Patents

Literature

93results about How to "Little degree of degradation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

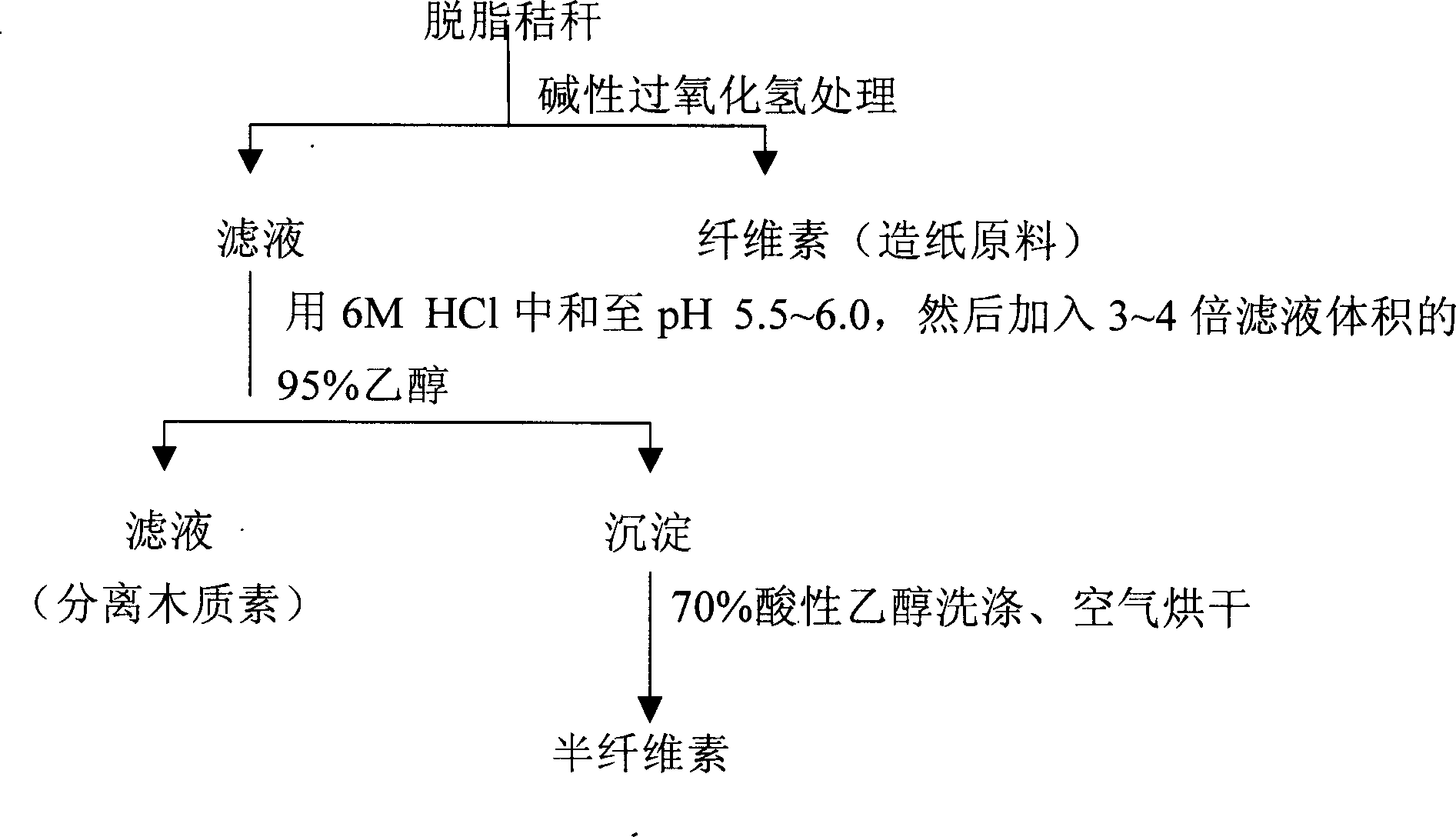

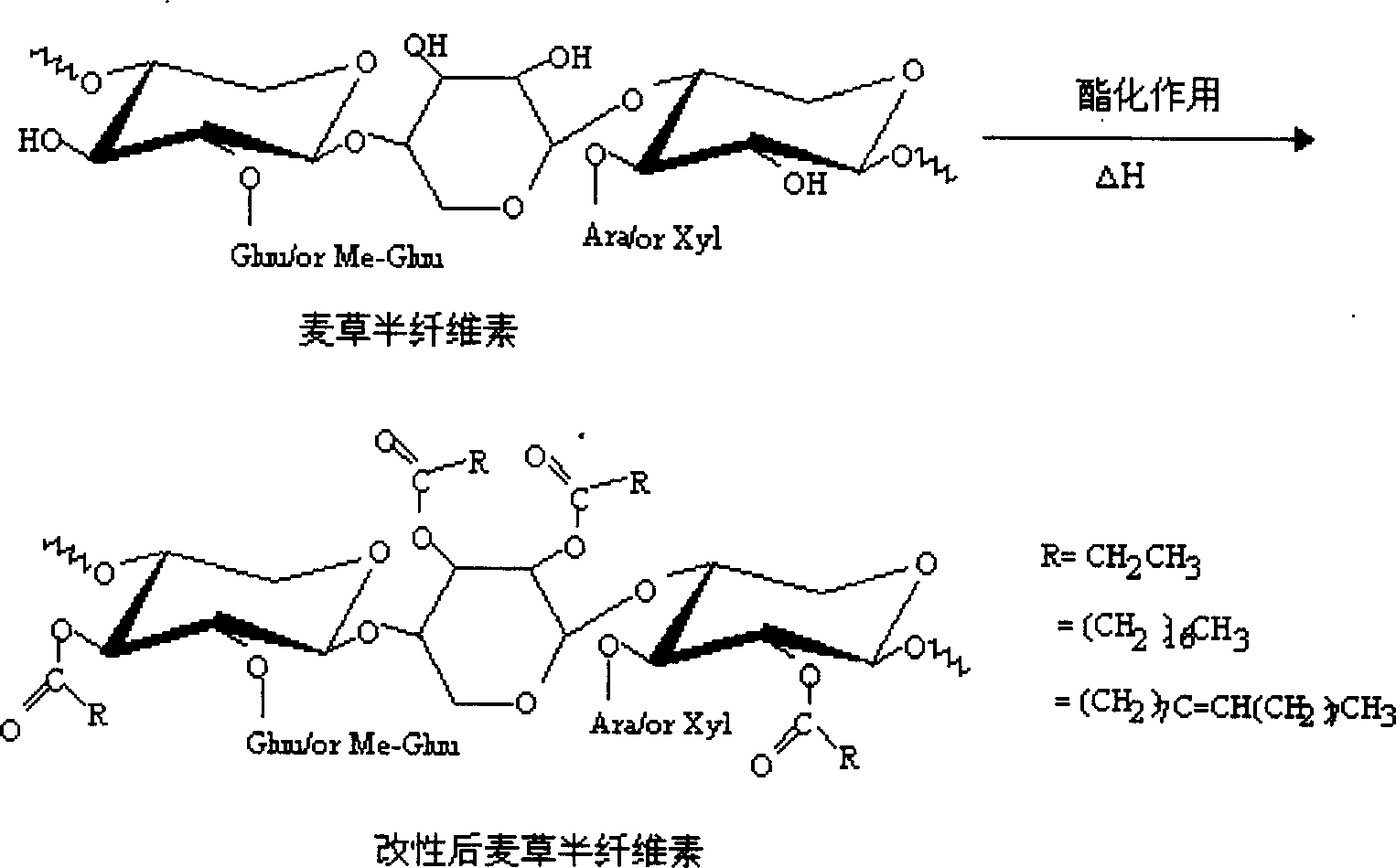

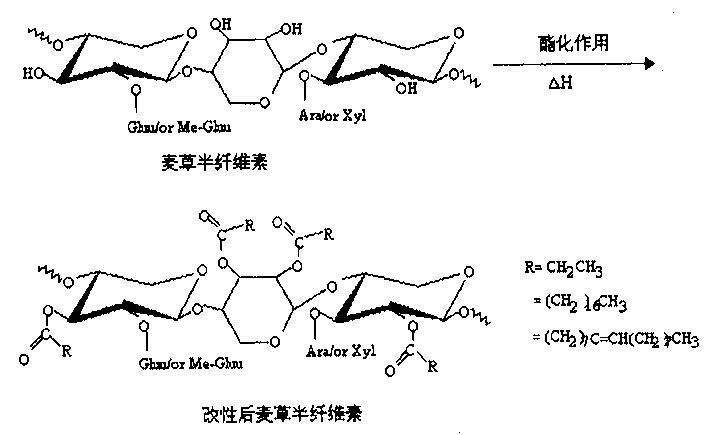

Homogeneous chemical modification of hemicellulose of stalks

A homogeneous process for chemically modifying the straw's hemicellulose includes such steps as extracting hemicellulose from straw by H2O2, activating by distilled water, adding acid chloride, reacting in homogeneous medium system (N, N-dimethylformamide / lithium chloride), adding the reacted mixture to alcohol, filtering, washing and baking. Its advantages are less environmental pollution, high speed and output and low cost.

Owner:SOUTH CHINA UNIV OF TECH

Waterproof nanometer aqueous coating

InactiveCN104673028AImprove water qualityHigh hardnessAntifouling/underwater paintsPaints with biocidesTin dioxideAluminum silicate

The invention discloses a waterproof nanometer aqueous coating. The coating comprises, by weight, 7 parts of nanometer magnesium dioxide, 5 parts of nanometer titanium dioxide, 6 parts of nanometer alumina, 6 parts of nanometer silica, 8 parts of nanometer ferrum dioxide, 8 parts of nanometer copper dioxide, 8 parts of nanometer tin dioxide, 8 parts of nanometer zinc dioxide, 8 parts of sodium dioxide, 8 parts of active carbon, 5 parts of a pure acrylic copolymer emulsion, 5 parts of rutile titanium dioxide, 3 parts of diatomite, 5 parts of aluminum silicate, 4 parts of gypsum powder, 1 part of a thickener, 1 part of a dispersant, 0.5 parts of ethanol modified polyurea, 0.2 parts of propylene glycol, 0.3 parts of glycerin, 2 parts of polyurethane and 2 parts of isopropanol. All nanometer materials especially added in the invention reduce agglomeration reactions and make the coating have an efficient lasting antibacterial property. The coating has the advantages of small degradation degree, stability, long service life, safety, environmental protection, adsorption of toxic gases, and sound insulation.

Owner:胡建辉

Preparation method of hydrogenated C9 petroleum resin

The invention relates to a preparation method of hydrogenated C9 petroleum resin, which is characterized by comprising the following steps of: (1) preparation of supported noble metal hydrogenated catalyst: preparing by using a coating method, selecting noble metal palladium and platinum and transition metal cobalt or nickel as metal active components, preparing a spherical alumina supporter, then coating the active components of palladium and platinum and transition metal on the alumina supporter, and activating to obtain a hydrogenated catalyst; (2) selective hydrogenation: desulfurizing and denitrifying; (3) high pressure hydrogenation reaction: controlling the weight ratio of resin to solvent to ensure that the concentration of resin is 20-40% by weight, taking chain-like or annular saturated hydrocarbon or aromatic hydrocarbon or hydrocarbon mixture as a solvent, and taking a supported noble metal hydrogenated catalyst as a catalyst, wherein the temperature of the high pressure hydrogenation reaction is 250-350 DEG C, the pressure is 8.0-20.0 MPa and the liquid volume space velocity is 0.5-2h<-1>. The properties of the final product hydrogenated C9 petroleum resin are as follows: Gardner is not more than 1, and the softening point is not smaller than 100 DEG C.

Owner:CHINA NAT OFFSHORE OIL CORP +1

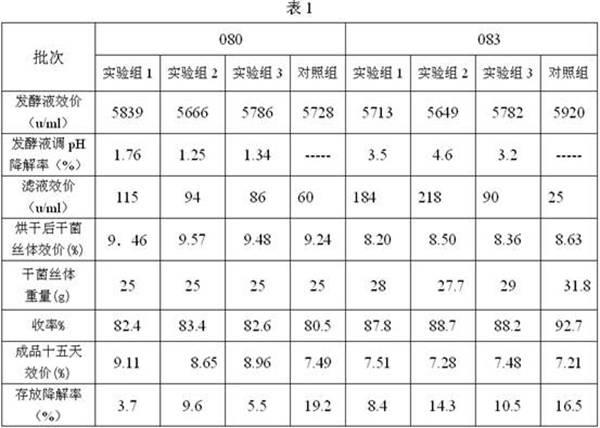

Method for pretreating enramycin fermentation liquor and method for preparing enramycin premix by using enramycin fermentation liquor

ActiveCN102633865ALow costLittle degree of degradationAnimal feeding stuffMicroorganism based processesAluminium saltsAluminum sulphate

The method discloses a method for pretreating an enramycin fermentation liquor. The method comprises the following steps of: before extracting enramycin from the enramycin fermentation liquor, firstly adjusting the pH value of the fermentation liquor to a range of 4.0 to 7.0 by using an acid, and then adding aluminum sulfate accounting for 0.8-1.0% the weight of the fermentation liquor. The invention also discloses a method for preparing an enramycin premix. The method, compared with the existing enramycin production technique, is mainly characterized by pretreating the fermentation liquor of the enramycin so as to improve the quality of the finished product of the enramycin premix. The method for preparing the enramycin premix disclosed by the invention is simple and easy to implement and low in cost; and compared with the finished product without being subjected to pretreatment, the degradation degree of the enramycin obtained through the pretreated fermentation liquor is obviously reduced and the stability of the obtained enramycin premix finished product in the storage process is obviously improved. Furthermore, by adopting the method for preparing the enramycin premix disclosed by the invention, the enramycin finished product is more convenient and stable for storing, transporting and applying.

Owner:山东胜利生物工程有限公司

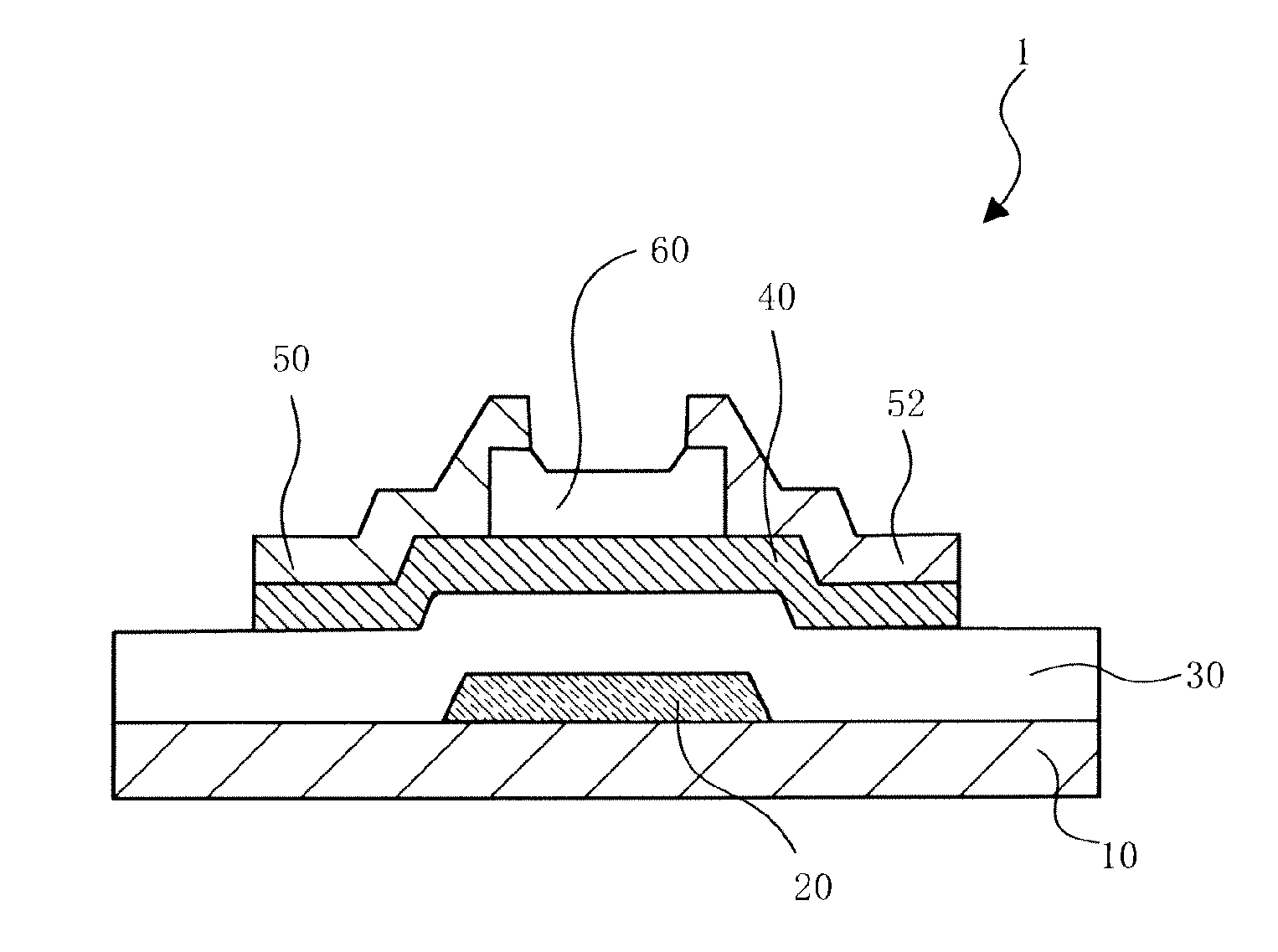

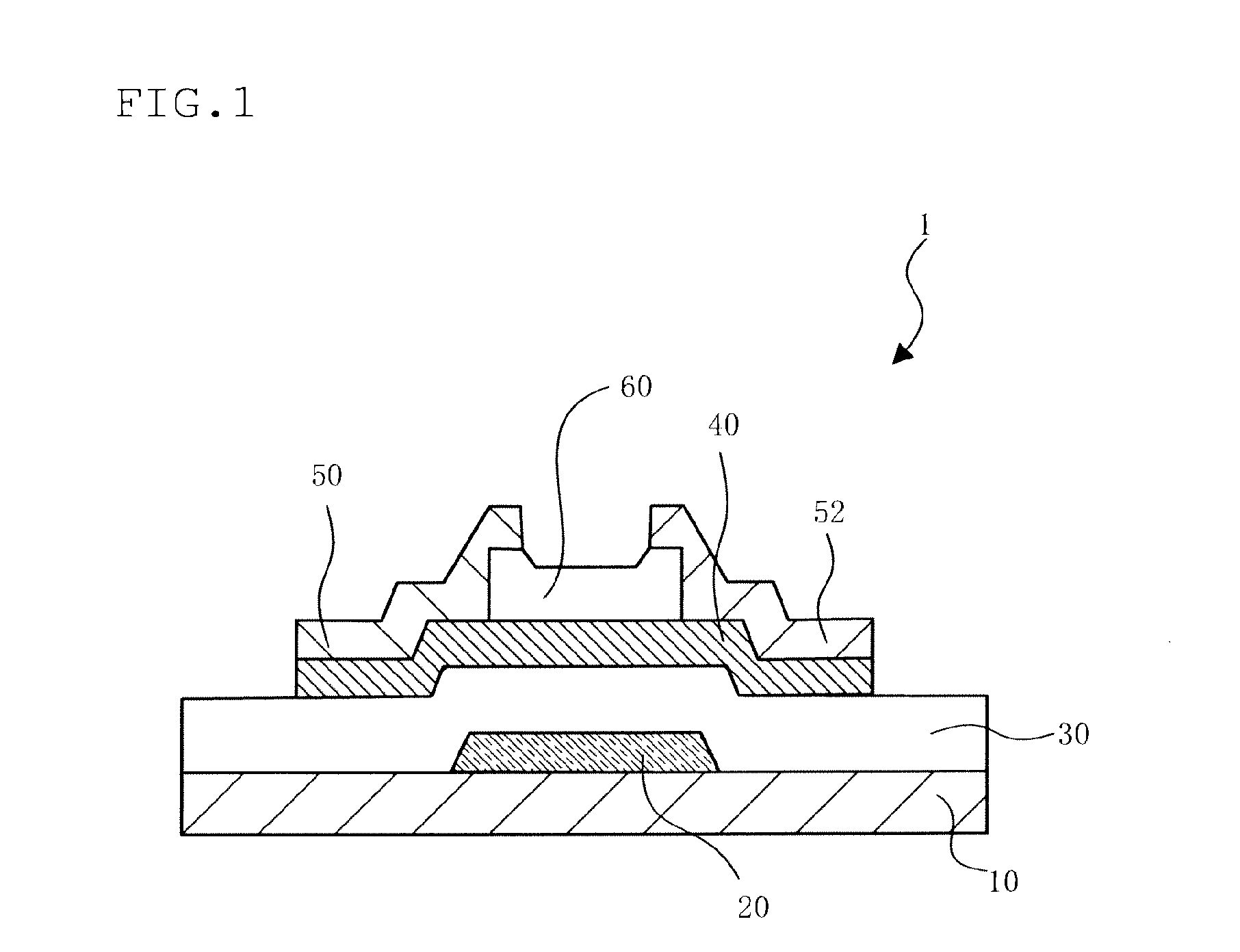

In-Ga-Sn OXIDE SINTER, TARGET, OXIDE SEMICONDUCTOR FILM, AND SEMICONDUCTOR ELEMENT

ActiveUS20120313057A1Improve the immunitySelectivity of wetConductive materialVacuum evaporation coatingIndiumGallium alloy

Owner:IDEMITSU KOSAN CO LTD

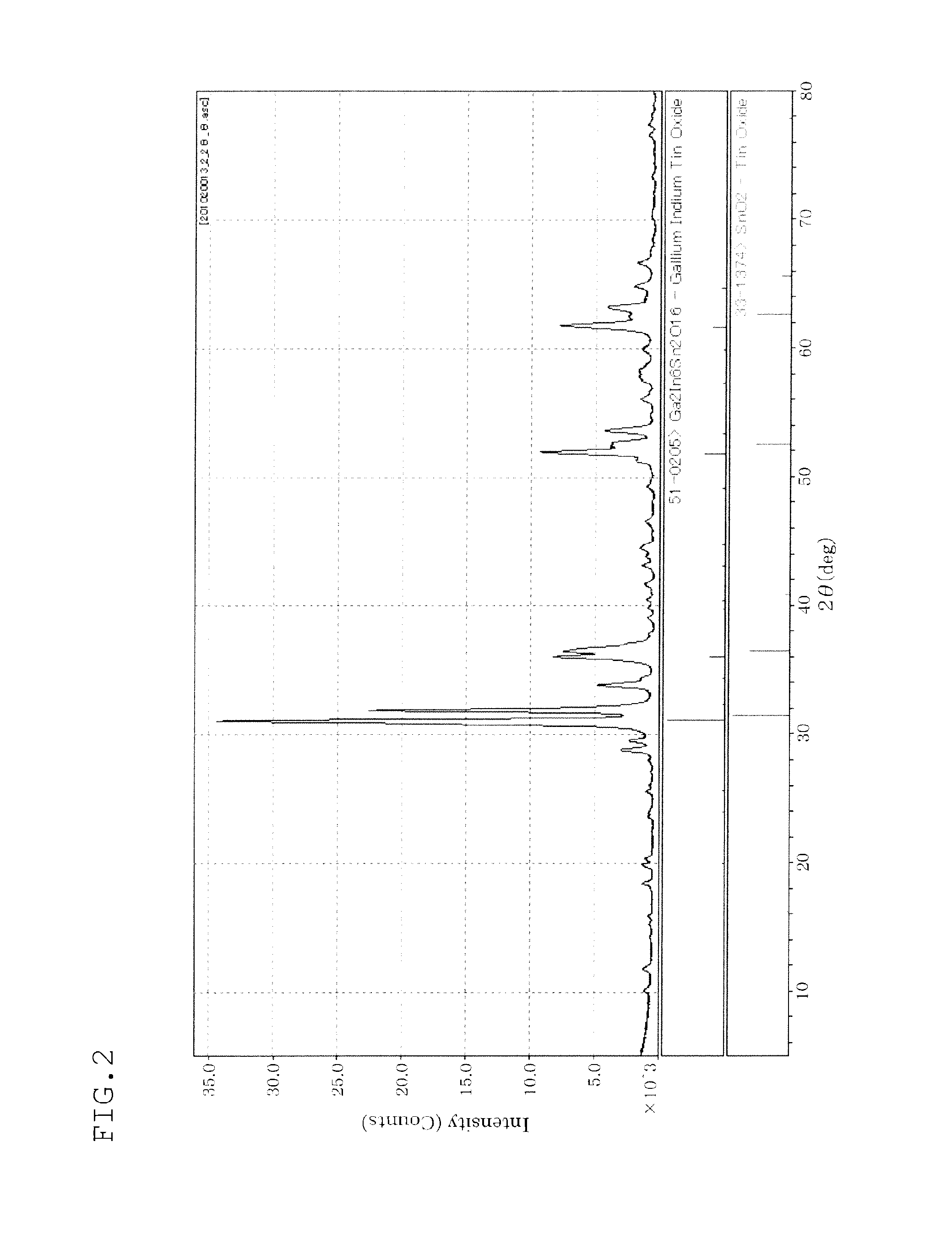

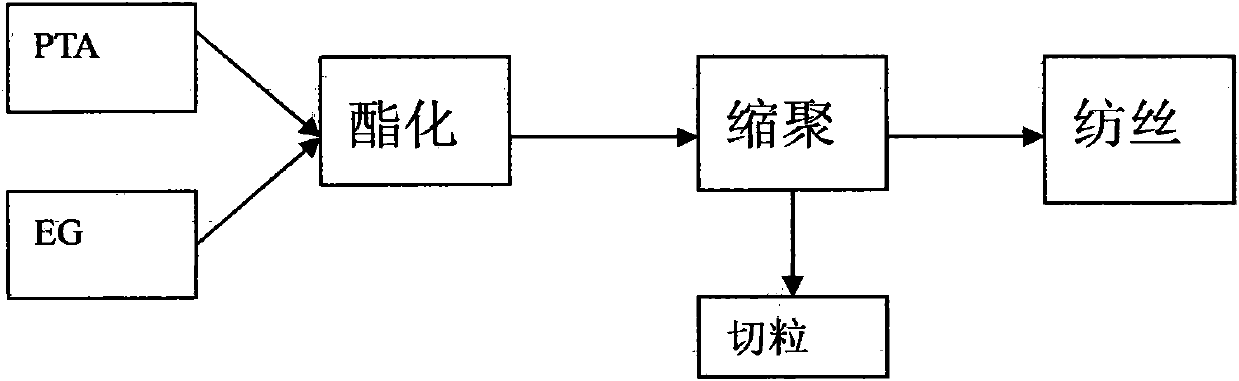

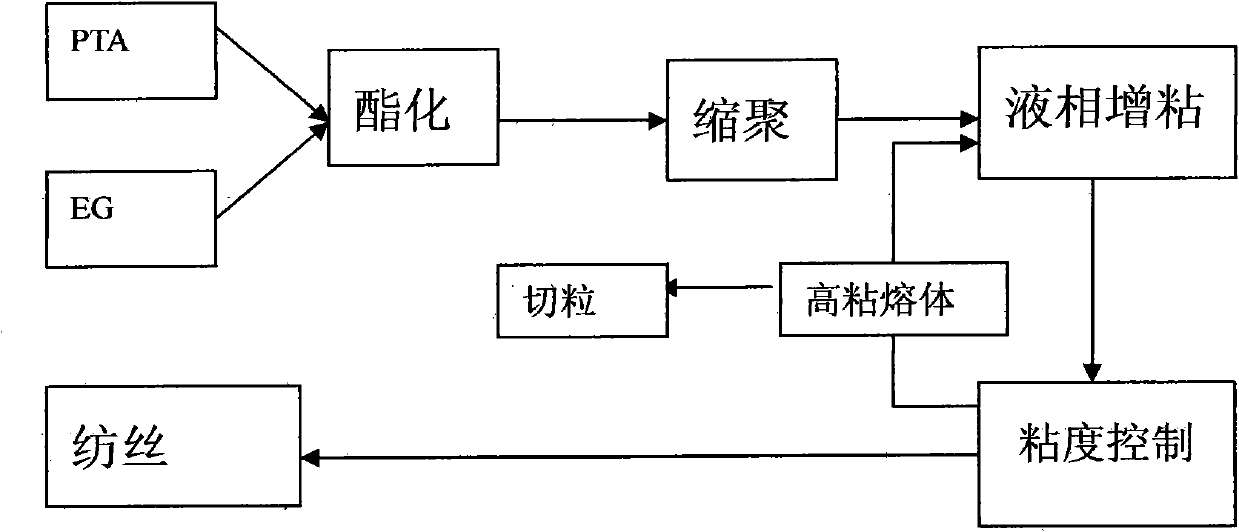

Production process for directly-spun terylene industrial filament of liquid-phase tackifying fusant

ActiveCN101768788AEasy to degradeReduce manufacturing costFilament forming substance formingMelt spinning methodsChemistryPolyester

The invention discloses a production process for a directly-spun terylene industrial filament of a liquid-phase tackifying fusant, belonging to the technical field of spinning. The production process includes the following steps: esterification, polycondensation, liquid-phase tackification and spinning. The production process is characterized in that: in a vertical reaction kettle, liquid-phase tackfication is carried out on the fusant obtained through esterification and polycondensation of glycol and phthalic acid; the vertical reaction kettle adopts a tower type film forming structure; the fusant enters the vertical reaction kettle from the top part for distribution, and the film forming is naturally finished under the action of gravity; a backflow pipeline is provided for the discharging of the reaction kettle, the viscosity and flow rate of the fusant are controlled by the backflow adjusting, the intrinsic viscosity of the polyester fusant after being tackified in a liquid-phase manner is within 0.85 to 1.0dl / g, and the fusant is conveyed to a spinning box body by a gear pump for spinning. By reasonably designing the reaction kettle and allocating the process, the invention effectively solves the consistency between the fusant reacting condition and the staying time; meanwhile, the consumption of a public medium is reduced, and the cost is lowered; by optimizing the process, the invention increases the production efficiency of a system and improves the product quality.

Owner:ZHEJIANG GUXIANDAO POLYESTER DOPE DYED YARN CO LTD

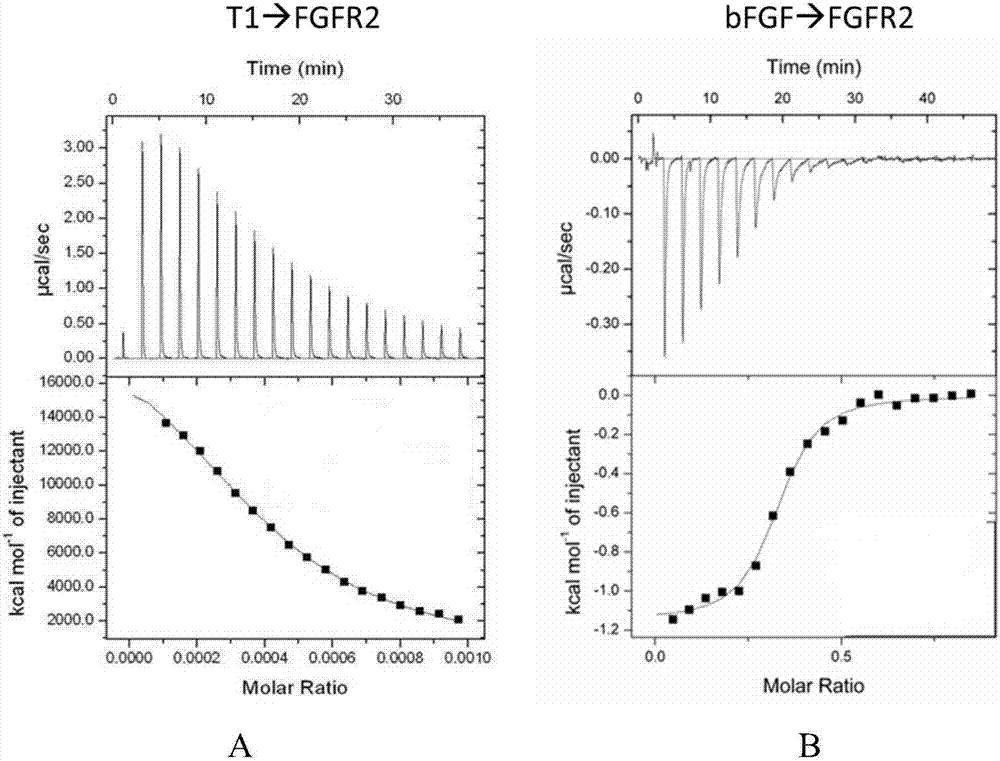

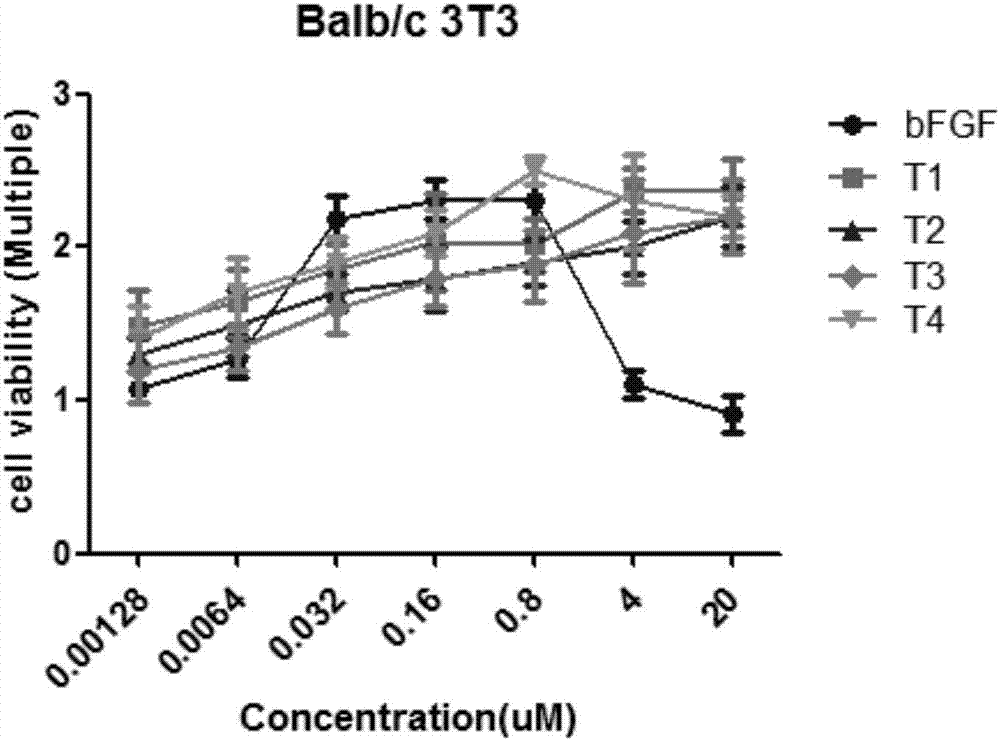

Small molecular polypeptide promoting skin damage repair and application thereof

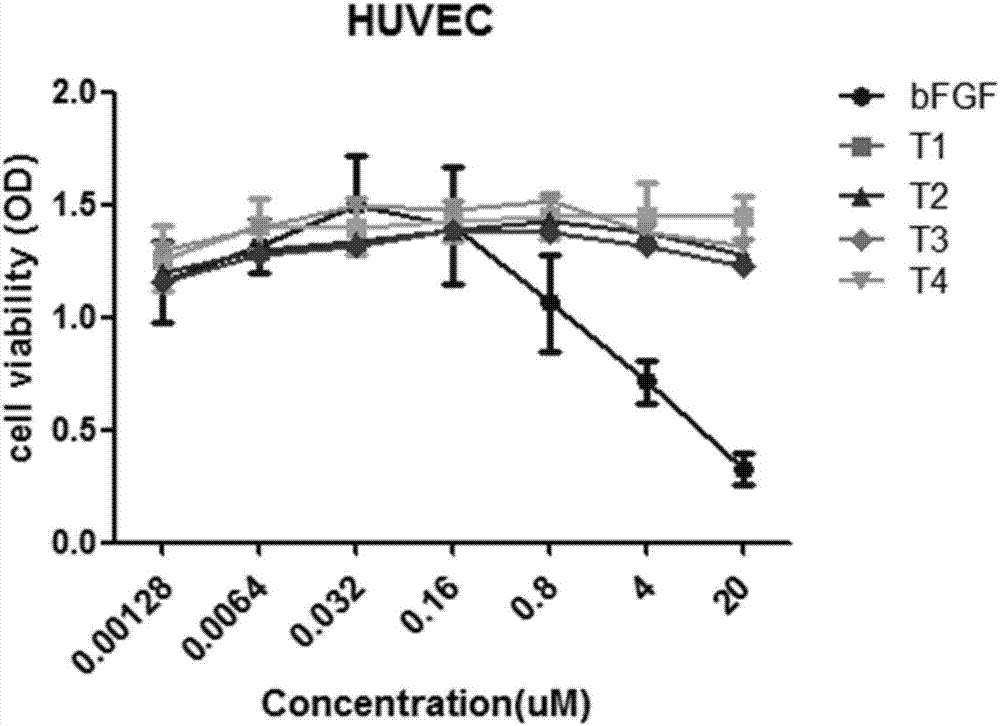

ActiveCN107973838AHigh affinitySmall molecular weightCosmetic preparationsPeptide/protein ingredientsCyclic peptideChemical synthesis

The invention discloses a small molecular polypeptide promoting skin damage repair and application thereof, belonging to the field of biological medicines. The small molecular polypeptide is consecutive four or more linear peptides or cyclic peptides of the length of 4-12 consecutive amino acid containing a core sequence of SNFLHLG. Compared with the existing similar product-a recombined bFGF forexternal use, the small molecular polypeptide has equivalent proliferation effect but higher affinity and smaller molecule weight; the small molecular polypeptide adopts a chemical synthesis method rather than a genetic engineering method, so that under the use condition of equal molar concentration, the production cost and use cost are lower, therefore, the small molecular polypeptide promoting skin wound repair and cell proliferation is an ideal product replacing the recombined bFGF. Compared with the bFGF, the polypeptide provided in the invention has several or a dozen of amino acid, thereby being decomposed much more easily; further, experimental results disclosed in the invention show that the polypeptide can keep acting on a to-be-treated position, thereby having technological advancement.

Owner:广州恒宁生物科技有限公司

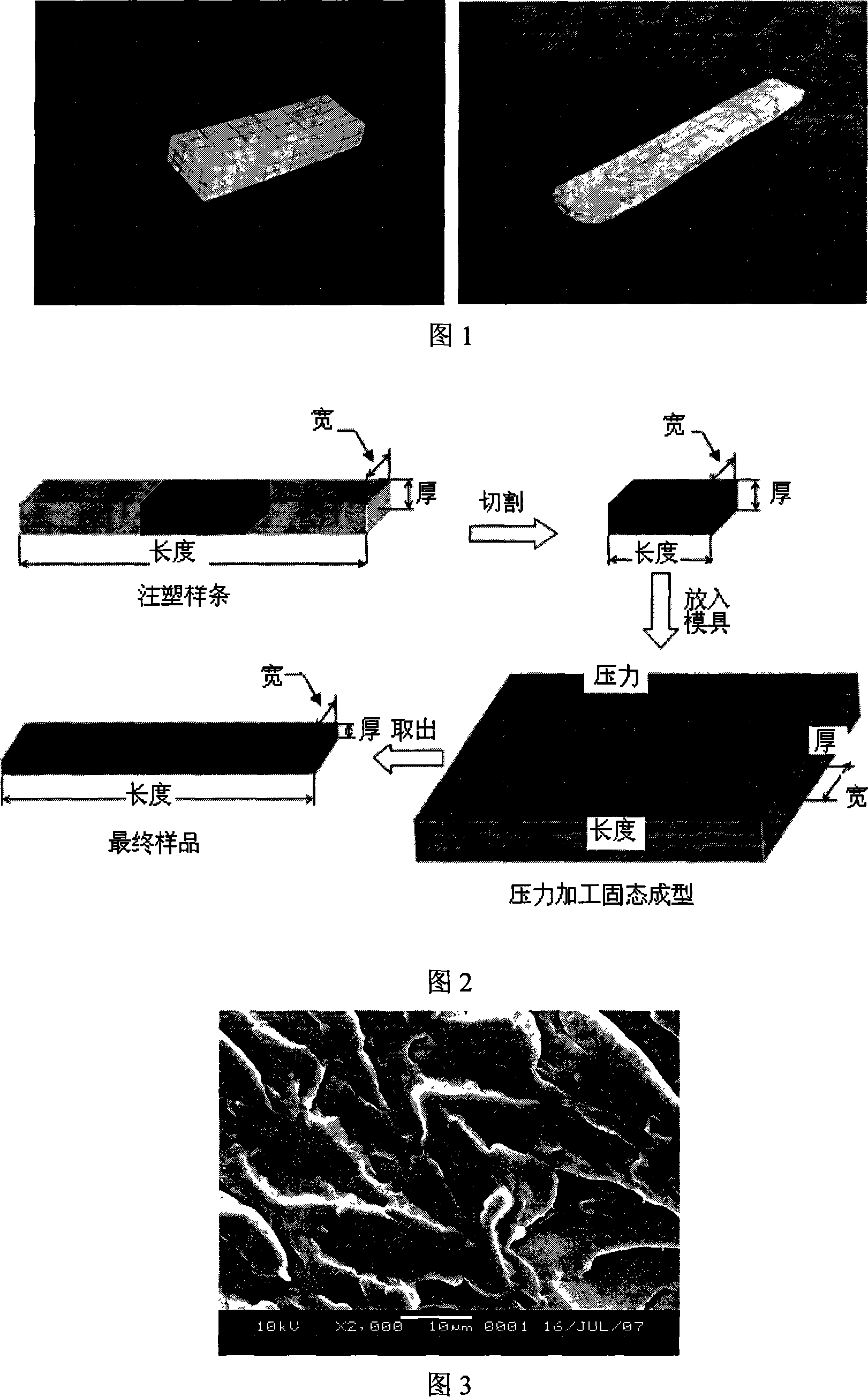

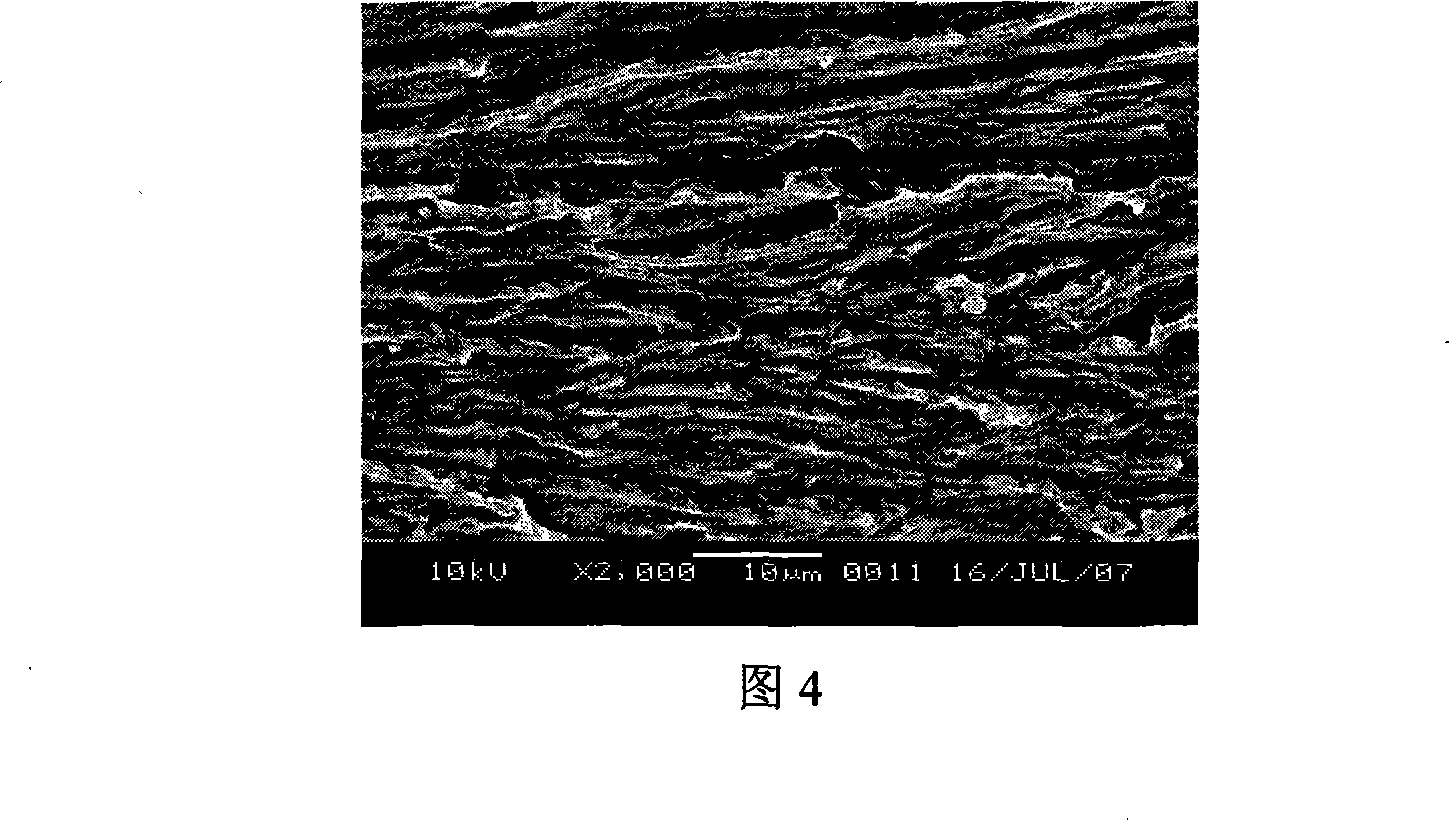

Method for improving polyglycol plasticization polylactic acid strength of materials capability by process

InactiveCN101195273AImprove performanceImprove bending performancePolyethylene glycolStrength of materials

The invention relates a press-working and solid forming method for improving the mechanical properties of polylactic acid (PLA) material plasticized with polyethylene glycol (PEG). The steps include: (1) preparation of PLA spline plasticized with PEG; (2) press-working and solid forming of the PLA spline plasticized with PEG; (3) heat treatment after the forming. The impacting property of PLA plactics plasticized with PEG can be increased by dozens of times, the stretching property can be increased by two times, solid motion of samples occurs by employing the method to give force on the samples, and in the process of solid motion, the internal microstructure of the material is improved, thereby achieving the purpose of improving the mechanical properties.

Owner:DONGHUA UNIV

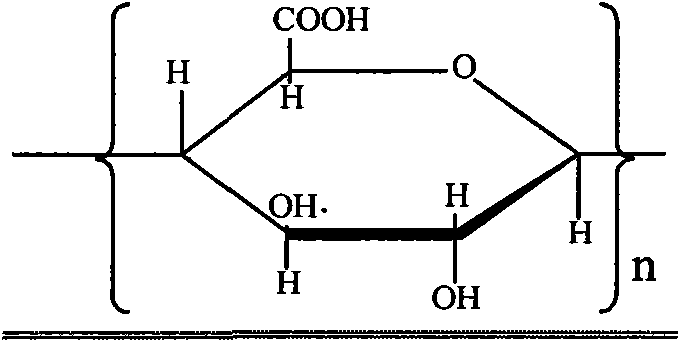

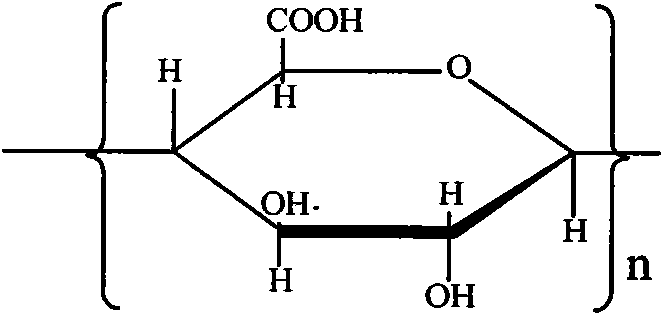

Medical absorbable oxycellulose material and preparation method thereof

The invention belongs to the technical field of a biologically medical material, and concretely relates to a medical absorbable oxycellulose material and a preparation method thereof. The material has dual functions of stopping bleeding and restoring wound. The material takes natural cellulose as a raw material, and is oxidized by an oxidation system under certain technology condition, the obtained product is subjected to acid treatment, washing by water and drying to prepare the medical absorbable oxycellulose material. The oxidation system has the advantages of strong selectivity, mild and controllable condition, and environmental protection of preparation technology. The prepared material has the advantages of rapidly stopping bleeding and rapidly being absorbed, has wound restoration function, can promote the healing of wound, and has wide application value on medical science.

Owner:HEBEI AINENG BIOTECH CO LTD

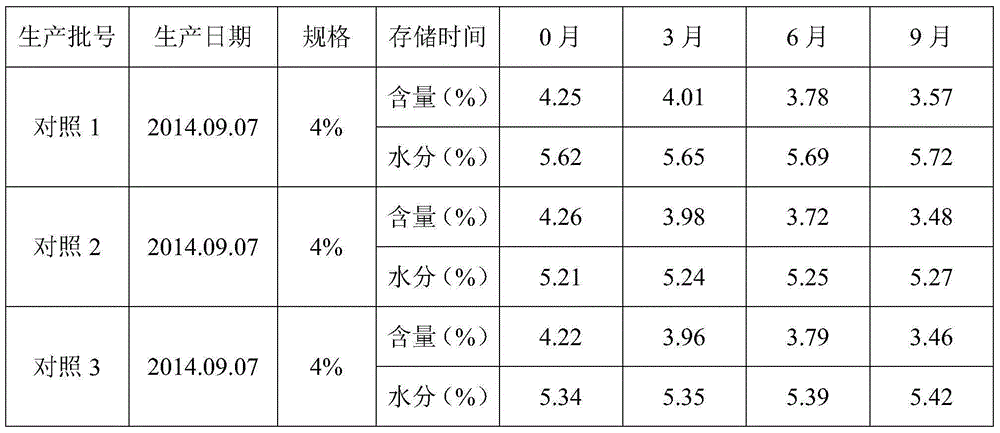

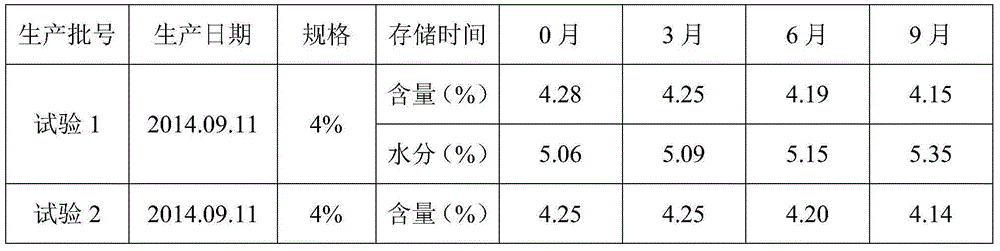

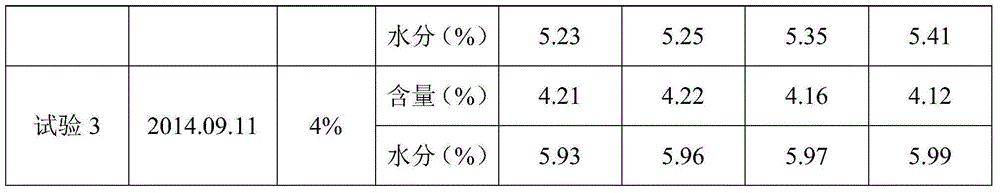

Method for preparing enramycin premix

InactiveCN105104761AChange stabilityImprove stabilityFood processingAnimal feeding stuffAntioxidantEnramycin

The invention discloses a method for preparing enramycin premix. The method comprises the steps that the temperature of enramycin fermentation liquor is firstly increased to 70-75 DEG C, then complex antioxidants of which the mass accounts for 0.5-1.0% of that of the enramycin fermentation liquor and filter aid of which the mass accounts for 0-12% of that of the enramycin fermentation liquor are added, and the mixture is stirred fully and evenly; frame filter and flash drying are performed on the evenly stirred mixture, auxiliary materials are added in the mixture for dilution, and then the enramycin premix is prepared. The method is simple, easy to operate and low in cost, and compared with finished enramycin premix which is not preprocessed, the enramycin premix has the advantages that the degradation degree is obviously weakened and the stability is obviously improved.

Owner:SHIJIAZHUANG GAOKE ANIMAL HEALTH PROD CO LTD

Compatilizer for cellulose material reinforced composite material and preparation method for compatilizer

The invention relates to a compatilizer for a cellulose material reinforced composite material and a preparation method for the compatilizer, and belongs to the technical field of high polymer material modification. A reaction interface compatilizer is prepared by cografting acrylate monomers, styrene, an initiator, polyolefin, a bonding agent and the like on the polyolefin through a solid-phase grafting method. The compatilizer has the advantages that the grafting ratio of functional monomers on a polymer substrate main chain is high, the functional monomers can form covalent bonds with hydroxyl on the surface of a cellulose material efficiently, and the dispersibility of the cellulose material in a plastic substrate is promoted; meanwhile, the macromolecular main chain has proper molecular weight, can be subjected to chain entanglement with the plastic substrate in the composite material to improve the compatibility, has high melting fluidity, can effectively infiltrate the composite material during processing, is closely meshed at the interface to form an interface layer for effectively transmitting stress and effectively relieves fine cracks generated due to deformation of the material, the mechanical properties and water resistance of the composite material are improved, and the application range of the composite material in various fields is widened.

Owner:SHANGHAI UNIV

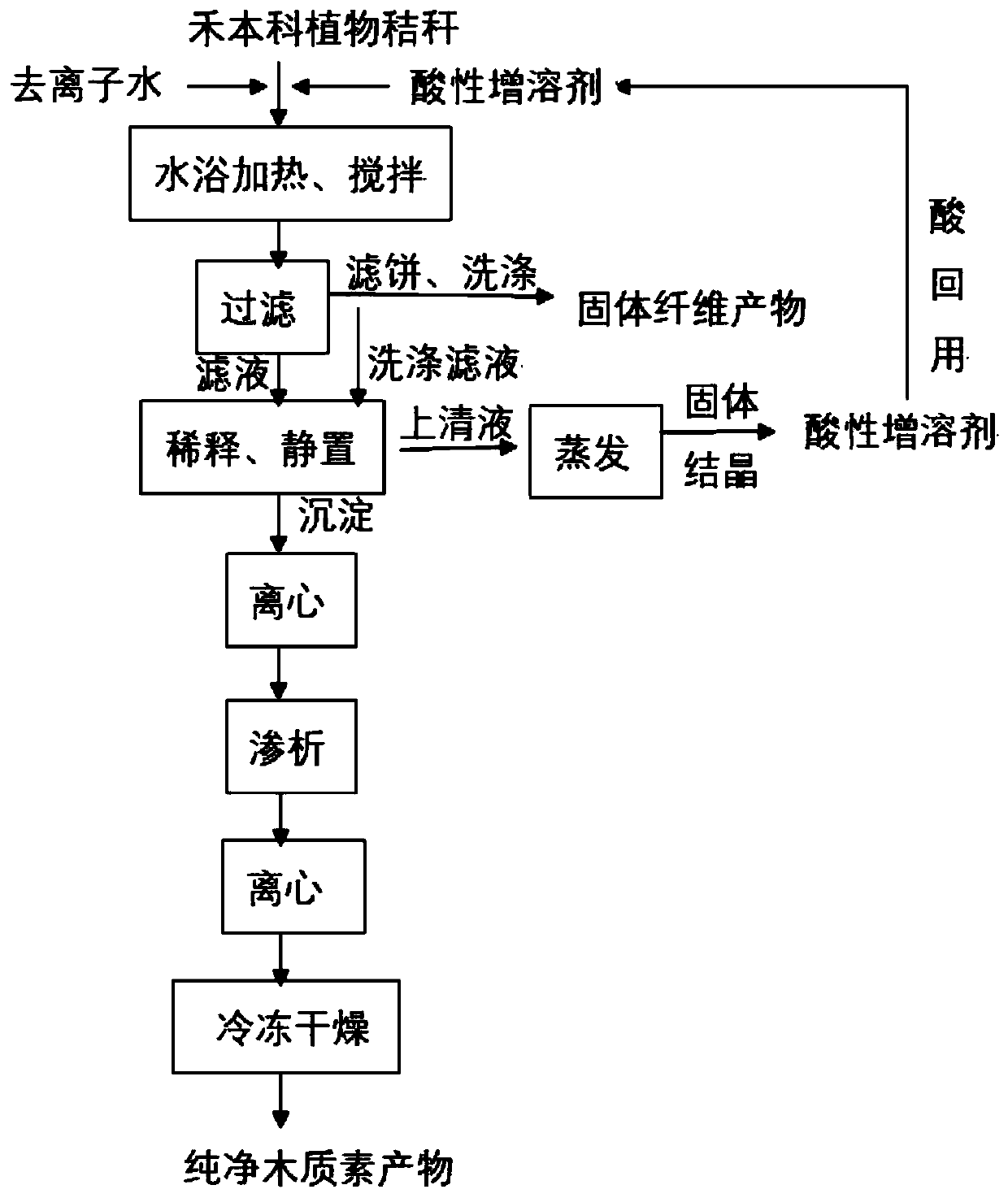

Method for separating chemical components of grass family plants and purifying lignin

The invention provides a method for separating chemical components of grass family plants and purifying lignin. According to the method, grass family plant straw is taken as raw materials, the ligninis dissolved through an acid solubilizer, through the steps of filtering, washing, diluting, still standing and centrifuging, a cellulose solid product and a lignin sediment are obtained, and the sediment is subjected to dialysis to obtain the pure lignin. The convenient-to-recover acid solubilizer is utilized, thus the plant components can be effectively separated, the method is an environment-friendly technology, the chemical components of the grass family straw are separated under the condition of low temperature and short time, a high-temperature and high-pressure pressure vessel is not needed, the production cost can be saved, the production efficiency is improved, and energy consumption is reduced.

Owner:NANJING FORESTRY UNIV

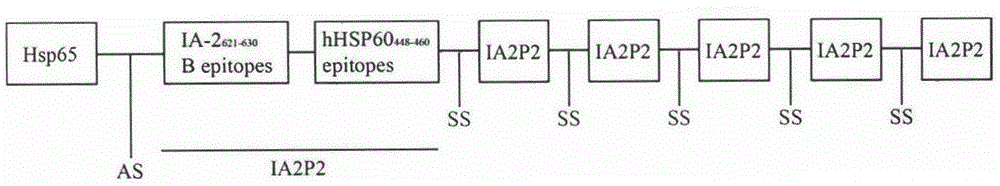

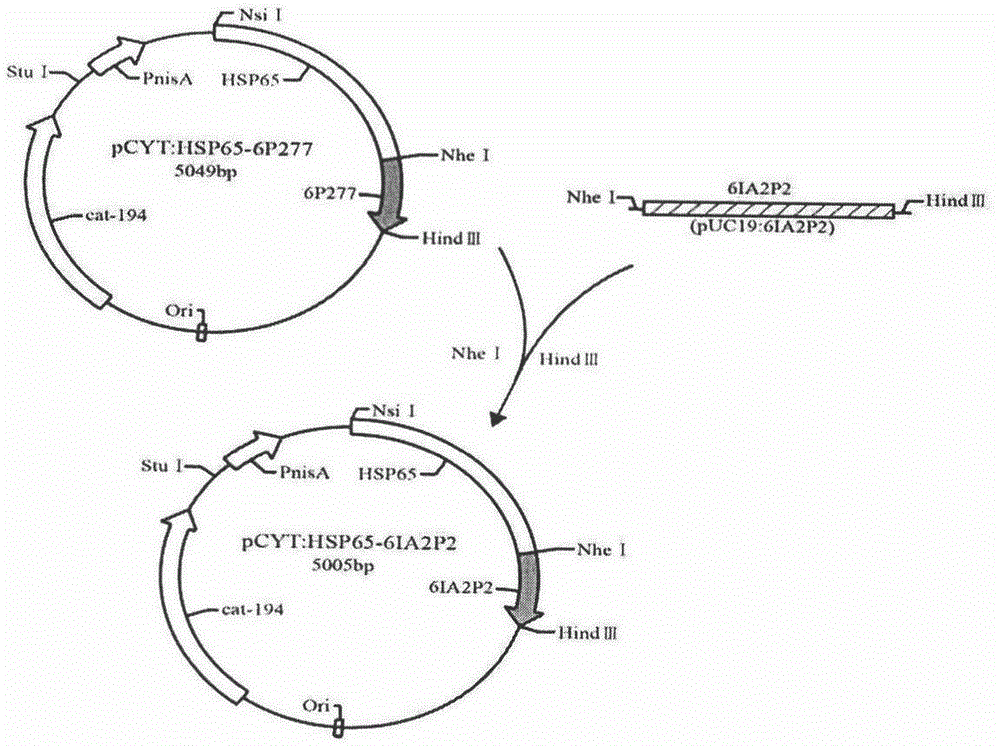

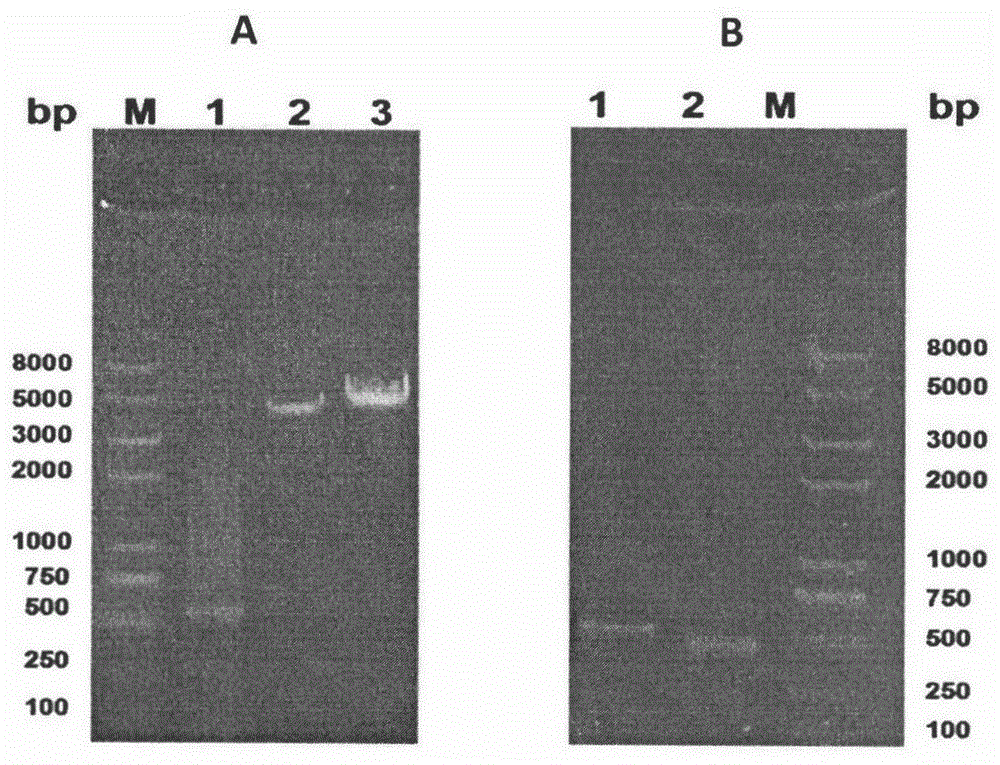

Recombination lactic acid bacteria and application thereof

InactiveCN105255800AImproving immunogenicityHigh titerBacterial antigen ingredientsBacteriaWestern blotIn vivo

The invention relates to novel I-type diabetes resisting recombination lactic acid bacteria and application thereof, belongs to the field of biological medicine, and discloses an I-type diabetes resisting vaccine with lactococcus lactics as a carrier and a preparing method and application of I-type diabetes resisting vaccine. A micro genetic technology platform of a laboratory is used, the recombination lactococcus lactics vaccine with lactococcus lactics as the carrier, and the recombination lactococcus lactics vaccine expresses fusion protein HSP65-6IA2P2 after induction. The correct expression of the fusion protein vaccine is detected through Western blot authentication. It is proved through in-vivo animal experiments that the vaccine can remarkably reduce the occurrence of NOD mouse diabetes through an oral administration way, can perform the function of controlling I-type diabetes and has good clinical application prospects on preventing diabetes.

Owner:CHINA PHARM UNIV

Nano waterproof decorative material

The invention discloses a nano waterproof decorative material which is composed of the following components in parts by weight: 20-25 parts of elastic emulsion, 1-3 parts of wetting agent, 0.5-3 parts of dispersant, 1.5-3 parts of thickener, 3-10 parts of flame retardant, 0.1-5 parts of defoaming agent, 0.1-3 parts of bactericide, 10-20 parts of kieselguhr, 10-25 parts of open-pore expanded perlite, 2-6 parts of nano silicon dioxide, 3-5 parts of nano ferrum dioxide and 1-4 parts of pigment. The pigment is any one or more of rutile titanium white, anatase titanium white or lithopone. The product has the advantages of small degradation degree, high stability and long service life; and all the production raw materials are environment-friendly, and thus, no waste water, waste gas, waste slag or pollution is generated in the production and construction process.

Owner:QINGDAO LONGMEI ELECTROMECHANICAL TECH

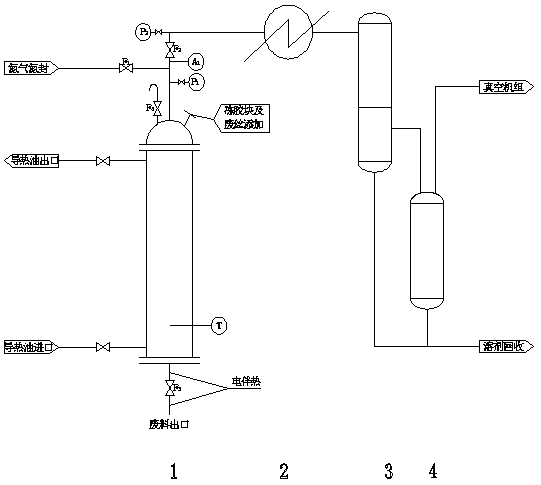

Recovery processing method of ultrahigh molecular weight polyethylene dry spinning jelly and waste fiber solvent

ActiveCN103628184AHigh recovery rateLittle degree of degradationArtificial filament recoveryTextile/flexible product manufactureRecovery methodFiber

The invention relates to a recovery method used for extracting a solvent from waste, and especially relates to a solvent recovery processing method of ultrahigh molecular weight polyethylene jelly waste fiber. The solvent recovery method comprises following steps: a melting pot is used for melting jelly waste fiber and jelly; a rectification unit in a dry spinning solvent recovery system is used for recycling an organic solvent of the dry spinning solvent recovery system; and solid jelly blocks are recycled. The recovery processing method is capable of solving a problem that the waste jelly fiber solvent generated in ultrahigh molecular weight polyethylene fiber production processes can not be recycled; production cost is reduced; the recycled jelly material and waste fiber can be directly delivered to downstream processors for recycling; and the solvent recovery processing processes are performed in sealed environment, so that no environmental pollution is caused.

Owner:CHINA PETROLEUM & CHEM CORP +1

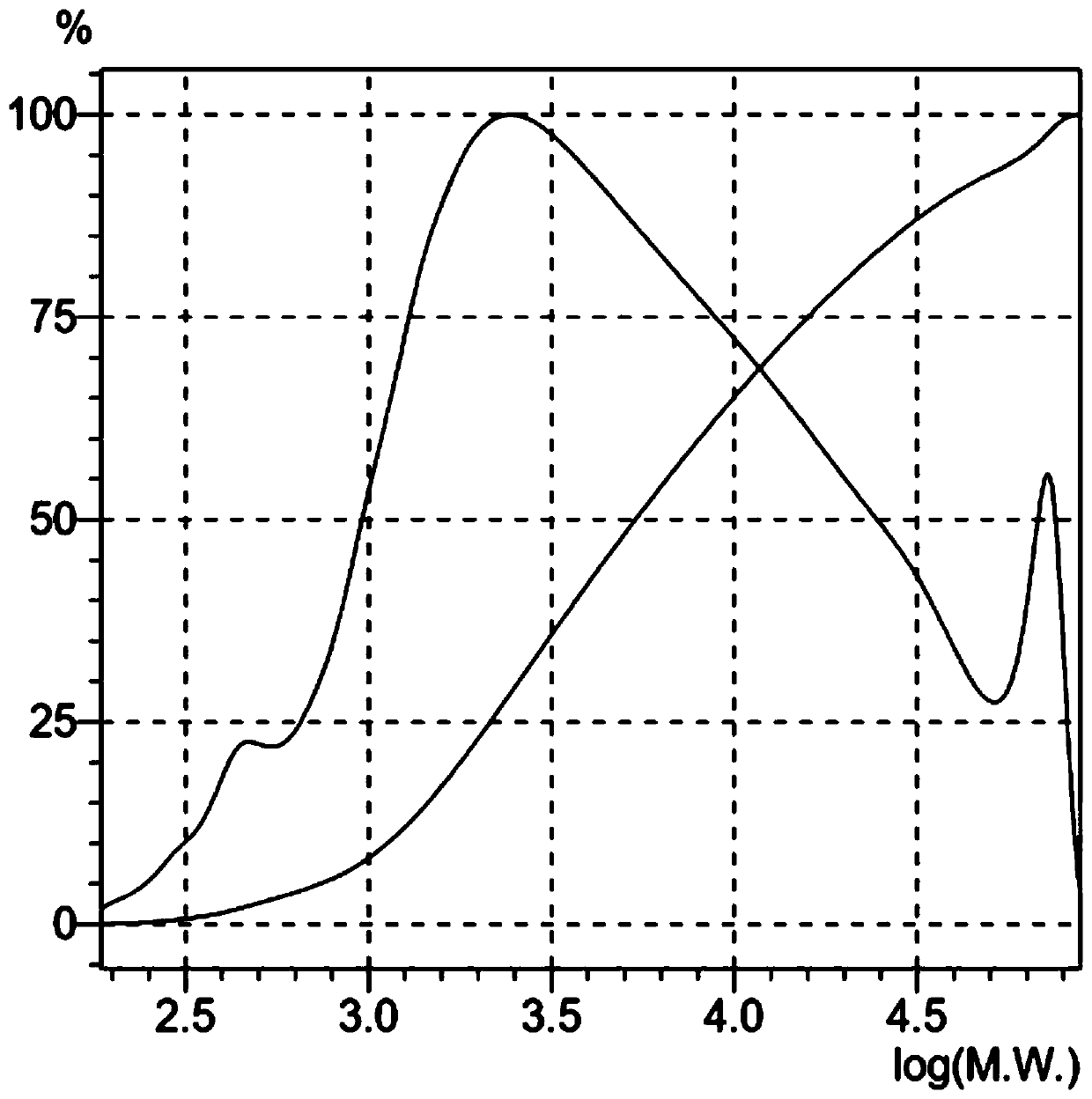

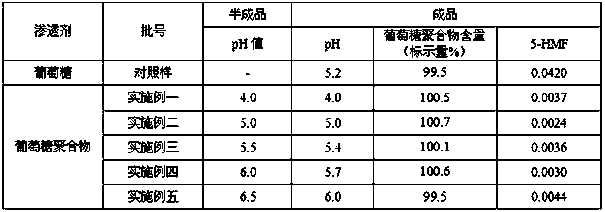

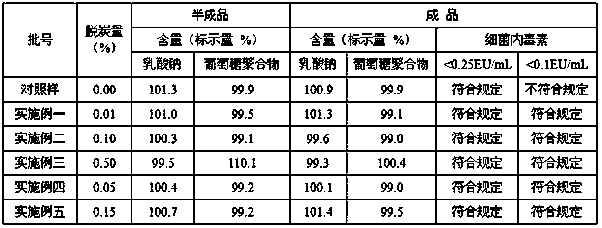

Glucose polymer peritoneal dialysis solution and preparation process thereof

InactiveCN107550928AAvoid damageImprove ultrafiltration effectAluminium/calcium/magnesium active ingredientsAnhydride/acid/halide active ingredientsThermal insulationUltrafiltration

The invention discloses a glucose polymer peritoneal dialysis solution and a preparation process of the glucose polymer peritoneal dialysis solution, belonging to the technical field of peritoneal dialysis. The glucose polymer peritoneal dialysis solution is prepared from the following components in parts by weight: 50-150 g / L of glucose polymer, 80-150 mEq / L of sodium ions, 80-110 mEq / L of chloride ions, 0-4.0 mEq / L of calcium ions, 0-4.0 mEq / L of magnesium ions, 10-45 mEq / L of lactate radical ions, and an appropriate amount of water for injection. The components are mixed and dissolved, active carbon is added, thermal insulation and adsorption are carried out, decarburization and filtering are carried out, the pH value is adjusted, filling is carried out, opening sealing is carried out,sterilization is carried out, and thus the product is obtained. Compared with the traditional peritoneal dialysis solution, the product provided by the invention has the advantage that little glucosedegradation products, especially 5- hydroxymethylfurfural, are generated, and injuries caused by the product to the peritoneum during clinical use of the product are reduced; meanwhile, the stabilityof the molecular weight of the glucose polymer is guaranteed, and the effective ultrafiltration during the long abdomen indwelling period is realized.

Owner:HUAREN PHARMACEUTICAL CO LTD

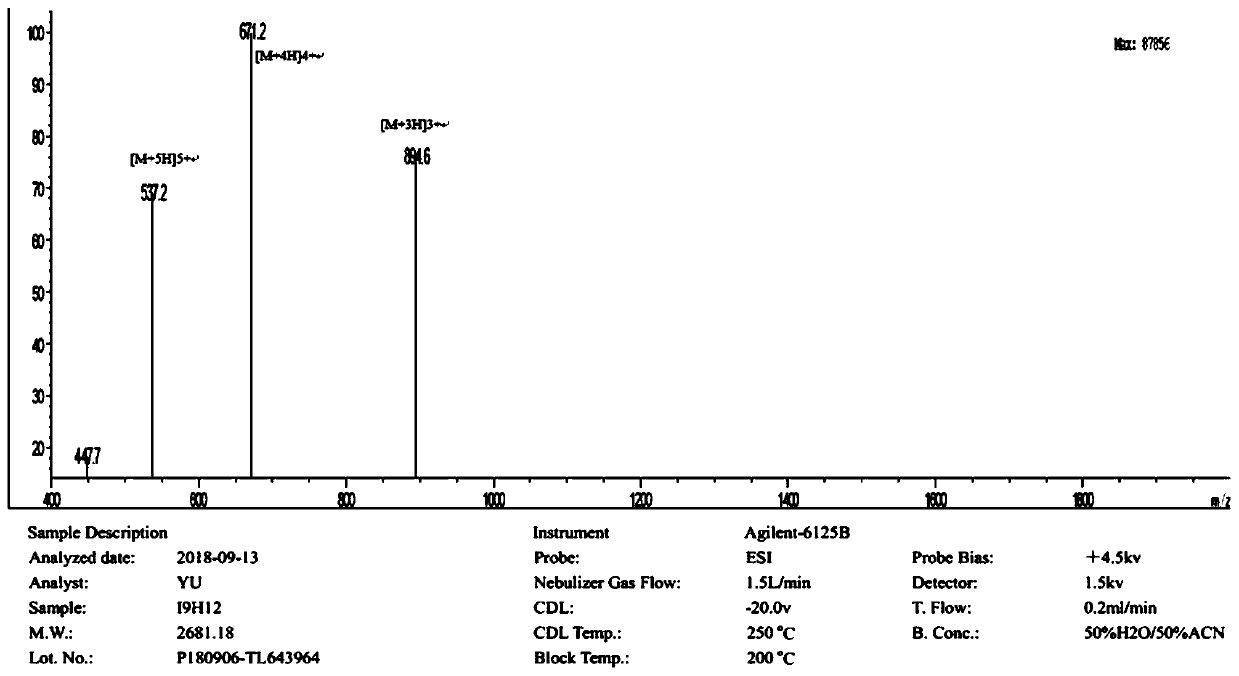

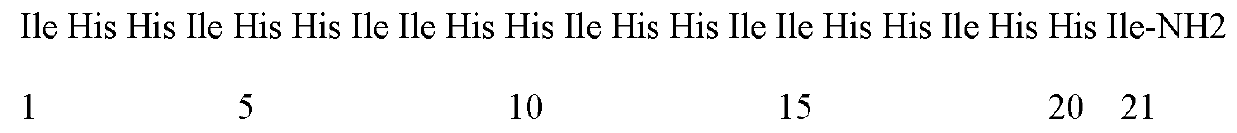

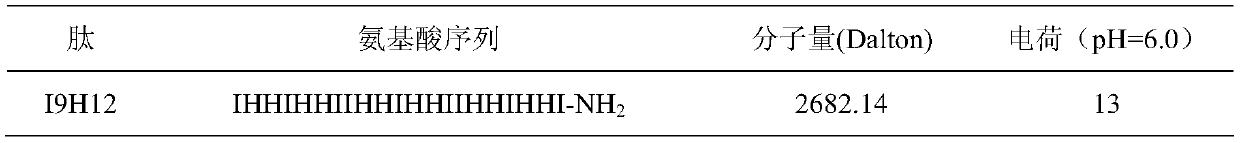

Enzymolysis-resisting antibacterial peptide I9H12 as well as preparation method and application thereof

ActiveCN109810178ASimple experimental techniqueHigh application potentialAntibacterial agentsAntimycoticsEnzyme digestionFungal Infectious Disease

The invention provides enzymolysis-resisting antibacterial peptide I9H12 as well as a preparation method and application thereof. A sequence of the antibacterial peptide I9H12 is shown as SEQ ID No. 1in a sequence table. The preparation method comprises the following steps: referring to the properties of amino acids; meanwhile, avoiding enzyme digestion sites of main proteinase in a body as muchas possible, and selecting hydrophobic amino acid isoleucine (Ile) and positive-charge amino acid histidine (His) as main amino acids to newly design the antibacterial peptide I9H12; carrying out amidation on a carboxyl terminal of the peptide to improve one positive charge and increase the stability of the peptide. The invention also provides the application of the antibacterial peptide to the preparation of targeting antibacterial medicines for treating gram-negative bacterium or fungus infectious diseases. According to the enzymolysis-resisting antibacterial peptide I9H12, the enzymolysis-resisting capability of the antibacterial peptide is effectively improved, and the application potential in actual production is improved.

Owner:NORTHEAST AGRICULTURAL UNIVERSITY

Preparation method of multi-antibiotics premix

ActiveCN104621156ALittle degree of degradationImprove stabilityBiocideFungicidesChemistryFilter cake

The invention discloses a preparation method of multi-antibiotics premix. The method comprises the steps of heating fermented multi-antibiotics fermentation liquor up to 60-70 DEG C, and maintaining for 5-10 minutes; cooling, adjusting the pH to 2.5-5.0 by acid, feeding a stabilizing agent and an auxiliary agent, fully stirring, and carrying out plate-frame filtering on the fermented liquor to obtain a multi-antibiotics wet filter cake; then, carrying out flash drying on the filter cake, grinding, feeding auxiliary materials and diluting to obtain the multi-antibiotics premix. The preparation method of the multi-antibiotics premix is simple and easy to operate and low in cost; the stability of the obtained multi-antibiotics premix finished product is obviously improved in the storage process, so that the multi-antibiotics premix is more convenient and stable in the processes of storage, transportation and application.

Owner:NANJING UNIV OF TECH

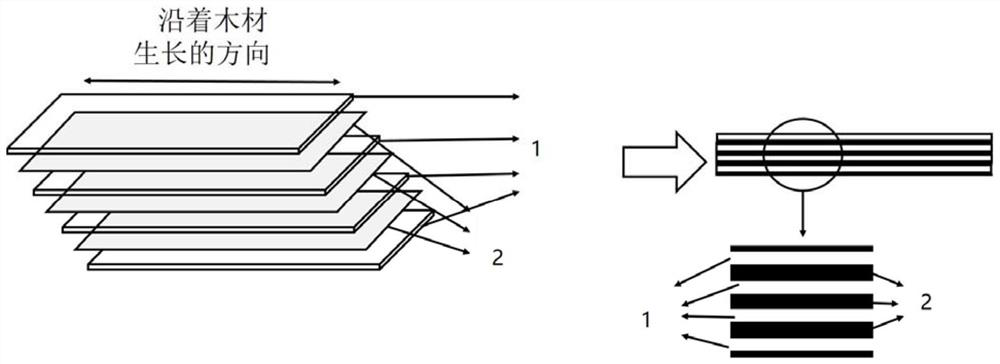

Preparation method of wood-reinforced thermoplastic resin-based environment-friendly formaldehyde-free composite material

PendingCN112078217AHigh static bending strengthHigh porosityWood treatment detailsLaminationSolid woodWood processing

The invention relates to a preparation method of a wood-reinforced thermoplastic resin-based environment-friendly formaldehyde-free composite material, and belongs to the field of composite material manufacturing and the field of wood processing. The method comprises the steps of manufacturing the solid wood into veneers by adopting a rotary cutting process; putting the veneers into a lignin removing agent solution to completely immerse the veneers, cleaning the veneers after high-temperature and high-pressure heating, adding water and hydrogen peroxide again, boiling, cleaning the veneers anddrying; soaking the veneers in a soaking solution containing one or more of a coupling agent, a flame retardant and a preservative, taking out the veneers and drying the veneers; unidirectionally aligning and stacking or vertically and horizontally crossing and stacking the veneers, and placing thermoplastic resin between every two adjacent layers of veneers, or placing the thermoplastic resin and a compatilizer at the same time; performing feeding into a cold press for high-pressure pre-pressing, and then heating to melt the thermoplastic resin, so as to obtain the multifunctional high-strength wood-based composite material. The product has extremely high static bending strength, elasticity modulus and surface wear resistance, the thickness expansion rate of the product is small, the dimensional stability is good, and meanwhile, the product is endowed with excellent corrosion resistance and weather resistance.

Owner:RES INST OF FORESTRY NEW TECH CHINESE ACAD OF FORESTRY

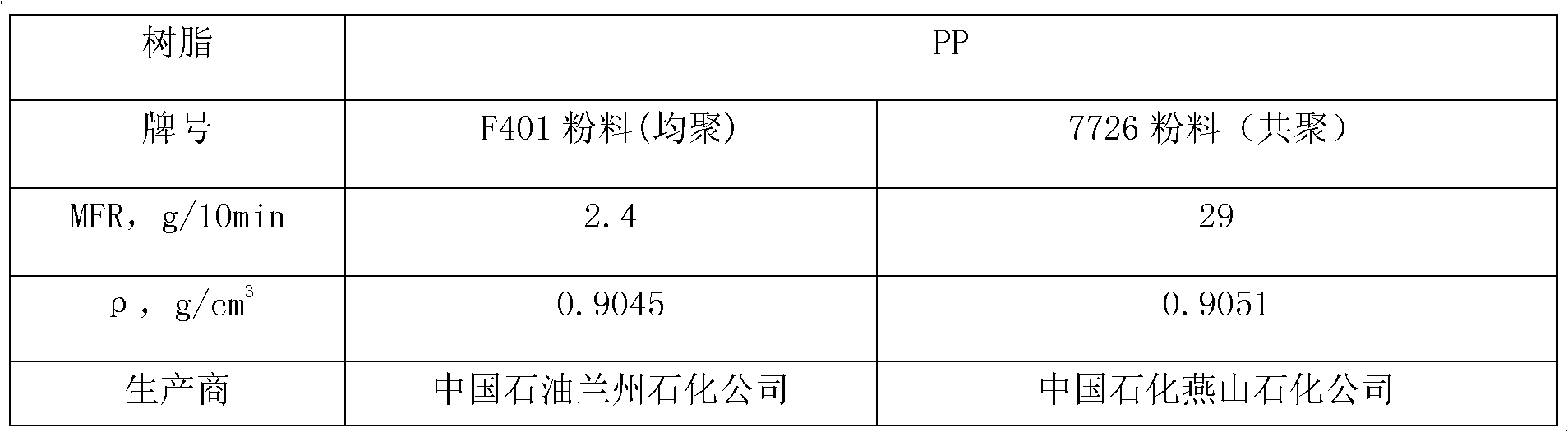

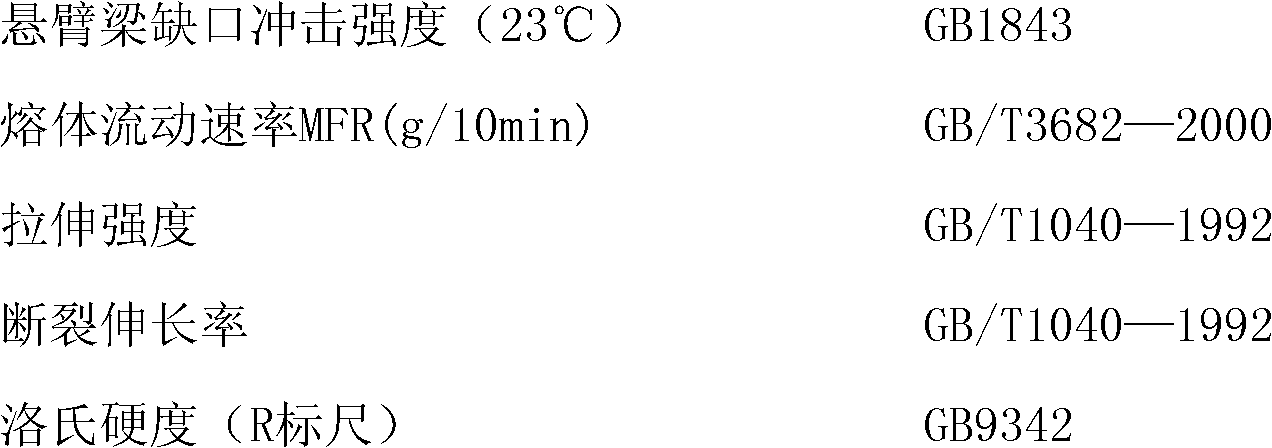

High-strength polypropylene composition and preparation method thereof

The invention discloses a high-strength polypropylene (PP) composition which comprises the following components based on the mass of the PP being 100%: 100 percent of PP matrix, 1.0-3.0 percent of crosslinking agent comprising 0.95-2.5 percent of organic peroxide / sulphur mixture and 0.05-0.5 percent of assistant crosslinking agent which are in a weight ratio of 1:5-1:10, 10-30 percent of carboxylic butadiene-styrene latex modified powder butadiene styrene rubber and 2-5 percent of polar monomer graft PP, wherein 1.0-3.0 percent of crosslinking agent comprises 0.95-2.5 percent of organic peroxide / sulphur mixture and 0.05-0.5 percent of assistant crosslinking agent and the mass ratio of organic peroxide to sulphur is 1:5-1:10. A specific crosslinking system is selected and is matched with other components, so that the degradation of PP in a mixing system can be effectively controlled, the properly crosslinked powder rubber is maximally, stably and uniformly dispersed in PP in a fine particle form, and finally the high-strength PP composition is obtained. The invention further provides a method for preparing the high-strength PP composition through dynamic vulcanization.

Owner:PETROCHINA CO LTD

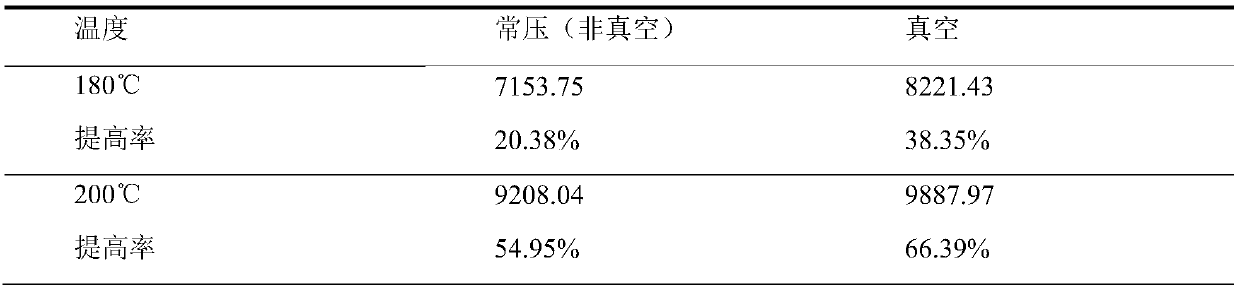

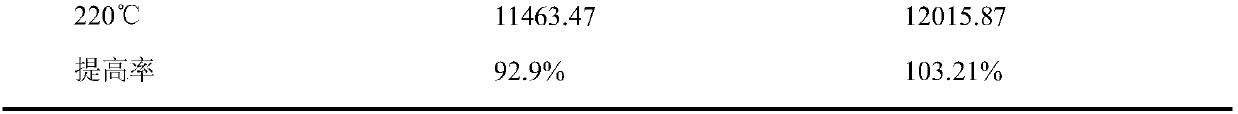

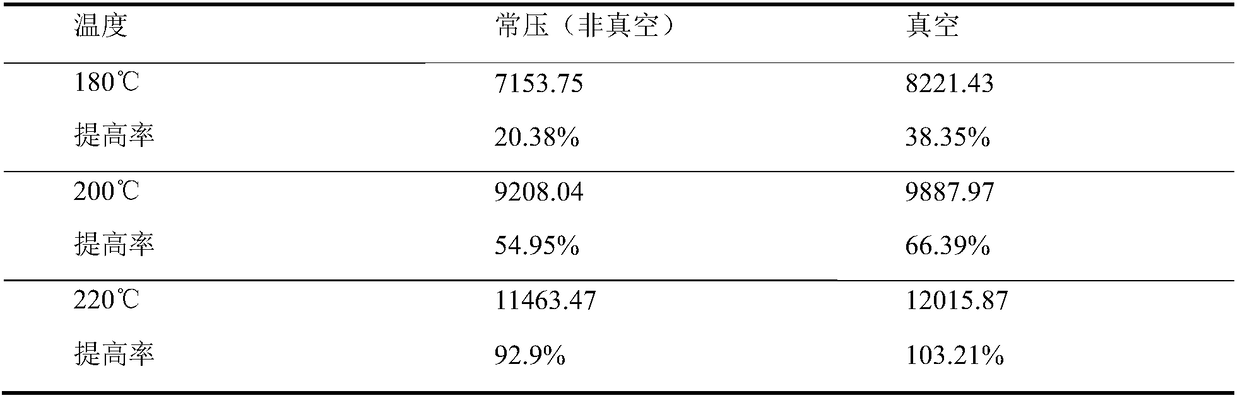

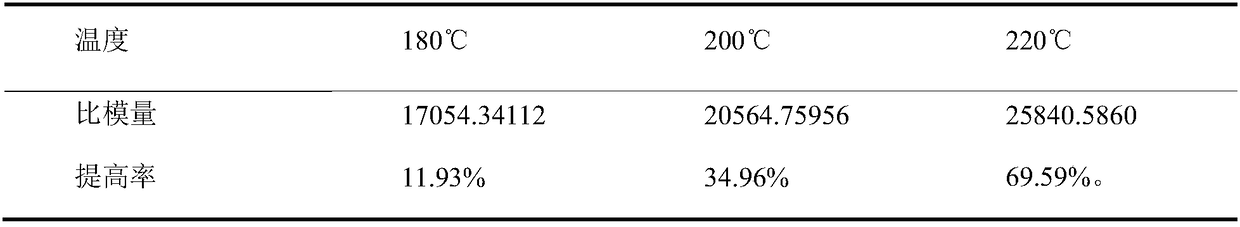

Method for compressing and compacting wood materials in vacuum

ActiveCN109591122ASolve easy discolorationFix stability issuesWood veneer joiningColor changesUltimate tensile strength

The invention discloses a method for compressing and compacting wood materials in vacuum, and belongs to the field of wood material production and preparation. According to the method, the wood materials undergo hot-pressing setting treatment under the vacuum condition, the treated wood materials are large in specific modulus, so that the technical problems that in the case of an existing wood material compression and compaction technology, the hot-pressing setting time is long, the manufacturing efficiency is low, the color change and the size are not stable are solved, the compression and compaction manufacturing of the wood materials is performed under the vacuum condition, so that the gluing strength of the wood gluing materials is also improved.

Owner:NANJING FORESTRY UNIV

Preparation method of hydrogenated C9 petroleum resin

The invention relates to a preparation method of hydrogenated C9 petroleum resin, which is characterized by comprising the following steps of: (1) preparation of supported noble metal hydrogenated catalyst: preparing by using a coating method, selecting noble metal palladium and platinum and transition metal cobalt or nickel as metal active components, preparing a spherical alumina supporter, then coating the active components of palladium and platinum and transition metal on the alumina supporter, and activating to obtain a hydrogenated catalyst; (2) selective hydrogenation: desulfurizing and denitrifying; (3) high pressure hydrogenation reaction: controlling the weight ratio of resin to solvent to ensure that the concentration of resin is 20-40% by weight, taking chain-like or annular saturated hydrocarbon or aromatic hydrocarbon or hydrocarbon mixture as a solvent, and taking a supported noble metal hydrogenated catalyst as a catalyst, wherein the temperature of the high pressure hydrogenation reaction is 250-350 DEG C, the pressure is 8.0-20.0 MPa and the liquid volume space velocity is 0.5-2h<-1>. The properties of the final product hydrogenated C9 petroleum resin are as follows: Gardner is not more than 1, and the softening point is not smaller than 100 DEG C.

Owner:CHINA NAT OFFSHORE OIL CORP +1

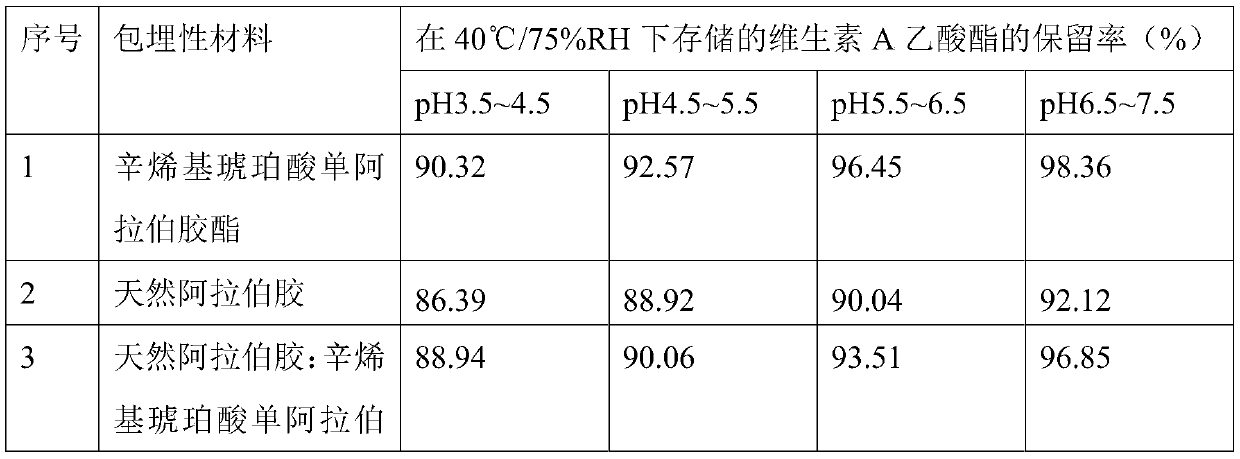

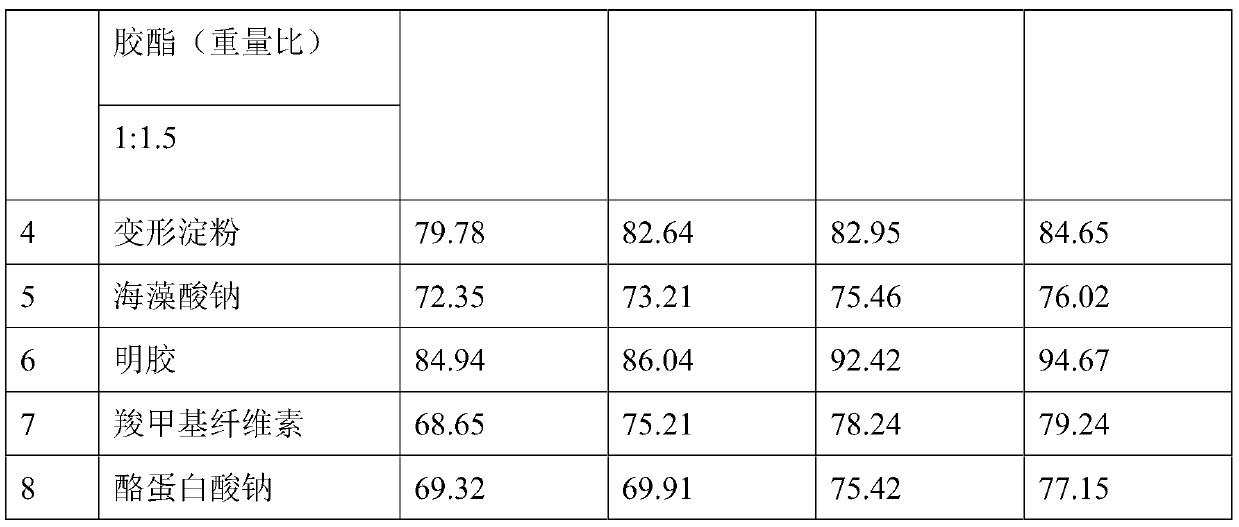

High-acid-resistance vitamin A product and preparation method thereof

ActiveCN111544415ASmall particle sizeReduce the amount of floating oilHydroxy compound active ingredientsMacromolecular non-active ingredientsVitamin A AlcoholPalmitates

The invention discloses a high-acid-resistance vitamin A product and a preparation method thereof. The high-acid-resistance vitamin A product is prepared from the following raw materials in parts by weight: 10-40 parts of vitamin A substance, 30-60 parts of an embedding wall material, 5-35 parts of a filling material and 0-8 parts of an antioxidant. The vitamin A substance is selected from vitaminA, vitamin A acetate and palmitate. According to the invention, the defects of the vitamin A raw material in application are overcome, and the stability and acid resistance of the vitamin A ester microencapsulated product are greatly improved through the combined use of the embedding wall material, the filling material and the antioxidant. High-temperature melting and high-speed shearing processtreatment is not needed, the degradation degree of the raw materials in the processing process can be effectively reduced, the safe and environment-friendly effects are achieved, the preparation process is simple, and industrial production is facilitated.

Owner:INNOBIO CORP LTD

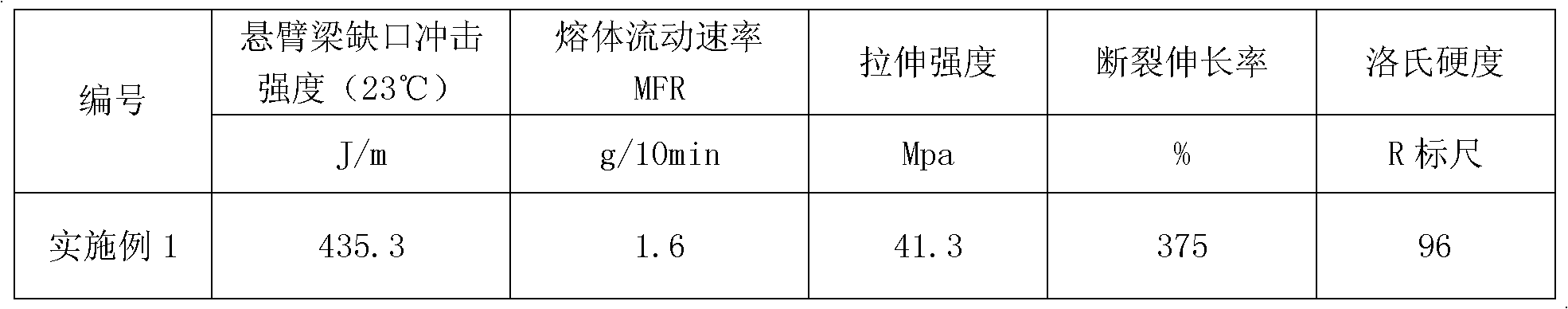

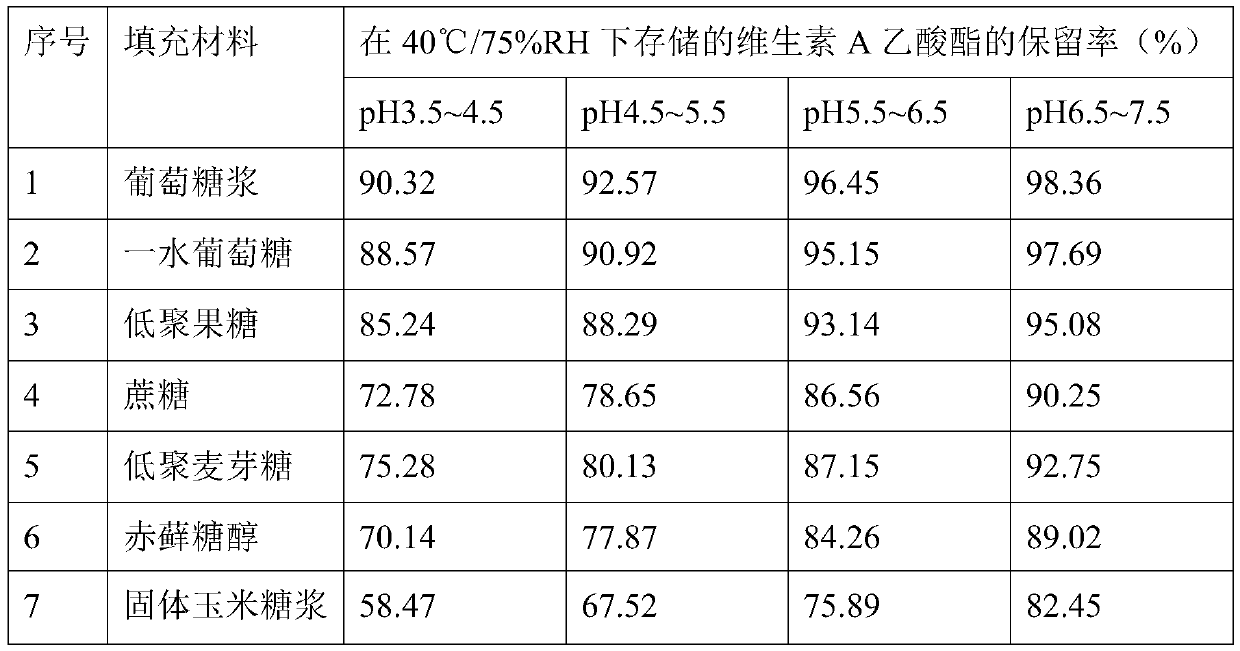

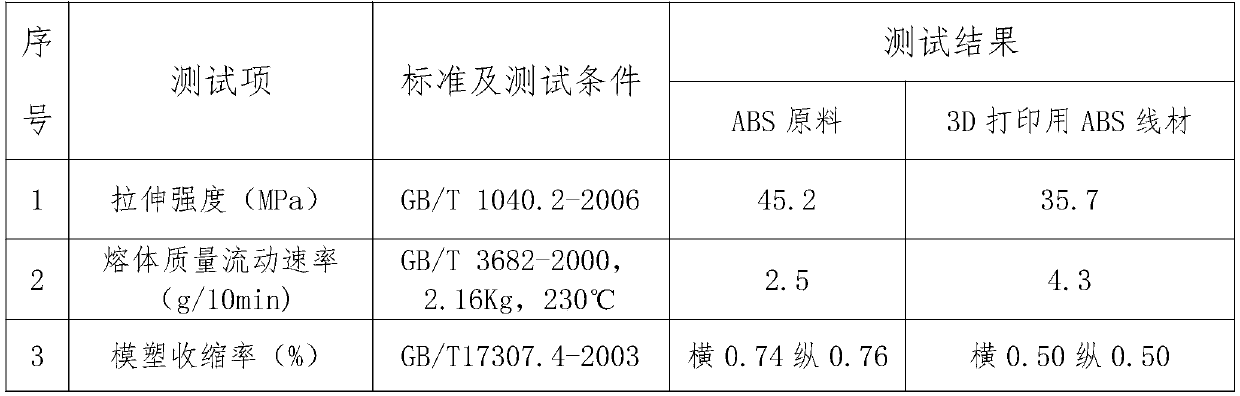

ABS consumable for 3D printing, and preparation method thereof

InactiveCN109651752AImprove performanceLow priceAdditive manufacturing apparatusPolymer scienceAntioxidant

The invention provides an ABS consumable for 3D printing, and a preparation method thereof. The ABS consumable for 3D printing comprises acrylonitrile-butadiene-styrene resin, talcum powder master batches, calcium carbonate, a styrene-butadiene-styrene block copolymer, an antioxidant, a lubricant, a compatibilizer and color master batches. The preparation method comprises the following steps: rawmaterial drying, high-speed mixing, blending extrusion granulation, secondary drying and wire extrusion preparation. The product has the characteristics of low production cost, high mechanical strength, excellent processing fluidity, good impact resistance, long service life, uniform wire diameter, smooth surface, high glossiness and low shrinkage rate.

Owner:GUIZHOU AEROSPACE TIANMA ELECTRICAL TECH

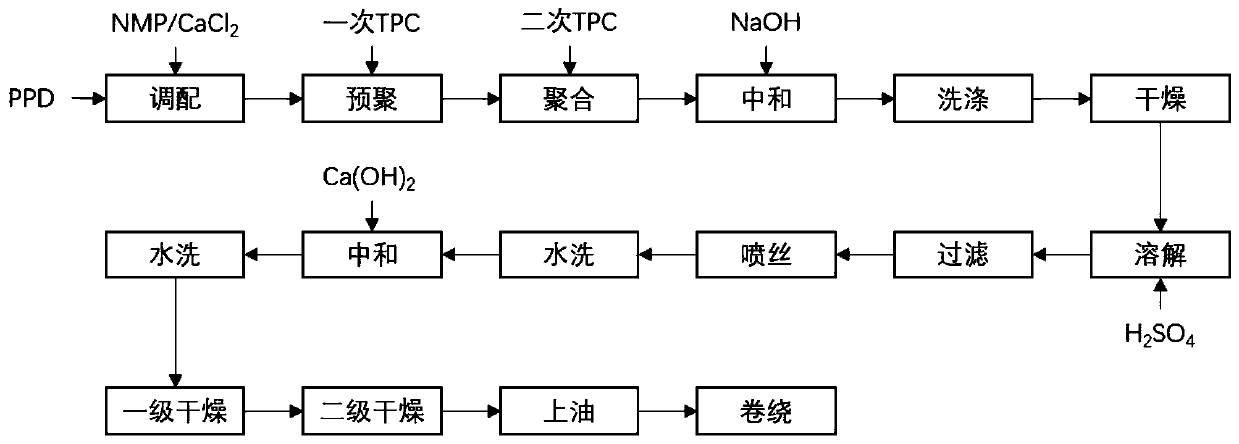

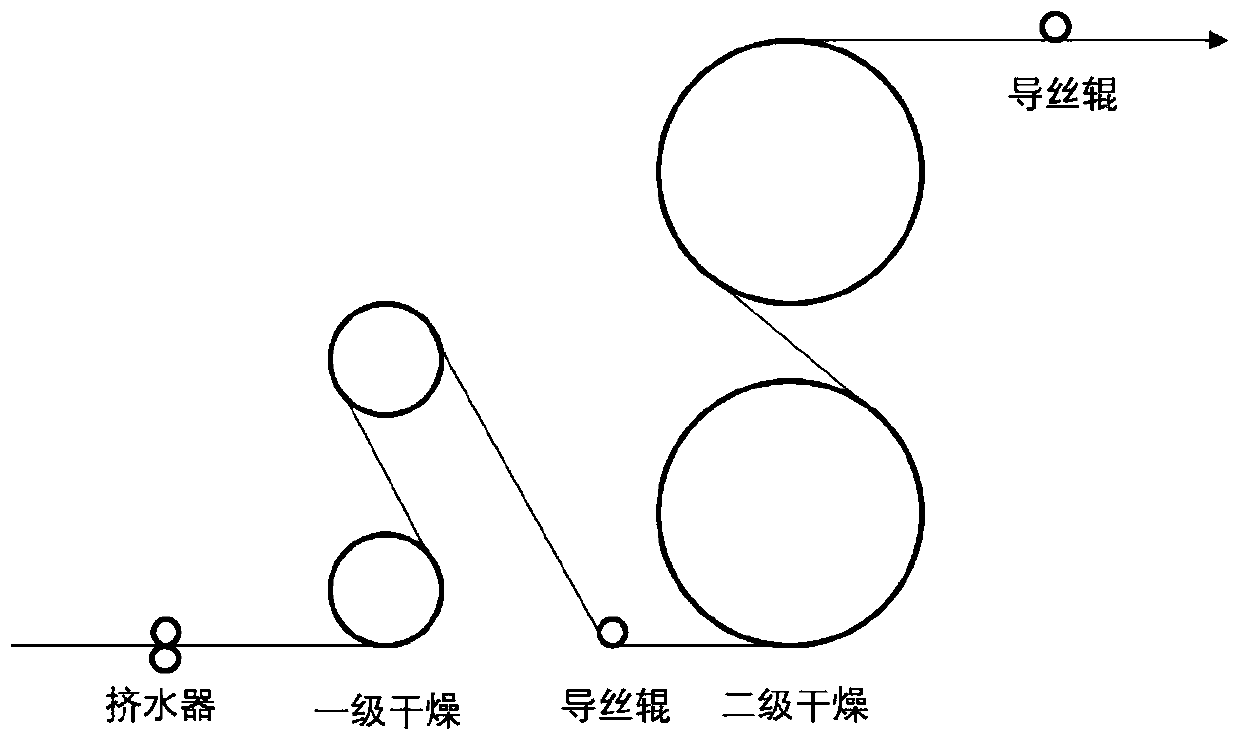

Preparation method for high-modulus para-aramid fiber

PendingCN111501126AHigh modulusHigh degree of continuous productionSpinning head liquid feederArtificial filament washing/dryingHigh concentrationPolymer science

The invention provides a preparation method for a high-modulus para-aramid fiber. The preparation method comprises the following steps: adopting a low-temperature polycondensation method to prepare poly(terephthaloyl-p-phenylene diamine) (PPTA) polymer with intrinsic viscosity of 7.5-8.5dL / g; utilizing high-concentration sulfuric acid for dissolving the polymer to prepare a spinning solution, obtaining fiber tow through a dye-spraying wet-spinning method; and obtaining the high-modulus para-aramid fiber through processes such as washing, neutralizing, washing, drying, oil-applying and winding,wherein modulus of the PPTA fiber is 850-1000g / D, and intrinsic viscosity is 7.0-8.0 dL / g. The high-modulus para-aramid fiber prepared by the method has high strength, high modulus, small degradation, high crystal-degree loss, fewer broken filaments, excellent mechanical property, short drying time and low energy consumption. Drying equipment domestication replaces import, so that technical locking of the drying equipment is broken through, and therefore, industrial development speed is increased.

Owner:宁夏泰和芳纶纤维有限责任公司 +1

Method for compressing and compacting wood materials

ActiveCN108177209ASolve easy discolorationFix stability issuesWood veneer joiningColor changesSpecific modulus

The invention discloses a method for compressing and compacting wood materials, and belongs to the field of wood material production and preparation. According to the method for compressing and compacting the wood materials, the wood materials are subjected to hot-pressing and setting treatment under the vacuum condition, and the processed wood materials are large in specific modulus, and the technical problems that, in an existing wood material compressing and compacting technology, the hot-pressing and setting time of is long, manufacturing efficiency is low, the color changes, and the sizeis not stable are solved; and the wood materials are subjected to compressing and compacting manufacture under the vacuum condition, so that bonding strength of the wood materials laminated with glueis also improved.

Owner:NANJING FORESTRY UNIV

Waterproof building decoration material

InactiveCN106244016ALittle degree of degradationExtended service lifeAntifouling/underwater paintsPaints with biocidesEmulsionKaolin clay

The invention discloses a waterproof building decoration material, which is prepared from the following components in parts by mass: 20 to 30 parts of elastic emulsion, 3 to 5 parts of wetting agent, 0.5 to 1.3 parts of dispersing agent, 0.1 to 2.5 parts of defoaming agent, 10 to 20 parts of diatomaceous earth, 10 to 15 parts of opened-pore expanded perlite, 2 to 6 parts of nano-silica, 3 to 5 parts of nano-iron dioxide, 1 to 5 parts of leveling agent, 1 to 6 parts of epoxy solidifying agent, 3 to 10 parts of deionized water, 2 to 4 parts of thickening agent, 5 to 10 parts of flame retardant, 1 to 3 parts of bactericide, 10 to 40 parts of kaolin clay, 5 to 30 parts of hexabromocyclododecane and 10 to 60 parts of quartz sand. The product provided by the invention has the advantages of low degradation degree, high stability and long service life, environment-friendly selected production raw material, no waste water, waste steam and waste residue in the production and construction process, and no pollution.

Owner:WUHU TIANXIONG NEW MATERIAL TECH

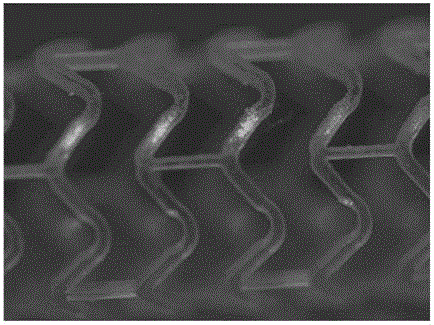

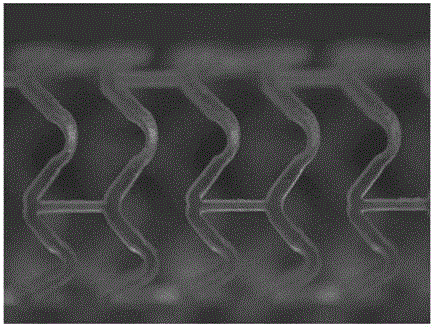

Machining method for degradable polymer intravascular stent

InactiveCN105149888ASegment stabilizationCompact structureSurgeryPharmaceutical delivery mechanismMelting Point TemperatureSlow cooling

The invention provides a machining method for a degradable polymer intravascular stent. The machining method comprises the following steps that firstly, a pipe is formed; secondly, a stent base body is formed through laser engraving; thirdly, the surface of the stent base body is polished. In the first step, the pipe is formed through the extrusion technology that cold pressurization is carried out on a plastic pipe, wherein polymer raw materials for the stent base body are heated in a plastic extruder to the temperature higher than the corresponding melting point temperature Tm and lower than the extruding temperature in the normal pressure extruding technology by 5-15 DEG C, 5-20 MPa pressure is applied at the same time, the raw materials are extruded out of a mold of the extruder with the temperature and the pressure maintained, and slow cooling is carried out. Compared with the prior art, by means of the machining method for the degradable polymer intravascular stent, the strength of the obtained intravascular stent is higher, the overall radial supporting force is higher, and the surface of the stent is smoother and free of flaws.

Owner:天津索玛科技有限公司

Nanometer decoration material

InactiveCN104046242ALittle degree of degradationExtended service lifeAntifouling/underwater paintsPaints with biocidesFire retardantSilicon dioxide

The invention discloses a nanometer decoration material, which comprises the following components in parts by weight: 20-25 parts of elastic emulsion, 1-3 parts of a wetting agent, 0.5-3 parts of a dispersing agent, 1.5-3 parts of a thickener, 3-10 parts of a flame retardant, 3-6 parts of a lubricant, 2-5 parts of an antioxidant, 2-6 parts of a barium-zinc stabilizer, 0.1-5 parts of a defoaming agent, 0.1-3 parts of bactericide, 10-20 parts of diatomaceous earth, 10-25 parts of opened expanded perlite, 2-6 parts of nanosilicon dioxide, and 1-4 parts of nano ferrum dioxide. The nanometer decoration material is small in degradation degree, stable, long in service life, the selected production raw materials are environmental friendly; during the production and construction processes, no waste water, waste vapor and waste residues as well as no pollution are generated.

Owner:QINGDAO BOYANG BIOTECH

Nano waterproof material

InactiveCN104194632ALittle degree of degradationExtended service lifeAntifouling/underwater paintsPaints with biocidesEmulsionWastewater

The invention discloses a nano waterproof material which is composed of the following components in parts by weight: 20-25 parts of elastic emulsion, 2-5 parts of film formation assistant, 15-25 parts of titanium white, 5-20 parts of filler, 1-3 parts of wetting agent, 5-15 parts of dispersing agent, 1-3 parts of thickener, 1-5 parts of bactericide, 10-20 parts of kieselguhr, 10-25 parts of open-cell expanded perlite, 3-5 parts of calcium stearate, 10-20 parts of hexamethyl phosphoryl triamide, 1-5 parts of epoxy solid increasing agent, 10-15 parts of defoaming agent and 1-4 parts of pigment. The product has the advantages of low degradation degree, higher stability and long service life; and all the production raw materials are environment-friendly, so no waste water, waste gas, waste residue or pollution is generated in the production and construction process.

Owner:QINGDAO UWELL INFORMATION TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com