Deflection mechanism used for drilling machine and application method

A deflection mechanism and drilling rig technology, applied in drilling equipment and methods, drilling equipment, directional drilling, etc., can solve the problem that the adjustment of the position of the drilling arm can not achieve the desired effect, the position of the adjustment of the drilling arm is limited, and the rotation of the pin shaft is easy to wear and other problems, to achieve the effect of easy maintenance and maintenance, small friction and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

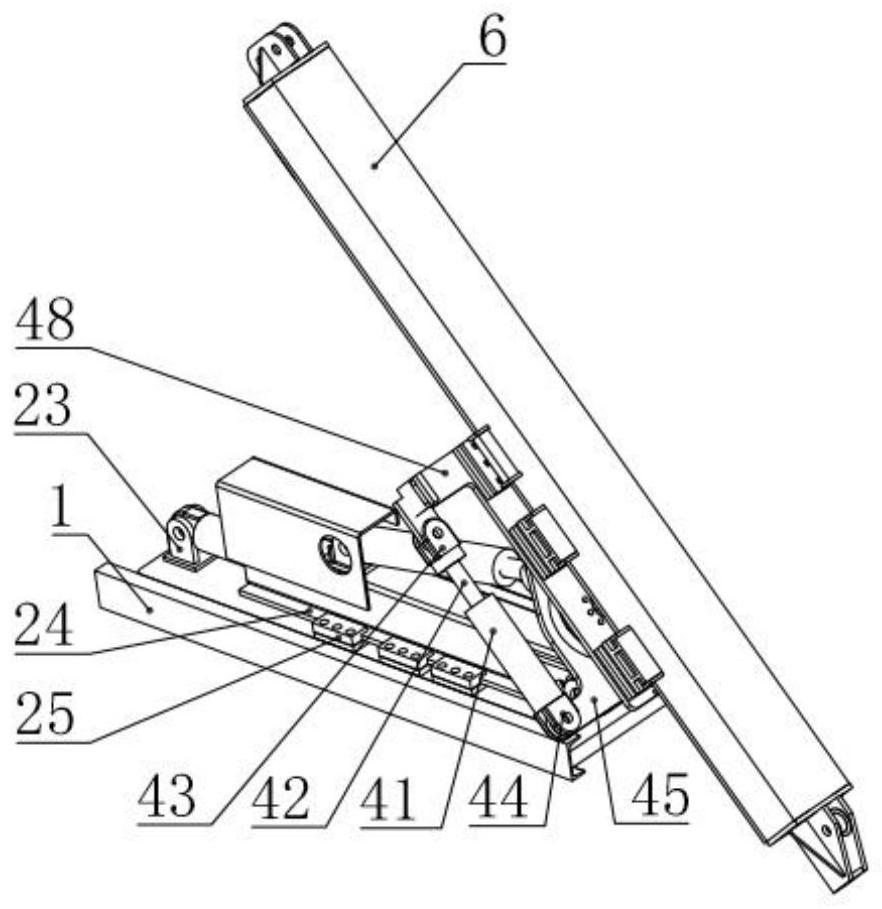

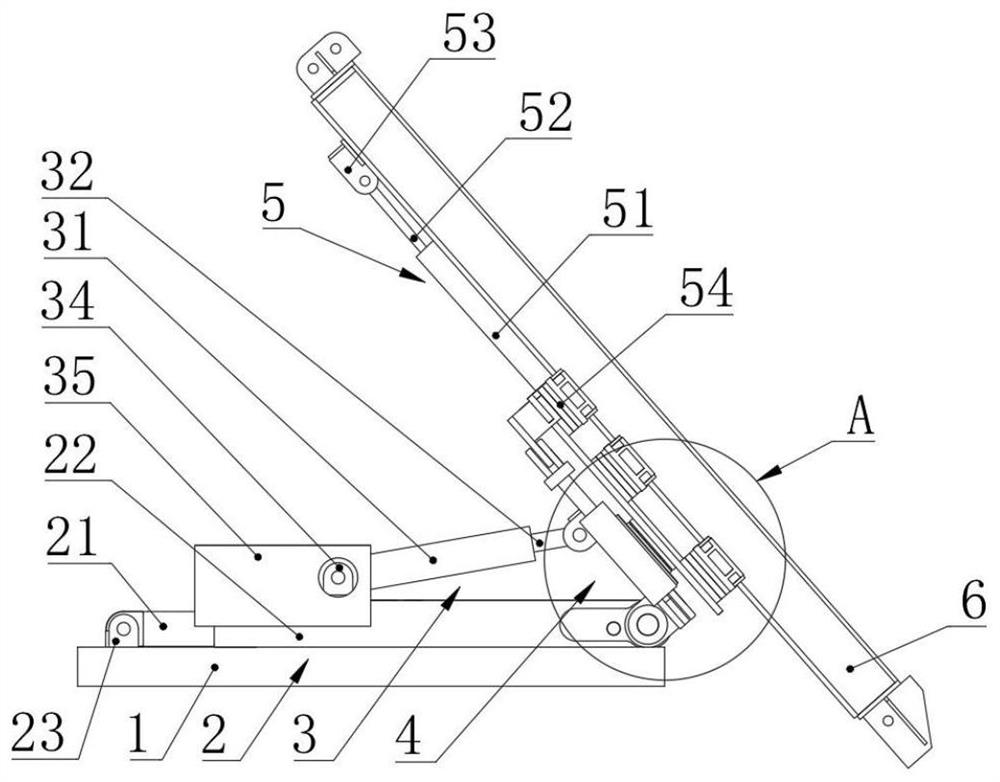

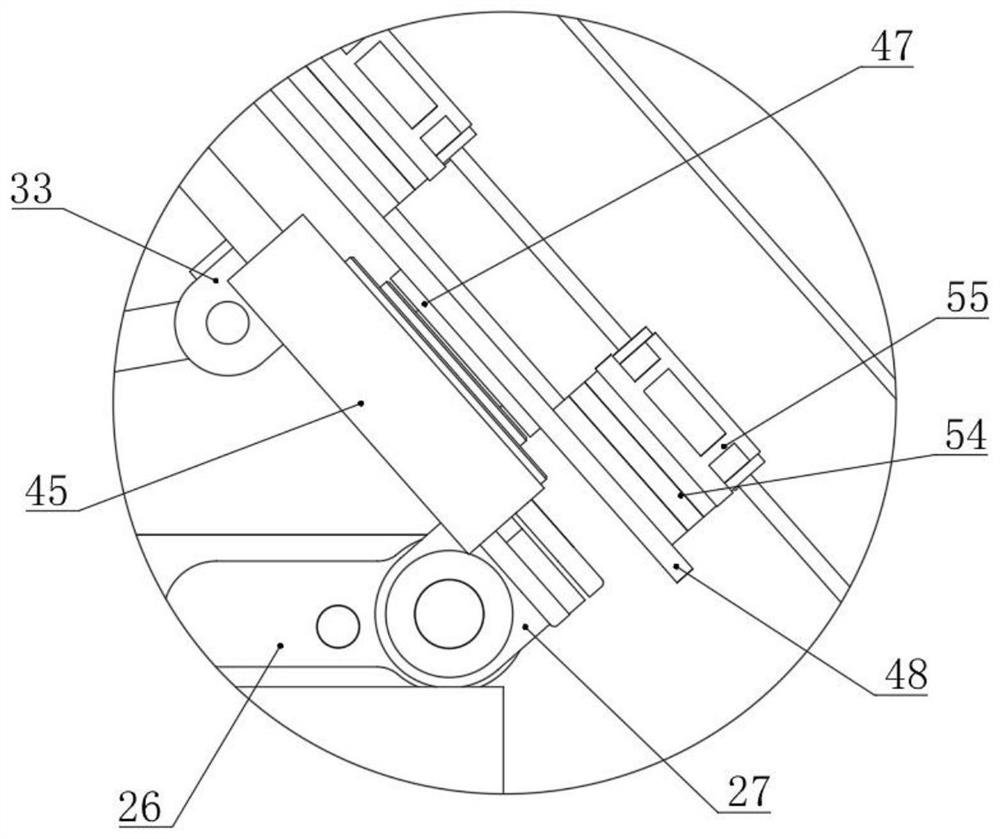

[0046] Such as Figure 1-4 As shown, a deflection mechanism for a drilling machine includes a base 1, a first sliding unit 2, an angle adjustment unit 3, a deflection unit 4 and a drill arm 6;

[0047] The first sliding unit 2 is arranged on the upper part of the base 2, the first sliding unit 2 is connected with the lower part of the deflection unit 4, and the first sliding unit 2 and the deflection unit 4 move synchronously; the angle adjustment unit 3 is installed on the upper part of the first sliding unit 2, the second A sliding unit 2 drives the angle adjustment unit 3 to perform synchronous movement, one end of the angle adjustment unit 3 is connected to the lower part of the deflection unit 4, the angle adjustment unit 3 drives the deflection unit 4 to flip relative to the base 1, and the drill arm 6 passes through the deflection unit 4 and the upper part of the base 1 connect.

[0048] When the present invention adjusts the spatial position of the drill arm 6, the fr...

Embodiment 2

[0058] This embodiment is a further improvement of the previous embodiment, such as Figure 1-4 As shown, a deflection mechanism for a drilling machine includes a base 1, a first sliding unit 2, an angle adjustment unit 3, a deflection unit 4 and a drill arm 6;

[0059] The first sliding unit 2 is arranged on the upper part of the base 2, the first sliding unit 2 is connected with the lower part of the deflection unit 4, and the first sliding unit 2 and the deflection unit 4 move synchronously; the angle adjustment unit 3 is installed on the upper part of the first sliding unit 2, the second A sliding unit 2 drives the angle adjustment unit 3 to perform synchronous movement, one end of the angle adjustment unit 3 is connected to the lower part of the deflection unit 4, the angle adjustment unit 3 drives the deflection unit 4 to turn over relative to the base 1, and the drill arm 6 passes through the deflection unit 4 and the upper part of the base 1 connect.

[0060] When the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com