Alumite hot stamping adhesive and preparation method thereof

A technology of hot stamping glue and anodized aluminum, which is applied in the direction of copying/marking methods, printing, adhesives, etc., can solve the problems of hot stamping glue hot stamping limitations, hot stamping flying gold, paste, increase production costs, etc., and achieve good results Thermal performance, complete hot stamping pattern, and the effect of improving leveling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

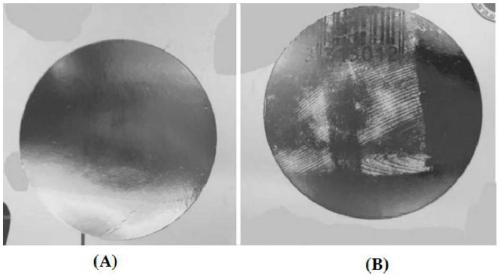

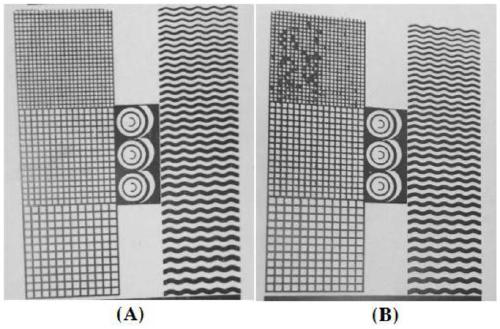

Image

Examples

preparation example Construction

[0027] Embodiments of the present invention also provide a preparation method of anodized aluminum hot stamping glue, comprising the following steps:

[0028] (1) prepare materials by weight;

[0029] (2) After dissolving the styrenic thermoplastic elastomer, the tackifying resin and the auxiliary resin, obtain the styrenic thermoplastic elastomer solution, the tackifying resin solution and the auxiliary resin solution respectively, and then dissolve the styrenic thermoplastic elastomer solution , tackifying resin solution, additive resin solution and fumed silicon dioxide are uniformly mixed to obtain a finished product.

[0030] In the present invention, when the tackifying resin is dissolved, the dissolving temperature is 40-70° C. to ensure that the tackifying resin can be fully dissolved.

[0031] In the present invention, the styrene-based thermoplastic elastomer and the auxiliary resin may be dissolved at room temperature.

[0032] In the present invention, when disso...

Embodiment 1

[0037] Example 1 of the present invention provides an anodized aluminum hot stamping glue, which includes the following components in parts by weight: 40 parts of C9 petroleum resin, 10 parts of SBS, 5 parts of vinyl chloride resin and 8 parts of fumed silica.

[0038] The anodized aluminum hot stamping glue is prepared by the following method:

[0039] (1) Under the condition of constant stirring, add C9 petroleum resin to the toluene solution, heat the mixture to 40°C, and stir at 300r / min for 30-60min until the C9 petroleum resin is completely dissolved to obtain C9 resin solution;

[0040] (2) Under the condition of constant stirring, add SBS to the toluene solution, and stir at 300r / min at room temperature for 30-60min until the SBS is completely dissolved to obtain the SBS solution;

[0041] (3) Under the condition of constant stirring, add chloroacetic resin to the mixed solvent of butanone and toluene (the volume ratio of butanone and toluene is 1:1, the same below), ...

Embodiment 2

[0045] Embodiment 2 of the present invention provides a kind of anodized aluminum hot stamping glue, comprises the following components by weight: 45 parts of C9 petroleum resin, 15 parts of SBS, 10 parts of vinyl chloride resin, 5 parts of rosin and 10 parts of fumed silica .

[0046] The preparation method of the anodized aluminum hot stamping glue is the same as that in Example 1, the difference is that: under the condition of constant stirring, rosin is added to the ethyl acetate solution, the mixed solution is heated to 40 ° C, and at 300 r / Stir for 30 to 60 minutes at a speed of 1 min until the rosin is completely dissolved to obtain a rosin solution; then, under constant stirring, add C9 resin solution, SBS solution, vinyl chloride resin solution, rosin solution and fumed silica to methyl ethyl ketone In a mixed solvent with toluene, adjust the solid content to 20%, and stir at 300r / min for 30-60min at room temperature to obtain the finished product.

[0047] The sof...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com