Preparation method of hydrolysis-resistant modified polylactic acid fibers

A polylactic acid fiber, anti-hydrolysis technology, applied in the direction of melt spinning, stretch spinning, single-component polyester rayon, etc., to avoid deterioration of mechanical properties, excellent hand feel and softness, and realize large-scale production Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

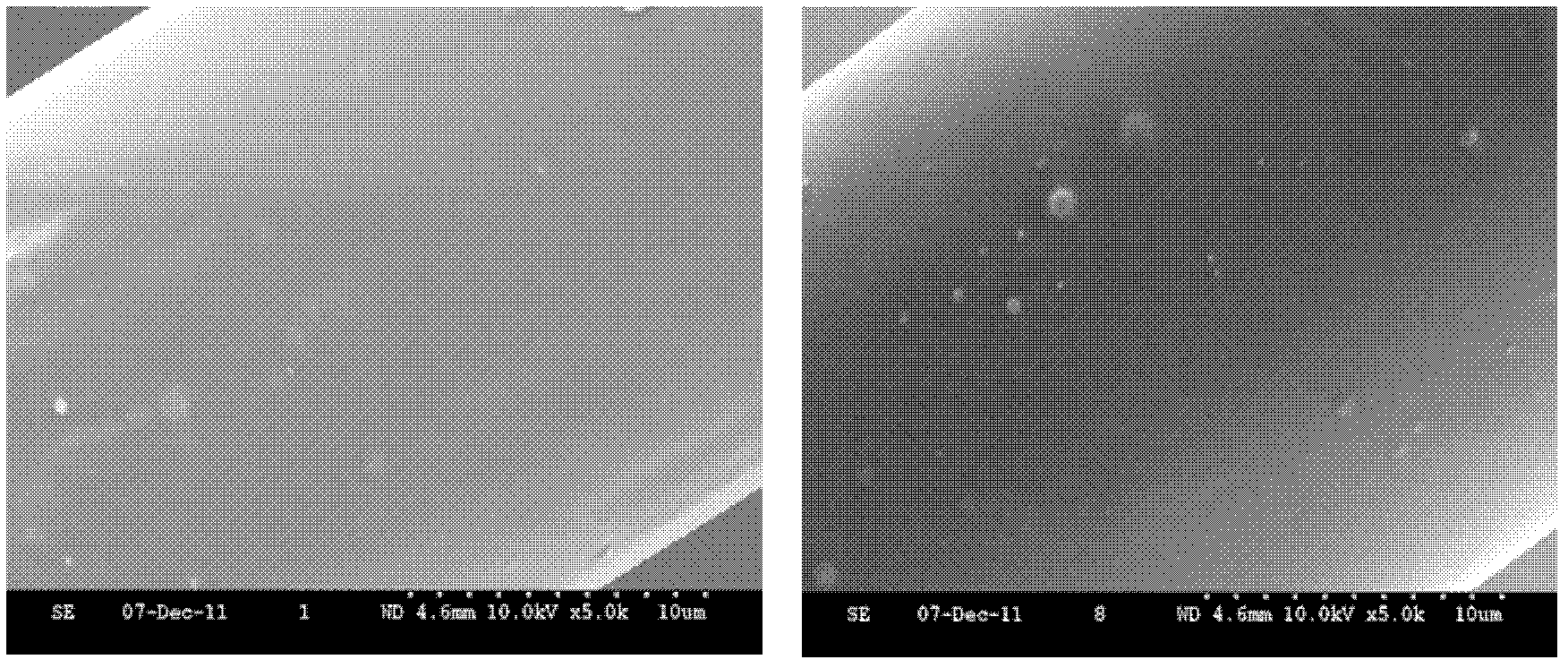

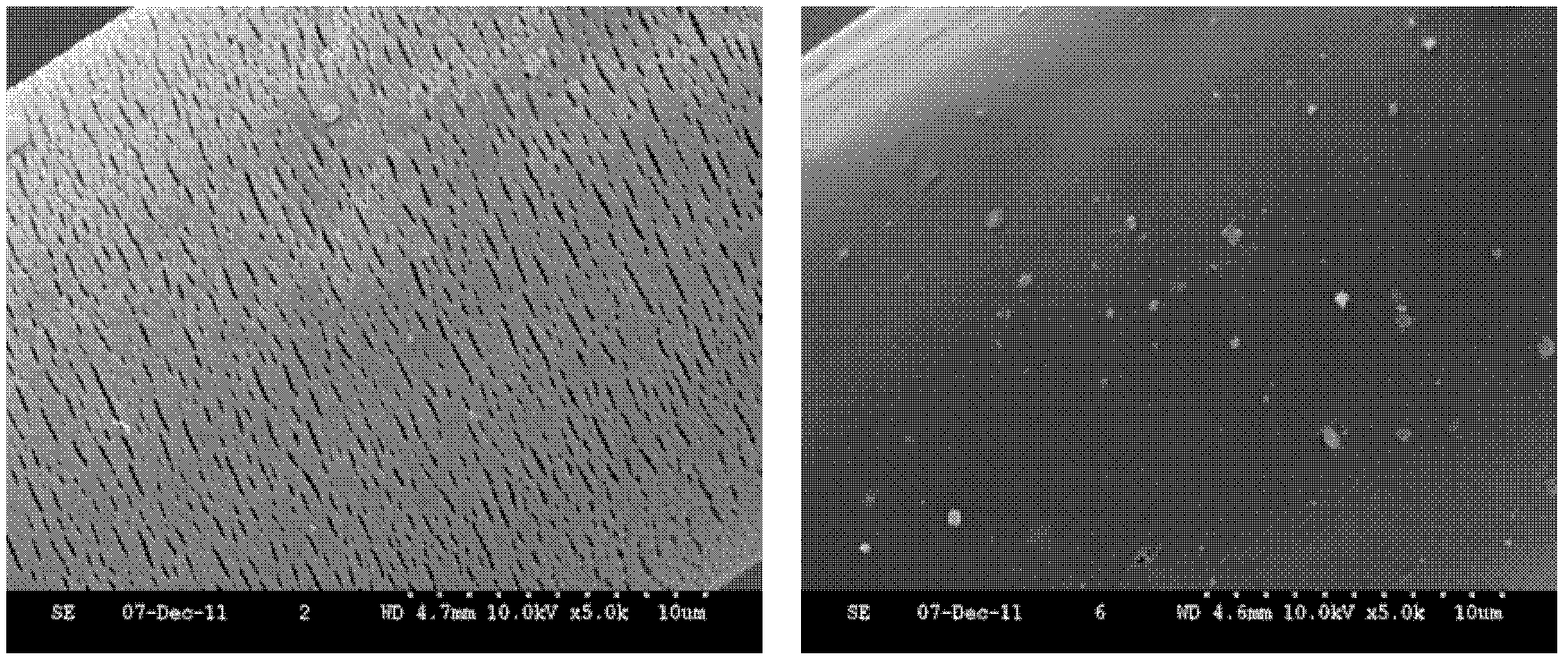

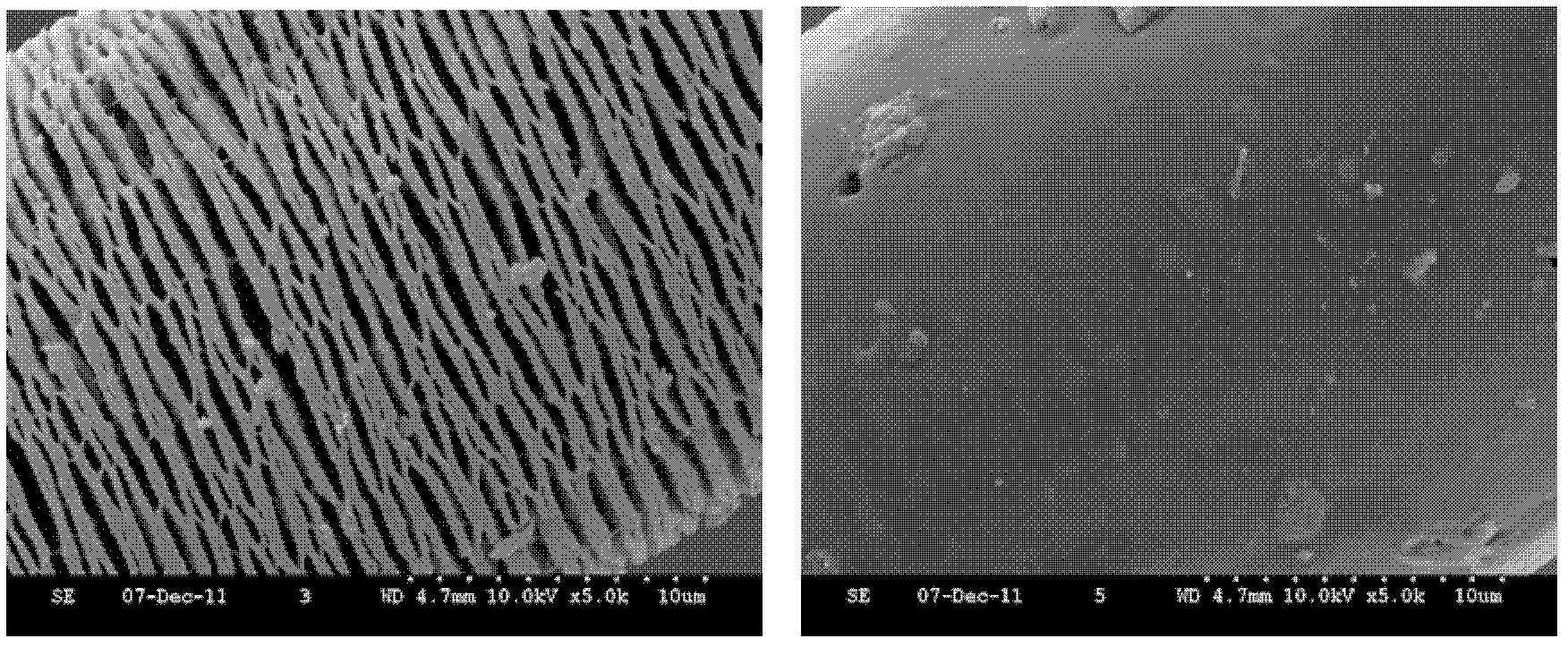

Image

Examples

Embodiment 1

[0031] Dry the PLA particles in vacuum until the moisture content is 100ppm-500ppm, mix 945g polylactic acid, 50g polytrimethylene adipate (weight average molecular weight 20000-30000), and 5g multifunctional polycarbodiimide in a container , and then use a twin-screw extruder for melt blending, the extrusion temperature is 190°C, the screw speed is 100rpm, and it can be cooled and dried after granulation. The vacuum-dried masterbatch chips were melt-spun by a single-component spinning machine, wherein the spinning temperature was 215° C. and the winding speed was 600 m / min to obtain pre-drawn filaments. The post-drawing of the as-spun fibers was carried out with a hot plate and a hot plate, the temperature of the hot plate was 90°C, the temperature of the hot plate was 120°C, and the draft ratio was 4.5.

[0032] The main components of the multifunctional polycarbodiimide include carbodiimide oligomers (with a weight-average molecular weight of 500) and poly(p-phenylene carbo...

Embodiment 2

[0034] Dry the PLA particles in vacuum until the moisture content is 100ppm-500ppm, put 890g polylactic acid, 100g polybutylene adipate (weight average molecular weight 6000-7000), and 10g multifunctional polycarbodiimide in a container Mix evenly, and then use a twin-screw extruder for melt blending, the extrusion temperature is 185°C, the screw speed is 150rpm, and it can be cooled and dried after granulation. The vacuum-dried masterbatch slices were melt-spun by a single-component spinning machine, wherein the spinning temperature was 210° C. and the winding speed was 600 m / min to obtain pre-drawn filaments. The post-drawing of the as-spun fibers was carried out with a hot plate and a hot plate, the temperature of the hot plate was 90°C, the temperature of the hot plate was 115°C, and the draft ratio was 4.3.

[0035] The main components of the multifunctional polycarbodiimide include carbodiimide oligomers (with a weight average molecular weight of 600) and poly(diisopropy...

Embodiment 3

[0037] Dry the PLA particles in vacuum until the moisture content is 100ppm-500ppm, mix 840g polylactic acid, 150g polytrimethylene sebacate (weight average molecular weight 4000-5000), and 10g multifunctional polycarbodiimide in a container , and then use a twin-screw extruder for melt blending, the extrusion temperature is 180°C, the screw speed is 80rpm, and it can be cooled and dried after granulation. The vacuum-dried masterbatch slices are melt-spun by a single-component spinning machine, wherein the spinning temperature is 200°C and the winding speed is 800m / min to obtain pre-drawn filaments. The post-drawing of the as-spun fibers was carried out with a hot plate and a hot plate, the temperature of the hot plate was 80°C, the temperature of the hot plate was 120°C, and the draft ratio was 4.1.

[0038]The main components of the multifunctional polycarbodiimide include carbodiimide oligomers (with a weight-average molecular weight of 700) and poly(diisopropylcarbodiimide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com