Patents

Literature

198results about How to "Change quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

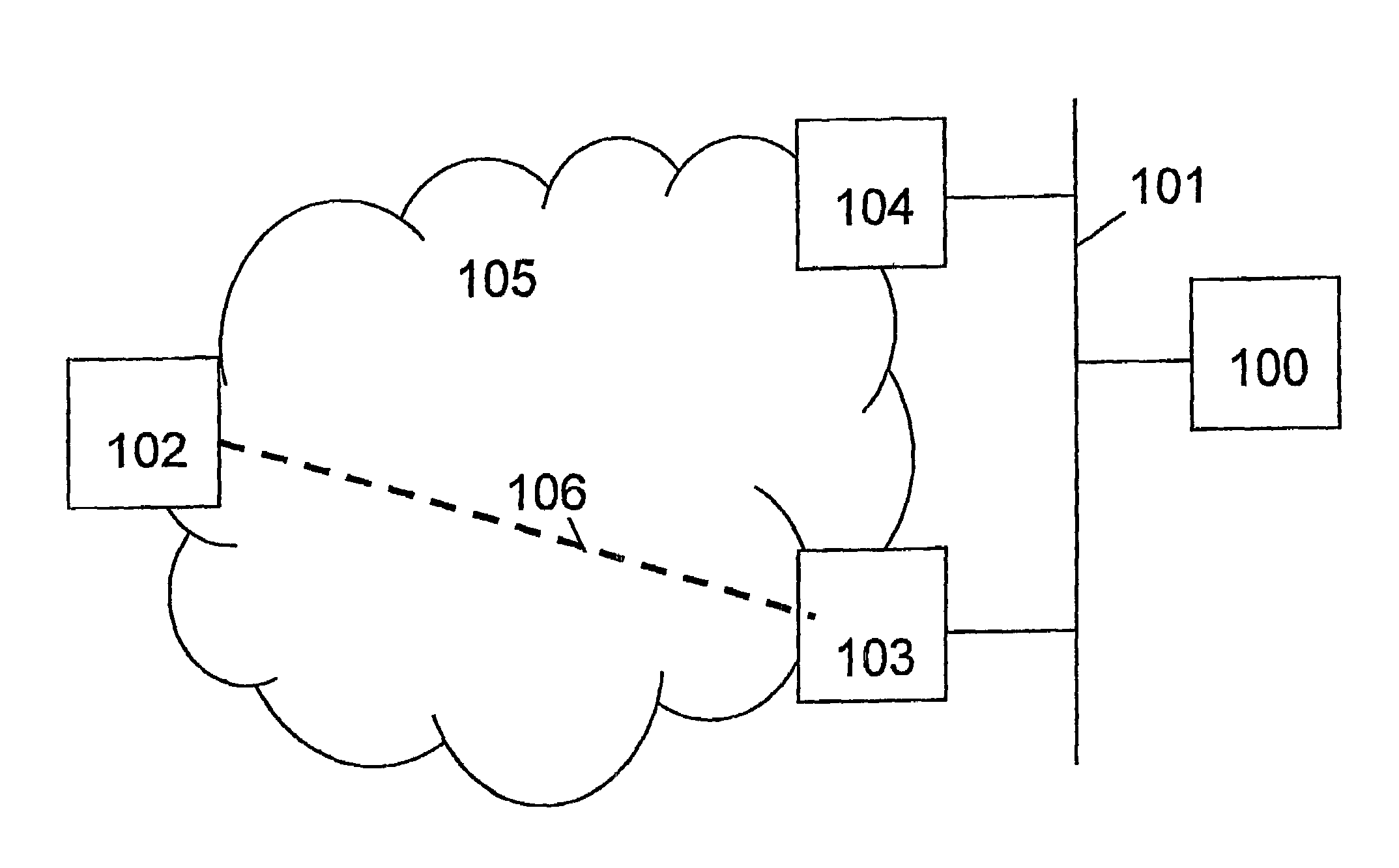

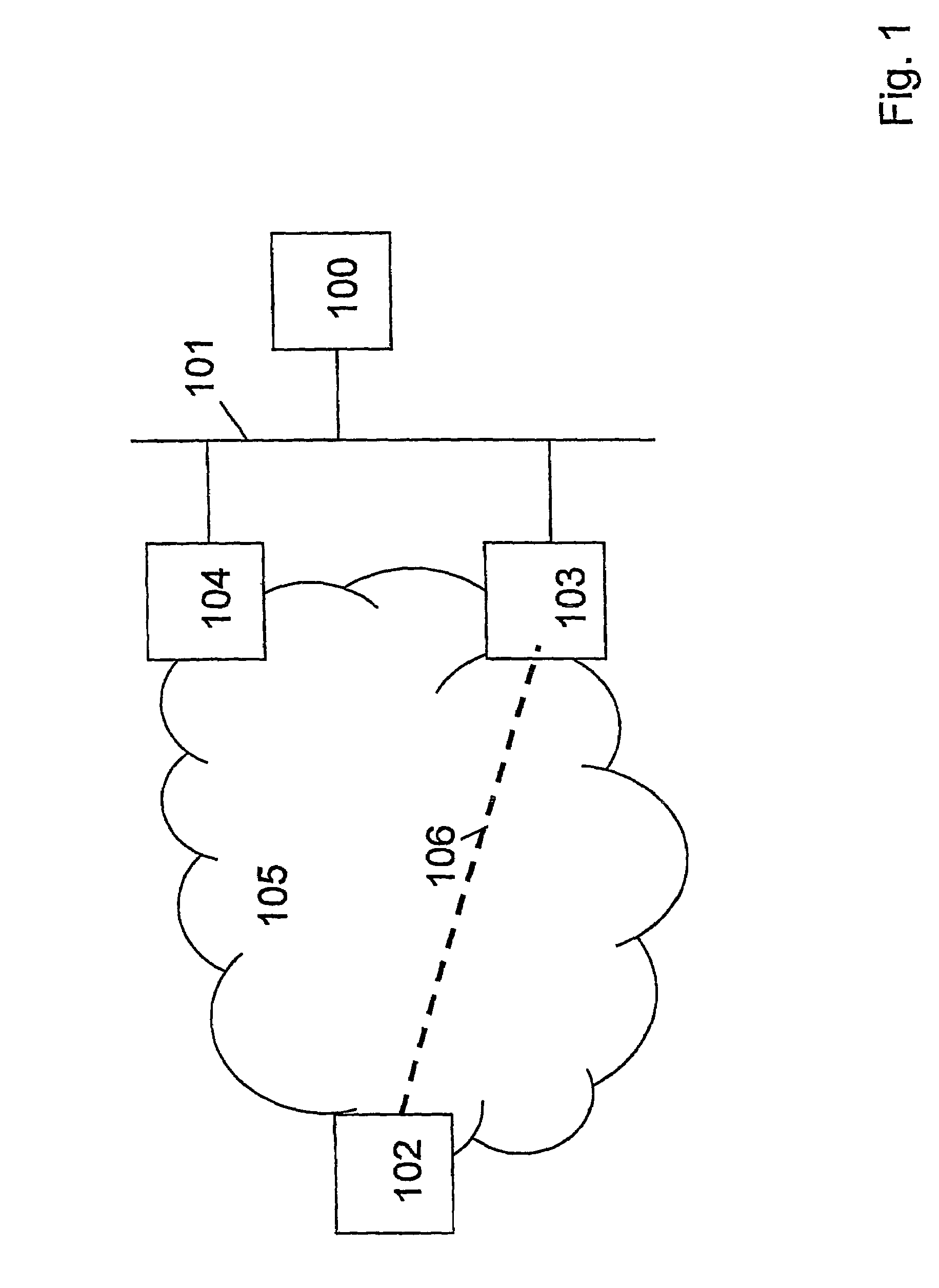

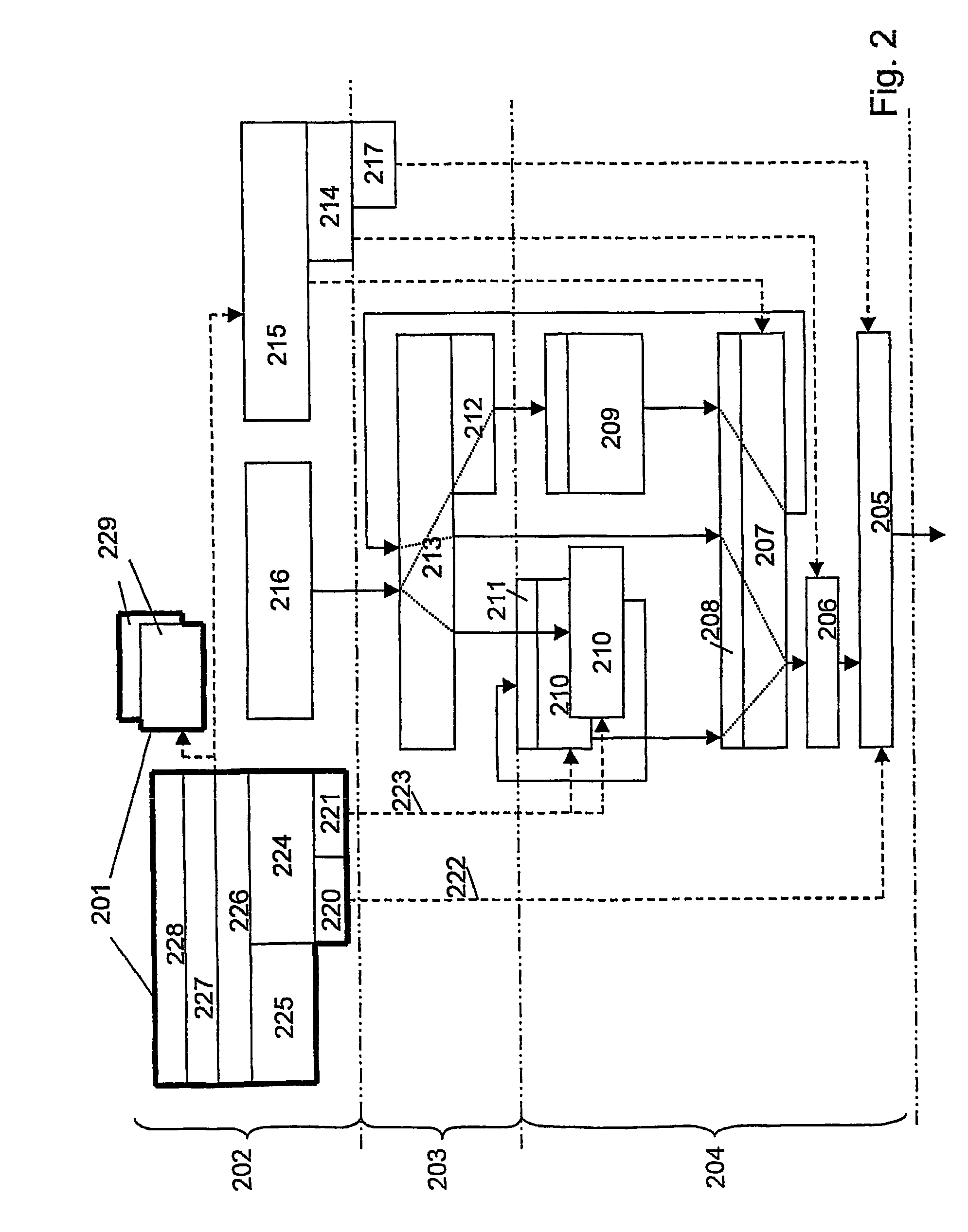

Method and arrangement to secure access to a communications network

InactiveUS7152160B2Reduce interventionSession is shortUser identity/authority verificationUnauthorized memory use protectionCommunications systemProtocol for Carrying Authentication for Network Access

The present invention relates to a method and an arrangement in a data communications system in Internet Protocol (IP) environments. The object of the invention is to achieve a simple way of remote and secure access of a computer to a private data communications network. The solution according to the invention is a Remote Access Login system profiled for accessing the private data communications network via a so-called Pseudo-Connectionless Technology (PCT) device.

Owner:BIRDSTEP TECH

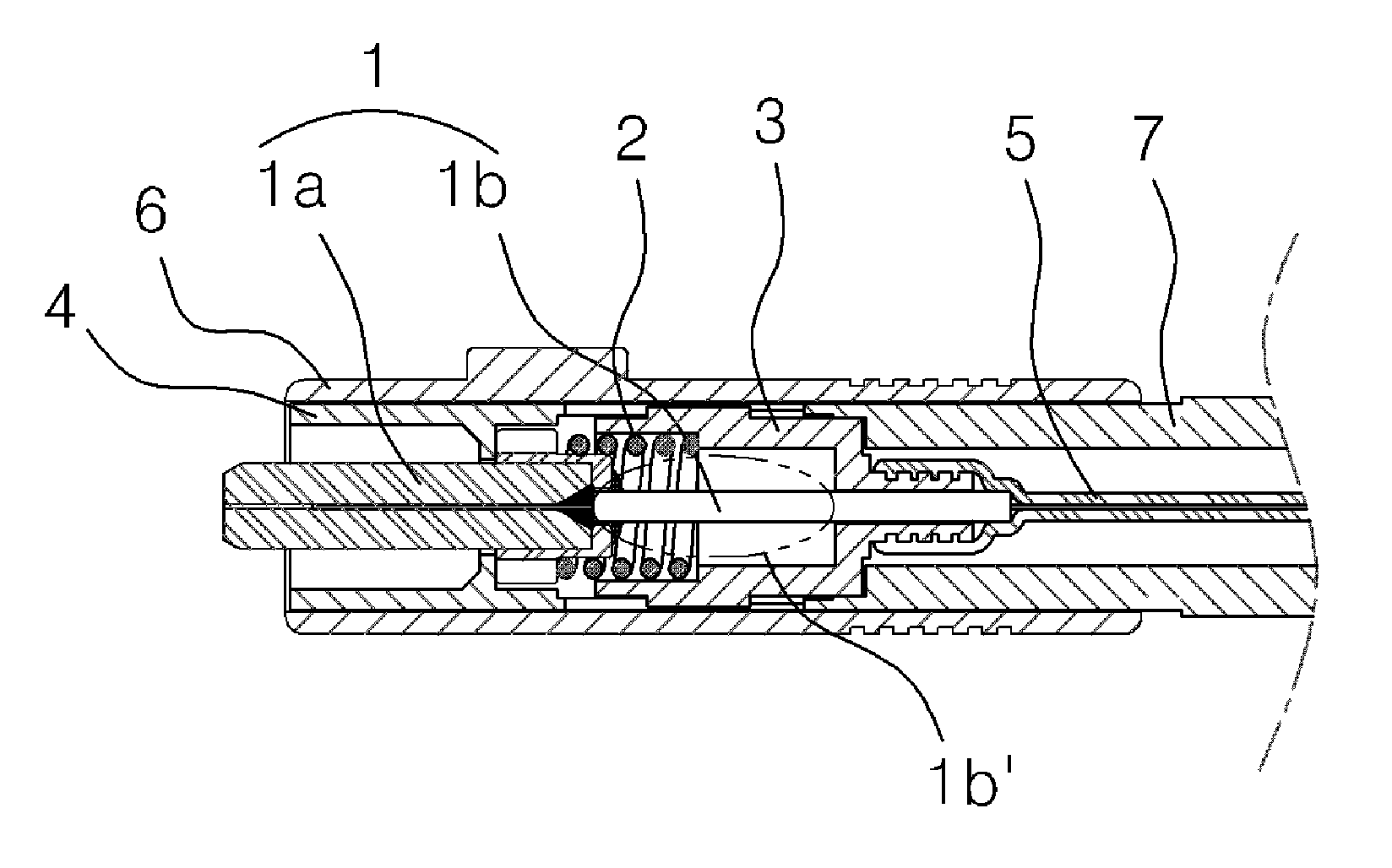

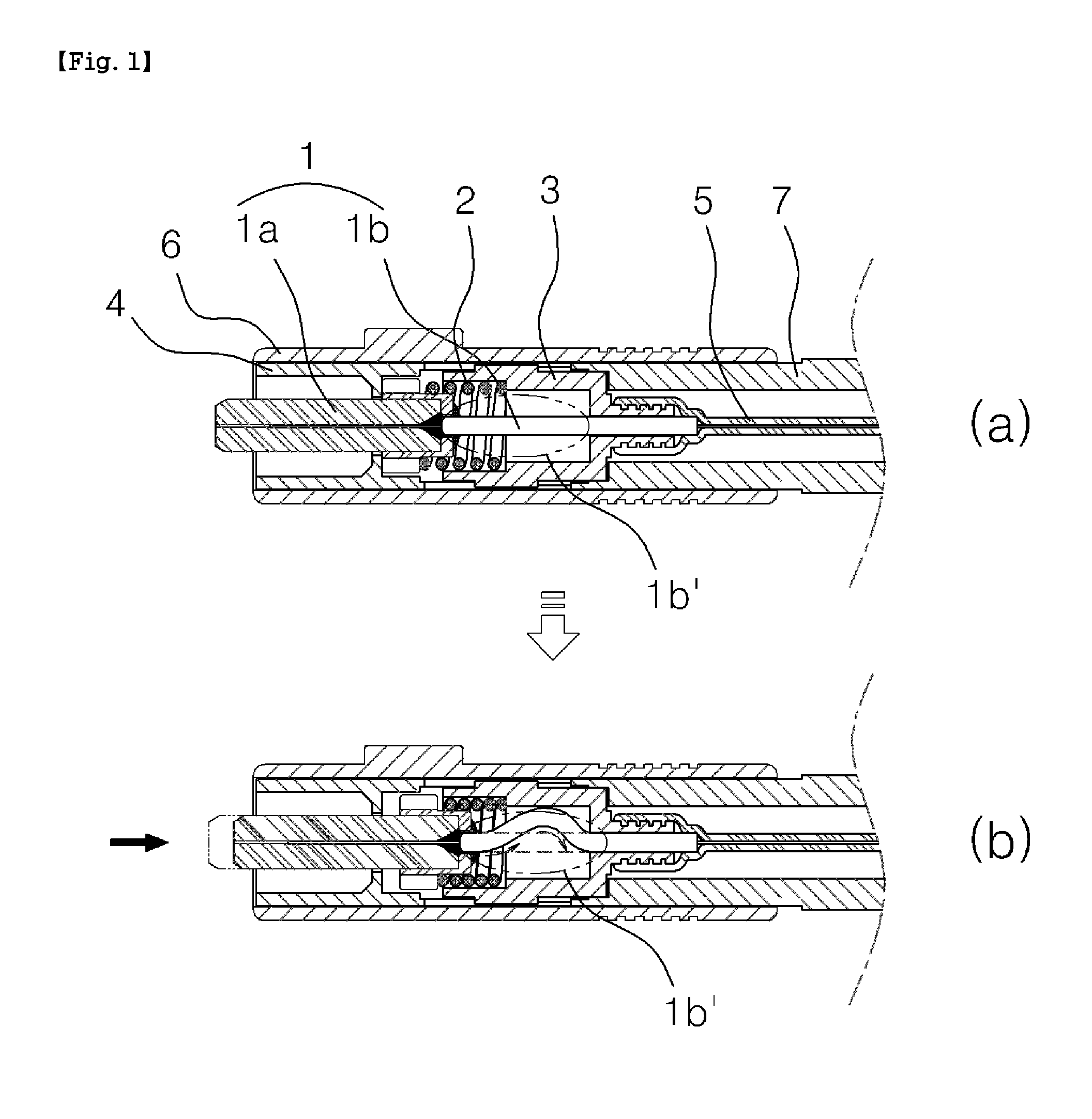

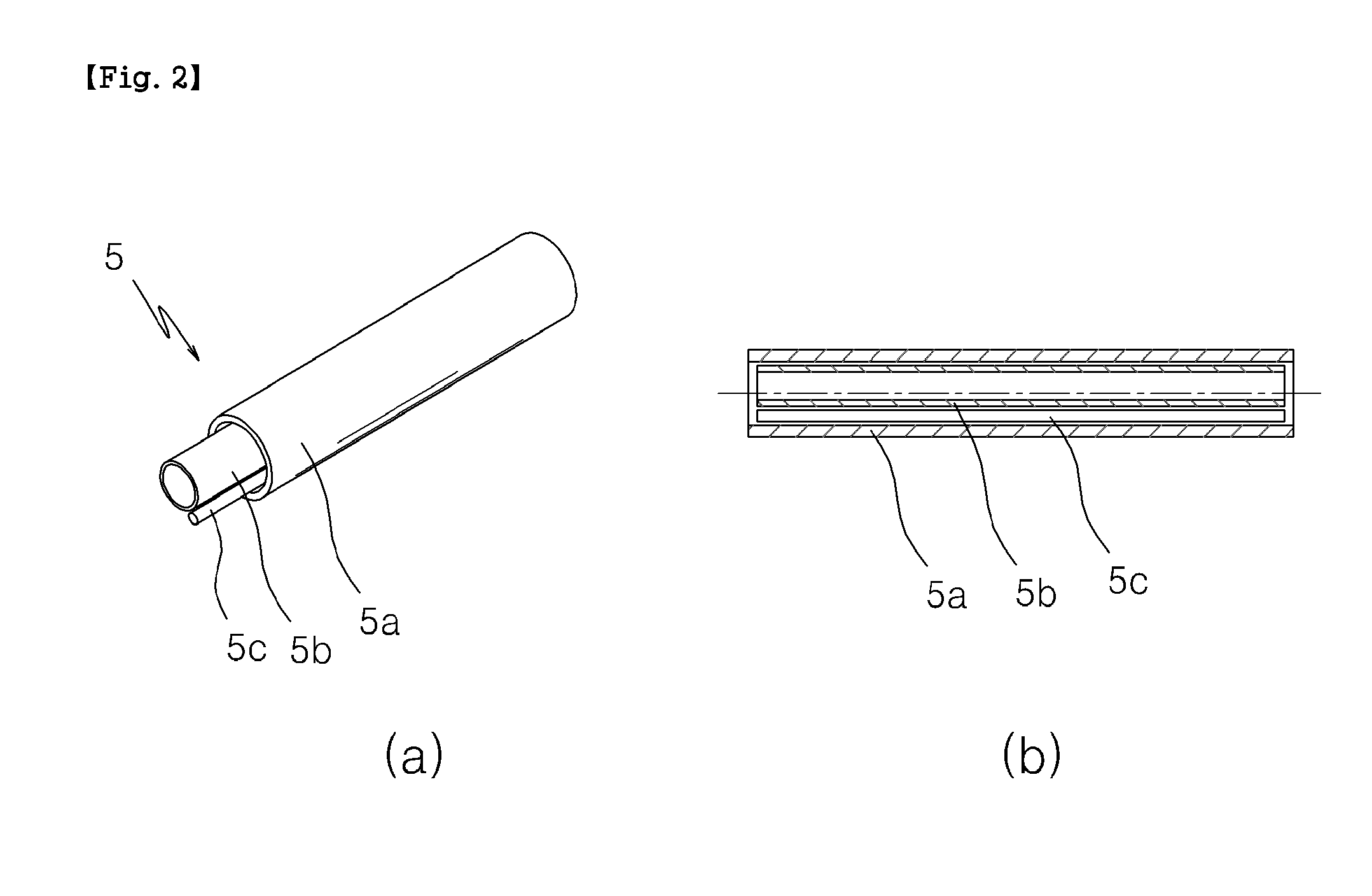

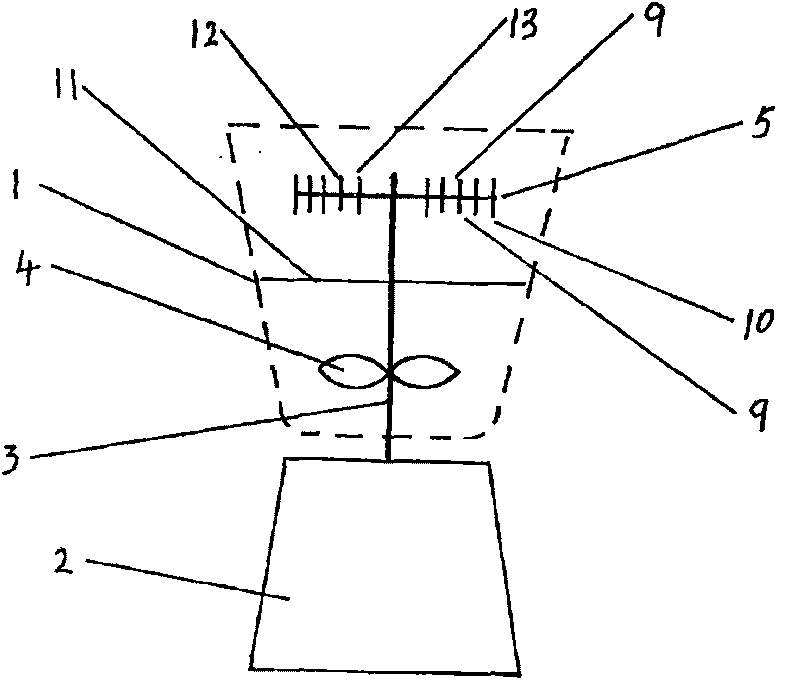

Optical fibre connector and an assembly method for the same

ActiveUS20120288238A1Avoid damageQuality of optical changeCoupling light guidesMetal working apparatusCoil springEngineering

The present invention relates to an optical fiber connector whereby an operator can easily couple optical fibers on site, and to an assembly method for the same. More specifically the invention relates to: an optical fiber connector wherein a guide ferrule bush is provided between a ferrule and a coil spring so as to be able to solve a problem whereby a ferrule optical fiber between a ferrule body and a reinforcing sleeve is bent, and a problem whereby contact between the ferrule body and the ferrule optical fiber is broken due to frequent movement, when the ferrule moves within a range of movement provided for by a resilient member due to the resilient member; and to an assembly method for the same.

Owner:ILSIN OTS

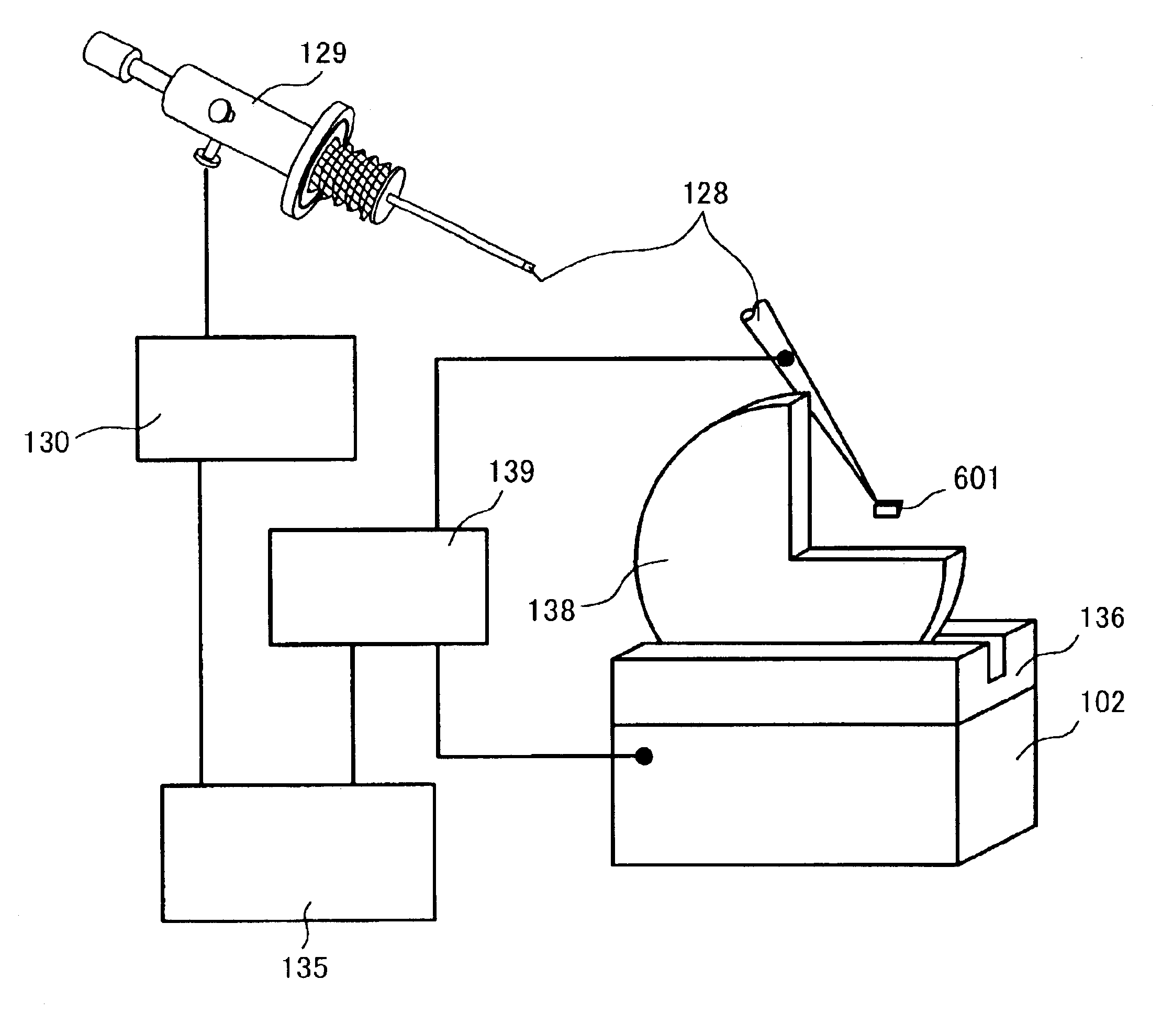

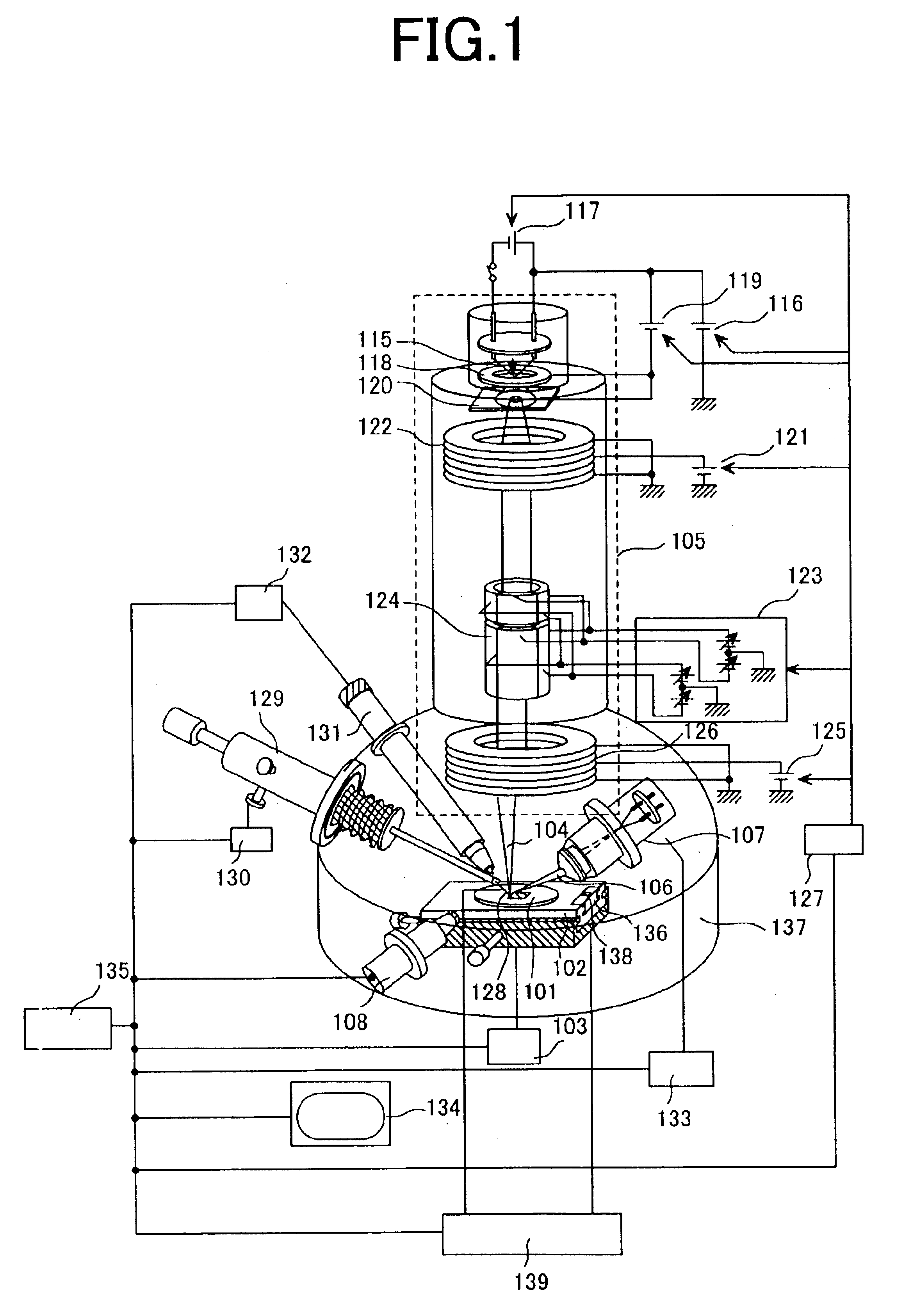

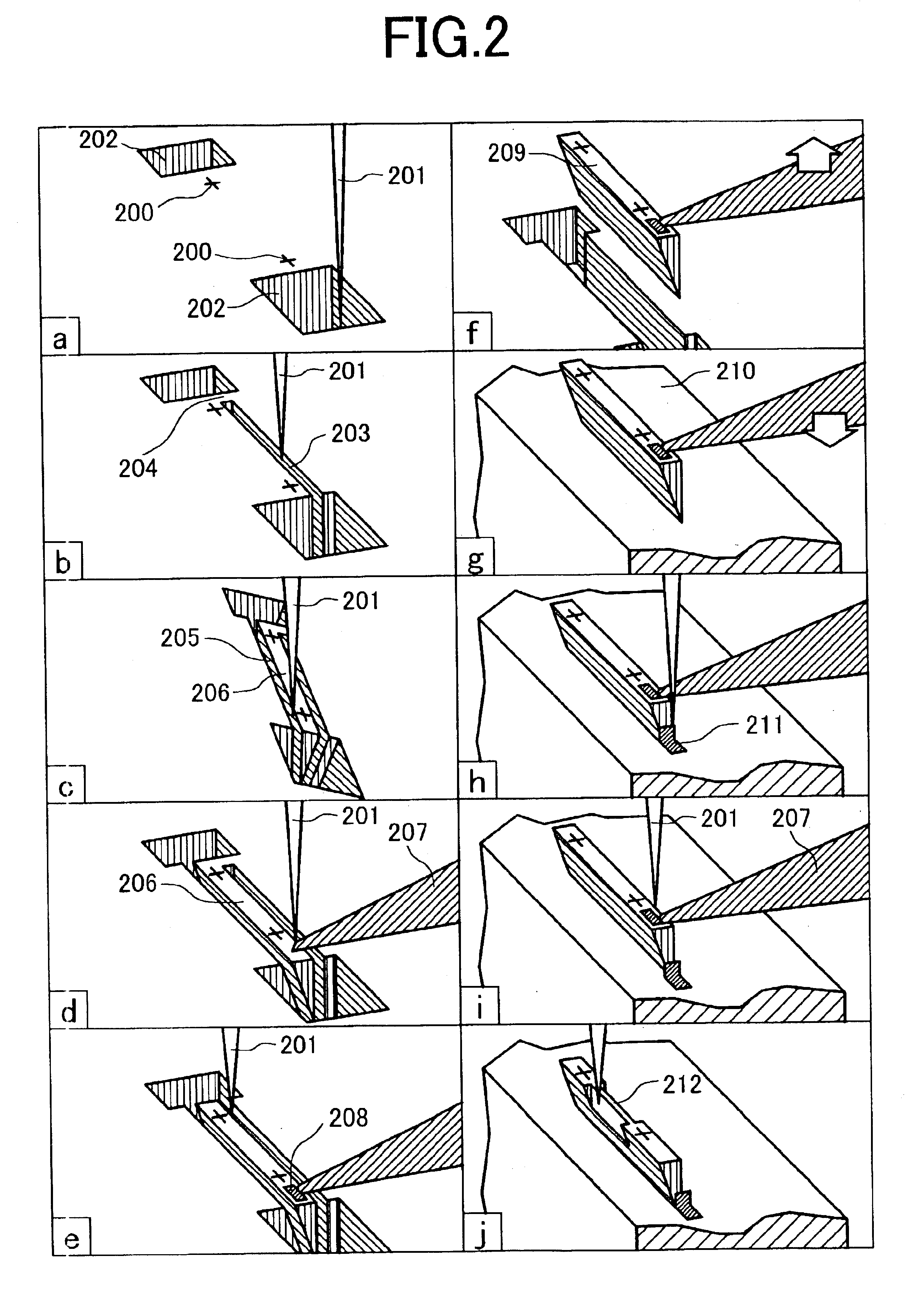

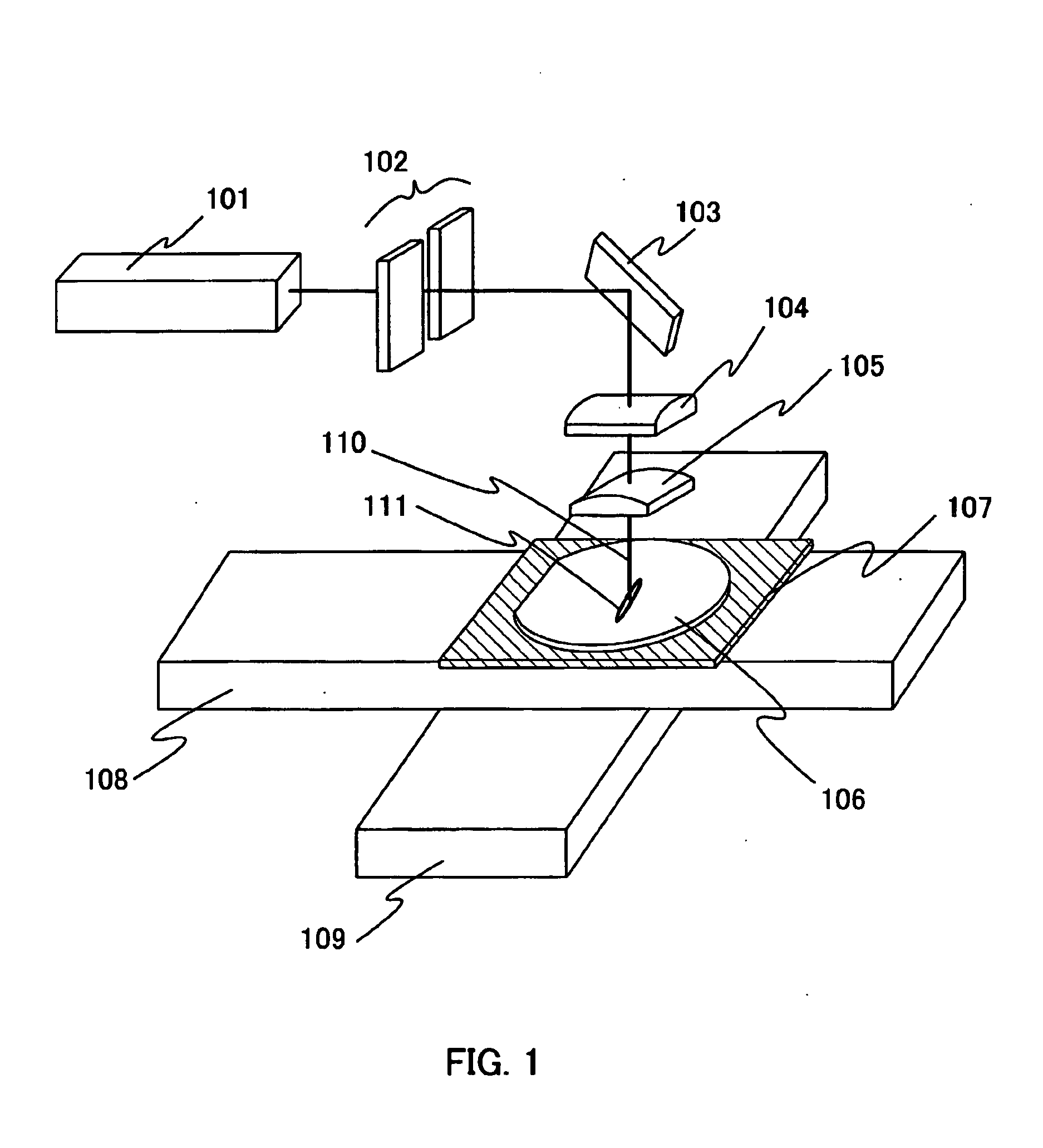

Apparatus for specimen fabrication and method for specimen fabrication

InactiveUS6858851B2Various problemReduce the possibilityMaterial analysis using wave/particle radiationElectric discharge tubesIon beam processingEngineering

A micro-sample prepared by processing with an ion beam is extracted by a probe and, in this state, a voltage is applied across the probe and a micro-sample holder by a circuit for sending electric current to probe. Thereafter, a probe driver is moved by a probe position controller to cause a portion of the probe distanced from the tip thereof by about 5 μm toward the root side thereof to approach an end surface of an ear portion of the micro-sample holder, so that the probe and the micro-sample holder are fixed together at a bonding point by current welding. Then, by cutting a root-side portion, relative to the bonding point, of the probe using an ion beam, fixation of the micro-sample to the micro-sample holder via the tip of the probe is completed.

Owner:HITACHI HIGH-TECH CORP

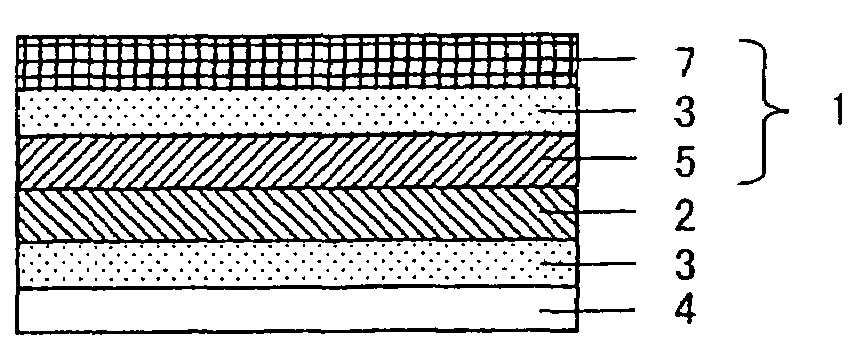

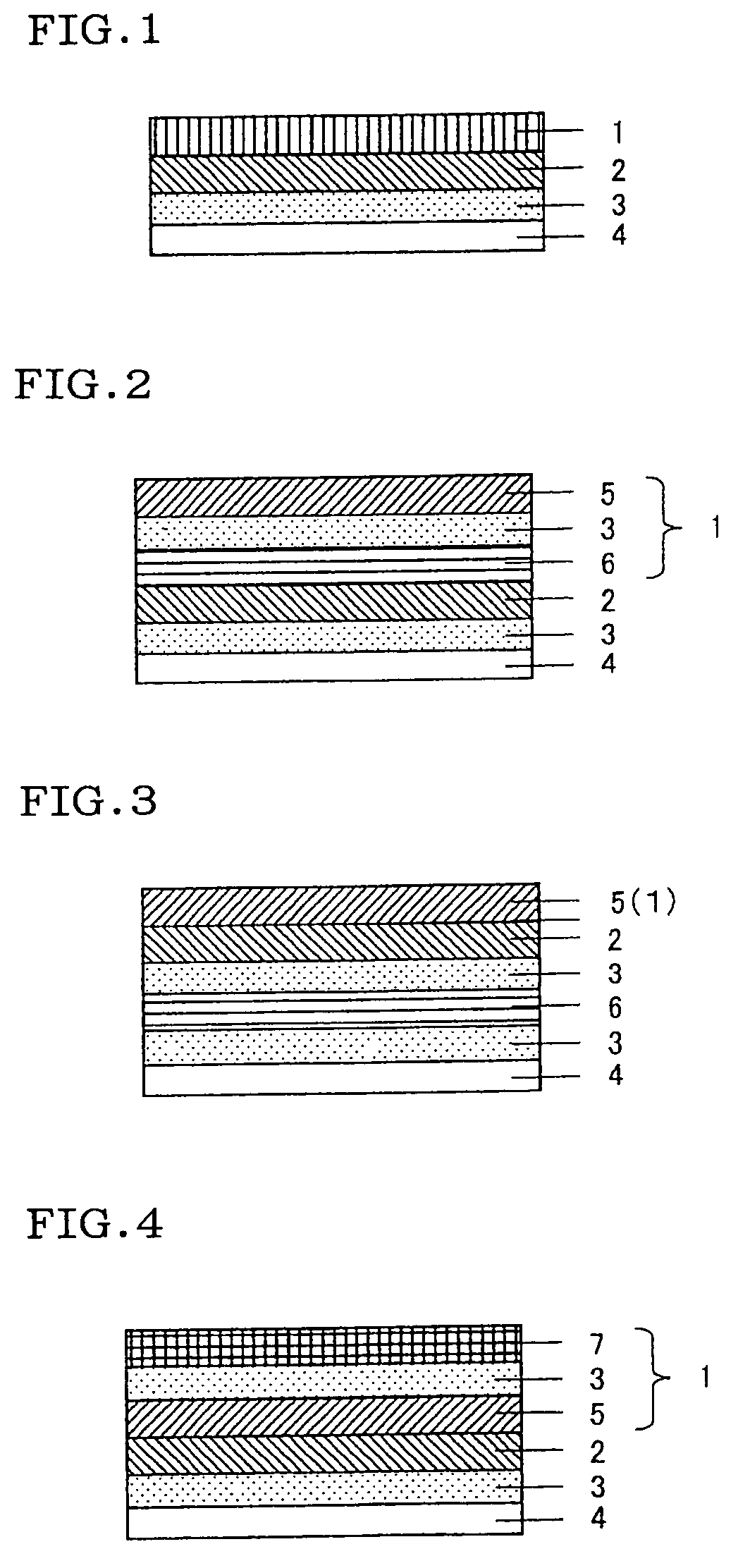

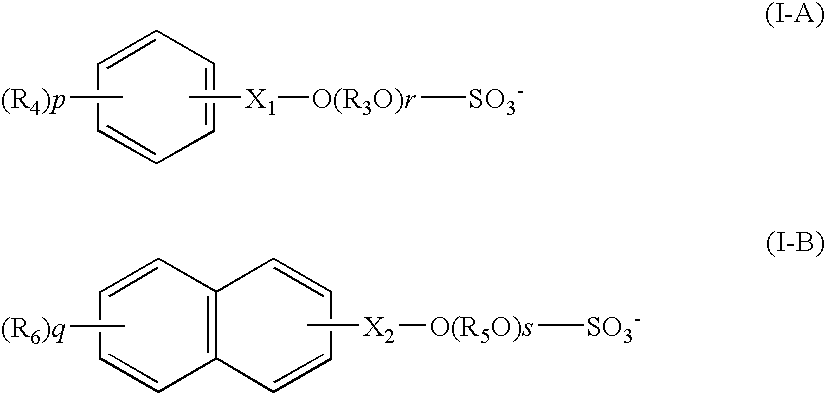

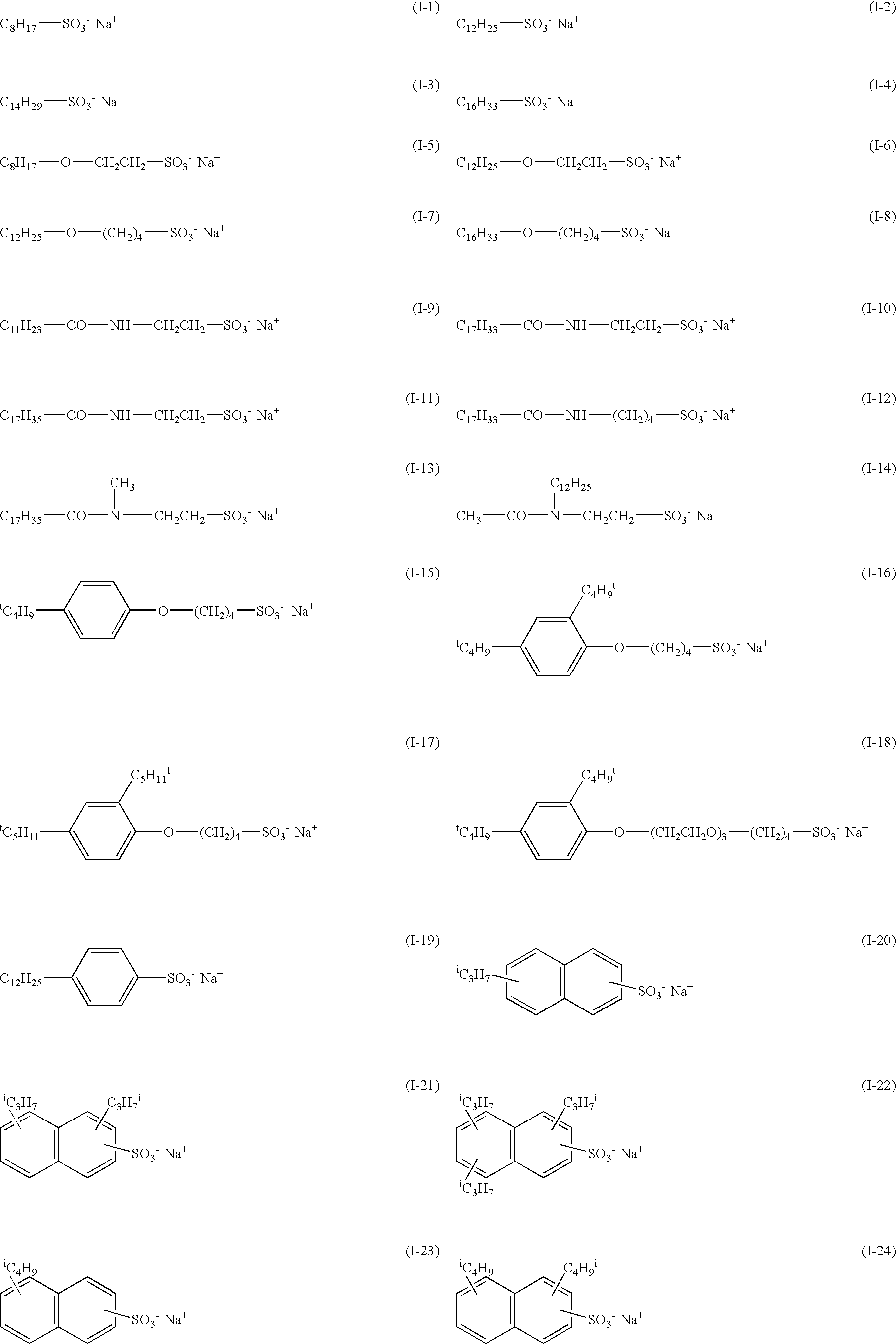

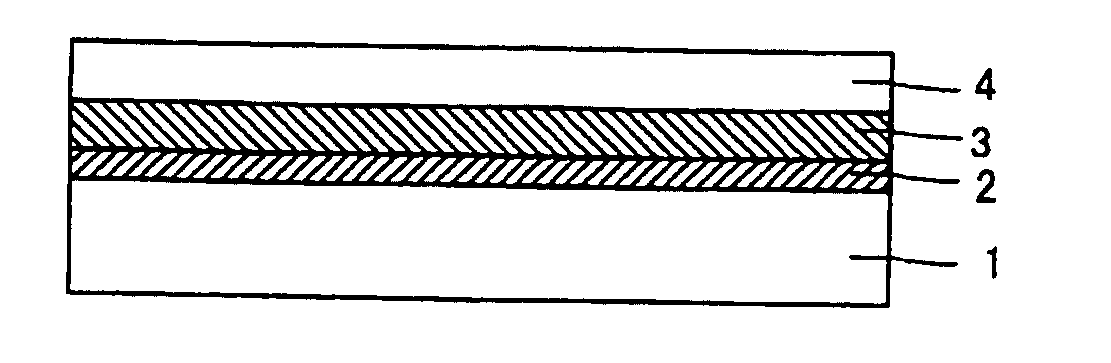

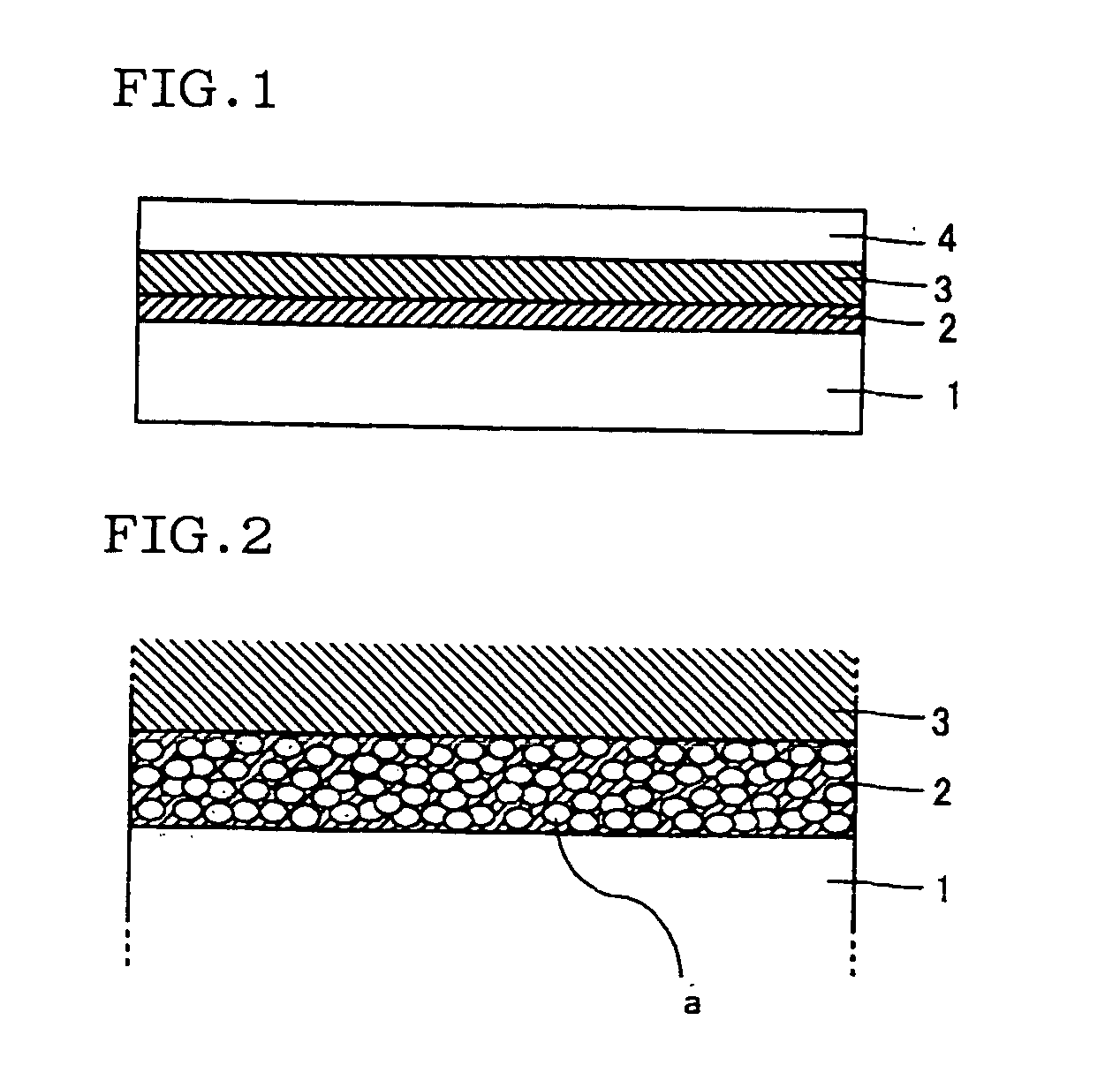

Antistatic optical film, method for manufacturing the same and image viewing display

ActiveUS7413766B2Suppress change qualityEasy to useLiquid crystal compositionsSolid-state devicesWater dispersibleImage View

An antistatic optical film comprising an antistatic layer laminated on at least one side of an optical film, wherein the antistatic layer comprises a water soluble or a water dispersible conductive polymer, has excellent antistatic effect, optical characteristics and appearance.

Owner:NITTO DENKO CORP

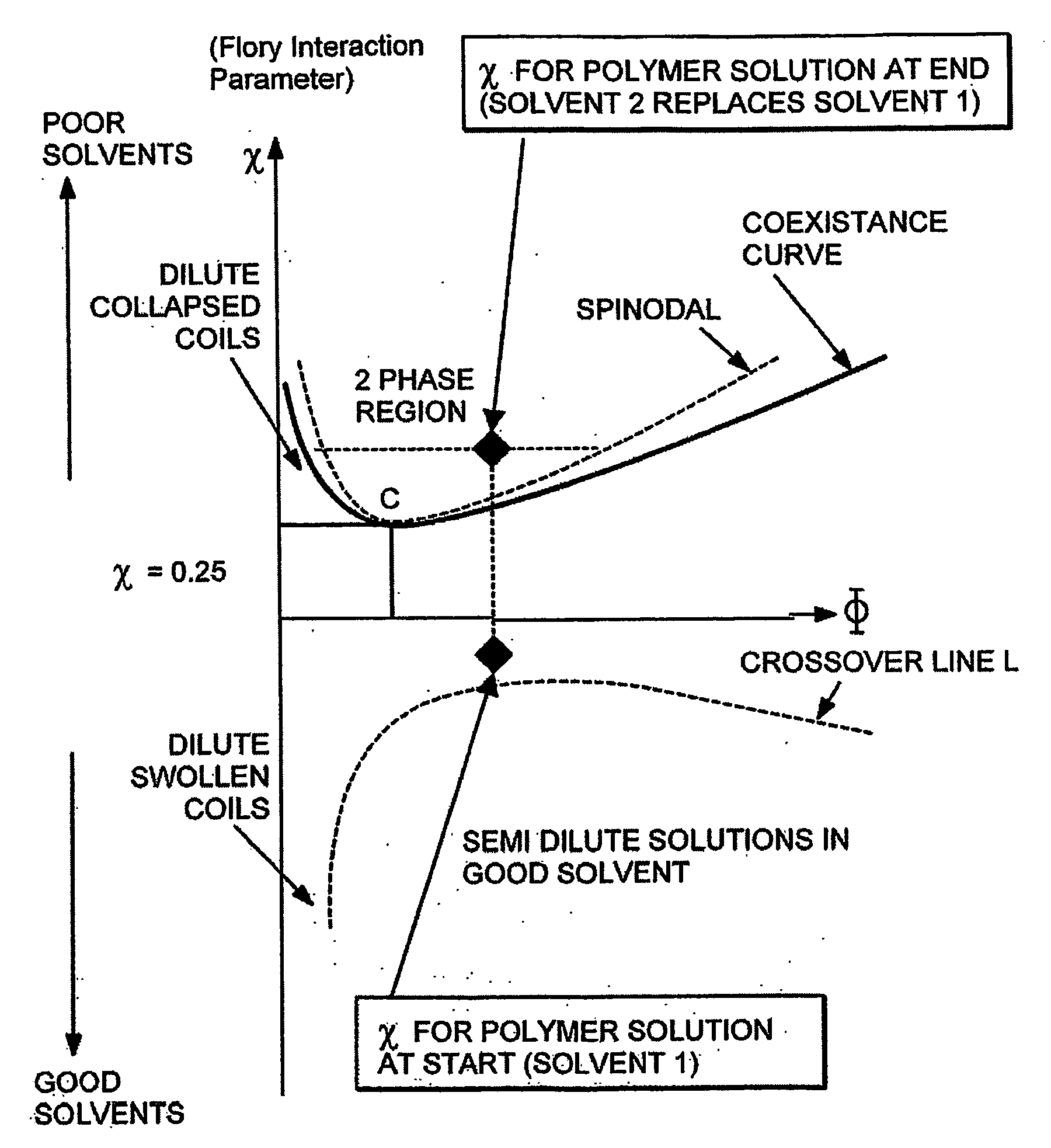

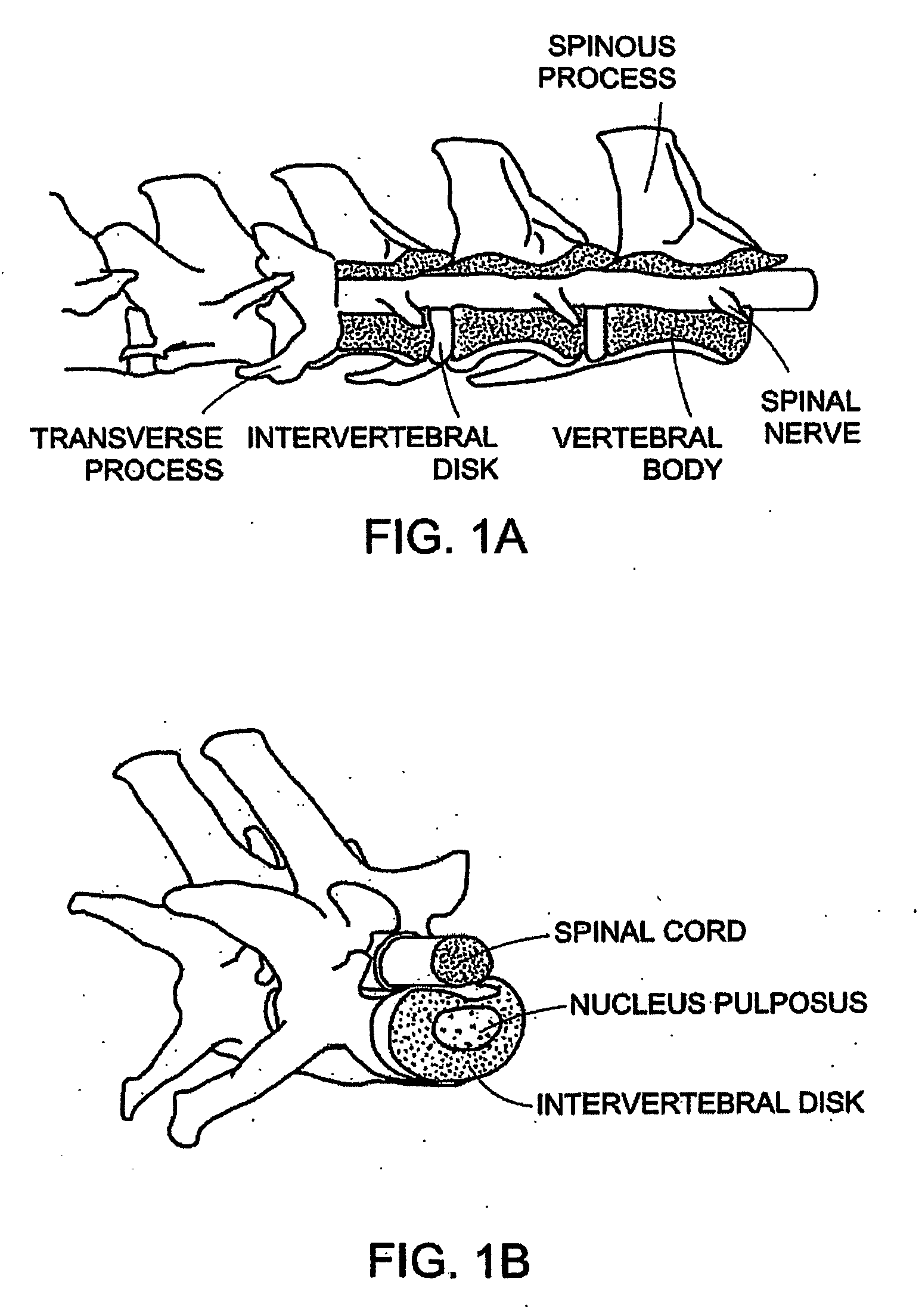

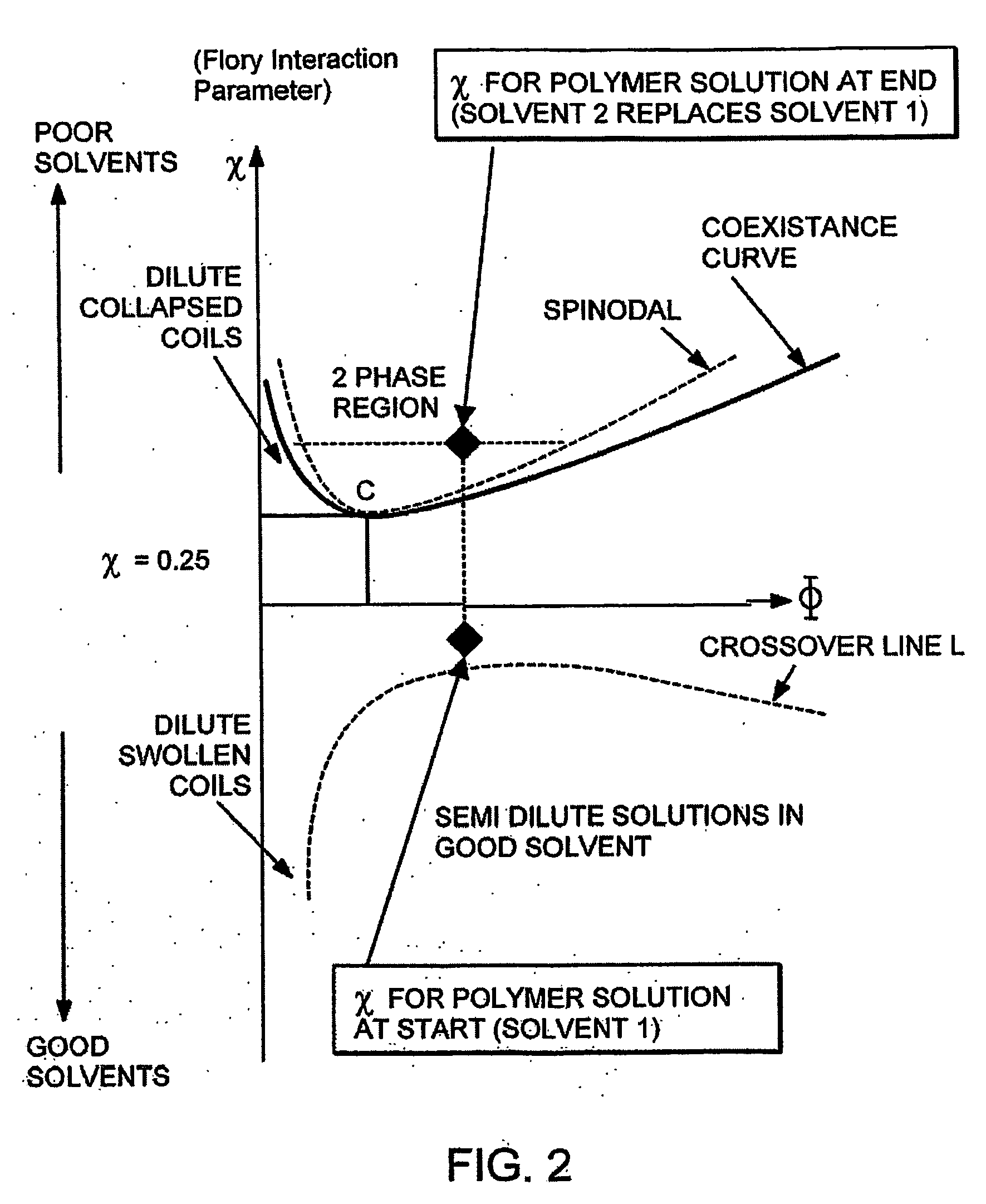

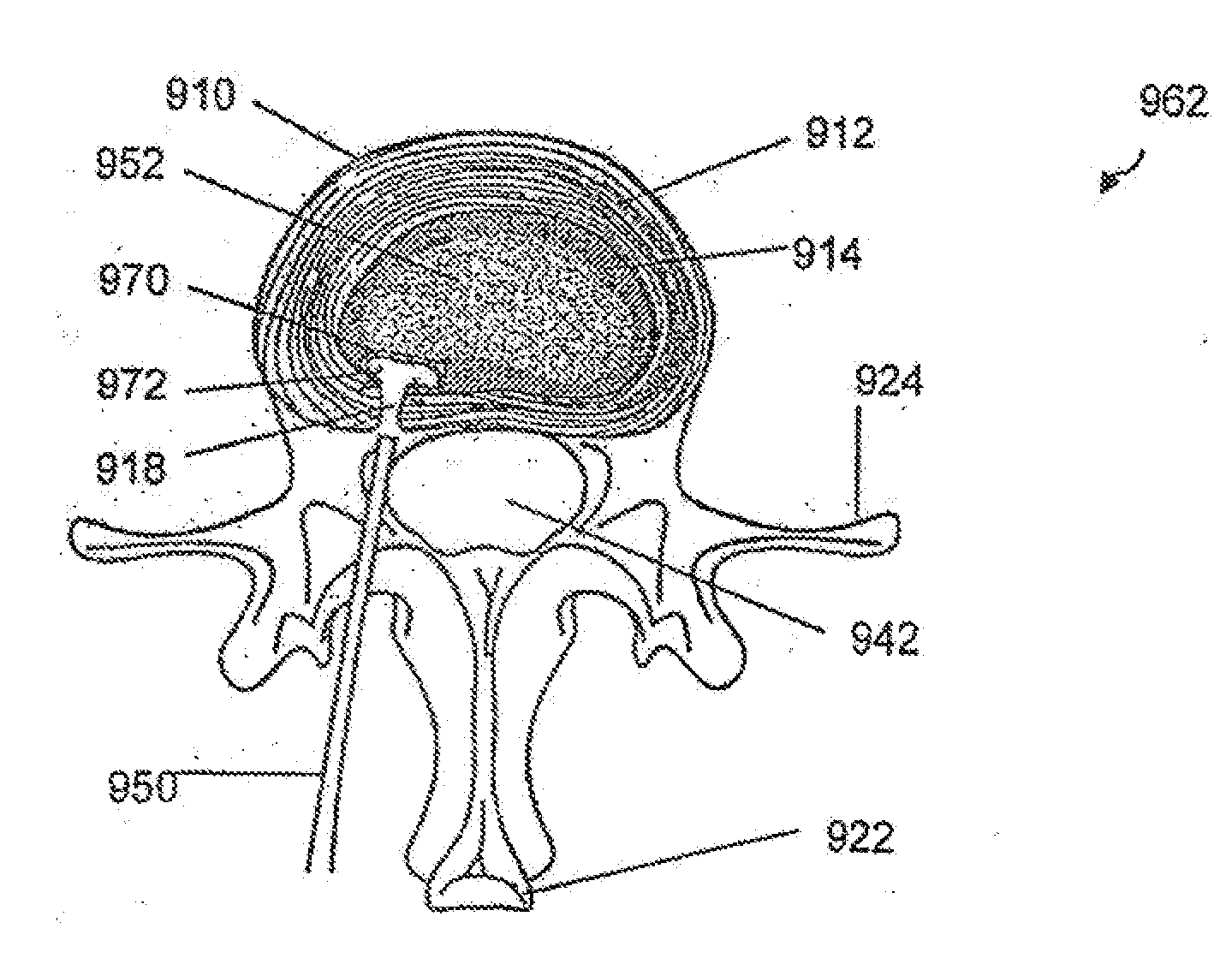

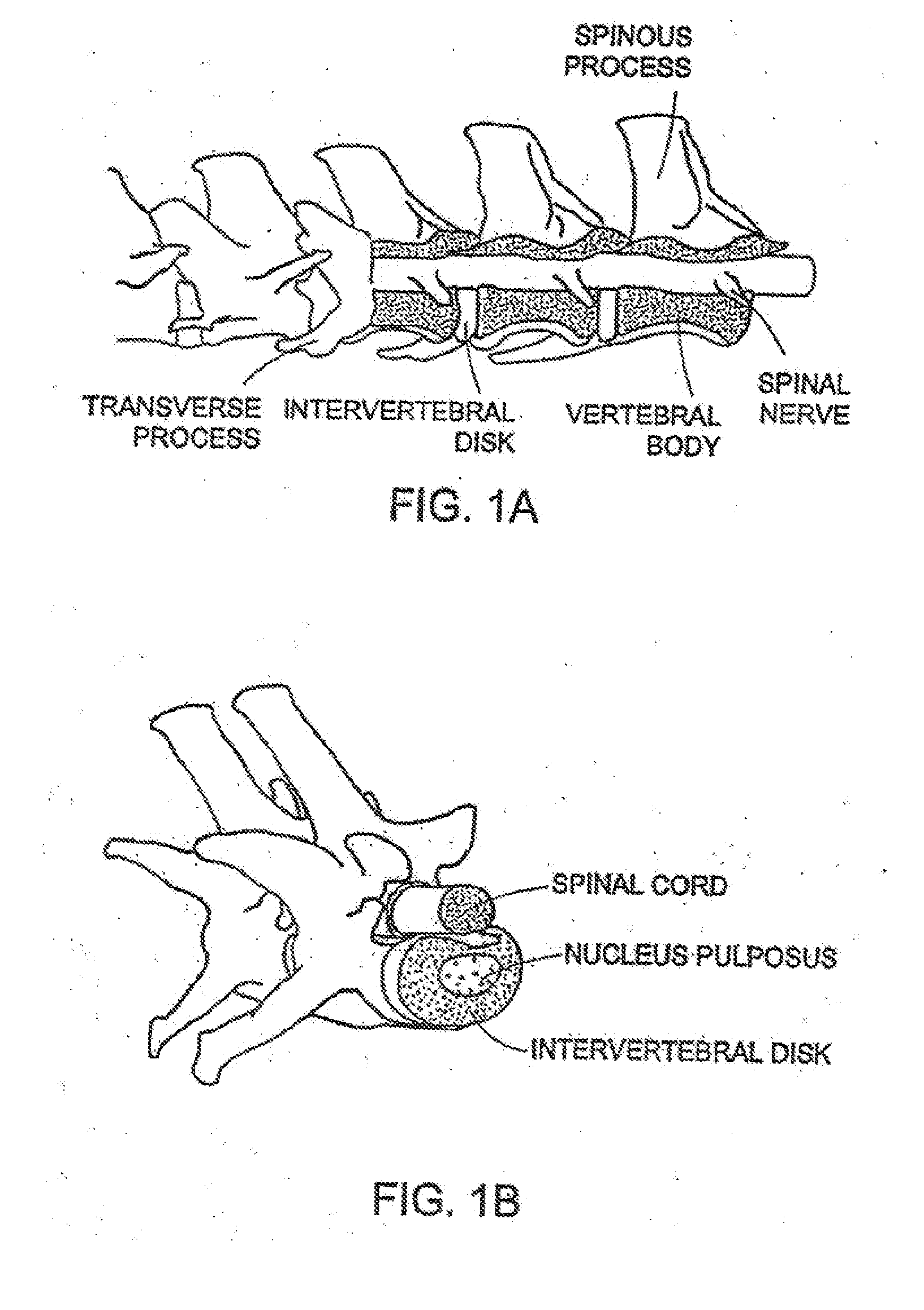

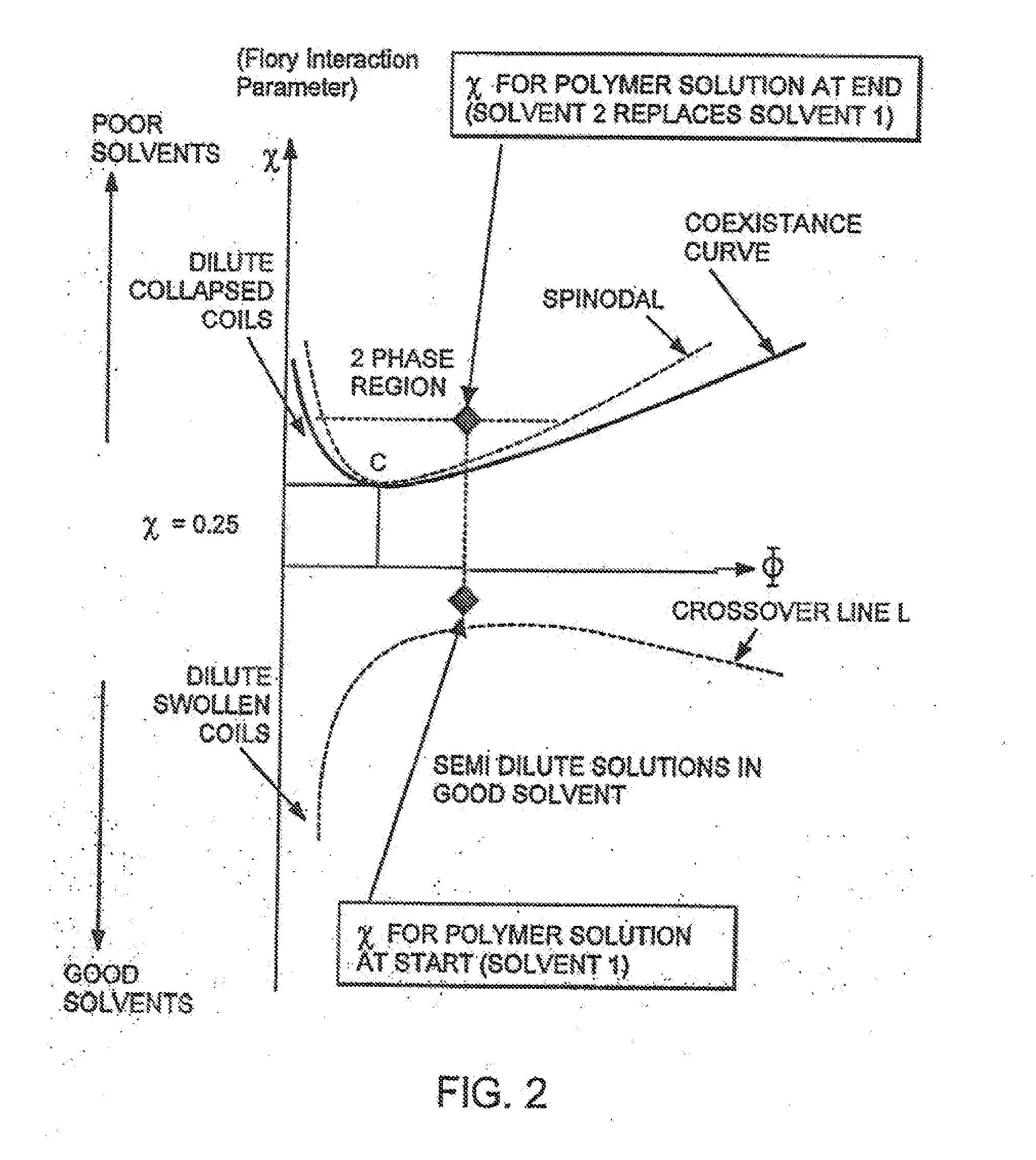

Systems and methods for controlling and forming polymer gels

InactiveUS20070167541A1Minimizing damageHigh Flory interaction parameterInksGranular deliveryCross-linkViscoelastic Solutions

In preferred embodiments, the present invention provides methods of controllably making a vinyl polymer hydrogel having desired physical properties without chemical cross links or radiation. The gelation process is modulated by controlling, for example the temperature of a resultant vinyl polymer mixture having a gellant or using active ingredients provided in an inactive gellant complex. In accordance with a preferred embodiment the method of manufacturing a vinyl polymer hydrogel includes the steps of providing a vinyl polymer solution comprising a vinyl polymer dissolved in a first solvent; heating the vinyl polymer solution to a temperature elevated above the melting point of the physical associations of the vinyl polymer, mixing the vinyl polymer solution with a gellant wherein the resulting mixture has a higher Flory interaction parameter than the vinyl polymer solution: inducing gelation of the mixture of vinyl polymer solution and gellant; and controlling the gelation rate to form a viscoelastic solution wherein workability is maintained for a predetermined period thereby making a vinyl polymer hydrogel having the desired physical property. In further preferred embodiments the present invention provides physically crosslinked hydrogels produced by controlled gelation of viscoelastic solution wherein workability is maintained for a predetermined period. In another aspect, the present invention provides kits for use in repairing intervertebral disks or articulated joints including components that form the vinyl polymer hydrogel and a dispenser.

Owner:CAMBRIDGE POLYMER GROUP

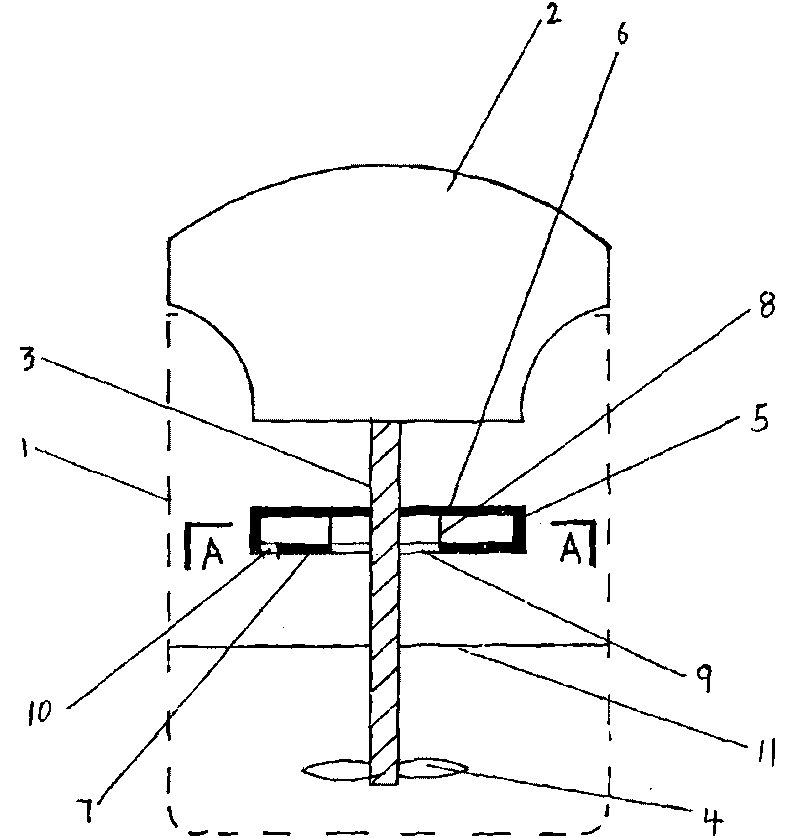

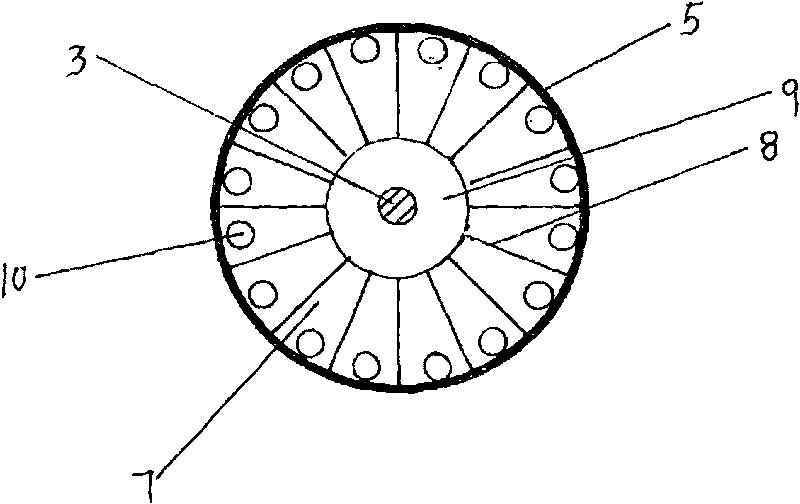

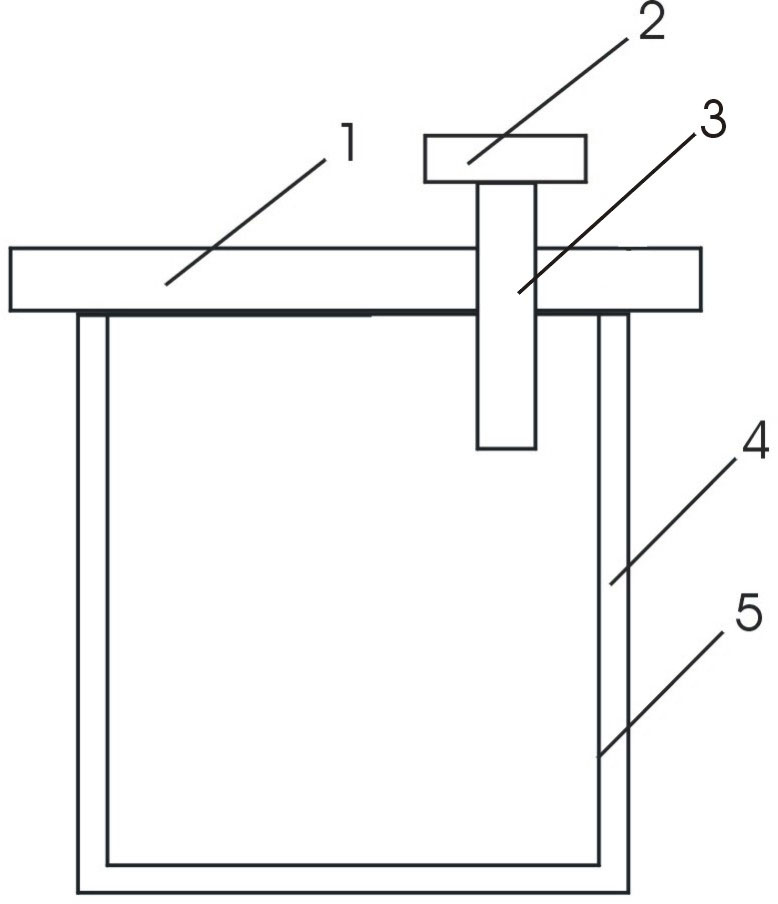

Food processor with rotary type defoaming device

InactiveCN101703365AEliminate generationContinuous heatingBeverage vesselsStrainersSocial benefitsEconomic benefits

The invention relates to a food processor with a rotary type defoaming device. A main body of the food processor comprises a pulverization cutter, a motor, a pulverization knife shaft and a barrel body; a rotary type defoaming device is arranged on the food processor; the rotary type defoaming device comprises a defoamer main body, wherein the rotation center position of the defoamer main body is provided with a shaft center installation hole, or the defoamer main body is provided with a rotating shaft; and the defoamer main body is connected with a power shaft, and the power shaft is the self pulverization knife shaft or other power shafts of the food processor. The invention can actively eliminate foam generated when foods are pulverized, heated and cooked in time, enables the pulverization operation or the heating and cooking operation to be continuously and quickly carried out without intermittent stop, shortens the pulverization or cooking time greatly, enhances the working efficiency, can meet the rhythm of the modern family life and the requirement of quick rhythm of the modern commercial management, enhances the quality of the modern family life and the efficiency of the commercial management obviously and has great economic benefit and social benefit.

Owner:王晓东

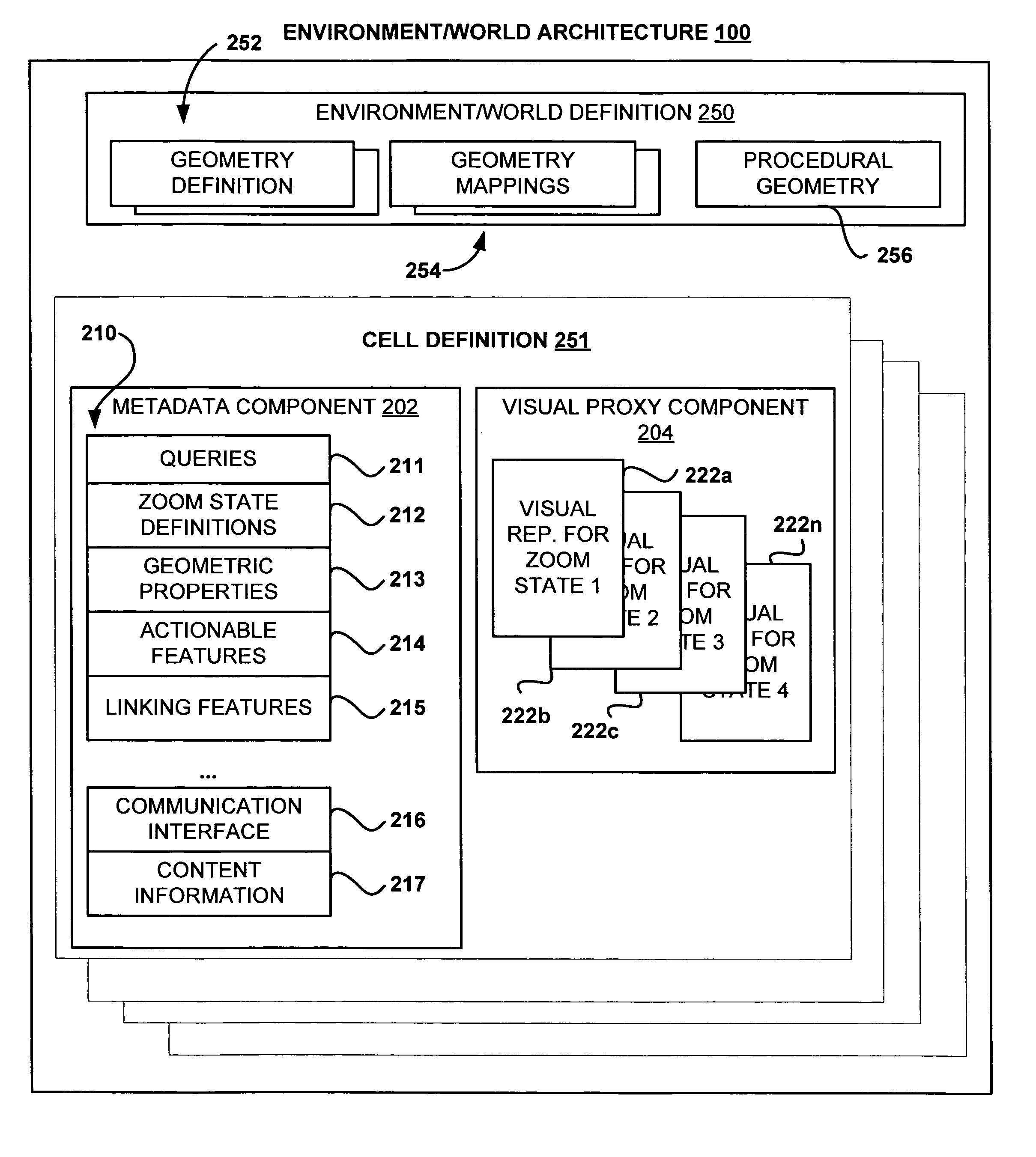

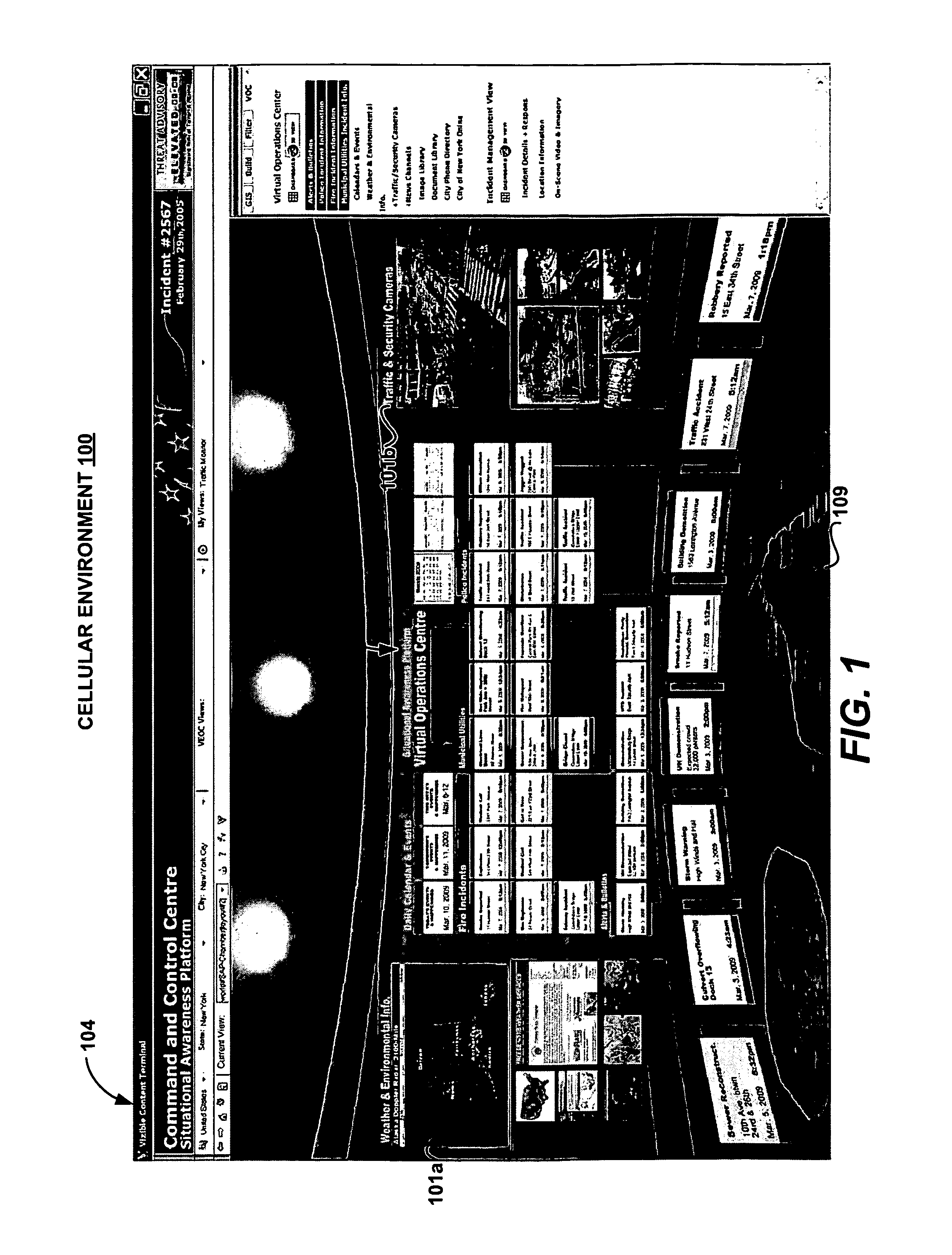

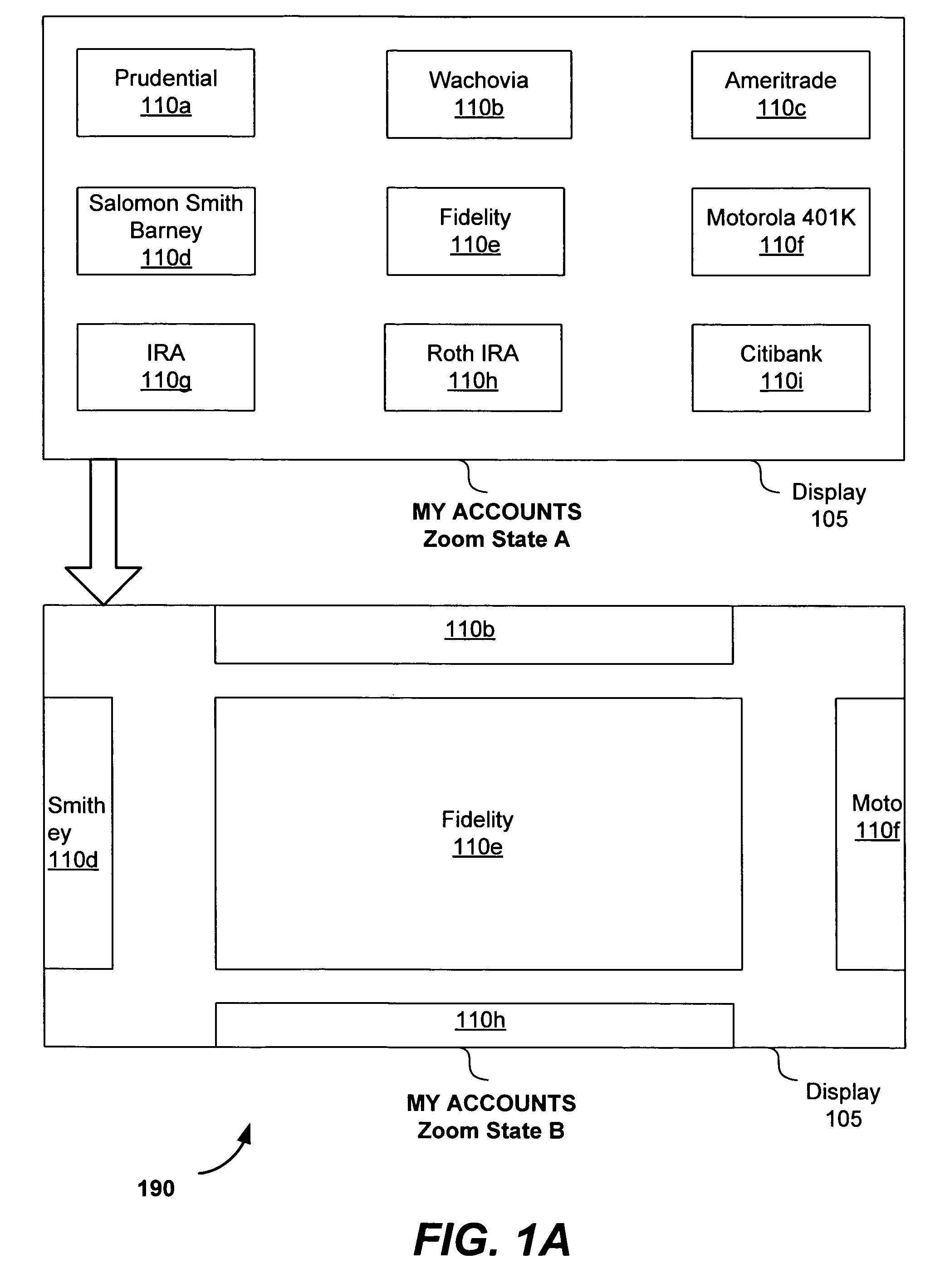

Spatially driven content presentation in a cellular environment

InactiveUS8418075B2Maintaining senseFacilitate decision-makingDigital data information retrievalText processingMedia typeState dependent

Techniques are provided for integrated content presentation via cells arranged geometrically in a cellular environment. Users can navigate various orientations and zoom states of the cellular environment to access information via different applications, different media types, different visual representations and from different underlying content sources. The information can be organized according to various logical relationships. Upon receiving an indication of a zoom state associated with a cell or a group of cells arranged in the cellular environment, a content reference at that zoom state is retrieved. Further, the content reference is resolved to retrieve and output content, including a visual representation associated with the zoom state.

Owner:OPEN TEXT SA ULC

Systems and methods for controlling and forming polymer gels

ActiveUS20060270781A1Change qualityPrevent gelationNon-fibrous pulp additionDiagnosticsCross-linkViscoelastic Solutions

In preferred embodiments, the present invention provides methods of controllably making a vinyl polymer hydrogel having desired physical properties without chemical cross links or radiation. The gelation process is modulated by controlling, for example, the temperature of a resultant vinyl polymer mixture having a gellant or using active ingredients provided in an inactive gellant complex. In accordance with a preferred embodiment, the method of manufacturing a vinyl polymer hyrodgel includes the steps of providing a vinyl polymer solution comprising a vinyl polymer dissolved in a first solvent; heating the vinyl polymer solution to a temperature elevated above the melting point of the physical associations of the vinyl polymer, mixing the vinyl polymer solution with a gellant, wherein the resulting mixture has a higher Flory interaction parameter than the vinyl polymer solution; inducing gelation of the mixture of vinyl polymer solution and gellant; and controlling the gelation rate to form a viscoelastic solution, wherein workability is maintained for a predetermined period, thereby making a vinyl polymer hydrogel having the desired physical property. In further preferred embodiments, the present invention provides physically crosslinked hydrogels produced by controlled gellation of viscoelastic solution wherein workability is maintained for a predetermined period. In another aspect, the present invention provides kits for use in repairing intervertebral disks or articulated joints including components that form the vinyl polymer hydrogel and a dispenser.

Owner:CAMBRIDGE POLYMER GROUP

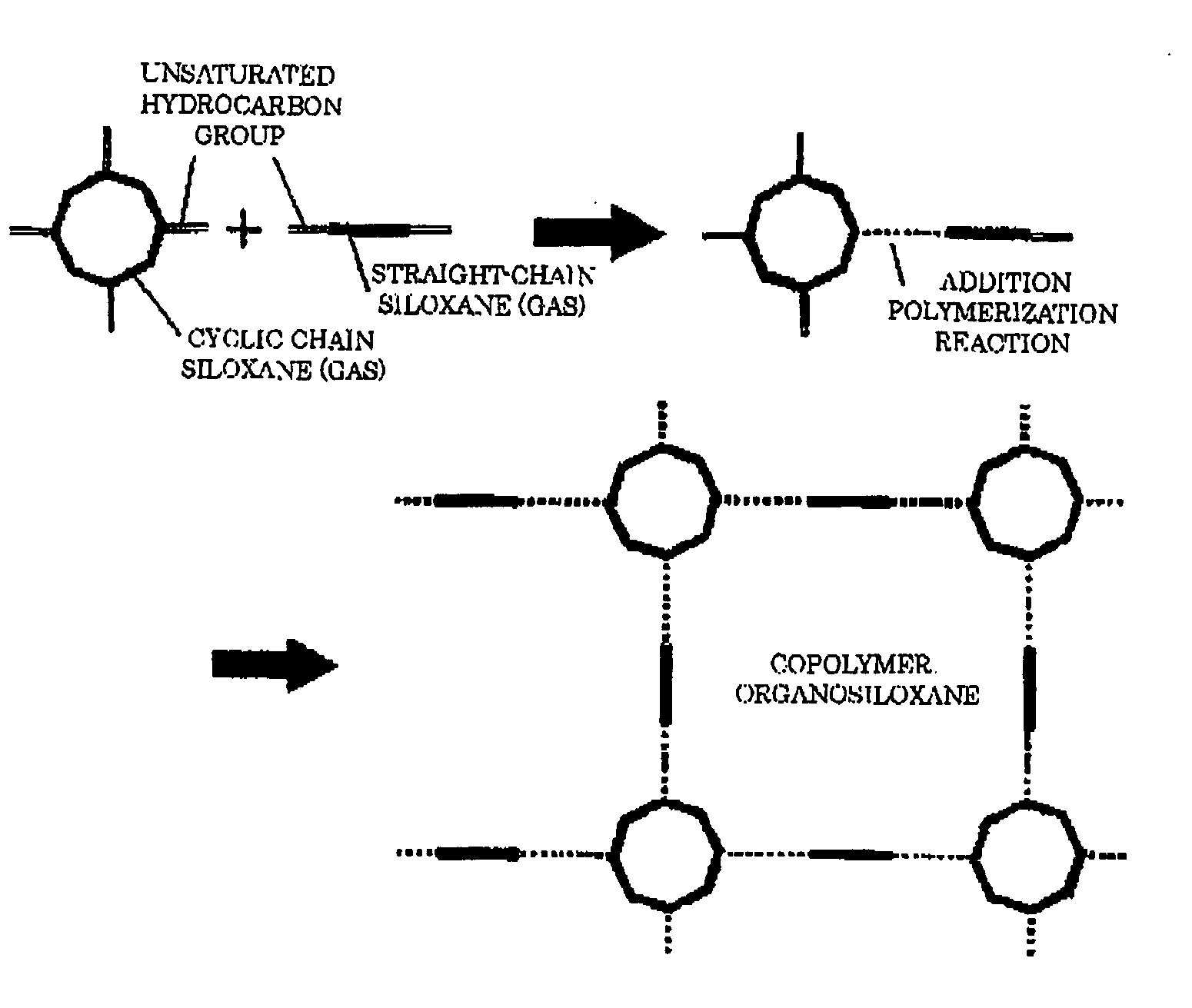

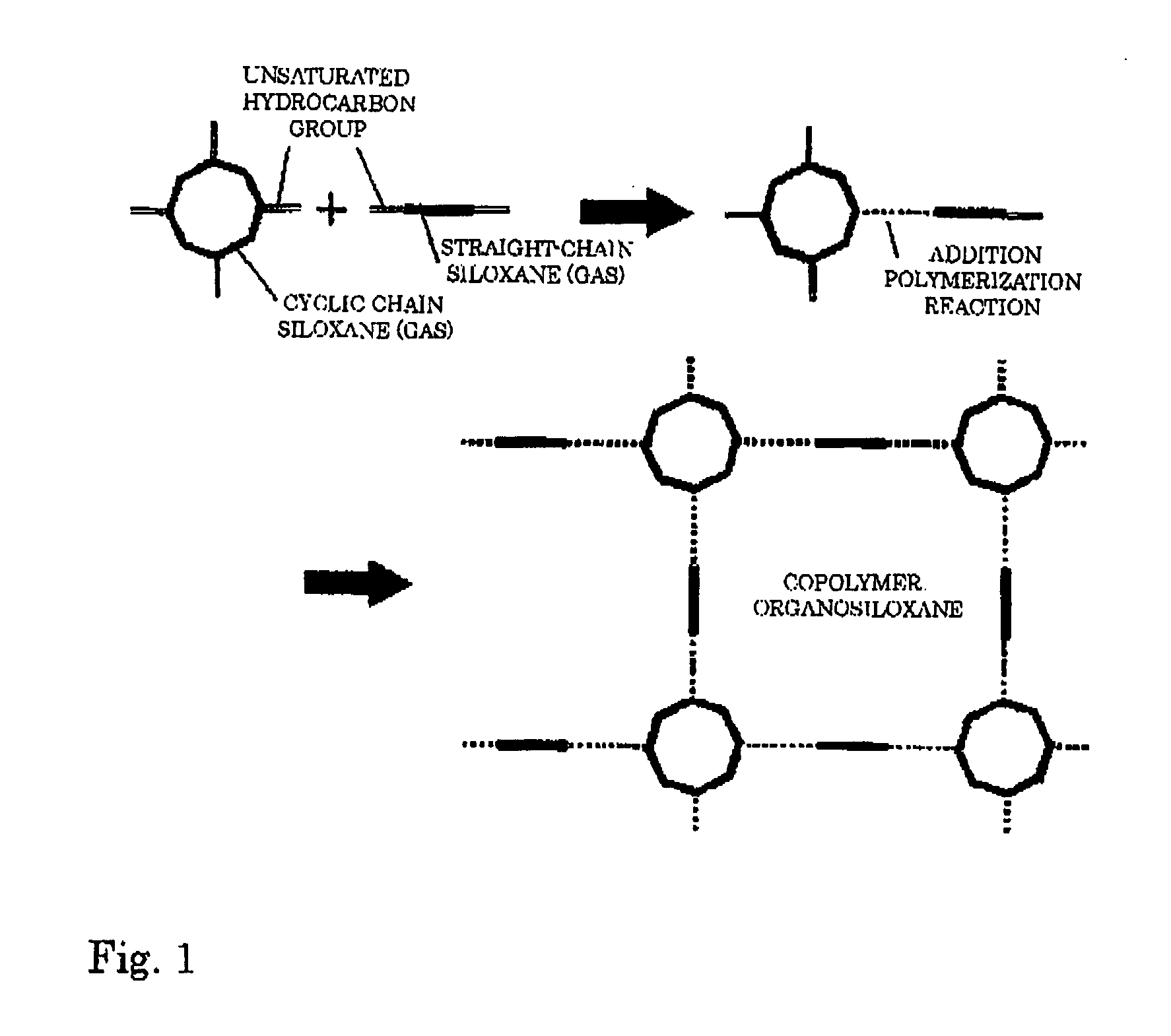

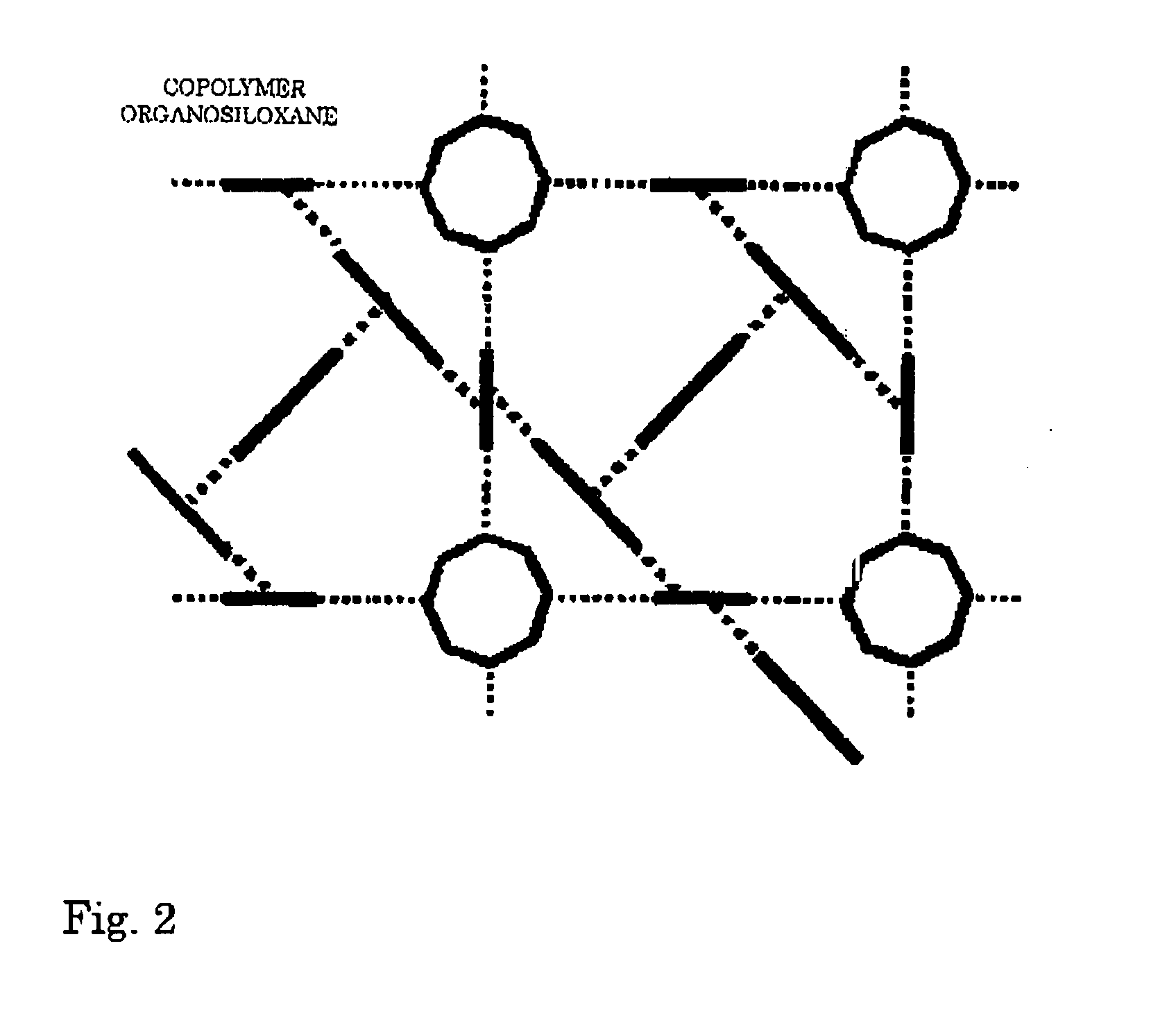

Organic siloxane copolymer film, method and deposition apparatus for producing same, and semiconductor device using such copolymer film

ActiveUS20050267253A1Improve film qualityHigh bridge densityVacuum evaporation coatingSputtering coatingDielectricCopper-wiring

An insulated organic copolymer is provided, having the excellent mechanical strength and deposition property at an interface contacting the lower base or the upper layer of the inorganic insulation film, and the effective dielectric constant is low as the whole film, which is suitable as the interlayer insulation film that separates the multi-layer copper wirings of the semiconductor device. The organosiloxane copolymer film is obtained by the polymerization of the cyclosiloxane and the straight-chain siloxane as the raw materials by the plasma excitation of both. At the interfaces contacting the inorganic insulation films, the interface layers having a film quality that is intricate and excellent in deposition property are prepared whereby the main component of the film composition is the straight-chain siloxane. The inner section of the copolymer film mixes the cyclosiloxane component having pores surrounded by the cyclosiloxane backbone and the straight-chain siloxane components, has the network structure layer relatively suppressing the density, and has the composition changing in the thickness direction whereby the multi-layer wirings embedding the copper thin film is formed.

Owner:GK BRIDGE 1

Processing system and method of processing

InactiveUS20070044824A1Slow changeChange qualityTransportation and packagingMixer accessoriesHandling systemComputer science

This invention relates to a processing system, a method of processing and products produced by said process. Such system and method can reduce change over time and / or off quality product.

Owner:THE PROCTER & GAMBLE COMPANY

Hybrid wheat breeding method

InactiveCN102484980ABreak the situation of stagnant productionSimple stepsHorticulture methodsPlant genotype modificationBiotechnologyBotany

The invention relates to a hybrid wheat breeding method. The hybrid wheat breeding method comprises the following steps of parent selection and emasculation, generation-adding breeding and systematic selection. Through the hybrid wheat breeding method, novel hybrid wheat is obtained. The hybrid wheat breeding method has the advantages of simple processes, strong operability and high rate of emergence. A yield per mu of the novel hybrid wheat obtained by the hybrid wheat breeding method is improved by about 15%. The hybrid wheat obtained by the hybrid wheat breeding method has strong lodging resistance and disease resistance, good quality and a stable and high yield. A planting cost of the hybrid wheat obtained by the hybrid wheat breeding method is reduced in the case that a seed utilization amount per mu is saved by above 30%.

Owner:弭尚岭

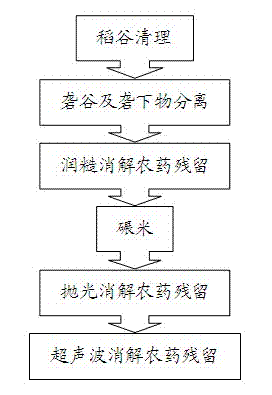

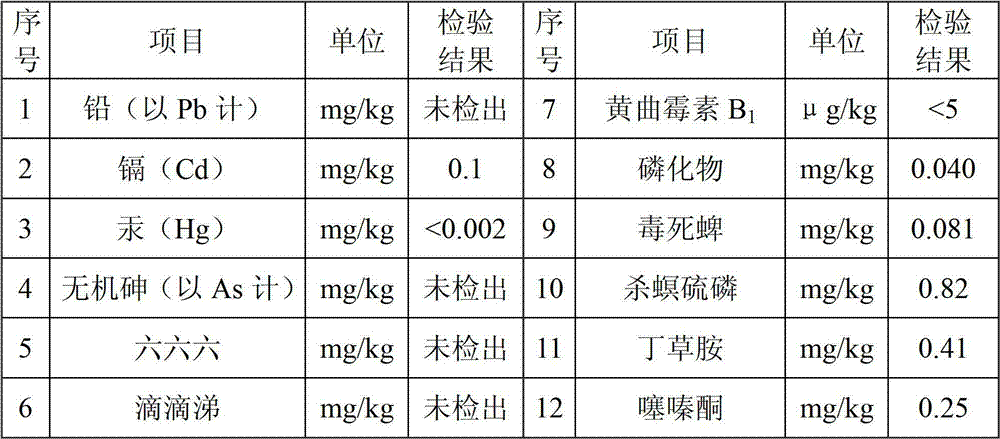

Paddy rice producing production technology for removing pesticide residue

ActiveCN102824934ASolve the problem of pesticide residuesChange qualityGrain huskingGrain polishingFlavorPesticide residue

The invention provides a paddy rice producing production technology for removing pesticide residue, and relates to the technical field of the processing and the producing of food, wherein the production technology comprises the following steps of: cleaning paddy, separating hull grains from hulled materials, removing the pesticide residue by means of coarseness humidifying, milling rice, removing the pesticide residue in a polishing way, and removing the pesticide residue by ultrasonic wave. The paddy rice producing production technology for removing the pesticide residue provided by the invention combines with the production of paddy rice producing, mainly aims at solving the problem that the paddy contains the pesticide residue, is scientific in technological process design, reasonable in technical method, and low in production cost, effectively and reliably removes the pesticide residue, can subsidiarily kill the toadstool in the paddy, can produce the paddy clearly, guarantees the quality safety of paddy-processed products, is free from secondary pollution of rice products in the process of processing and producing, can not change the original quality, nutrition and special flavor of the paddy, is particularly suitable for preparing the products which are higher in nutrition value and economic value such as germ-remaining rice, the clean rice and the like besides the common rice, and is further good for reducing the pesticide residue of byproducts prepared by comprehensive utilization.

Owner:DANYANG JIAHE RICE

Exhaust system of internal combustion engine

ActiveUS20060037814A1Long processEasy to adjustSilencing apparatusMachines/enginesExhaust pipeMuffler

In an exhaust system, exhaust manifolds are connected to two banks provided in a V-type engine of a vehicle, respectively, to which front pipes each having a catalytic converter are connected to the exhaust manifolds, respectively. A muffler is provided at an exhaust downstream side of the exhaust pipes, and a rear pipe is further connected to the exhaust downstream side of the muffler. The front pipe has its rear end portion located near a through hole formed in the rear pipe. A path length of one of the front pipes from the bank to the muffler is made shorter than that of the other front pipe.

Owner:TOYOTA JIDOSHA KK

Chinese medicinal additive for livestock and poultry feeds and preparation method thereof

InactiveCN101653589AImprove conversion rateImprove meat qualityAnthropod material medical ingredientsFood processingFlosDisease

The invention relates to a Chinese medicinal additive for livestock and poultry feeds and a preparation method thereof. The additive comprises the following compositions in portion by weight: 0.8 to 1portion of angelica, 1 to 2 portions of Chinese angelica, 3 to 5 portions of gypsum, 1 to 2 portions of indigowoad root, 0.5 to 1.5 portions of skullcap, 1 to 2 portions of hawthorn fruit, 1 to 2 portions of malt, 1 to 2 portions of stored yeast, 1 to 2 portions of danshen root, 1 to 3 portions of pilose asiabell root, 1 to 3 portions of astragalus mongholicus, 0.5 to 1.5 portions of flos caryophyllata, 1 to 3 portions of anise, 0.5 to 1.5 portions of cumin, 1 to 3 portions of cassia, 1 to 2 portions of amomum globosum loureiro, 1 to 3 portions of fennel, 1 to 2 portions of drill seeds, 1 to2 portions of villous amomum fruit, 1 to 3 portions of tangerine peel, 2 to 5 portions of dried ginger, 5 to 10 portions of cypress seeds, 2 to 5 portions of mugwort leaves, 2 to 5 portions of ginkgoleaves, 1 to 3 portions of netmeg, 1 to 2 portions of white cardamom, 5 to 10 portions of maggot, 5 to 10 portions of yellow mealworm, 5 to 10 portions of earthworm, 3 to 8 portions of pricklyash peel, 40 to 60 portions of corn, and 20 to 40 portions of lucerne. The preparation method comprises the following steps: firstly, carrying out frying pre-treatment on the hawthorn fruit, the malt and thestored yeast; and then, mixing the three compositions with other compositions evenly. The additive can improve the capability of disease prevention and disease resistance of livestock and poultry, improves the meat quality of the livestock and the poultry, and has low cost.

Owner:崔志常

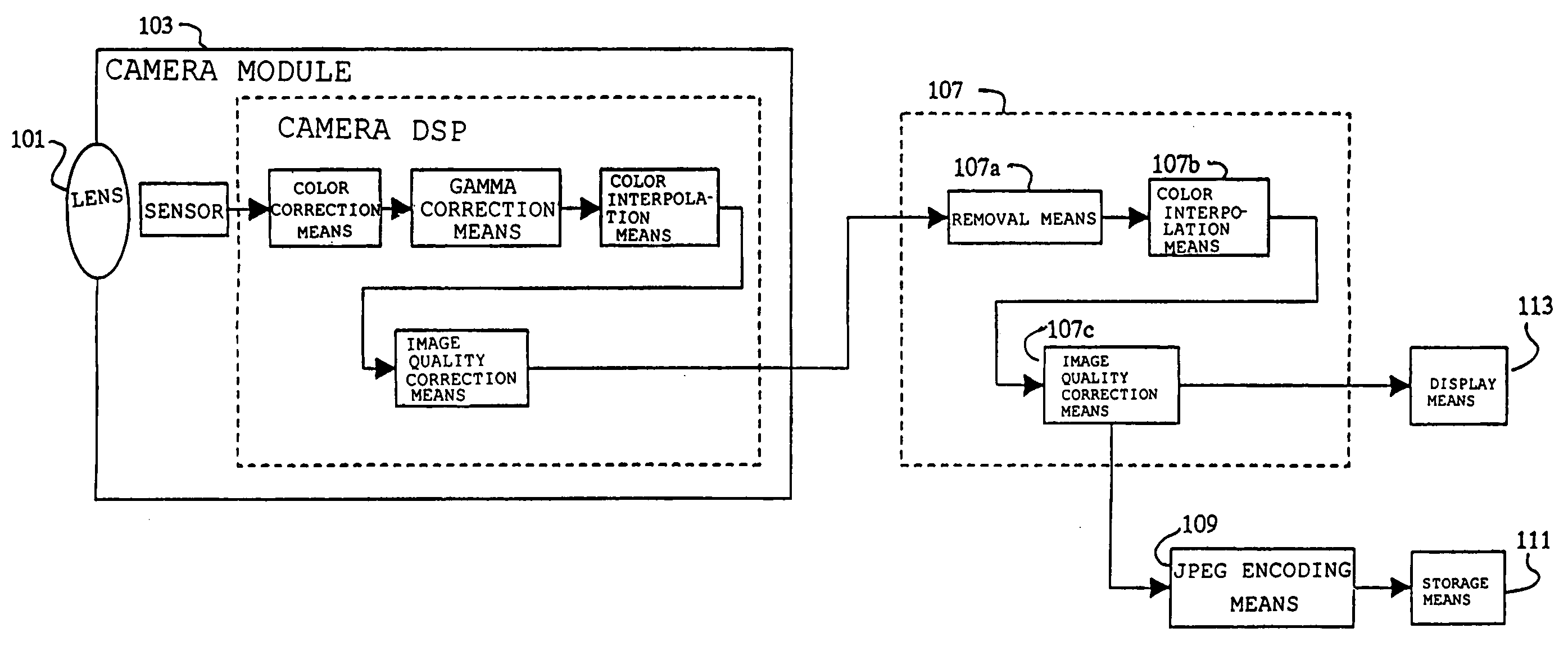

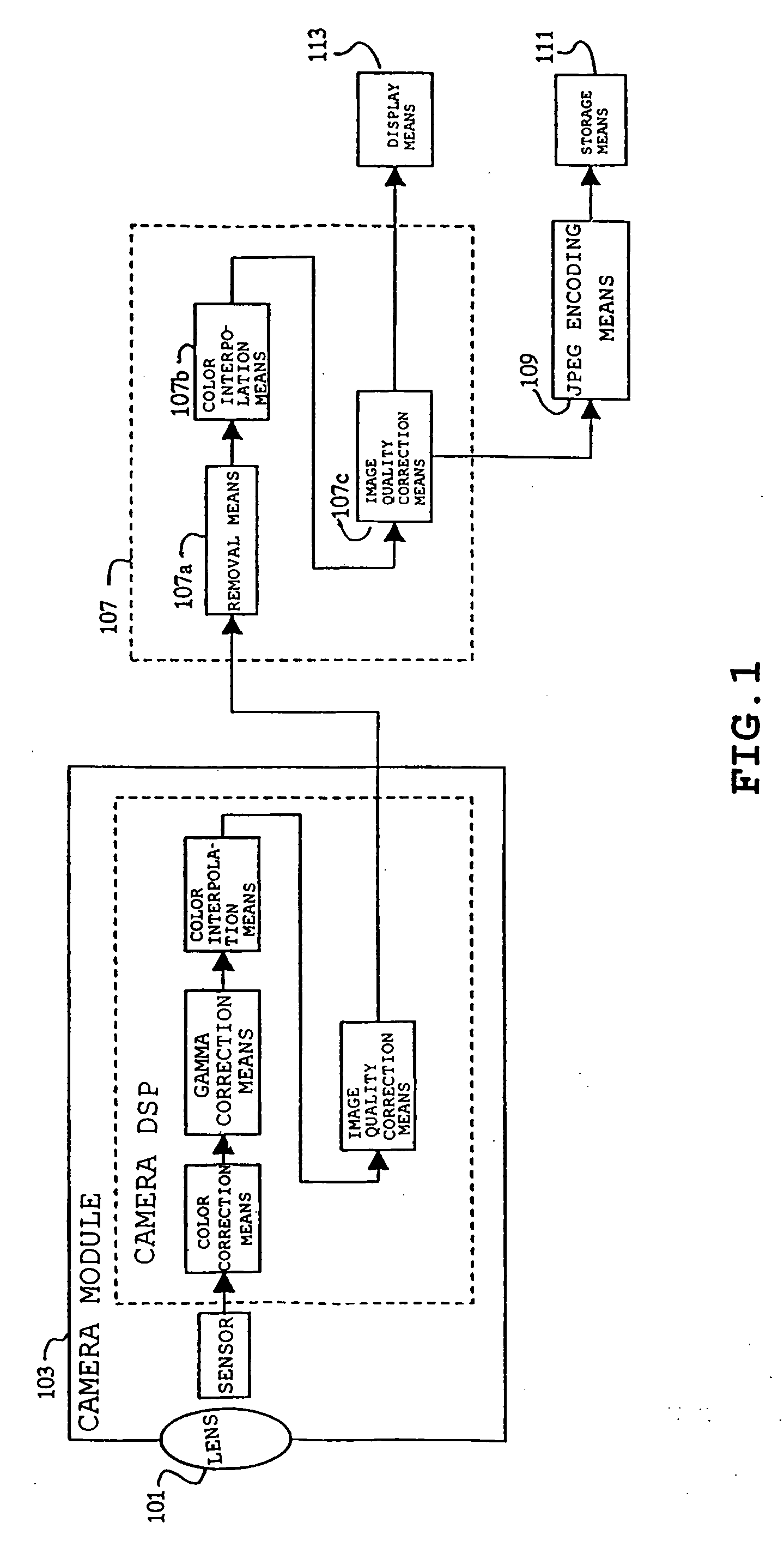

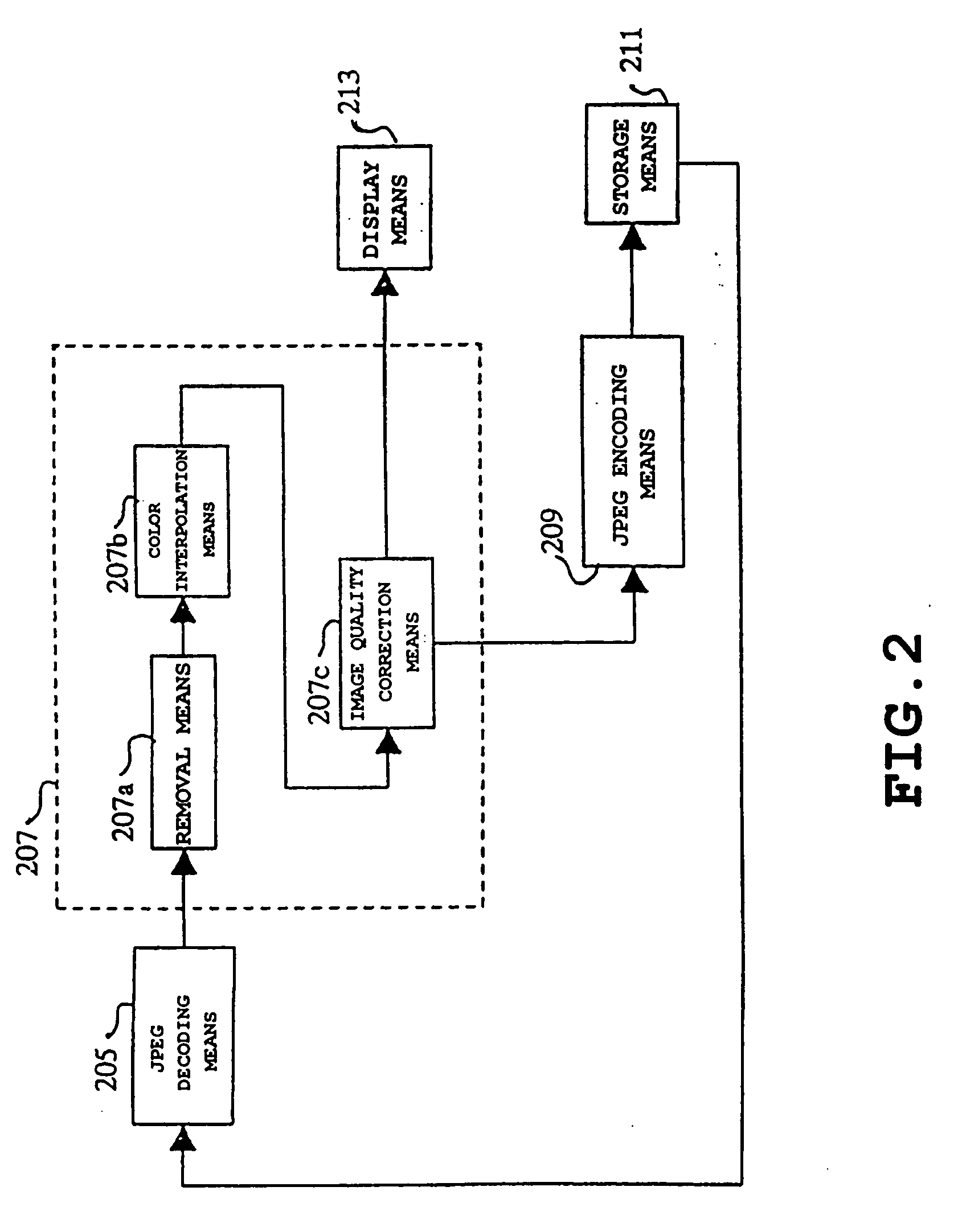

Information terminal

InactiveUS20060101080A1Minimize alterationLow costTelevision system detailsCharacter and pattern recognitionImaging qualityJPEG

An information terminal that can perform image processing in consonance with the use state and the use purpose. When a retrial module is started, removal means removes part or all of the interpolation processing performed for a Bayer-type module. Thereafter, data obtained by the removal are transmitted to color interpolation means, another color interpolation process is performed for the data, and the resultant data are transmitted to image quality correction means. The image quality correction means performs another image quality correction process for the data, and transmits the obtained data to JPEG encoding means.

Owner:NOKIA CORP

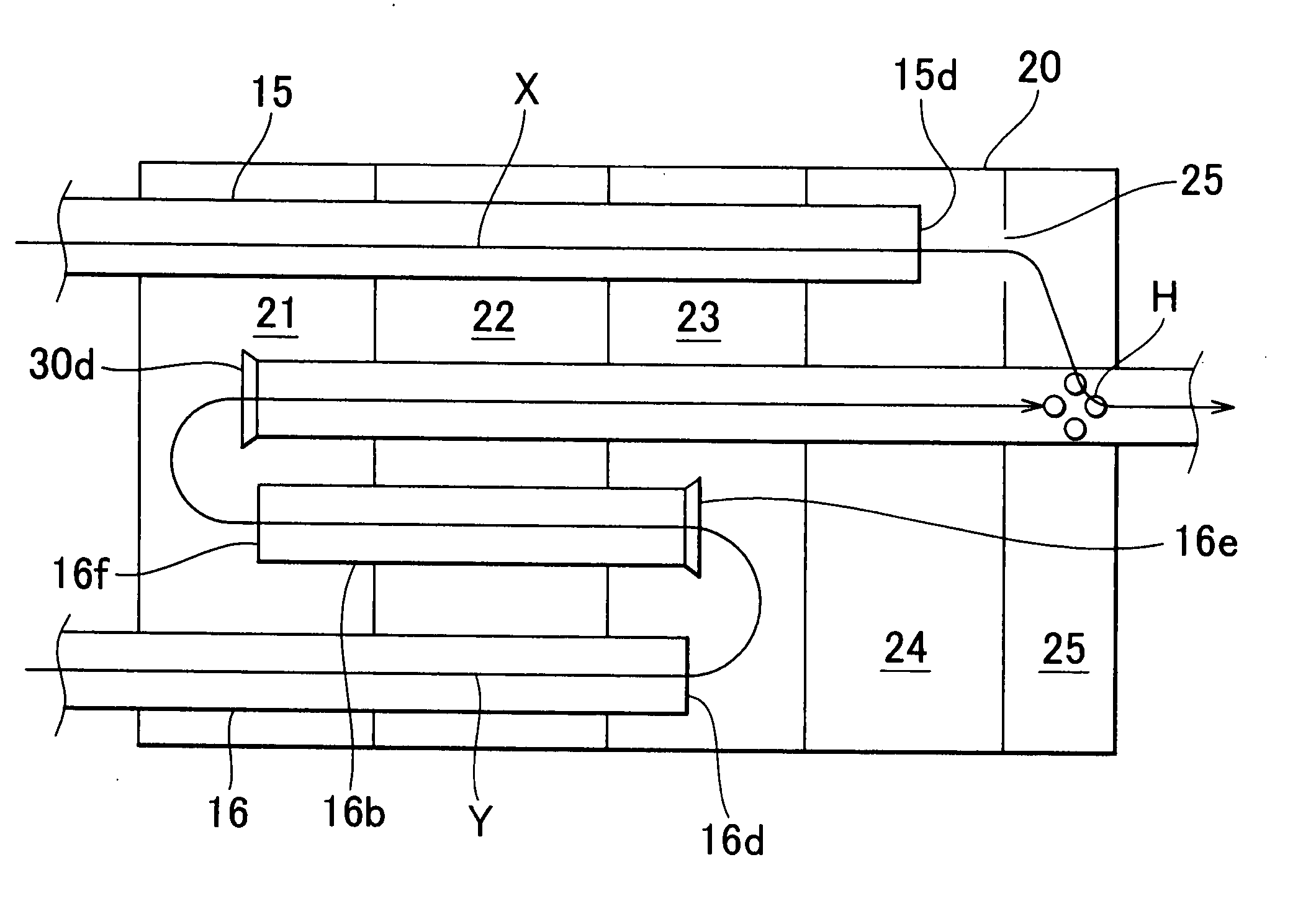

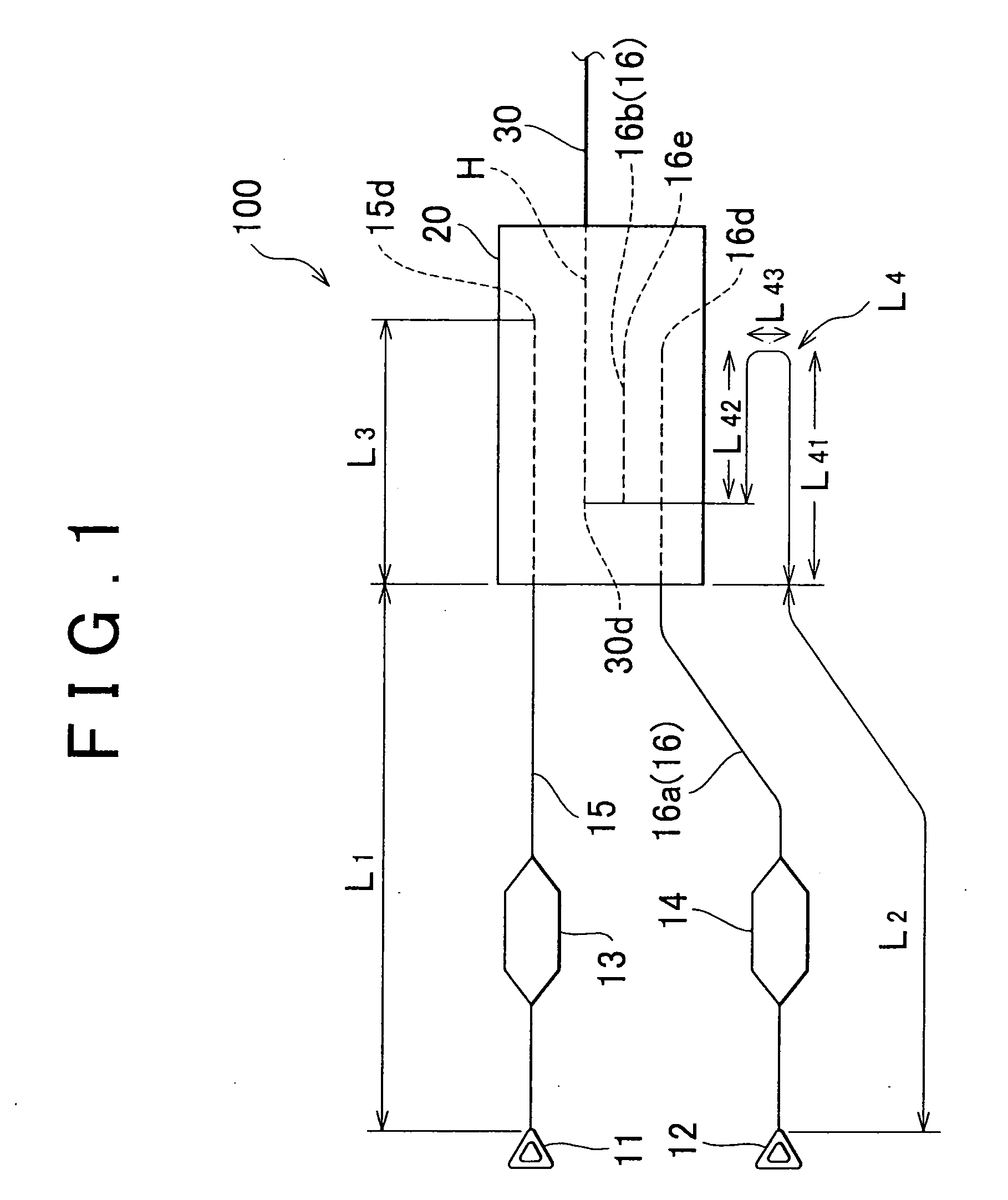

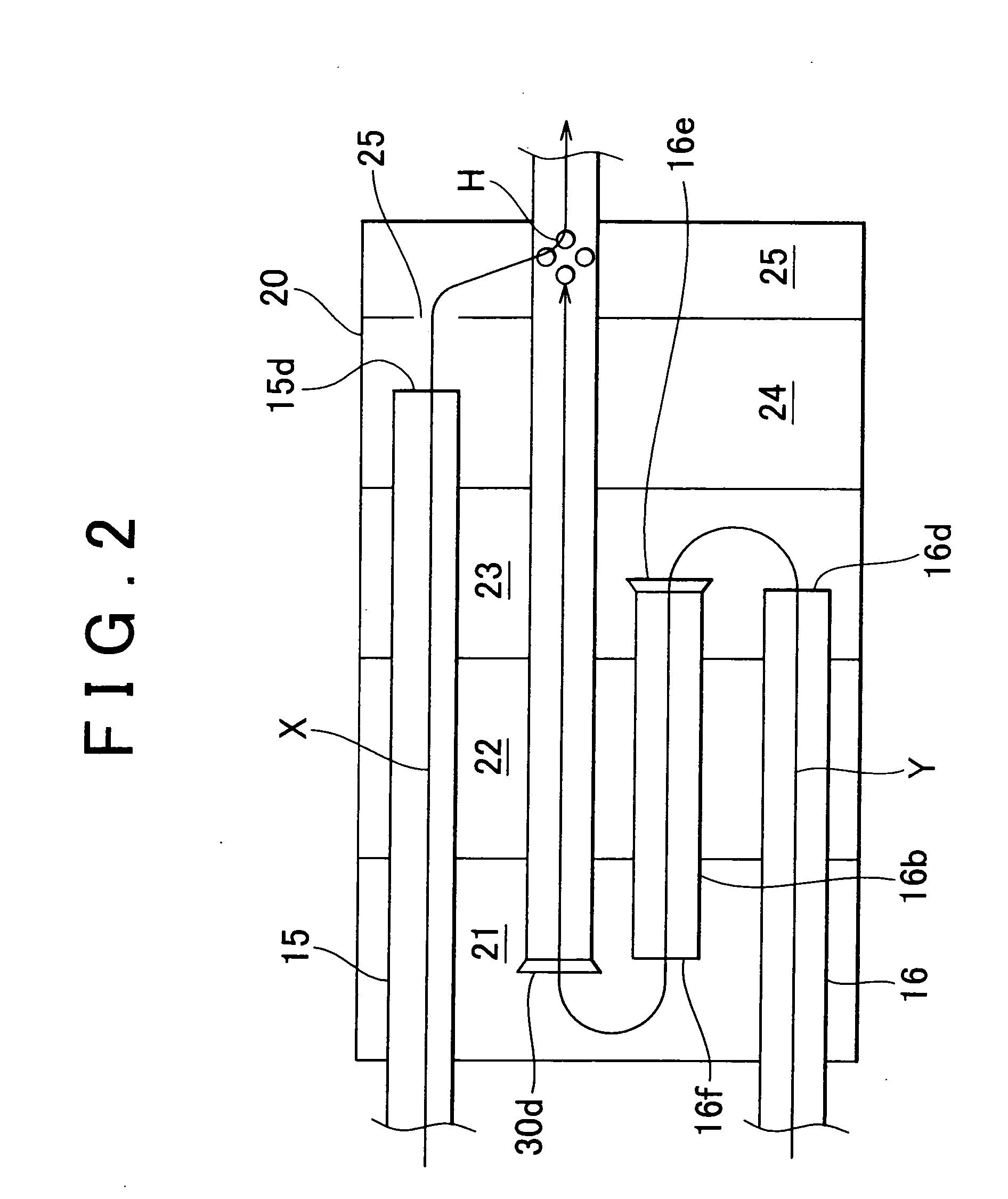

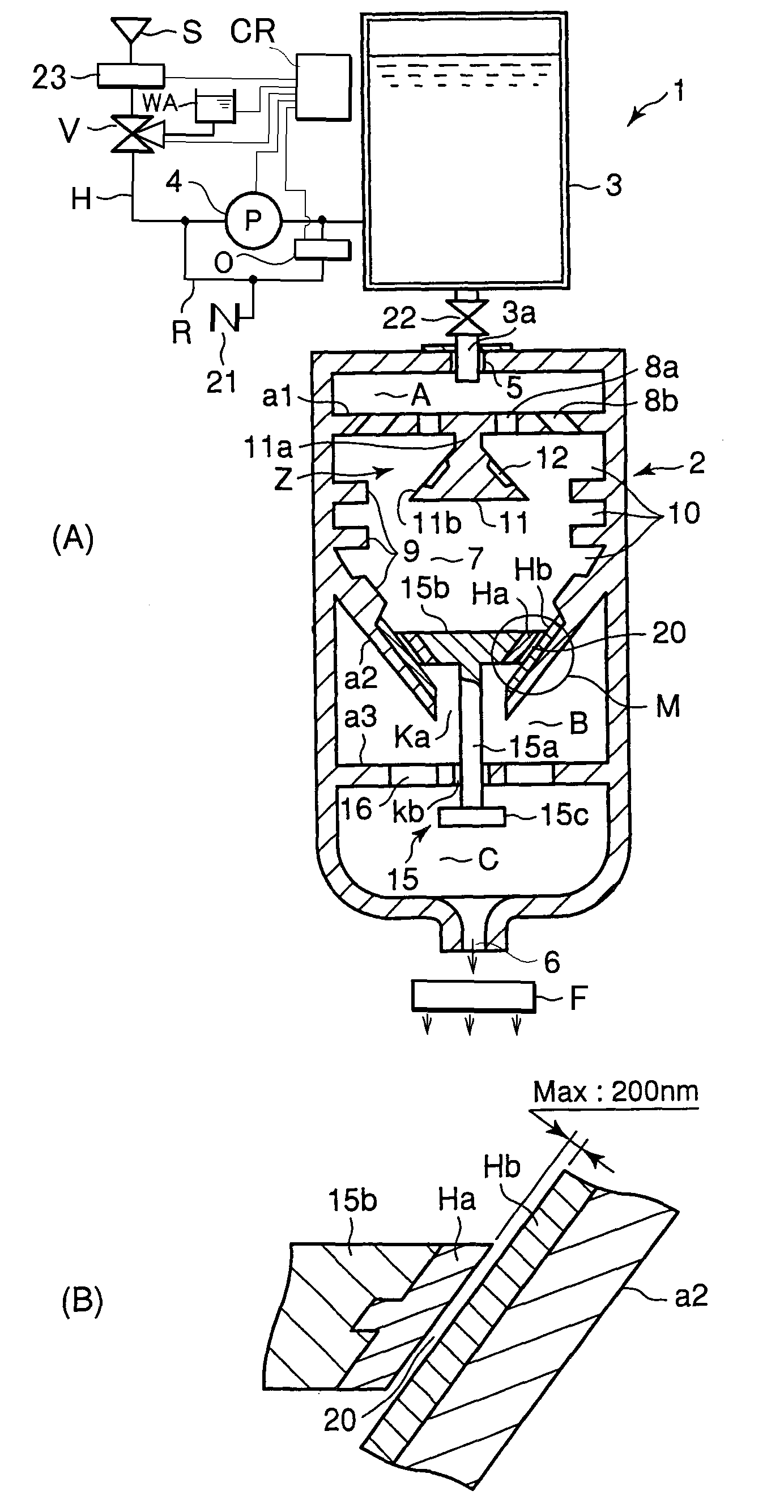

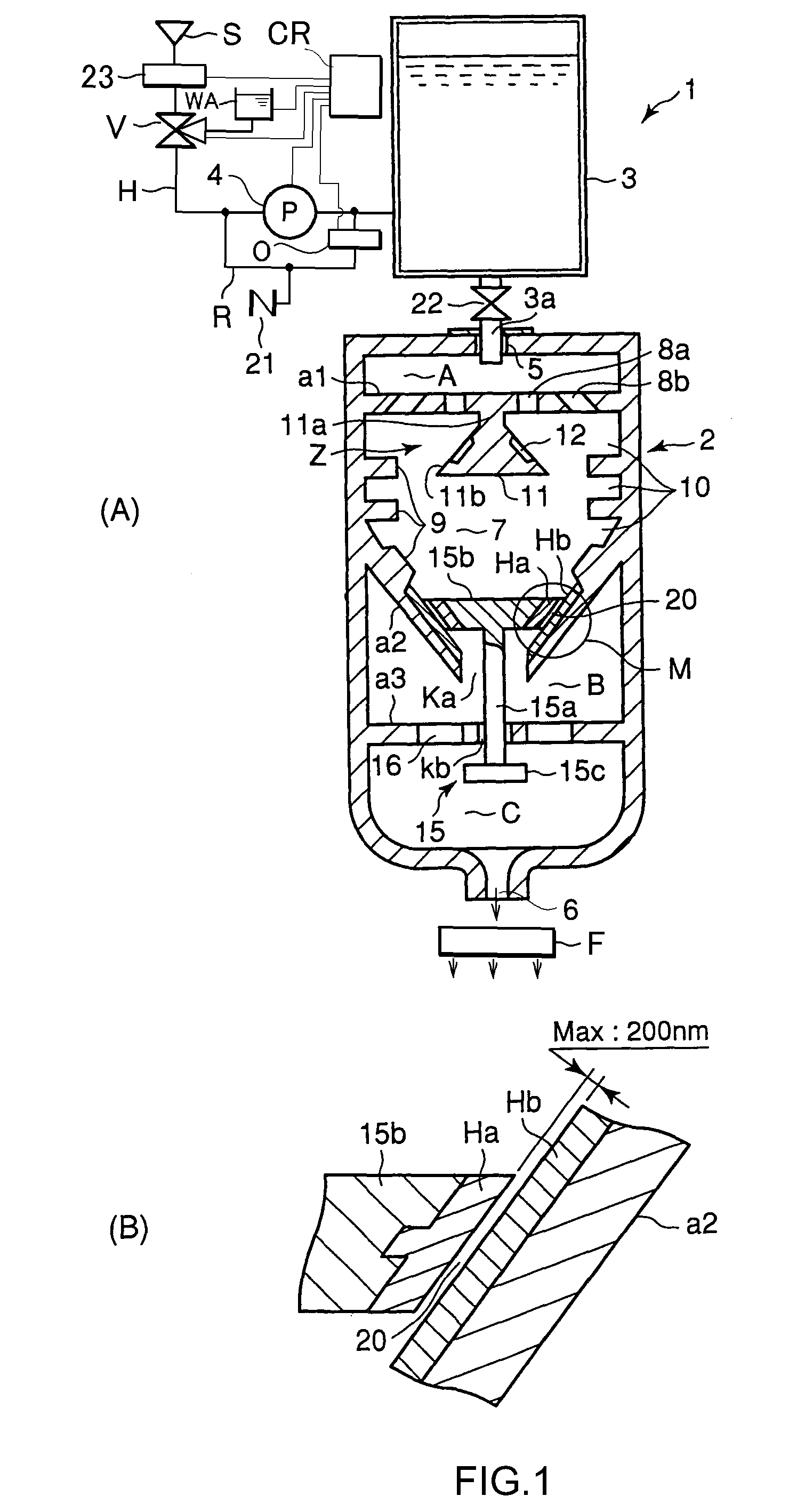

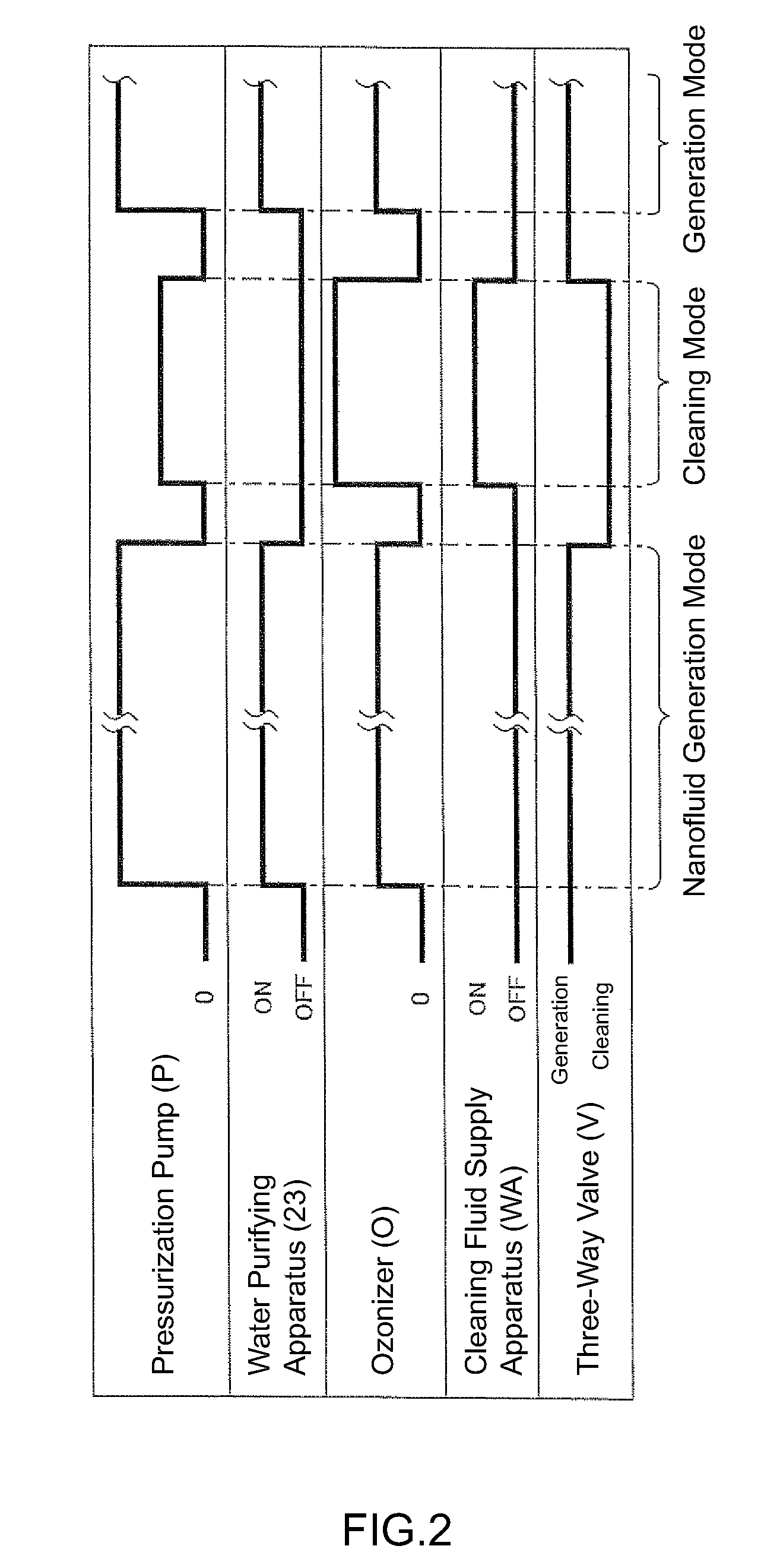

Nanofluid Production Apparatus and Method

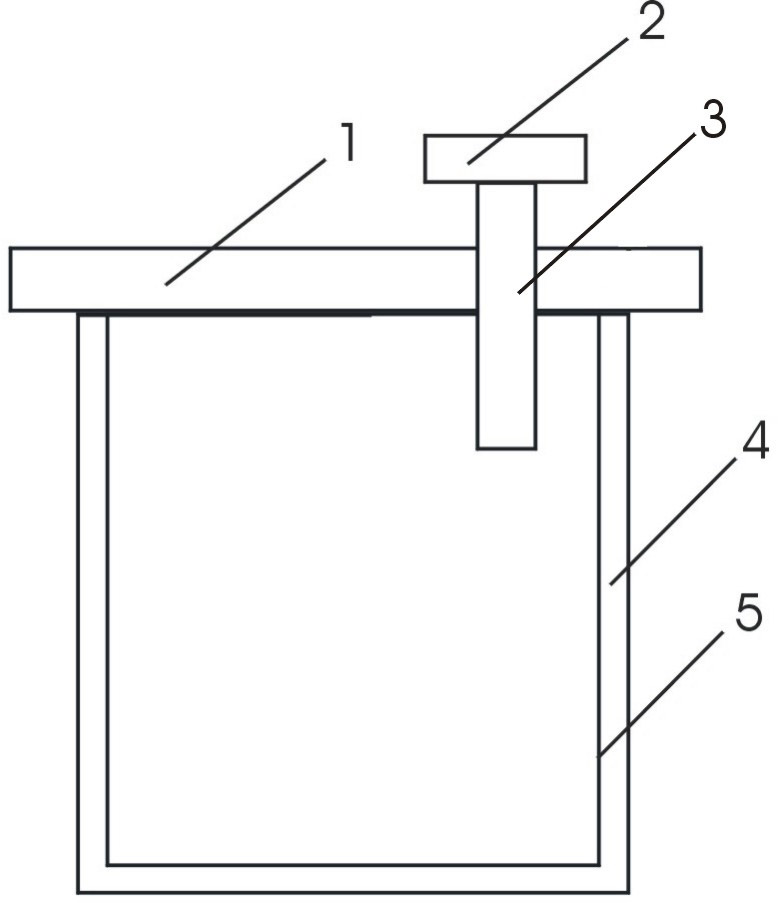

InactiveUS20100010422A1Simple and inexpensive structureEasy to useFlow mixersUsing liquid separation agentNanofluidProcess engineering

The object of the invention is to provide an apparatus and a method for generating a large amount of nanofluid continuously and stably with a relatively simple, inexpensive and easy-to-use structure, and for efficiently performing an intra-apparatus cleaning operation to substantially reduce the nanofluid manufacturing cost.A nanofluid generating apparatus 1 for generating nanofluid containing nanobubbles, wherein the nanobubbles are gas bubbles with diameter less than 1 μm, comprises a gas-liquid mixing chamber 7, comprising a turbulence generating mechanism for forcibly mixing supplied gas and liquid by generating turbulence, and a nano-outlet 20 for discharging the gas-liquid mixture fluid to outside of the gas-liquid mixing chamber to generate nanofluid; a gas-liquid supply apparatus 21, 23, . . . for supplying gas and liquid to the gas-liquid mixing chamber 7; a pressurization pump for applying pressure to the gas and liquid; and a control unit CR for controlling operations of the pressurization pump 4 and the gas-liquid supply apparatus. The control unit CR controls the gas-liquid supply apparatus and the pressurization pump 4 to switch between a nanofluid generation mode and a cleaning mode for cleaning the inside of the gas-liquid mixing chamber 7.

Owner:WATANABE SADATOSHI

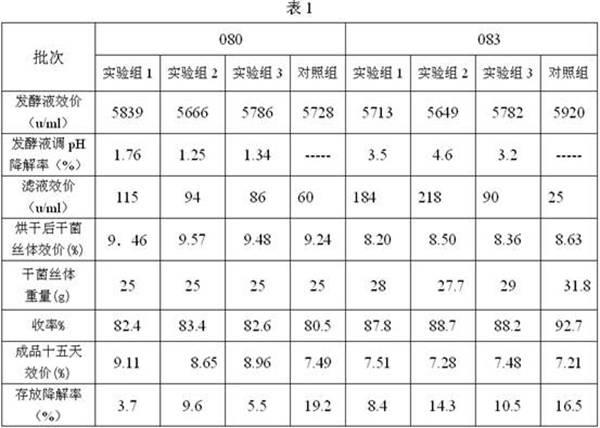

Method for pretreating enramycin fermentation liquor and method for preparing enramycin premix by using enramycin fermentation liquor

ActiveCN102633865ALow costLittle degree of degradationAnimal feeding stuffMicroorganism based processesAluminium saltsAluminum sulphate

The method discloses a method for pretreating an enramycin fermentation liquor. The method comprises the following steps of: before extracting enramycin from the enramycin fermentation liquor, firstly adjusting the pH value of the fermentation liquor to a range of 4.0 to 7.0 by using an acid, and then adding aluminum sulfate accounting for 0.8-1.0% the weight of the fermentation liquor. The invention also discloses a method for preparing an enramycin premix. The method, compared with the existing enramycin production technique, is mainly characterized by pretreating the fermentation liquor of the enramycin so as to improve the quality of the finished product of the enramycin premix. The method for preparing the enramycin premix disclosed by the invention is simple and easy to implement and low in cost; and compared with the finished product without being subjected to pretreatment, the degradation degree of the enramycin obtained through the pretreated fermentation liquor is obviously reduced and the stability of the obtained enramycin premix finished product in the storage process is obviously improved. Furthermore, by adopting the method for preparing the enramycin premix disclosed by the invention, the enramycin finished product is more convenient and stable for storing, transporting and applying.

Owner:山东胜利生物工程有限公司

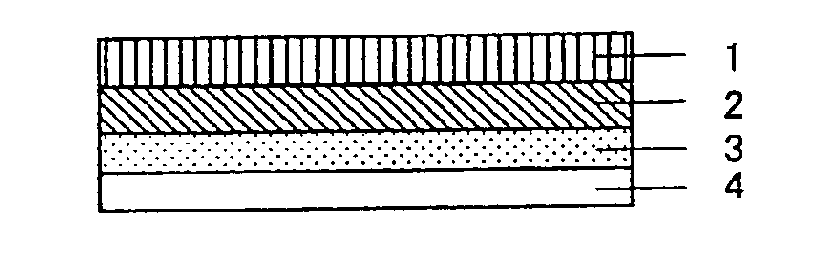

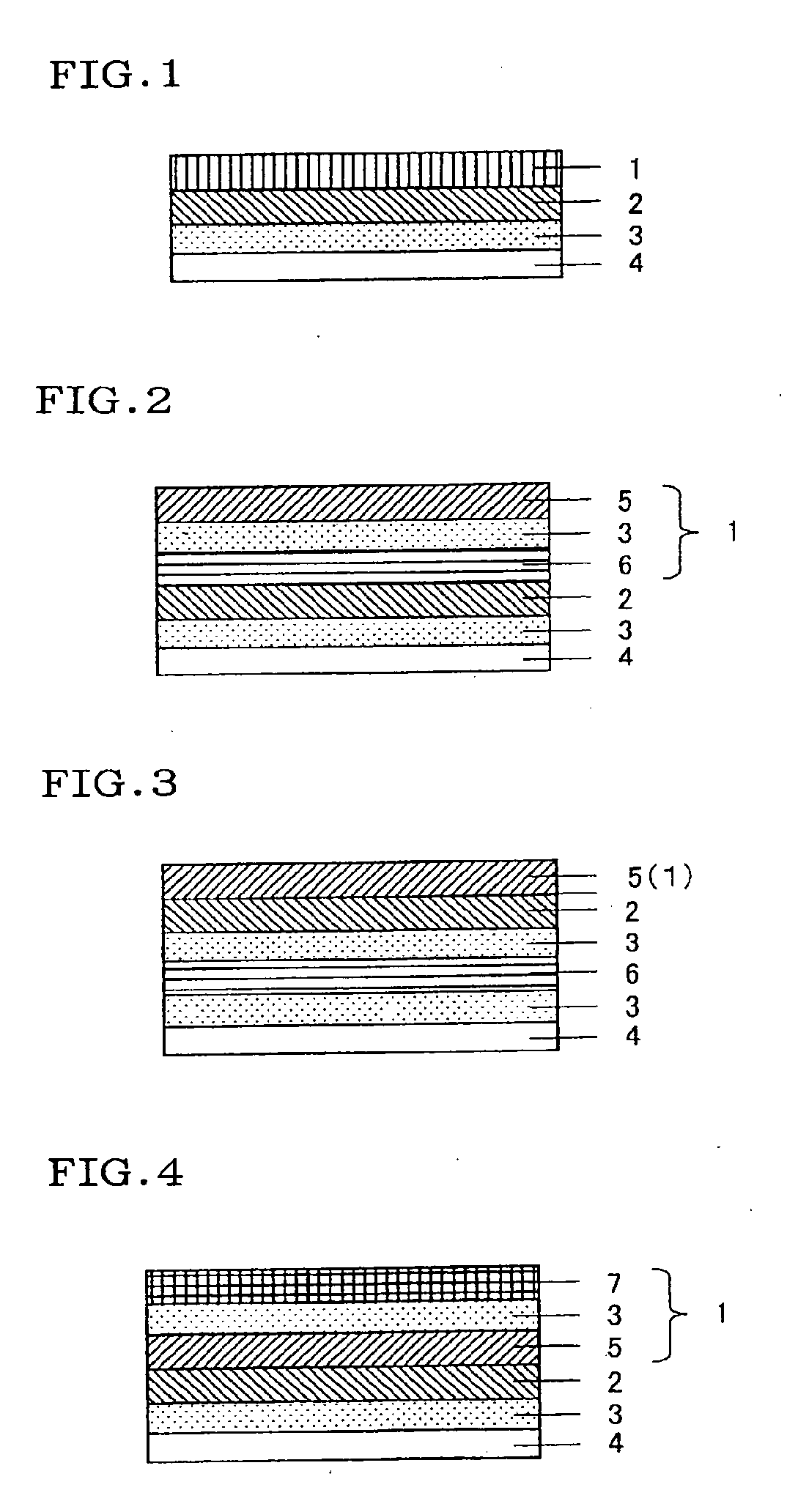

Antistatic optical film, method for manufacturing the same and image viewing display

ActiveUS20080274272A1Reduce manufacturing costExcels in productivitySolid-state devicesSemiconductor/solid-state device manufacturingWater dispersibleConductive polymer

An antistatic optical film comprising an antistatic layer laminated on at least one side of an optical film, wherein the antistatic layer comprises a water soluble or a water dispersible conductive polymer, has excellent antistatic effect, optical characteristics and appearance.

Owner:NITTO DENKO CORP

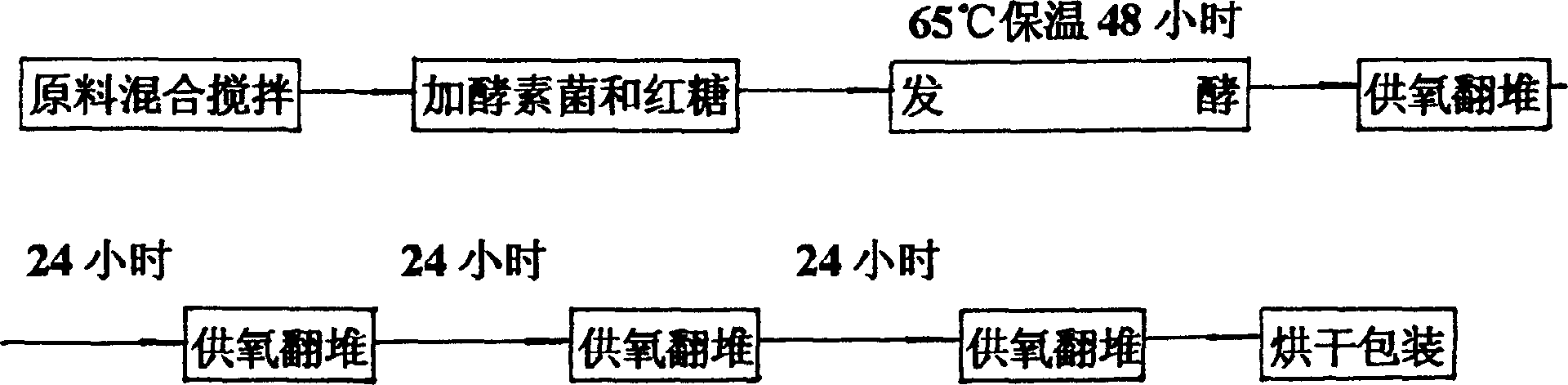

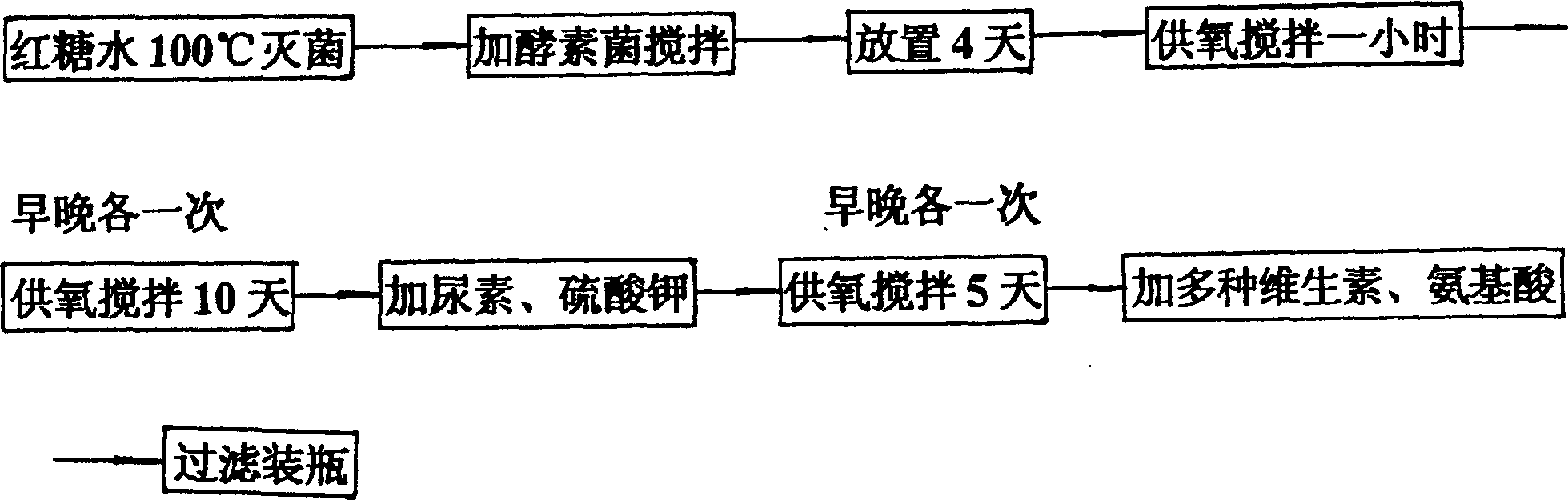

Active biological and organic compositie fertilizer

InactiveCN1534005AEfficient killingSimple structureFungiBio-organic fraction processingMicroorganismPesticide residue

An active biological organic mixed fertilizer in the form of solid or liquid is disclosed. It can play the roles of killing karmful microbes in soil, improve soil, and increase quality and yield of crops. It is prepared from straw, stalk, and peat through microbial fermenting. Its advantages are high effect, low cost and no environmental pollution.

Owner:张玉华

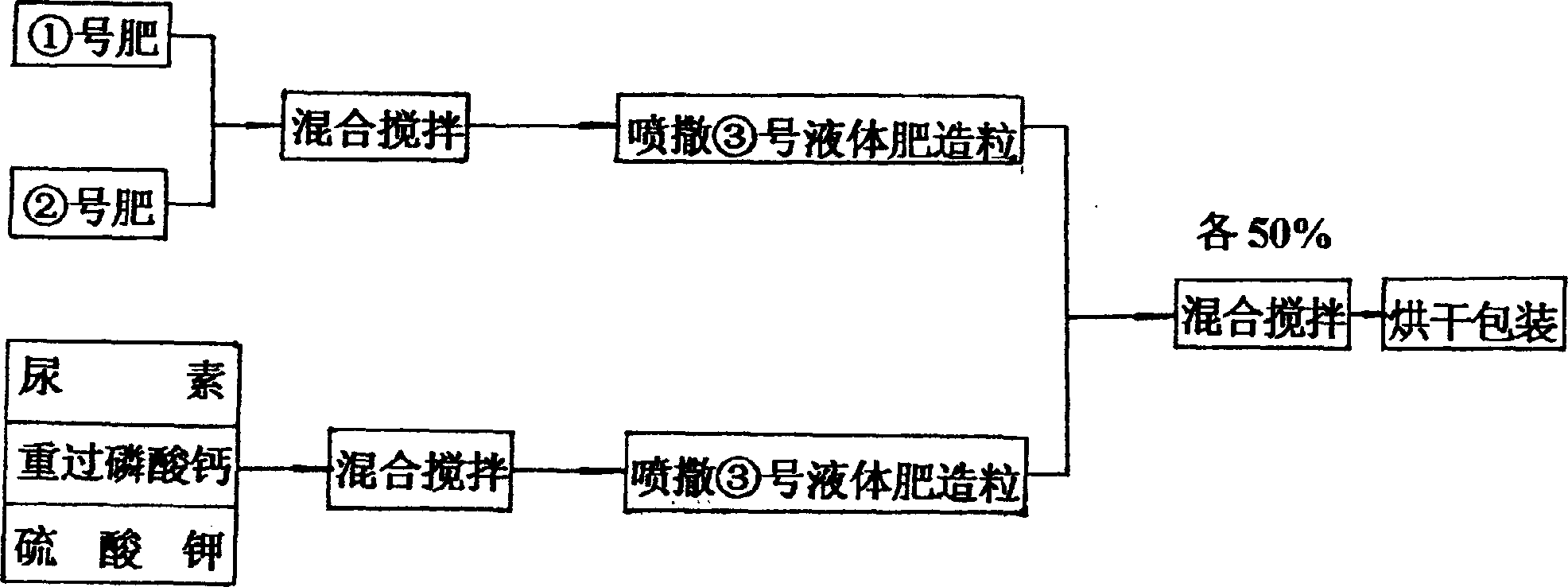

Image-forming method and developer

InactiveUS20050026092A1Good developing propertiesReduce harmPhotoprinting processesSemiconductor/solid-state device manufacturingDicarbonateRecording layer

Owner:FUJIFILM CORP

Pressure-sensitive adhesive type optical film and image display

InactiveUS20050084670A1Improve adhesionReduce partial omissionAdhesive processes with surface pretreatmentElectroluminescent light sourcesEmulsionDisplay device

A pressure-sensitive adhesive type optical film which comprises an optical film and a pressure-sensitive adhesive layer superposed on at least one side thereof through an anchor layer formed from a resin emulsion. It is easy to handle because the pressure-sensitive adhesive does not peel off even when an edge of the film comes into contract during handling in use.

Owner:NITTO DENKO CORP

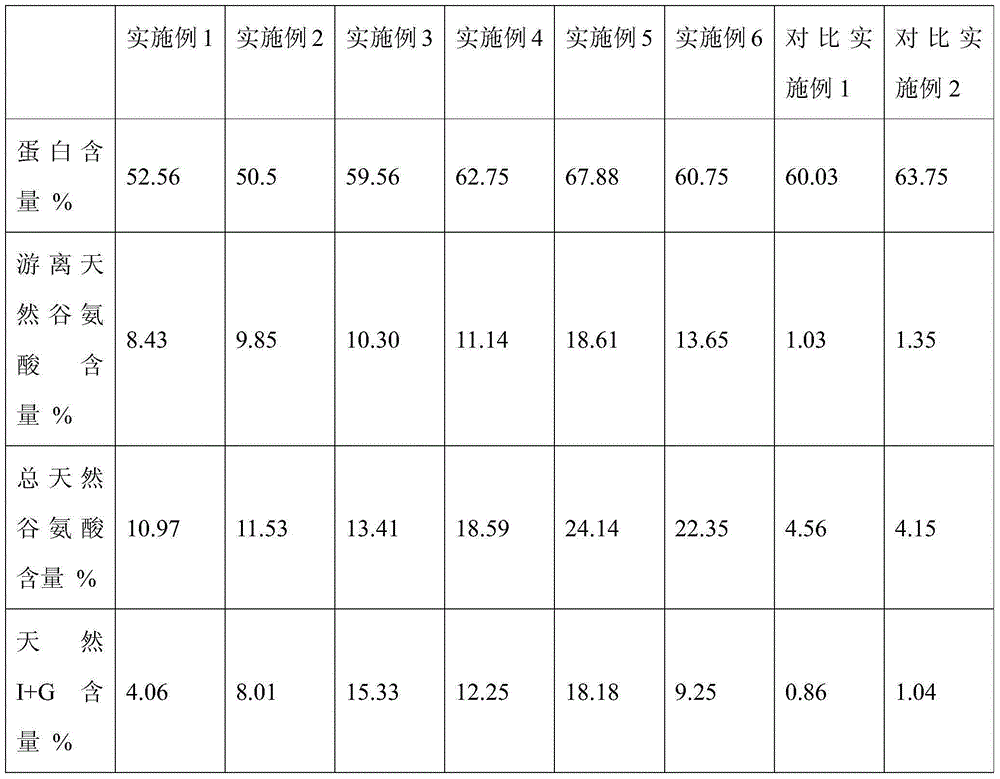

Yeast extract and preparation method thereof

The present invention provides a yeast extract and a preparation method thereof. The method comprises the following steps that firstly yeast milk is subjected to autolysis and then subjected to hydrolysis separately in three stages, and at the same time by adjusting the addition order of enzymes, reaction pH, reaction time and temperature, the yeast extract is finally obtained through separating, concentrating or spray-drying. The yeast extract solves the problems that the yeast extract in the prior art only contains a high content of natural glutamic acids or natural I + G, but cannot have high contents of the both indexes. For the yeast extract prepared by the method, the content of natural glutamic acids in total is 10-25% (weighing by desalted dry matter), the content of free natural glutamic acids is 8-20% (weighing by desalted dry matter), and the content of natural I + G is 4-20% (weighing by desalted dry matter).

Owner:珠海天香苑生物科技发展股份有限公司

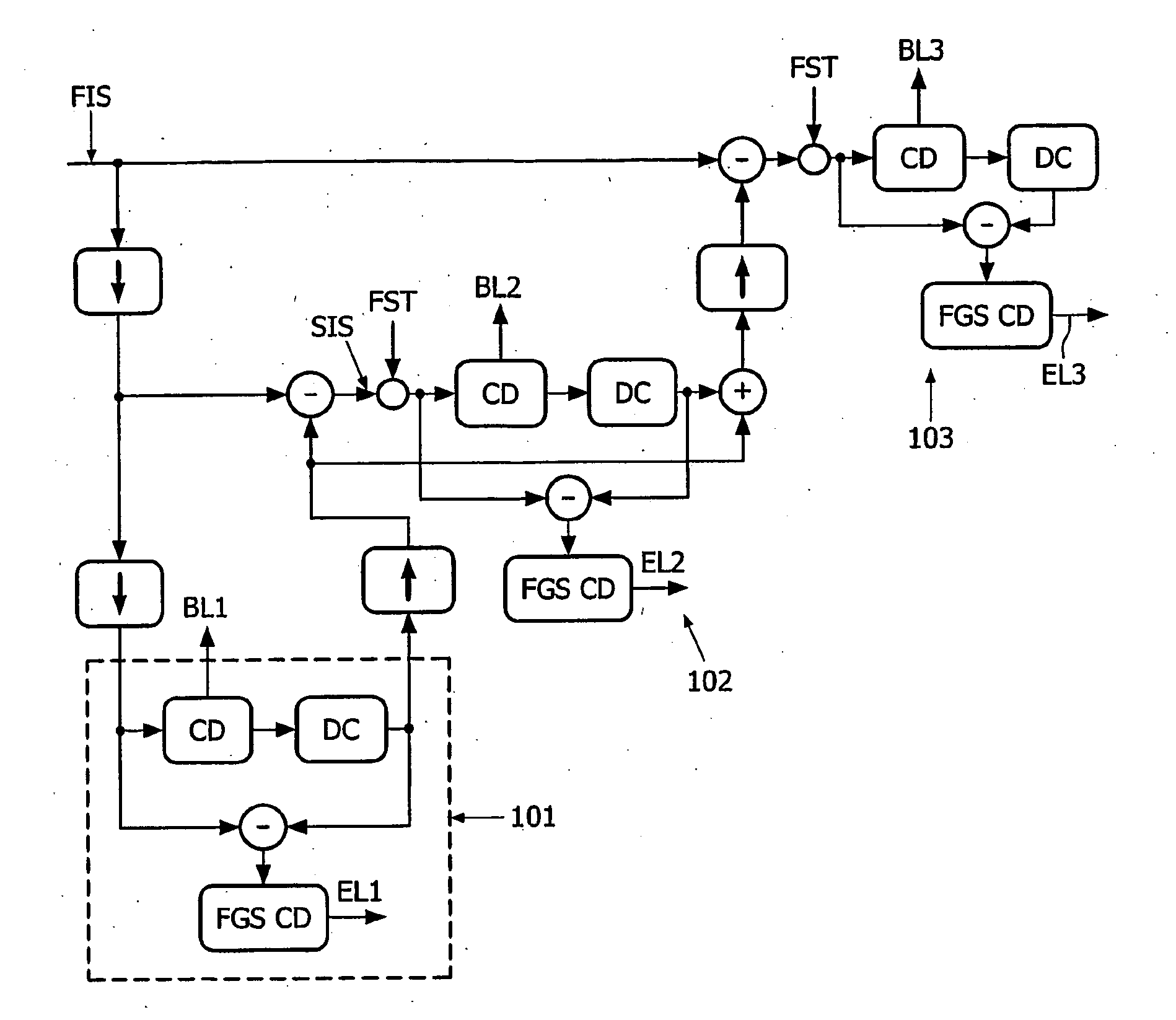

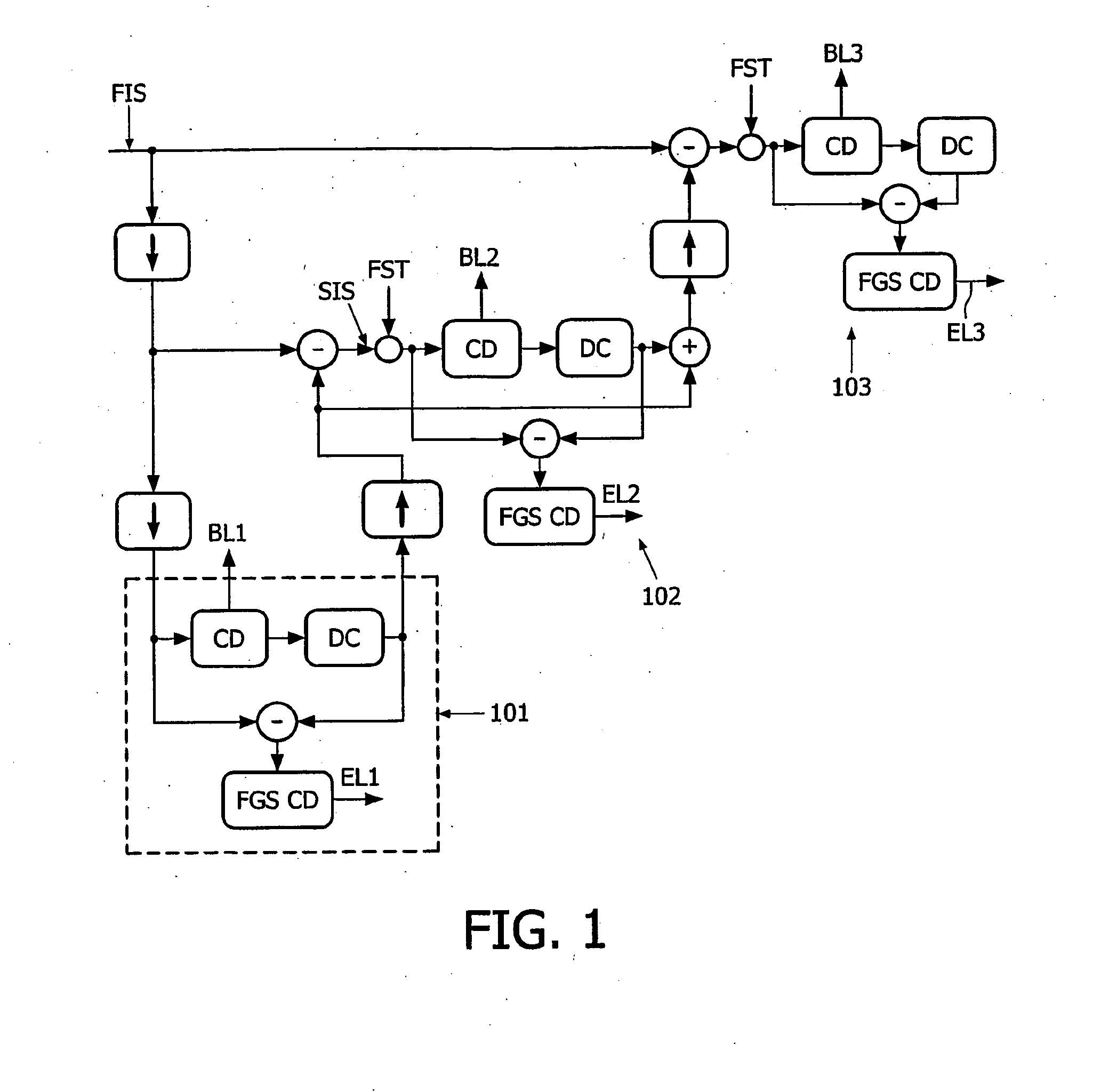

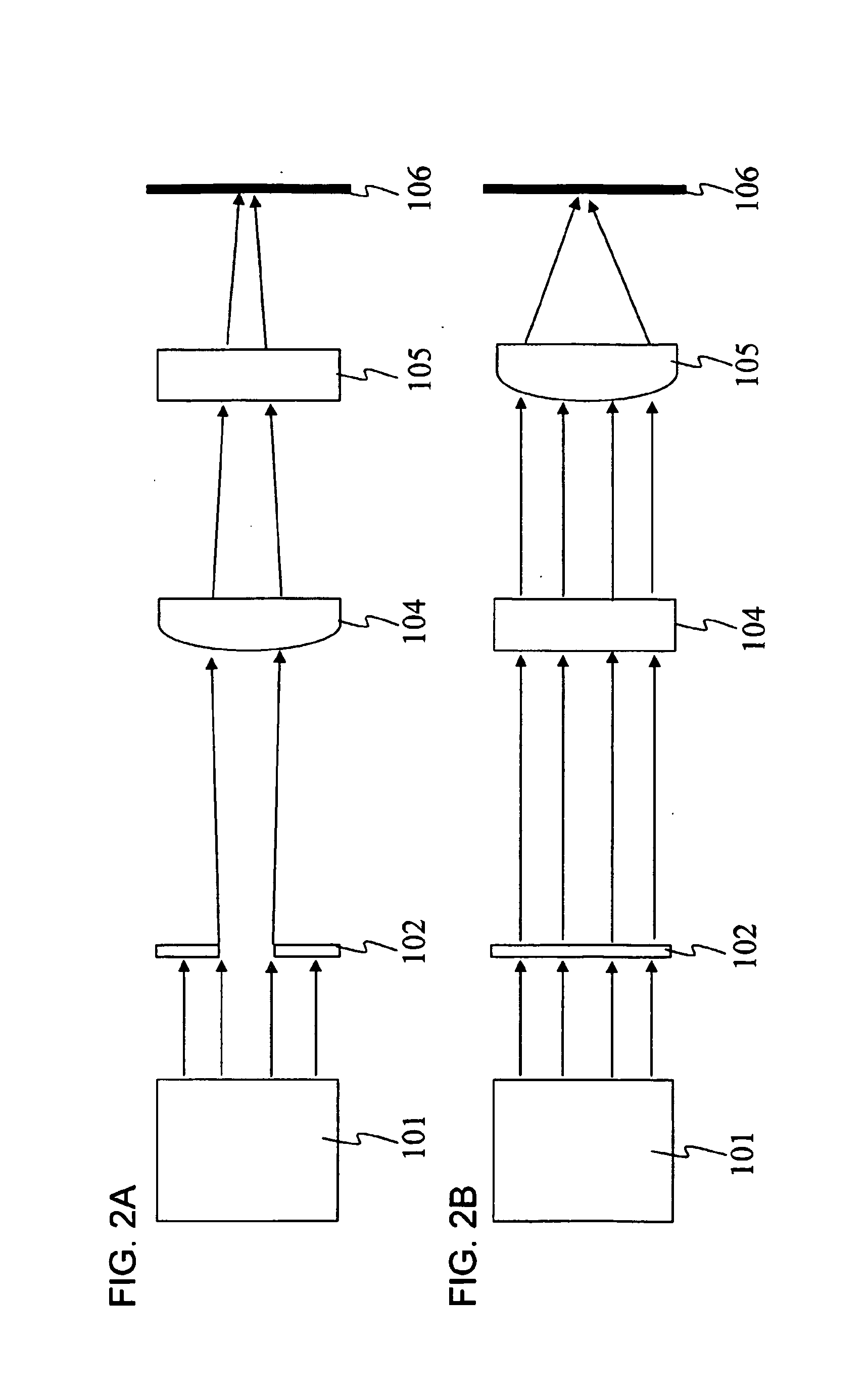

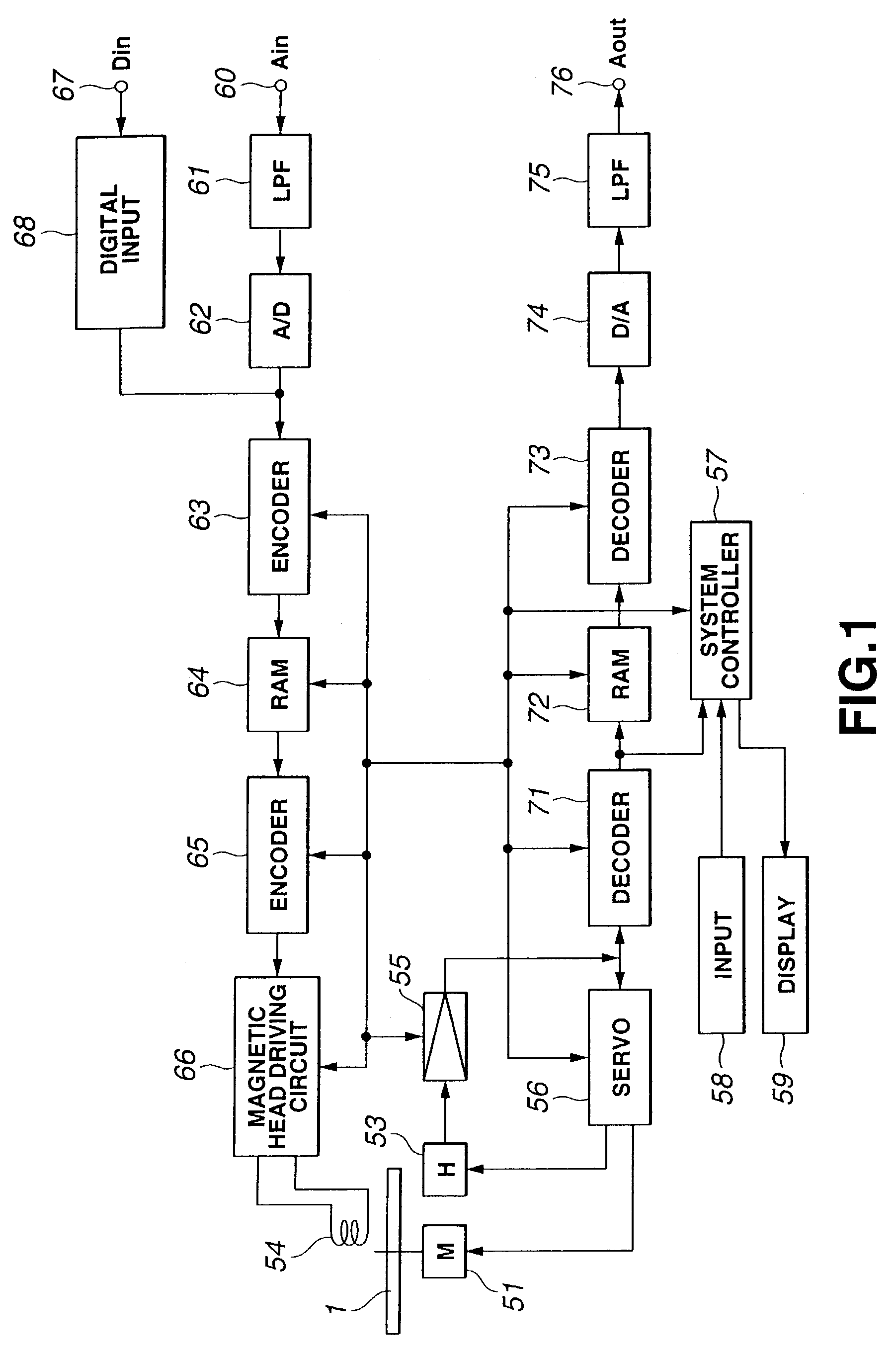

Method of spatial and snr fine granular scalable video encoding and transmission

InactiveUS20090022230A1Fine granularityReduce bitrateColor television with pulse code modulationColor television with bandwidth reductionGranularityVideo encoding

The invention relates to a method of coding video data available in the form of a first input stream of video frames, and to a corresponding coding device. This method, implemented for instance in three successives stages (101, 102, 103), comprises the steps of (a) encoding said first input stream to produce a first coded base layer stream (BL1) suitable for a transmission at a first base layer bitrate; (b) based on said first input stream and a decoded version of said encoded first base layer stream, generating a first set of residual frames in the form of a first enhancement layer stream and encoding said stream to produce a first coded enhancement layer stream (EL1); and (c) repeating at least once a similar process in order to produce further coded base layer streams (BL2, BL3, . . . ) and further coded enhancement layer streams (EL2, EL3, . . . ). The first input stream is thus, for obtaining a required spatial resolution, compressed by encoding the base layers up to said spatial resolution with a lower bitrate and allocating a higher bitrate to the last base layer and / or to the enhancement which corresponds to said required spatial resolution. A corresponding transmission method is also proposed.

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

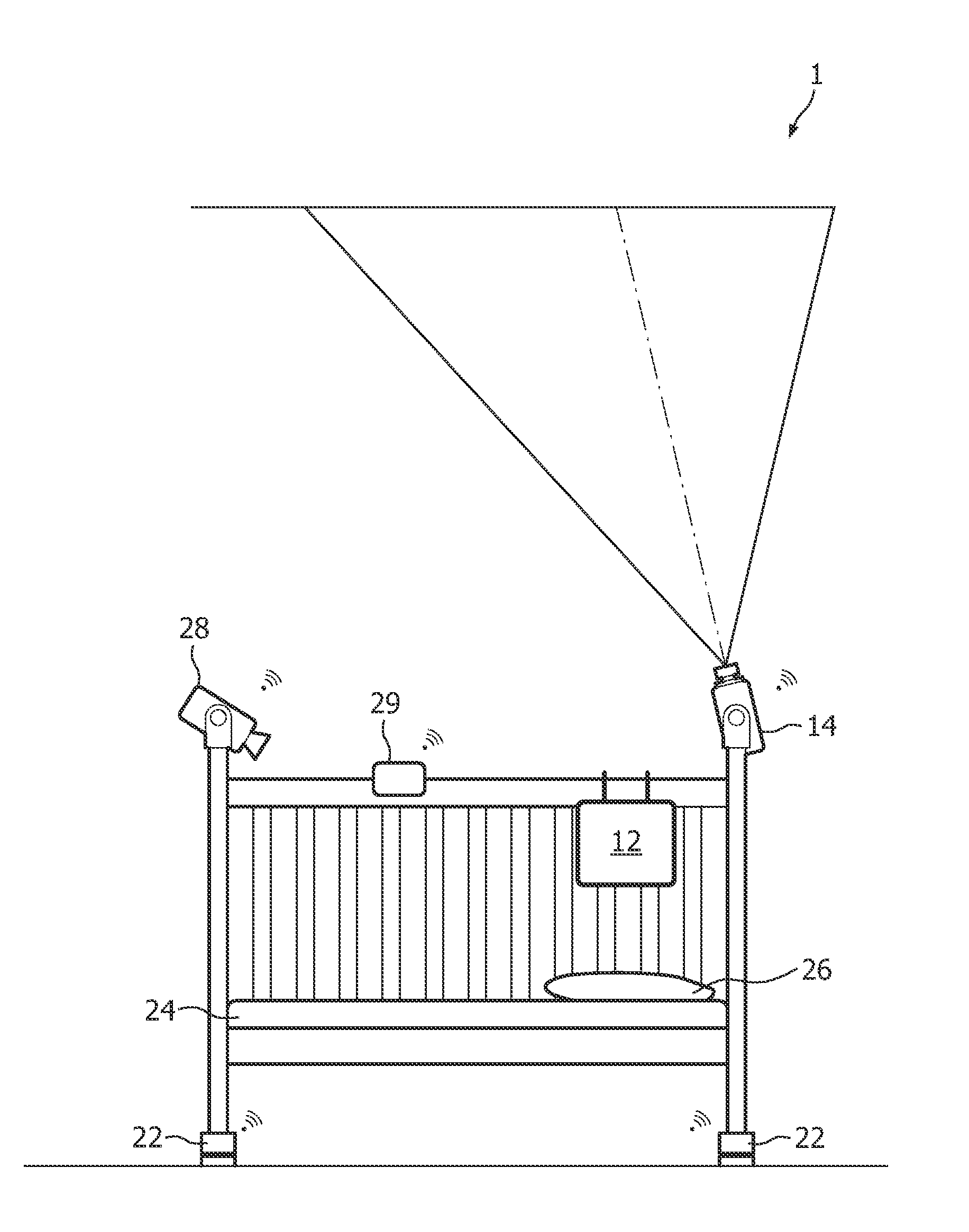

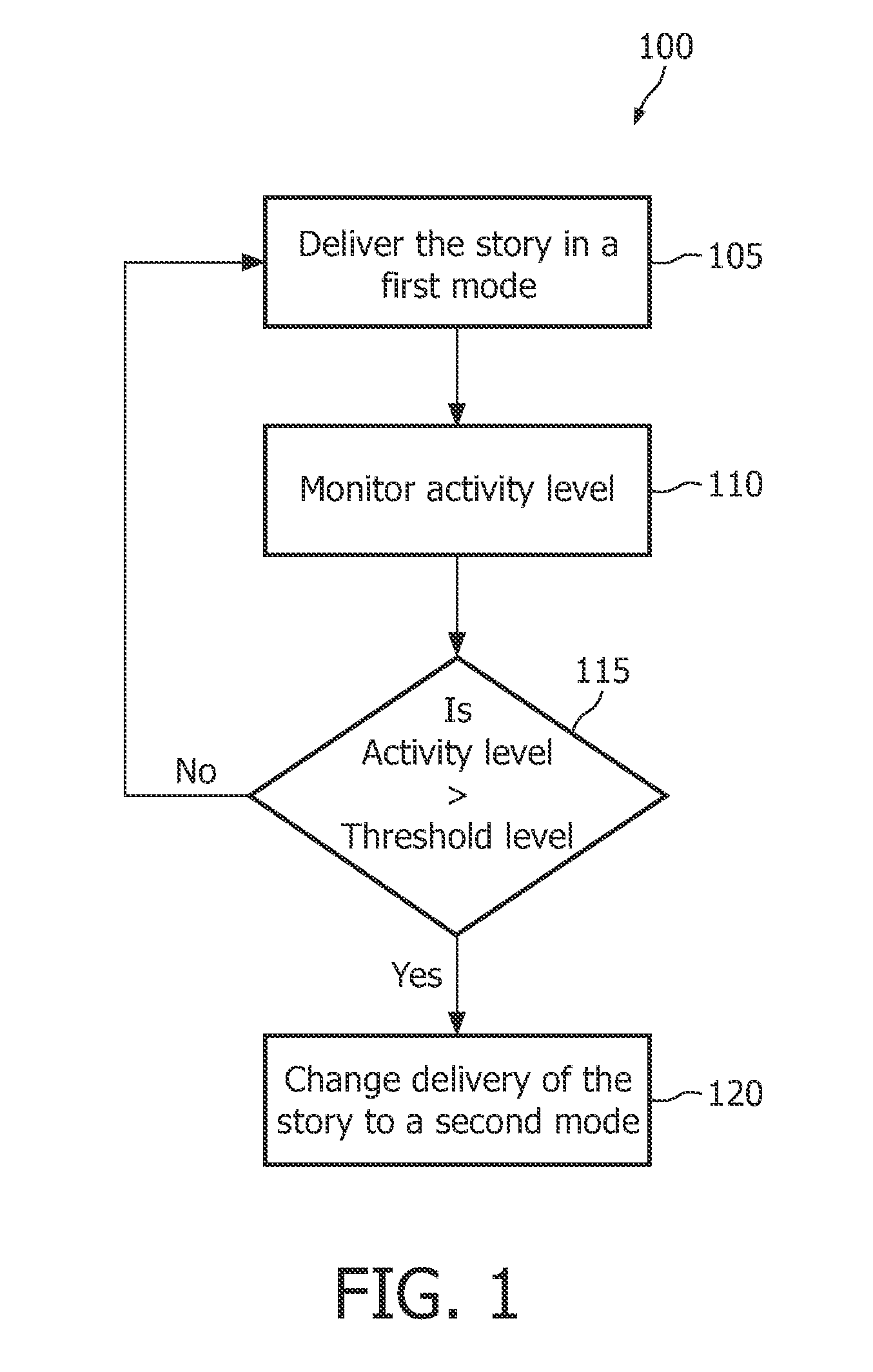

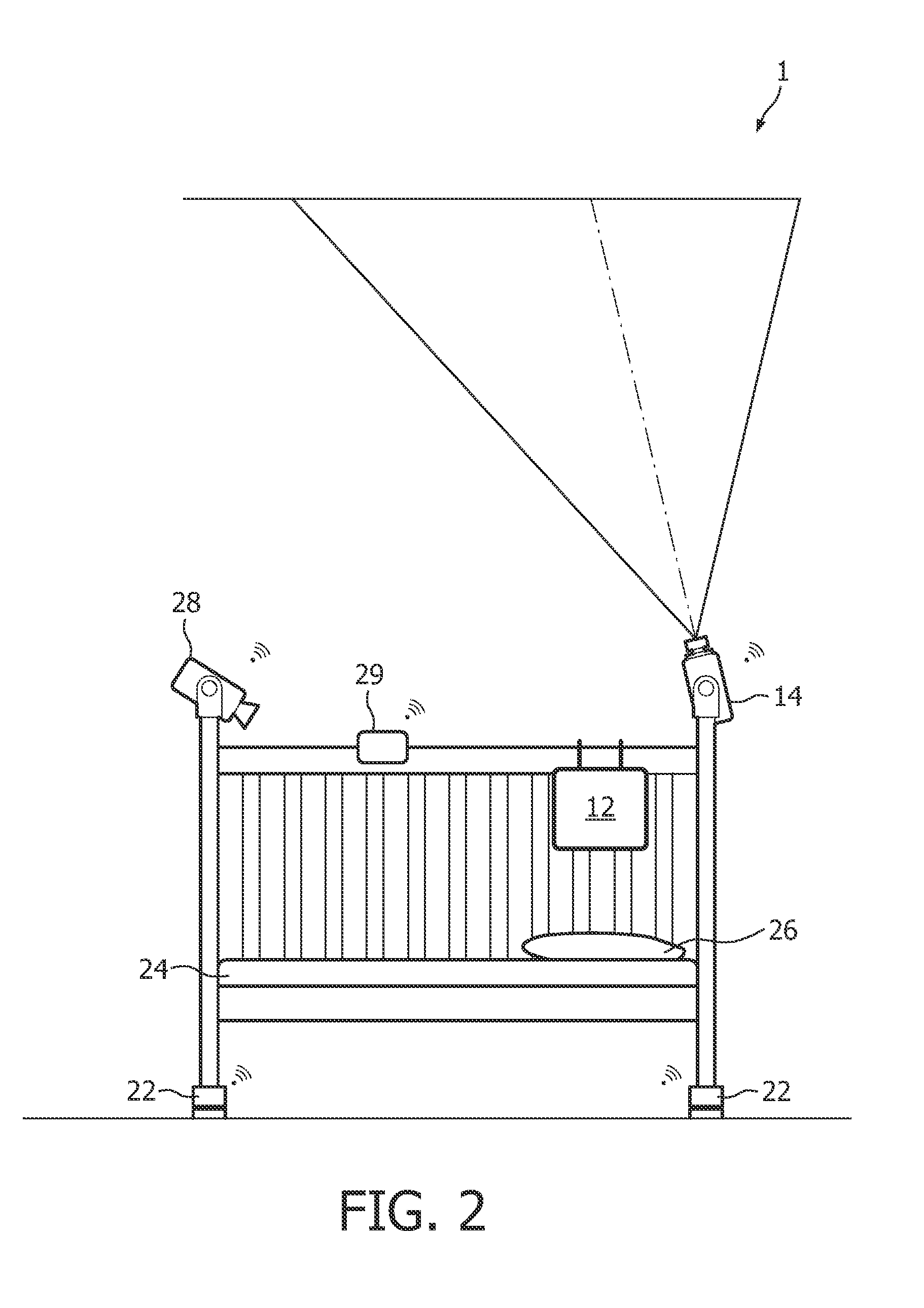

Calming device

ActiveUS20110137110A1Easy and timelyInduce boredomElectrocardiographyIndoor gamesEngineeringActivity level

A device (1), for calming down a subject, comprises a content delivering means (12,14) adapted for delivering a content in a first mode, at least one sensor (22, 24, 26, 28, 29) configured to detect an activity level of the subject and a controlling unit operatively coupled to the at least one sensor. The controlling unit receives the detected activity level and compares the detected activity level with a pre-determined threshold activity level. The controlling unit is capable of changing the delivery of the content to a second mode when the detected activity level is above the threshold activity level.

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

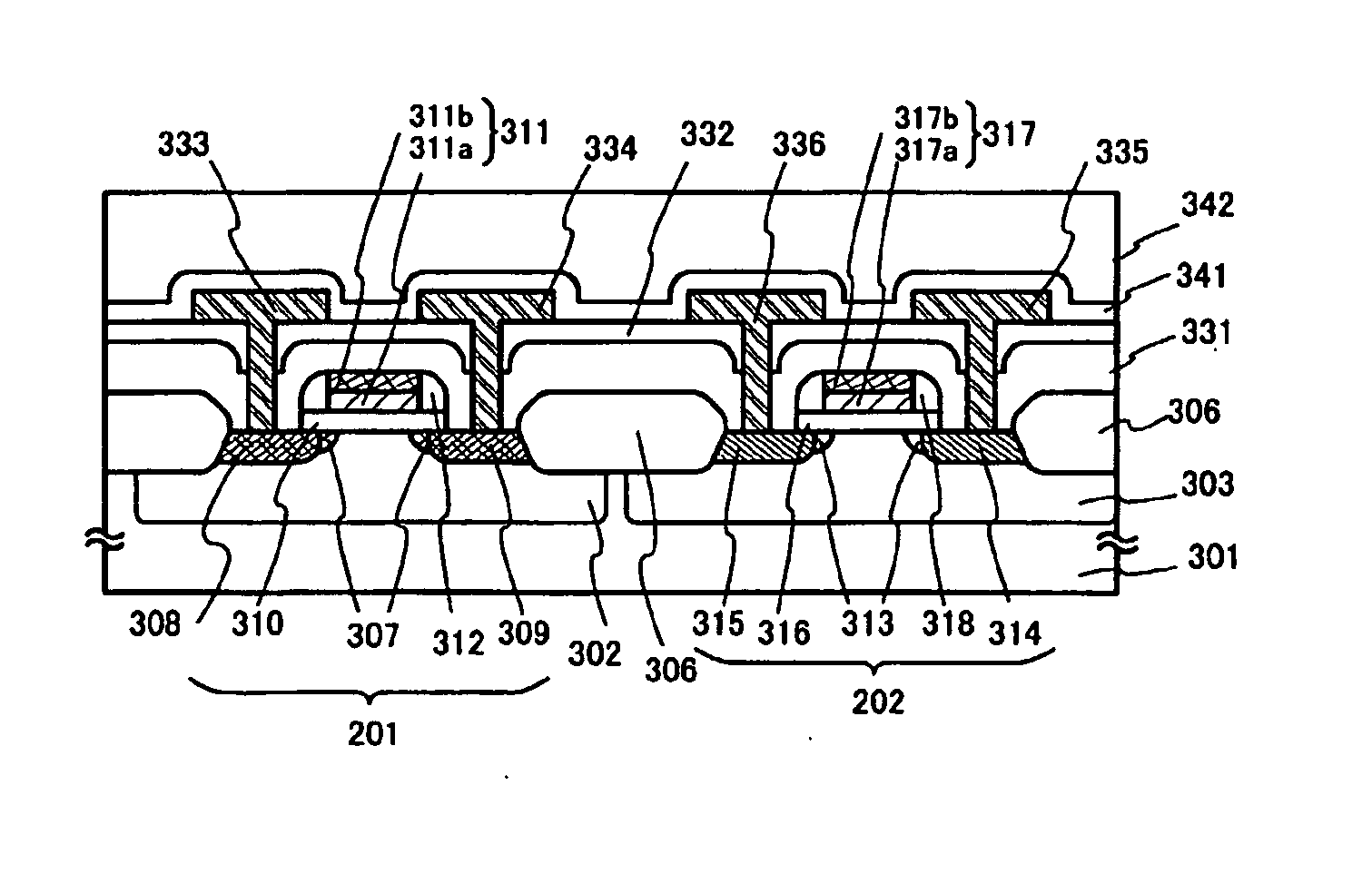

Semiconductor device and manufacturing method of the same

An RTA method has a limitation on miniaturization. The RTA method needs a heating time of several seconds, and has a risk that impurities are diffused into a deep portion, since a semiconductor substrate is heated at a high temperature. Thus, the RTA method has a difficulty in responding miniaturization which is expected in the future. According to the present invention, a fundamental wave is used without putting laser light into a non-linear optical device, and laser annealing is conducted by irradiating an impurity diffusion layer with pulsed laser light having high intensity and a high repetition rate, so as to electrically activate the impurities. By the present invention, a thin layer on the surface of a silicon substrate can be partially melted to conduct activation. Further, the width of the region activated by laser-scanning once can be increased, and thus the productivity can be enhanced dramatically.

Owner:SEMICON ENERGY LAB CO LTD

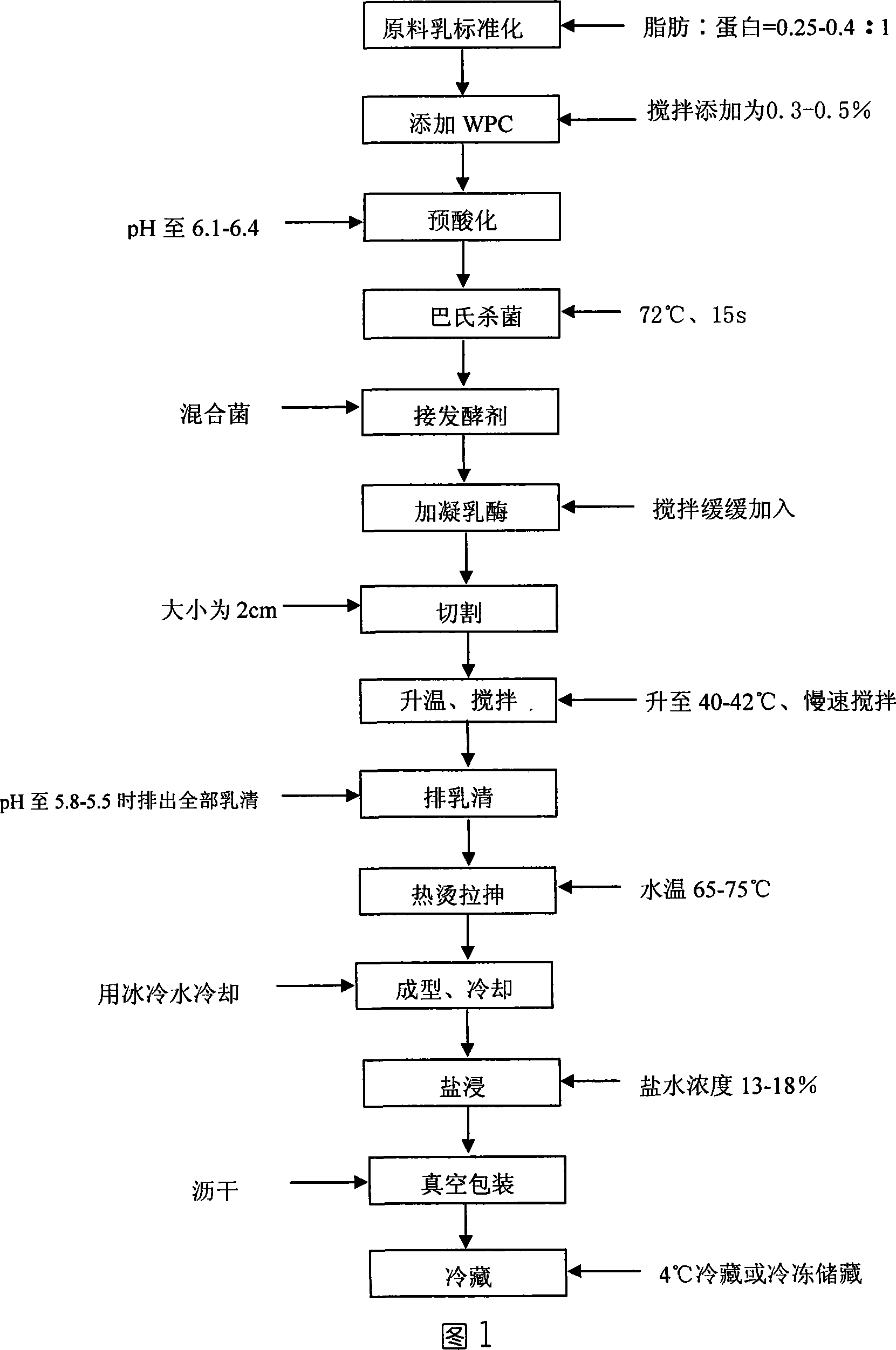

Low fat wire-drawing type cheese and preparation method thereof

InactiveCN101180993AImprove qualityImprove water holding capacityCheese manufactureFlavorMozzarella cheese

The invention provides a preparation method of a low fat Mozzarella cheese, aiming at improving flavor and taste of low fat cheese. The cheese is endowed with excellent qualities by adding whey protein concentrate (WPC) into low fat milk, adopting selective compound bacteria as ferment, and optimizing technique parameters. The preparation steps of the low fat drawing cheese comprise: degrease disposing of cowmilk, pasteurization, preparatory culture, adding renninum, discharging whey, drawing and salting, etc. The cheese obtained with the invention method has the advantages that: the cheese has good plasticity, supple taste and soft incense; fat content of the cheese is 1 / 3 to 1 / 4 of that of the common cheese, and requirements of cheese favorer and specific population are met; quality of the product is easier to be accepted by consumers, therefore the product has practical application significance.

Owner:SANLU GROUP

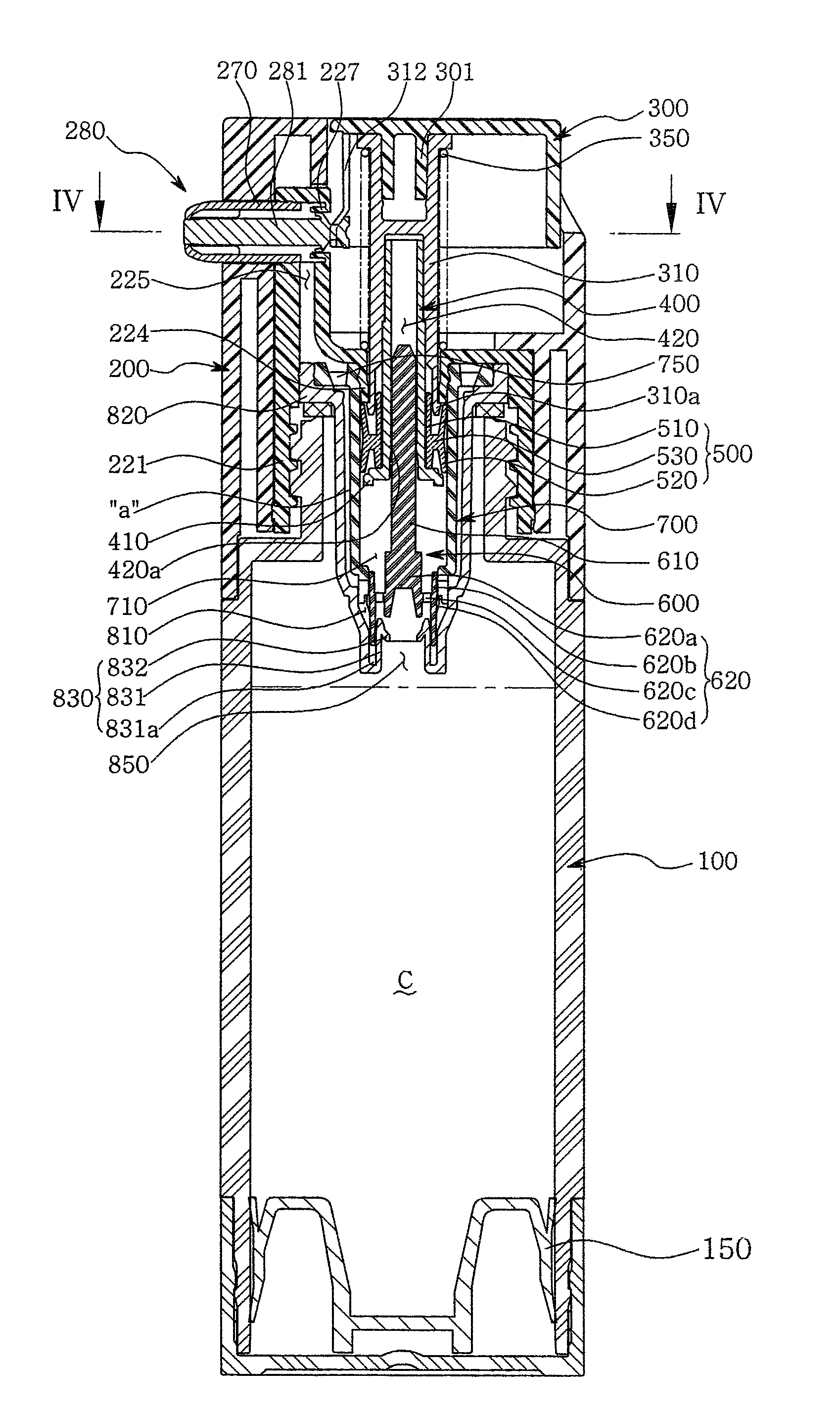

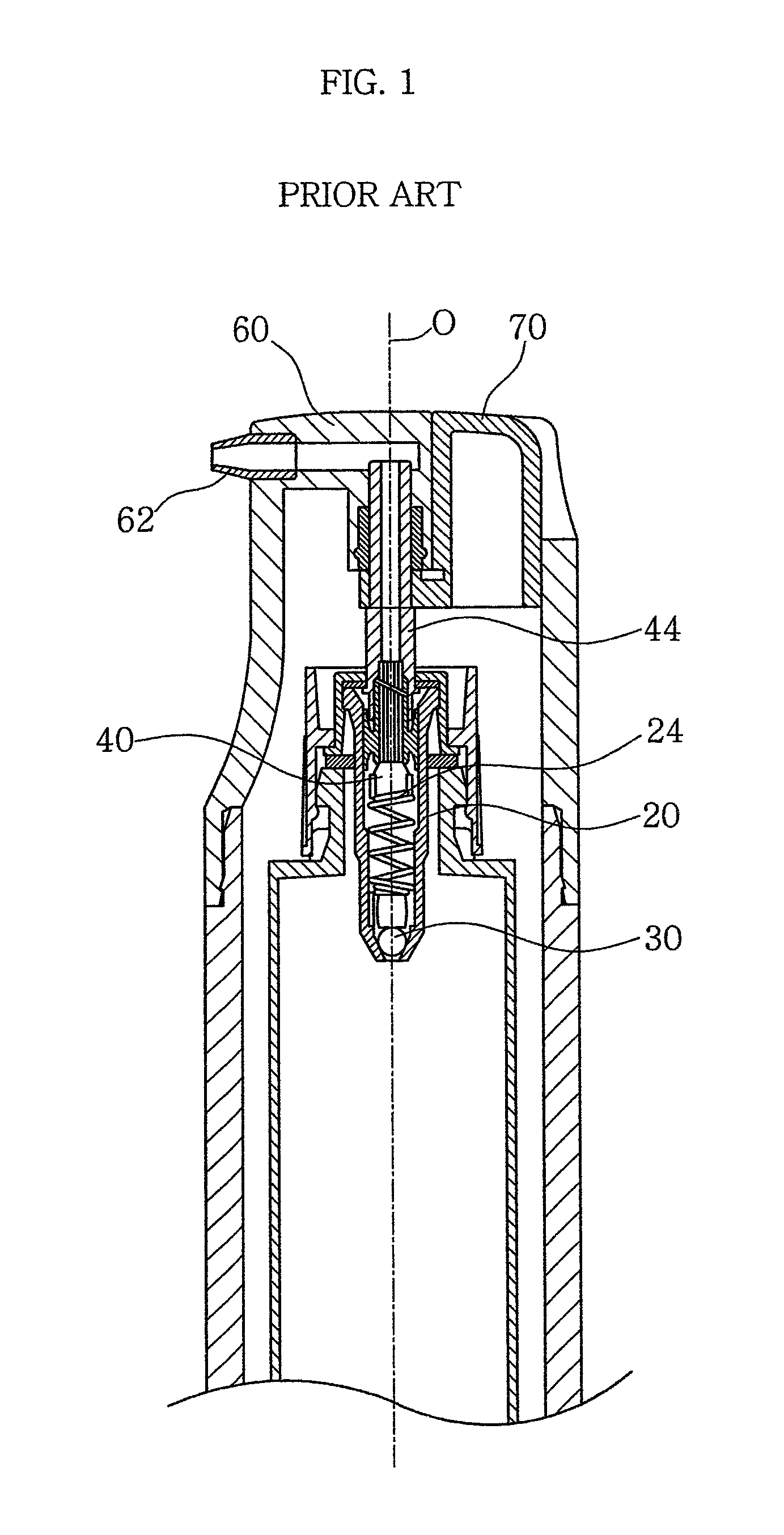

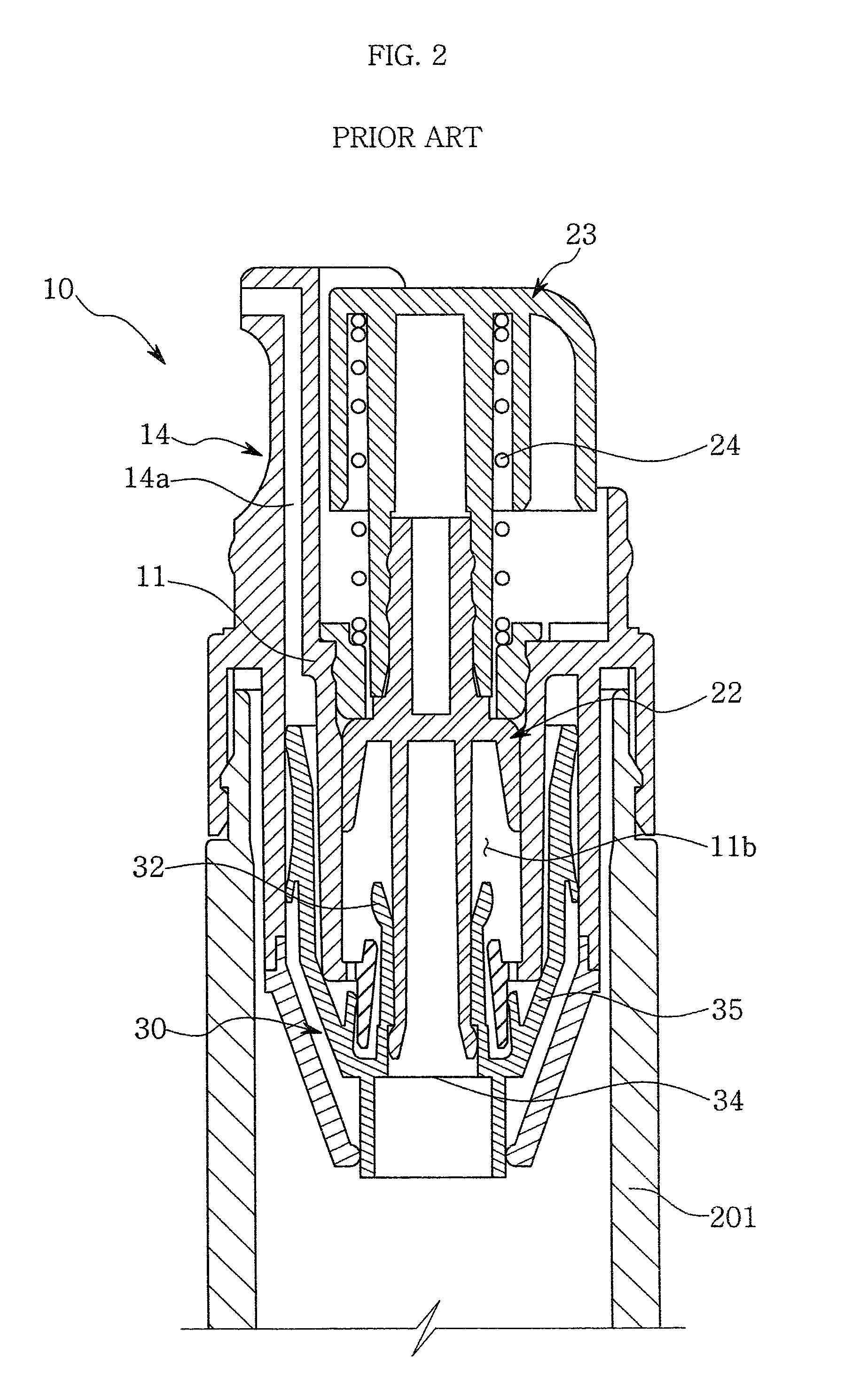

Airless type cosmetics vessel

ActiveUS8245884B2Change qualityClose reliableLarge containersCleaning machinesMechanical engineeringPiston

An airless type cosmetics vessel, in which, in order to suck a gel type cosmetic from a vessel body into a cylinder chamber, an axial valve primarily opens an inlet passage and closes an outlet passage according to stepwise upward movement of a piston and an axial valve, and the piston is further moved upwards, thus sucking the cosmetic into the cylinder chamber, and, in order to discharge the cosmetic from the cylinder chamber, the axial valve is primarily moved downwards so as to close the inlet passage and open the outlet passage, and the piston is further moved downwards, thus compressing the cosmetic in the cylinder chamber and discharging the cosmetic from the chamber, so that a precise cosmetic suction and discharge operation can be executed by the stepwise suction and discharge actions of the axial valve and the piston, separately provided, without malfunctioning.

Owner:BYEON JAE SAM

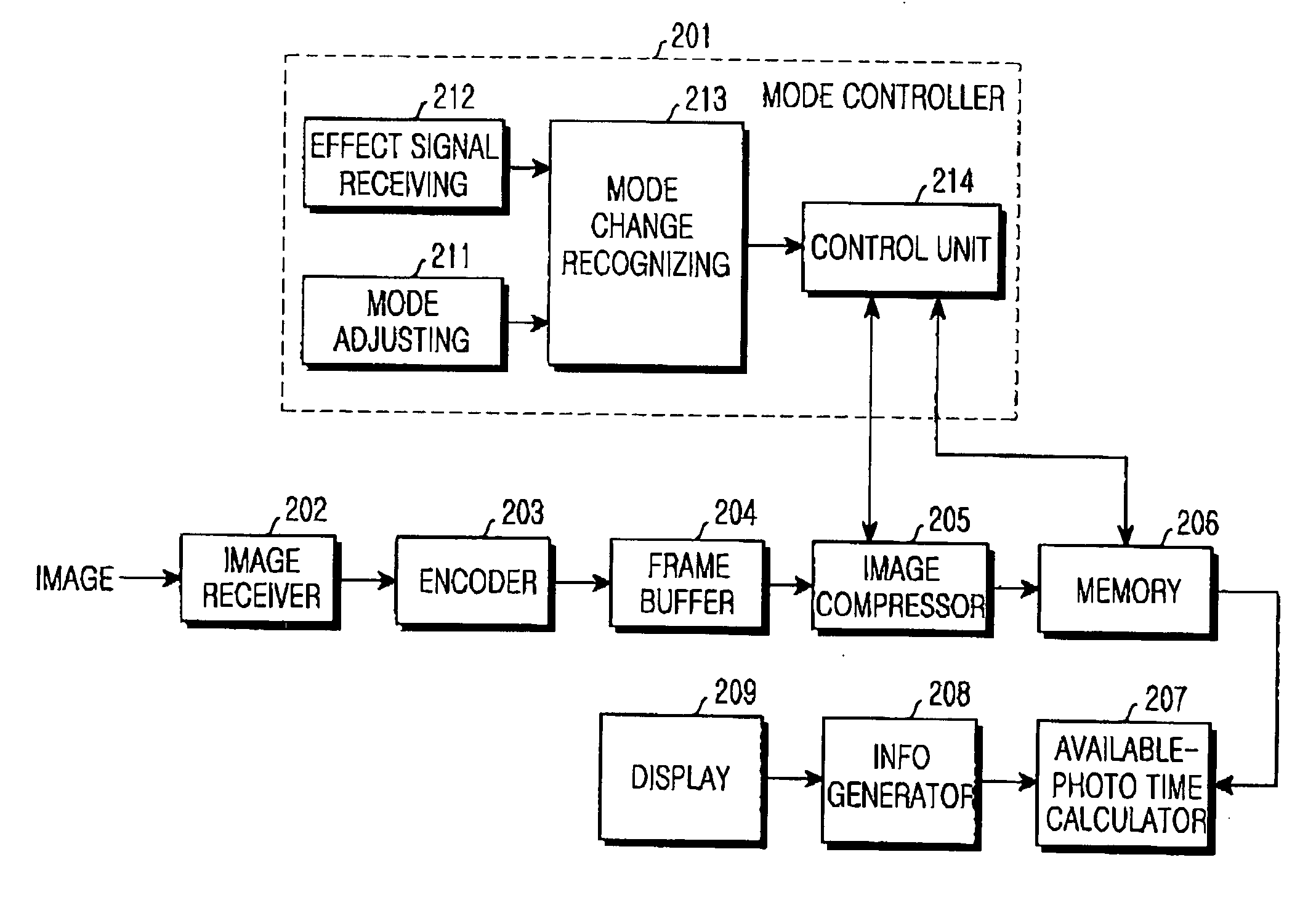

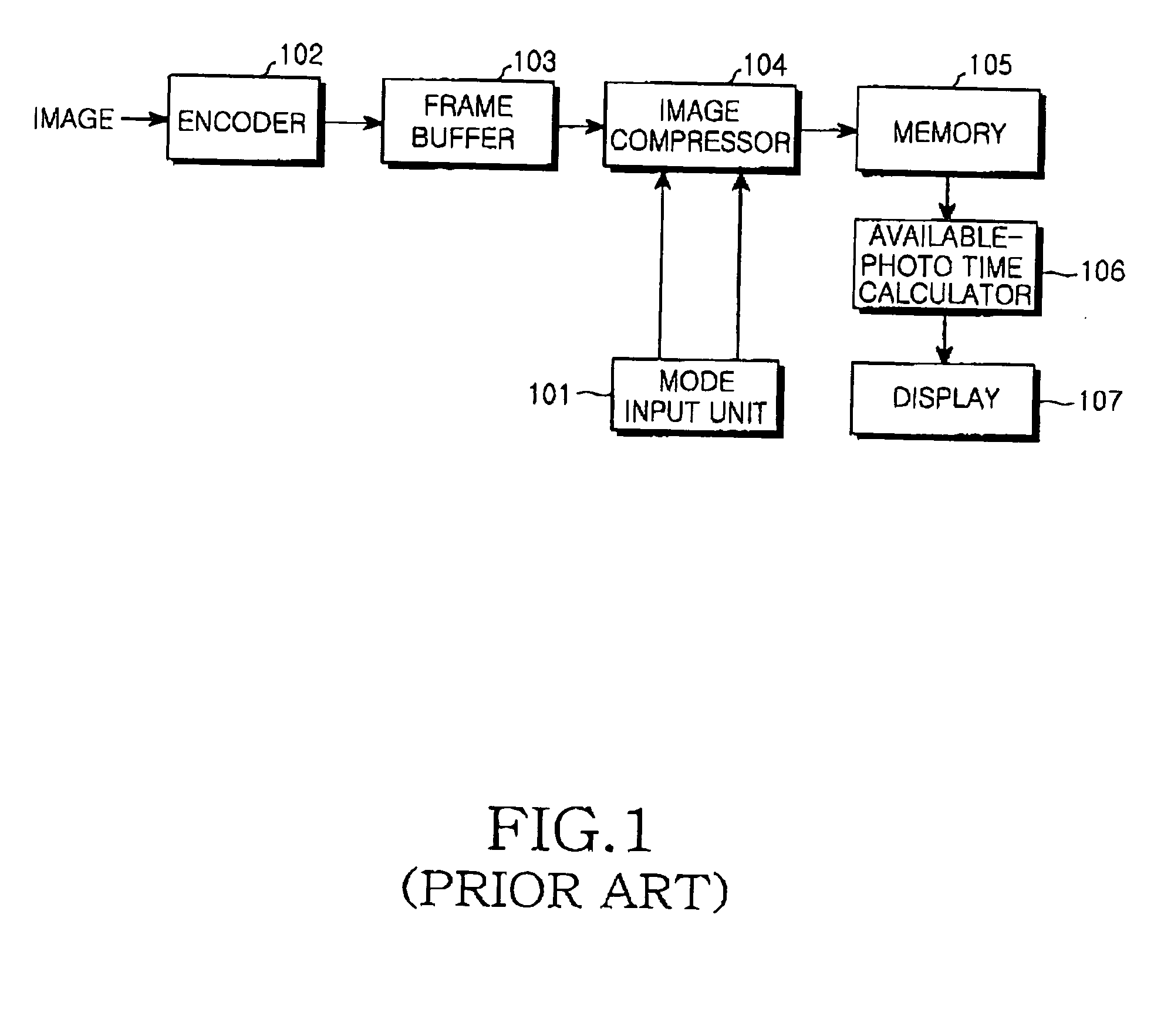

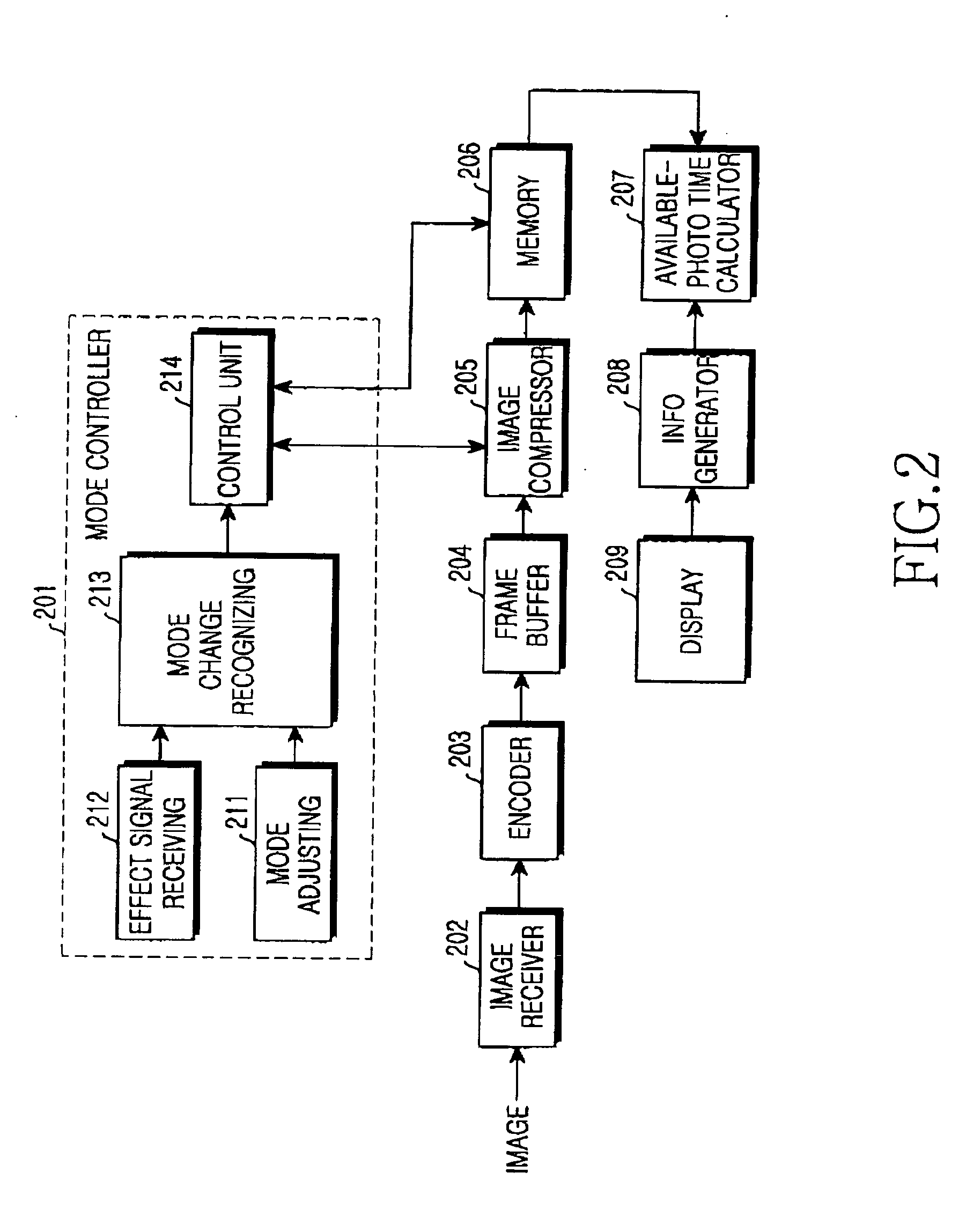

Apparatus and method for changing image quality in real time in a digital camcorder

InactiveUS20050232351A1Change qualityMaximize efficiencyTelevision system detailsPicture reproducers using cathode ray tubesComputer graphics (images)Imaging quality

Apparatus and method are provided for changing an image quality storage in real time. In the apparatus and method, an effect signal receiving unit receives an image mode change request signal from a user while photographing an image. A mode change recognizing unit determines an image mode in response to an output signal of the effect signal receiving unit, and generates an image quality adjust command according to the determination result. A control unit generates a mode control signal for changing an image mode of a moving image in response to the image quality adjust command output from the mode change recognizing unit. An image compressor compresses an input image according to the mode control signal output from the control unit.

Owner:SAMSUNG ELECTRONICS CO LTD

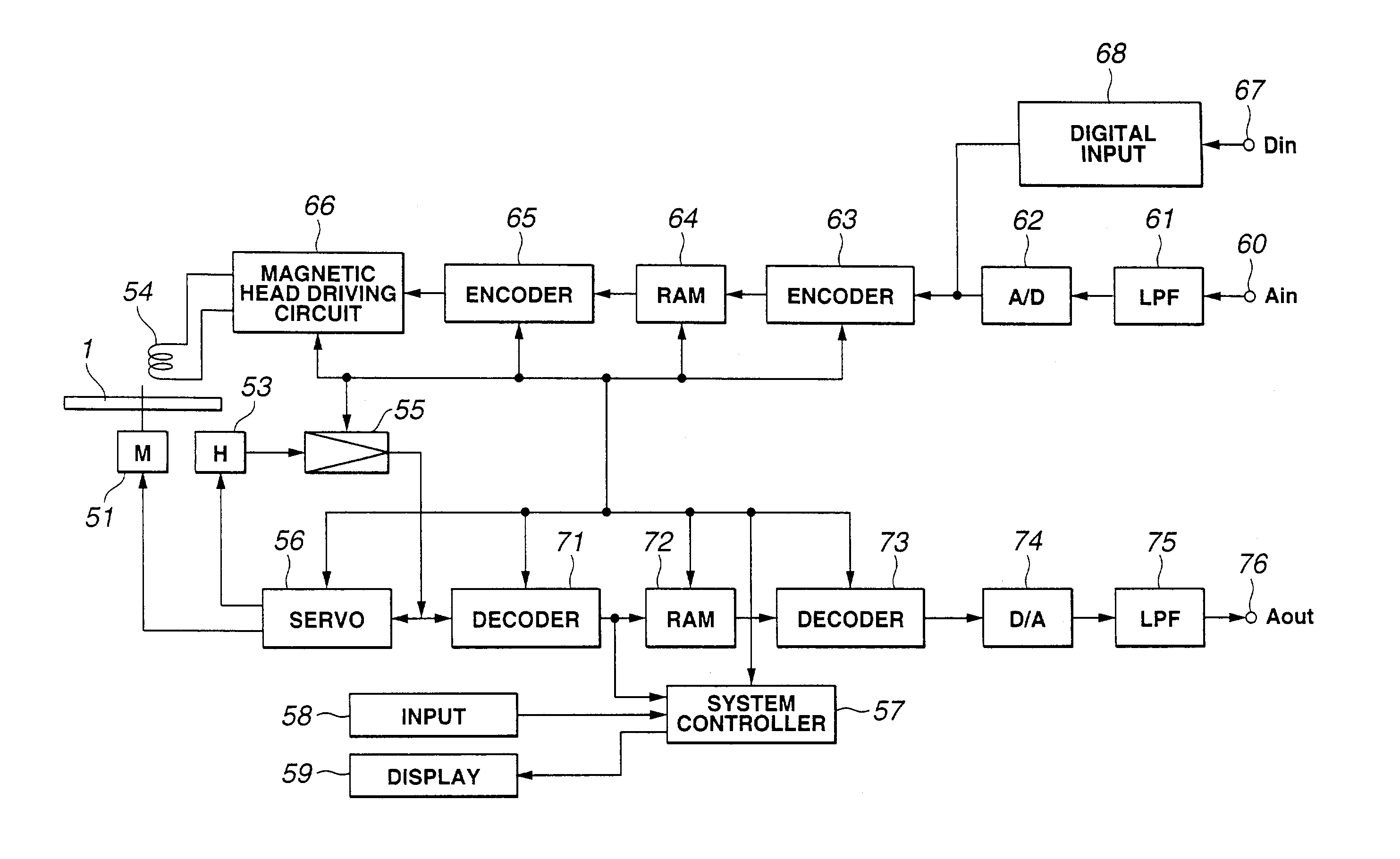

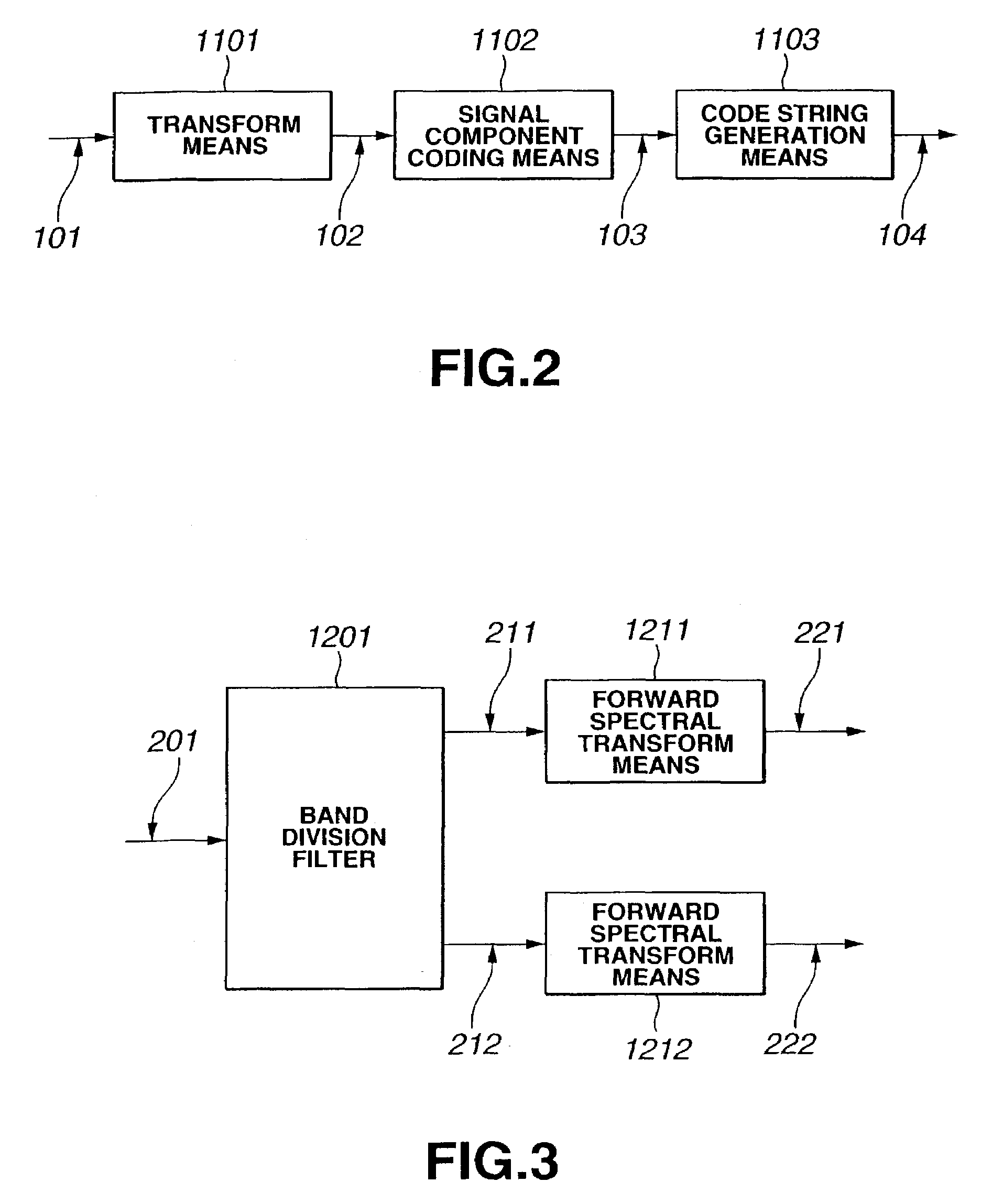

Signal reproducing apparatus and method, signal recording apparatus and method, signal receiver, and information processing method

InactiveUS7140037B2Rule out the possibilityChange qualityTelevision system detailsPulse modulation television signal transmissionInformation processingComputer hardware

A signal (801) of a first code string made through replacing a part of a code string of a predetermined format with dummy data is sent to code string rewriting means (1802) via code string resolution means (1801). A signal (806) of a second code string for complementing the dummy data part in the signal (801) is sent to the code string rewriting means (1802) via control means (1805) and the dummy data in the first code string is rewritten to the second code string. At the time of trial viewing / listening, a signal (802) from the code string resolution means (1801) is selected by a switch (1808), and when the second code string (806) is acquired through content purchase, a signal (803) from the code string rewriting means (1802) is selected by the switch (1808). Thus, trial viewing / listening of a content such as music is made possible while the possibility of decryption is eliminated. By acquiring a relatively small quantity of data, reproduction of a high-quality content is made possible.

Owner:SONY CORP

Wine-flavored pig feed and formula production and feeding methods thereof

InactiveCN102318756AReduce drip lossIncrease glycogen contentFeeding-stuffFood processingBiotechnologyTotal amino acids

The invention relates to a wine-flavored pig feed and formula production and feeding methods thereof. The making method of feed fine fodder comprises the following steps of: activating 1% of fermentation agent, then mixing with 2% of brown sugar, 10% of rice flour, 37% of corn meal, 5% of soybean meal, 5% of sorghum powder, 5% of barley or wheat flour, 15% of wheat bran, 5% of fly maggot powder or blood meal and 15% of bean residue, then adding equal amount of water, uniformly stirring until the water content is optimally 50-60%, then adding to a fermentation tank, sealing and carrying out anaerobic fermentation. The making method of fermented straw coarse fodder comprises the following steps of: kneading corn straw, cutting into 3-7 cm in length, adding 1% of fermentation agent, adding 10% of corn meal, adding 1% of salt, adding water, mixing until the water content reaches optimally 60%. Feeding technique and feed formula are as follows: the feed is fed twice at 8-9 in morning and 4-5 in afternoon, and water is freely drunk in the whole day. By using the wine-flavored pig feed, the slaughtering rate of pig body is improved, water drop loss and body skin thickness of pork are reduced, and total amino acid content and fresh amino acid content in muscle are improved.

Owner:郑晓华

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com