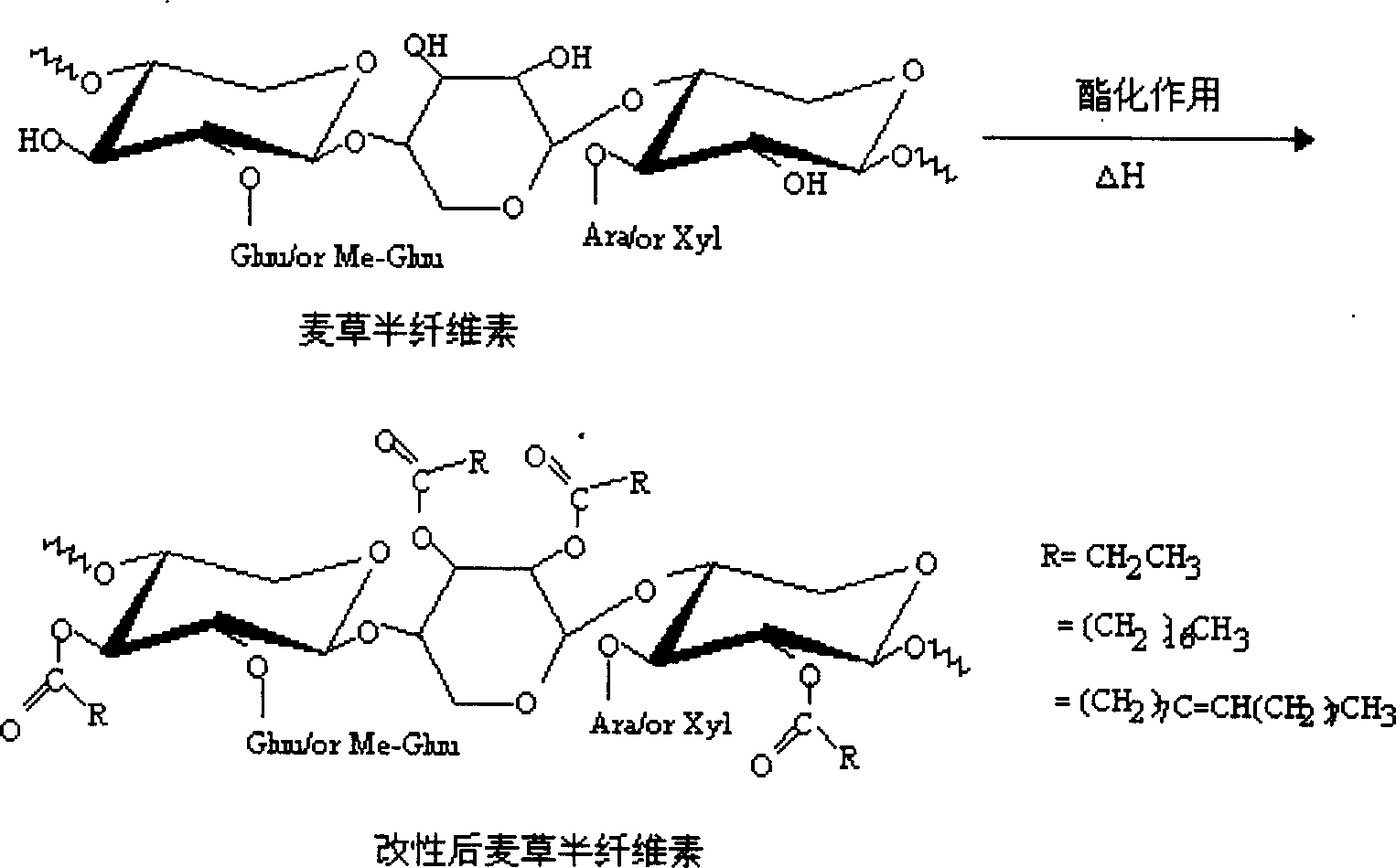

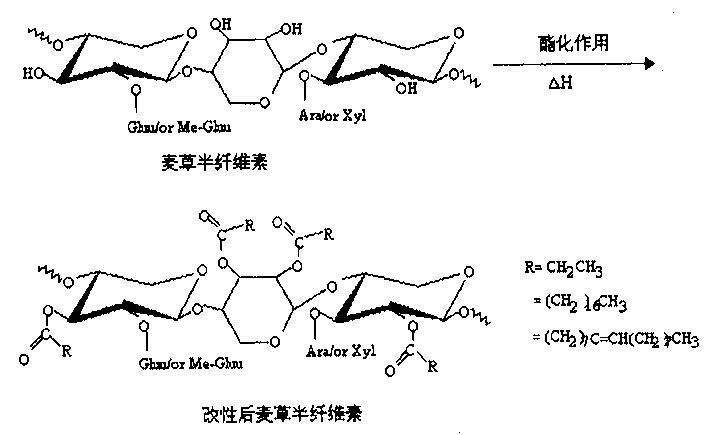

Homogeneous chemical modification of hemicellulose of stalks

A technology of hemicellulose and chemical modification, applied in the new process field, can solve the problems of pre-activation treatment of hemicellulose, low yield of modification reaction, limited industrial application, etc., to improve hydrophobicity, reduce production cost, reduce The effect of pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

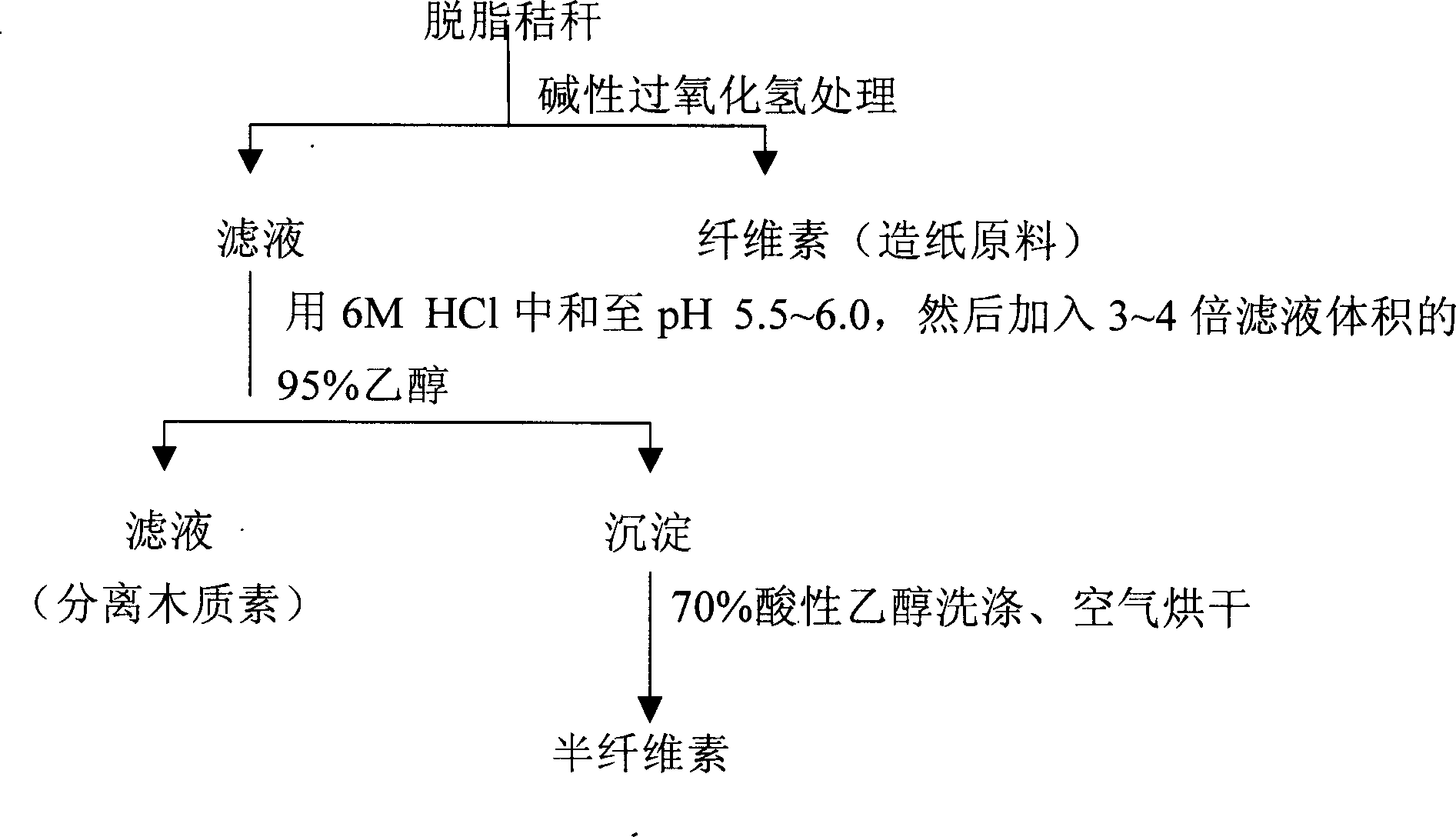

Method used

Image

Examples

Embodiment 1

[0019] In the first step, 50 grams of pulverized stalks are placed in a 3000ml glass reactor, and 950ml of 2% H 2 o 2 Aqueous solution, adjust the pH value of the solution with 20% NaOH aqueous solution to be 12.0, control the reaction temperature to be 40 ℃, react under stirring for 18 hours, filter and wash the residue with distilled water, combine the filtrate, then adjust the acidity to pH= 5.5, Concentrate the filtrate to 500ml under reduced pressure, add 3 times the volume of 95% ethanol to precipitate the soluble hemicellulose, after filtering, wash the obtained hemicellulose fully with 70% ethanol and air dry to obtain 10.8 grams of hemicellulose vegetarian products;

[0020] In the second step, 6.0 grams of purified hemicellulose (equivalent to 0.08 moles of xylose hydroxyl groups in hemicellulose composition) are placed in a 1000ml glass reactor, add 100ml of distilled water, and stir at 80°C for about 5 minutes until the hemicellulose completely dissolved;

[002...

Embodiment 2

[0025] In the first step, 50 grams of pulverized stalks are placed in a 3000ml glass reactor, and 950ml of 2% H 2 o 2 Aqueous solution, adjust the pH value of the solution with 20% NaOH aqueous solution to be 12.3, control the reaction temperature to be 50 ℃, react under stirring for 12 hours, filter and wash the residue with distilled water, combine the filtrate, then adjust the acidity to pH= with 6M HCl solution 5.5. Concentrate the filtrate to 600ml under reduced pressure, add 4 times the volume of 95% ethanol to precipitate the soluble hemicellulose, after filtering, wash the obtained hemicellulose fully with 70% ethanol and air-dry to obtain 14.1 grams of hemicellulose vegetarian products;

[0026] In the second step, 6.0 grams of purified hemicellulose (equivalent to 0.08 moles of xylose hydroxyl groups in hemicellulose composition) are placed in a 1000ml glass reactor, add 100ml of distilled water, and stir at 80°C for about 5 minutes until the hemicellulose complete...

Embodiment 3

[0031] In the first step, 50 grams of pulverized stalks are placed in a 3000ml glass reactor, and 950ml of 2% H 2 o 2 Aqueous solution, adjust the pH value of the solution with 20% NaOH aqueous solution to be 12.5, control the reaction temperature to be 60 ℃, react under stirring for 5 hours, filter and wash the residue with distilled water, combine the filtrate, then adjust the acidity to pH= 6.0, concentrate the filtrate to 800ml under reduced pressure, add 4 times the volume of 95% ethanol to precipitate the soluble hemicellulose, after filtration, fully wash the obtained hemicellulose with 70% ethanol and air dry to obtain 16.6 grams of hemicellulose vegetarian products;

[0032]In the second step, 6.0 grams of purified hemicellulose (equivalent to 0.08 moles of xylose hydroxyl groups in hemicellulose composition) are placed in a 1000ml glass reactor, add 100ml of distilled water, and stir at 70°C for about 10 minutes until the hemicellulose is completely dissolve;

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com