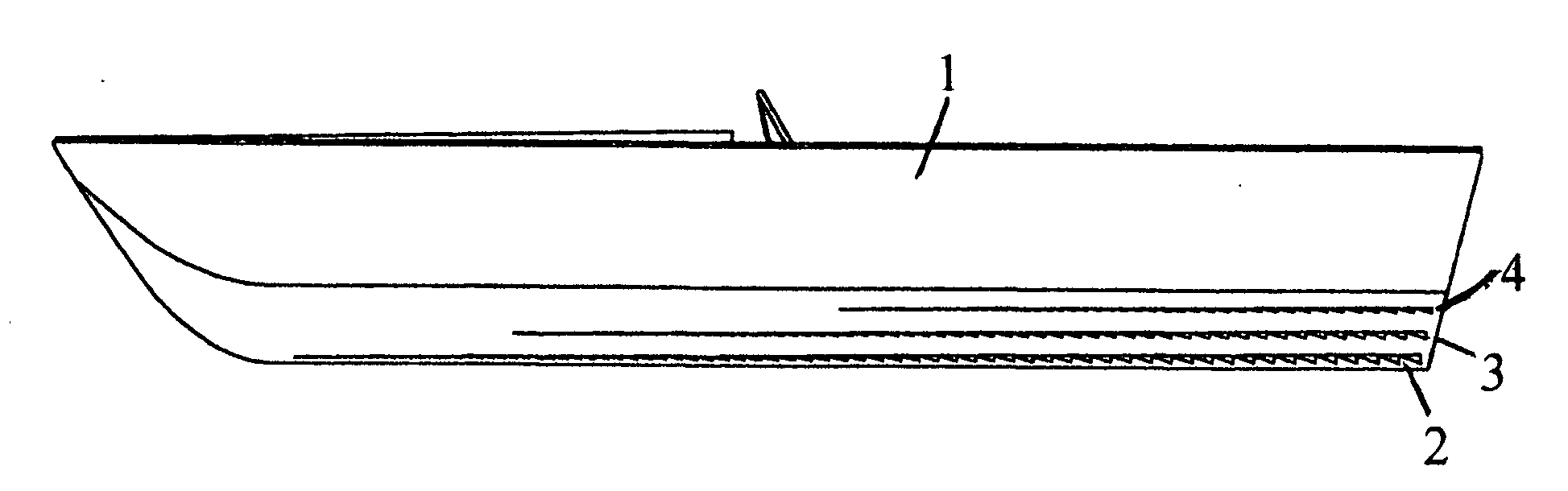

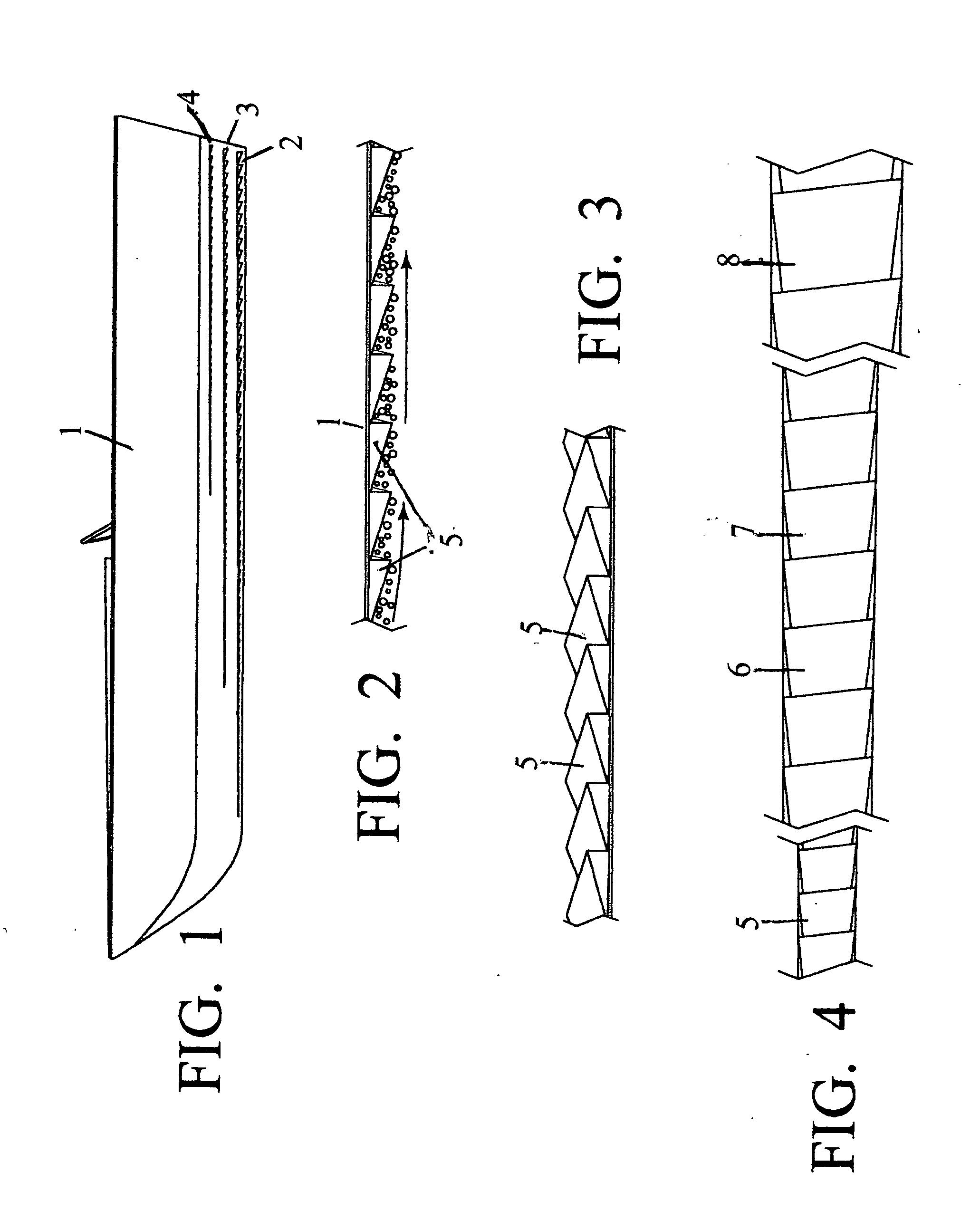

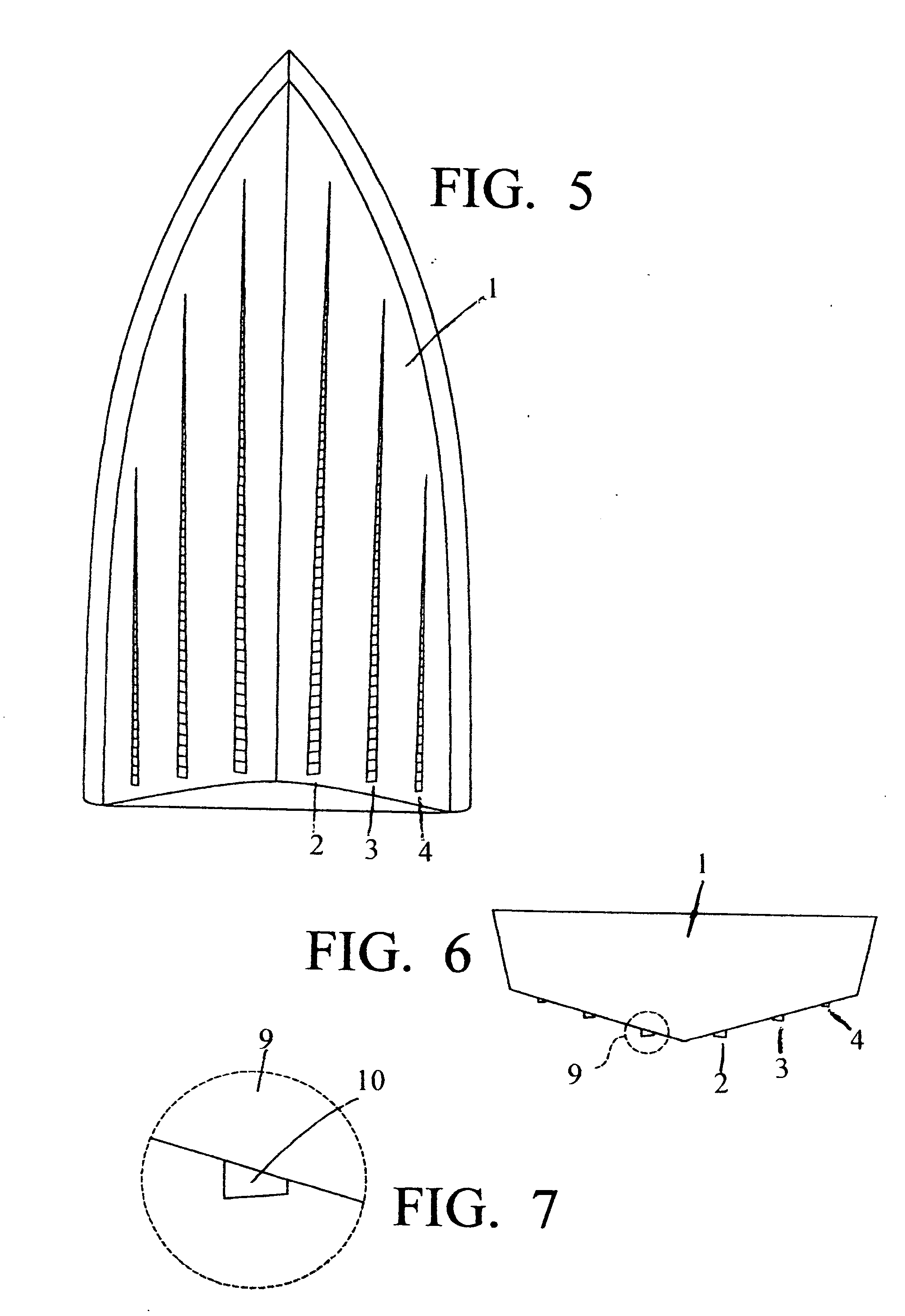

Boat hull strake design

InactiveUS20110297069A1Reduce surface frictionLow frictionWatercraft hull designFloating buildingsSurface frictionStern

A system for increasing the buoyancy of a boat operating in the water and to reduce the wetted-surface-friction of the water against the hull of the boat. The system includes a multiple of strakes attached to the bottom side of the boat. The strakes are instrumental in creating a multitude of bubbles on which the hull of the boat will ride which increases the efficiency of the power of the motor or motors powering the boat. The strakes are arranged in series along the hull of the boat and can increase in size from the bow of the boat to the stern. The strakes are also increasing in depth from the bow of the boat to the stern. The strakes may be attached to the boat as a retro-fit or may be added when manufacturing the boat.

Owner:QUIMBY JOHN I

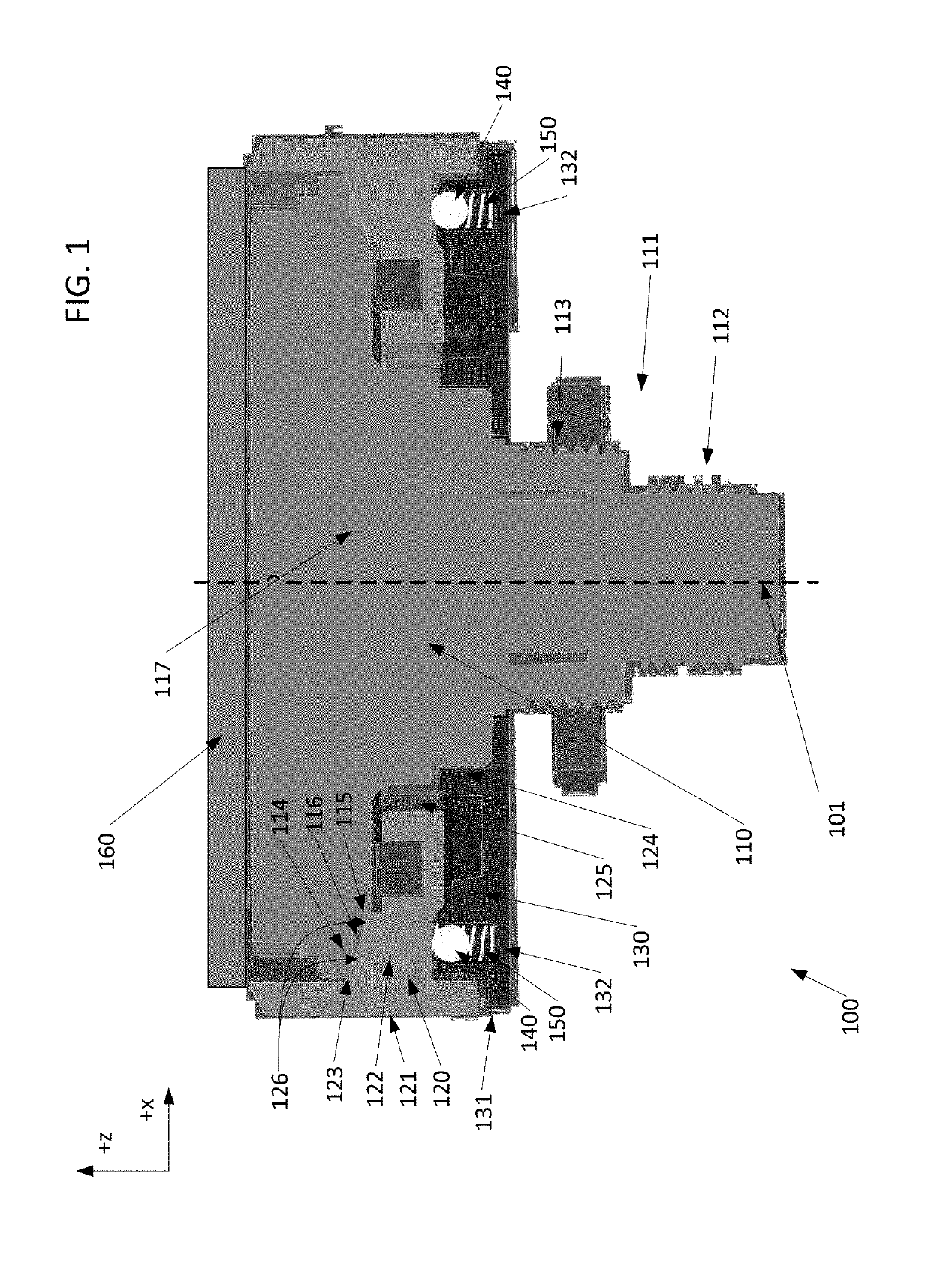

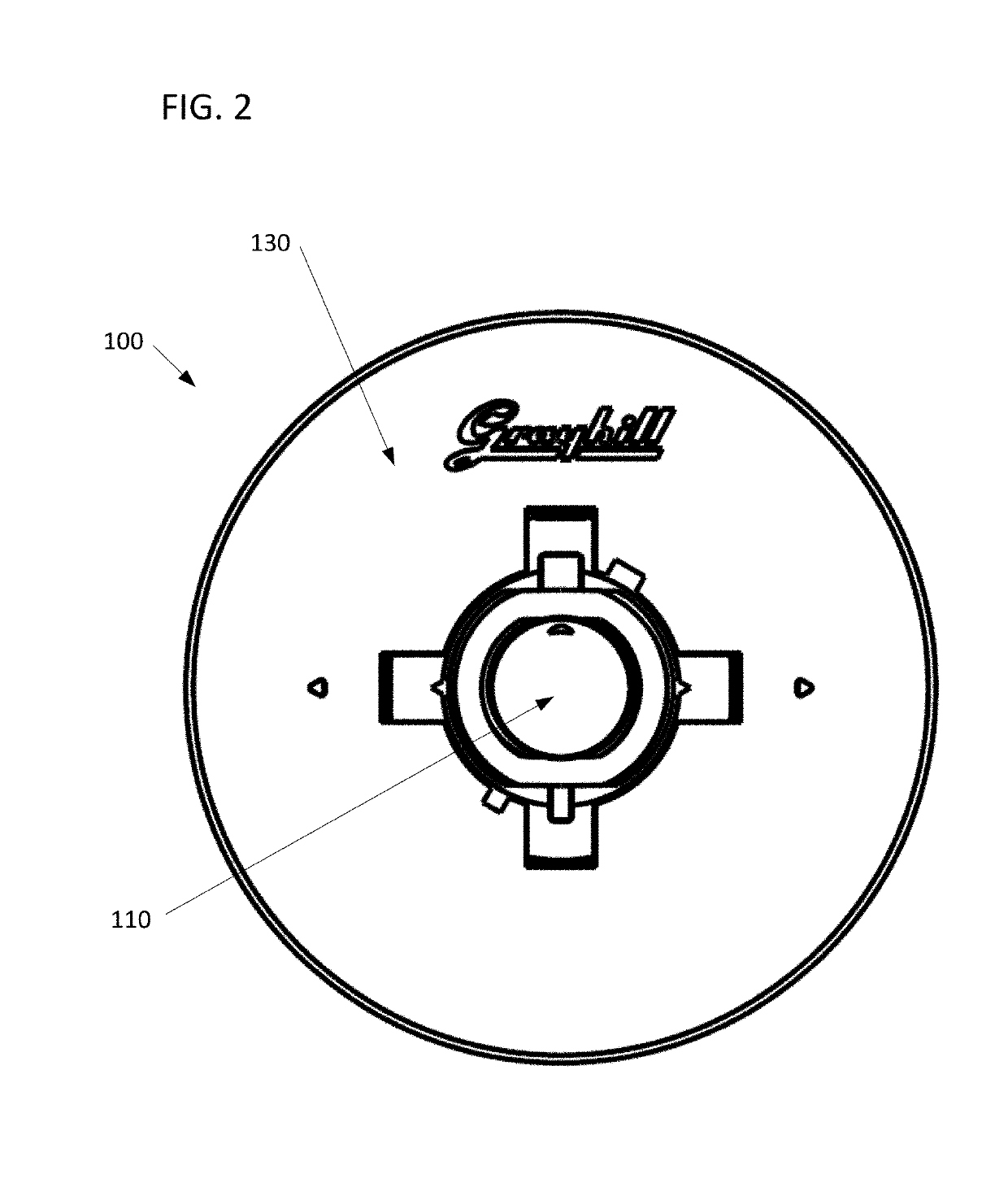

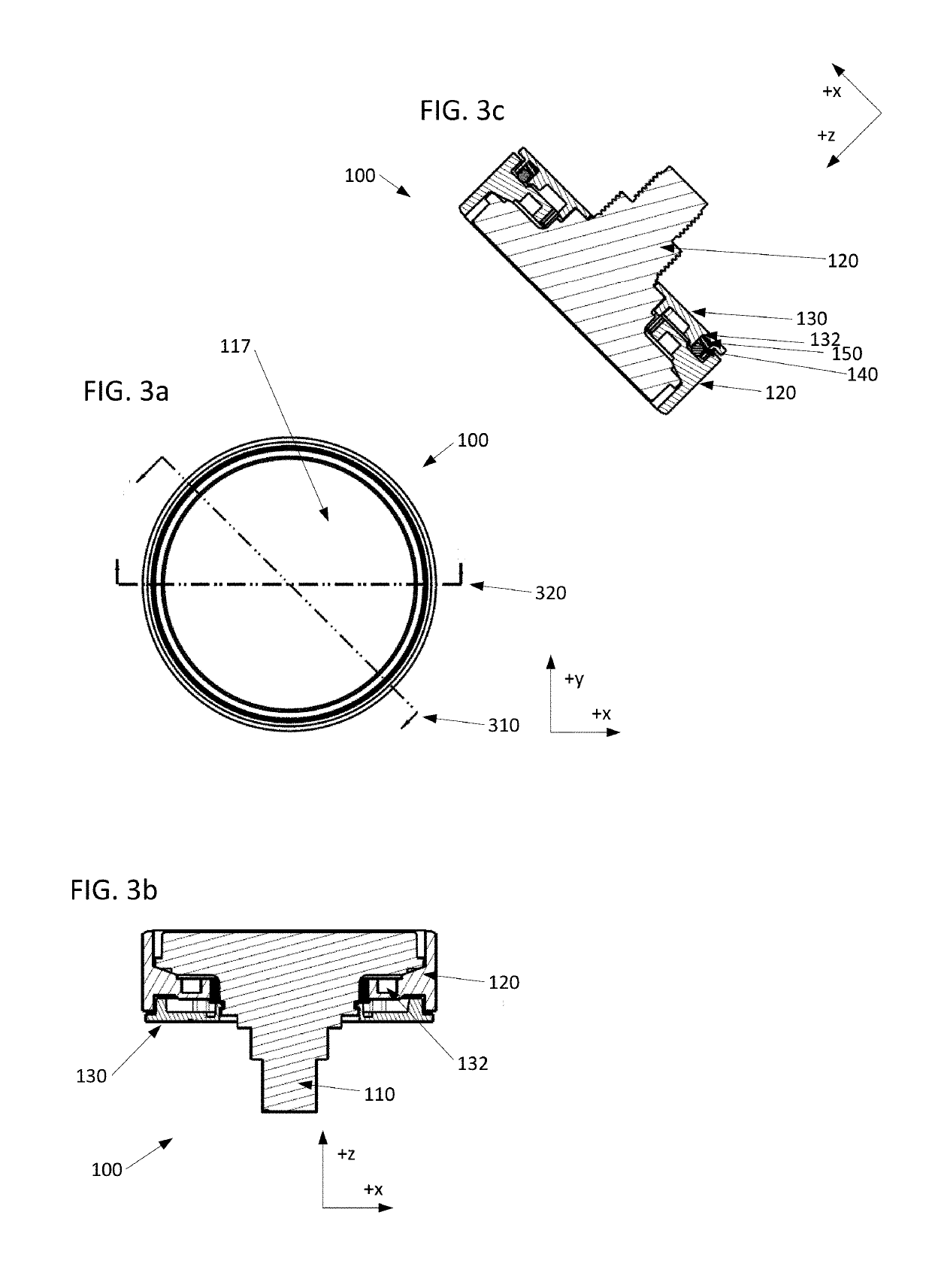

No/low-wear bearing arrangement for a knob system

The present disclosure is directed to knob systems and methods to permit a smooth turning user input device that minimizes unintended horizontal displacement, along the X- or Y-axis, or unintended vertical displacement, along the Z-axis. The disclosed knob system may achieve this goal through the use of a back plate, a knob and a main housing extending through the knob and the back plate, the back plate comprises a plurality of Z-stop bearings, comprising a plurality of Z-stop balls and a plurality of Z-support springs, wherein the Z-stop bearings are in contact with the back plate and are configured to separate the knob from the back plate when the main housing is depressed in a vertical direction and wherein each of the plurality of Z-stop balls are attached to one of the plurality of Z-support springs, the Z-support springs bias the Z-stop ball against the knob.

Owner:GRAYHILL

Imaging member

InactiveUS20070020539A1Low frictionSilicon organic compoundsPhotosensitive materialsPHENOL LIQUIDChemistry

Provided are a silane-phenol compound, a crosslinked siloxane outmost protective layer thereof, and an electrophotographic imaging member such as photoreceptor. The silane-phenol compound comprises (i) a phenol group and (ii) a silane group selected from the group consisting of alkoxysilyl, arylalkoxysilyl, aryloxysilyl, alkylaryloxysilyl, and combination thereof. The crosslinked siloxane outmost protective layer comprises the product of hydrolysis and condensation of a silanized hole transport compound and the silane-phenol compound. The crosslinked protective outmost layer may be used to manufacture an electrophotographic imaging member such as photoreceptor with improved properties such as image quality and cleanability, etc.

Owner:XEROX CORP

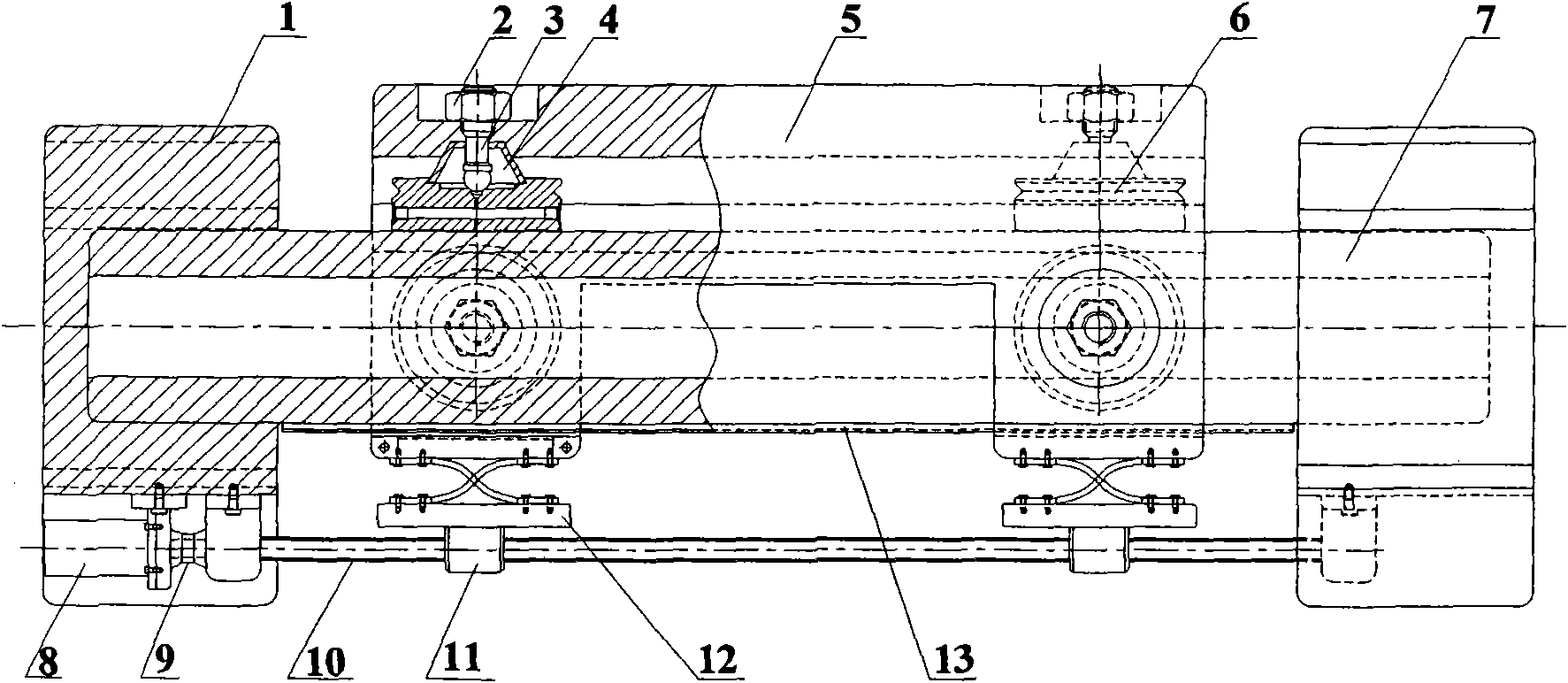

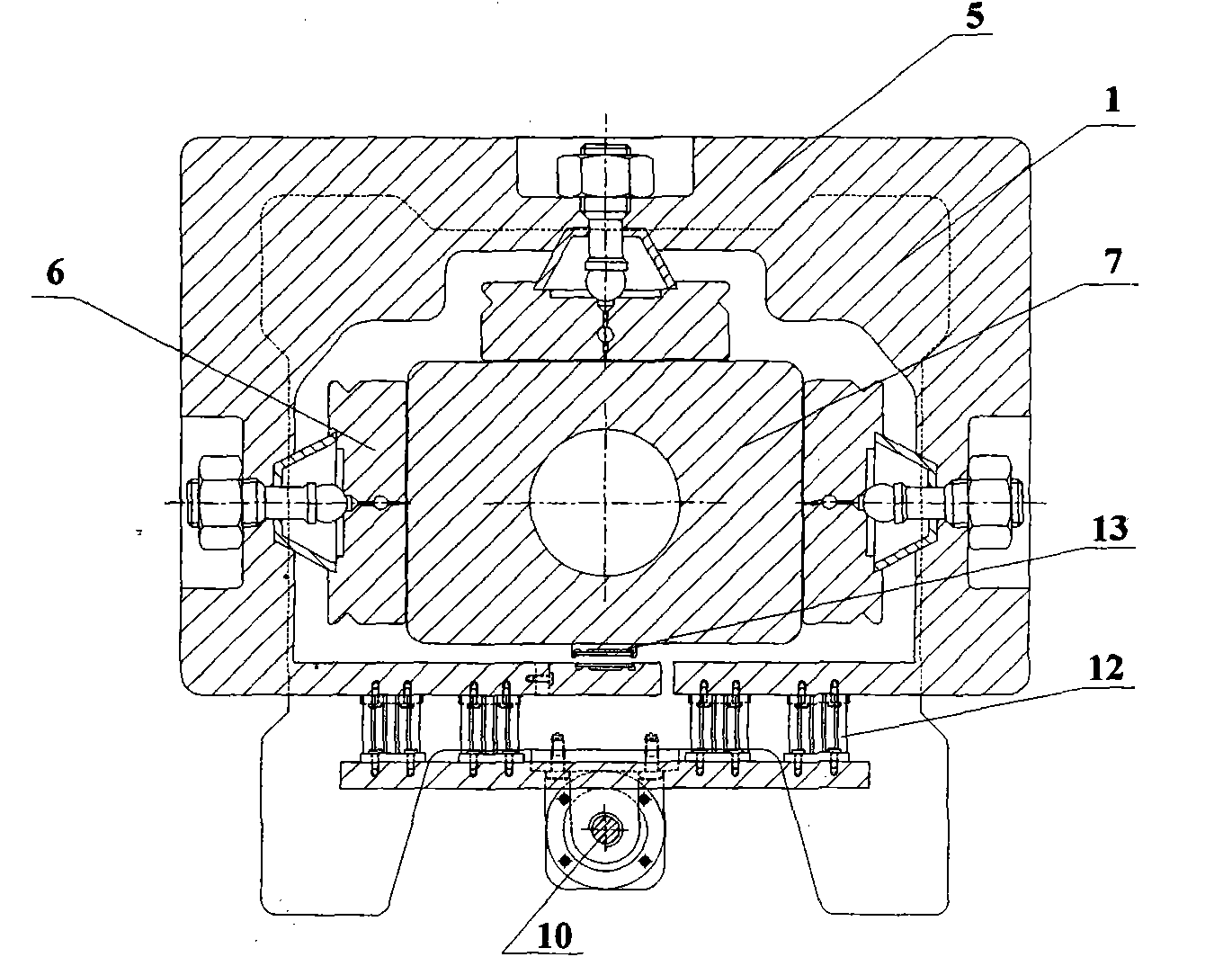

II-type gas static pressure guide rail for horizontal use

The invention discloses an II-type gas static pressure guide rail for horizontal use. Guide rail fixing stations are arranged on brackets at two ends; six air flotation blocks in triplet are symmetrically fixed at the upper end, the left end and the right end of an II-type workbench respectively; the air flotation blocks are matched with the upper surface, the left side and the right side of the guide rail fixing stations respectively to form the II-type gas static pressure guide rail for horizontal use; grating rulers are arranged at the central positions of the lower surfaces of the guide rail fixing stations; one end of a ball screw is connected with a motor arranged on one bracket through a coupling, and the other end of the ball screw is connected with the other bracket; and a guide rail workbench and the ball screw are connected through two groups of metallic flexible connectors in pairs. The II-type gas static pressure guide rail of the design has the advantages of high moving precision, low vibration and convenience for processing and assembly, and is applicable in the ultra-precise gas static pressure guide rail field.

Owner:CHINA JILIANG UNIV

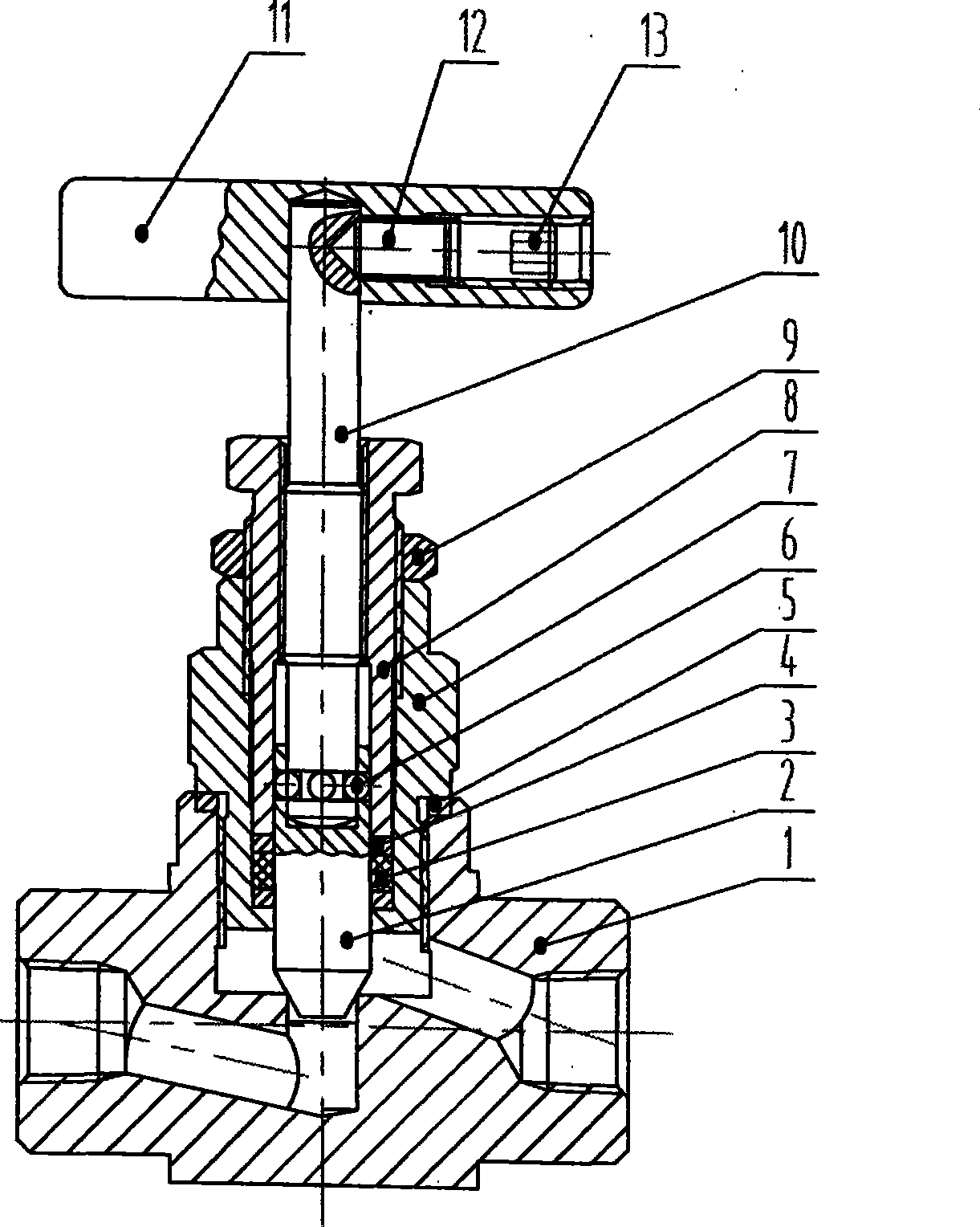

Instrument break valve with lower valve stem non-rotation sealing structure

InactiveCN101368647AHigh integrity sealingHigh integrity operabilitySpindle sealingsOperating means/releasing devices for valvesSteel ballEngineering

The invention provides an instrument stop valve with a non-rotary lower valve rod seal structure, which is widely applied to the industrial pipelines and is characterized in that one end of the lower valve rod is the valve core; the other end is a hole; a plurality of pores are evenly distributed on the circumference of the hole; the ditch groove end of the upper valve rod is inserted into the hole of the lower valve rod; a steel ball is respectively loaded into the ditch groove through each pore and screwed into a thread guide sleeve to form the steel ball flexible connection structure; the filler, the mounted upper valve rod and the lower valve rod are mounted into the valve cover and screwed into the thread guide sleeve to push the filler cushion to enable the filler to be pressed tightly between the lower valve rod and the valve cover, so as to form the filler seal structure. The valve cover is threaded through the seal washer to be screwed into the inner thread of the valve body and tightly sealed; a handle or a hand wheel is mounted on the top part of the upper valve rod; the handle or the hand wheel is rotated to drive the upper valve rod to lift spirally; under the effect of the steel ball flexible connection structure, the lower valve rod is prevented from rotating and moving up and down in the sealed filler so that the opening and closing of the valve are executed accordingly.

Owner:江苏星河集团有限公司 +1

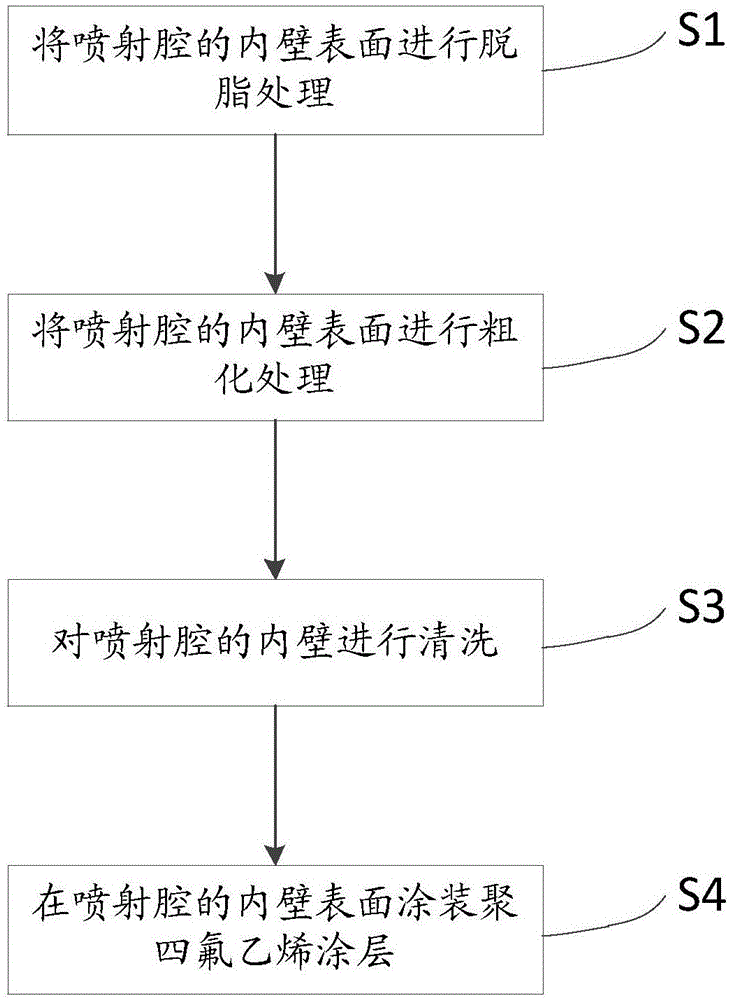

Method for increasing jetting gluing quality and gluing device

InactiveCN106475291ALow frictionSolve jetting difficultiesPretreated surfacesCoatingsResultant forcePolytetrafluoroethylene

The invention discloses a method for increasing jetting gluing quality. The method comprises the following steps: performing degreasing treatment on the surface of an inner wall of a jetting chamber; performing roughening treatment: roughening the inner wall of the jetting chamber for improving the roughening degree of the inner wall of the jetting chamber; cleaning the inner wall of the jetting chamber; and then coating a polytetrafluoroethylene layer on the surface of the inner wall of the jetting chamber. When a high-viscosity glue solution moves relative to the smooth polytetrafluoroethylene layer, the pressure, including driving force, resistance, and the like, exists along the flowing direction. The polytetrafluoroethylene layer is arranged, so that the resistance of the glue drop along the flowing direction can be effectively reduced, the driving resultant force along the motion direction can be increased, the external force for driving the high-viscosity glue solution to flow can be effectively increased, the directions of the acting forces can be more consistently pointed to a jet orifice, the high-viscosity glue solution can be more easily, quickly and stably jetted, the gluing forming quality can be increased, and the jetting gluing efficiency can be increased. The invention also provides a gluing device capable of achieving the same technical effect.

Owner:GUANGDONG UNIV OF TECH

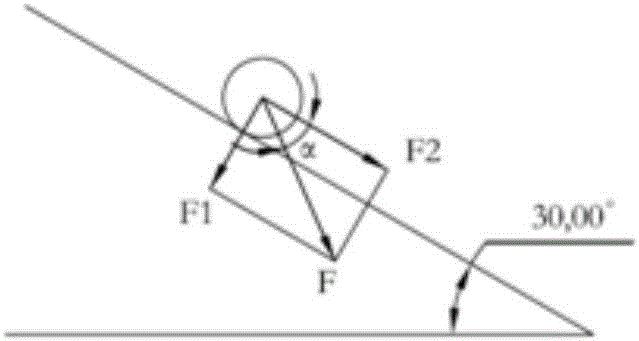

Deflection mechanism used for drilling machine and application method

InactiveCN111764827AEasy to operateExtended service lifeDerricks/mastsDirectional drillingClassical mechanicsSlope angle

The invention belongs to the technical field of drilling machines, and particularly relates to a deflection mechanism used for a drilling machine. The deflection mechanism comprises a base, a first sliding unit, an angle adjusting unit, a deflection unit and a drilling arm. The first sliding unit, the angle adjusting unit, the deflection unit and the drilling arm are all arranged on the upper portion of the base. The drilling arm is mounted above the deflection unit. The invention further relates to an application method of the deflection mechanism. The application method comprises the steps that firstly, the front-and-back position is adjusted; secondly, the vertical inclination angle is adjusted; thirdly, the deflection angle is adjusted; fourthly, the distance between a drill bit and the ground is adjusted; and fifthly, the drilling machine is made perpendicular to the construction ground. The deflection mechanism is simple in structure, convenient to operate, stable, reliable and long in service life, and when the drilling arm needs to work at a special place, the position of the drilling arm can be comprehensively adjusted.

Owner:云南云内动力机械制造有限公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com