Method for improving polyglycol plasticization polylactic acid strength of materials capability by process

A technology of plasticizing polylactic acid and polyethylene glycol, which is applied in the field of polylactic acid, can solve the problems of toughening effect and mechanism, and achieve the effect of improving appearance performance, tensile performance and bending performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

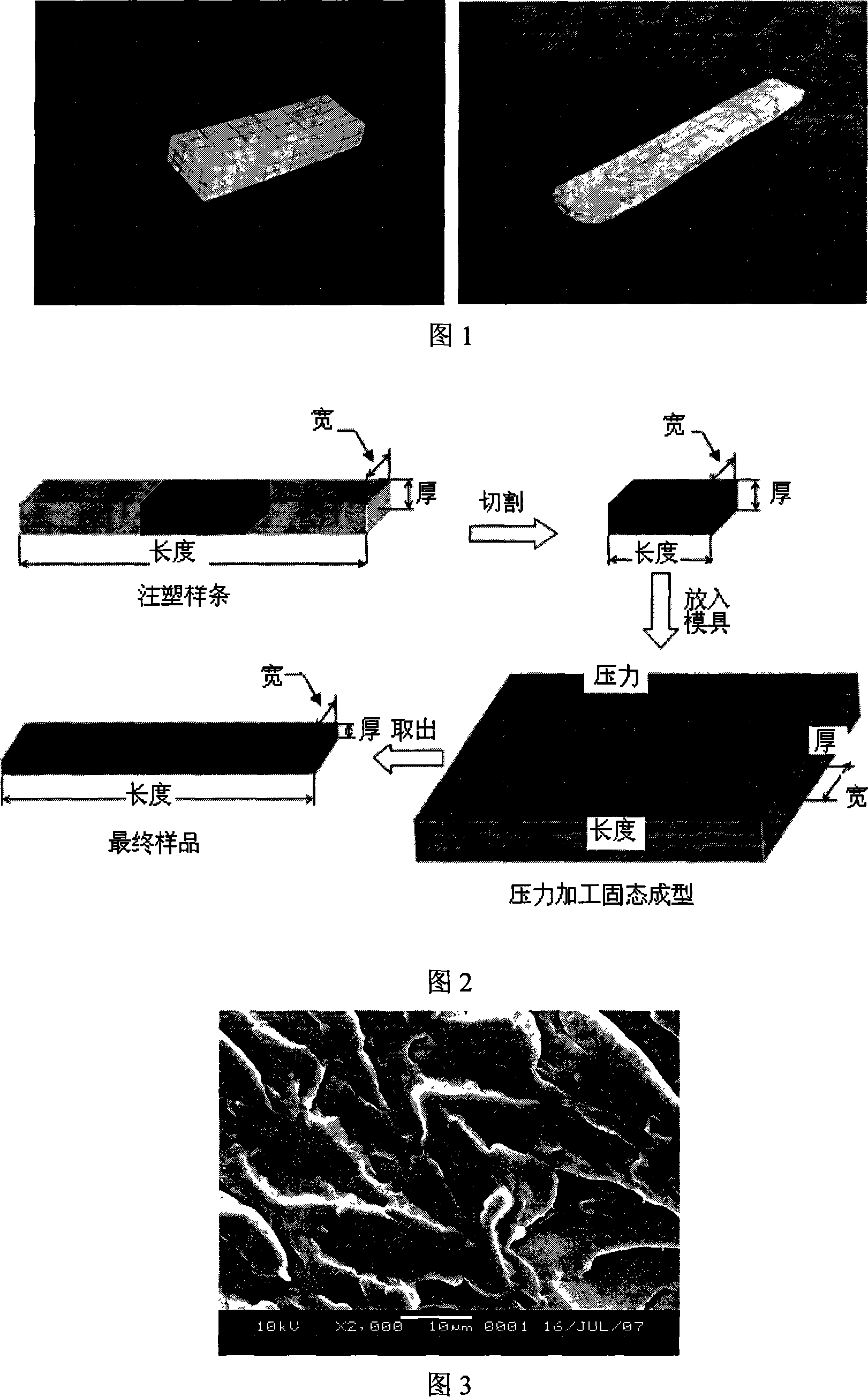

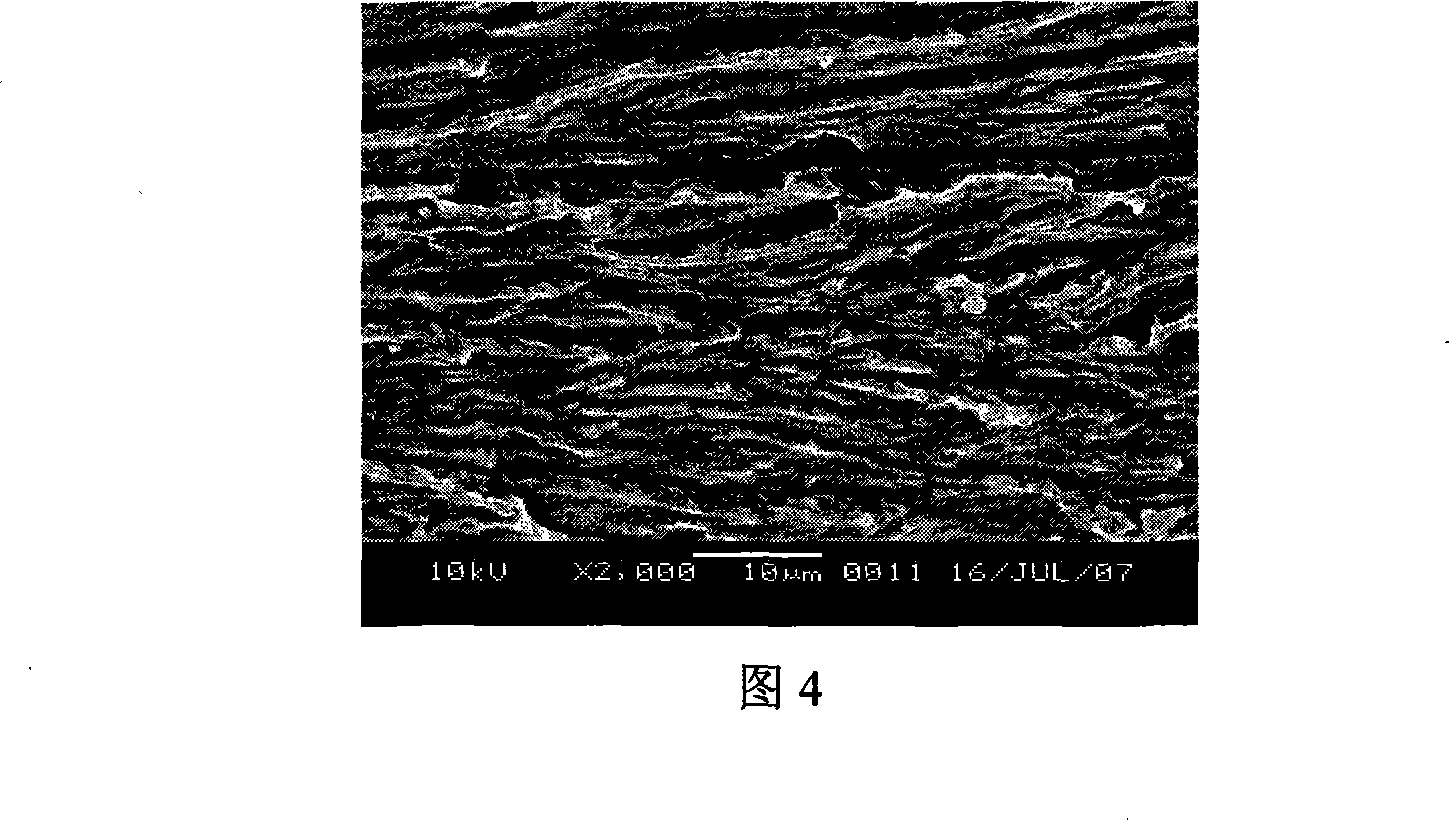

[0028] The shape of the PEG plasticized PLA sample prepared by injection molding and the processed shape (as shown in Figure 1) and the schematic diagram of the self-made mold processing process (as shown in Figure 2), the impact section of the unprocessed PEG plasticized PLA sample (as shown in Figure 3 ).

Embodiment 2

[0030] According to the method described in Example 1, PEG-plasticized PLA strips with different crystallization times at 80°C were kept at 70°C and a pressure of 250 MPa for 5 minutes. The mechanical properties of the strips without heat treatment after molding are shown in Table 1.

[0031] Table 180°C Mechanical properties of molded strips without heat treatment at different crystallization times

[0032] Crystallization time of the strip at 80°C

Embodiment 3

[0034] According to the method described in Example 1, the PEG-plasticized PLA strips crystallized for 2.5 minutes were kept at 250 MPa for 5 minutes under different temperature conditions. The mechanical properties of the molded strips without heat treatment are shown in Table 2.

[0035] Table 2 Mechanical properties of unheated strips after molding at different processing temperatures

[0036] Spline processing temperature (°C)

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com