Environment-friendly high-strength self-compacting fair-faced concrete for bridge bent cap and preparation process thereof

A clean-faced concrete, green and environmentally friendly technology, applied in the direction of clay preparation equipment, manufacturing tools, ceramic molding machines, etc., to achieve the effect of high cost performance, low manufacturing cost, and easy pouring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

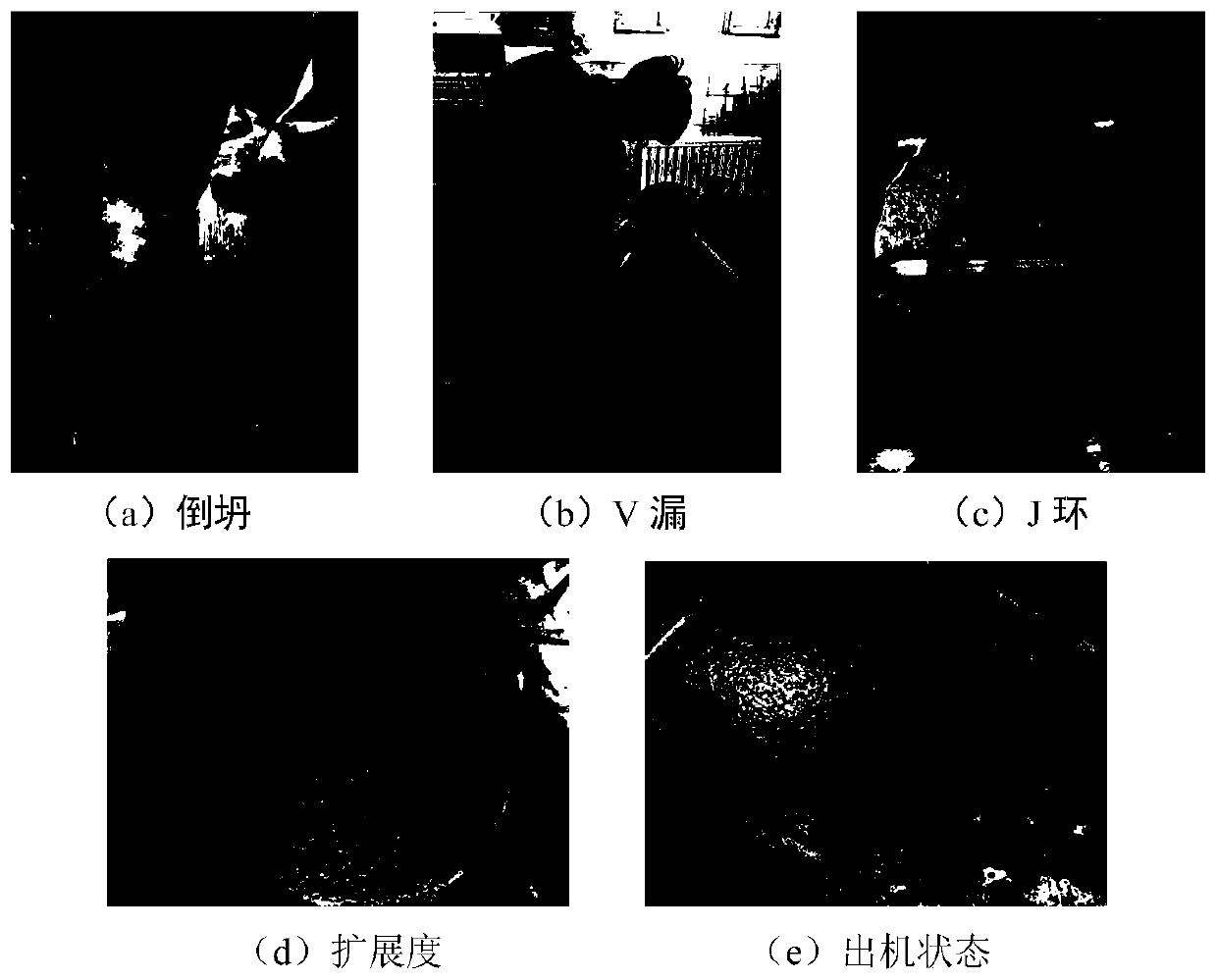

Problems solved by technology

Method used

Image

Examples

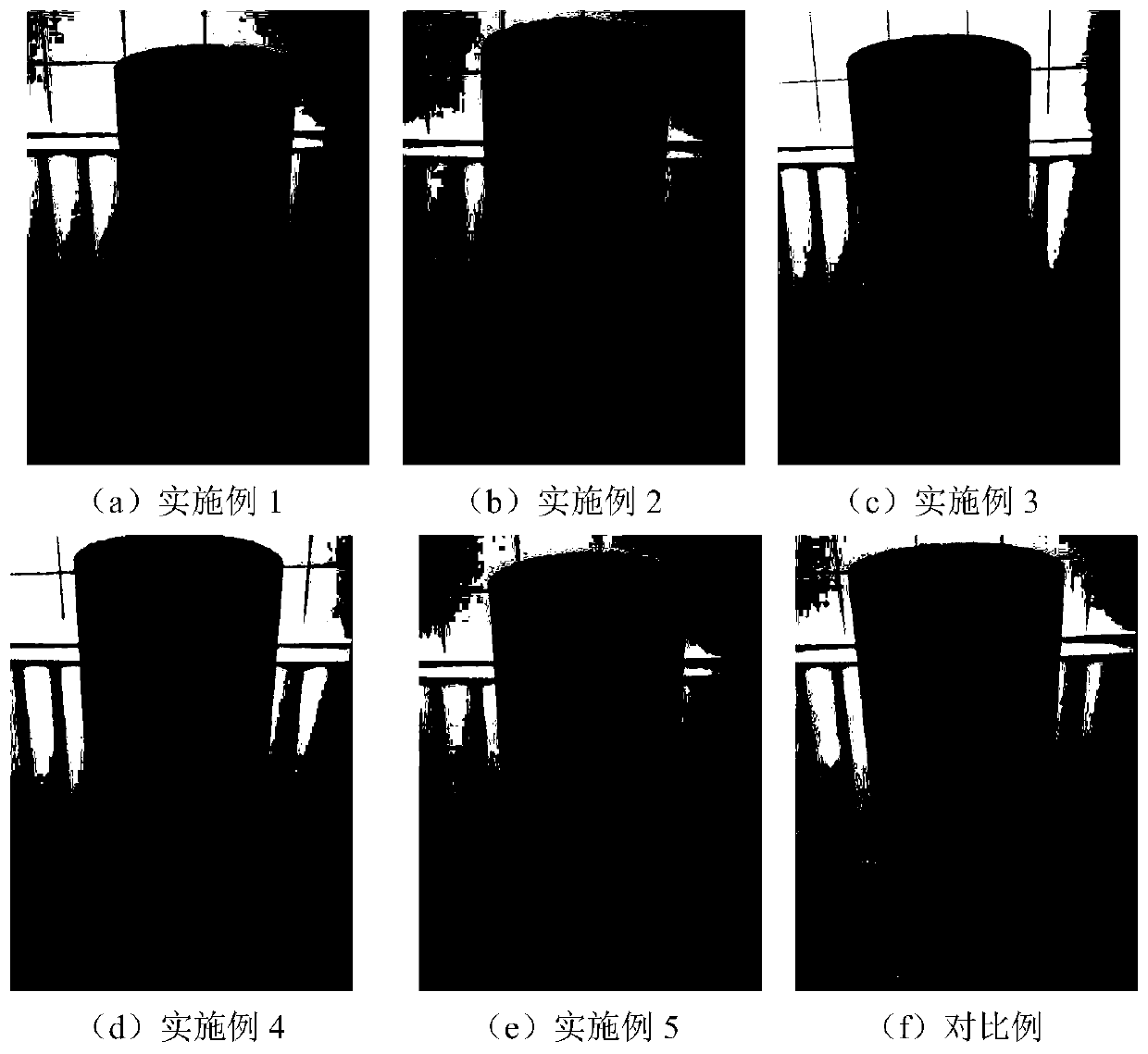

Embodiment 1

[0029] A high-strength self-compacting fair-faced concrete, the mix ratio is as follows (unit: kg / m 3 ), numbered 1:

[0030]

[0031]

[0032] The admixture consists of water-reducing component (PCA-JS02 water-reducing polycarboxylate superplasticizer), defoaming component (DF-2006 defoamer) and slump-retaining component (PCA-BT02 slump-retaining polycarboxylate acid superplasticizer) composition; the bulk density of the high-strength self-compacting fair-faced concrete is 2445kg / m 3 , the water-binder ratio is 0.32, and the sand rate is 50%.

Embodiment 2

[0034]A high-strength self-compacting fair-faced concrete, the mix ratio is as follows (unit: kg / m 3 ), numbered 2:

[0035]

[0036] The admixture consists of water-reducing component (PCA-JS02 water-reducing polycarboxylate superplasticizer), defoaming component (DF-2006 defoamer) and slump-retaining component (PCA-BT02 slump-retaining polycarboxylate acid superplasticizer) composition; the bulk density of the high-strength self-compacting fair-faced concrete is 2445kg / m 3 , the water-binder ratio is 0.32, and the sand rate is 47%.

Embodiment 3

[0038] A high-strength self-compacting fair-faced concrete, the mix ratio is as follows (unit: kg / m 3 ), numbered 3:

[0039]

[0040]

[0041] The admixture consists of water-reducing component (PCA-JS02 water-reducing polycarboxylate superplasticizer), defoaming component (DF-2006 defoamer) and slump-retaining component (PCA-BT02 slump-retaining polycarboxylate acid superplasticizer) composition; the bulk density of the high-strength self-compacting fair-faced concrete is 2445kg / m 3 , the water-binder ratio is 0.32, and the sand rate is 47%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com