Water dispersible fluorocarbon finish coating and preparation method thereof

A fluorocarbon topcoat, dispersion-type technology, applied in the field of coatings, can solve problems such as limited use, and achieve the effects of improving wear resistance, appearance performance, and good stain resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

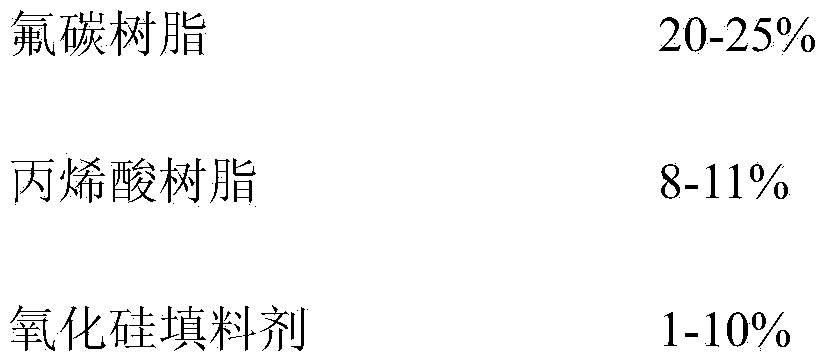

[0030] The formula of water-dispersible fluorocarbon topcoat coating in the present embodiment is as follows:

[0031]

[0032]

[0033] The fluorocarbon resin described in this example is polyvinylidene fluoride (PVDF) fluorocarbon resin or similar products with the trademark "Kynar500"; the acrylic resin is pure acrylic emulsion with a solid content of 40-60%; Foaming agent, anti-settling agent, antifoaming agent, dispersant, emulsifier, antibacterial agent; solvent is a mixture of water and the aforementioned organic solvent; silica filler is 30±5nm nano-silicon dioxide.

[0034] Add the fluorocarbon resin, acrylic resin and additives in this example to the solvent to disperse evenly; add silica filler at a temperature of 25-45°C, disperse evenly and grind to obtain a water-dispersible fluorocarbon topcoat.

Embodiment 2

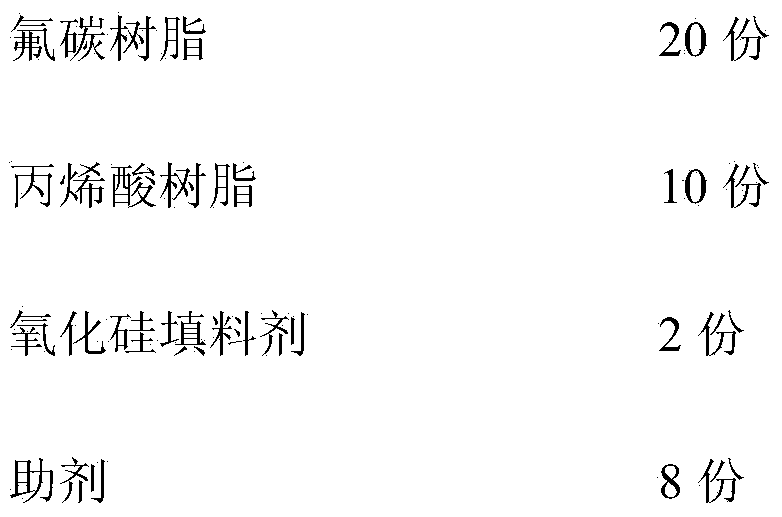

[0036] The formula of water-dispersible fluorocarbon topcoat coating in the present embodiment is as follows:

[0037]

[0038] The fluorocarbon resin, acrylic resin, additives, and solvents described in this embodiment are the same as those in Embodiment 1; the silica filler is nano-silica with a particle size of 50±5nm.

[0039] Add the fluorocarbon resin, acrylic resin and additives in this example to the solvent to disperse evenly; add silica filler at a temperature of 25-45°C, disperse evenly and grind to obtain a water-dispersible fluorocarbon topcoat.

Embodiment 3

[0041] The formula of water-dispersible fluorocarbon topcoat coating in the present embodiment is as follows:

[0042]

[0043]

[0044] The fluorocarbon resin, acrylic resin, additives, and solvents described in this example are the same as in Example 1; the silica filler is 6000-mesh silica micropowder.

[0045]Add the fluorocarbon resin, acrylic resin and additives in this example to the solvent to disperse evenly; add silica filler at a temperature of 25-45°C, disperse evenly and grind to obtain a water-dispersible fluorocarbon topcoat.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com