Hydrolysis-resistant glass fiber reinforced polyamide 66 (PA66) composite material and preparation method thereof

A technology of PA66 and composite materials, applied in the field of preparation of hydrolysis-resistant glass fiber reinforced PA66 composite materials, can solve the problem of easy water absorption of PA66, and achieve the effect of improving hydrolysis resistance, enhancing physical and mechanical properties, and enhancing tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Below in conjunction with example, the present invention is described in further detail:

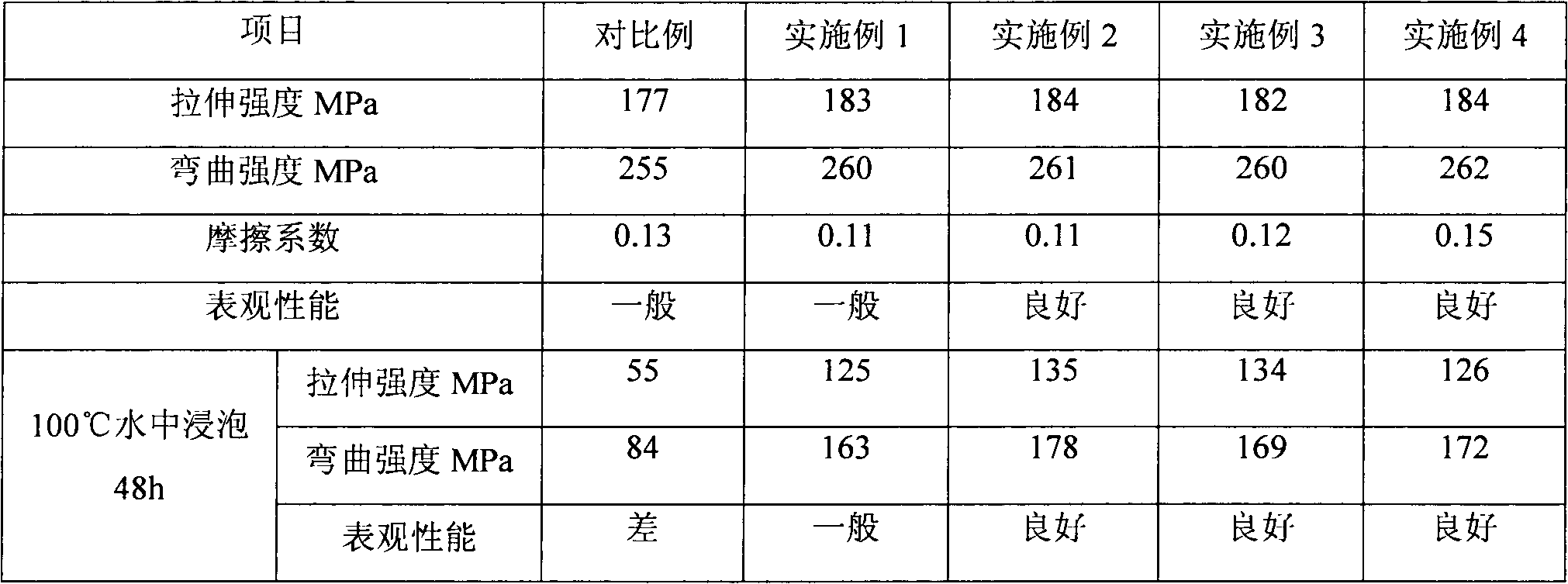

[0023] PA66 is used as matrix, aromatic amines are used as hydrolysis-resistant agent, surface-treated alkali-free glass fiber is used as reinforcement, antioxidant 2921 is used as antioxidant, and EBO is used as lubricant. The specific ratio is shown in Table 1 below.

[0024] Table 1 Experimental Proportion Table (parts by weight)

[0025] Raw material name

comparative example

Example 1

Example 2

Example 3

Example 4

PA66

64

61

56

56

56

Anti-hydrolysis agent

0

2

2

2

2

EBO

0

0

2

2

2

2921

1

1

1

0

1

glass fiber

30

30

40

30

30

nanoparticles

3

3

3

2

1

[0026] Prepare PA66 composite materials according to the specific formula i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com