Method for pretreating enramycin fermentation liquor and method for preparing enramycin premix by using enramycin fermentation liquor

A technology of enramycin and fermentation liquid, which is applied in the field of preparation of enramycin premix, can solve the problems of poor stability and reduced enramycin degradation degree, and achieve convenient application process, low cost and low degradation The effect of reducing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

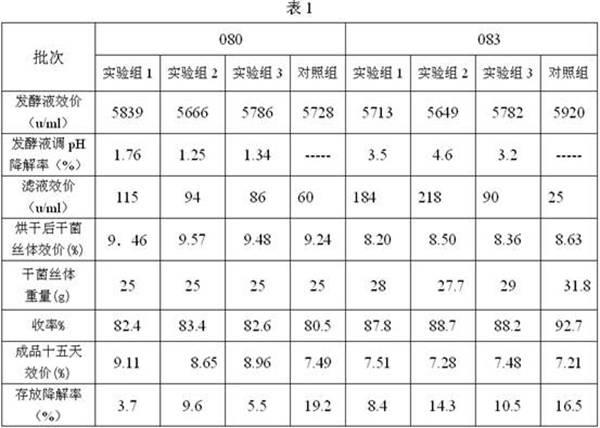

[0015] Get 2 batches of fermented broths that have been fermented, and process them as follows: 1. Control group: no treatment; 2. Experimental group 1: adjust the pH value of the fermented broth to 5.0 with phosphoric acid, and then add 0.9% aluminum sulfate of the fermented broth quality; 3. Experimental group 2: Use hydrochloric acid to adjust the pH value of the fermentation broth to 5.0, and then add 0.9% aluminum sulfate in the mass of the fermentation broth; 4. Experimental group 3: Use citric acid to adjust the pH value of the fermentation broth to 5.0, and then add 0.9% of the mass of the fermentation broth of aluminum sulfate. Then, under the same conditions, the fermentation broth was subjected to plate-and-frame filtration (pressure 0.6MPa, time 2h), and the filter cake was flash-dried (inlet air temperature 100°C, outlet air temperature 80°C), and the obtained enramycin mycelium was dried The body is dried and pulverized into enramycin fine powder (80-100 mesh), a...

Embodiment 2

[0019] 1. Fermentation broth pretreatment:

[0020] Adjust the pH value of the enramycin fermentation broth with phosphoric acid so that the pH value of the fermentation broth is in the range of 4-5, and then add aluminum sulfate with a quality of 0.9% of the fermentation broth to prepare for extraction;

[0021] 2. Extraction of enramycin:

[0022] The fermentation broth is filtered with a plate and frame filter, the pressure of the plate and frame is 0.6MPa, press filter for 2 hours, the temperature of the inlet air is controlled at 90-95°C, the temperature of the material is 70-80°C, and the filter cake is flash-dried , to obtain the dried product of enramycin mycelium, the dried product is pulverized into 80-100 mesh enramycin fine powder, finally, adding auxiliary materials such as rice husk powder and zeolite powder to the fine powder to adjust its concentration, and mixing uniformly to obtain Enramycin premix finished product, the storage stability of the resulting fin...

Embodiment 3

[0024] 1. Fermentation broth pretreatment:

[0025] Phosphoric acid is used to adjust the pH value of the enramycin fermentation broth, so that the pH value of the fermentation broth is in the range of 5.0-6.0, and then adding aluminum sulfate with a mass of 0.9% of the fermentation broth to prepare for extraction;

[0026] 2. Extraction of enramycin:

[0027] The fermented liquid is filtered with a plate and frame filter. The pressure of the plate and frame is 0.5MPa, press filter for 2 hours, control the inlet air temperature at 105-110°C, and the material temperature at 85-90°C, and flash dry the filter cake. Obtain the dried product of enramycin mycelium, crush the dried product into 80-100 mesh enramycin fine powder, and finally add auxiliary materials such as rice husk powder and zeolite powder to the fine powder to adjust its concentration, mix evenly, and obtain Lamycin premix finished product, the storage stability of gained finished product has improved by 12.6%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com