Method for compressing and compacting wood materials

A wood material and densification technology, which is applied in the direction of wood processing appliances, wooden veneer joints, manufacturing tools, etc., can solve the problems of low utilization efficiency of production equipment, poor mechanical properties of products, and long production cycle, so as to improve mechanical properties. Effects of strength, molecular number reduction, and orientation improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] The specific test steps of this experiment are as follows:

[0042] 1) Drying and surface sanding treatment of fir boards: sanding fir boards with a thickness of 23-24mm to 22mm, and the moisture content after drying is 10%.

[0043] 2) Cutting the dried and surface-sanded Chinese fir board: use a sliding table saw to make a fir specimen of 200mm×100mm×20mm (axial direction×chord direction×radial direction). Accurately measure the quality, width, thickness and length of the test piece (mark the position when measuring the thickness), accurate to 0.02mm, record and number the data of the test piece.

[0044] 3) Use a hot press to compress the numbered specimens under the conditions of vacuum and normal pressure (vertical wood chord direction compression): the pressure of the high-temperature thermal compression treatment is 2MPa, the compression rate is 30%, and the heat The pressing time is 30 minutes, and the hot pressing temperature is 180°C, 200°C and 220°C. After ...

Embodiment 2

[0057] The implementation steps of this test are the same as in Example 1, the difference is that

[0058] 1) Sawing: sand the fir board with a thickness of 21-23mm to 20mm, and the moisture content is 10%.

[0059] 2) Vacuum hot pressing: the hot pressing pressure is 2 MPa, the compression ratio is 30%, the hot pressing time is 15 min, and the hot pressing temperatures are 180°C, 200°C and 220°C.

[0060] 4) Pressure relief.

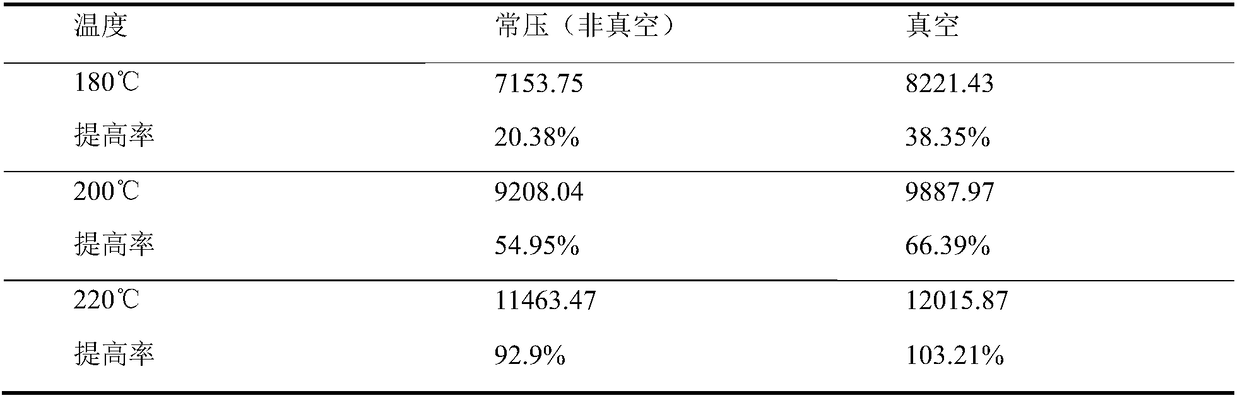

[0061] The detection data of the wood material obtained according to the procedure of Example 2 are as follows.

[0062] Table 4 Experimental detection data

[0063]

[0064] The vacuum compression time in Example 2 was shortened by 15min compared with Example 1. Compared with Example 1, the strength improvement rate of the compressed wood was lower, and the color difference value was smaller, that is, the surface color was less likely to change.

Embodiment 3

[0066] The steps are the same as in Example 2, except that the sanding is to 18mm, the water content is 12%, the compression rate during vacuum hot pressing is 20%, and the compression time is 30 minutes.

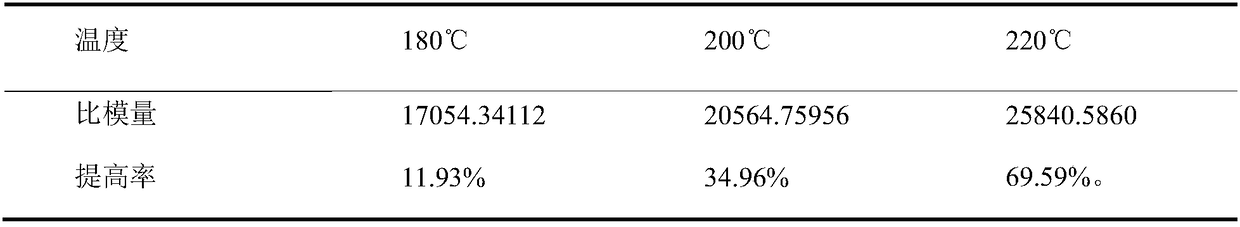

[0067] According to the detection data table 5 of the wooden material that the operation of embodiment 3 obtains:

[0068] Table 5 Experimental detection data

[0069]

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com