Antiscratch resin and preparation method thereof

A scratch-resistant and resin technology, applied in the field of scratch-resistant resin and its preparation, can solve the problems of poor scratch resistance, low surface hardness, limited application, etc., and achieve stable product quality, high production efficiency, flexible transparency and other problems. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

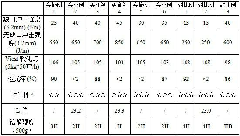

Examples

Embodiment 1

[0026] Stir 85kg of PMMA resin, 15kg of toughening agent, 0.2kg of light stabilizer, 0.4kg of antioxidant, and 0.6kg of lubricant through a high-speed mixer and mix them uniformly. The temperature of the screw extruder is 180~230°C. Under the shearing, conveying, and mixing of the twin-screw, it is fully melted and compounded, and then extruded through the machine head, drawn, cooled, pelletized, and dried to obtain scratch resistance. resin. Among them, the PMMA resin is Arkema V040; the toughening agent has a core-shell structure, the shell is PMMA, the core rubber is butyl acrylate grafted butadiene, the particle size is 300nm, and the rubber content is 60wt% of the total weight of the toughening agent ; Light stabilizer: Ciba 770; lubricant is EBS; antioxidant is B900.

Embodiment 2

[0028] Stir 75kg of PMMA resin, 25kg of toughening agent, 0.3kg of light stabilizer, 0.5kg of antioxidant, 0.5kg of lubricant, and 2kg of toner through a high-speed mixer, and mix evenly. Then, the above-mentioned mixture is accurately metered into the extruder Inside, the temperature of the twin-screw extruder is controlled at 180~230°C. Under the shearing, conveying, and mixing of the twin-screw, it is fully melted and compounded, and then extruded through the head, drawn, cooled, pelletized, and dried. A scratch-resistant resin is obtained. Among them, the PMMA resin is Arkema V040; the toughening agent has a core-shell structure, the shell is PMMA, the core rubber is butyl acrylate grafted siloxane, the particle size is 200nm, and the rubber content is 70wt% of the total weight of the toughening agent ;Light stabilizer: Ciba 770; lubricant is EBS; antioxidant is B900; toner is carbon black masterbatch.

Embodiment 3

[0030] Stir 75kg PMMA resin, 25kg toughening agent, 0.2kg light stabilizer, 0.6kg antioxidant, 0.8kg lubricant through a high-speed mixer, and mix evenly. The temperature of the screw extruder is 180~230°C. Under the shearing, conveying, and mixing of the twin-screw, it is fully melted and compounded, and then extruded through the machine head, drawn, cooled, pelletized, and dried to obtain scratch resistance. resin. Among them, the PMMA resin is Degussa 7N; the toughening agent has a core-shell structure, the shell is PMMA, the core rubber is ethyl methacrylate grafted styrene, the particle size is 200nm, and the rubber content is 80wt of the total weight of the toughening agent %; light stabilizer: Ciba 770; lubricant is EBS; antioxidant is B900.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com