Patents

Literature

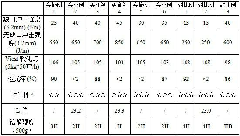

142results about How to "Improve appearance performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Adhesive, its preparation method and application method

ActiveCN102417804AHigh bond strengthImprove appearance performanceLaminationLamination apparatusSteel platesChemistry

The invention provides an adhesive, its preparation method and an application method. The adhesive contains a resin ingredient and a cured ingredient, wherein the resin ingredient contains a main resin, a flexibilizer and a filling material. The main resin contains a first epoxy resin and a second epoxy resin, wherein epoxy equivalent of the first epoxy resin is 150-300 and softening point of the second epoxy resin is 65-100 DEG C. The cured ingredient contains a normal-temperature curing agent. After the adhesive is coated on the surface of steel plates, the bonding strength between the steel plates is very high without the need of spot welding or riveting.

Owner:BYD CO LTD

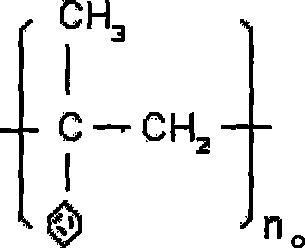

Antiscratch resin and preparation method thereof

The invention relates to an antiscratch resin. The antiscratch resin comprises the following components in part by weight: 50 to 90 parts of polymethyl methacrylate (PMMA) resin, 10 to 50 parts of toughening agent, 0.2 to 0.6 part of light stabilizer, 0.2 to 1 part of antioxidant, 0.2 to 2 parts of lubricating agent, 0 to 3 parts of pearl pigment, 0 to 3 parts of metal pigment and 0 to 3 parts of toner. The antiscratch resin is prepared by the following steps of: stirring and mixing all the components in a high-speed mixing machine; conveying the mixture to a double-screw extruder; melting and compounding the materials under conveying, cutting and mixing action of screws; and extruding, bracing, cooling and dicing to obtain the antiscratch resin. The antiscratch resin has high impact strength, high antiscratch property, high heat resistance, various appearance effects and a wide application range, and can avoid spraying completely.

Owner:SHANGHAI KUMHO SUNNY PLASTICS +1

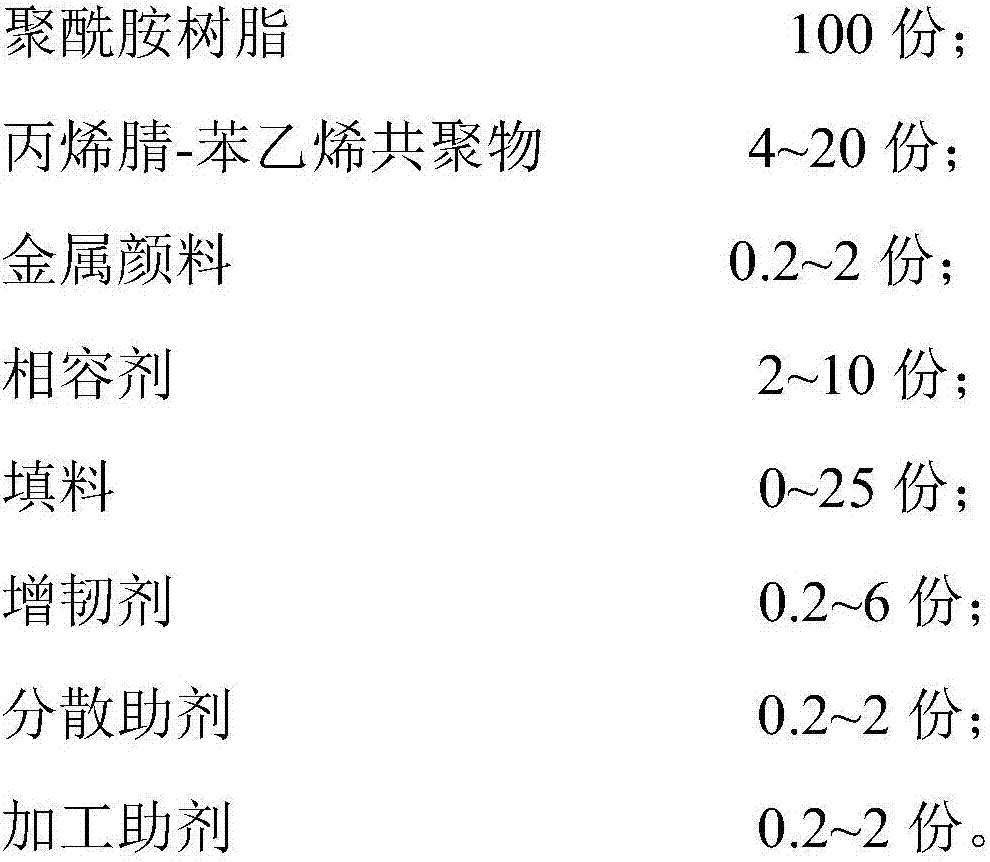

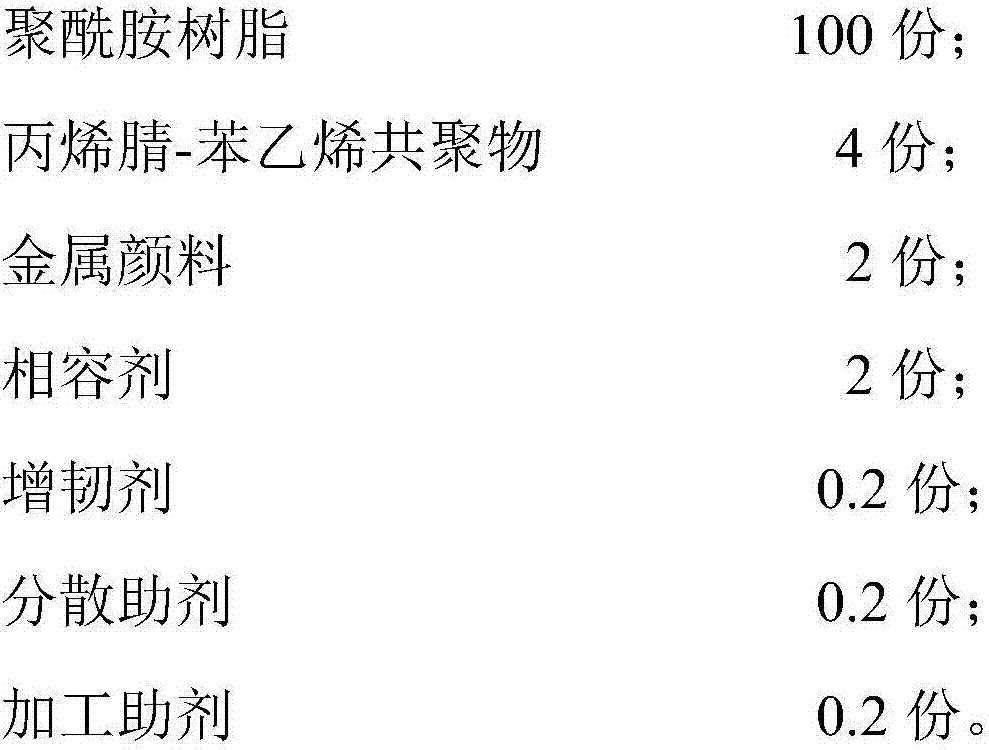

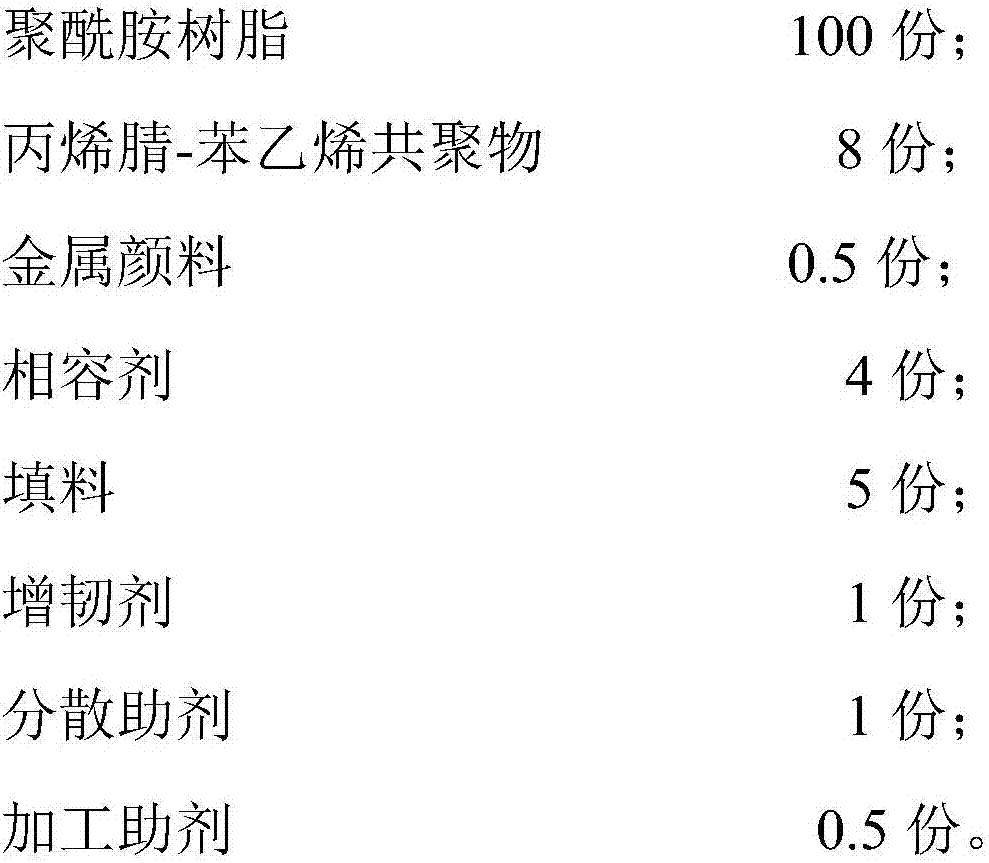

Spray-free polyamide compound with metallic luster and preparation method thereof

The invention discloses a spray-free polyamide compound with metallic luster. The spray-free polyamide compound is prepared from the following raw materials in parts by weight: 100 parts of polyamide resin, 4-20 parts of acrylonitrile-styrol copolymer, 0.2-2 parts of metallic pigment, 2-10 parts of compatilizer, 0-25 parts of filler, 0.2-6 parts of flexibilizer, 0.2-2 parts of dispersing auxiliary and 0.2-2 parts of processing agent. According to the invention, the acrylonitrile-styrol copolymer used as a modifier and the polyamide resin are compounded as a matrix resin of the compound, and meanwhile, the other raw material components are adjusted and the compatilizer, the dispersing auxiliary and the flexibilizer at a specific ratio are supplemented, so that the processing performance of the polyamide compound and the mechanical property and appearance effect of the formed polyamide compound are optimized.

Owner:GUANGDONG ALDEX NEW MATERIAL CO LTD

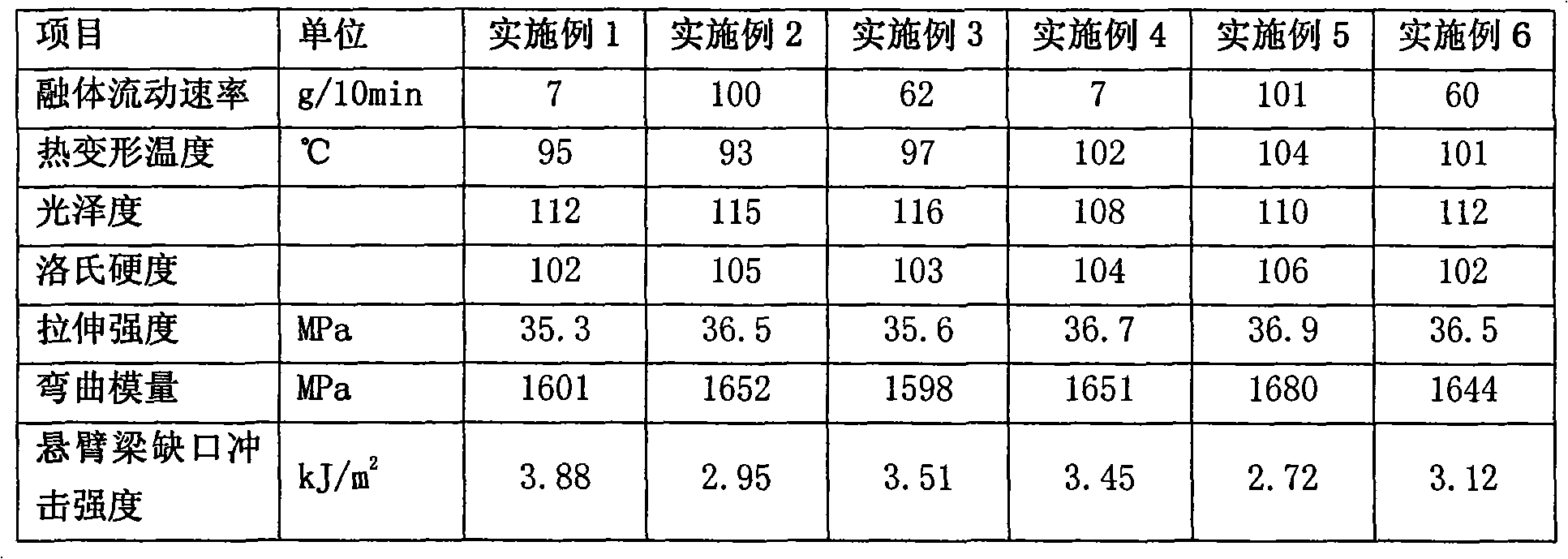

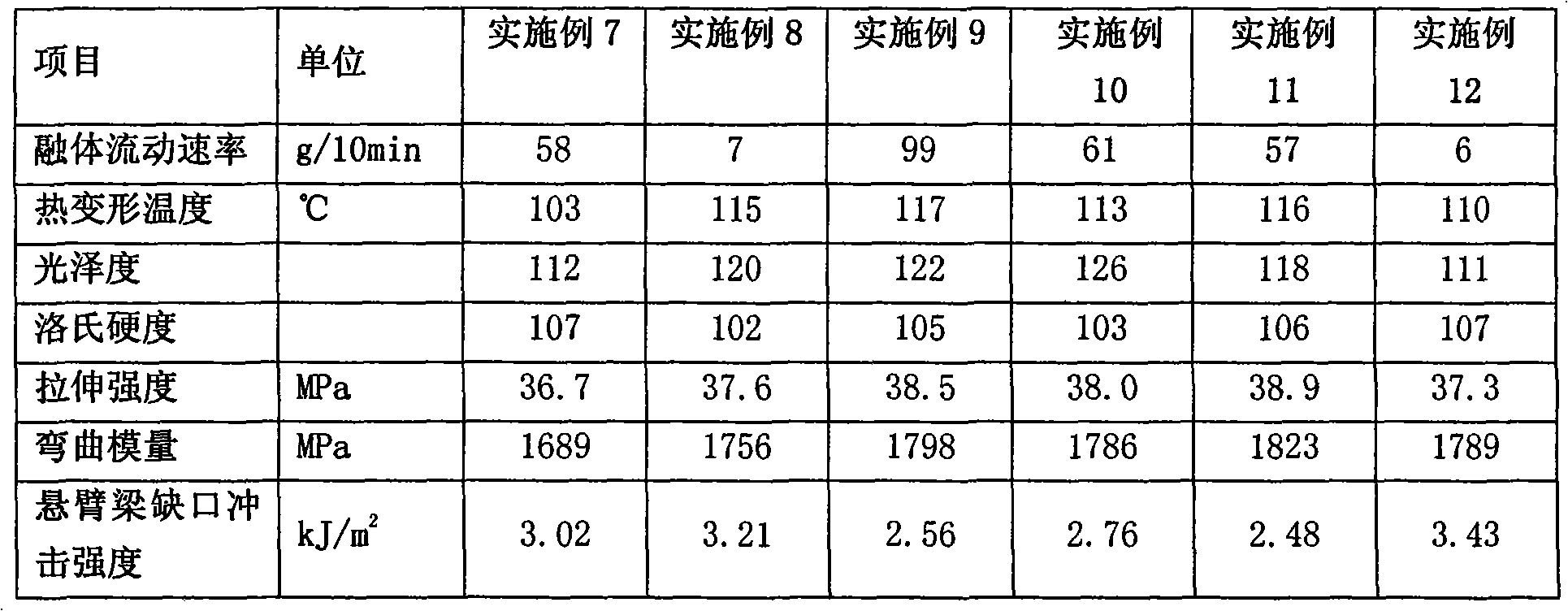

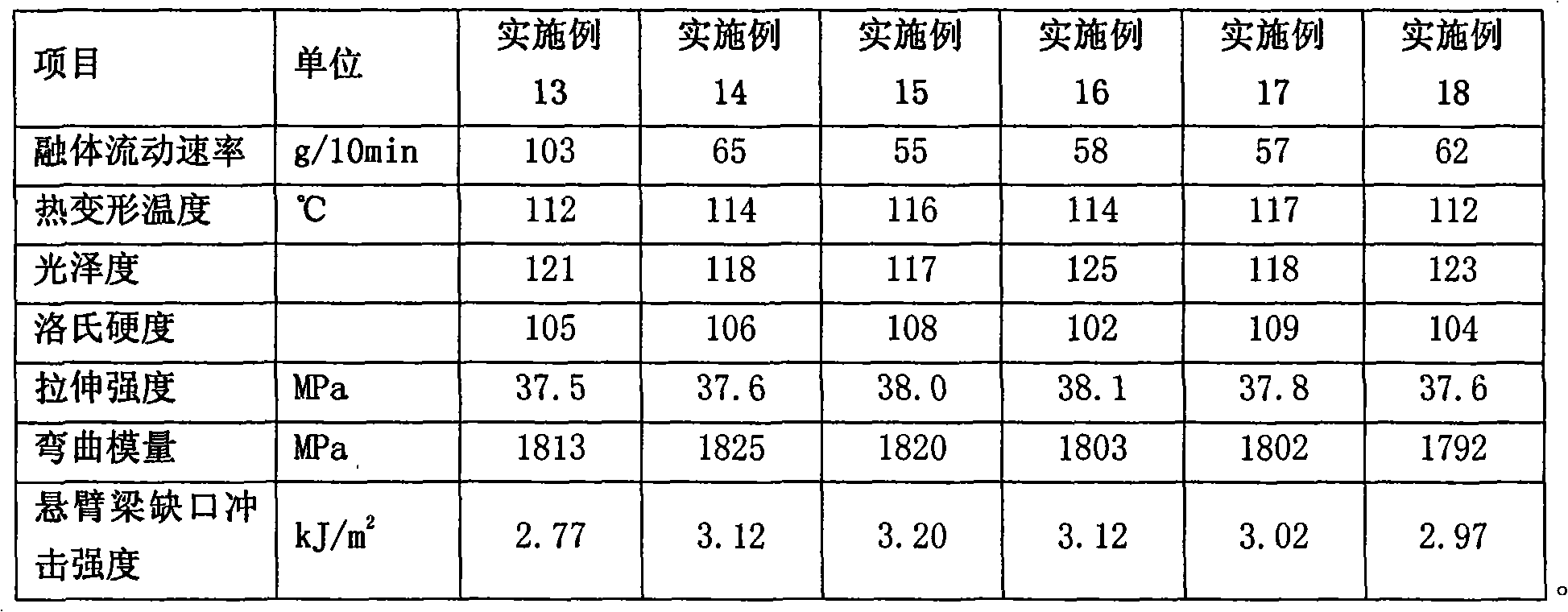

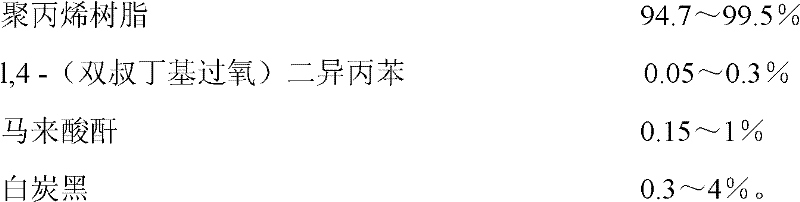

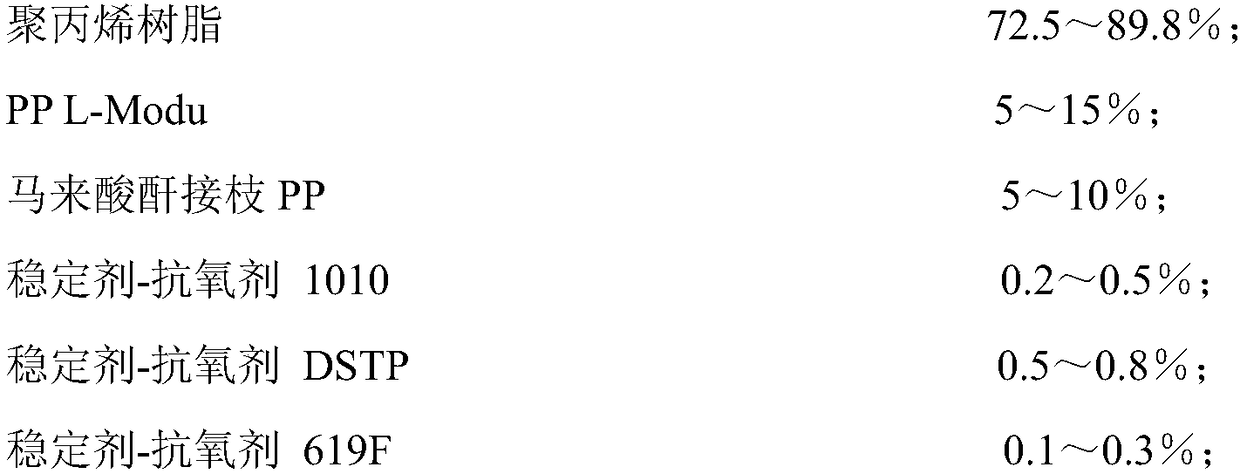

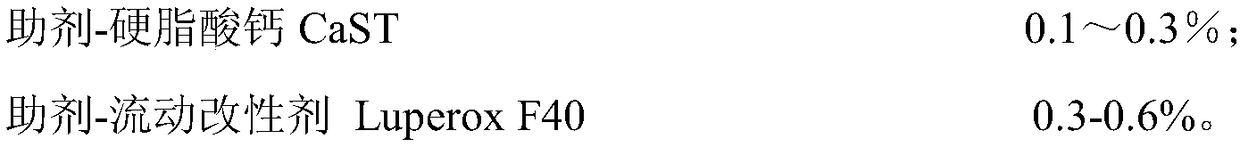

Controllable rheological high-gloss polypropylene resin and preparation method thereof

The invention discloses a controllable rheological high-gloss polypropylene resin which is composed of the following components in parts by weight: 100 parts of homo polypropylene as a base material, 0.1-0.25 part of processing agent, 0.15-0.2 part of nucleating agent, 0-1.5 parts of hardness regulator, 0.05-0.1 part of glossiness regulator and 1-12 parts of oxide master batch, wherein the number-average molar mass of the homo polypropylene is 61235-65210; the oxide master batch is formed by mixing 100 parts of homo polypropylene and 0.1-0.65 part of peroxide. Thus, the rheological behaviour of the resin can be changed by regulating the additive amount of the peroxide master batch. The controllable rheological high-gloss polypropylene resin of the invention has favourable heat resistance (heat distortion temperature is more than or equal to 110 DEG C) and higher rigidity (bending modulus is more than or equal to 1800 MPa). Because of adopting the controllable rheological technology, the invention can flexibly regulate the melt flowing rate of the material, and the material has excellent processability, heat-resistant quality and mechanical property.

Owner:CHINA PETROLEUM & CHEM CORP +1

Flame retardant polypropylene material

InactiveCN102040775ALow shrinkageImprove toughnessCell component detailsHeat resistanceFire retardant

The invention discloses a flame retardant polypropylene material, relating to the technical field of high molecule plastics. The flame retardant polypropylene material comprises the following compositions in percentage by weight: 25-50 percent of high fluidity homo polypropylene, 25-50 percent of high fluidity propylene copolymer, 10-33 percent of flame retardant, 5-30 percent of inorganic strengthening agent, 1-10 percent of barrier additive, 0.1-3 percent of heat resistance strengthening agent, 0.1-4 percent of antioxygen and nucleating agent, 0.1-3 percent of compound pigment and 1-5 percent of internal and external lubricant. The flame retardant polypropylene material reaches V0 grade flame retardation property without lowering the mechanical performance of the material and has good heat resistance and good anti-seep performance.

Owner:LUOYANG CITY HEZHIYANG MACROMOLECULE MATERIAL

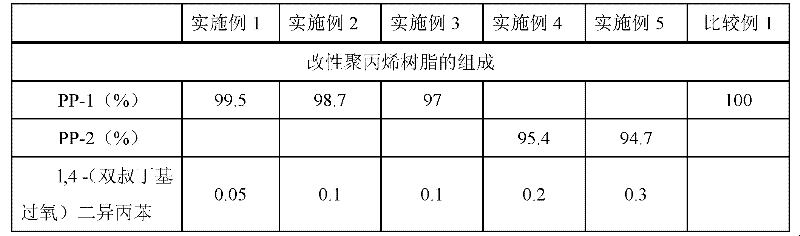

Low-VOC (volatile organic compound) long glass fiber reinforced polypropylene composite material and preparation method thereof

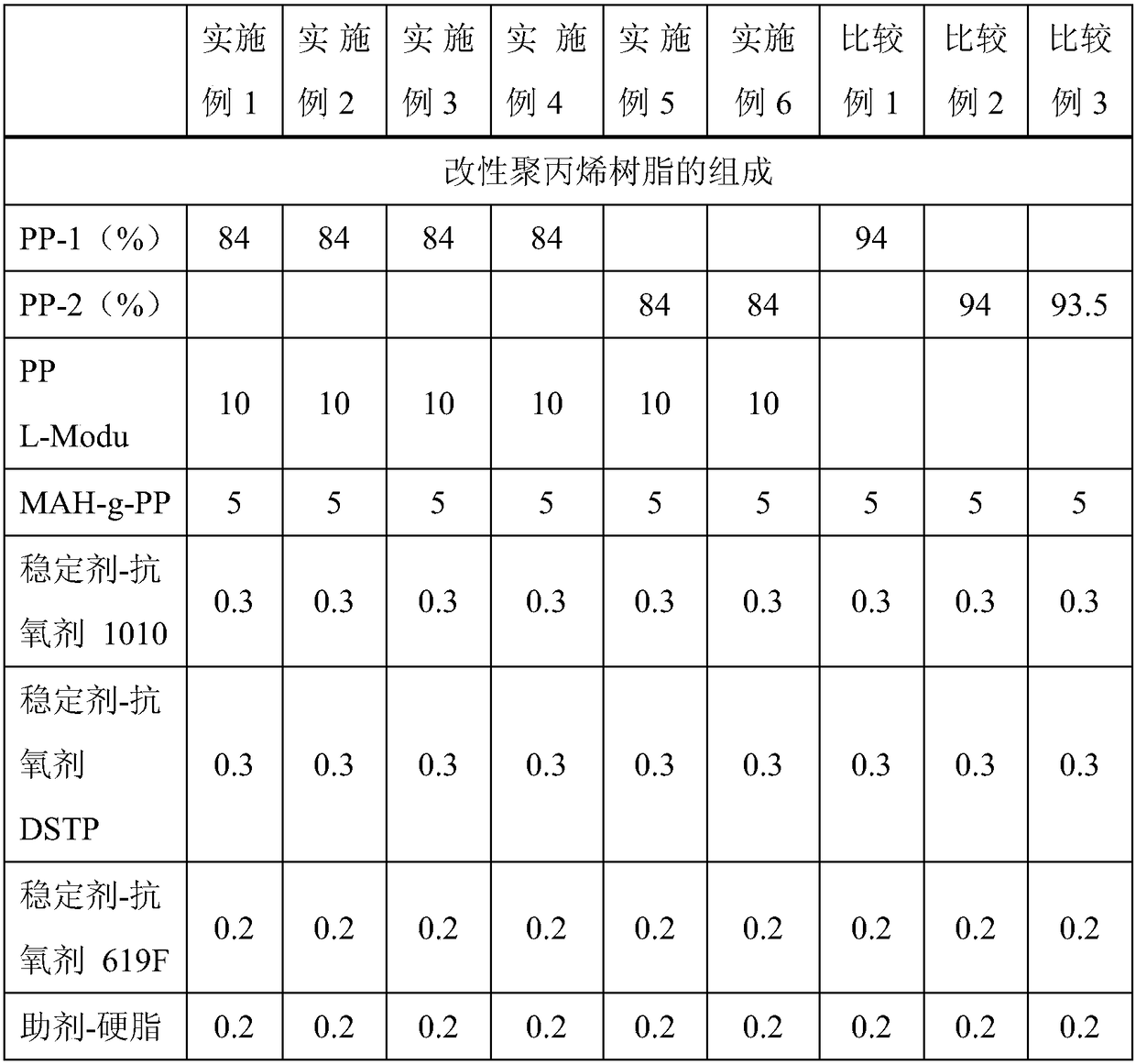

The invention discloses a low-VOC (volatile organic compound) long glass fiber reinforced polypropylene composite material and a preparation method thereof. The composite material comprises the following components by weight percent: 10-60% of long glass fiber arranged parallel to particle length and 90-40% of modified polypropylene resin, wherein the modified polypropylene resin is prepared by carrying out reaction and extrusion on known commercialized polypropylene resin through melting and kneading equipment such as a two-screw extruder. The preparation method has the beneficial effects that high-flowability polypropylene resin does not need to be singly produced or purchased in advance, and the production process is simplified. The prepared low-VOC long glass fiber reinforced polypropylene composite material has the beneficial effects of good apparent performance, no exposed glass fiber, no warping, good heat resistance, and easiness for processing. The product prepared by the method has the advantages of good low-VOC diffusion property and good mechanical properties such as good stretch and bending strengths and good impact resistance.

Owner:SHANGHAI PRET COMPOSITES

Cold pad-batch dyeing process for pure cotton fabric

InactiveCN102535201ALower average tensionLow frictionTextile storage in superimposed formTextile storage in wounded formRoom temperaturePlastic film

The invention discloses a cold pad-batch dyeing process for pure cotton fabric. The process flow comprises the steps of: padding and rolling a mixed liquor of a dye and an alkaline agent, coiling and plastic film coating, rotating stacking, primary water washing, soaping, secondary water washing and drying. In the padding and rolling process, an active dye at a concentration of 10g / l is adopted, 10-15 g / l of water glass is adopted as the alkaline agent, a concentration of urea is 3 to 5g / l and a concentration of sodium sulfate is 10g / l. The rotating stacking process is performed for 16h at a room temperature of 10-15 DEG C. By the adoption of the process of the invention, energy can be saved, consumption can be reduced, the fixation ratio of the dye is increased, the grade of the product is improved, and the process cost is low. Besides, the conditions of the cold pad-batch dyeing process are moderate, the fabric is subjected to low tension and small friction, and the apparent effects and hand-feel of the fabric are improved to a great extent.

Owner:CHANGSHU KAIDA PRINTING & DYEING

Low-floating-fiber glass fiber reinforced polypropylene material and preparation method thereof

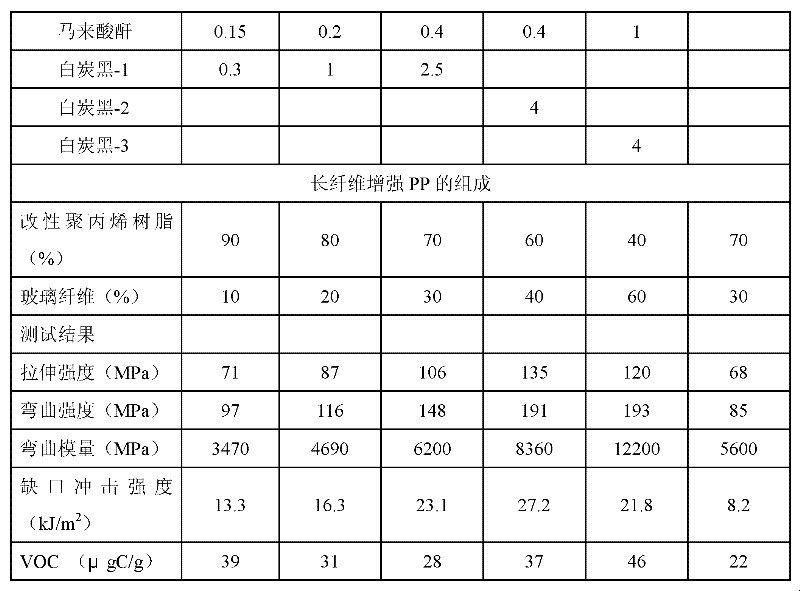

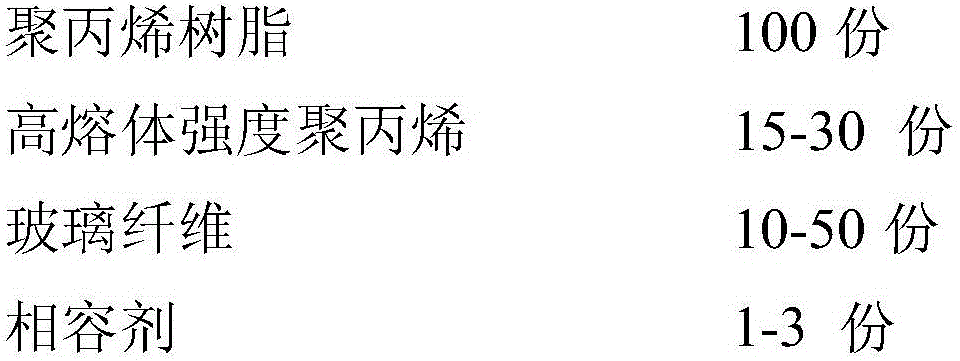

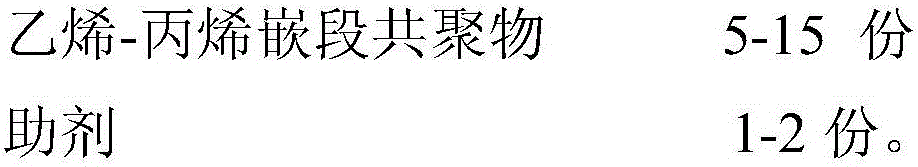

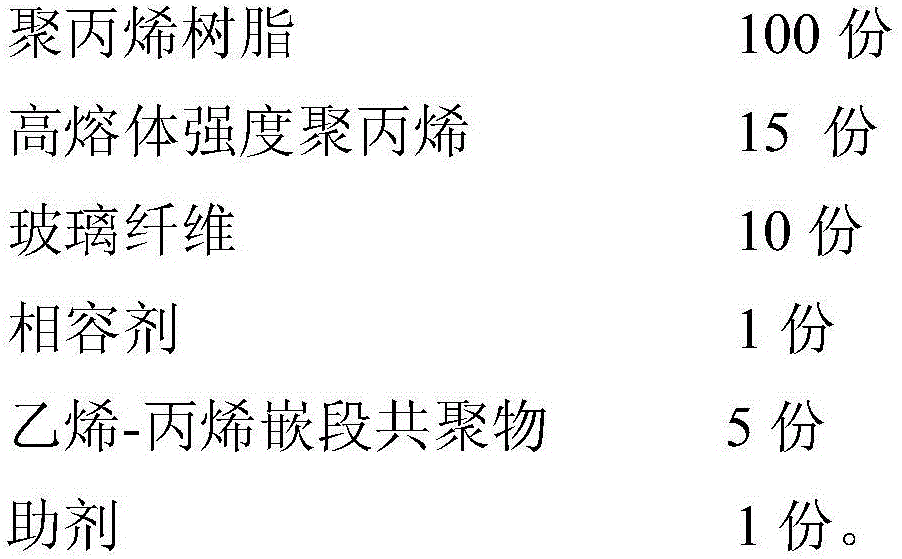

The invention relates to a low-floating-fiber glass fiber reinforced polypropylene material and a preparation method thereof. The low-floating-fiber glass fiber reinforced polypropylene material is prepared from, by weight, 100 parts of polypropylene resin, 15-30 parts of high-melt-strength polypropylene, 10-50 parts of glass fiber, 1-3 parts of a compatilizer, 5-15 parts of an ethylene-propylene segmented copolymer and 1-2 parts of other auxiliaries. According to the preparation method of the low-floating-fiber glass fiber reinforced polypropylene material, screw extrusion processing is adopted, and the screw combination design principle is adopted, wherein the first region and the second region are only composed of conveying components, the third, fourth, fifth, sixth and seventh regions comprise shearing components, the eighth, ninth and tenth regions are composed of conveying components, and the extrusion temperature is 165-230 DEG C. According to the low-floating-fiber glass fiber reinforced polypropylene material, the mechanical property is excellent, and the surface of the obtained low-floating-fiber glass fiber reinforced polypropylene material is smooth, clean and free of floating fiber.

Owner:上海日之升科技有限公司

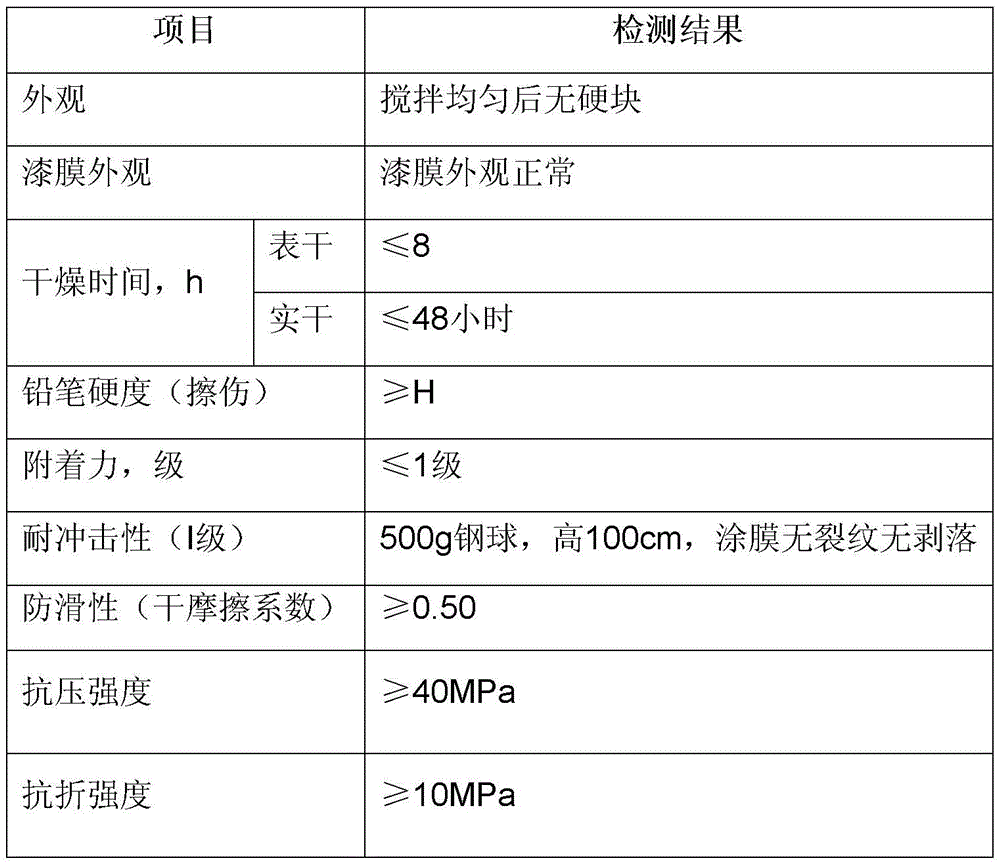

Aqueous epoxy coating for terraces, and preparation method thereof

The invention discloses an aqueous epoxy coating for terraces, and a preparation method thereof. The aqueous epoxy coating for terraces comprises 1.2-1.3 parts of an aqueous epoxy curing agent, 1 part of bisphenol A liquid epoxy resin, and 7-8 parts of a third component, wherein the third component is prepared through mixing 20-30 parts of high grade cement, 15-20 parts of coarse quartz sand, 40-50 parts of fine quartz sand, 0.1-0.2 parts of a water reducer, 0.1-0.3 parts of an antifoaming agent and 0.1-0.3 parts of cellulose. The aqueous epoxy coating for terraces, disclosed in the embodiment of the invention, has good strong acid, strong alkali, wear, pressure, impact, mildew, water, dust and skid resistance, has the advantages of simple preparation method and long service life, avoids obvious connection seams between an original coating layer and a new repairing coating layer as a maintaining and repairing material, and keeps good cracking resistance, flexural strength and compressive strength in the repairing position.

Owner:FIRST NEW MATERIAL TECH DEV

Extrusion grade ASA resin with easy processing and high apparent property and preparation method thereof

The invention relates to an extrusion grade ASA resin with easy processing and high apparent property and a preparation method thereof. The extrusion grade ASA resin comprises the following components in part by weight: 50 to 70 parts of SAN resin, 30 to 50 parts of ASA rubber powder, 0 to 10 parts of inorganic filler, 0.1 to 3 parts of low molecular wax, 0.01 to 1 part of boron nitride, 0.5 to 3 parts of plasticizer, 0.2 to 0.6 part of light stabilizer, 0.2 to 1 part of antioxidant and 1 to 3 parts of lubricant. The preparation method comprises the following steps of: stirring and fully mixing the raw materials in a high-speed mixer, delivering the materials into a double-screw extruder through a metering device, melting and compounding the materials under the delivery, shearing and mixing of the screws, and extruding, bracing, cooling and granulating the materials to obtain the extrusion grade ASA resin with easy processing and high apparent property. Compared with the prior art, the preparation method reduces the production energy consumption, improves the bending phenomenon of profiles and plates, and improves the apparent property of ASA.

Owner:SHANGHAI KUMHO SUNNY PLASTICS

Environment-protecting elastic wall putty and its compounding process

The environment-protecting elastic wall putty is prepared by mixing densifier, polyacrylate emulsion, anti-mildew agent, plasitcizer, defoaming agent, antifreezing, agent, and filming agent and two -component calcium carbonate powder and light calcium carbonate, or gypsum powder, talcum powder and heavy calcium carbonate powder. The environment-protecting elastic wall putty is used in base coating with strong adhesion, high elasticity, high alkali resistance, safety no toxicity and no crack, no stripping, no yellowing, no mildew and no powdering.

Owner:罗国波

Method for preparing ultra-thick graphene heat dissipation film

The invention relates to the field of graphene heat dissipation, in particular to a method for preparing an ultra-thick graphene heat dissipation film. The graphene heat dissipation film obtained by the method can be used as a rapid heat dissipation film for a 3C product, such as a smart phone, a notebook computer, VR wearable equipment and the like. The preparation method mainly comprises the following steps: dissolving, stripping and dispersing graphite oxide filter cake in deionized water; coating and stripping the dispersed slurry; and carrying out thermal reduction on the obtained graphene film to prepare the ultra-thick graphene heat dissipation film. The method is simple in process and low in production cost and energy consumption, and the defects that an original artificially synthesized graphite film is low in heat flux, poor in mechanical property, capable of generating tar pollutants in the production process and the like are overcome; compared with a traditional artificially synthesized graphite film, the disclosed graphene heat dissipation film prepared by the method is adjustable in thickness and can be used as a rapid heat dissipation film of a 3C product.

Owner:STONEPLUS THERMAL MANAGEMENT TECH

Manufacturing method of aluminum alloy shell

InactiveCN105598351AImprove mechanical propertiesImprove appearance performanceHollow articlesSolution treatmentSolid solution

A manufacturing method of an aluminum alloy shell comprises the following steps: blanking: cutting an aluminum alloy blank according to a preset size to obtain a blanked component; performing solid solution treatment: performing solid solution treatment on the blanked component to obtain a solid solution treatment component; forging and shaping: forging and shaping the solid solution treatment component to obtain a forged and shaped component; and performing aging treatment: performing aging treatment on the forged and shaped component to obtain the aluminum alloy shell. The manufacturing method of the aluminum alloy shell is simple in process and relatively high in production efficiency; the aluminum alloy shell is relatively good in mechanical properties and appearance effect; manufacturing requirements of the shell with complicated structural characteristics can be met.

Owner:GUANGDONG EVERWIN PRECISION TECH

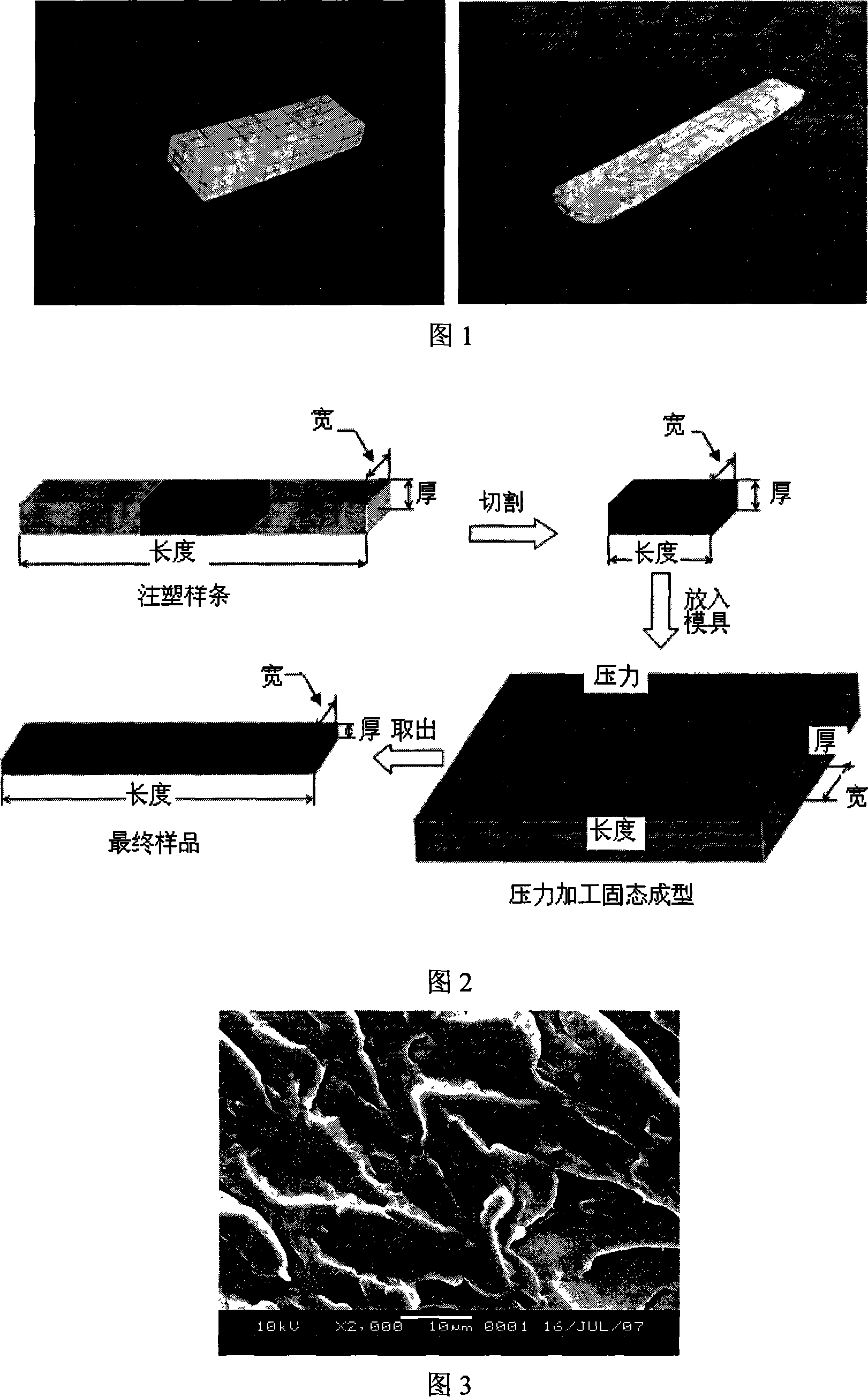

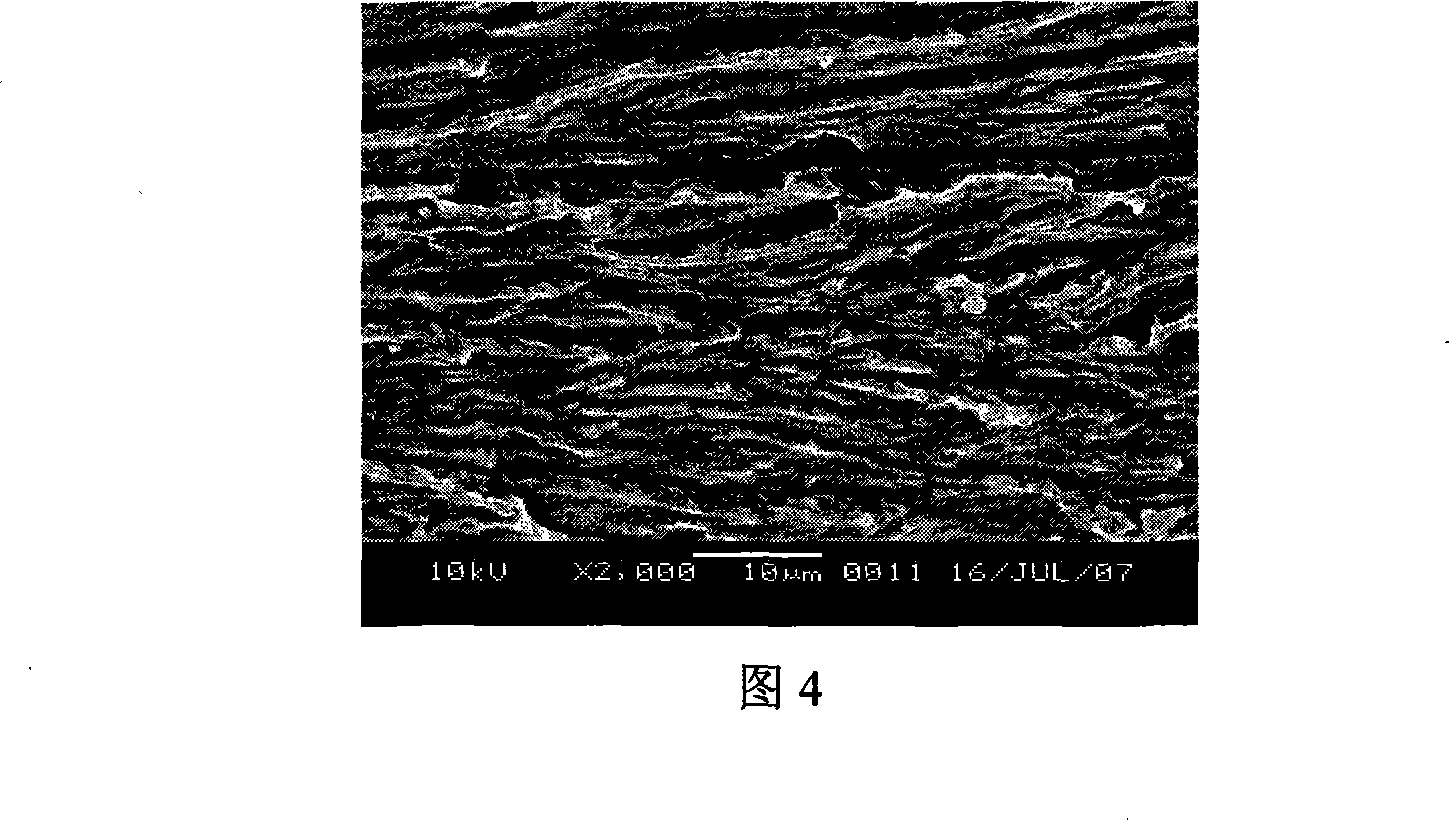

Method for improving polyglycol plasticization polylactic acid strength of materials capability by process

InactiveCN101195273AImprove performanceImprove bending performancePolyethylene glycolStrength of materials

The invention relates a press-working and solid forming method for improving the mechanical properties of polylactic acid (PLA) material plasticized with polyethylene glycol (PEG). The steps include: (1) preparation of PLA spline plasticized with PEG; (2) press-working and solid forming of the PLA spline plasticized with PEG; (3) heat treatment after the forming. The impacting property of PLA plactics plasticized with PEG can be increased by dozens of times, the stretching property can be increased by two times, solid motion of samples occurs by employing the method to give force on the samples, and in the process of solid motion, the internal microstructure of the material is improved, thereby achieving the purpose of improving the mechanical properties.

Owner:DONGHUA UNIV

Environment-friendly type modified master batch and preparation method thereof

InactiveCN101186730AHigh impact strengthImprove mechanical propertiesWaxLinear low-density polyethylene

The invention relates to an environment-friendly modified master batch and process for preparation, the product can not only reduce the cost of production, but also enhance mechanical property of filling plastics, and has the advantages of simple technique preparing of the preparation, good fluidity of the prepared master batch and easy forming. The environment-friendly modified master batch comprises the following components by weight: heavy calcium carbonate of 2000-3000 mesh sizes, linear low density polyethylene, polyethylene wax, corrdination type titanate coupling agent, thinner, compound wax, zinc stearate grease, calcium stearate and auxiliary agent. The process for preparation of the invention is that the heavy calcium carbonate of 2000-3000 mesh sizes is placed in a mixer under the rapid of 200-300 r / min to mix for 15 minutes, the corrdination type titanate coupling agent and the thinner are charged to churn up for 5-10 minutes, and then the rest raw materials are charged for mixing 1-3 minutes to obtain mixture, the mixture is placed in a co-rotating twin-screw granulator for granulating, hot cutting, cooling and packing to prepare the environment-friendly modified master batch.

Owner:NANTONG BAOJIALI NEW MATERIAL CO LTD

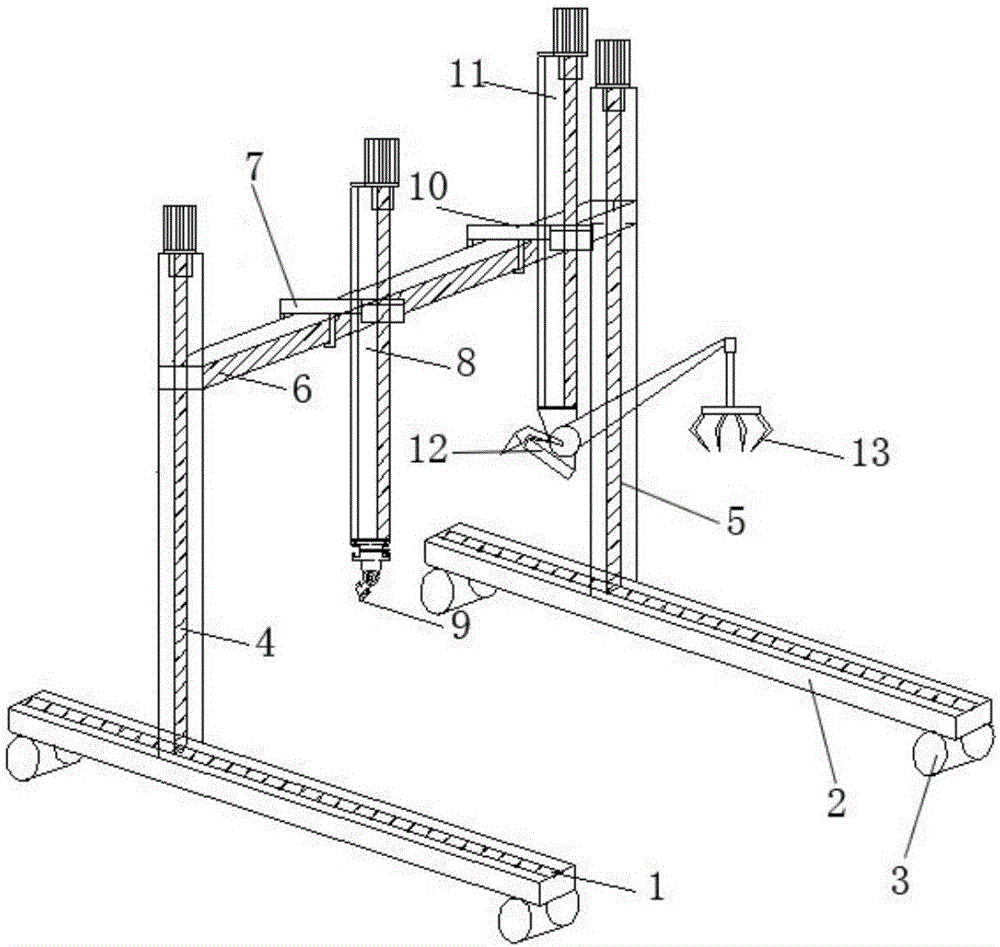

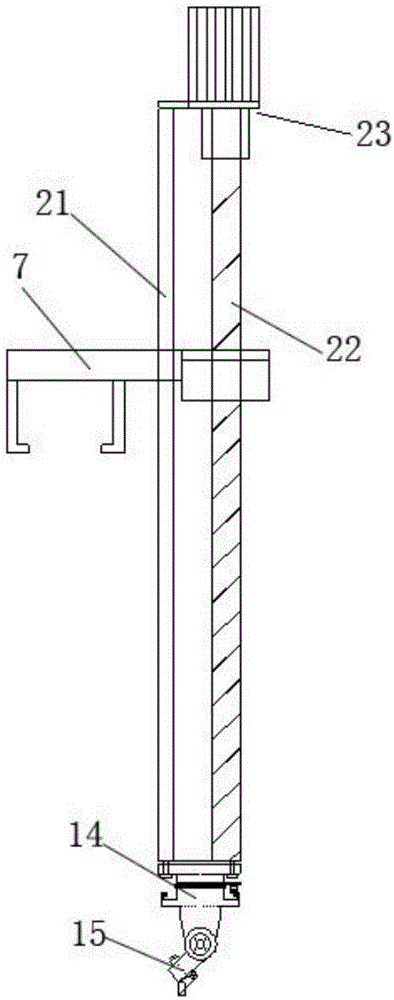

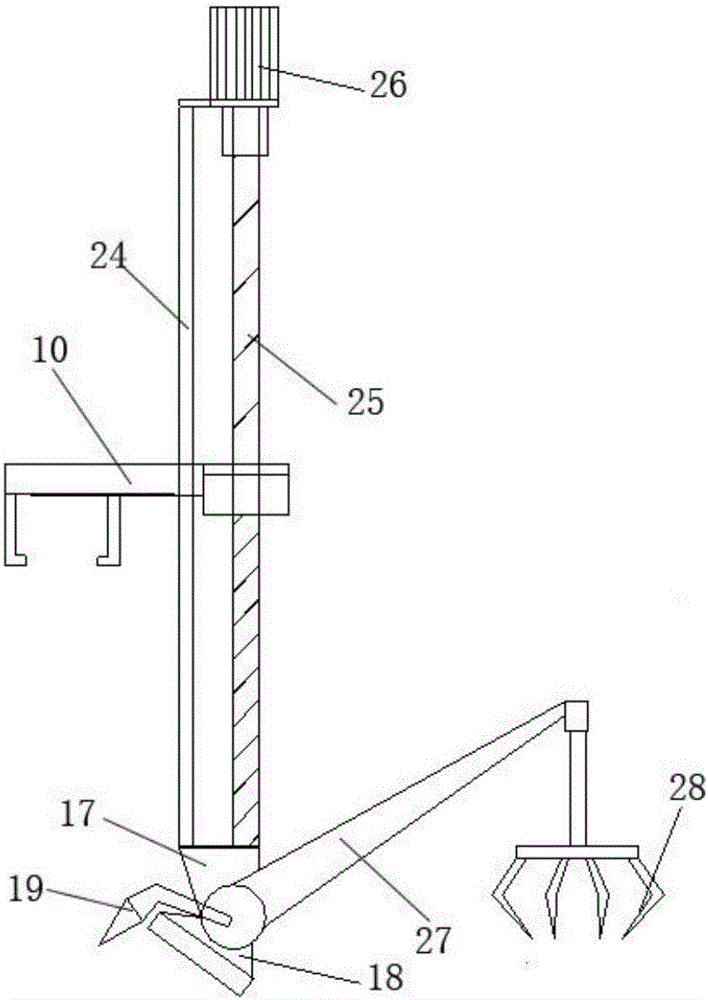

Building additive manufacturing device capable of arranging steel bars

ActiveCN106592980ASimple structureIncrease flexibilityBuilding material handlingArchitectural engineeringBuilding construction

The invention provides a building additive manufacturing device capable of arranging steel bars. The building additive manufacturing device comprises a base, a support, a printing mechanism and a multi-function mechanism; the base comprises a left base board and a right base board, wherein the left base board and the right base board are symmetrically arranged; the support comprises a left upright, a right upright and a beam, wherein the left upright and the right upright are symmetrically arranged; the bottoms of the left upright and the right upright are connected with the left base board and the right base board correspondingly and can horizontally slide along the left base board and the right base board, and the two ends of the beam are connected with the left upright and the right upright correspondingly and perpendicularly slide along the left upright and the right upright; the printing mechanism comprises a first pedestal, a printing arm and a printing assembly; the multi-function mechanism comprises a second pedestal, and a multi-function arm, a spraying maintenance assembly and a grabbing assembly; the first pedestal and the second pedestal are both arranged on the beam and can horizontally slide along the beam, the printing arm is connected with the side end of the first substrate, and the printing assembly is connected with the bottom of the printing arm; and the multi-function arm is connected with the side end of the second substrate, and the spraying maintenance assembly and the grabbing assembly are both connected with the bottom of the multi-function arm. According to the building additive manufacturing device capable of arranging the steel bars, steel bar arranging and constructing printing, spraying and maintenance of a construction structure can be integrally completed, structural quality is guaranteed, and labor efficiency is improved.

Owner:CHINA STATE CONSTR READY MIXED CONCRETE CO LTD +1

Butanone-wiping-resistant insulating intaglio printing black ink for thin-film materials

The invention discloses butanone-wiping-resistant insulating intaglio printing black ink for thin-film materials and belongs to the technical field of insulating intaglio printing black ink. The butanone-wiping-resistant insulating intaglio printing black ink for thin-film materials comprises ingredients: a resin binder, a solvent, a dispersant, a carbon black filler, a blue pigment / filler, an extinction filler, a curing agent and an assistant. According to the butanone-wiping-resistant insulating intaglio printing black ink, the selected resin binder achieves a good compatible effect under the condition that a prime solvent and a cosolvent are matched according to a certain proportion, and a prepared ink coating is good in apparent effect; the ink disclosed by the invention not only can simultaneously achieve the characteristics of matte black blue phase, good coverage, high insulatibity, solvent resistance, storage stability, constructability, and the like, but also can achieve theseproperties without stacking a variety of coatings; and meanwhile, the ink can achieve very excellent adhesive power on PI materials.

Owner:SUZHOU BETELY POLYMER MATERIALS CO LTD +1

Permanent antistatic and low-temperature-resistant polystyrene material as well as production method and application thereof

InactiveCN107955313AImprove low temperature toughnessImproved rheological propertiesFlexible coversWrappersAntistatic agentPolystyrene

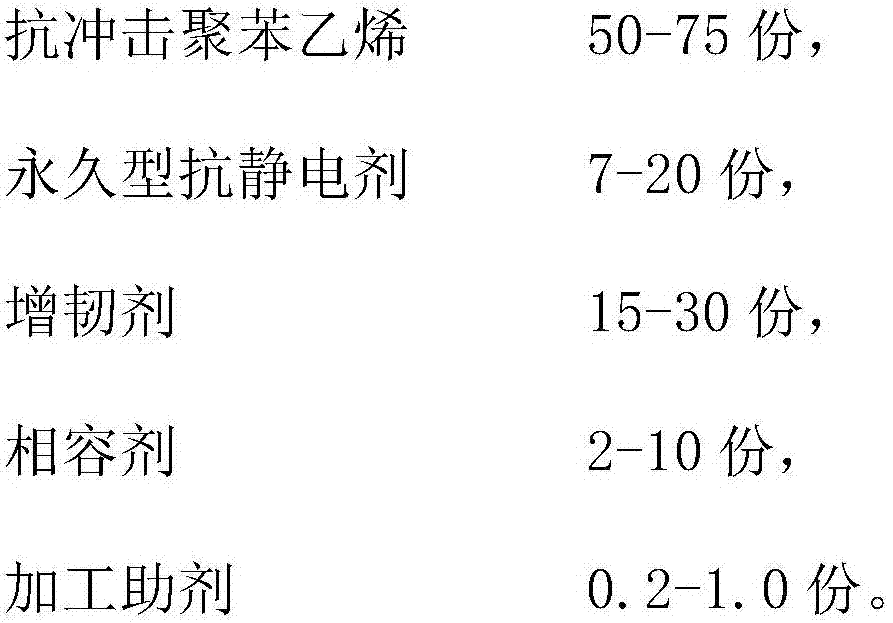

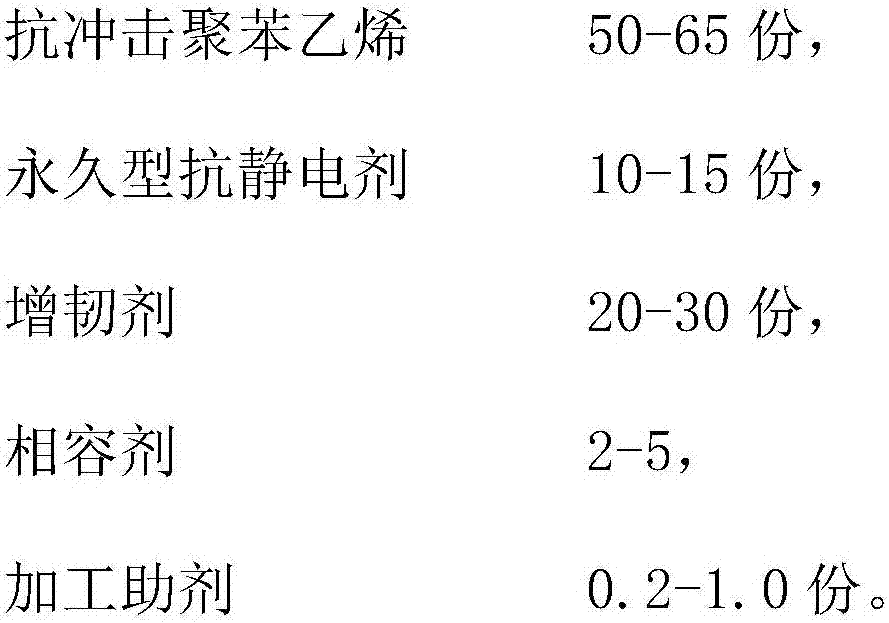

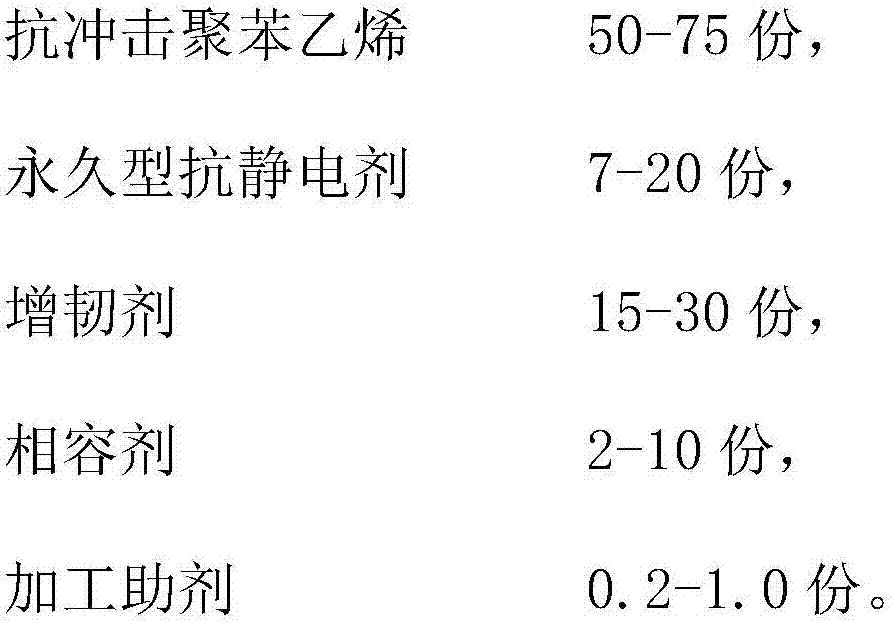

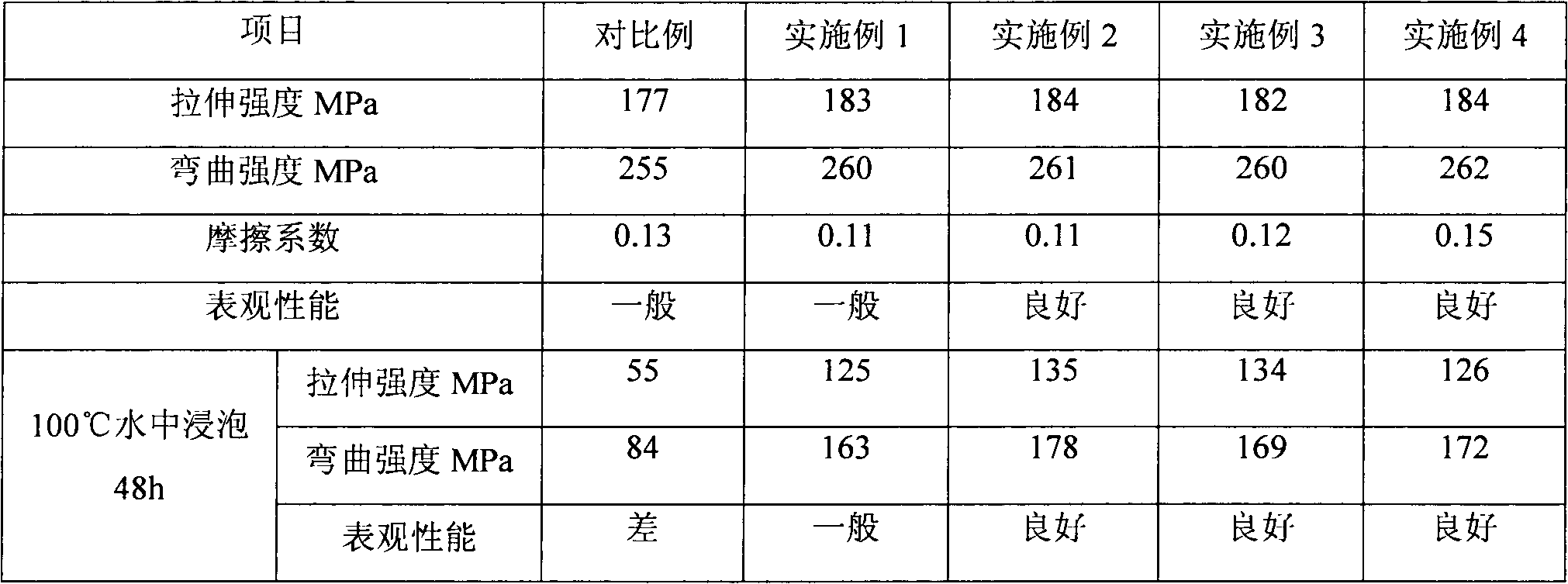

The invention provides a permanent antistatic and low-temperature-resistant polystyrene material as well as a production method and application thereof. The permanent antistatic and low-temperature-resistant polystyrene material is prepared from the following raw materials in parts by weight: 50 to 75 parts of anti-impact polystyrene, 7 to 20 parts of permanent antistatic agent, 5 to 30 parts of toughening agent, 2 to 10 parts of compatilizer, and 0.2 to 1.0 part of processing aid. By adopting the permanent antistatic and low-temperature-resistant polystyrene material, by virtue of the combination of the low-temperature toughening effect of the toughening agent and the compatilizer for improving the interface strength, excellent low-temperature toughness of the material can be realized.

Owner:TIANJIN KINGFA NEW MATERIAL

Polyamide 6 composition for gas-assisted injection

The invention relates to a polyamide 6 composition used for gas aided injection molding, which is characterized by comprising the following compositions by weight percentage: 40 to 80 percent of polyamide 6 slice, 5 to 30 percent of fiber glass, 5 to 30 percent of inorganic mineral, 1 to 10 percent of compatilizer, 0.1 to 0.5 percent of antioxidant, and 0.1 to 0.5 percent of coupling agent. The polyamide 6 composition has the characteristics of higher melt strength, excellent dimension stability, good chemical resistance, smooth product surface and the like, and can be both used for gas aided injection molding of an automobile door pull and other automobiles and mechanical and electrical products suitable for gas aided injection molding.

Owner:SHANGHAI SUNNY

Hydrolysis-resistant glass fiber reinforced polyamide 66 (PA66) composite material and preparation method thereof

InactiveCN102585495AImprove hydrolysis resistanceGood physical and mechanical propertiesGlass fiberAntioxidant

The invention relates to the field of modification of polymer engineering plastic, in particular to a method for preparing a hydrolysis-resistant glass fiber reinforced polyamide 66 (PA66) composite material. The composite material is characterized by consisting of the following materials in part by weight: 55 to 65 parts of PA66, 0.1 to 2 parts of hydrolysis-resistant agent, 30 to 40 parts of glass fibers, 1 to 3 parts of nanoparticles, 0.5 to 2 parts of antioxidant and 0.5 to 2 parts of lubricating agent. According to the preparation method, extrusion granulation is performed by a double screw extruder. By introducing the high-efficiency hydrolysis-resistant agent, the hydrolysis resistance of the PA66 is improved, and the physical and mechanical properties of the glass fiber reinforced PA66 in a high-humidity environment are enhanced; and meanwhile, by introducing the nanoparticles, the mechanical properties such as tensile strength, hardness and the like of the PA66 are further enhanced, the wear resistance of the PA66 is enhanced, and the application range of the PA66 is further expanded.

Owner:上海聚威新材料股份有限公司

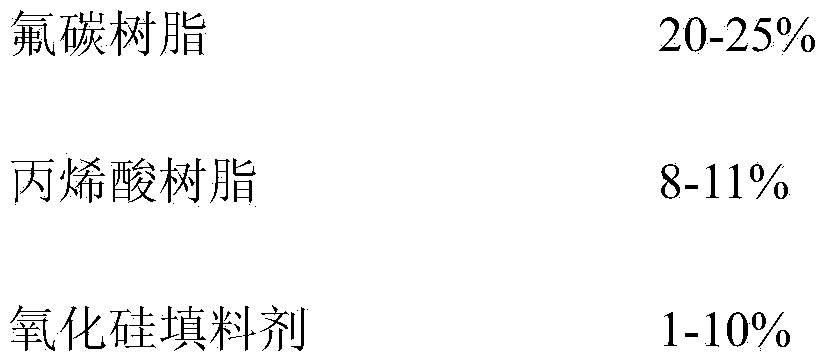

Water dispersible fluorocarbon finish coating and preparation method thereof

InactiveCN103709854AImprove stain resistanceImprove appearance performanceAntifouling/underwater paintsPaints with biocidesWater dispersibleAcrylic resin

The invention discloses a water dispersible fluorocarbon finish coating. The finish coating consists of the following components in percentage by weight: 20-25% of fluorocarbon resin, 8-11% of acrylic resin, 1-10% of silicon oxide filler, 5-10% of auxiliaries and 50-60% of a solvent. The water dispersible fluorocarbon finish coating disclosed by the invention has a self-cleaning effect and is excellent in stain resistance; meanwhile, the coating improves apparent property through addition of the inorganic filler silicon oxide; the finish coating, through regulating proportion of the silicon oxide filler, can achieve coating effects of high light, semi matte and lusterless, and can improve wear-resisting property of the coating.

Owner:SHANGHAI JIAO TONG UNIV

Aluminum product surface treatment method

An aluminum product surface treatment method comprises the following steps that oil removing and wax removing treatment is carried out on the surface of an aluminum product; first-time leveling treatment is carried out on the aluminum product subjected to oil removing and wax removing treatment; first-time neutralizing treatment is carried out on the aluminum product subjected to first-time leveling treatment; second-time leveling treatment is carried out on the aluminum product subjected to first-time neutralizing treatment; second-time neutralizing treatment is carried out on the aluminum product subjected to second-time leveling treatment; and die removing treatment is carried out on the aluminum product subjected to second-time neutralizing treatment. According to the aluminum product surface treatment method, oil removing and wax removing treatment, first-time leveling treatment, second-time leveling treatment and die removing treatment are carried out on the aluminum product, mechanical patterns and surface spots of the aluminum product can be well removed, meanwhile, the aluminum product can be brightened, and the appearance effect of the aluminum product is effectively improved.

Owner:GUANGDONG EVERWIN PRECISION TECH

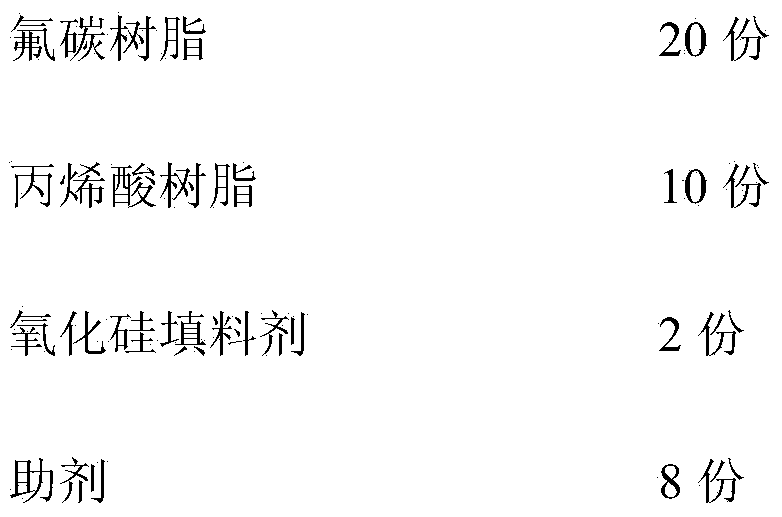

High-fluidity high-apparent-performance low-VOC long-glass-fiber reinforced polypropylene composite material and preparation method therefor

ActiveCN108164821ASimple preparation processImprove appearance qualityGlass fiberPolypropylene composites

The invention discloses a high-fluidity high-apparent-performance low-VOC long-glass-fiber-reinforced polypropylene composite material and a preparation method therefor. The polypropylene composite material is prepared from the ingredients in percentage by mass: 30% to 60% of long glass fibers, which are arranged in a manner of being parallel to particle length, and 40% to 70% of polypropylene modified resin, wherein the polypropylene modified resin is prepared through modifying commercial polypropylene resin on the market by a twin-screw extruder. According to the polypropylene composite material and the preparation method therefor, by adding low-melting-point polypropylene, processing windows of extruding and injection molding are increased, and the polypropylene resin can better impregnate glass fibers, so that injection-molded parts are good in apparent performance, free of glass fiber exposure, free of warping and easy in processing; and by the method, the application of a flow modifier in long-glass-fiber reinforced materials is avoided, the VOC can be effectively reduced, and the product prepared by the method has good mechanical properties and has very good application in the aspects of instrument board skeletons, front-end frameworks, automobile stern doors and the like.

Owner:CHONGQNG PRET NEW MATERIAL +4

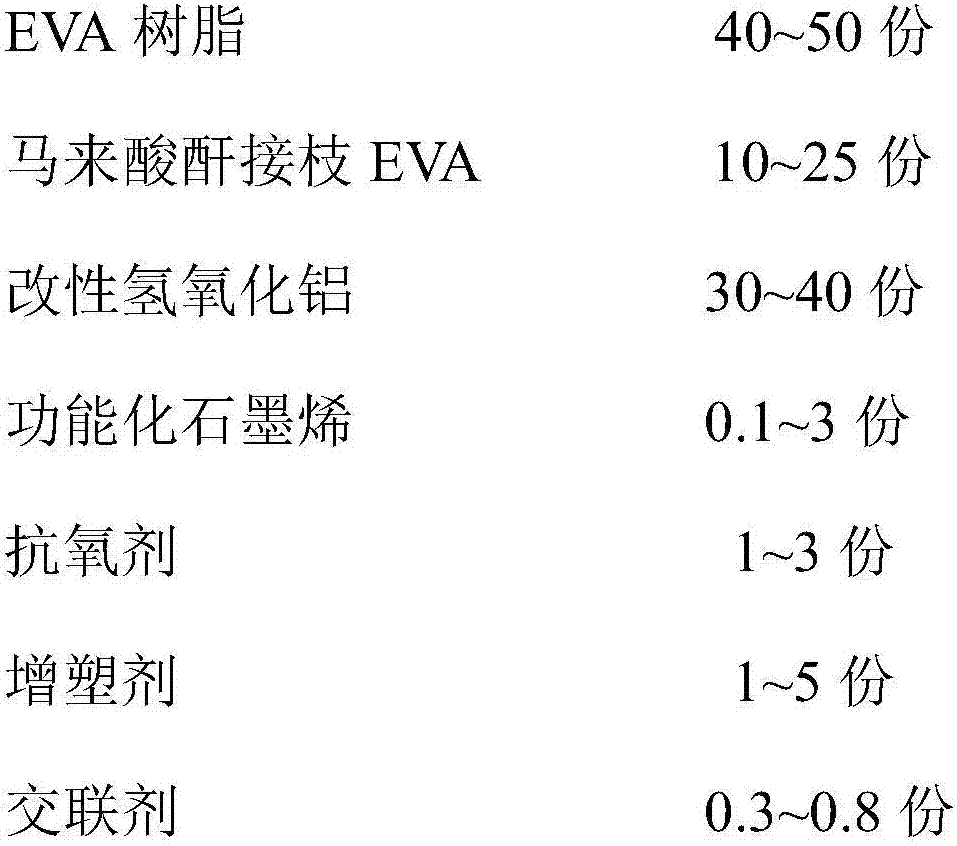

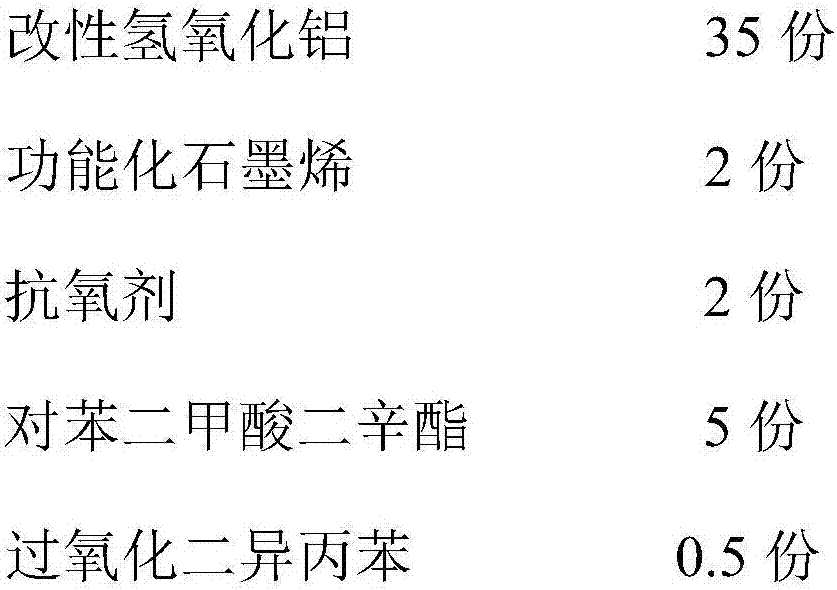

ATH (alumina trihydrate)/graphene-synergized flame-retardant EVA (ethylene-vinyl acetate copolymer) and preparation method thereof

The invention belongs to the field of flame-retardant EVA (ethylene-vinyl acetate copolymer) materials, and particularly relates to an ATH (alumina trihydrate) / graphene-synergized flame-retardant EVA material and a preparation method thereof. The flame-retardant material consists of EVA resin, maleic anhydride-grafted EVA, modified aluminium hydroxide, functionalized graphene, antioxidant, plasticizer and cross-linking agent. The formula of the ATH / graphene-synergized flame-retardant EVA material disclosed by the invention is reasonable, the amount of the added metal hydroxide flame retardant is small, the dispersibility is good, the good flame-retardant property of materials is met, the oxygen index is high, the UL-94 flammability grade can reach V-0, the mechanical properties of the material are good, the preparation method is simple and easy to implement, the operation cost is low, all the involved materials are easy to obtain and manufacture, and the invention is suitable for mass production in the industry.

Owner:张家港市科元高分子材料有限公司

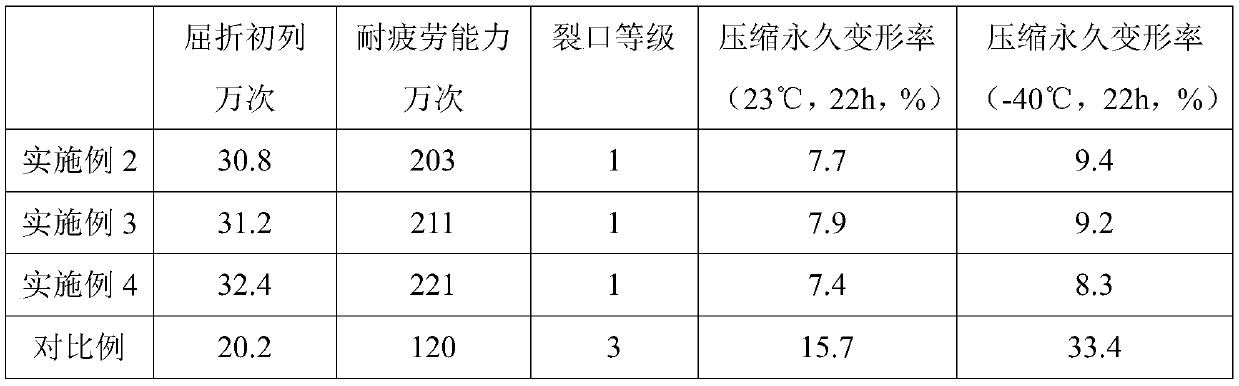

Graphene high-elasticity rubber elastomer high polymer material and preparation method thereof

The invention discloses a graphene high-elasticity rubber elastomer high polymer material and a preparation method thereof. The high polymer material is prepared from the following raw materials by weight: 45-50 parts of natural rubber, 15-19 parts of styrene-butadiene rubber, 10-14 parts of an ethylene-octene copolymer, 13-16 parts of an ethylene-butyl acrylate copolymer, 16-20 parts of an ethylene-vinyl acetate copolymer, 2.4-3.0 parts of grapheme, 6.5-8.5 parts of silane coupling agent modified glass fiber, 1.6-2.1 parts of a foaming agent, 0.82-0.95 part of a micropore regulator, 1.8-2.2 parts of a bridging agent, 2-4 parts of polyethylene wax, 3-5 parts of maleic anhydride grafted polypropylene, 1.8-2.4 parts of a cross-linking agent, 3.5-5.5 parts of an antioxidant and 3-4 parts of aheat stabilizer. The product disclosed by the invention has good resilience and memory function, also has high elasticity, still has very low permanent compression set value at -40DEG C, and has goodflexibility.

Owner:FUJIAN WUCHIHENG TECH DEV CO LTD

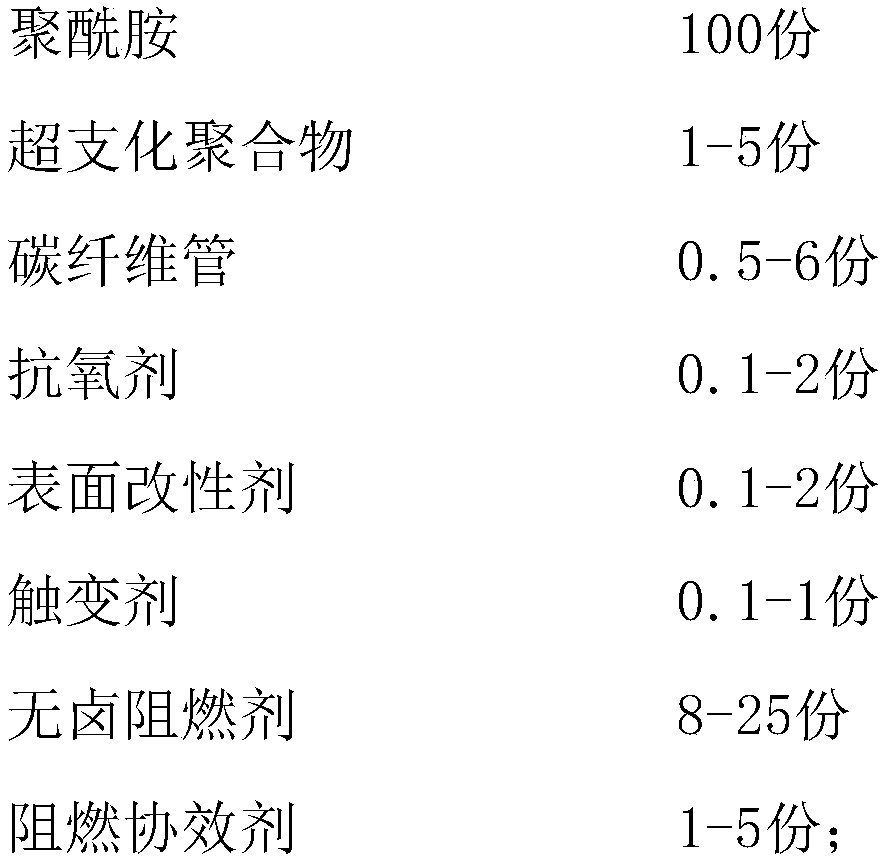

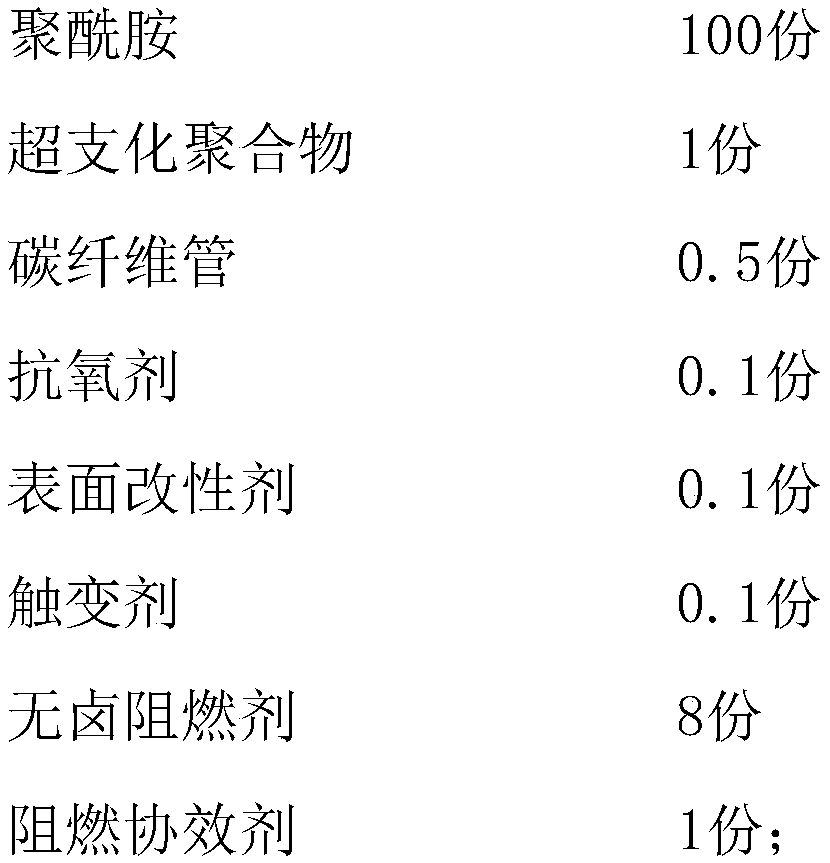

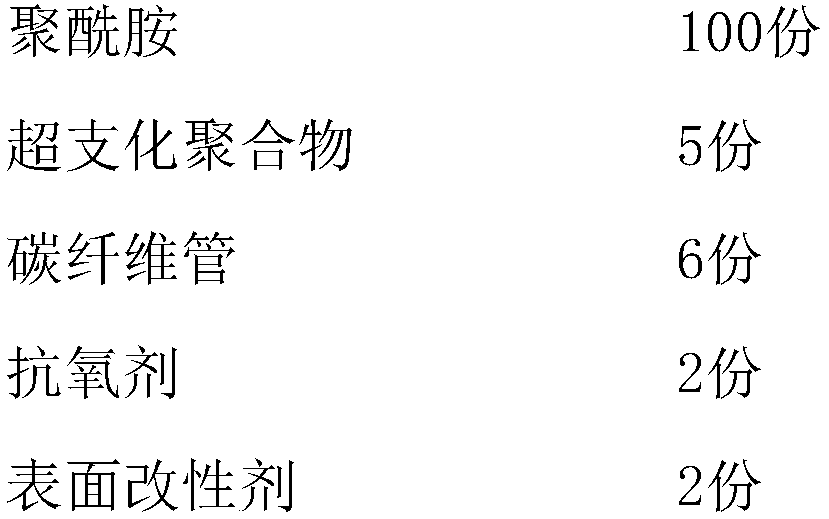

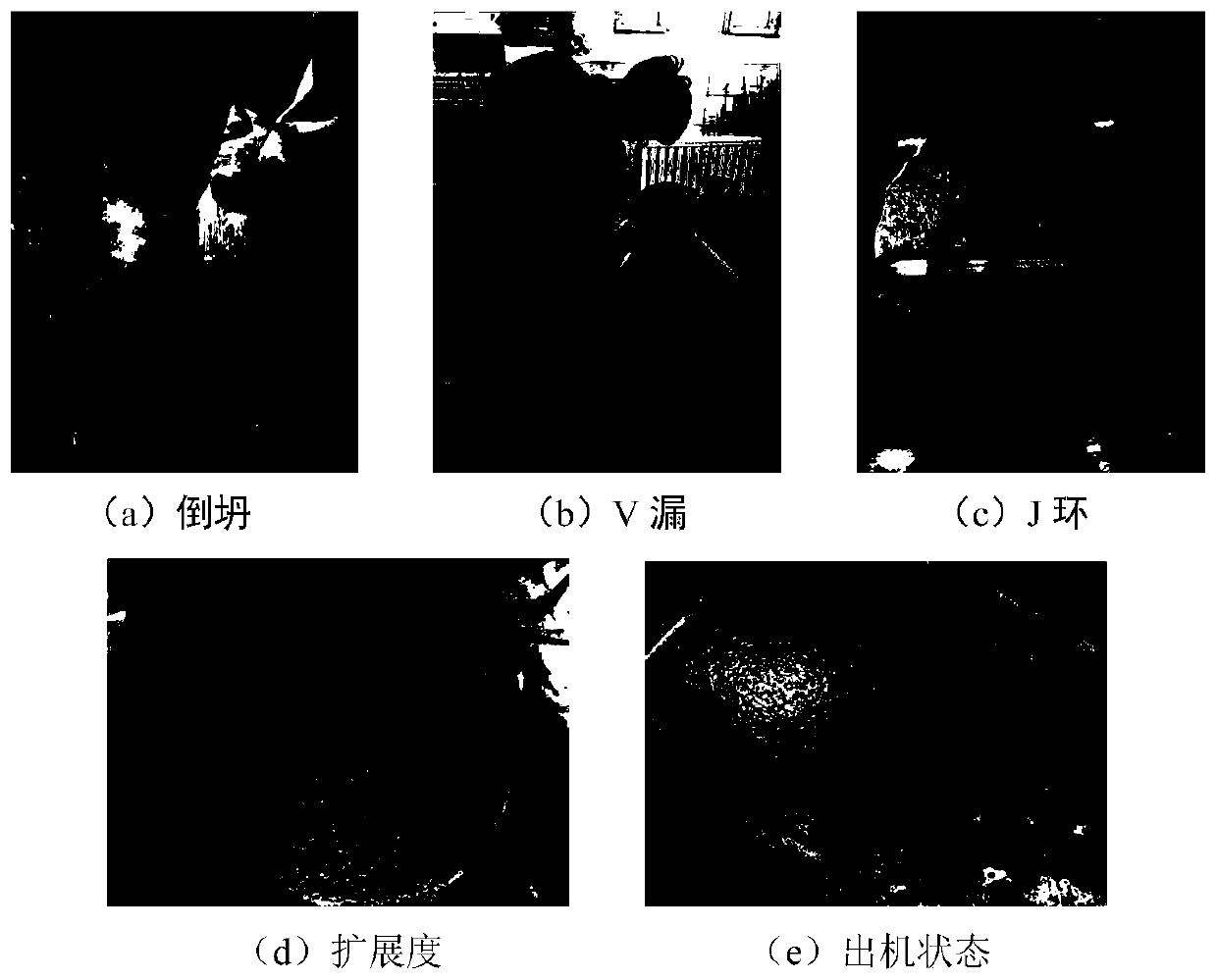

Halogen-free flame-retardant polyamide resin composition and preparation method thereof

The invention relates to the technical field of polymer materials, in particular to a halogen-free flame-retardant polyamide resin composition and a preparation method thereof. The composition is prepared from polyamide, hyperbranched polymer, carbon fiber tube, antioxygen, surface modifier, thixotropic agent, non-halogen flame-retardant and flame retardant synergist, wherein the hyperbranched polymer is amino-end-group hyperbranched polyamide. The polyamide is adopted as a resin substrate and cooperates with a certain amount of the hyperbranched polymer, the carbon fiber tube, the surface modifier, the non-halogen flame-retardant, the flame retardant synergist and the thixotropic agent, the carbon fiber tube, the non-halogen flame-retardant and the flame retardant synergist are uniformlydispersed in the polyamide, the prepared halogen-free flame-retardant polyamide resin composition has the advantages of being high in strength, good in dimensional stability, good in chemical resistance and excellent in electrical properties, outstanding physical performance can be maintained under severer temperature and humidity conditions, and the composition has high flame retardant performance which reaches UL94V0.

Owner:GUANGDONG GREAT MATERIAL CO LTD

Environment-friendly high-strength self-compacting fair-faced concrete for bridge bent cap and preparation process thereof

InactiveCN110563407AReduce manufacturing costMeet structural performance requirementsCeramic shaping apparatusCement mixing apparatusMaximum diameterSlurry

The invention belongs to the technical field of concrete foundation engineering, and particularly relates to environment-friendly high-strength self-compacting fair-faced concrete for a bridge bent cap and a preparation process thereof. The high-strength self-compacting fair-faced concrete comprises 500-550 parts of a cementing material per cubic meter, 740-880 parts of fine aggregate per cubic meter, 880-1020 parts of coarse aggregate per cubic meter and 9.36-10.40 parts of an additive per cubic meter. The cementing material comprises 360-400 parts of cement per cubic meter, 50-75 parts of mineral powder S75 per cubic meter and 65-90 parts of II-grade fly ash per cubic meter. The concrete disclosed by the invention is relatively good in apparent properties, basically consistent in color and free of obvious color difference; basically no repair trace exists; the maximum diameter of surface bubbles is not more than 5 mm, the depth of surface bubbles is not more than 2 mm, and the area of each square meter of bubbles is not more than 12 cm<2>; and the concrete is free of obvious cracks, slurry leakage, flowing and scouring traces, oil stains, ink marks, rust spots and pulverized substances.

Owner:中建西部建设新疆有限公司 +1

Method for producing polystyrene extruded sheet profiled bar through carbon dioxide foaming agent

InactiveCN105199252AImprove the mixing effectImprove appearance performancePolymer scienceFoaming agent

The invention discloses a method for producing a polystyrene extruded sheet profiled bar through a carbon dioxide foaming agent. The method includes the following steps: taking a polystyrene melt as the main component, and taking carbon dioxide as a polymer melt of the foaming agent, and simultaneously adding the two objects into an extruder according to a certain proportion to form a polymer melt; injecting carbon dioxide from the middle section of the extruder to the melt through a foaming agent injection system to form foamable gelatin; along with the forward conveying of the melt, and under the shearing action of a screw, fully mixing the foaming agent with the polystyrene melt; performing mixing and temperature reduction and cooling to the polymer melt through a heat exchanger, so as to reduce the temperature of the gelatin to the optimal foaming temperature; extruding the cooled gelatin through a die with required shapes to form the polystyrene extruded sheet profiled bar. The method for producing the polystyrene extruded sheet profiled bar through the carbon dioxide foaming agent, provided by the invention, is economic and environment-friendly, is simple in technology, and has excellent market prospect.

Owner:南京法宁格节能科技股份有限公司

Alumite hot stamping adhesive and preparation method thereof

ActiveCN110079257AImprove the level ofImprove the exhaust effectMineral oil hydrocarbon copolymer adhesivesNon-macromolecular adhesive additivesHot stampingGas phase

The invention discloses an alumite hot stamping adhesive. The alumite hot stamping adhesive is prepared from components in parts by weight as follows: 10-20 parts of a styrene thermoplastic elastomer,40-65 parts of tackifying resin, 5-25 parts of auxiliary resin and 8-18 parts of fumed silica. Due to addition of the styrene thermoplastic elastomer, the alumite hot stamping adhesive has good bonding performance and thermoplasticity at high temperature, the added tackifying resin can provide better initial viscosity, and the auxiliary resin can enhance adhesion to an aluminum layer. Under the synergistic effect of the styrene thermoplastic elastomer, the tackifying resin and the auxiliary resin, the hot stamping adhesive has proper softening point to meet high-speed hot stamping, good adhesion performance and certain temperature resistance; the added fumed silica improves the appearance effect and the hot stamping effect of the hot stamping adhesive. The invention also provides a preparation method of the alumite hot stamping adhesive.

Owner:WUHAN HUAZHONG KEDA FINE CHEM

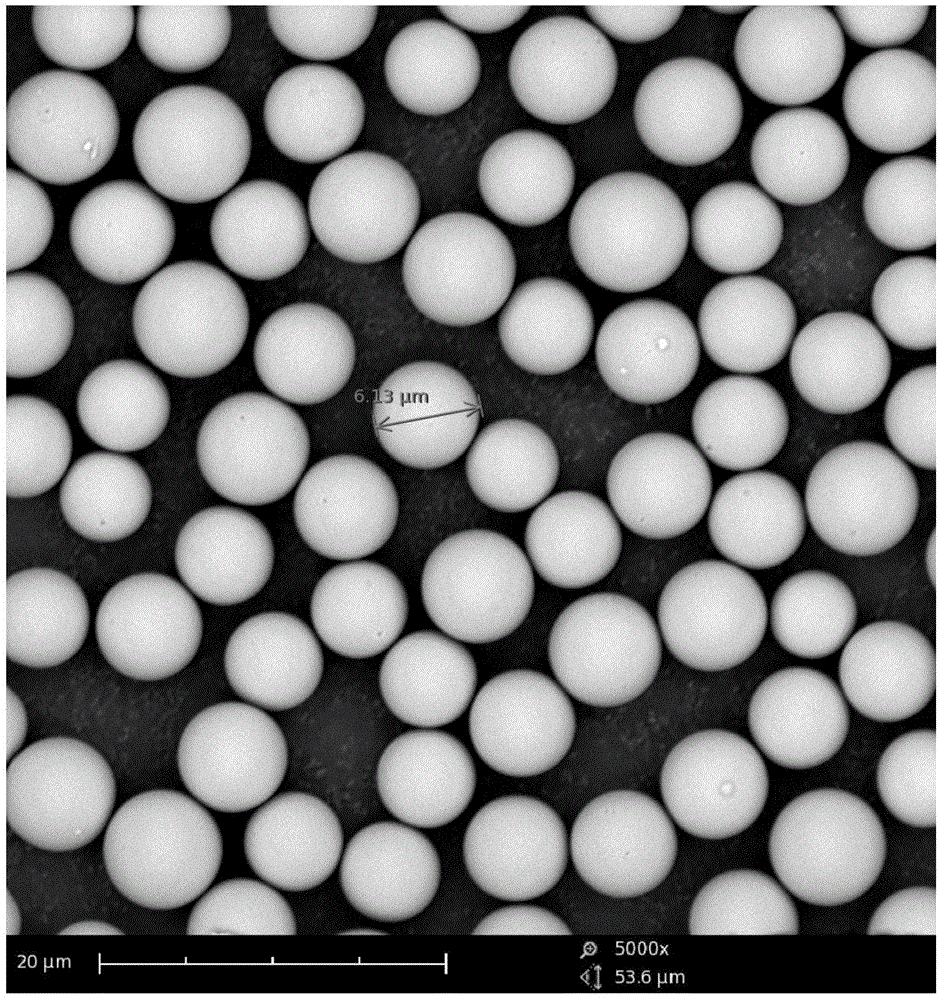

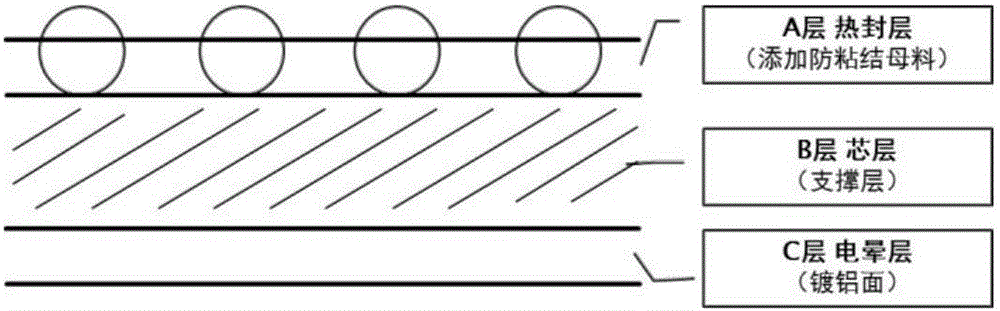

Low-friction coefficient anti-bonding master batch special for metallized base film and preparation method thereof

ActiveCN106519455ADoes not affect heat sealing temperatureDoes not affect heat sealing performanceMetallised filmPolypropylene

The invention relates to a low-friction coefficient anti-bonding master batch special for a metallized base film and a preparation method thereof. The low-friction coefficient anti-bonding master batch mainly comprises, by weight, 90-95 parts of polypropylene resin and 5-10 parts of polymethylsesquisiloxane-polyphenylsilsesquioxane. The polymethylsesquisiloxane-polyphenylsilsesquioxane is a ladder polymer with R3SiO terminated. The molecular formula of the polymethylsesquisiloxane-polyphenylsilsesquioxane is [CH3SiO1.5]n-[PhSiO1.5]m, wherein n is 5-8 and m is 2-5. According to the preparation method, an anti-sticking agent is added by means of side feeding through precision electronic weight loss scales, and pelleting is performed after melt blending by means of the special double-screw process. By the adoption of the method, the problem that no slipping agent (master batch) can be added into the metallized film and thus the friction coefficient is high and the problem that the low friction coefficient is required under the condition that no migration slipping agent can be added into an aluminum laminated film are effectively solved. The friction coefficient of the obtained metallized base film is lowered to 0.4 or below from 0.8 or above, the slipping property is good, no migration happens, and the product surface is not greasy, high in glossiness, resistant to abrasion, lasting and effective.

Owner:SHANTOU BEST SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com