Yeast extract and preparation method thereof

A technology of yeast extract and yeast extract enzyme, which is applied in food preparation, fermentation, food science, etc., and can solve the problem that the content of natural glutamic acid cannot meet the replacement requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

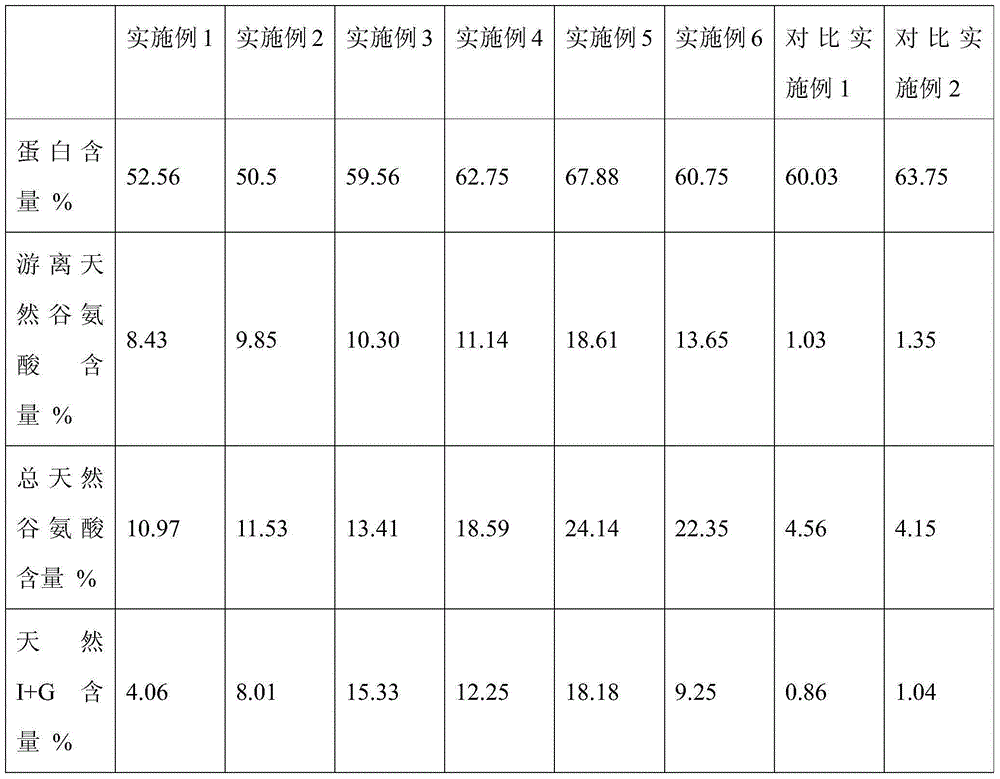

Examples

Embodiment 1

[0026] (1) Heat the yeast milk to 85°C and autolyze for 0.5h;

[0027] (2) Cool the yeast milk after step (1) to 60°C and adjust the pH value to 6.5, then add 0.1‰ yeast extractase, 5.0‰ papain and 0.1‰ alkaline protease, and carry out the hydrolysis reaction for 8 hours;

[0028] (3) Cool down the hydrolyzate obtained in step (2) to 40°C, and adjust the pH value to 4.5, then add 5.0‰ acid protease, 1.0‰ neutral protease and 5.0‰ nuclease to carry out the hydrolysis reaction for 10 hours;

[0029] (4) Heat the hydrolyzate obtained in step (3) to 50°C, and adjust the pH value to 5.5, then add 5.0‰ glutaminase, 0.5‰ flavor protease and 0.5‰ deaminase, and carry out the hydrolysis reaction for 10 hours;

[0030] (5) Heat the hydrolyzate obtained in step (4) to 75° C., inactivate it for 0.5 h, and then centrifuge. The supernatant after centrifugation is concentrated to obtain the yeast extract.

Embodiment 2

[0032] (1) Heat the yeast milk to 87°C and autolyze for 1.2 hours;

[0033] (2) Cool down the yeast milk after step (1) to 62°C, and adjust the pH value to 6.6, then add 1.0‰ yeast extractase, 4.0‰ papain and 0.5‰ alkaline protease, and carry out the hydrolysis reaction for 9 hours;

[0034] (3) Cool down the hydrolyzate obtained in step (2) to 42°C, and adjust the pH value to 4.6, then add 4.0‰ acid protease, 0.5‰ neutral protease and 4.0‰ nuclease, and carry out the hydrolysis reaction for 12 hours;

[0035] (4) Heat the hydrolyzate obtained in step (3) to 52°C, and adjust the pH value to 5.7, then add 4.0‰ glutaminase, 1.0‰ flavor protease and 1.0‰ deaminase, and carry out the hydrolysis reaction for 12 hours;

[0036] (5) Heating the hydrolyzate obtained in step (4) to 78° C., inactivating it for 1.0 h, then filtering, and spray-drying the filtrate to obtain the yeast extract.

Embodiment 3

[0038] (1) Heat the yeast milk to 90°C and autolyze for 1.3 hours;

[0039] (2) Cool down the yeast milk after step (1) to 64°C, and adjust the pH value to 6.7, then add 2.0‰ yeast extractase, 3.0‰ papain and 1.5‰ alkaline protease to carry out the hydrolysis reaction for 10 hours;

[0040] (3) Cool down the hydrolyzate obtained in step (2) to 44°C, and adjust the pH value to 4.7, then add 3.0‰ acid protease, 2.0‰ neutral protease and 3.5‰ nuclease, and carry out the hydrolysis reaction for 14 hours;

[0041] (4) Heat the hydrolyzate obtained in step (3) to 54°C, and adjust the pH value to 6.0, then add 3.0‰ glutaminase, 1.5‰ flavor protease and 2.0‰ deaminase, and carry out the hydrolysis reaction for 14 hours;

[0042](5) Heating the hydrolyzate obtained in step (4) to 80° C., inactivating it for 1.5 h, and then centrifuging. The supernatant after centrifugation was spray-dried to obtain the yeast extract.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com