Controllable rheological high-gloss polypropylene resin and preparation method thereof

A polypropylene resin, high-gloss technology, applied in the field of polypropylene resin, to achieve excellent heat resistance, improve appearance performance, and shorten the molding process cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

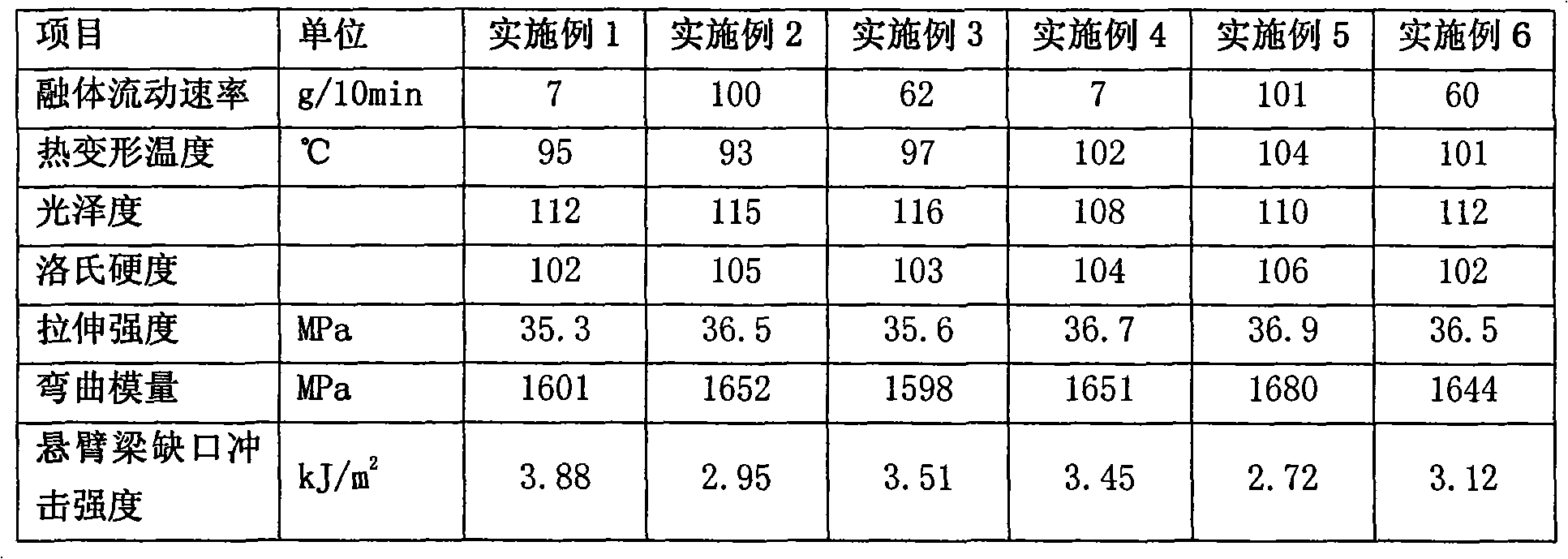

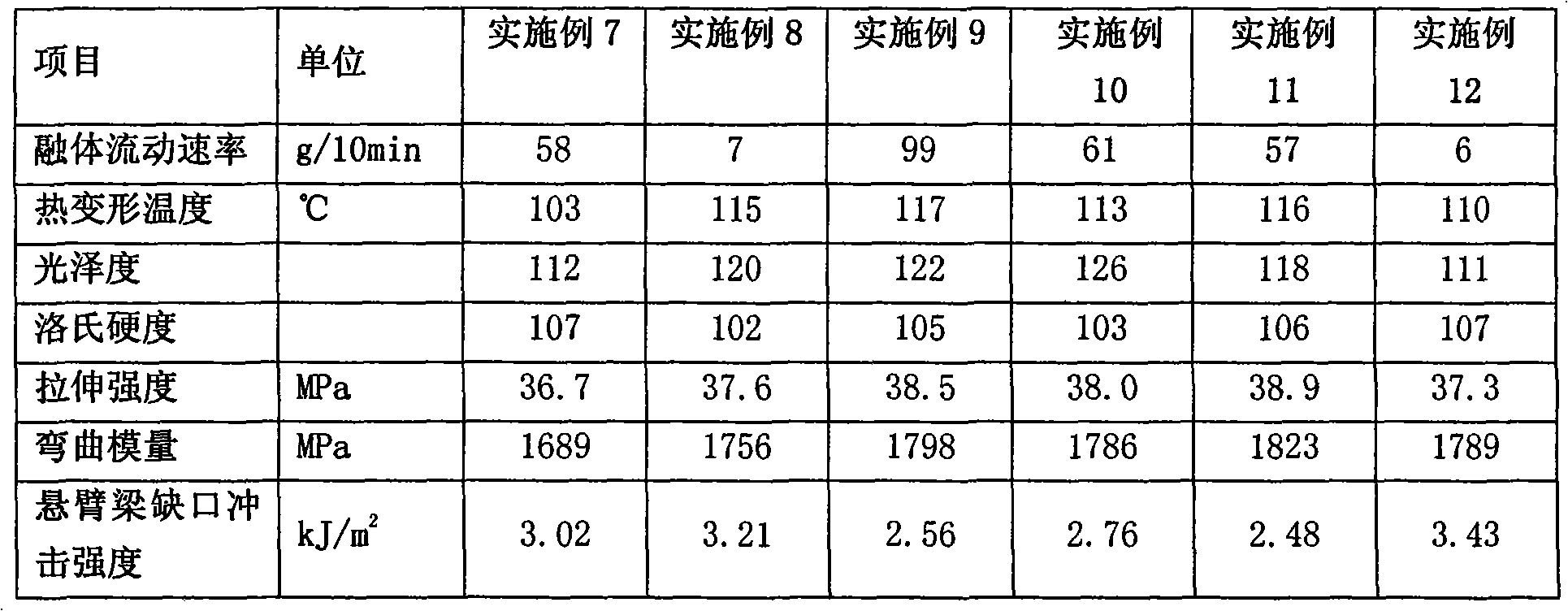

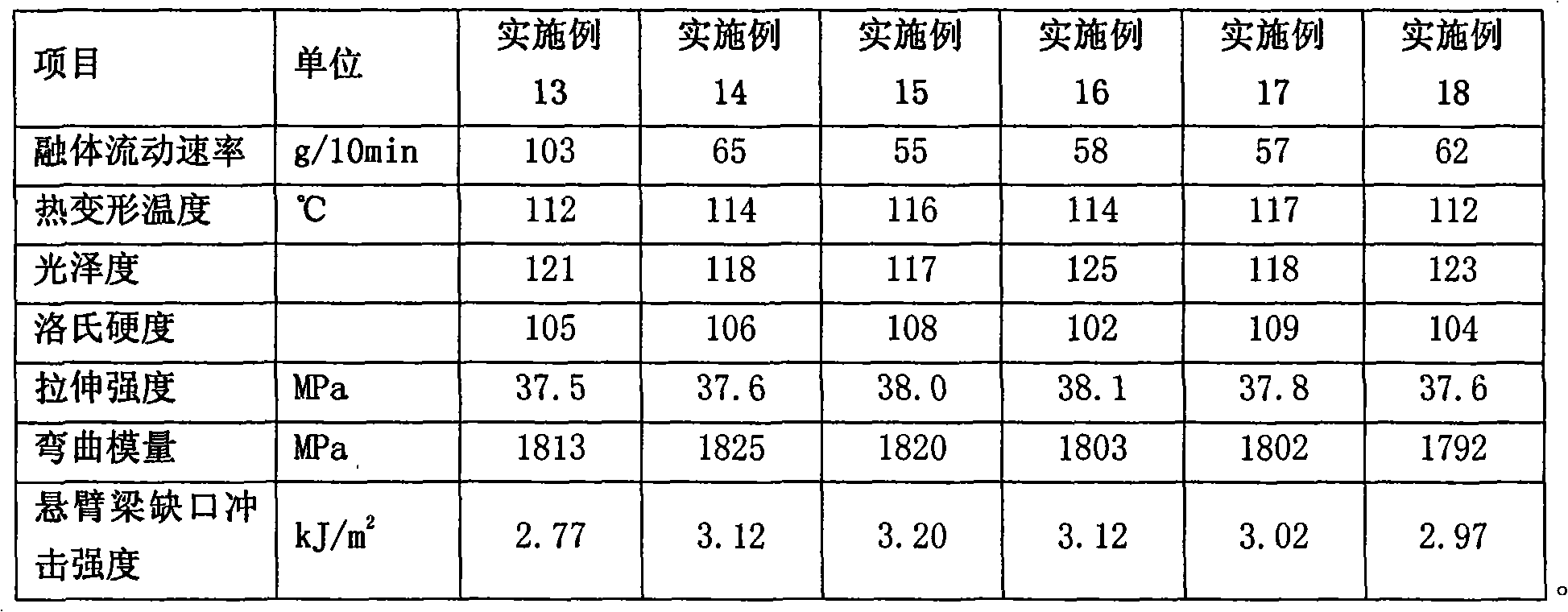

Examples

Embodiment 1

[0021] Take by weighing 100 parts of homopolypropylene (the number average molecular weight of homopolypropylene is 61235), phenolic antioxidant (tetra[β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionic acid] Pentaerythritol ester: tris (2.4-di-tert-butylphenyl) phosphite = 1: 1, mass ratio, hereinafter the same) 0.15 part, halogen absorbent (high-purity calcium stearate) 0.10 part, nucleating agent (( 3,4-dimethyldibenzylidene) sorbitol) 0.15 parts, the above materials were placed in a high-speed mixer and stirred evenly to obtain a base material for later use. Weigh 100 parts of homopolypropylene (the number average molecular weight of homopolypropylene is 63475), 0.65 parts of peroxide (dicumyl peroxide), put the above materials in a high-speed mixer and stir evenly, and use a twin-screw The extruder is processed into a peroxide masterbatch for later use. The obtained base material and peroxide masterbatch are respectively placed in the main material and auxiliary material ho...

Embodiment 2

[0023] Take by weighing 100 parts of homopolypropylene (the number average molecular weight of homopolypropylene is 63475), phenolic antioxidant (tetra[β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionic acid] Pentaerythritol ester: 0.15 part of tris (2.4-di-tert-butylphenyl) phosphite = 1: 1), 0.10 part of halogen absorbent (high-purity calcium stearate), nucleating agent ((3,4-dimethyl Dibenzylidene) sorbitol) 0.2 parts, put the above materials in a high-speed mixer and stir evenly to obtain the base material for later use. Take by weighing 100 parts of homopolypropylene (the number average molecular weight of homopolypropylene is 63475), peroxide (1,1-bis(tert-butyl peroxide)-3,3,5-trimethylcyclohexane ) 0.65 parts, the above-mentioned materials are placed in a high-speed mixer and stirred evenly, and processed into a peroxide masterbatch with a twin-screw extruder for subsequent use. The obtained base material and peroxide masterbatch were respectively placed in the main mate...

Embodiment 3

[0025] Take by weighing 100 parts of homopolypropylene (the number average molecular weight of homopolypropylene is 63475), phenolic antioxidant (tetra[β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionic acid] Pentaerythritol ester: 0.15 part of tris (2.4-di-tert-butylphenyl) phosphite = 1: 1), 0.10 part of halogen absorbent (high-purity calcium stearate), nucleating agent ((3,4-dimethyl Dibenzylidene) sorbitol) 0.15 parts, gloss modifier (polypropylene wax) 0.1 part, put the above materials in a high-speed mixer and stir evenly to obtain the base material for later use. Take by weighing 100 parts of homopolypropylene (the number average molecular weight of homopolypropylene is 63475), 0.65 part of peroxide (1,1-bis(tert-butylperoxide)-3,3,5-trimethylcyclo hexane), the above-mentioned materials are placed in a high-speed mixer and stirred evenly, and processed into a peroxide masterbatch with a twin-screw extruder for subsequent use. The obtained base material and peroxide master...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com