Systems and methods for controlling and forming polymer gels

a technology of polymer gel and control system, applied in the field of systems and methods for controlling and forming polymer gel, can solve the problems of disk shrinkage, affecting and affecting the stability of the solvent, so as to achieve the effect of changing the quality of the solven

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

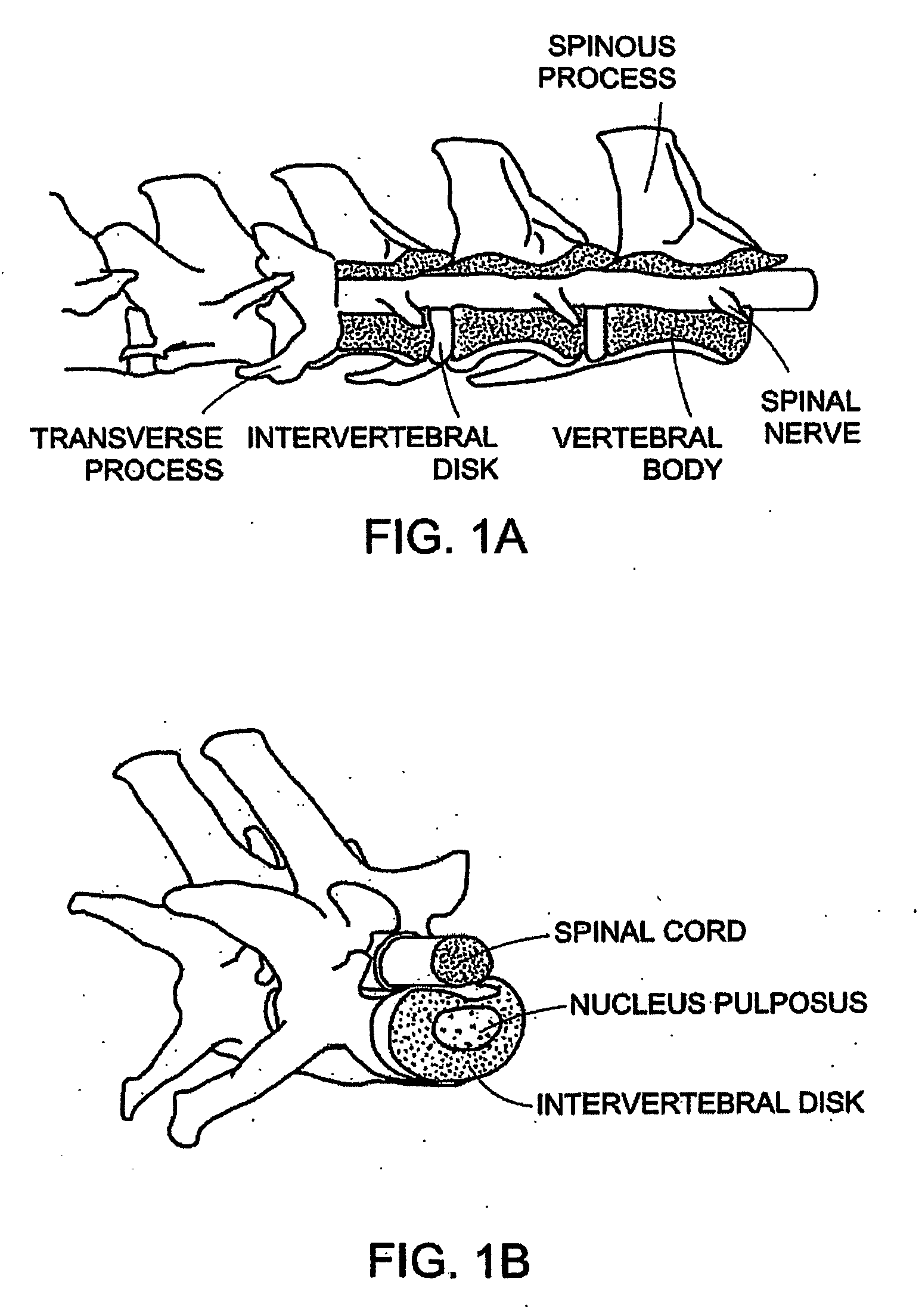

[0101] The preferred embodiments of the present invention are directed at the generation of uniform PVA hydrogels without chemical crosslinks or irradiation to produce a biocompatible material suitable for use as, for example, an intervertebral disk prosthesis. Further, a preferred embodiment of the present invention includes a method used to create the PVA gels that result in a new class of PVA hydrogels which can be designed for specific applications to have a potentially large range of mechanical properties, being controllable, and which can be engineered with gradients in structure and physical properties.

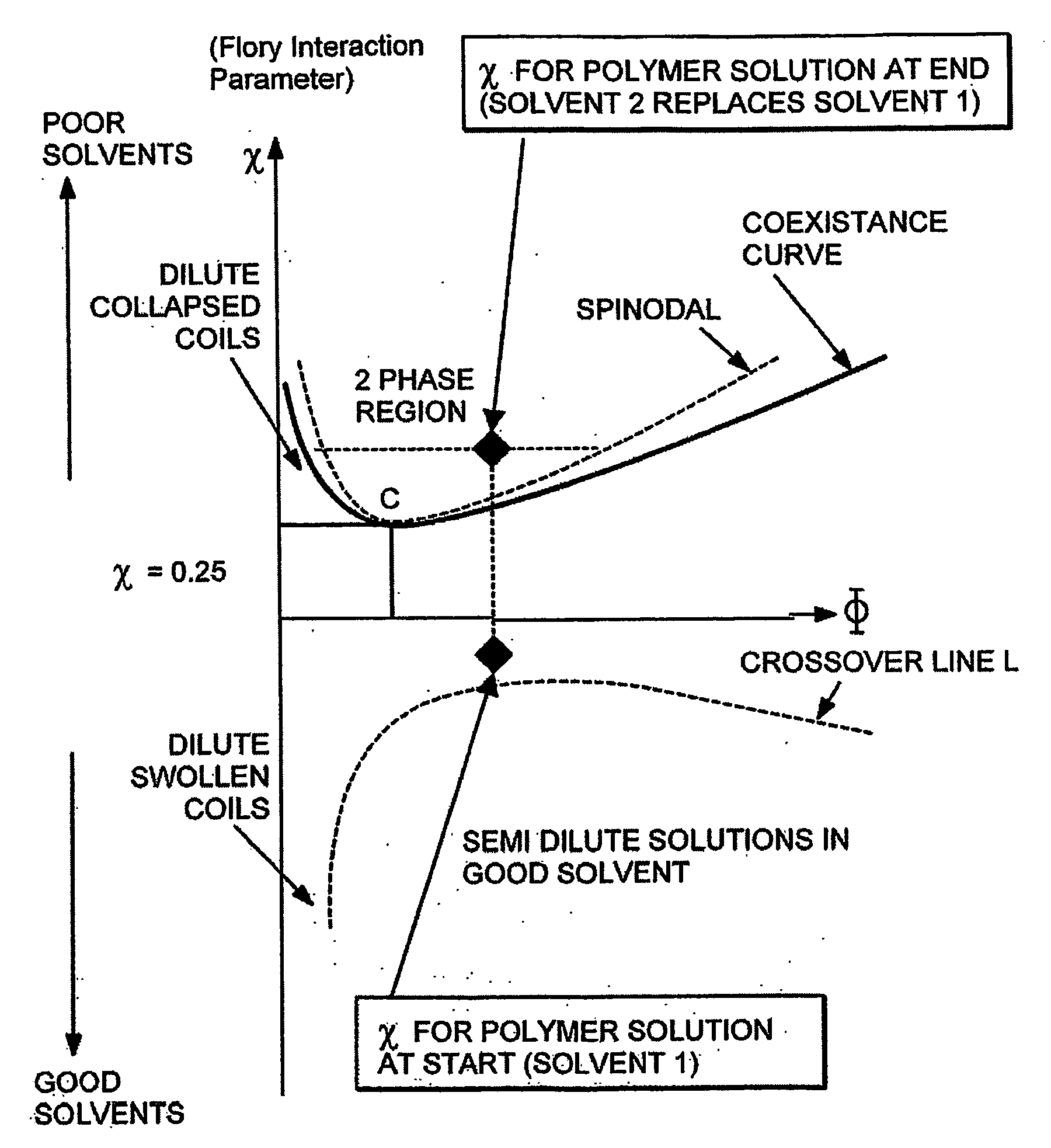

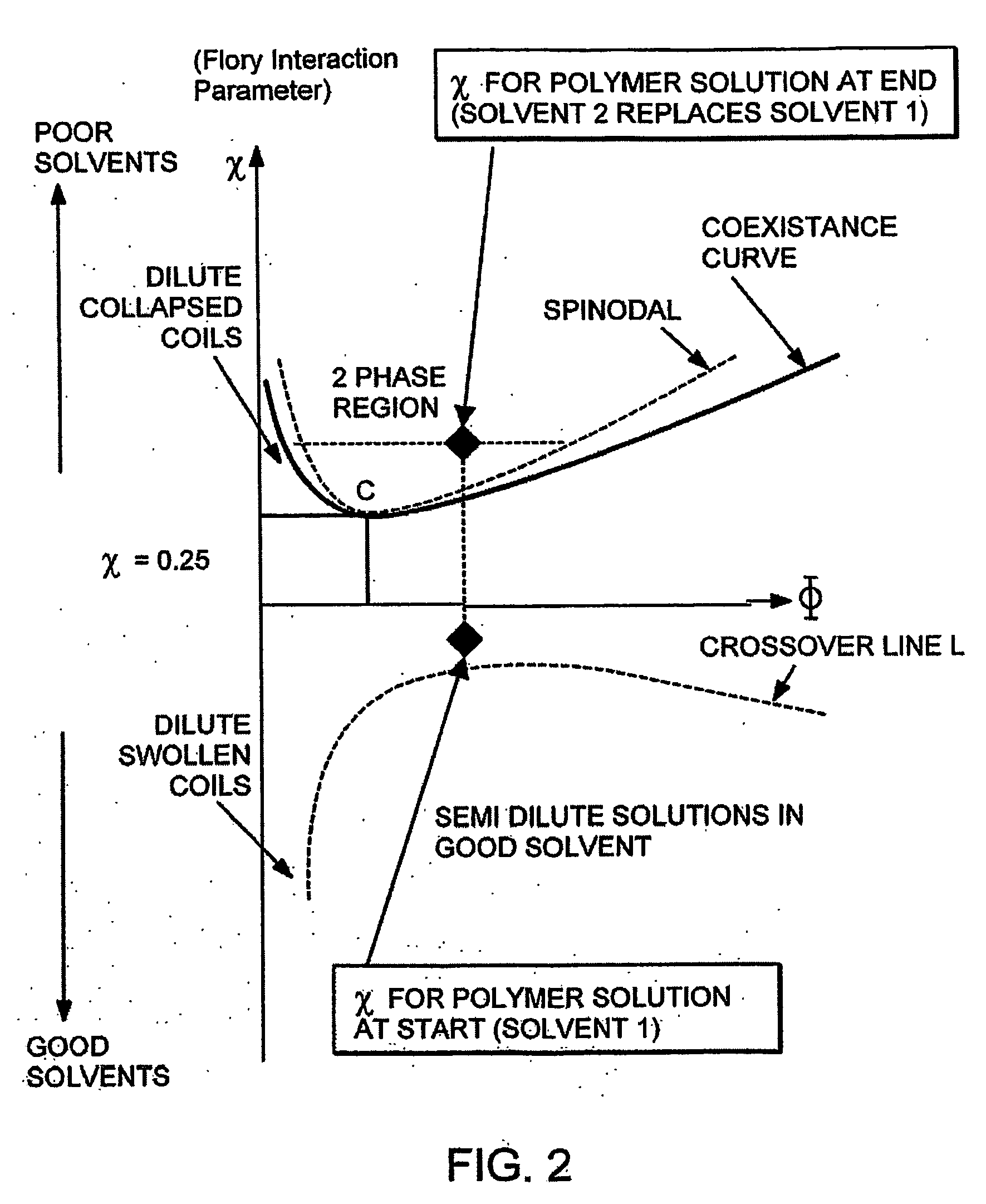

[0102] As used herein, “theta solvent” refers to a solvent that yields, at the theta temperature, solutions of a polymer in the theta state. Theta solvents may be composed of a single solvent or mixture of two solvents, a mixture of a solvent and a nonsolvent, or even a mixture of two nonsolvents in the case of co-solvency as described by Elias, H. G., “Theta Solvents,” in Bra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| temperatures | aaaaa | aaaaa |

| temperatures | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com